Piezo-stack pump

A piezoelectric stack, pump body technology, applied in the direction of pumps, pumps with flexible working elements, liquid variable capacity machines, etc. The effect of easy processing, high output pressure and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

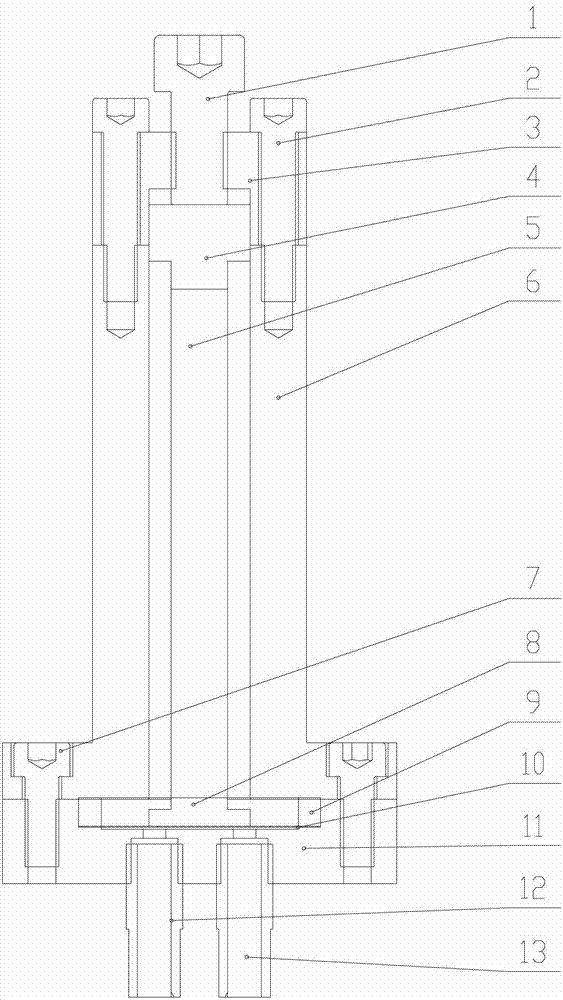

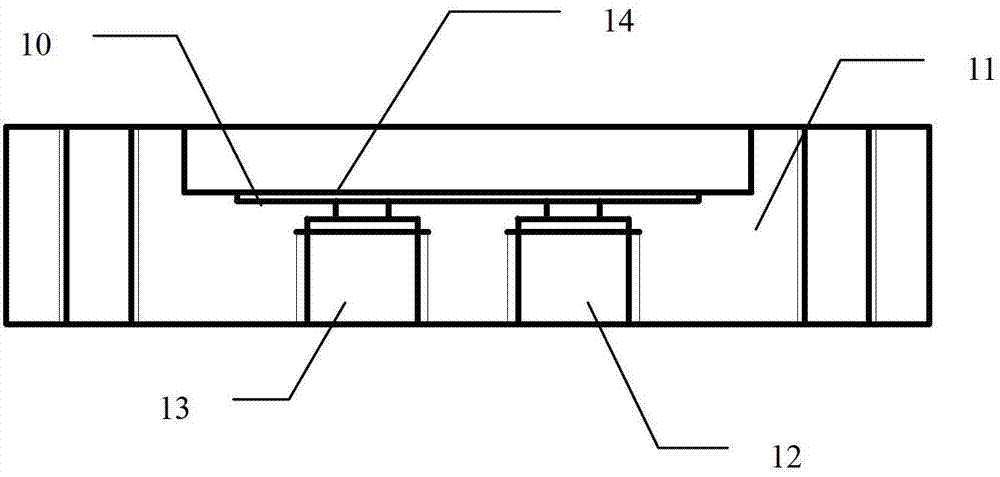

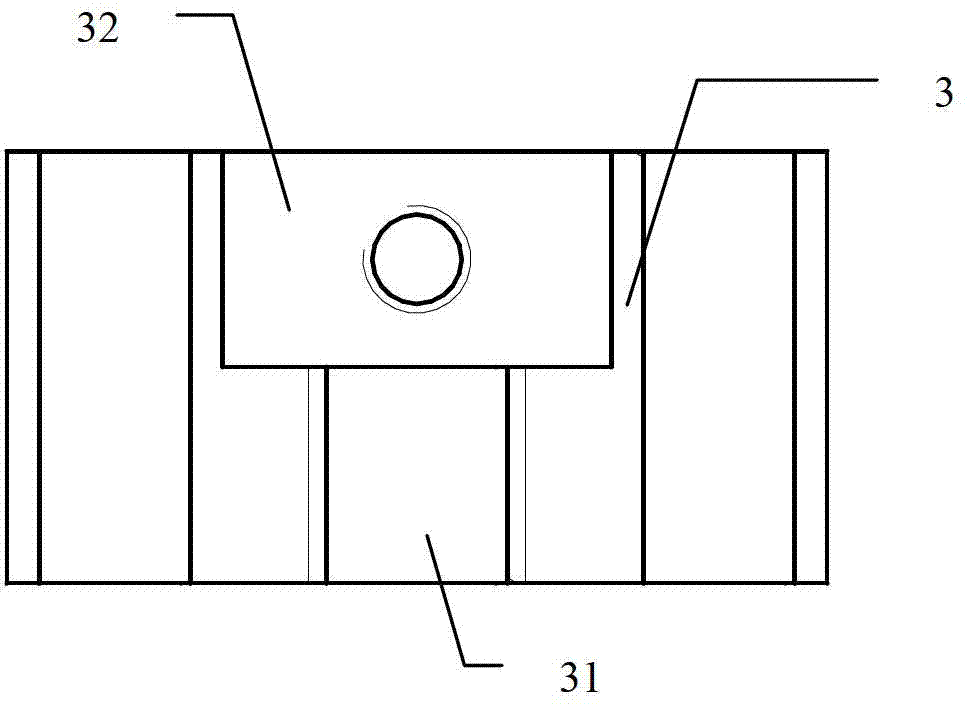

[0023] like figure 1 , figure 2 As shown, the piezoelectric stack pump of this embodiment includes a pump base 11 provided with a fluid inlet 13 and a fluid outlet 12, a pump body 6, a pump upper cover 3 and a piezoelectric stack 5 accommodated in the pump body 6, The fluid inlet 13 is provided with an inlet one-way valve 13, and the fluid outlet 12 is provided with an outlet one-way valve 12; the pump body 6 has a cylindrical cavity, and the piezoelectric stack 5 is accommodated in the cylindrical cavity. The electrical stack 5 is also cylindrical. A vibrating piston 8 is provided between one end of the piezoelectric stack 5 and the pump base 11, and a preloaded piston 4 is provided between the other end of the piezoelectric stack 5 and the pump upper cover 3; the vibrating piston 8 is pasted on the vibrating On the membrane 10 , a working fluid cavity 14 is formed between the vibration membrane 10 and the pump base 11 .

[0024] Specifically, the vibrating membrane 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com