A kind of sizing process of polyimide fiber

A technology of polyimide fiber and process, applied in the direction of fiber treatment, fiber type, wear-resistant fiber, etc., can solve the problems affecting the downstream product application of polyimide fiber, interface instability, fiber surface hairiness, etc. To achieve the effect of improving the ability of anti-ultraviolet, improving the surface performance and increasing the value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

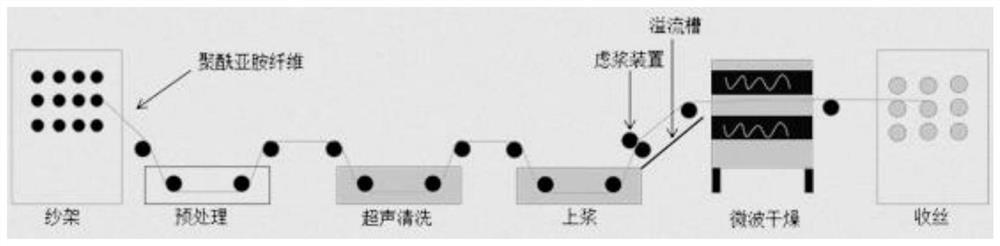

[0020] A polyimide fiber sizing process adopts a silicone wear-resistant sizing process, with 1500D polyimide fiber as the standard, and the specific process steps are as follows:

[0021] The fiber is put into the 6mol / L potassium hydroxide pretreatment solution from the wire drawing frame, and the surface of the fiber is etched in the potassium hydroxide pretreatment solution to modify it. The pretreatment time is 40s, and the pretreatment temperature is 30 ℃. Then enter the ultrasonic cleaning tank to clean the fiber until the cleaning solution is neutral. Then through the sizing tank, the silicone sizing agent used for weaving is used for sizing, wherein the concentration of the sizing agent is 1wt%, the sizing time is 10s, and the temperature of the solution during the sizing process is 30°C. Then it is filtered through the filter tank and then dried by microwave. The drying temperature is 220°C, the drying time is 120s, and finally it is wound up.

[0022] Technical ef...

Embodiment 2

[0024] A kind of polyimide fiber sizing process adopts the epoxy sizing process combined with epoxy resin, with 1500D polyimide fiber as the standard, the specific process steps are as follows:

[0025] The fiber is put into the 8mol / L sodium hydroxide pretreatment solution from the wire drawing rack, and the surface of the fiber is etched in the sodium hydroxide pretreatment solution to modify it. The pretreatment time is 40s, and the pretreatment temperature is 40 ℃.

[0026] Then enter the ultrasonic cleaning tank, clean the fibers until the cleaning solution is neutral, and then pass through the sizing tank, use epoxy sizing agent for sizing, wherein the sizing agent concentration is 1wt%, the sizing time is 20s, and the solution temperature during the sizing process is 35 °C. Then it is filtered through the filter tank and then dried by microwave. The drying temperature is 240°C, the drying time is 80s, and finally it is wound up.

[0027] Technical effect: After sizing,...

Embodiment 3

[0029] A polyimide fiber sizing process adopts a cluster sizing process, with 1500D polyimide fiber as the standard, and the specific process steps are as follows:

[0030] The fiber is drawn into the 2mol / L ammonia pretreatment solution from the drawing frame, and the surface of the fiber is etched in the ammonia pretreatment solution to modify it. The pretreatment time is 60s and the pretreatment temperature is 35°C. Then enter the ultrasonic cleaning tank, clean the fiber until the cleaning solution is neutral, and then pass through the sizing tank, use the cluster-type sizing agent PVA for sizing, where the sizing agent concentration is 1.5wt%, the sizing time is 30s, and the solution temperature during the sizing process is 50°C . Then it is filtered through the filter tank and then dried by microwave. The drying temperature is 80°C, the drying time is 300s, and finally it is wound up.

[0031] Technical effect: After sizing, the fiber bundles are gathered together to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com