Hydraulic assembly comprising a variable displacement pump and a relief valve

A hydraulic system and servo pump technology, applied in servo motors, servo meter circuits, fluid pressure actuators, etc., can solve problems such as hydraulic system damage, problems, high pressure peaks, etc., to avoid pressure peaks and simply output pressure. , Save the effect of hydraulic pressure medium pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

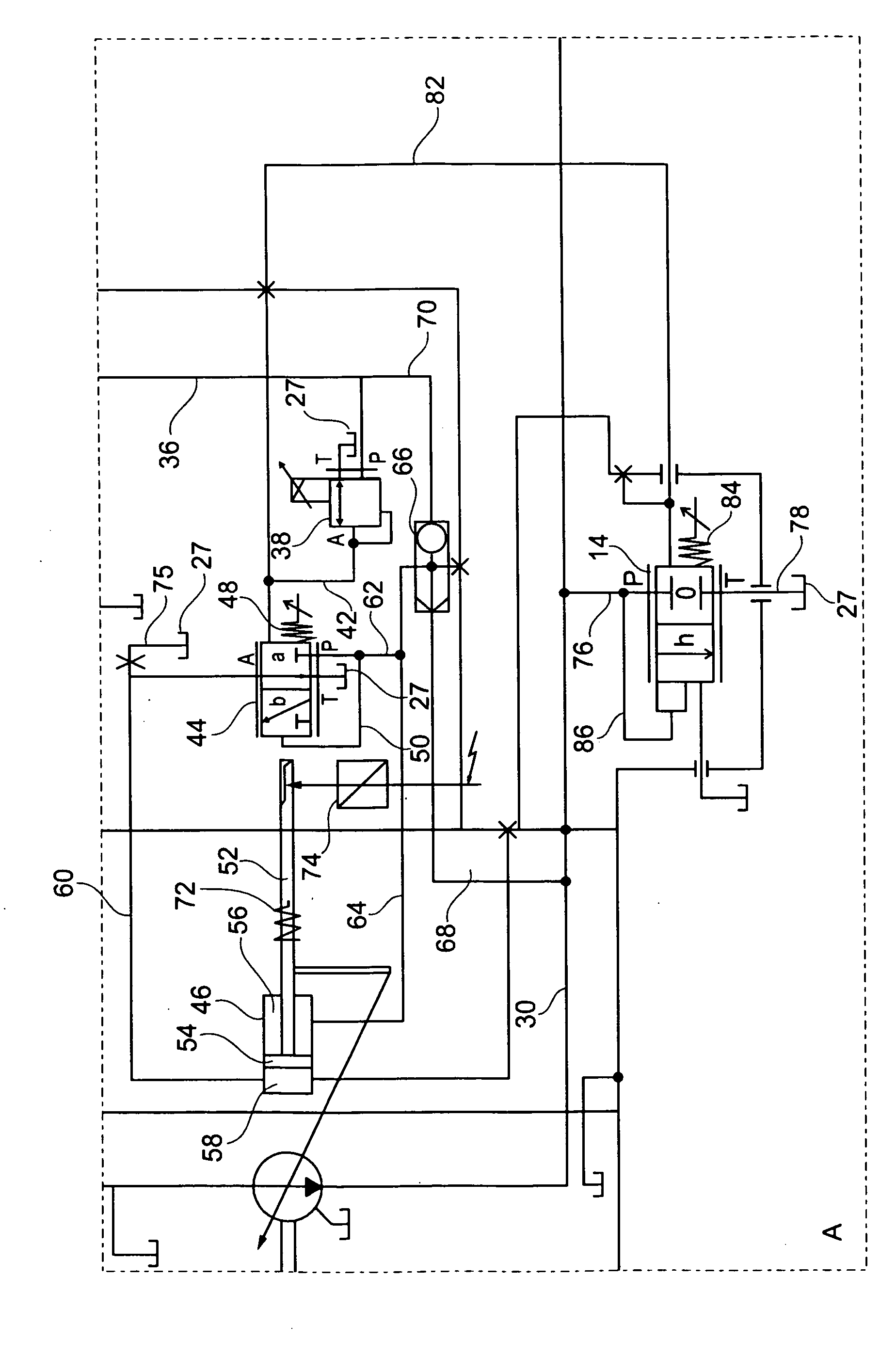

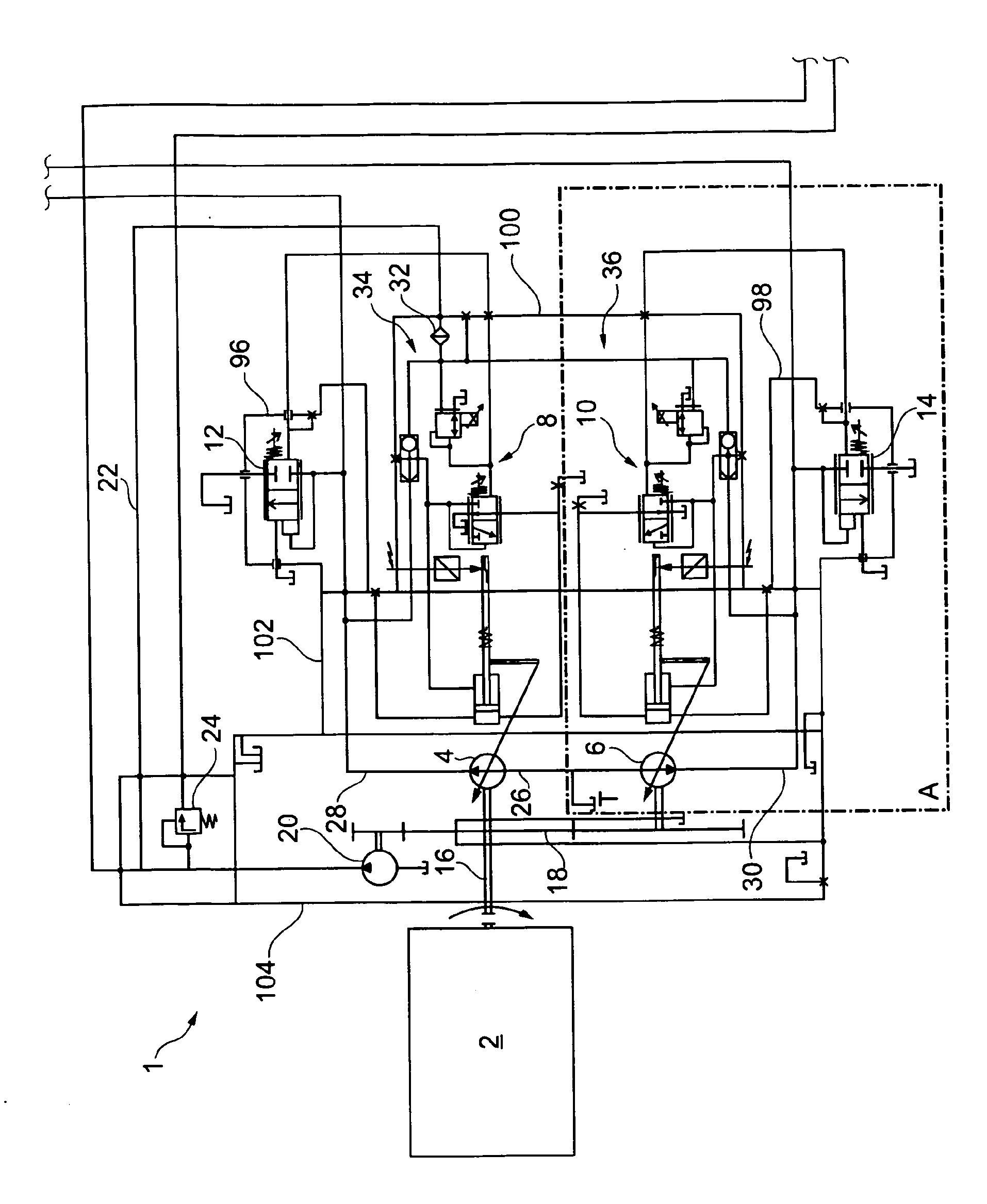

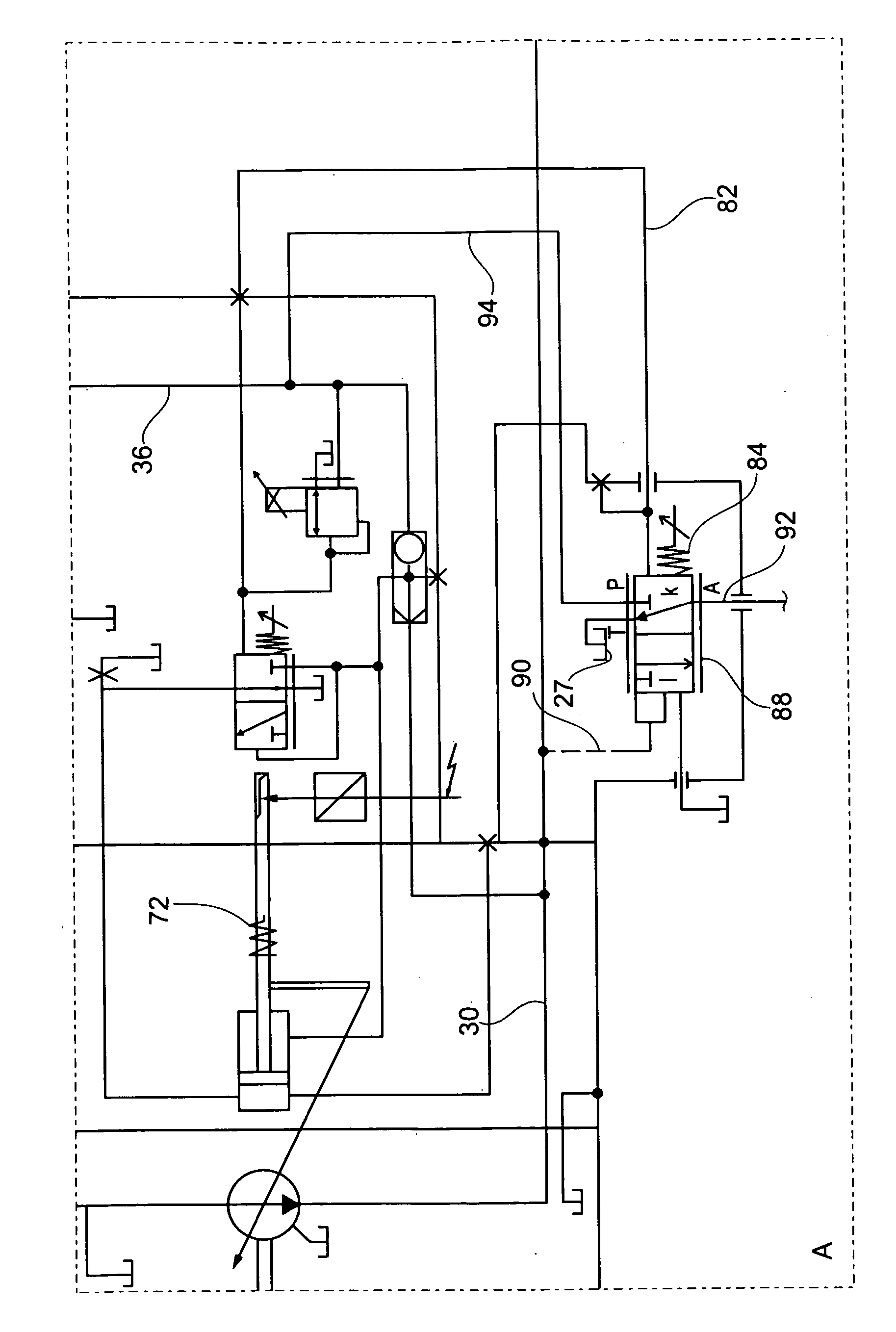

[0024] figure 1 According to the first embodiment, a schematic circuit diagram of the hydraulic system 1 according to the present invention is shown. The hydraulic system has two servo pumps or Verstell pumps 4, 6 driven by a drive unit 2 for supplying pump pressure or output pressure to a load not shown. The pump regulators 8, 10 are used to control the servo pumps 4, 6, respectively. In order to reduce the respective output pressure in relation to the pressure difference between the setpoint pressure and the output pressure, each servo pump 4 and 6 is equipped with a comparison valve or injection valve (Vergleichsventil) 12 or 14.

[0025] The servo pumps 4 and 6 have the same structure and hydraulic connection as the respective pump regulator 8 or 10 and the respective comparison valve 12 or 14 in terms of device technology. Therefore, for the sake of simplicity, the following main references are figure 1 The servo pump 6 shown below illustrates the hydraulic structure. In ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com