Patents

Literature

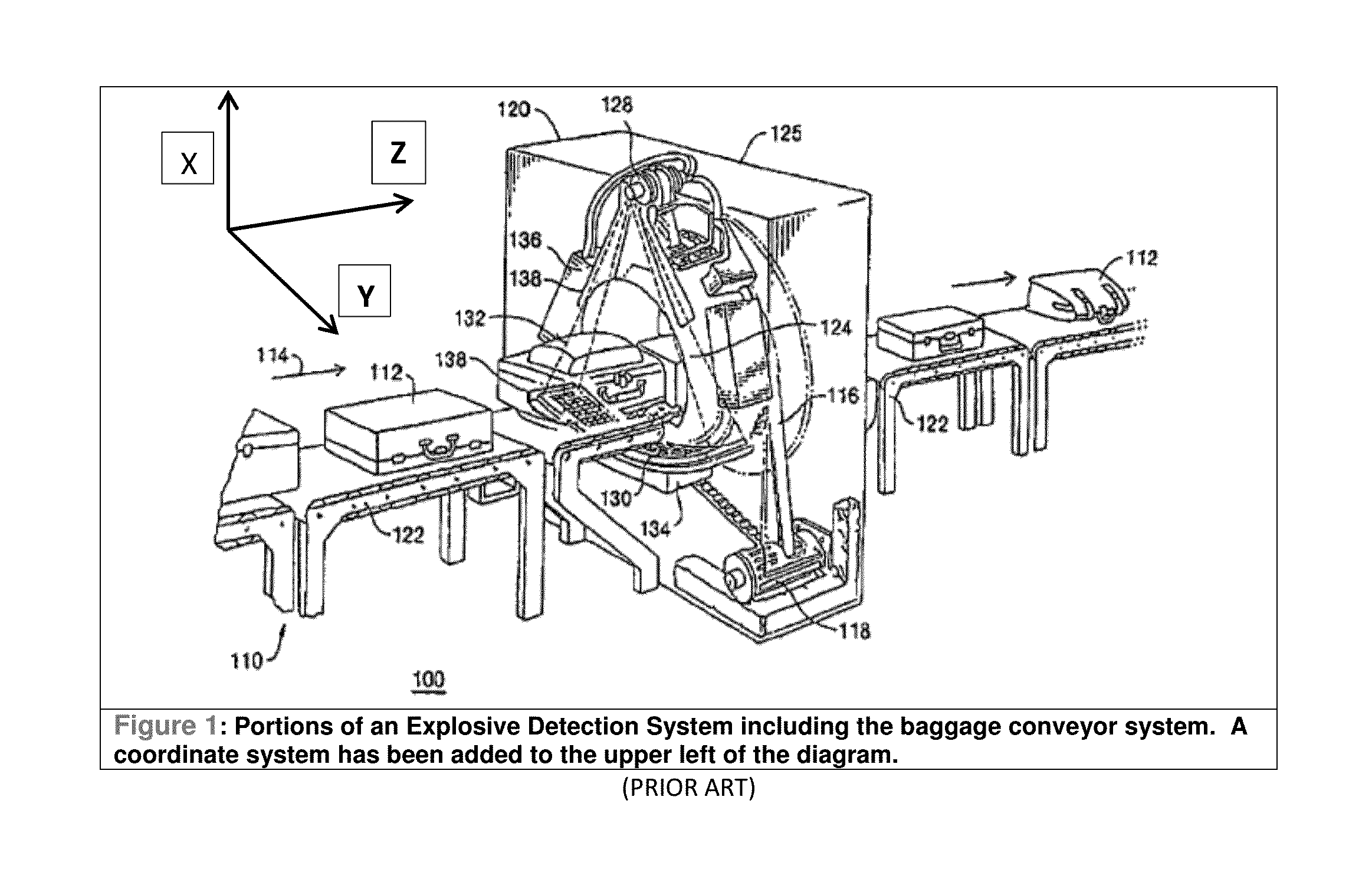

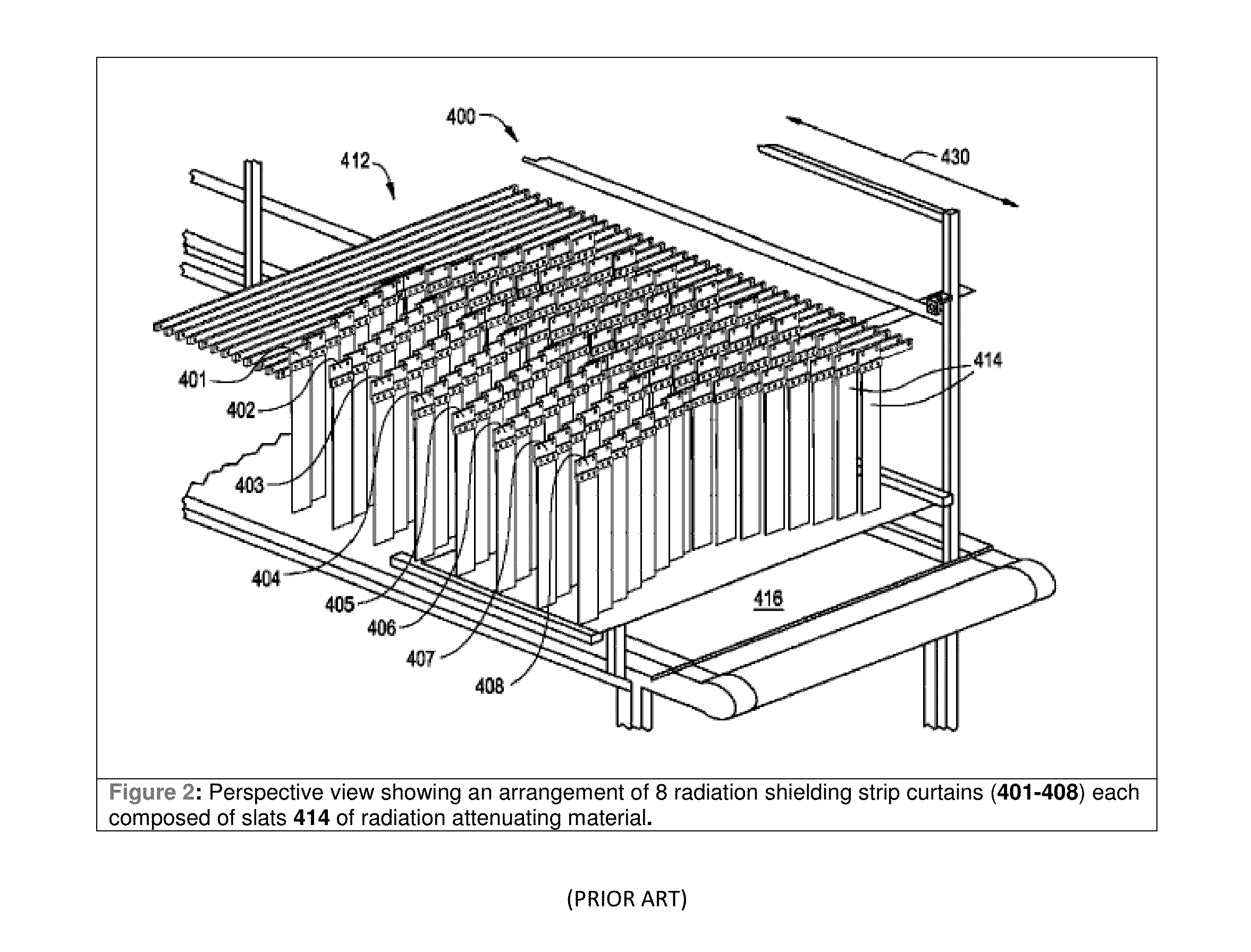

34results about How to "Solve the lack of wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

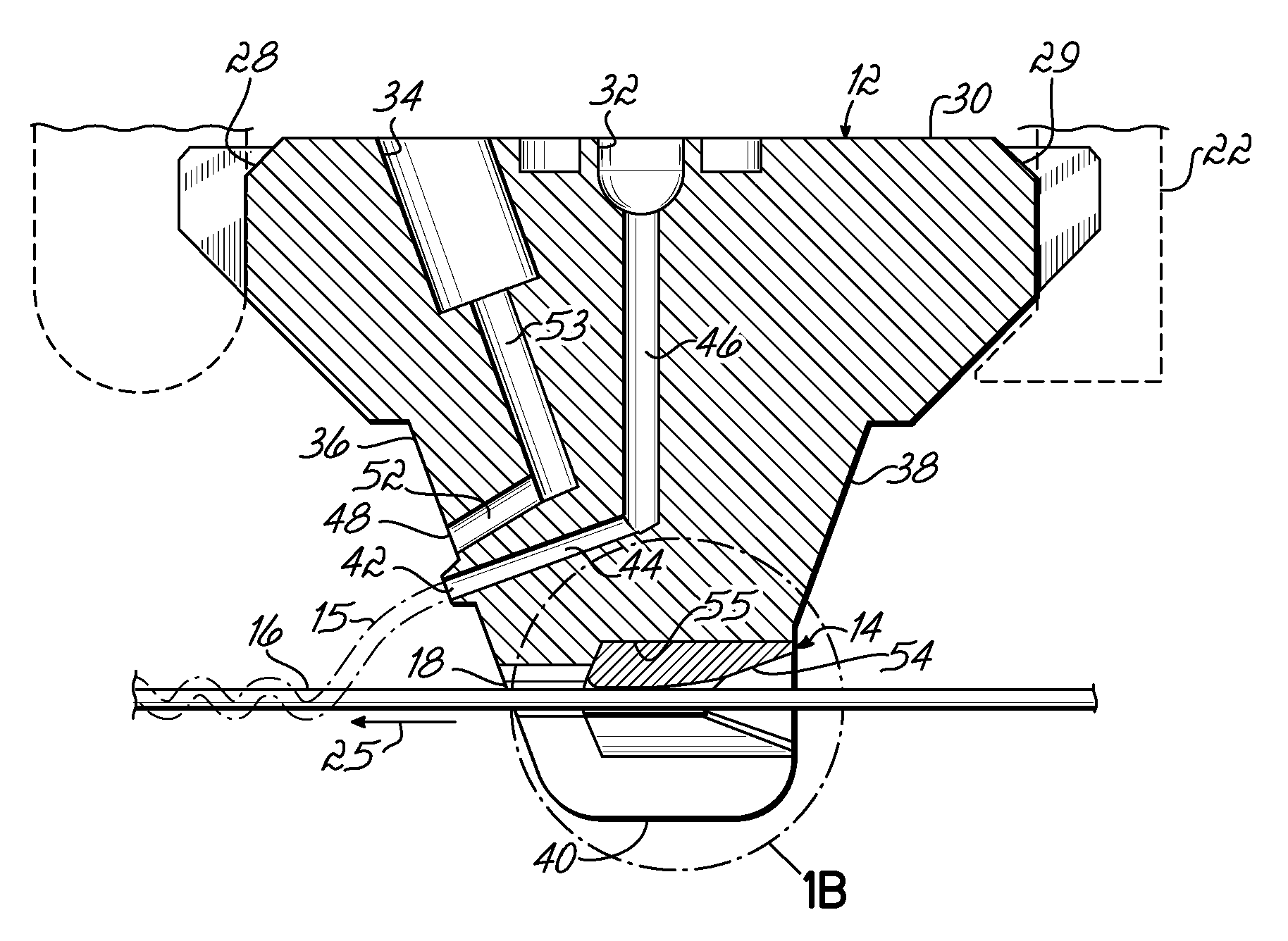

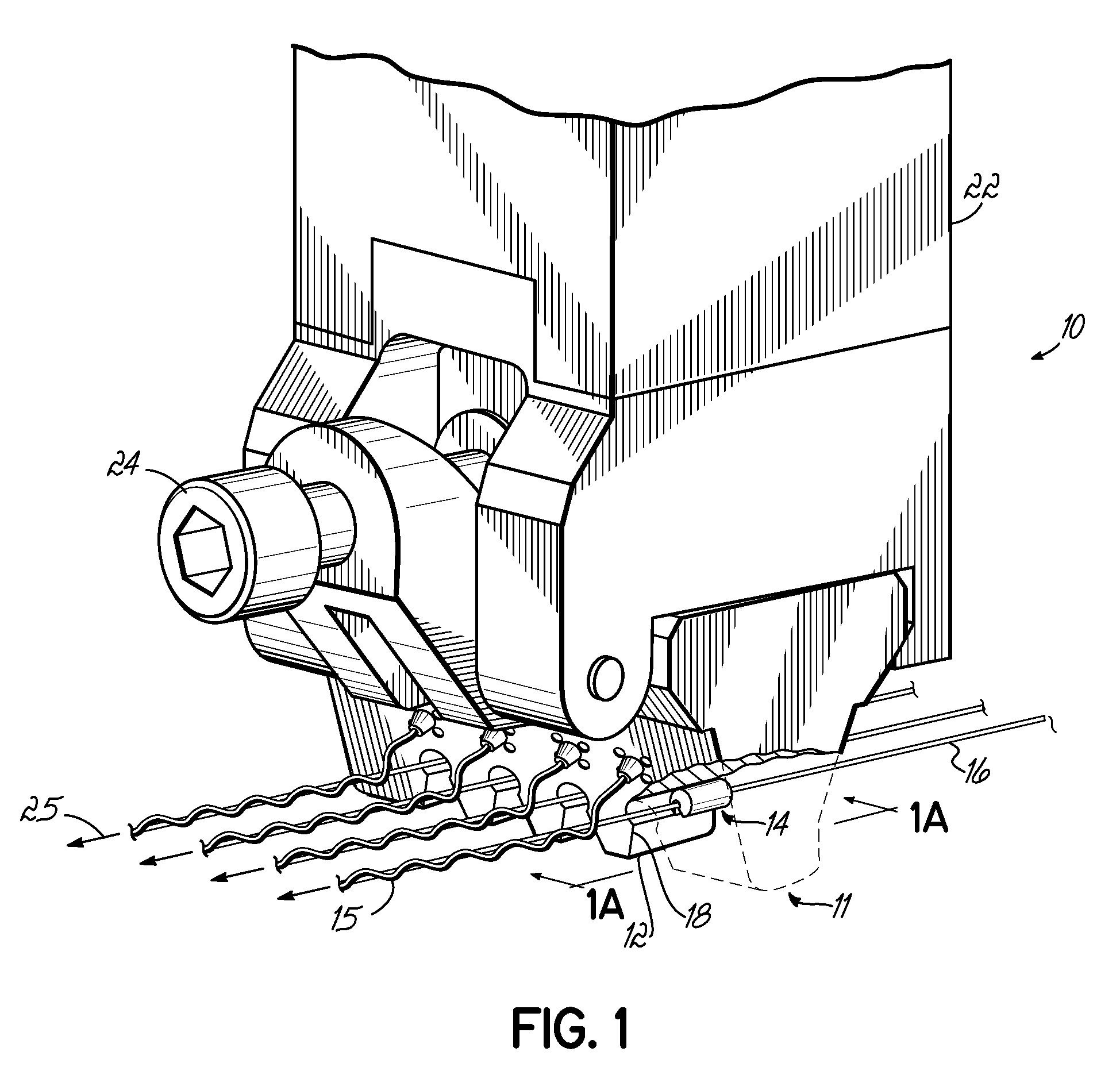

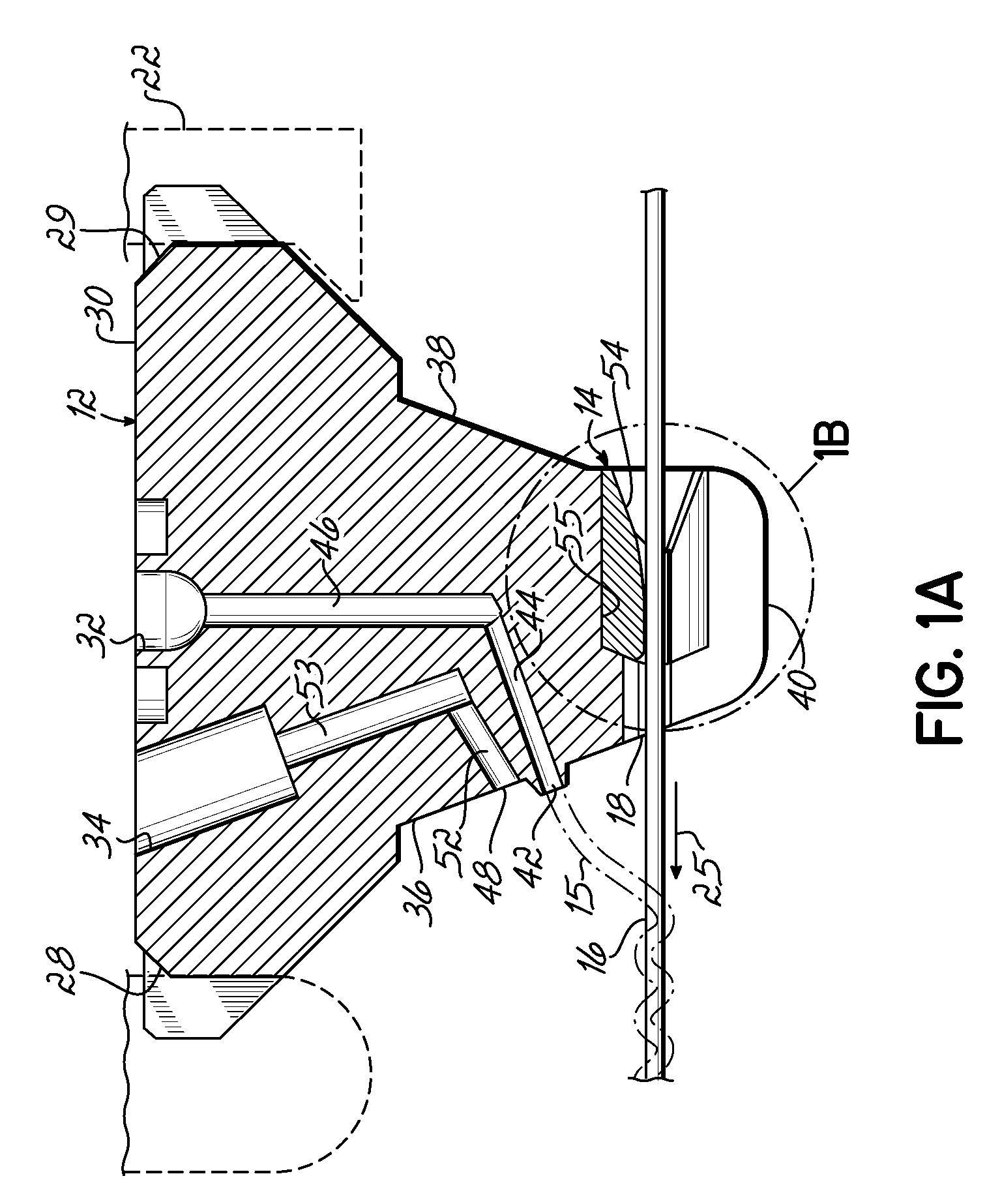

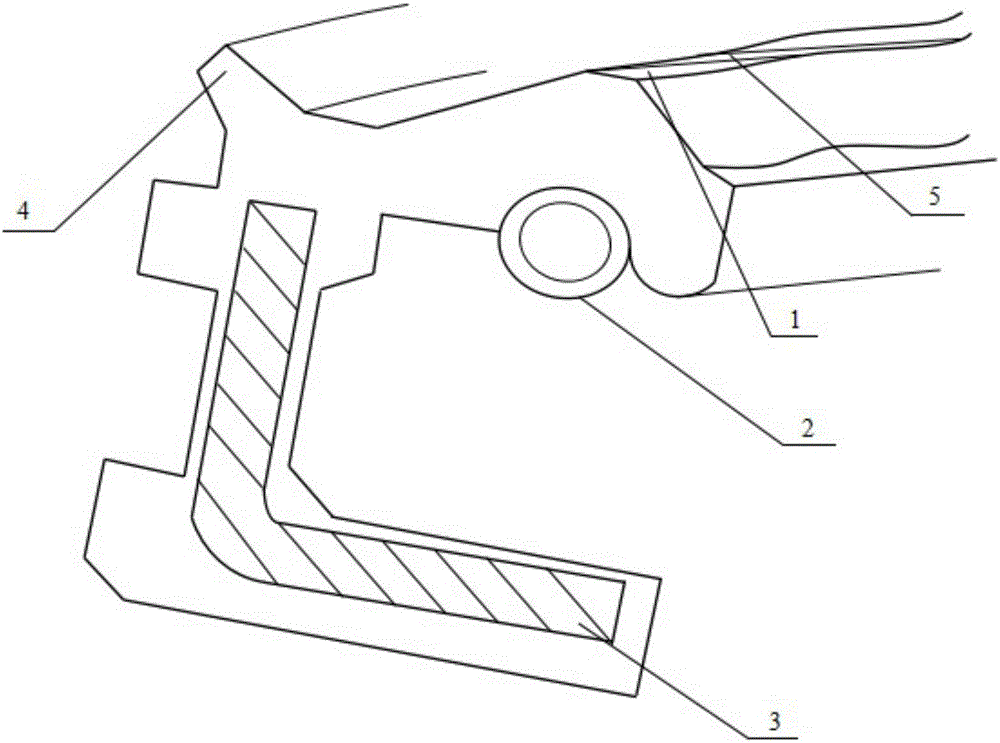

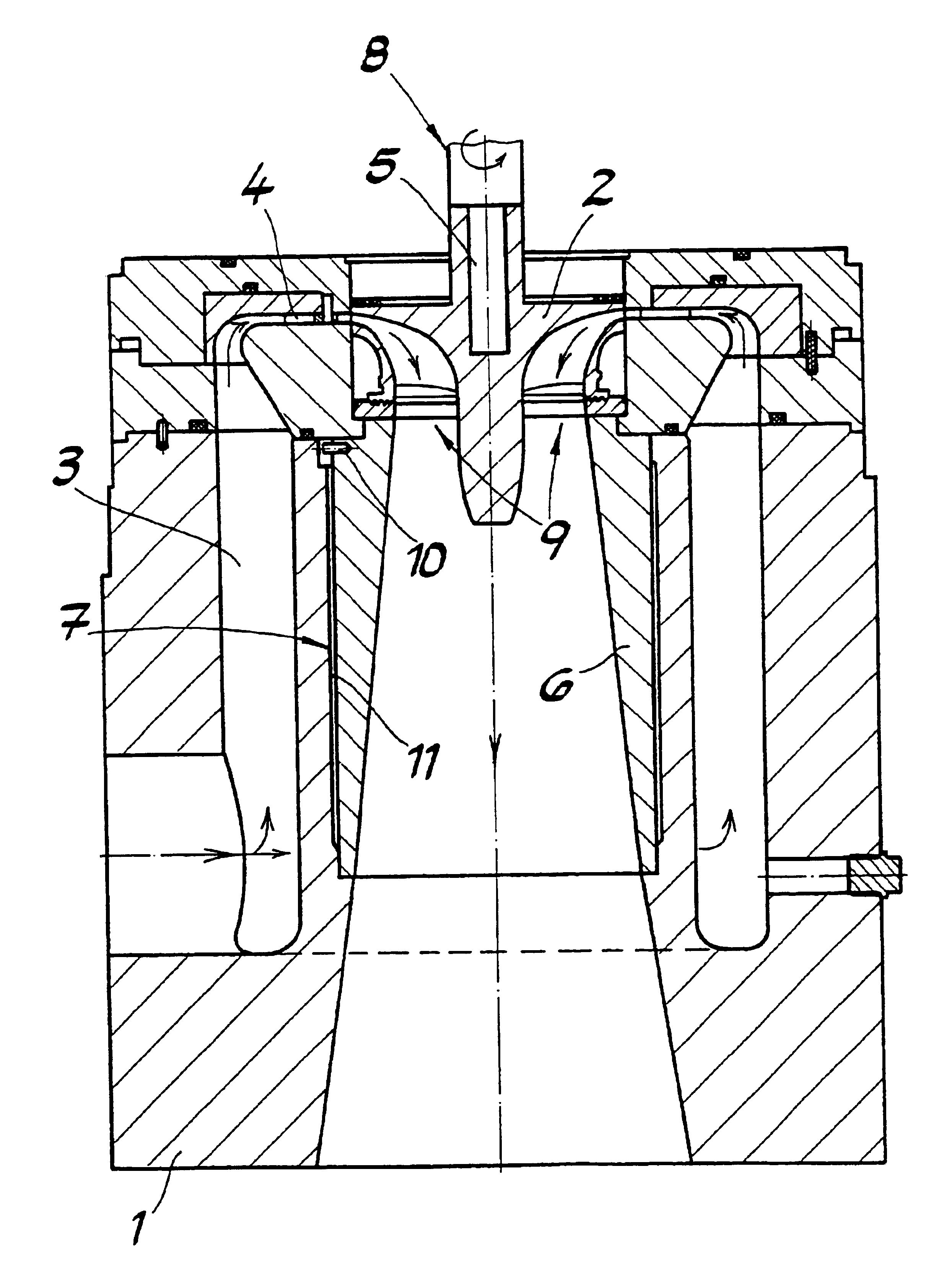

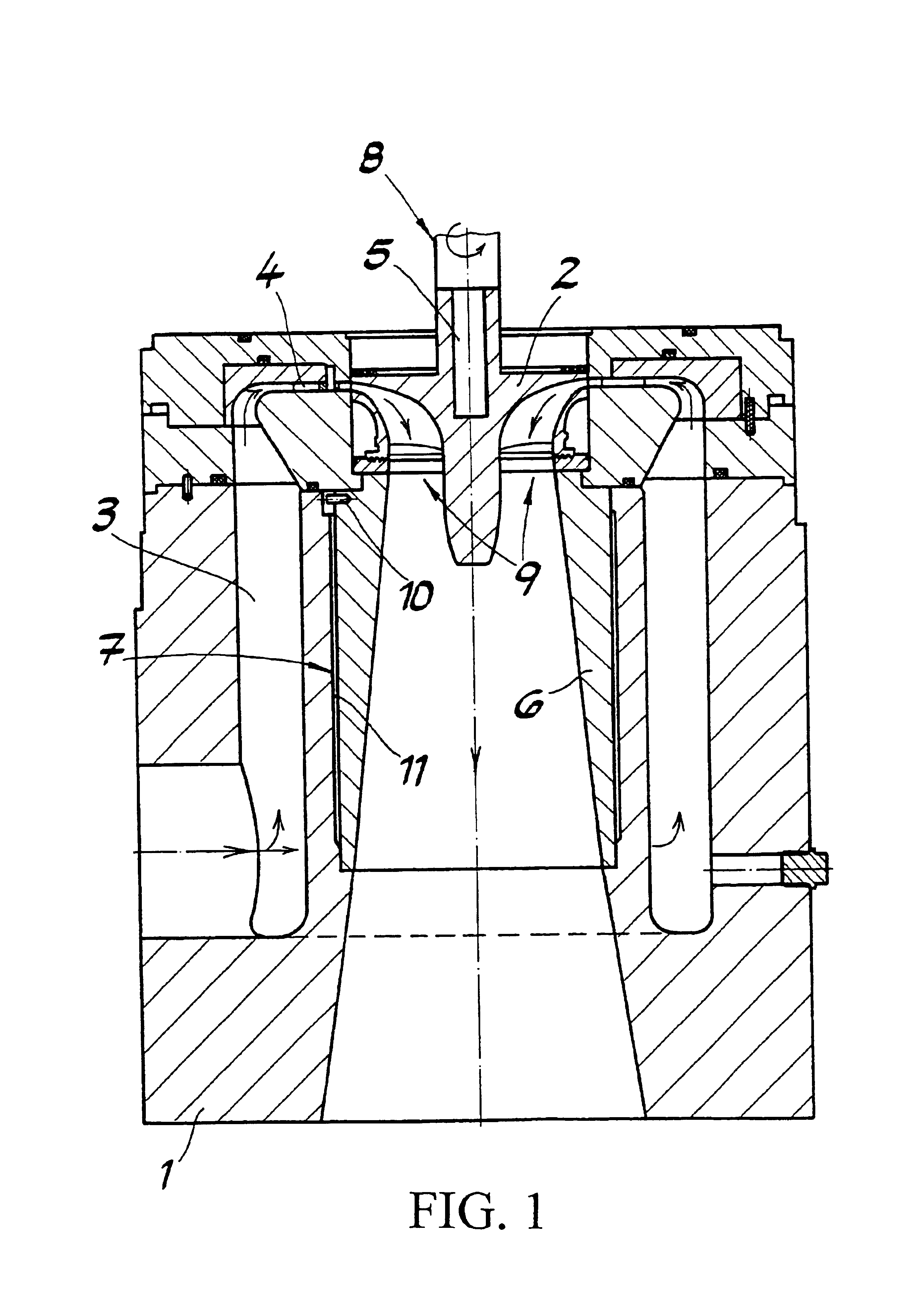

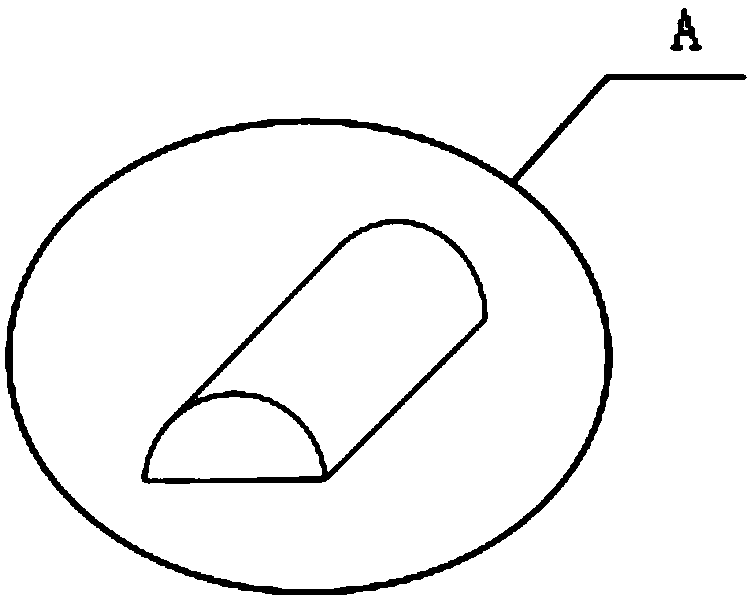

Protective member and nozzle assembly configured to resist wear

InactiveUS20100024987A1Avoid contactSolve the lack of wear resistanceTurning machine accessoriesFilament handlingWear resistanceNozzle

A protective member (14) and a nozzle assembly (11) incorporating the protective member (14) are provided. The protective member (14) is for use with a nozzle (12) having a strand guide passageway (18) for receiving a strand (16) of material. Protective member (14) comprises a body (60) configured to be received in the strand guide passageway (18) of the nozzle (12). The body (60) of the protective member (14) has a passageway (63) for the strand (16) and is disposed between the strand guide passageway (18) and the moving strand (16). The body (60) of the protective member (14) is composed, at least in part, of a material having a wear resistance sufficient to resist wear caused by the strand (16) being guided thereby. Alternatively, a portion of the body (60) may be coated with a material having a wear resistance sufficient to resist wear caused by the strand (16).

Owner:NORDSON CORP

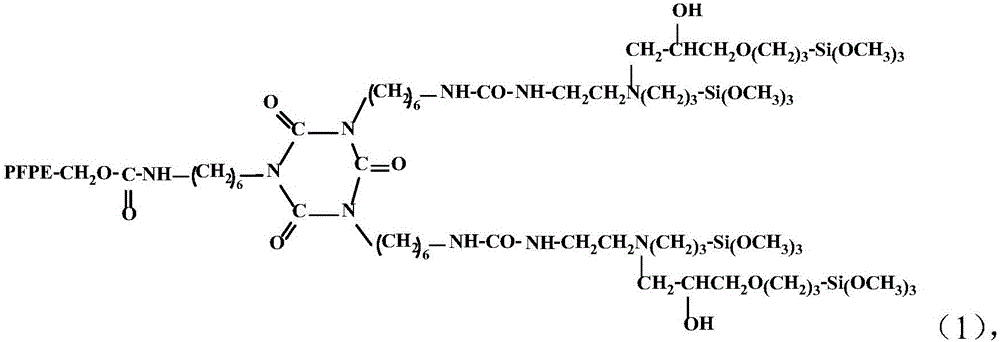

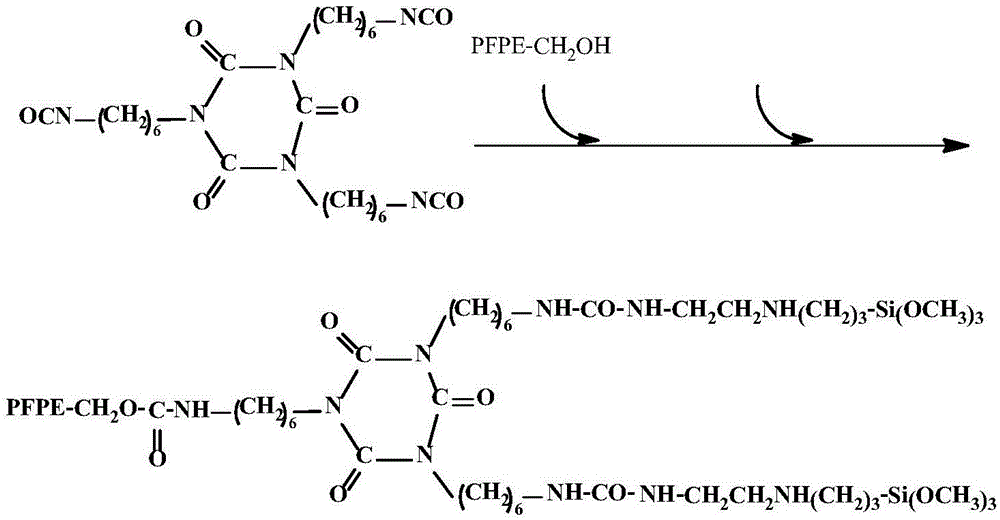

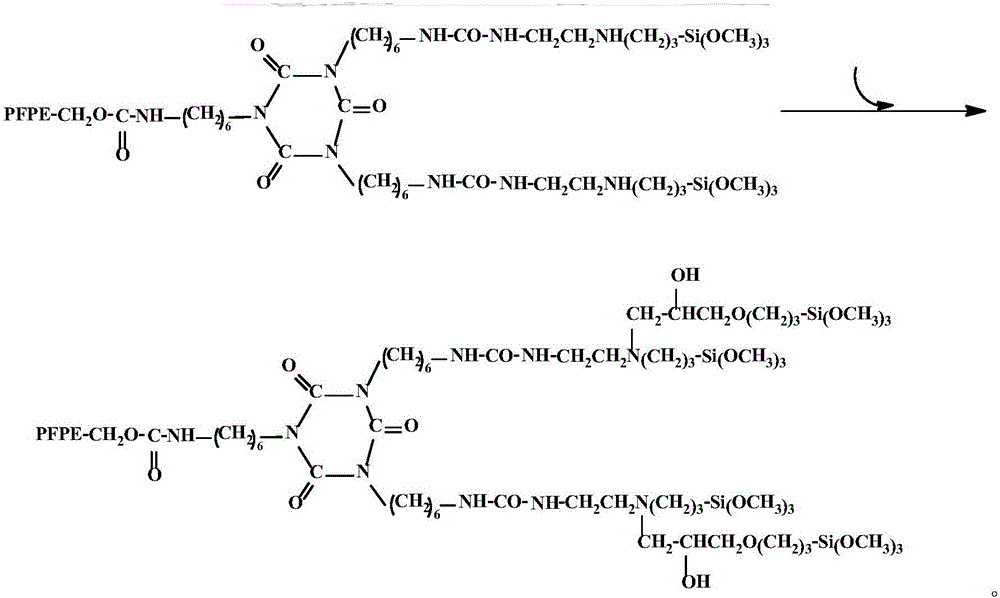

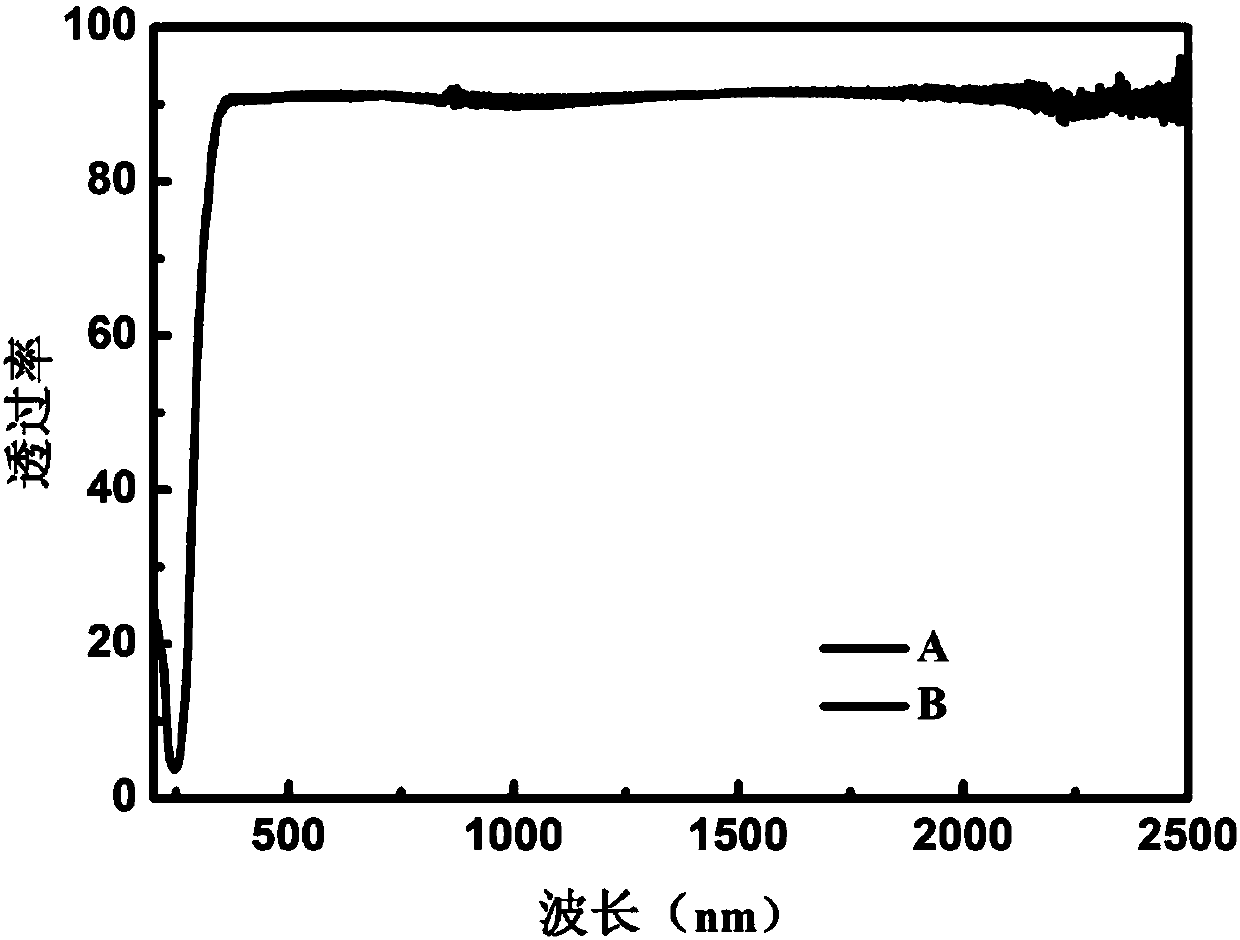

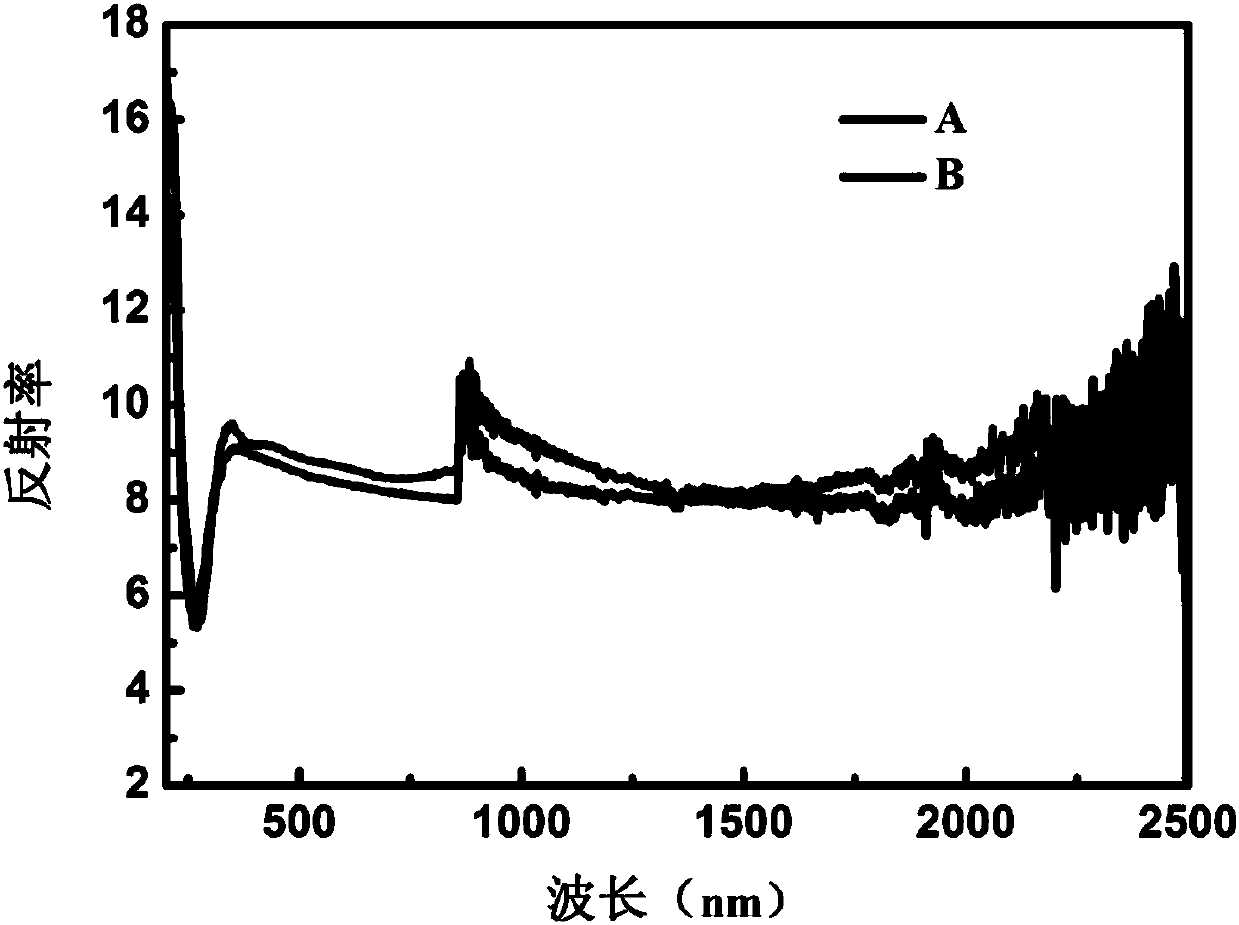

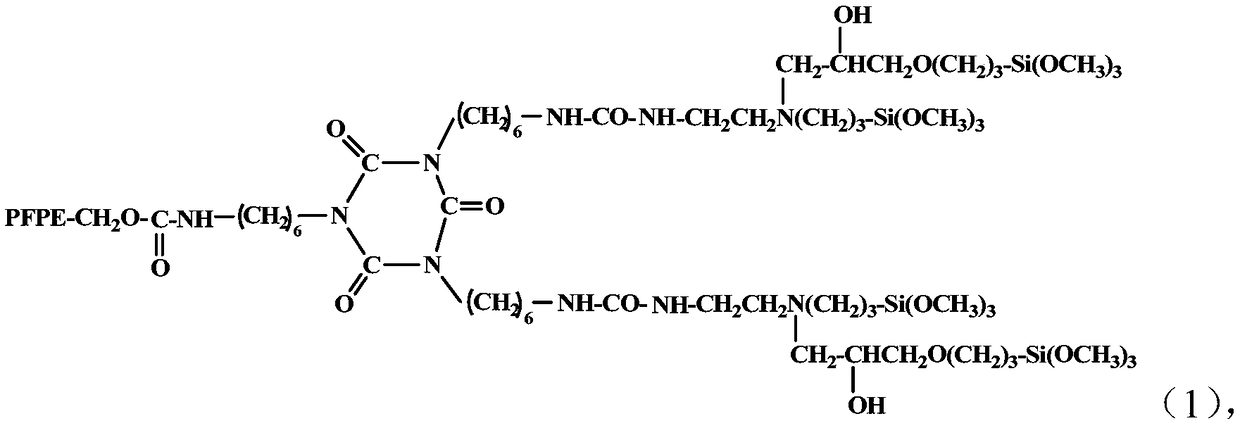

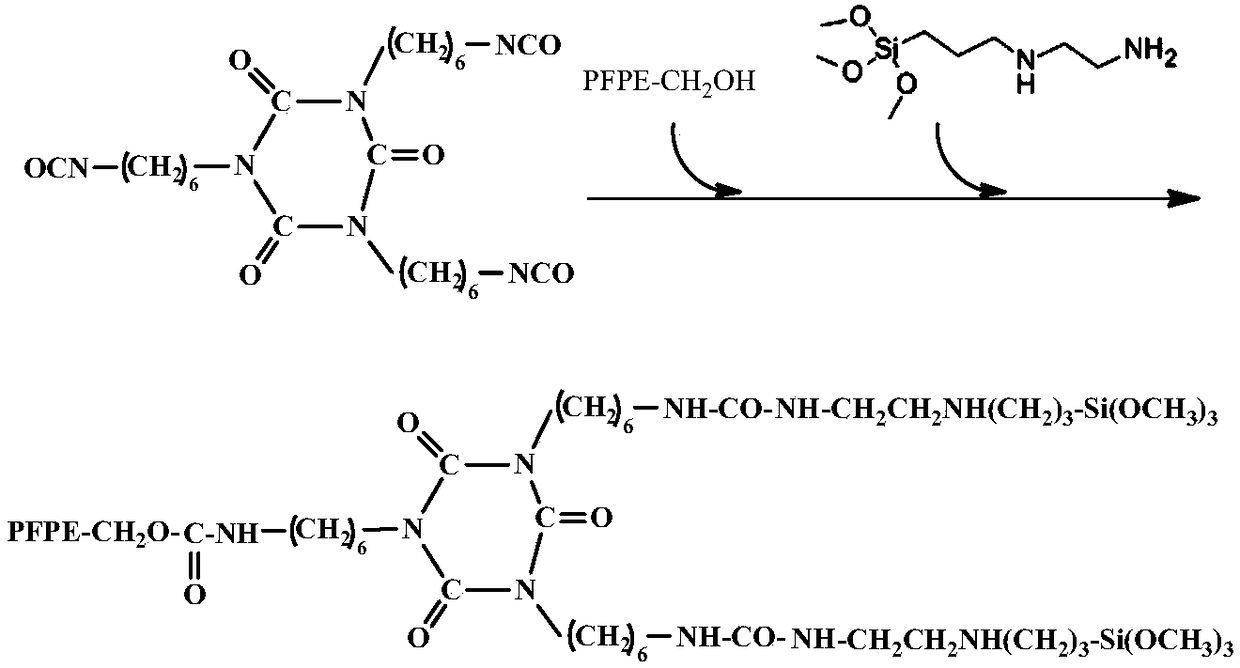

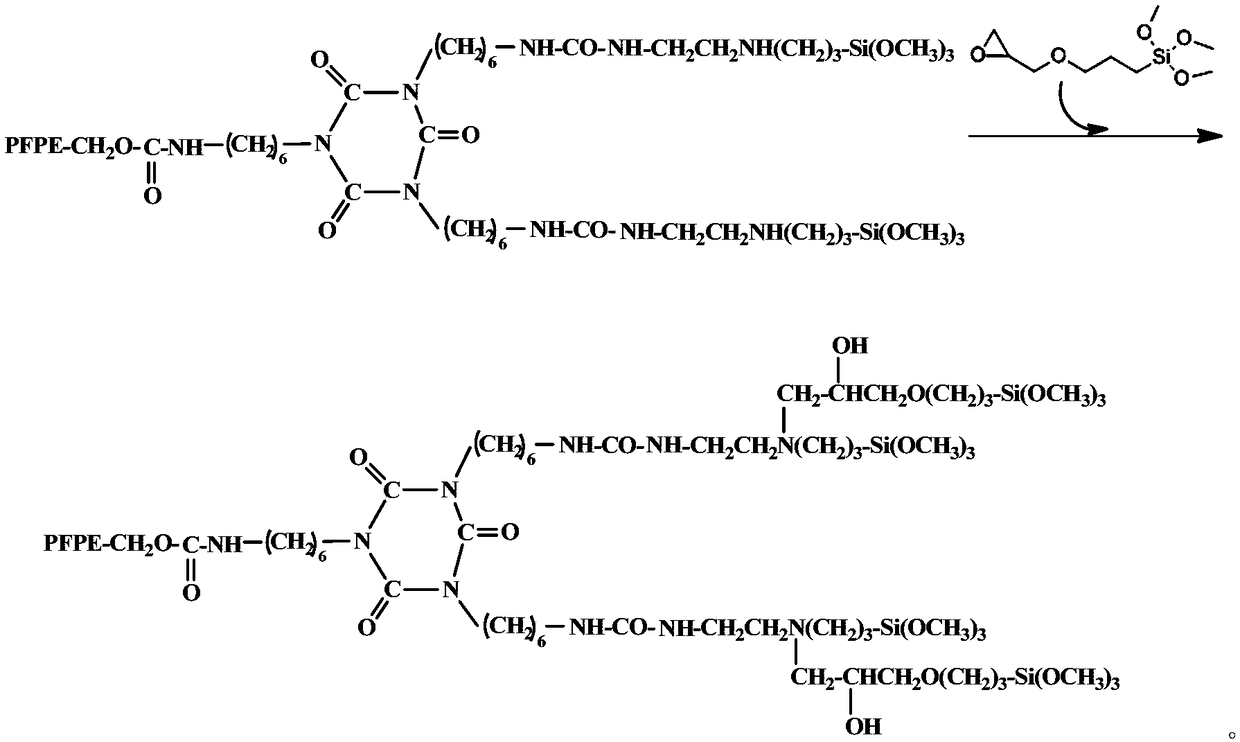

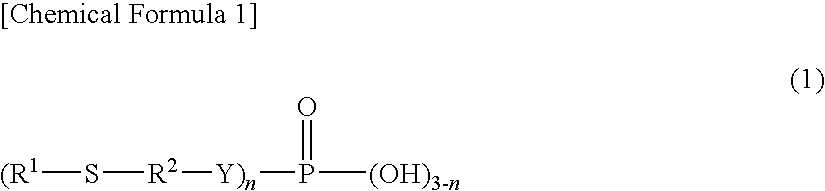

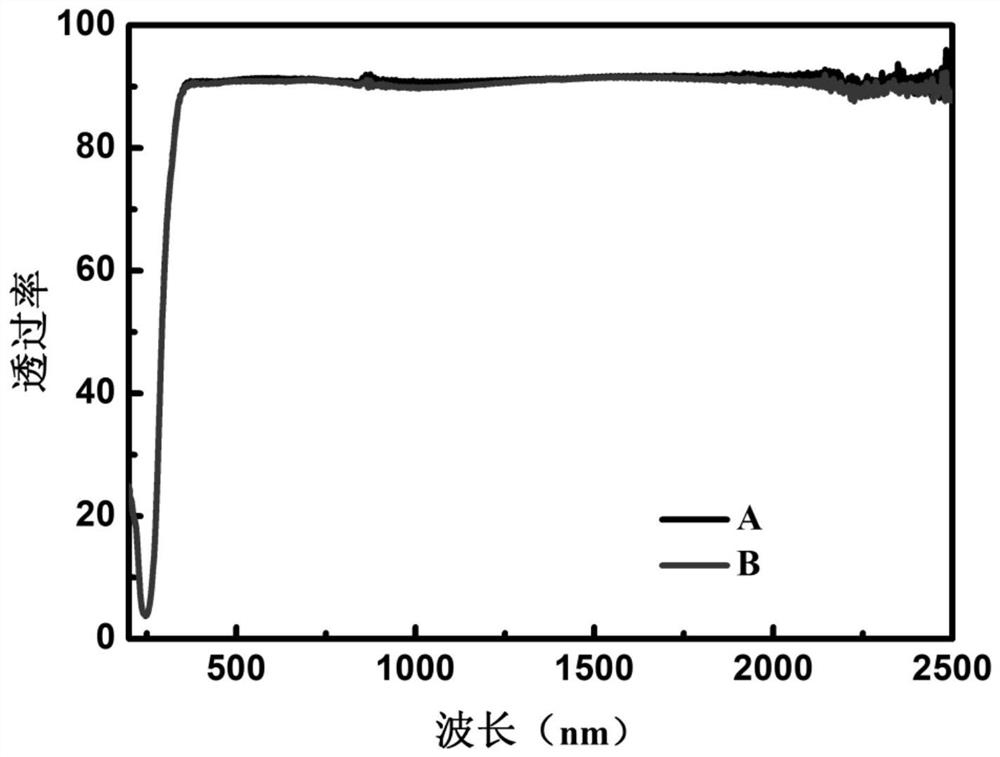

Novel perfluoropolyether alkoxy silane compound and synthesis method thereof

ActiveCN106432686AGood antifoulingGood anti-fingerprint effectAntifouling/underwater paintsPaints with biocidesSilane compoundsPerfluoropolyether

The invention discloses a novel perfluoropolyether alkoxy silane compound and a synthesis method thereof. The structure of the compound is shown as formula (1). The synthesis method includes: reacting hydroxyl terminated perfluoropolyether (PFPE), 3-(2-aminoethyl)aminopropyltrimethoxysilane, 3-(2, 3-epoxypropoxy)propyltrimethoxysilane (KH560), and an HDI trimer in a molar ratio of 1:2:2:1, during reaction, employing a certain amount of a solvent to dilute the mixed hydroxyl terminated perfluoropolyether and 3-(2-aminoethyl)aminopropyltrimethoxysilane, then adding the HDI trimer dropwise, carrying out reaction for 6h at certain temperature, then adding KH560 dropwise, and carrying out reaction for 6h again at certain temperature then reducing pressure and removing the solvent, thus obtaining the perfluoropolyether alkoxy silane compound. The compound can be coated on glass, plastic, film, and other substrate surfaces, and after crosslinking and curing, a layer of solid film can be formed, and the substrate is endowed with excellent anti-fingerprint and antifouling performance and abrasion resistance.

Owner:QUZHOU FLUORIDE & SILICON RES INST +1

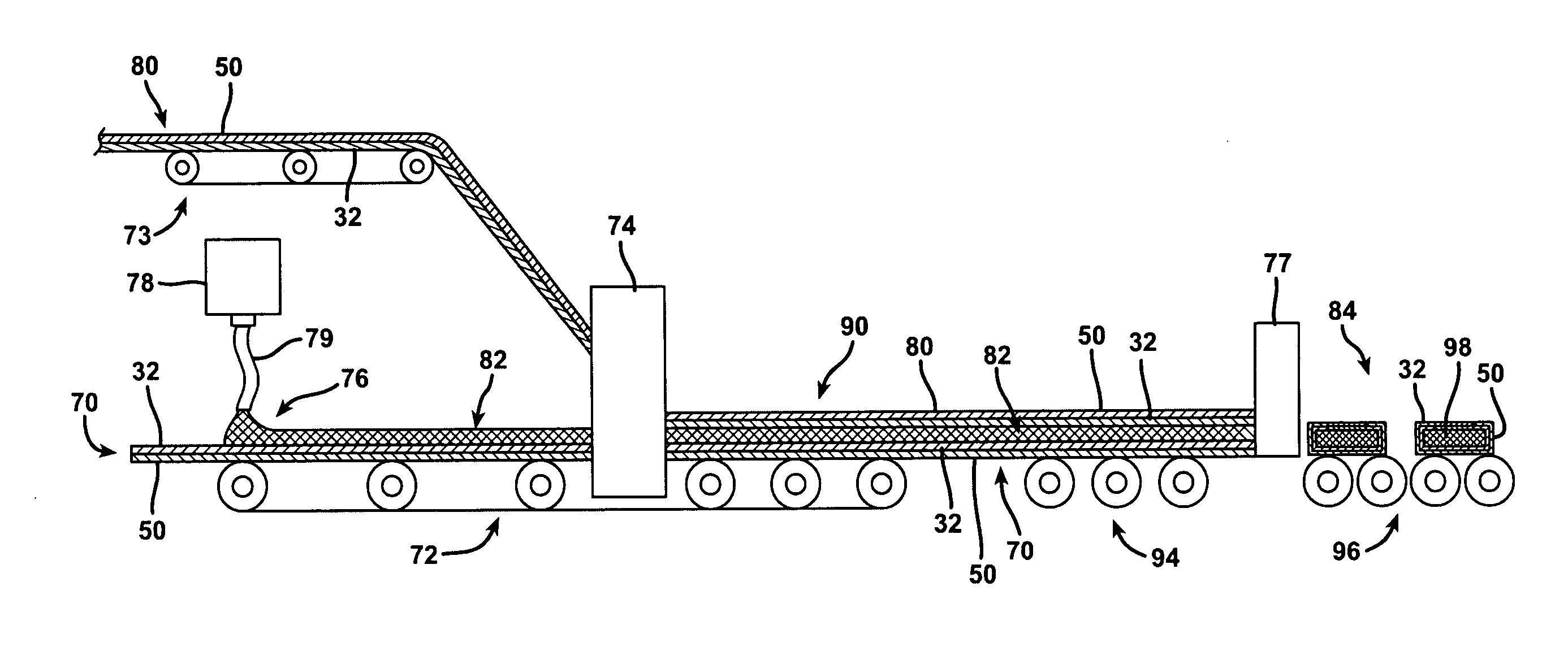

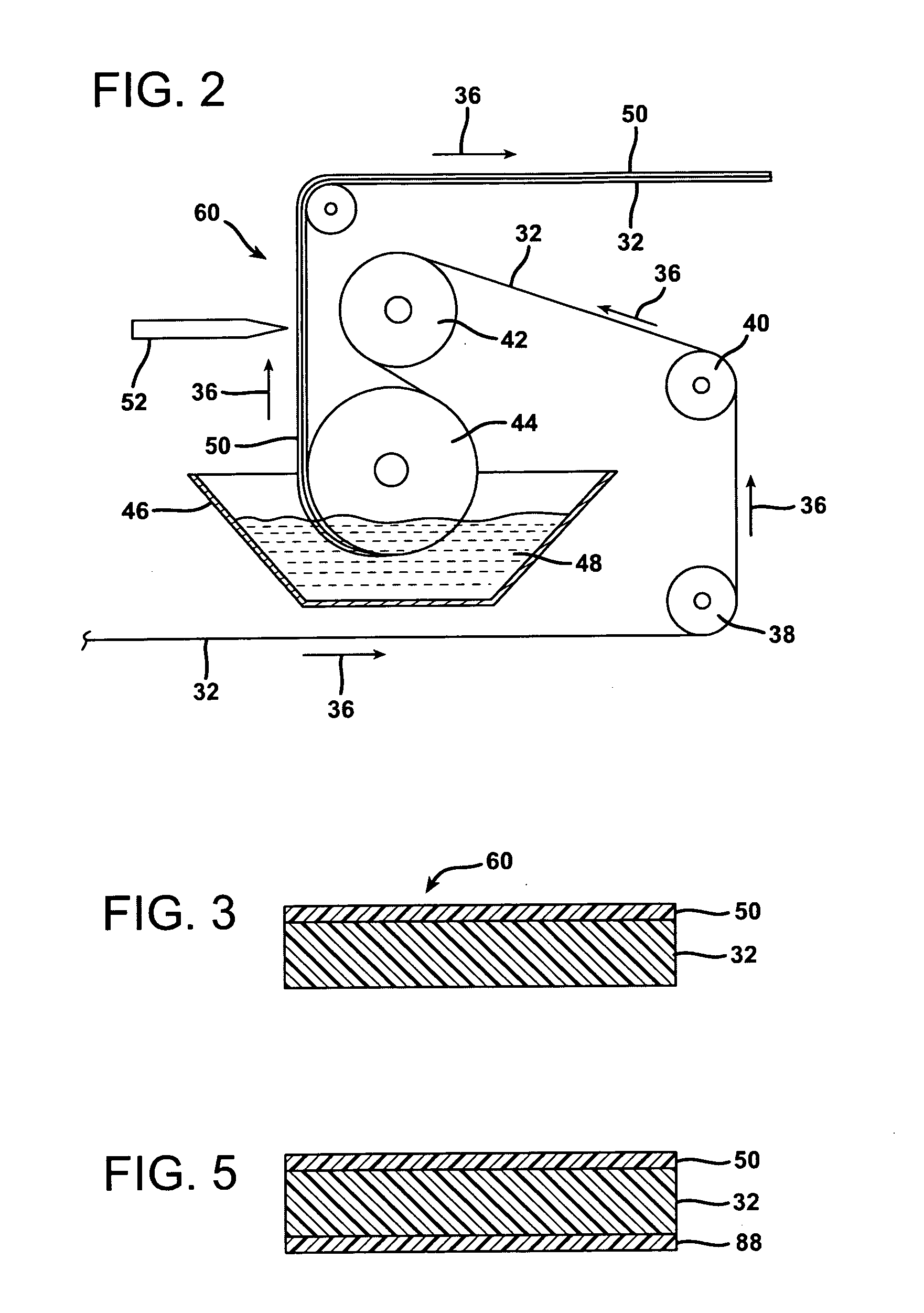

Wear resistant coating composition for a veil product

InactiveUS20070197114A1Harm reductionMore wear resistantSynthetic resin layered productsBuilding componentsMohs scale of mineral hardnessWear resistant

A coating composition that contains hard particles, a binder, and at least one thickening agent is provided. Pigment materials, a dispersant, a biocide, and a defoaming agent may also be included. The particles may have a size of about 1.0 to about 20.0 microns and a hardness of at least 5 on the Mohs Hardness Scale. The hard particles may be present in the composition in an amount from about 2.0 to about 15.0% by weight of the composition. The coating composition may be applied to a veil to form a wear resistant coating. The coated veil may then be used to form a coated gypsum product. The coating composition improves wear resistance and reduces damaging effects that may be caused by winding, workers handling the coated gypsum product during installation, and / or adverse conditions after installation. Methods of forming a coated veil and coated gypsum products are also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Sintered alloy, method for production thereof and valve sheet

InactiveUS20040194576A1Solve the lack of wear resistanceImprove wear resistanceMachines/enginesLift valveWear resistanceMaterials science

To provide a sintered alloy capable of showing wear resistance and a process for producing the same as well as a valve seat of good wear resistance. A sintered alloy comprising 4-30% by weight Mo, 0.2-3% by weight C, 1-30% by weight Ni, 0.5-10% by weight Mn, 2-40% by weight Co, and the balance of inevitable impurities and Fe when the entirety is taken as 100% by weight. Aprocess for producing a sintered alloy in which a green compact of a raw mixture powder including hard particles is sintered, thereby producing said sintered alloy. A valve seat comprising said sintered alloy.

Owner:TOYOTA JIDOSHA KK +1

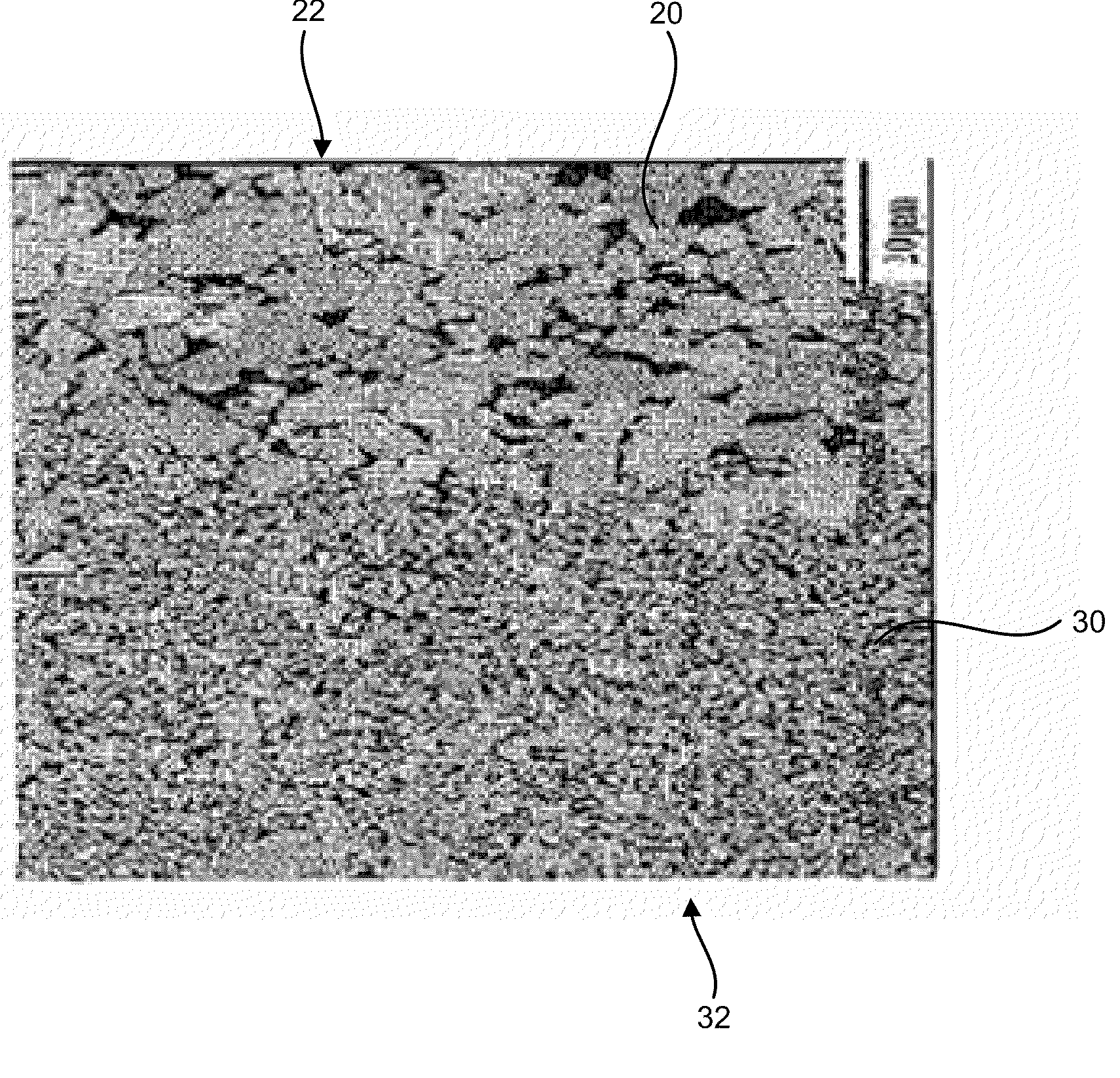

Thermal degradation and crack resistant functionally graded cemented tungsten carbide and polycrystalline diamond

InactiveUS20090226688A1Improve thermal conductivityDissipate frictional heatLamination ancillary operationsSynthetic resin layered productsPolycrystalline diamondHardness

A WC—Co material or polycrystalline diamond-Co material that has a gradient in the grain size of the particles. Specifically, the material may have a top layer that has coarse grains that is designed to dissipate the heat caused by friction (and thus prevent thermal cracking). The material will then have a bulk substrate that is made up of finer grains and provide adequate hardness for the material. The top layer is positioned on top of the bulk substrate.

Owner:UNIV OF UTAH RES FOUND

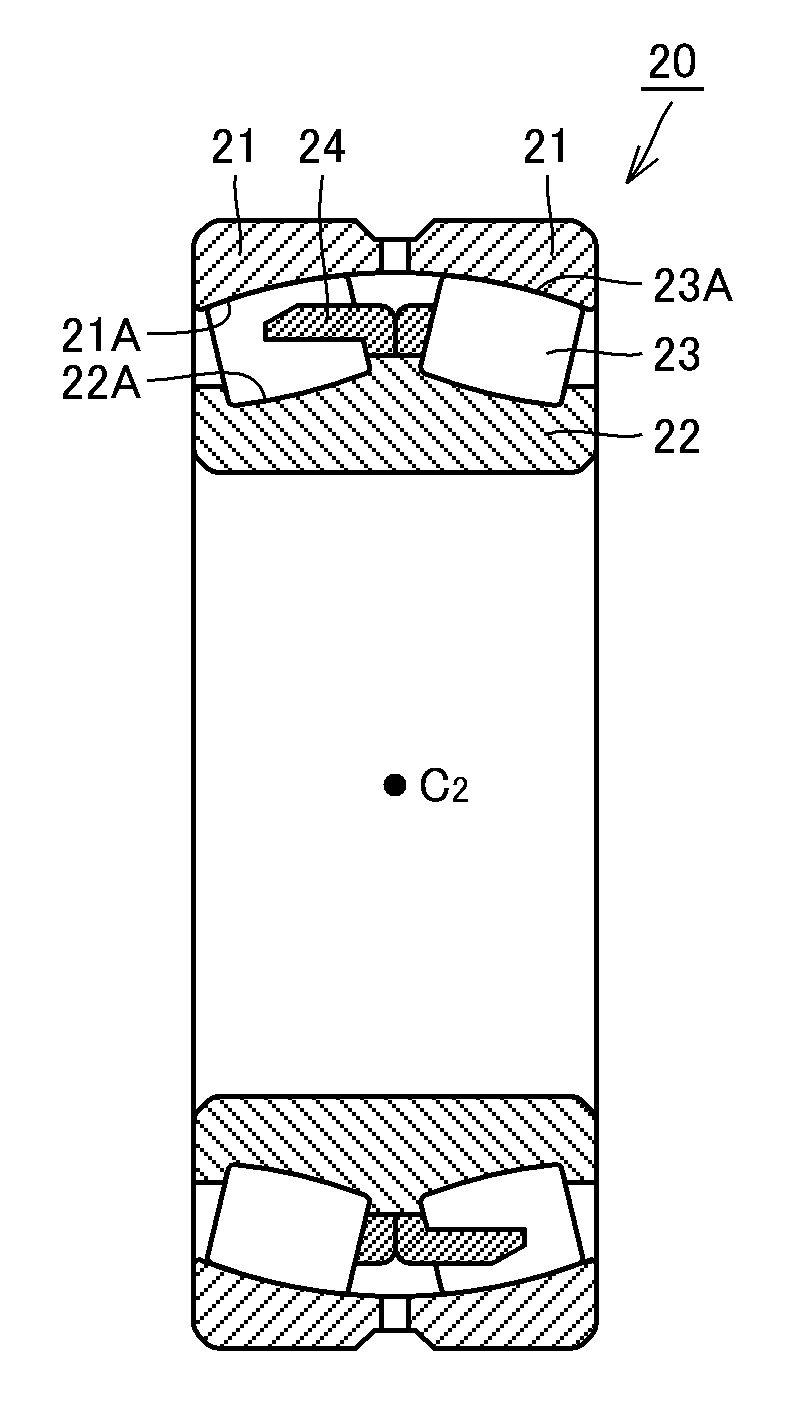

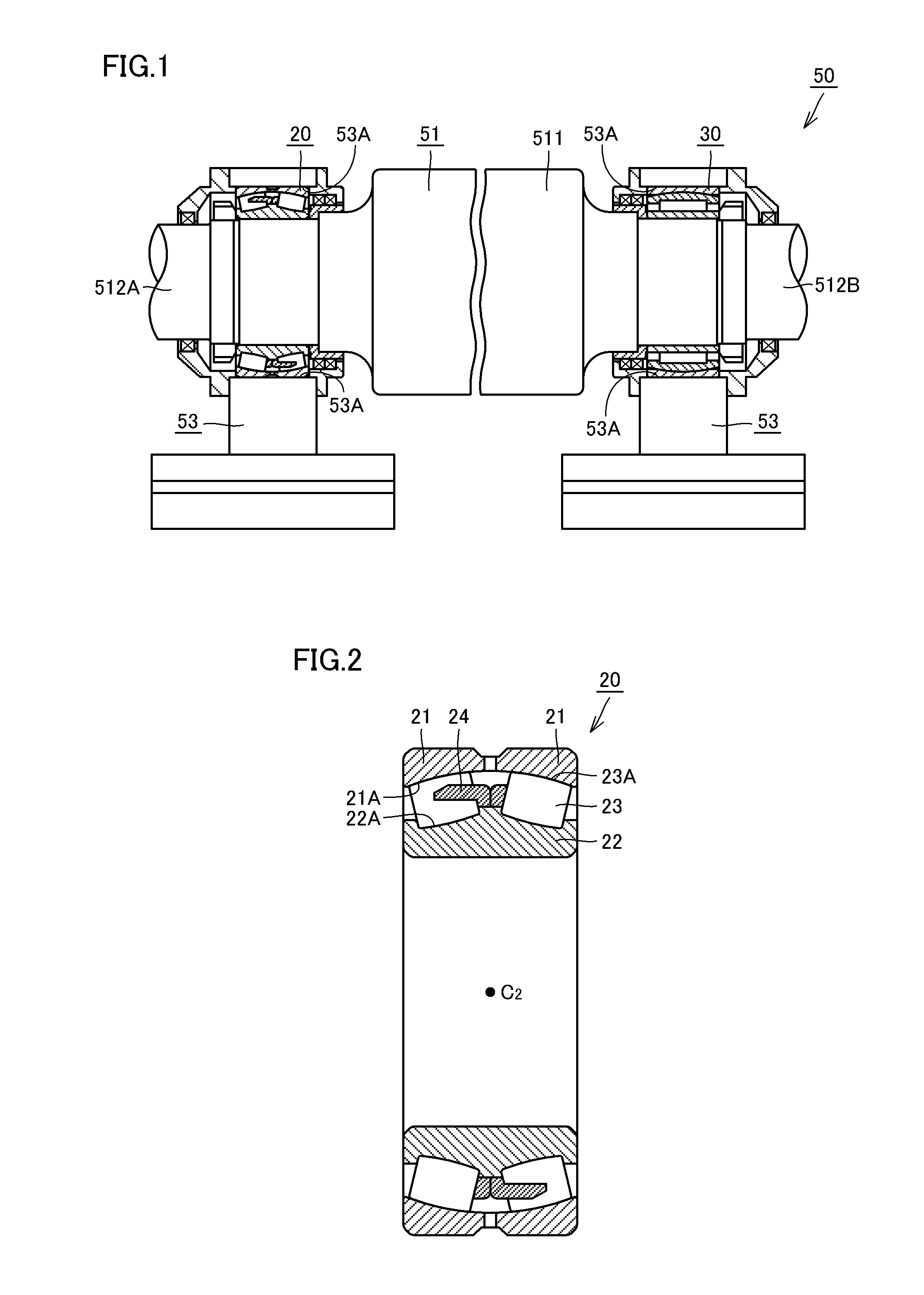

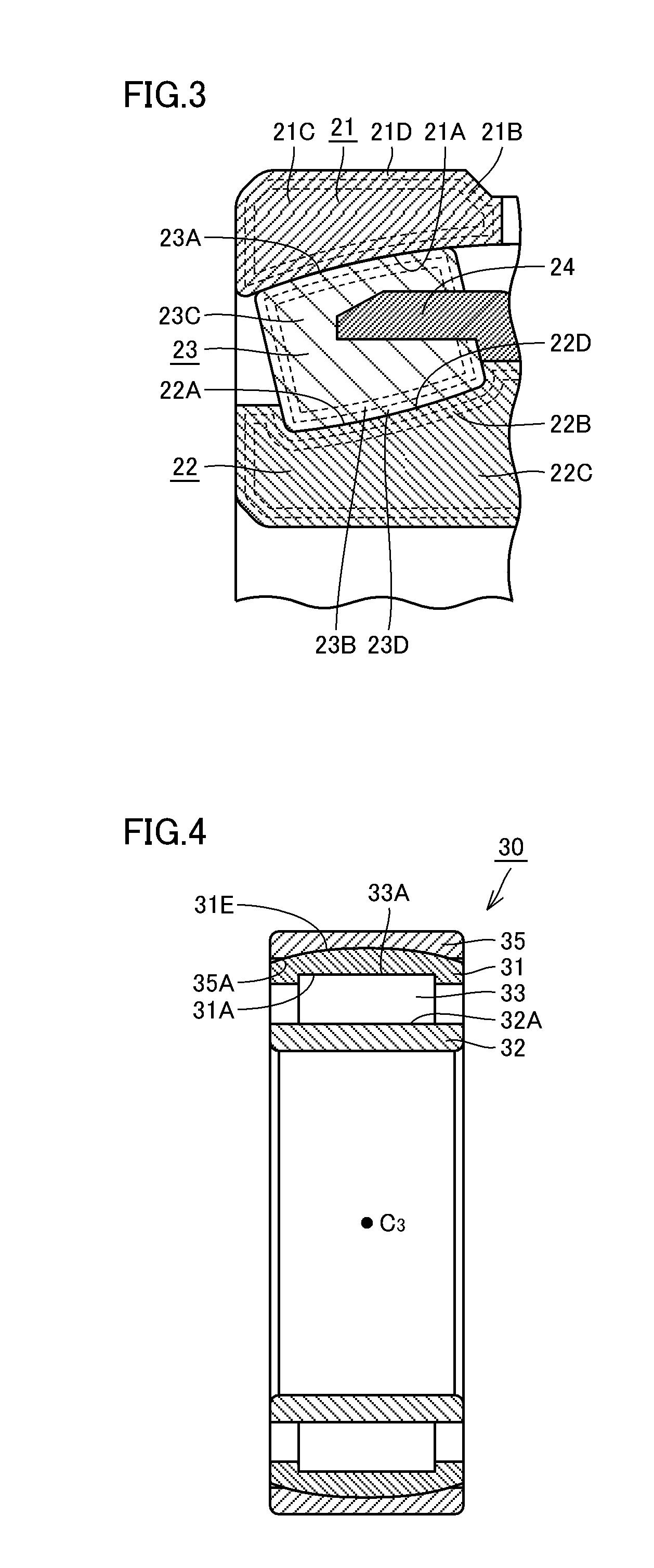

Bearing component, rolling bearing, and method for producing bearing component

ActiveUS20120020605A1Large fracture toughness valueSolve the lack of wear resistanceRoller bearingsBearing componentsSource materialRolling-element bearing

An outer ring, an inner ring and a roller serving as a bearing component that adopts as a source material a steel ensuring a large fracture toughness value and also having an alloy element added thereto in a reduced amount and also provides sufficient wear resistance, are configured of a steel containing 0.15-0.3% by mass of carbon, 0.15-0.7% by mass of silicon, and 0.15-1.0% by mass of manganese, with a remainder of iron and an impurity, and have a raceway / rolling contact surface included in a region having a carbon enriched layer and a nitrogen enriched layer. In the nitrogen enriched layer the raceway / rolling contact surface has a nitrogen concentration equal to or larger than 0.3% by mass.

Owner:NTN CORP

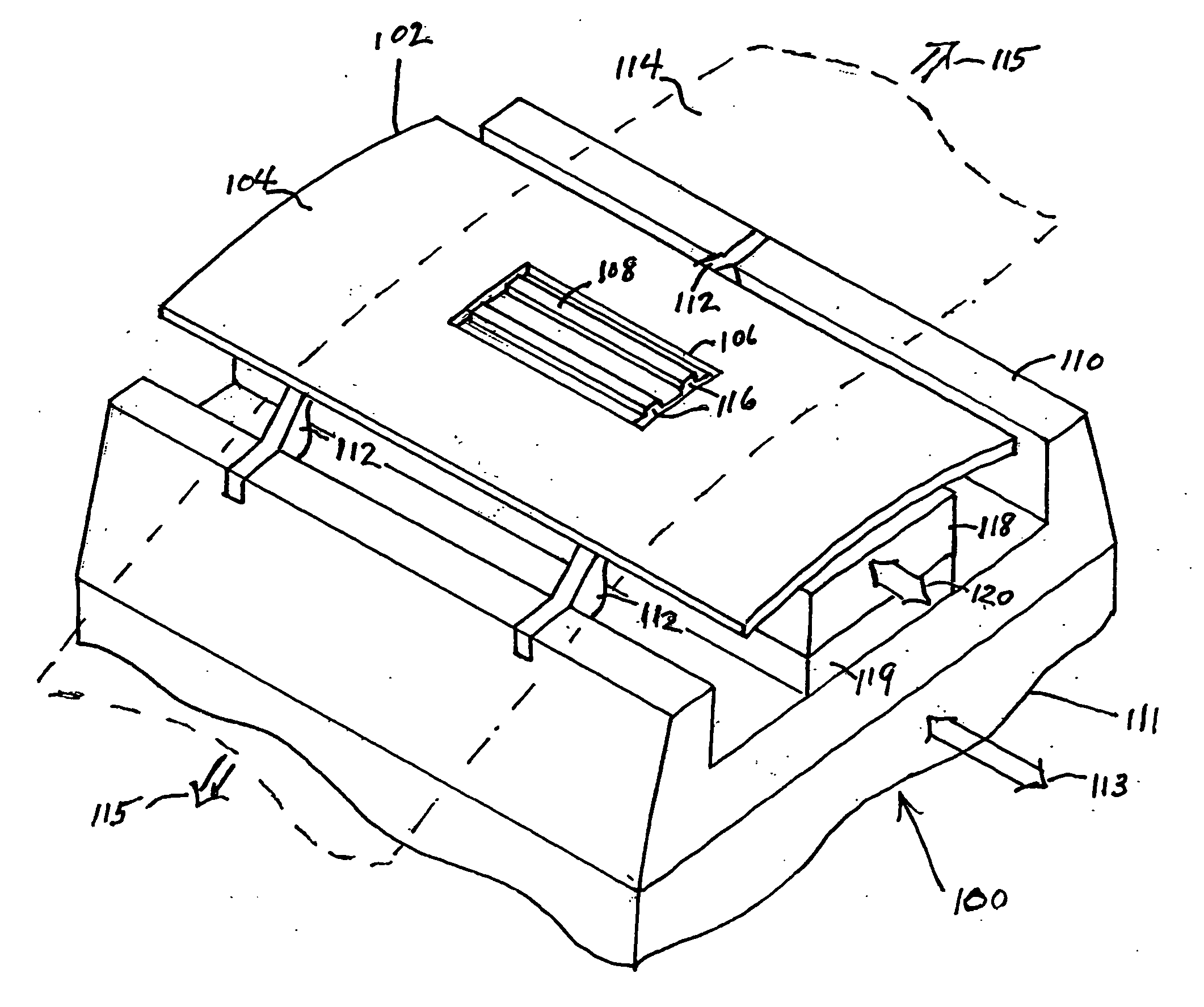

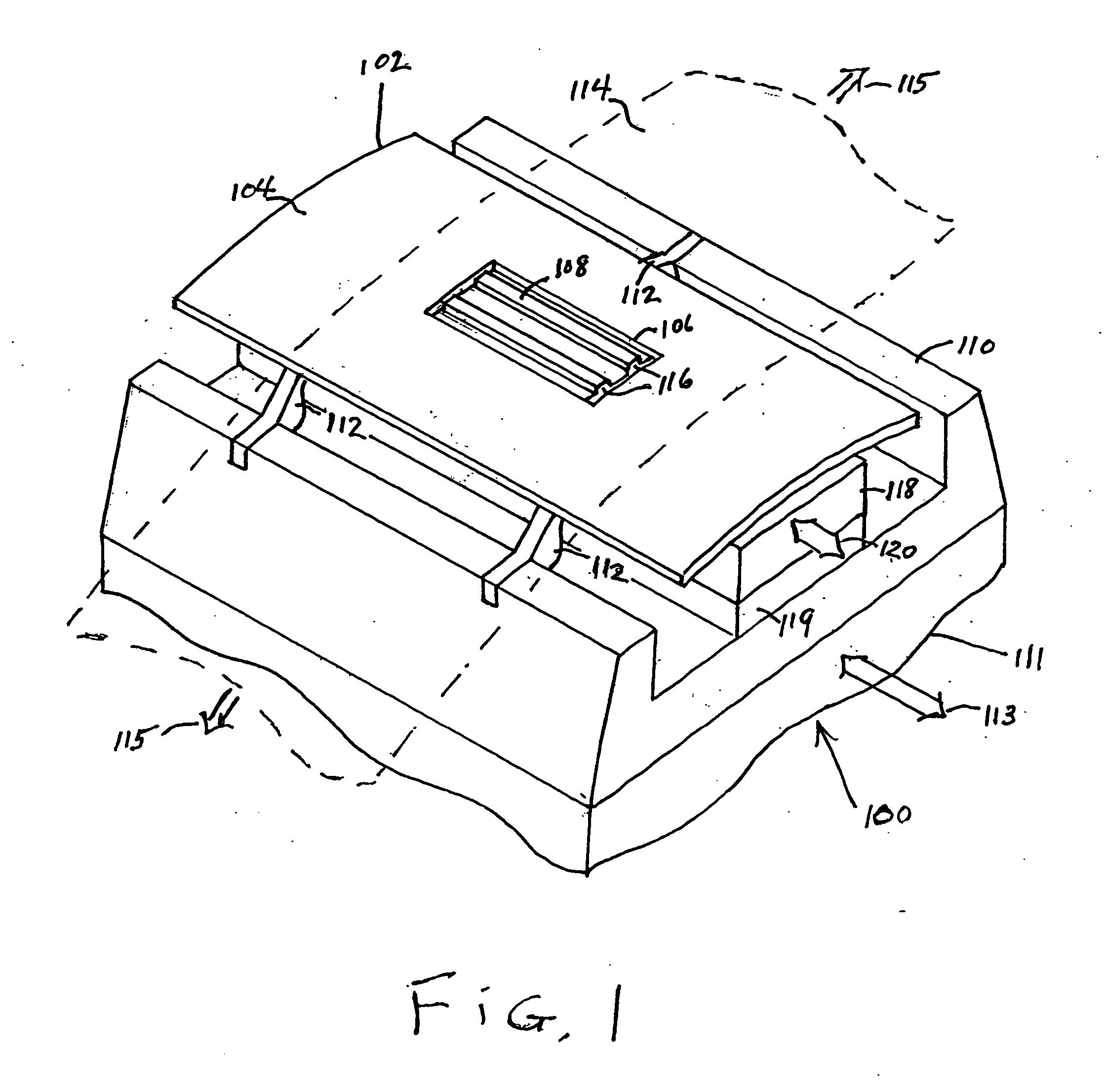

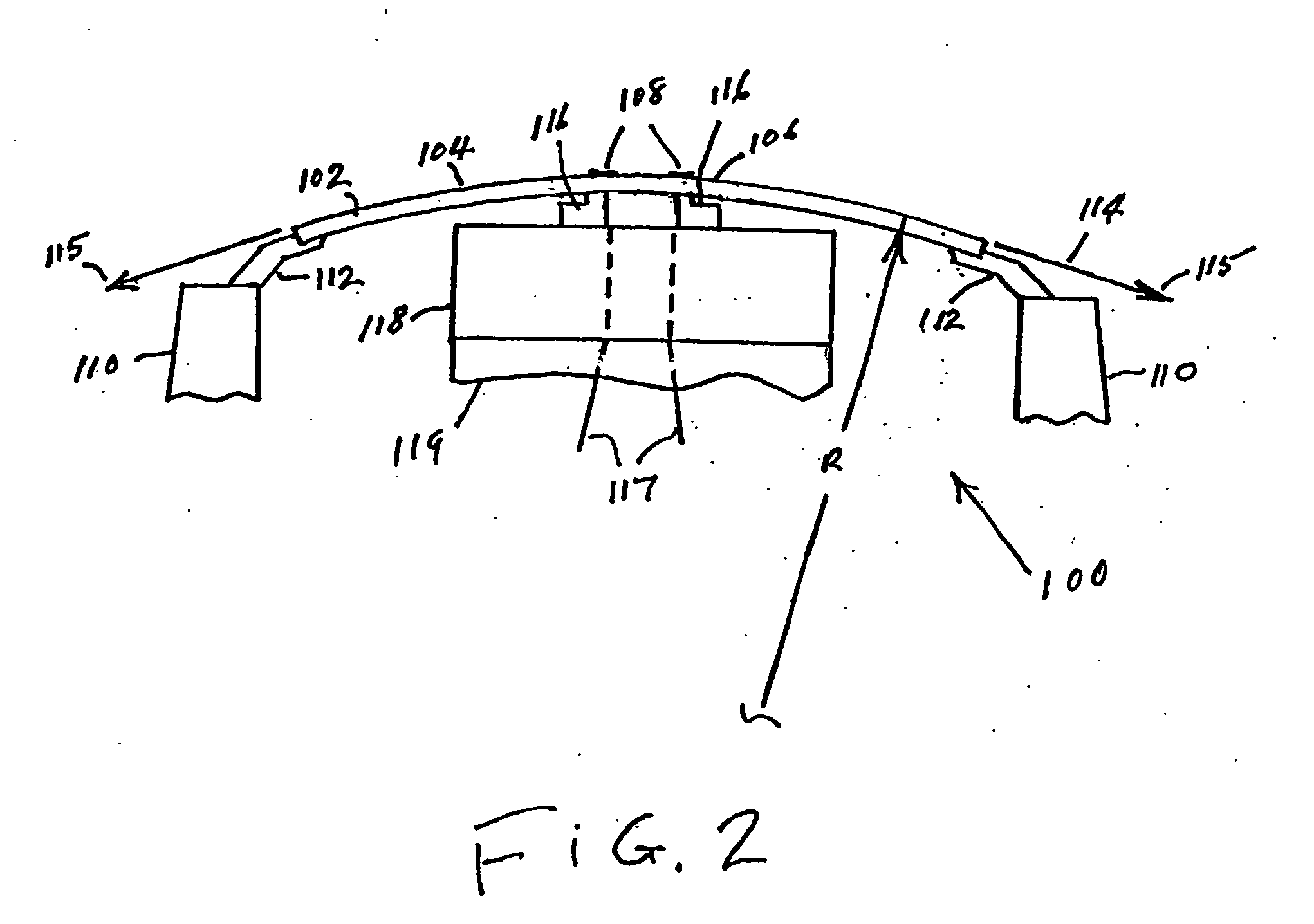

Tape recording head

ActiveUS20050135017A1Solve the lack of wear resistanceHigh bandwidthDisposition/mounting of recording headsManufacturing heads with multiple gapsMagnetic tapeActuator

A tape recording head is provided comprising a support plate having a contoured surface with an opening in the contoured surface which allows head chips to protrude far enough to allow proper head tape contact for recording. The support plate is fixed on a coarse actuator so that the support plate and coarse actuator move together perpendicular to the motion of the recording tape. The head chips comprising rowbar substrates containing a multiplicity of recording elements are supported on a carrier mounted on a fine actuator and are not fixed to the support plate to allow low mass fine actuation.

Owner:META PLATFORMS INC

High manganese steel containing tungsten

The invention discloses a high manganese steel which contains tungsten, and the high manganese steel contains chemical constituents in the following mass percent: C: 1.05%-1.35%, Si: 0.3%-0.9%, Mn: 11%-19%, W: 0.5%-1.5%, P<=0.070% and S<=0.045%, and the rest is Fe, furthermore, the high manganese steel also can contain a rare earth element RE, and the content of the RE is 0.01%-0.3%. The high manganese steel also can contain Cr and the content of the Cr is 1.2-2.5%. The high manganese steel which contains the tungsten of the invention is added with the elements of tungsten, rare earth element RE and chrome in particular when the content of the Mn is 16%-19%, which enables the whole high manganese steel to have the advantages of good toughness, high yield strength, high work hardening degree, better abrasive resistance and the like compared with the existing steel, and thereby the application range of the high manganese steel is enlarged. The high manganese steel of the invention is suitable for preparing fitting parts which are used in the working condition of abrasion and in particular to impact abrasion.

Owner:JINAN UNIVERSITY

Transparent antifogging agent and preparation method thereof

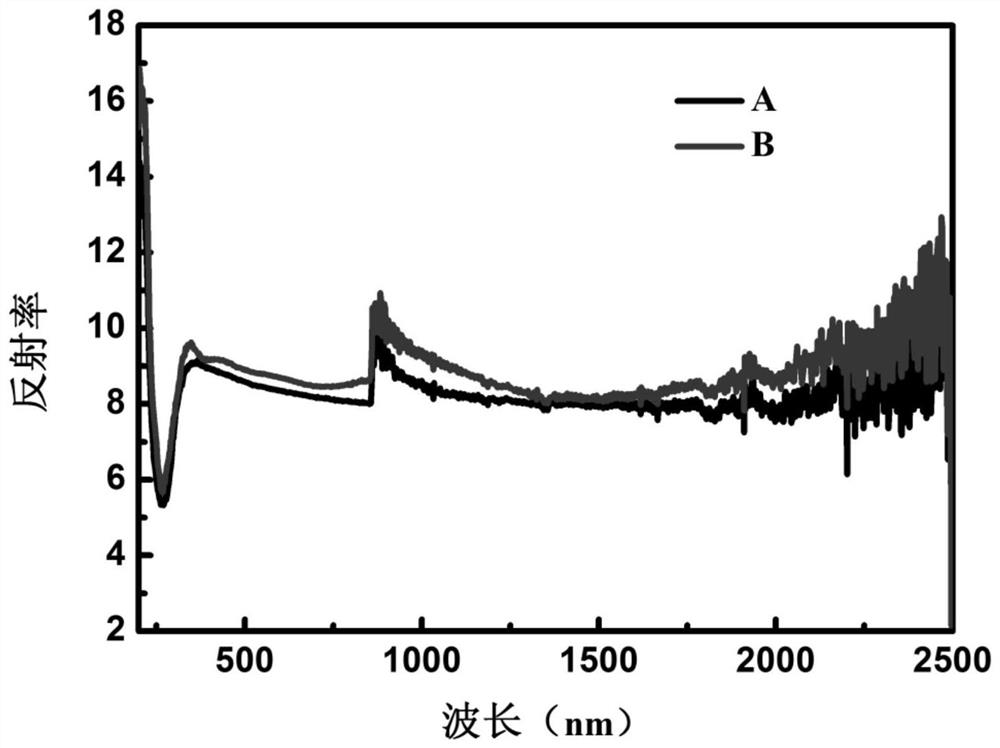

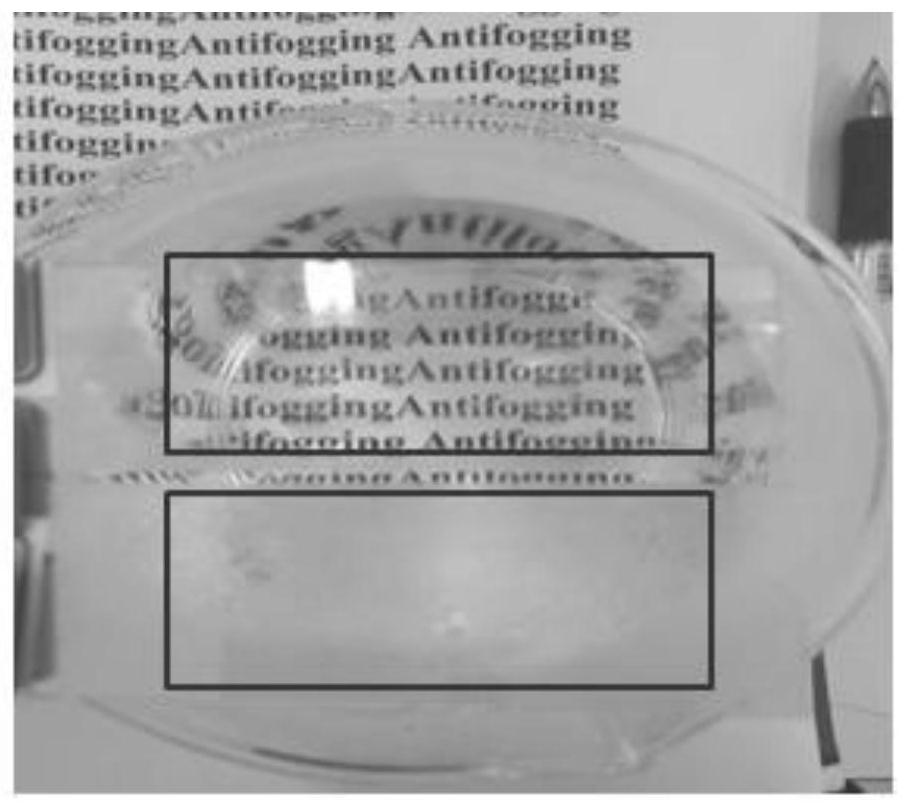

ActiveCN107629760AEnhanced ability to resist water vapor erosionImproved anti-fog durabilityOther chemical processesCoatingsChemistrySolution composition

The invention discloses a transparent antifogging agent. The transparent antifogging agent is composed of an organosilane-modified SiO2 sol and an aqueous polyvinyl alcohol solution, wherein a mass ratio of the organosilane-modified SiO2 sol to the aqueous polyvinyl alcohol solution is 1: 10-1, and the organosilane-modified SiO2 sol is prepared from ethyl orthosilicate and absolute ethyl alcohol under the action of an alkali catalyst, i.e., ammonia water. The invention also discloses a preparation method for the transparent antifogging agent. The transparent antifogging agent is low in cost; the preparation method is simple in steps; and an antifogging film has improved water vapor resistance, enhanced antifogging endurance and substantially improved mechanical strength.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Reinforced fishing net

InactiveCN105295168ASolve the lack of wear resistanceImprove wear resistanceSodium stearatePlasticizer

The invention relates to a reinforced fishing net, and relates to the technical field of fishing net manufacturing. The reinforced fishing net is prepared from the following components in parts by weight: 120-130 parts of polyethylene, 80-90 parts of nylon, 3-6 parts of titanium dioxide, 5-6 parts of triammonium bromide, 4-5 parts of sodium stearate and 8-10 parts of a modified plasticizer. By adopting the reinforced fishing net, the problem that a conventional fishing net is insufficient in abrasion resistance is solved, a fishing net which is high in strength and good in abrasion resistance is provided, the fishing net is solid and resistant to abrasion, not easy to break and long in service life, and the fish catching amount can be greatly increased.

Owner:六安市沪渔网具有限公司

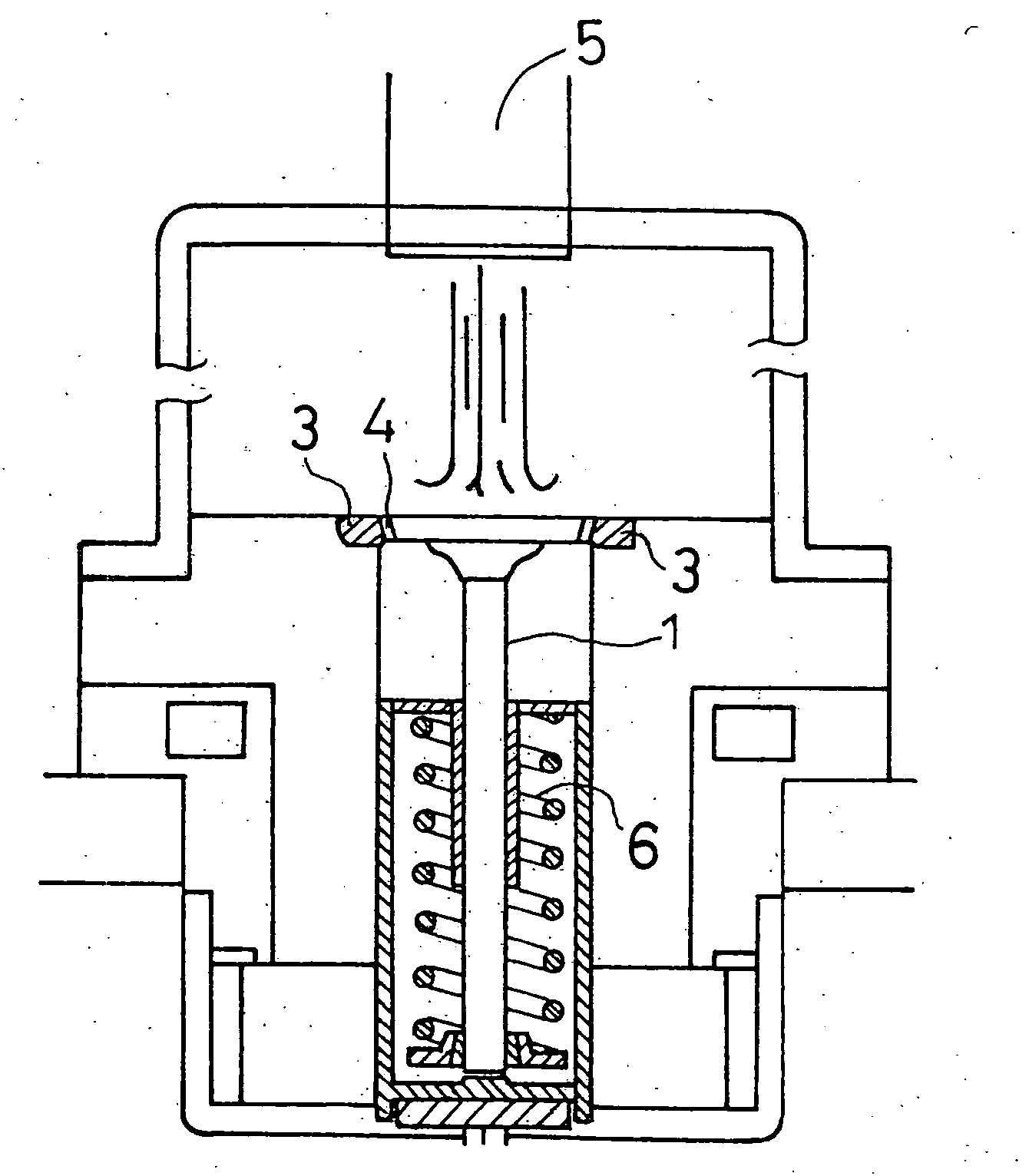

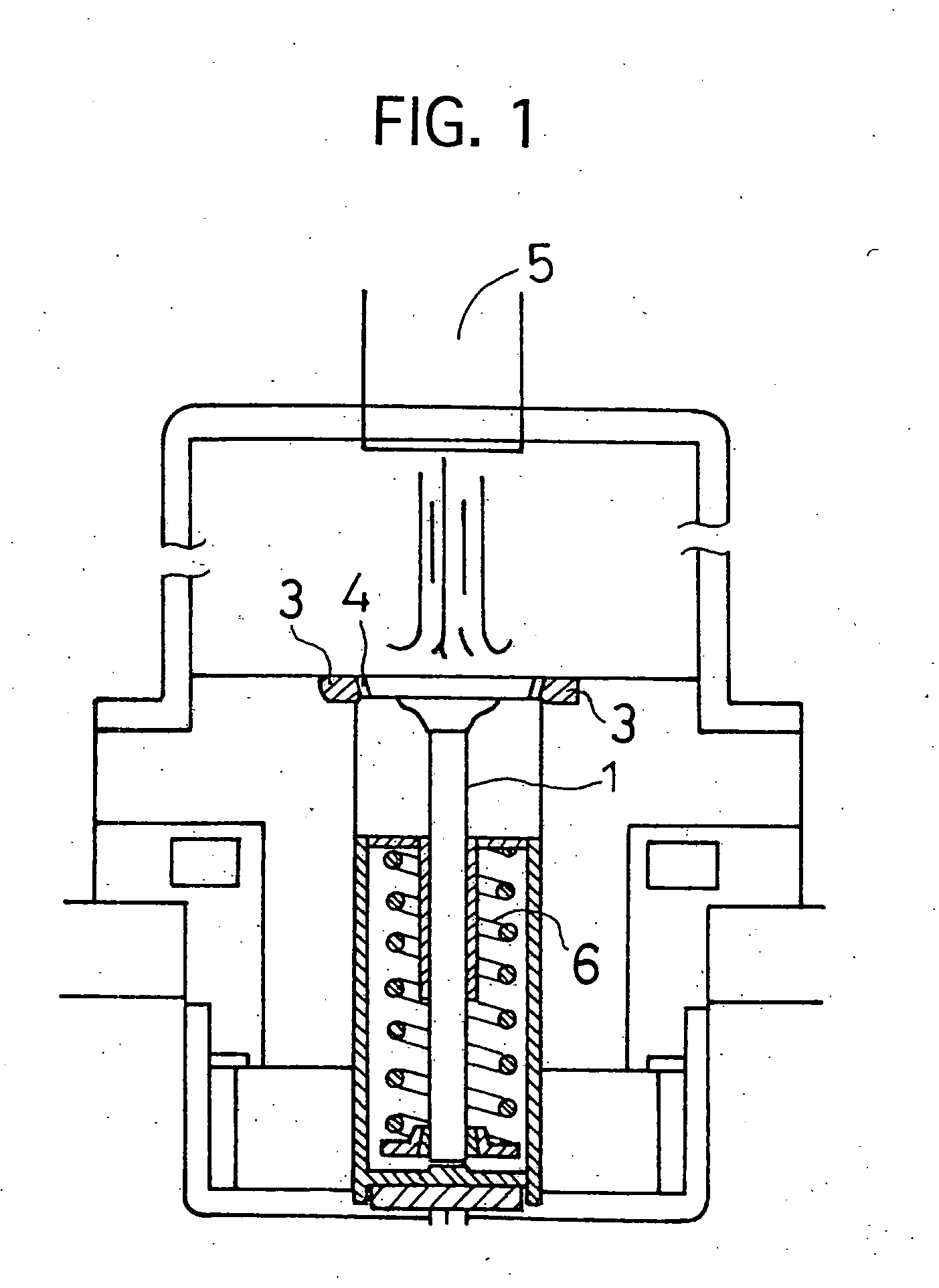

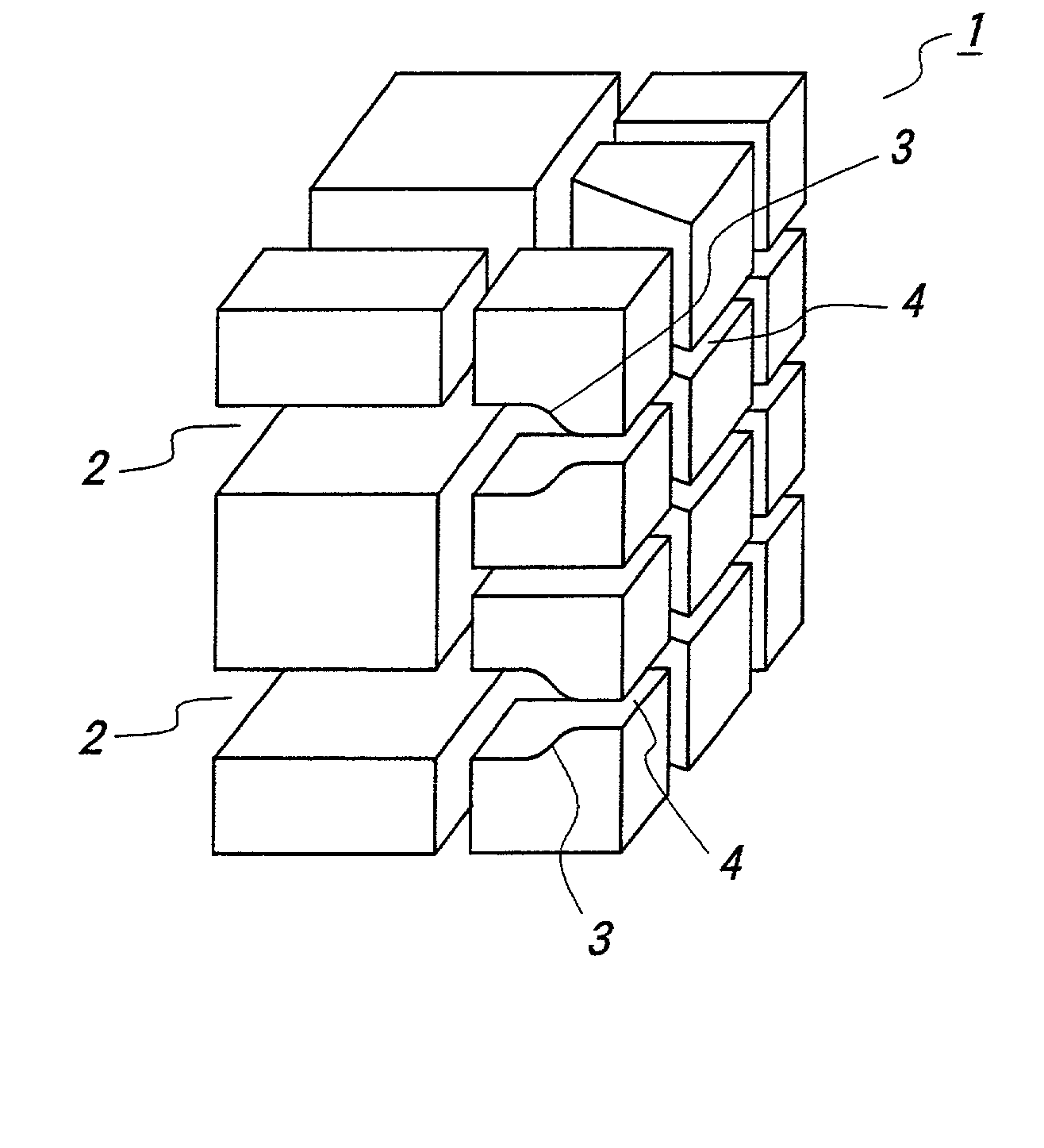

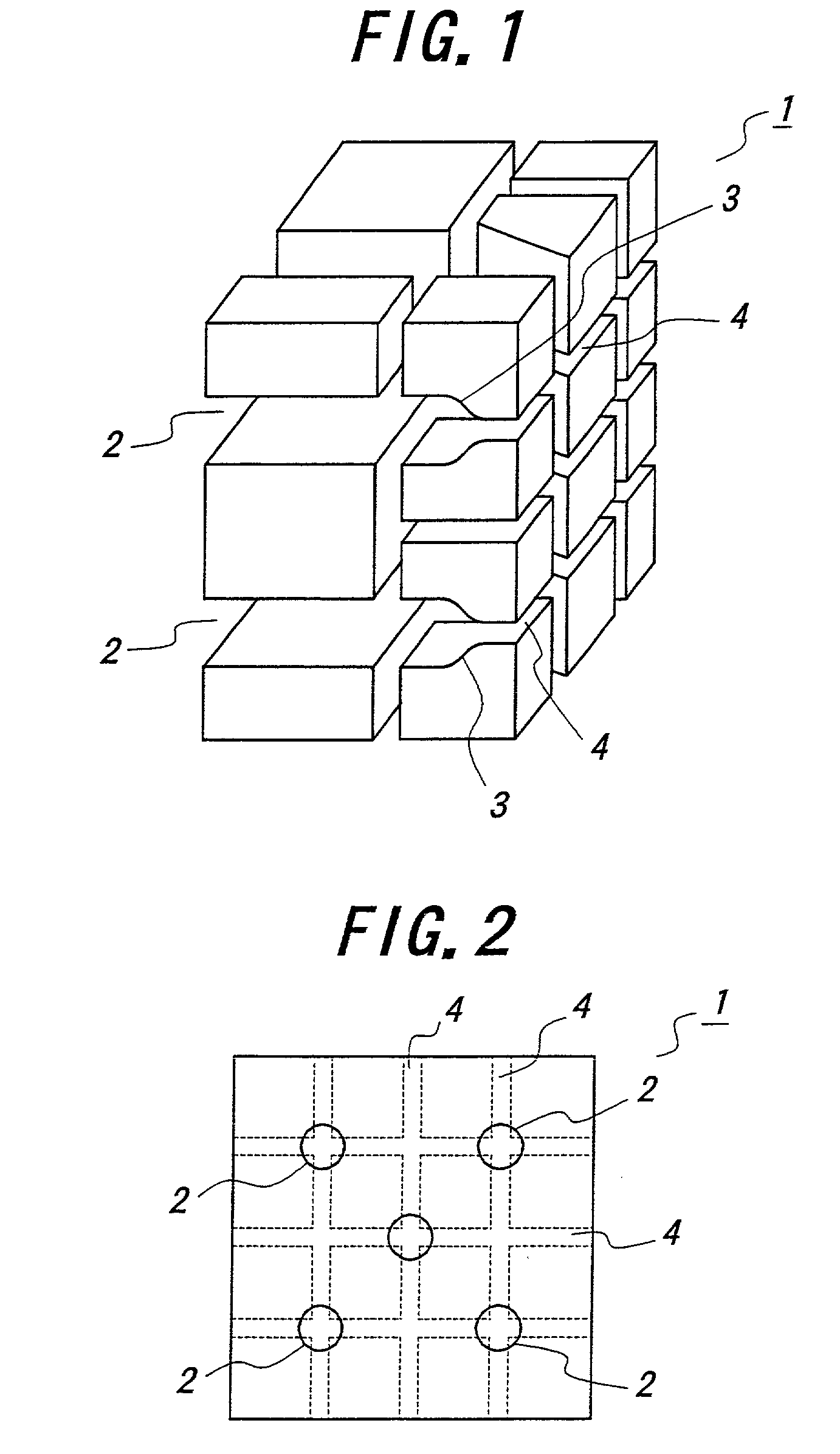

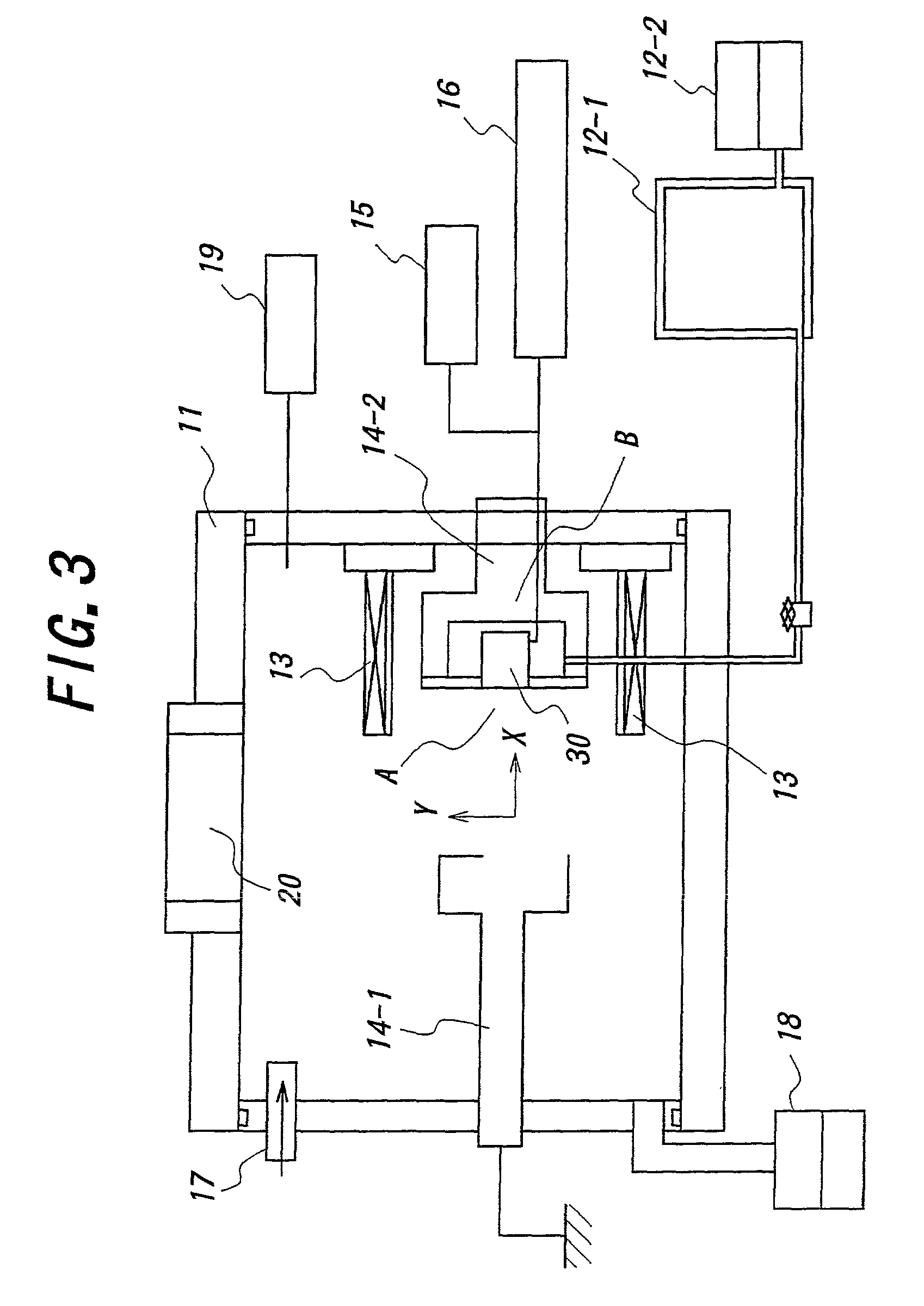

Mouth ring for forming a honeycomb-shaped green product, method for fabricating a mouth ring to form a honeycomb-shaped green product and apparatus for fabricating a mouth ring to form a honeycomb-shaped green product

InactiveUS20020172765A1Solve the lack of wear resistanceSolve the lack of resistanceLayered productsCeramic extrusion diesDiamond-like carbonHoneycomb

The back side space of a mouth ring for forming a honeycomb-shaped green product is evacuated by means of a pressure difference-creating means constructed of a pressure regulating chamber and a pump, and then, the pressure in the back side space of the mouth ring is set to be tenth or below of the pressure in the front space of the mouth ring. Then, a raw material gas is introduced and excited to generate a plasma raw material gas, which is introduced into the mouth ring efficiently commensurate with the pressure difference created by means of the pressure difference-creating means. As a result, a thin film made of diamond or diamond-like carbon is made in the mouth ring in good quality.

Owner:NGK INSULATORS LTD

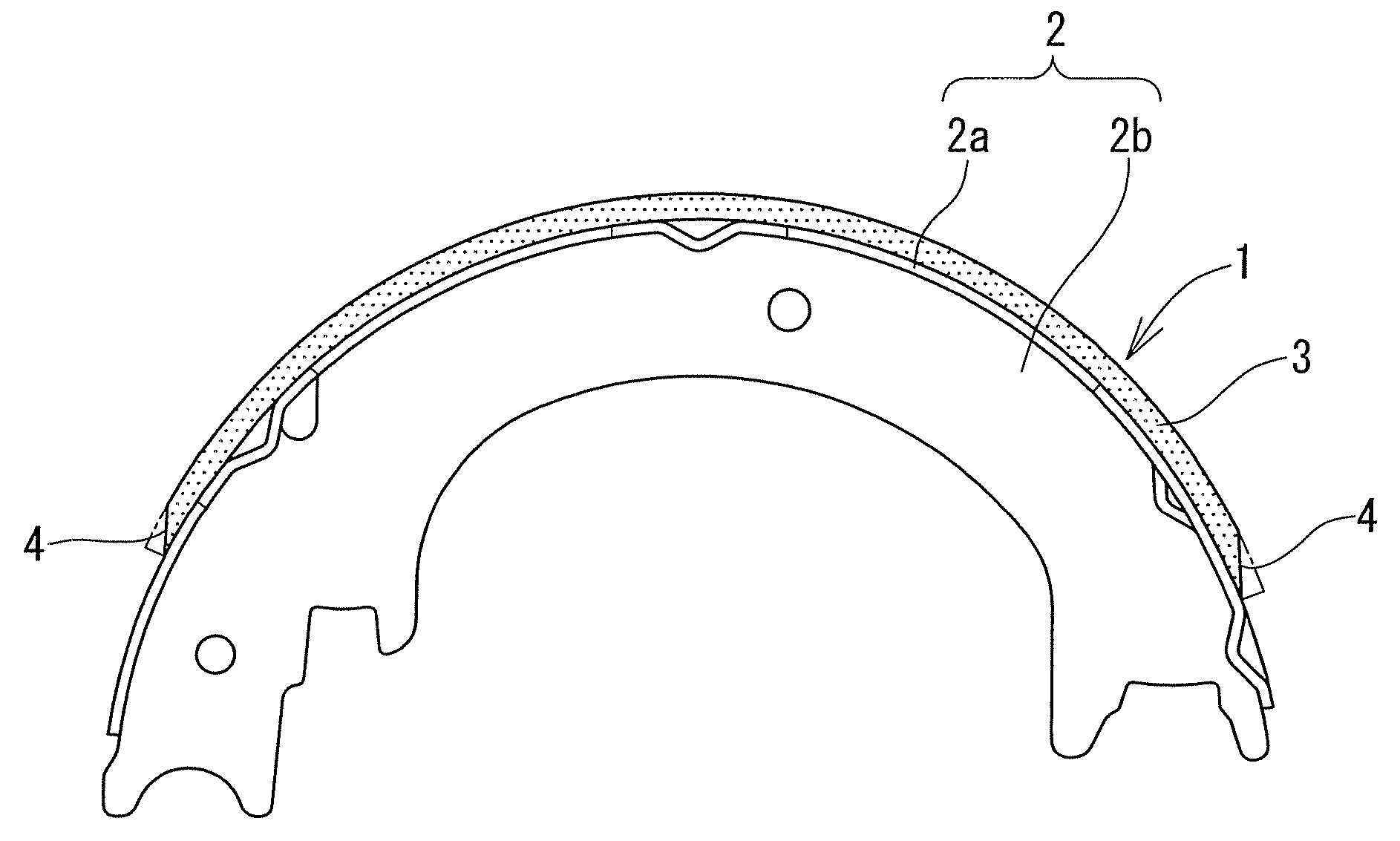

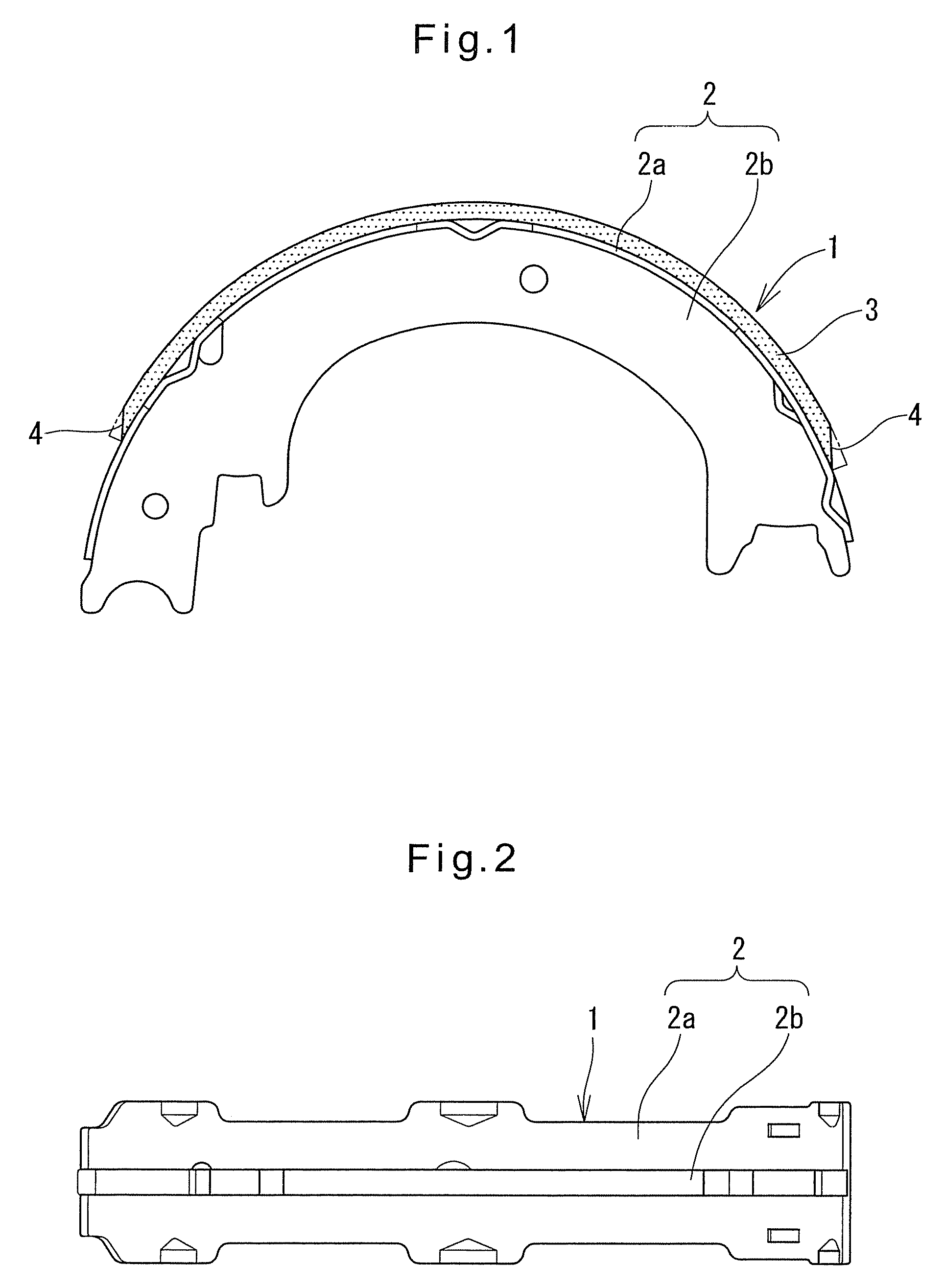

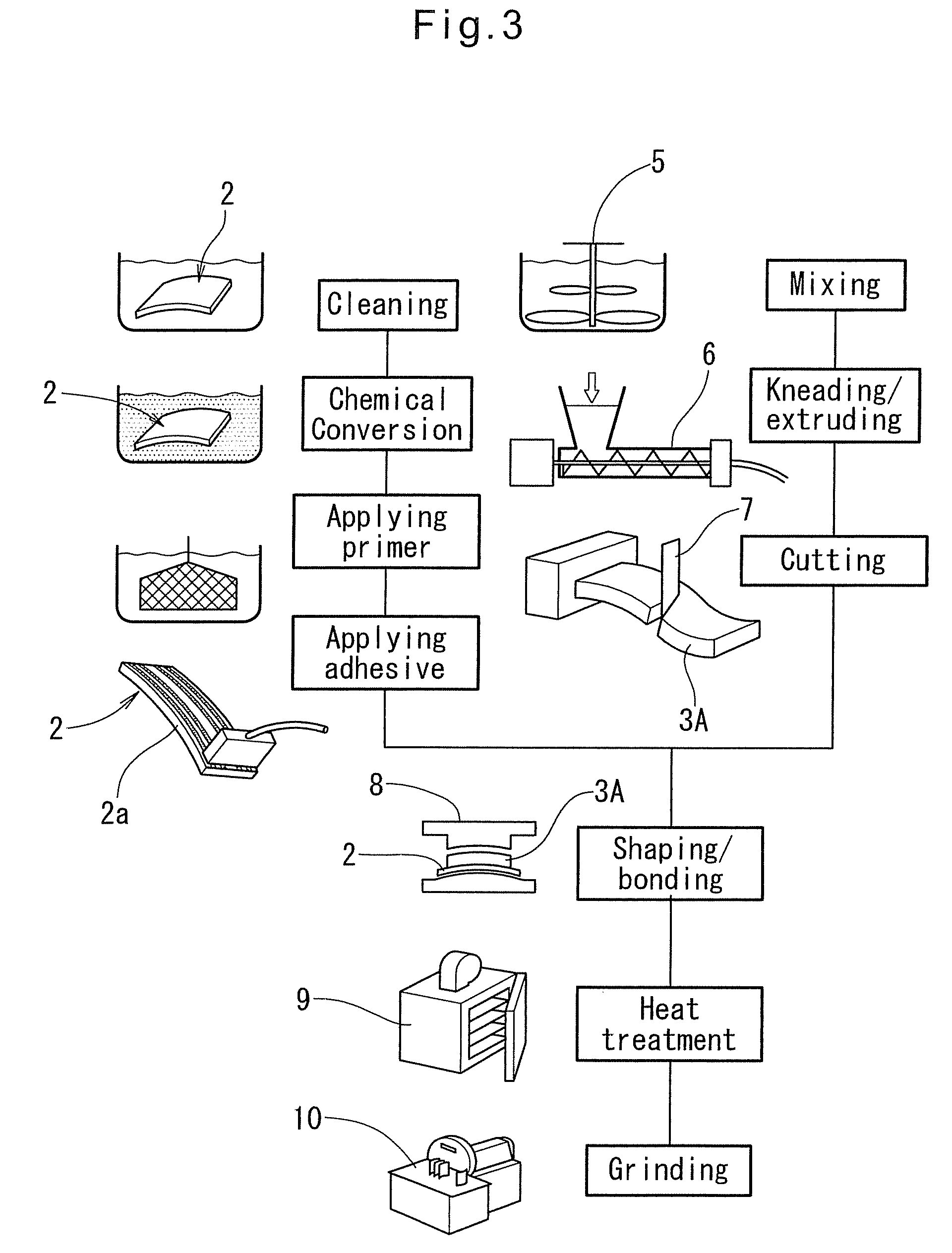

Brake Shoe and Method of Manufacturing the Same

InactiveUS20090159380A1Improve productivityReduce manufacturing stepsBraking membersFriction liningVulcanizationEngineering

An object is to provide a brake shoe which can be manufactured by a method comprising a reduced number of manufacturing steps, and such a method. A brake shoe 1 is manufactured by cutting a sheet blank formed by extrusion or calender sheeting into strips having a predetermined length, laying the strips on the shoe body 2, pressing and bonding the strips to the shoe body 2 and hardening the strips. The lining 3 is formed with tapered surfaces 4 at both ends thereof for facilitating release of the lining from a die. The lining 3 preferably contains as a binder a rubber that turns into ebonite when subjected vulcanization.

Owner:ADVICS CO LTD

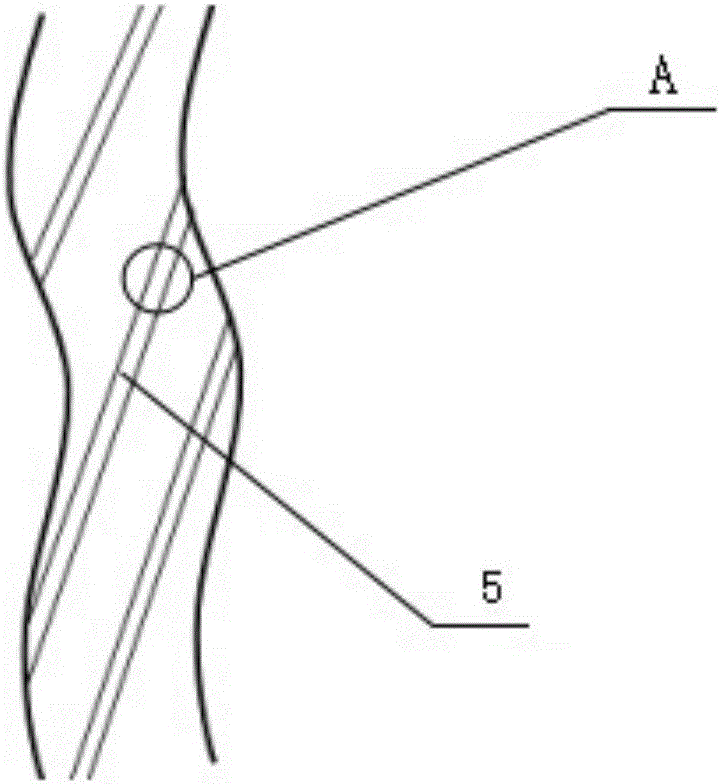

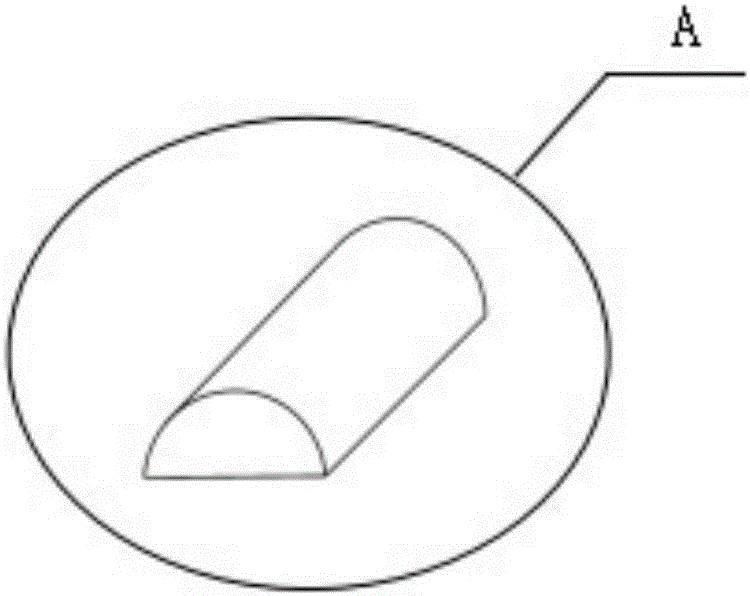

Wave-shaped lip oil seal with backflow stripes at lip opening and three-dimensional modeling method

InactiveCN106503339AImprove wear resistanceHigh oil pump rateGeometric CADDesign optimisation/simulationComputer Aided DesignWave shape

The invention relates to a wave-shaped lip oil seal with backflow stripes at a lip opening and a three-dimensional modeling method. Inclined outwards convex backflow stripes are arranged at the lip opening part of the wave-shaped lip oil seal; the oil seal integrates the advantages of the wave-shaped lip oil seal and the backflow stripe oil seal; specific good dynamic pressure performance of the wave-shaped lip oil seal is realized; the characteristic of good oil pumping effect of the backflow stripe oil seal is reserved; the problem of poor abrasion resistance of the lip opening of the wave-shaped lip oil seal is also solved. The oil seal three-dimensional modeling method based on a circumferential uncoiling conversion principle provided by the invention has the advantages that the wave-shaped lip oil seal precise three-dimensional solid modeling problem difficult to be completed by the existing CAD (computer-aided design) software is changed into a relatively simple half three-dimensional oil seal solid model modeling problem capable of being easily realized by the existing CAD software; conditions are provided for the design manufacturing and the simulation analysis of the wave-shaped lip oil seal; wide application values are realized.

Owner:SHANDONG UNIV OF SCI & TECH

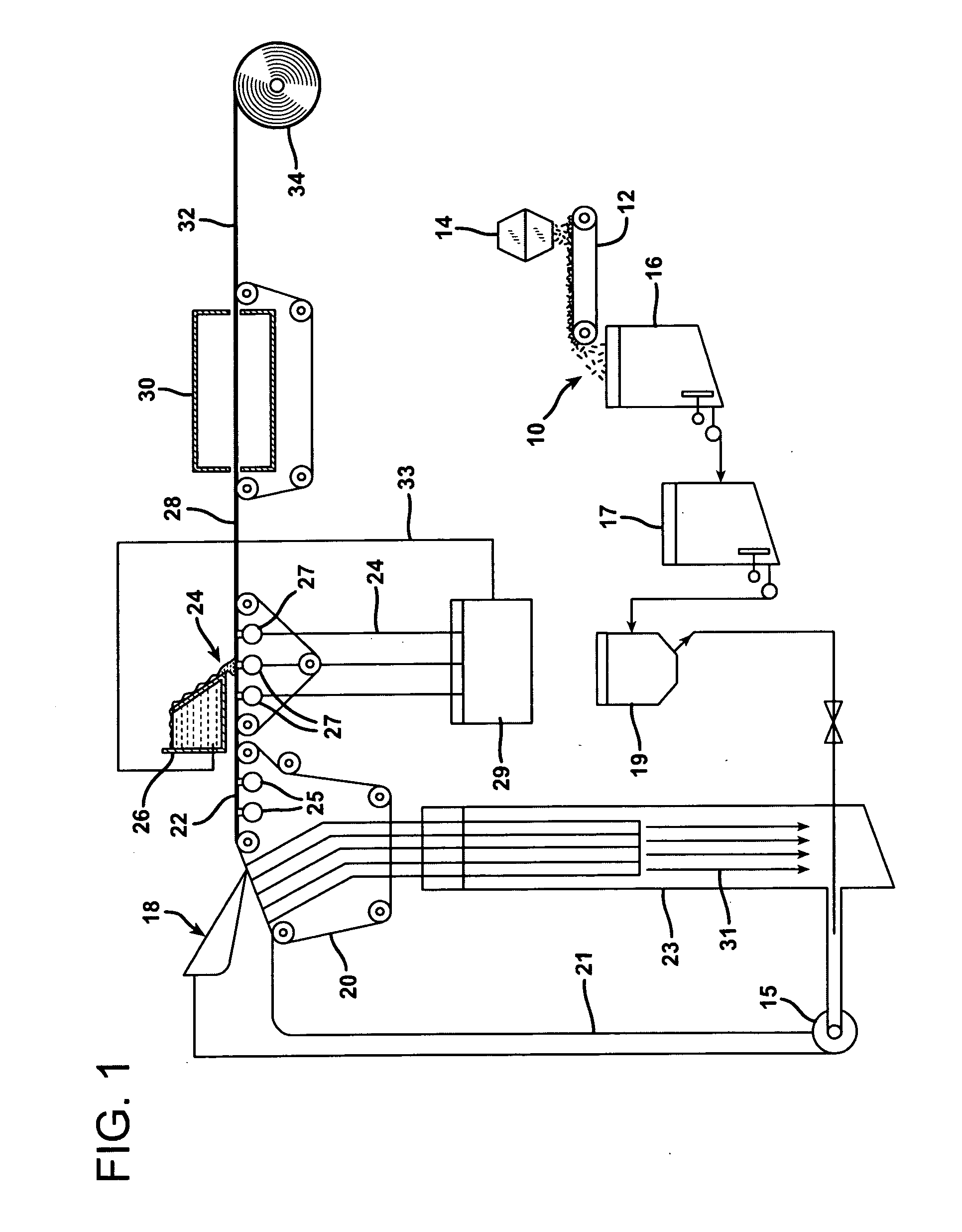

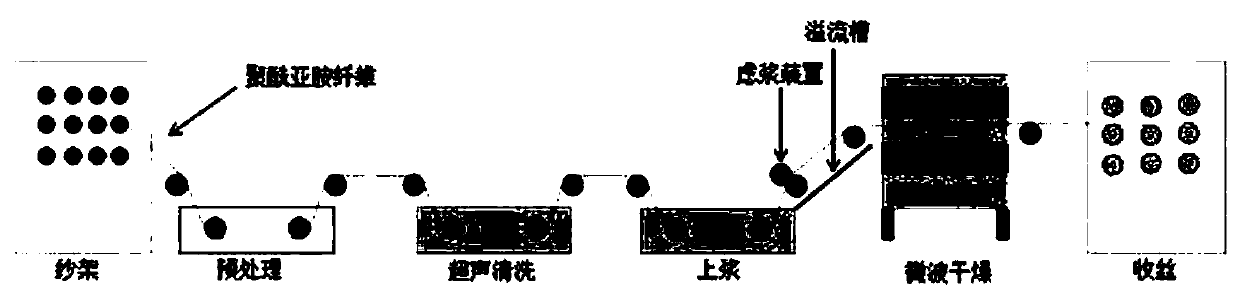

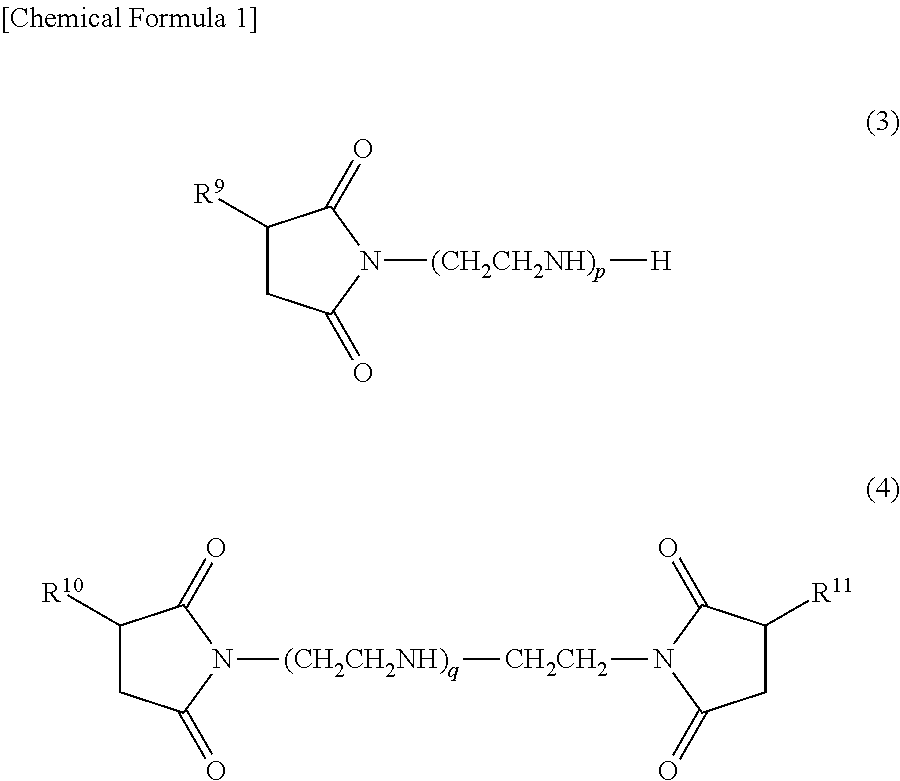

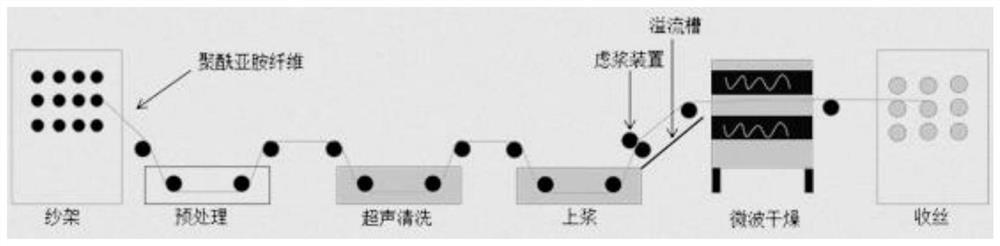

Sizing process of polyimide fibers

ActiveCN110295494AImprove surface propertiesSolve the lack of wear resistanceLight resistant fibresAbrasion resistant fibresImideFiber

The invention provides a sizing process of polyimide fibers. The sizing process includes the steps: silk paying-off; pretreating; ultrasonic cleaning, sizing; microwave drying; taking-up. Alkali liquor in a tank is pretreated to change microstructures of the surfaces of polyimide fibers, so that parts of imide bonds are opened, roughness and active groups of the surfaces of the fibers are increased, effective functional groups in a sizing agent and the opened imide bonds physically and chemically react, interface bond properties among the polyimide fibers and the sizing agent are enhanced, andlater application values of the fibers are improved.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

A kind of perfluoropolyether alkoxysilane compound and its synthesis method

ActiveCN106432686BGood antifoulingGood anti-fingerprint effectAntifouling/underwater paintsPaints with biocidesSilane compoundsSynthesis methods

The invention discloses a novel perfluoropolyether alkoxysilane compound and a synthesis method thereof. The compound structure is shown in formula (1), and the synthesis method is as follows: hydroxyl-terminated perfluoropolyether (PFPE), 3-(2 ‑Aminoethyl)aminopropyltrimethoxysilane, 3‑(2,3‑glycidoxy)propyltrimethoxysilane (KH560), HDI trimer in a molar ratio of 1:2:2:1 In the reaction process, a certain amount of solvent is used to dilute and mix the hydroxyl-terminated perfluoropolyether, 3-(2-aminoethyl) aminopropyltrimethoxysilane, and then dropwise add the HDI trimer. After reacting for 6 hours at a certain temperature , then add KH560 dropwise, react at a certain temperature for another 6 hours, and then remove the solvent under reduced pressure to obtain the perfluoropolyether alkoxysilane compound of the present invention. The compound can be coated on the surface of glass, plastic, film and other substrates, and after cross-linking and curing, it forms a solid film, endows the substrate with excellent anti-fingerprint and anti-fouling properties, and has excellent wear resistance.

Owner:QUZHOU FLUORIDE & SILICON RES INST +1

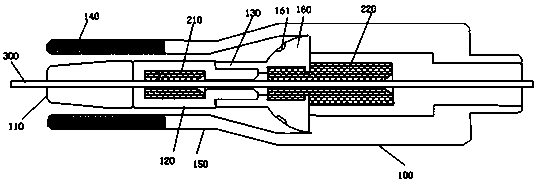

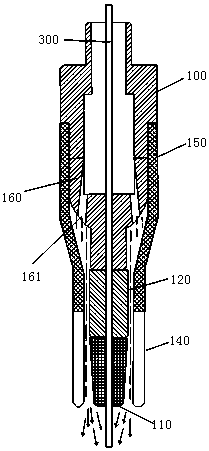

Gas shield welding contact tube

PendingCN108436237ASolve the lack of wear resistanceIncrease delivery speedElectrode accessoriesGas cylinderShielding gas

The invention discloses a gas shield welding contact tube which comprises a contact tube body, a gas diffuser arranged at the front end of the contact tube body, and a guide nozzle arranged at the front end of the gas diffuser. Ceramic protectors are arranged in the contact tube body and the gas diffuser. Core holes for allowing welding wires to pass are formed in the ceramic protectors. The welding wires pass through the ceramic protectors via the core holes and are guided out from the guide nozzle. Air holes for allowing protecting gases to pass are formed in the gas diffuser. After passingthrough the air holes, the protecting gases are linear and no interference airflow exists among the protecting gases. The airflow surrounds a soldering point of the guide nozzle to form protective atmosphere. The welding wires are automatically centered by the ceramic protectors, so that abrasion is reduced, heat conduction is isolated, and continuous welding at high temperature is realized. The gas transmission speed is increased and the output pressure of a gas cylinder is reduced by the gas diffuser, so that the utilization rate of carbon dioxide is effectively increased, the discharge is reduced, and the welding quality is improved. The contact tube adopts a split structure, and parts can be replaced as required, so that the using and maintaining costs are reduced.

Owner:青岛光峰自动化科技有限公司

Lead-free polymer-based composite materials

InactiveUS20160163403A1Good arc resistanceHigh dielectric constantConveyorsSynthetic resin layered productsParticulatesThermosetting polymer

The present invention relates to a lead-free, non-toxic and arc resistant composite material having a thermosetting polymer, at least one heavy particulate filler, at least one light particulate filler and, optionally, at least one arc resistant filler. The composite material may be utilized in manufacturing articles used in radiation shielding and other applications where arc resistant and dielectric strength are desired.

Owner:GLOBE COMPOSITE SOLUTIONS

Piston ring and its production method

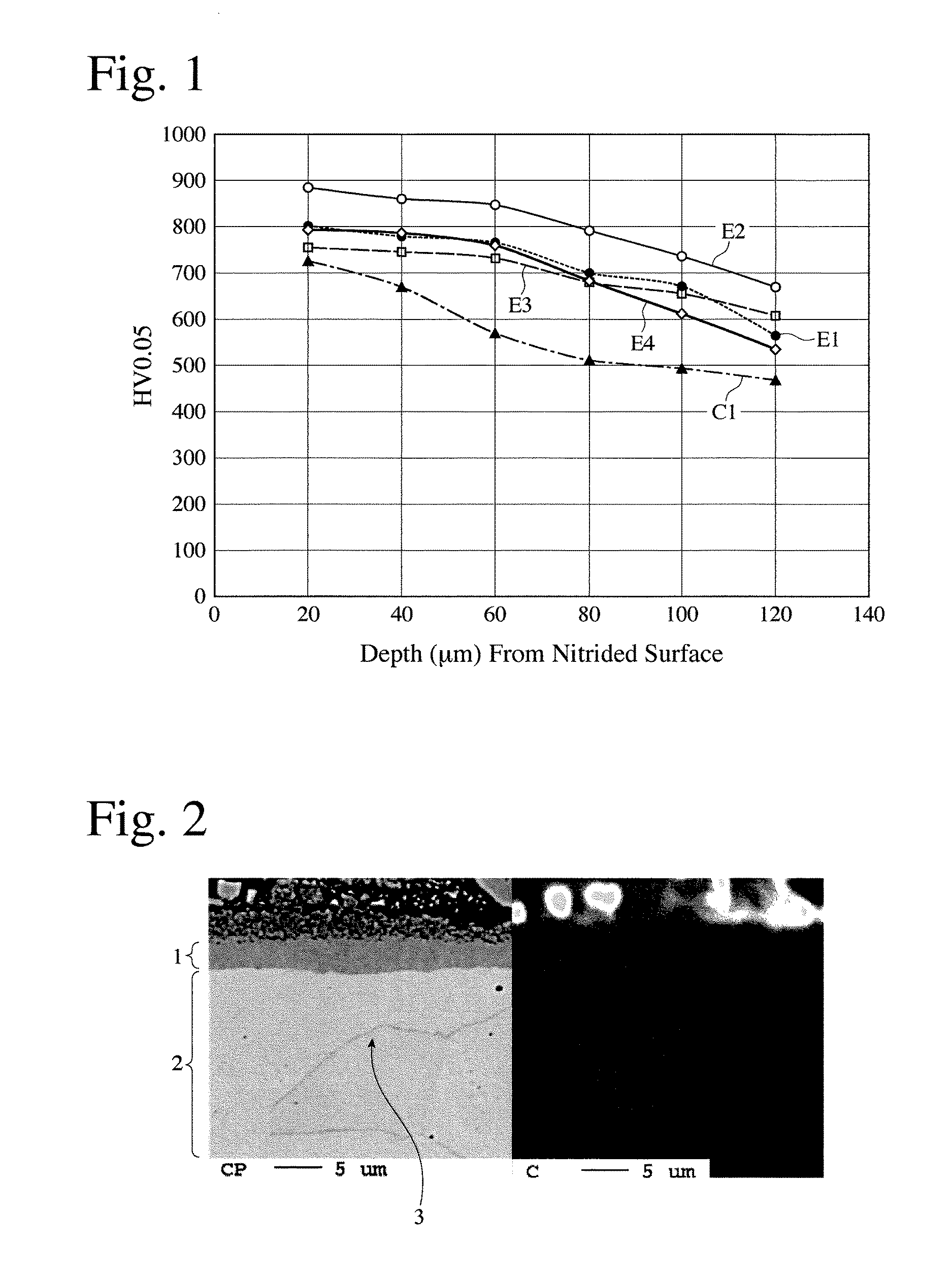

ActiveUS20170009314A1Improve machinabilityImprove thermal conductivityPiston ringsSolid state diffusion coatingPiston ringThermal conductivity

To provide a piston ring of low-alloy steel having excellent nitridability, namely, a piston ring of low-alloy steel having excellent thermal conductivity and capable of being provided with a sufficient nitrided layer, steel comprising by mass 0.45-0.65% of C, 0.15-0.35% of Si, 0.65-1.00% of Mn and 0.60-1.10% of Cr as indispensable alloy elements, and less than 0.35% of Mo, less than 0.25% of V and less than 0.001% of B as optional alloy elements, the total amount of the indispensable alloy elements and the optional alloy elements being less than 3.0% by mass, is formed into a piston ring; and the nitrided layer is formed on its surface.

Owner:RIKEN CO LTD

Lubricant composition

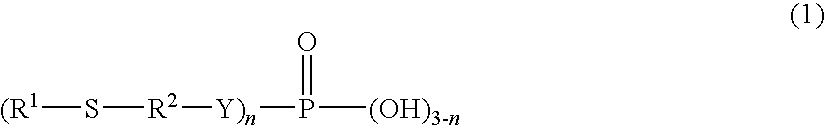

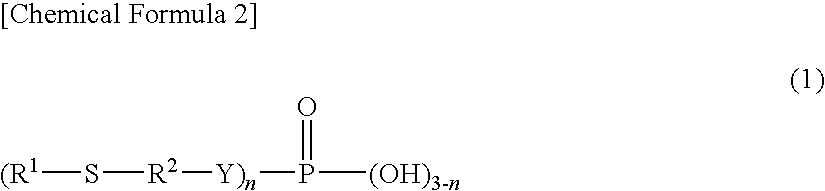

InactiveUS20100126461A1Sufficient propertySolve the lack of wear resistanceLubrication of auxillariesOrganic chemistryChemistryPhosphate

The lubricating oil composition contains a base oil, a phosphate ester derivative represented by a formula (1) below and a zinc compound. An element ratio (Zn / P) between zinc (Zn) and phosphorus (P) in the lubricating oil composition is 0.55 or more at a mole ratio.In the formula, Y represents S (sulfur) or O (oxygen); R1 represents an organic group having 4 to 24 carbon atoms; R2 represents a divalent organic group having 1 to 6 carbon atoms; and n represents an integer of 1 to 3.

Owner:IDEMITSU KOSAN CO LTD

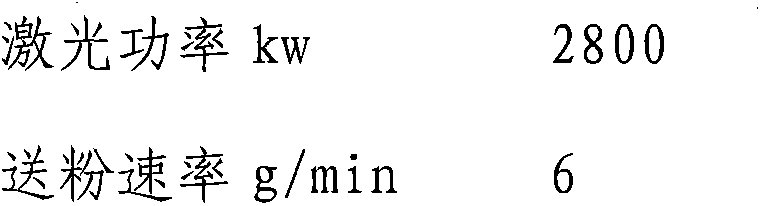

Wear-resistant layer of powder knife and processing technology

InactiveCN102071417AImprove surface wear resistanceSolve the lack of wear resistanceMetallic material coating processesWear resistantLaser beams

The invention relates to a wear-resistant layer of a powder knife and a processing technology, wherein the wear-resistant layer is a nano coating layer, and the processing technology comprises the steps of: (1) cleaning the surface of a metal sheet of the powder knife; (2) coating a nano powered material on the surface of the cleaned powder knife and drying the nano powdered material; and (3) cladding the powder material by laser beams, protecting the powder material by inert gas, and cooling. The processing technology of the powder knife realizes cladding of the nano coating on the metal powder knife by utilizing the laser cladding technology, increases the wear resistance, and repairs the old powder knife.

Owner:FOREVER TECH

Expansion turbine stage

InactiveUS6948320B2Degree of effectiveness is increasedHigh enthalpyPump componentsGas turbine plantsThermal insulationMetallic materials

An expansion turbine stage for compressed gases has a housing and a turbine rotor. The housing has flow guide channels for feeding the compressed gas to the turbine rotor. The turbine rotor, which is over-mounted and has centripetal flow through it, is followed by an out-flow diffuser enclosed by the housing, to delay the cold expanded gas. The out-flow diffuser is arranged in a holder bore in the housing, as a separate component. For thermal insulation of the housing relative to the cold expanded gas stream, the out-flow diffuser is made of a non-metallic material having a low heat conductivity.

Owner:ATLAS COPCO ENERGAS

Lubricating Oil Composition

InactiveUS20160257905A1Sufficient extreme pressure propertySolve the lack of wear resistanceAdditivesBase-materialsChemical compositionBase oil

Disclosed is a lubricating oil composition comprising: a lubricating base oil comprising 0.5% to 70% by mass of an ester base oil based on the total amount of the lubricating base oil, and having a kinematic viscosity at 40° C. of 18 to 28 mm2 / s; and an organic molybdenum compound in an amount of 100 to 1000 mass ppm in terms of the molybdenum element based on the total amount of the lubricating oil composition, wherein the lubricating oil composition has a kinematic viscosity at 40° C. of 50 mm2 / s or less.

Owner:JXTG NIPPON OIL & ENERGY CORPORATION

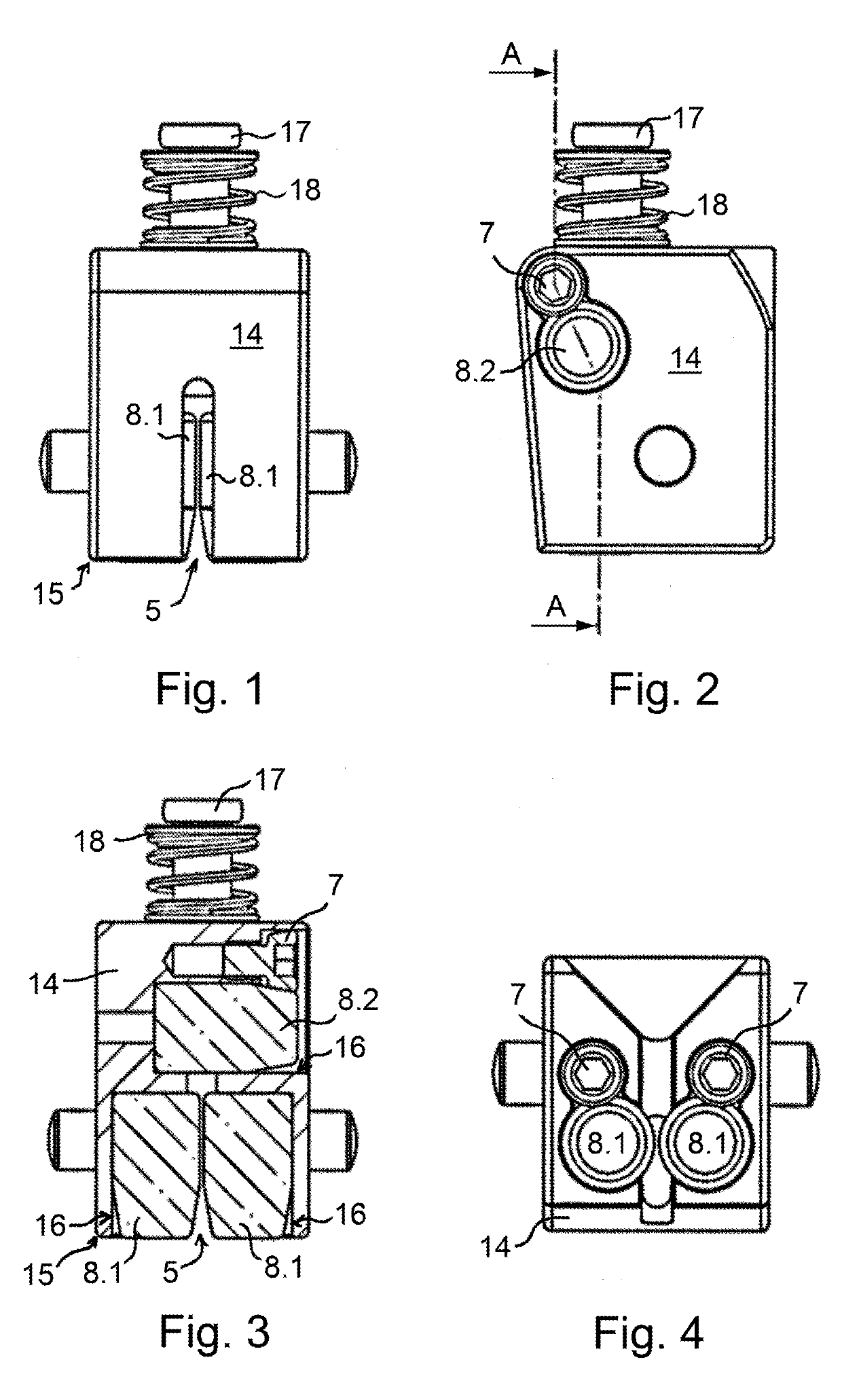

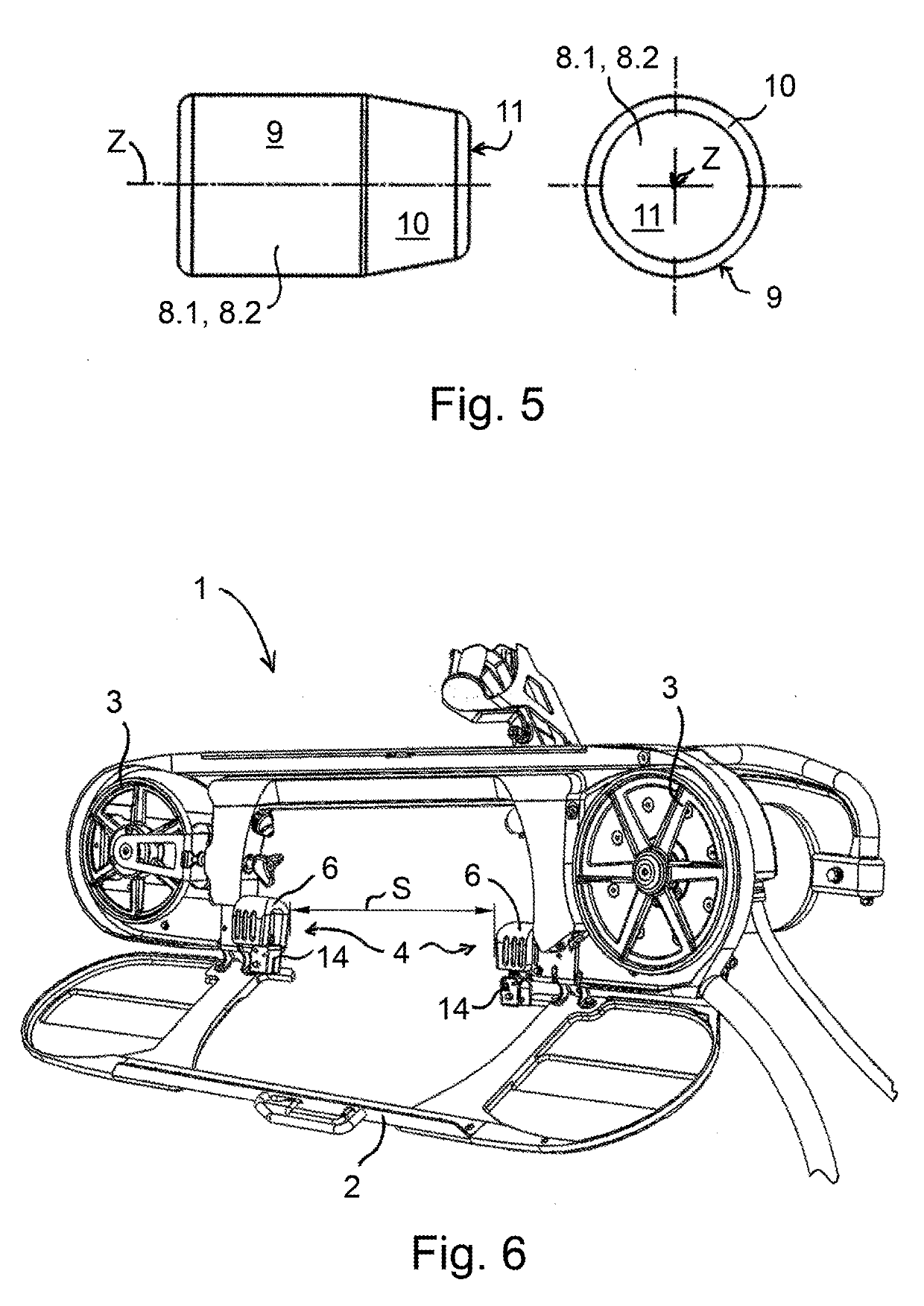

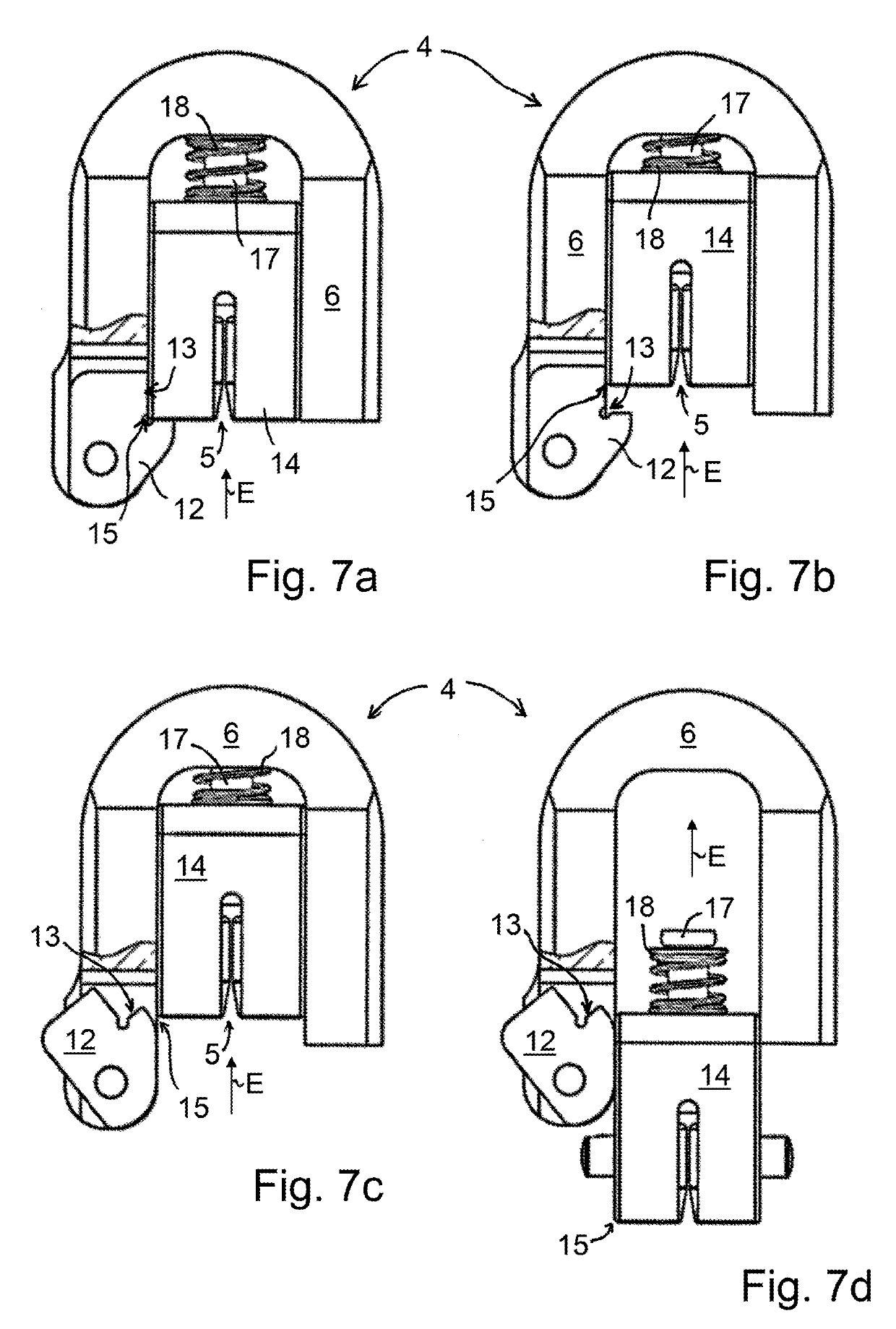

Guide insert and saw blade guide for a bandsaw

ActiveUS20190283156A1Cost-effective manufacturingLittle manufacturing complexityMetal sawing devicesAxis of symmetryEngineering

A guide insert for a saw blade guide for guiding a saw blade, including at least two blade guiding elements held in the guide insert, at least one pair of side blade guiding elements disposed in parallel and at the same height being accommodated in the guide insert, a slot for laterally guiding the saw blade being formed between a first side blade guiding element and a second side blade guiding element in a use position, the blade guiding elements having a rotationally symmetrical shape with respect to an axis of symmetry, including a cylindrical friction surface, the blade guiding elements each being held clamped in a cylindrical recess of the guide insert in a force-fitting and / or form-fitting manner via a loosenable clamp in the use position, and the blade guiding elements being able to be placed from a first rotational position into other rotational positions.

Owner:FREUND MASCHFAB

High-speed rail pantograph carbon contact strip and preparation method thereof

PendingCN112552049AImprove the lubrication effectReduce coefficient of frictionPower current collectorsCarbide siliconGraphite

The invention discloses a high-speed rail pantograph carbon contact strip and a preparation method thereof, belongs to the field of pantograph carbon contact strips and preparation thereof, and aims to solve the technical problem that an existing high-speed rail pantograph carbon contact strip is short in service life. The high-speed rail pantograph carbon contact strip is prepared from the following components in parts by mass: graphite powder, pitch coke powder, pitch, silicon carbide and modified molybdenum disulfide. The modified molybdenum disulfide is molybdenum disulfide obtained through granulation treatment. The preparation method comprises the following steps: step 1, mixing materials; step 2, extrusion molding; step 3, roasting treatment. The contact strip is reasonable in raw material composition and scientific in formula, and the prepared high-speed rail pantograph contact strip is excellent in wear resistance, good in electrical conductivity, long in service life, capableof well meeting various requirements of the high-speed rail pantograph carbon contact strip and wide in application range.

Owner:美尔森哈碳电碳(哈尔滨)有限公司

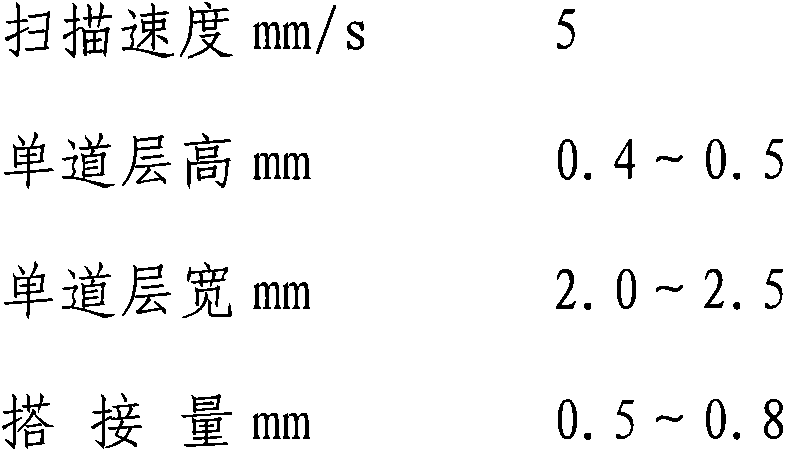

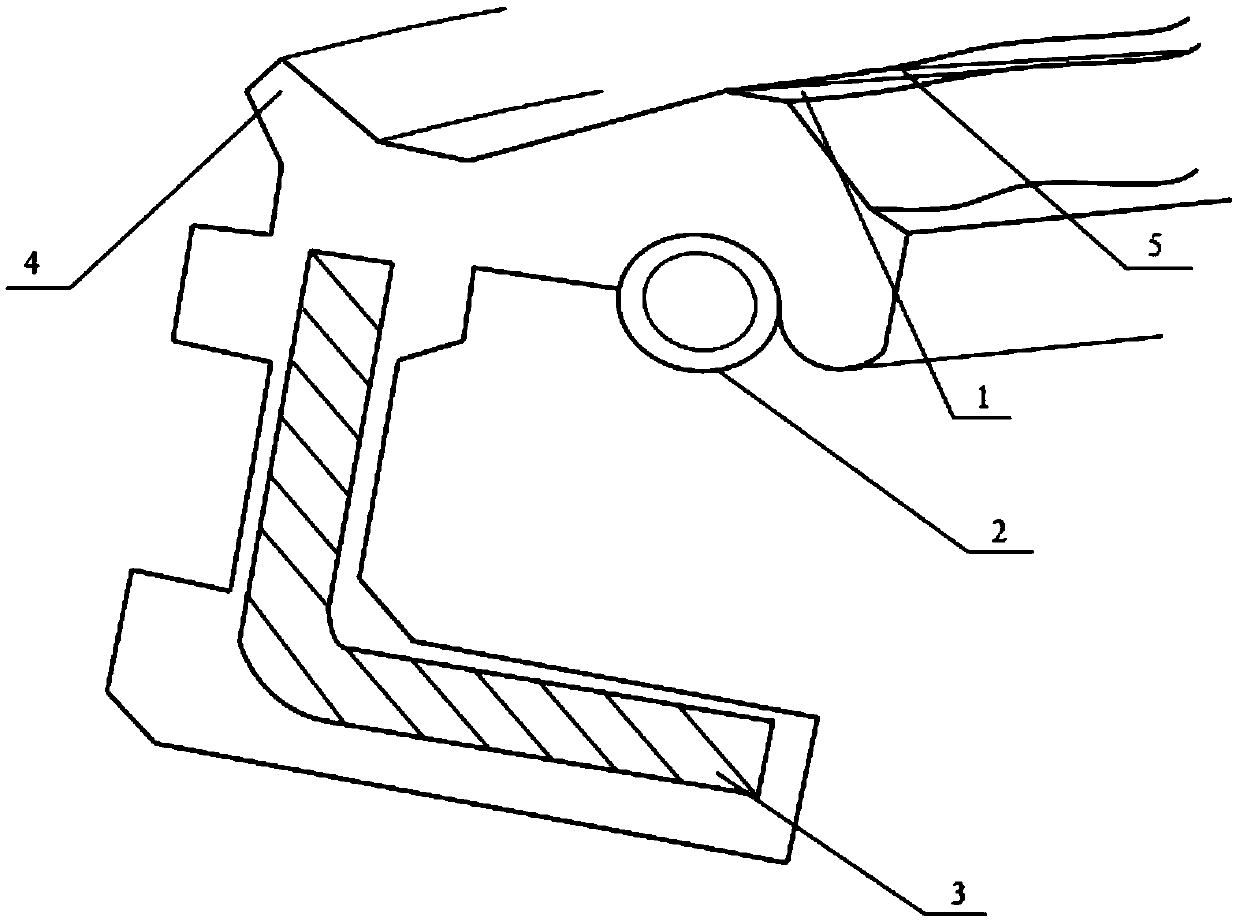

Strengthening Method of Tooth Surface of Drive Wheel Ring Gear of Tracked Vehicle

ActiveCN104195549BSolve the lack of wear resistanceMetallic material coating processesRare-earth elementDrive wheel

Owner:内蒙古一机集团瑞特精密工模具有限公司

Method for improving wear resistance of motor running bearing

Relating to the technical field of new material processing, the invention discloses a method for improving the wear resistance of a motor running bearing. By studying the performance of a superfine nano material, a prepared lubricating oil additive is added into base lubricating oil to lubricate a motor running bearing, thus greatly improving the lubricating properties of the lubricating oil, reducing the friction coefficient, and playing a pressure-resistant and antifriction role, even under the conditions of high load and high rotating speed, the bearing anti-wear capability of a rotating shaft can be permanently guaranteed. The lubricating oil additive material can reinforce the lubricating properties of base oil, reduce the roughness of a contact surface, has good dispersity in lubricating oil and small dosage, can effectively fill micro pits, scratches and the like on a friction contact surface in a motor running process, repair a damaged friction surface and reduce wear, and evenunder an oil shortage state, the material also can form an excellent surface lubricating protection film, thus broadening the use occasion of the material.

Owner:安徽实友电力金具有限公司

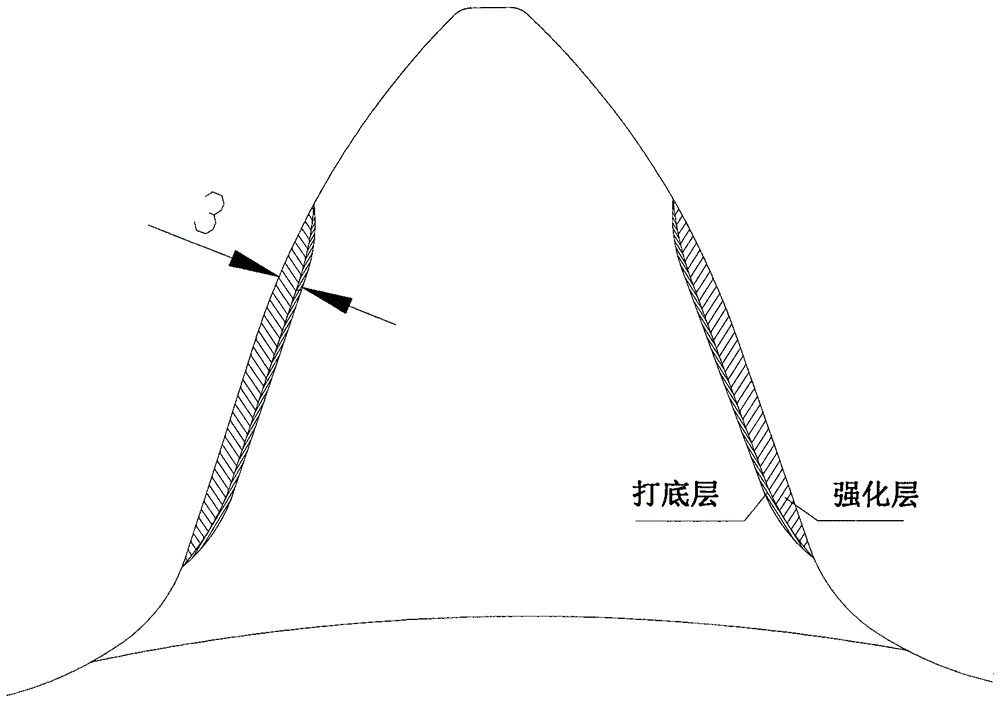

A corrugated lip oil seal with reflow lines on the lip and its three-dimensional modeling method

InactiveCN106503339BImprove wear resistanceHigh oil pump rateGeometric CADDesign optimisation/simulationComputer Aided DesignWave shape

The invention relates to a wave-shaped lip oil seal with backflow stripes at a lip opening and a three-dimensional modeling method. Inclined outwards convex backflow stripes are arranged at the lip opening part of the wave-shaped lip oil seal; the oil seal integrates the advantages of the wave-shaped lip oil seal and the backflow stripe oil seal; specific good dynamic pressure performance of the wave-shaped lip oil seal is realized; the characteristic of good oil pumping effect of the backflow stripe oil seal is reserved; the problem of poor abrasion resistance of the lip opening of the wave-shaped lip oil seal is also solved. The oil seal three-dimensional modeling method based on a circumferential uncoiling conversion principle provided by the invention has the advantages that the wave-shaped lip oil seal precise three-dimensional solid modeling problem difficult to be completed by the existing CAD (computer-aided design) software is changed into a relatively simple half three-dimensional oil seal solid model modeling problem capable of being easily realized by the existing CAD software; conditions are provided for the design manufacturing and the simulation analysis of the wave-shaped lip oil seal; wide application values are realized.

Owner:SHANDONG UNIV OF SCI & TECH

A kind of sizing process of polyimide fiber

ActiveCN110295494BImprove surface propertiesSolve the lack of wear resistanceLight resistant fibresAbrasion resistant fibresFiberImide

The invention provides a polyimide fiber sizing process. The sizing process includes spinning, pretreatment, ultrasonic cleaning, sizing, microwave drying and winding. The present invention changes the microscopic morphology of the polyimide fiber surface through the lye in the pretreatment tank, so that the imide bonds are partially opened, increasing the roughness and active groups on the fiber surface, and then utilizing the effective functional groups in the sizing agent to open The physical and chemical reaction of the imide bond will strengthen the interface bonding performance between the polyimide fiber and the sizing agent, and improve the value of the later application of the fiber.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

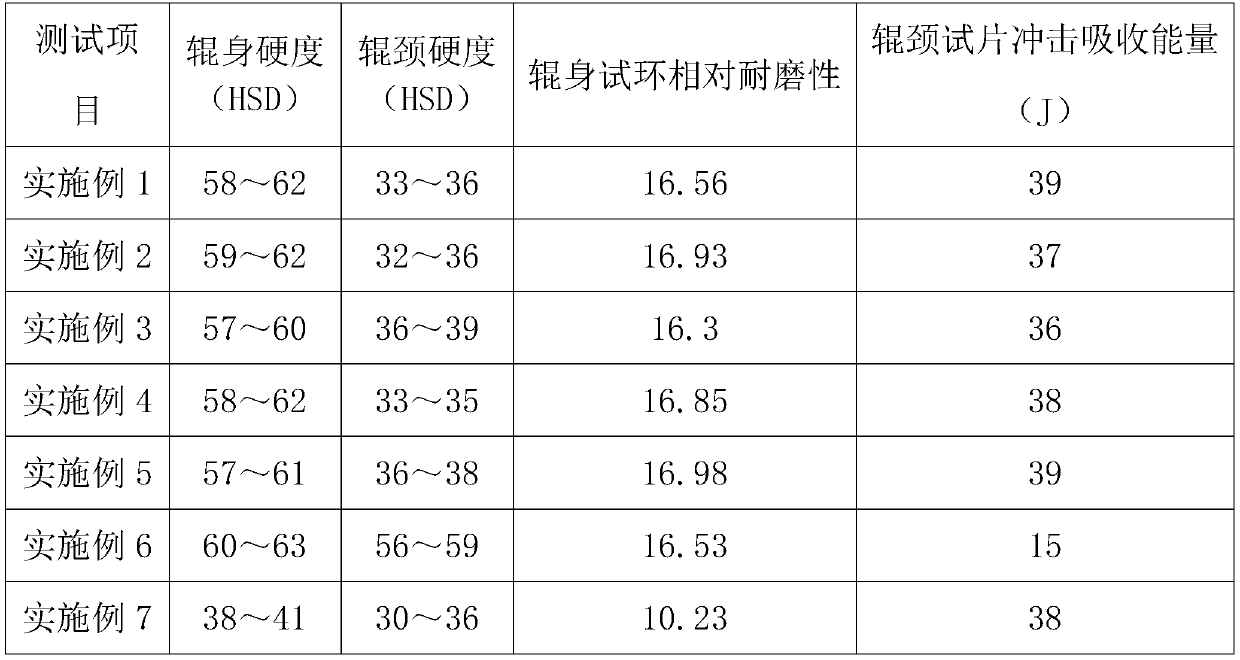

Differential-temperature thermal treatment process for forged steel BD roller

ActiveCN111139351AImprove wear resistanceImprove toughnessFurnace typesHeat treatment process controlHigh wear resistanceThermal treatment

The invention discloses a differential-temperature thermal treatment process for a forged steel BD roller, and relates to the technical field of high-performance roller special thermal treatment. Thedifferential-temperature thermal treatment process comprises three aspects of a forged steel BD roller thermal treatment process, pretreatment before heating, and thermal treatment process parameters.The differential-temperature thermal treatment process improves wear resistance of a roller body and toughness of a roller neck, avoids insufficient wear resistance caused by too low roller body hardness, and avoids insufficient impact toughness caused by too high hardness of the roller neck; and the roller body and the roller neck of the prepared forged steel BD roller have hardness which can meet the process requirements, and can meet the design purposes of high strength and high wear resistance of the roller body as well as high toughness of the roller neck.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

A kind of transparent antifogging agent and preparation method thereof

ActiveCN107629760BSolve the lack of wear resistanceEnhanced ability to resist water vapor erosionOther chemical processesCoatingsPtru catalystPolyvinyl alcohol

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com