Control and regulation device for safeguarding a conveyor device, conveyor device and crane unit

A technology for controlling and adjusting conveyors, applied to cranes, hoisting devices, clockwork mechanisms, etc., can solve the problems of expensive hydraulic control sliding structures and large maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

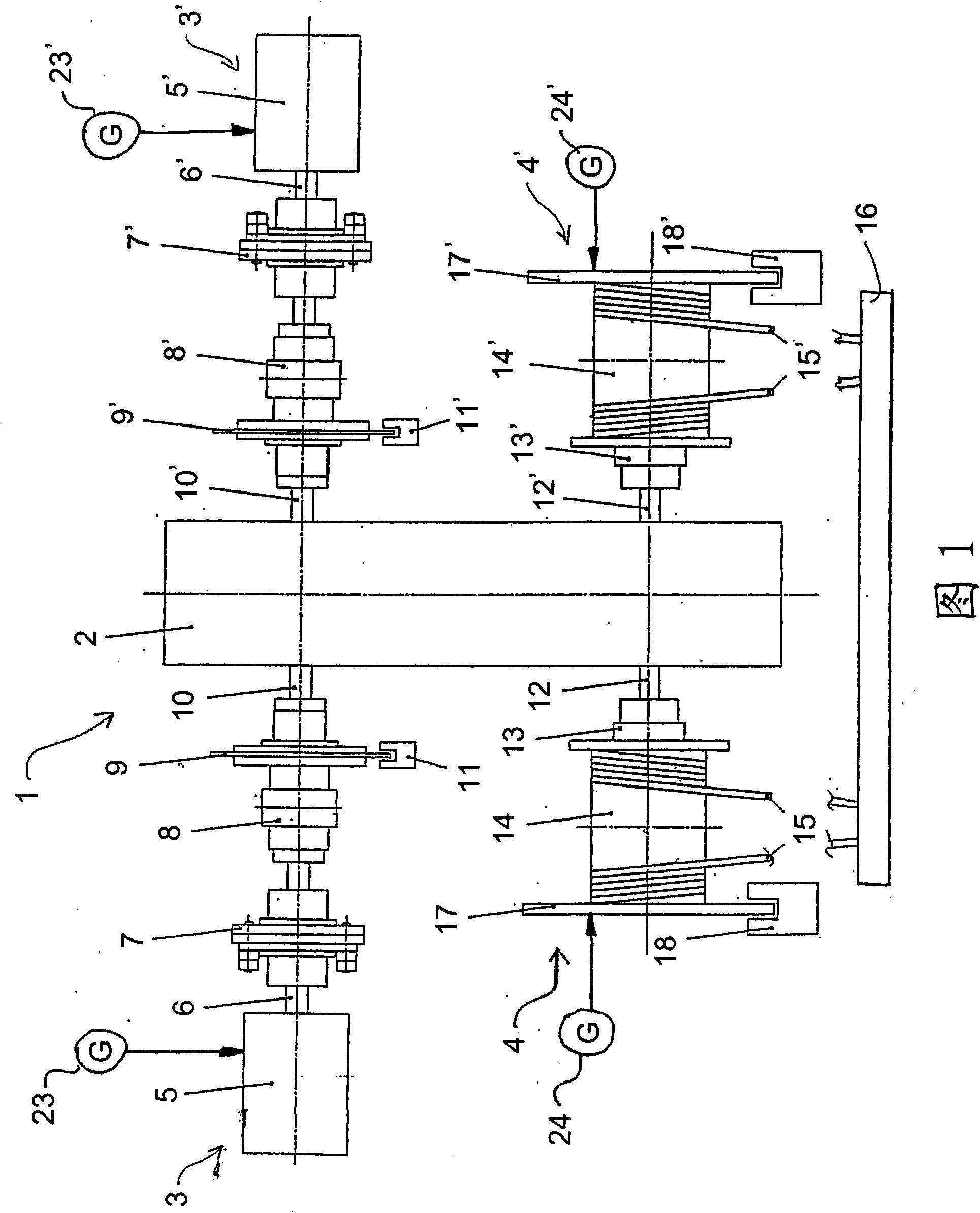

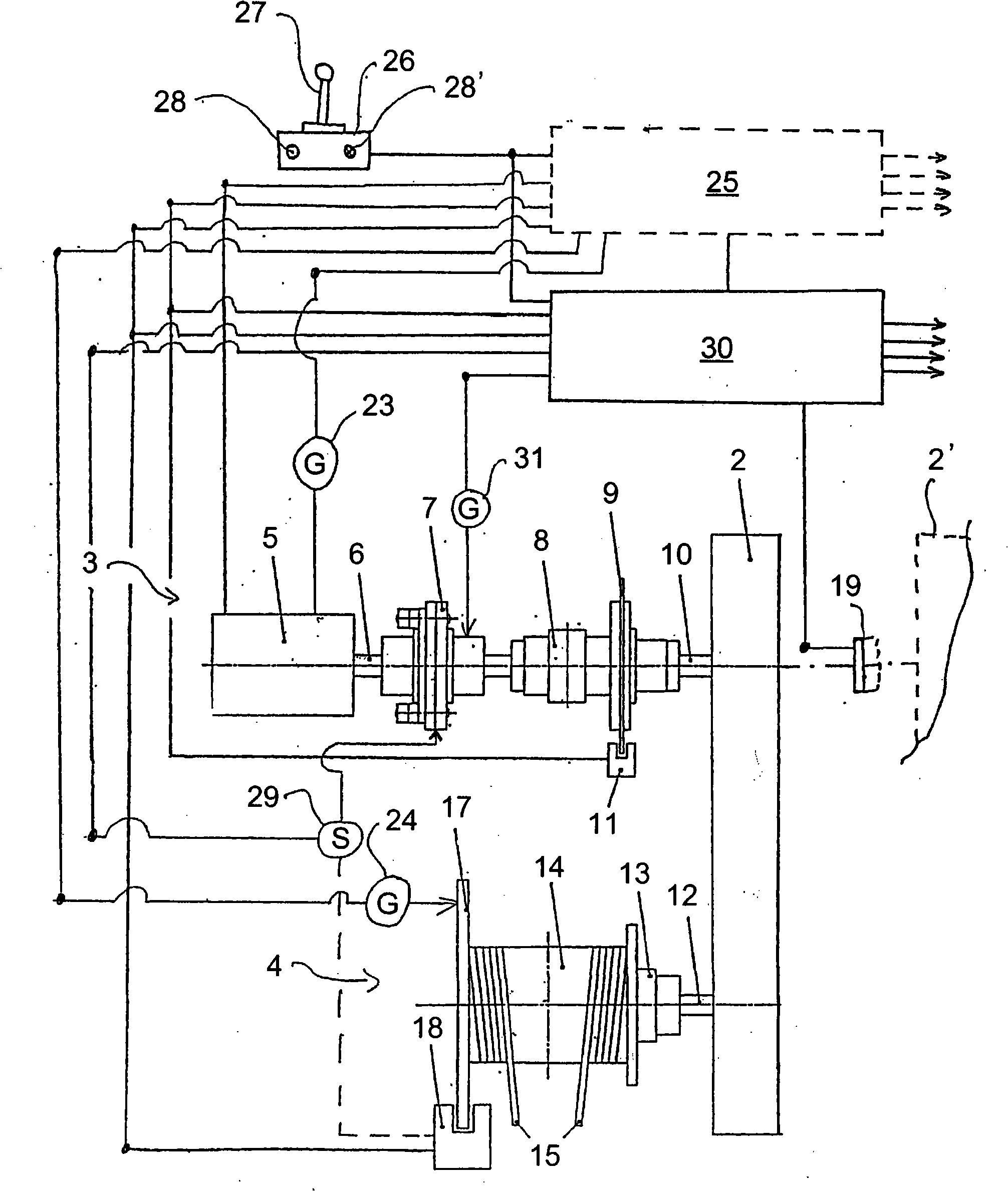

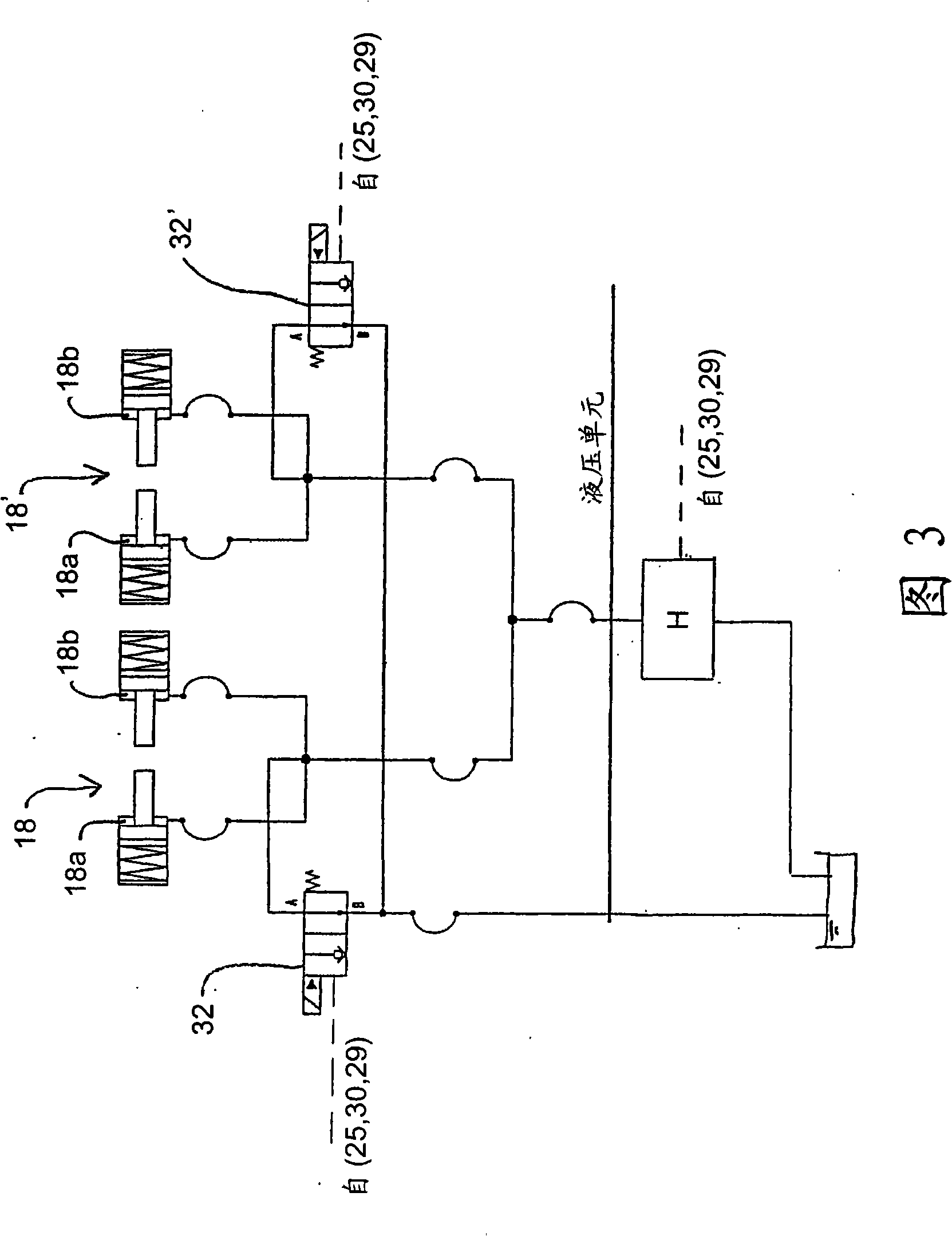

[0024] The lifting device 1 shown in Figure 1 comprises two cable-operated hoists and has, in combination with a gear transmission 2, forming two drive and driven systems (3, 3', 4, 4' respectively). In the following description the main elements of the power path system will be described, and in the drawings their corresponding parts are indicated by reference numerals on the left and by the same reference numerals on the right, the latter being distinguished by an apostrophe.

[0025] The drive motor 5, 5' rotates the drive shaft 6, 6' to activate the overload coupling 7, 7', where the torque is further transmitted through a conventional coupling 8, 8' which in turn is connected to the brake Disc 9, 9'. The part 10, 10' of the drive shaft provides power to the gear transmission 2. Said brake discs 9, 9' are managed by brake calipers 11, 11' (hereinafter referred to as "service brakes"). The output shafts 12, 12' of the gear transmission 2 act via couplings 13, 13' on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com