A kind of transparent antifogging agent and preparation method thereof

An anti-fogging agent and transparent technology, applied in chemical instruments and methods, other chemical processes, coatings, etc., can solve problems such as unsuitable for large-scale, long-term application, volatile surfactants, and inclusions in the preparation process. Achieve the effects of enhancing the ability to resist water vapor erosion, avoiding agglomeration, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

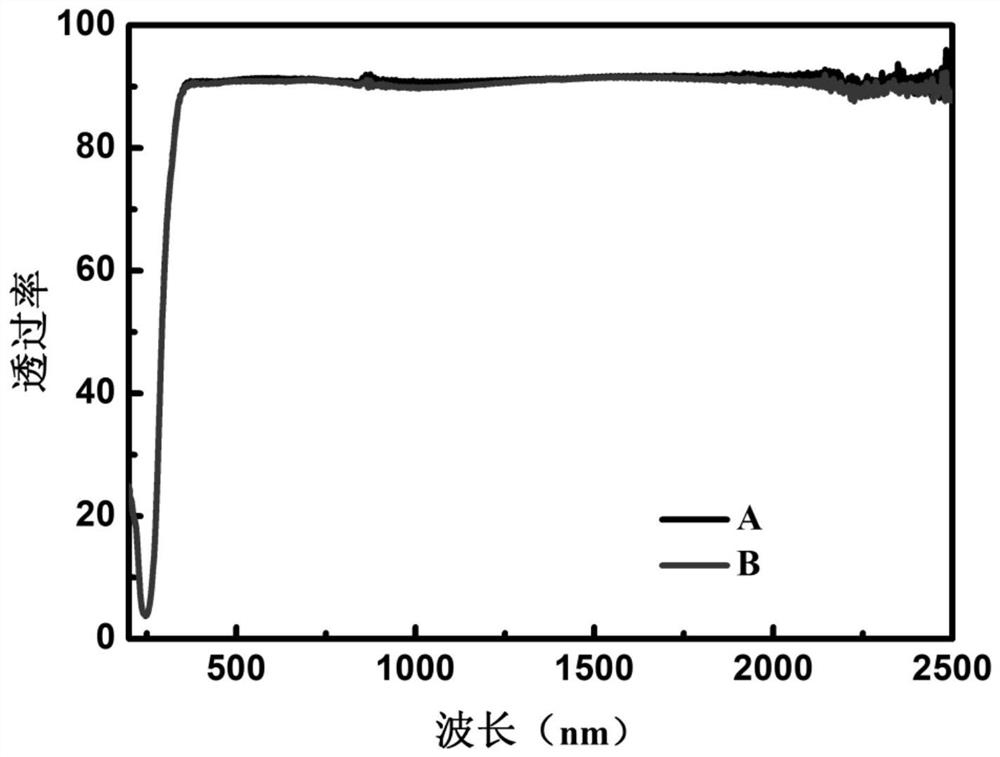

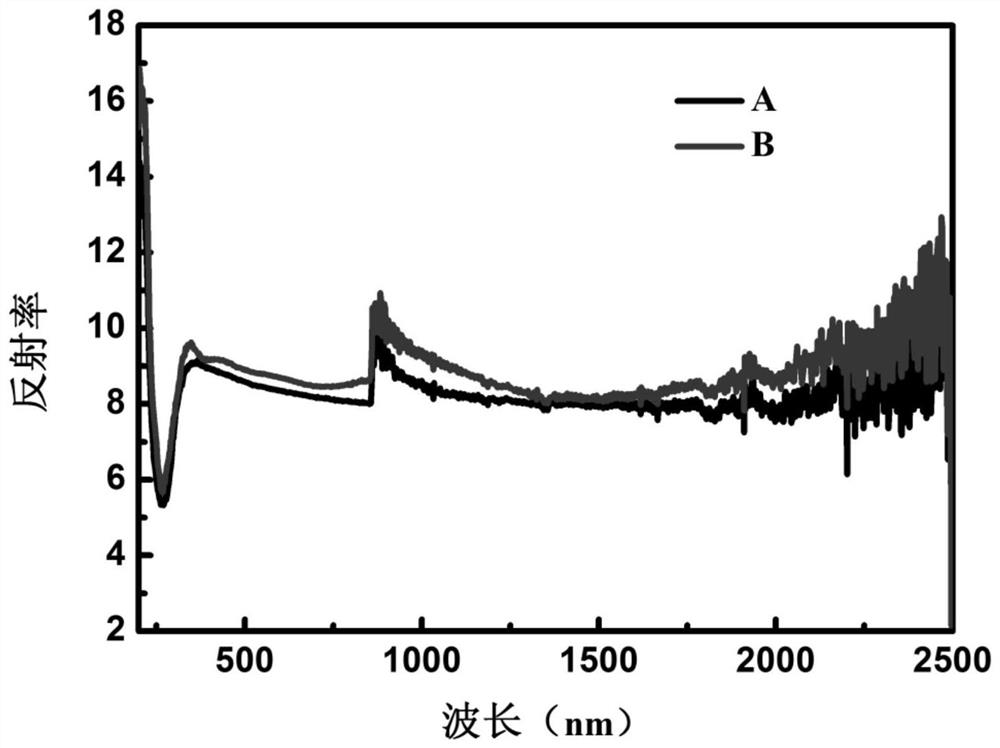

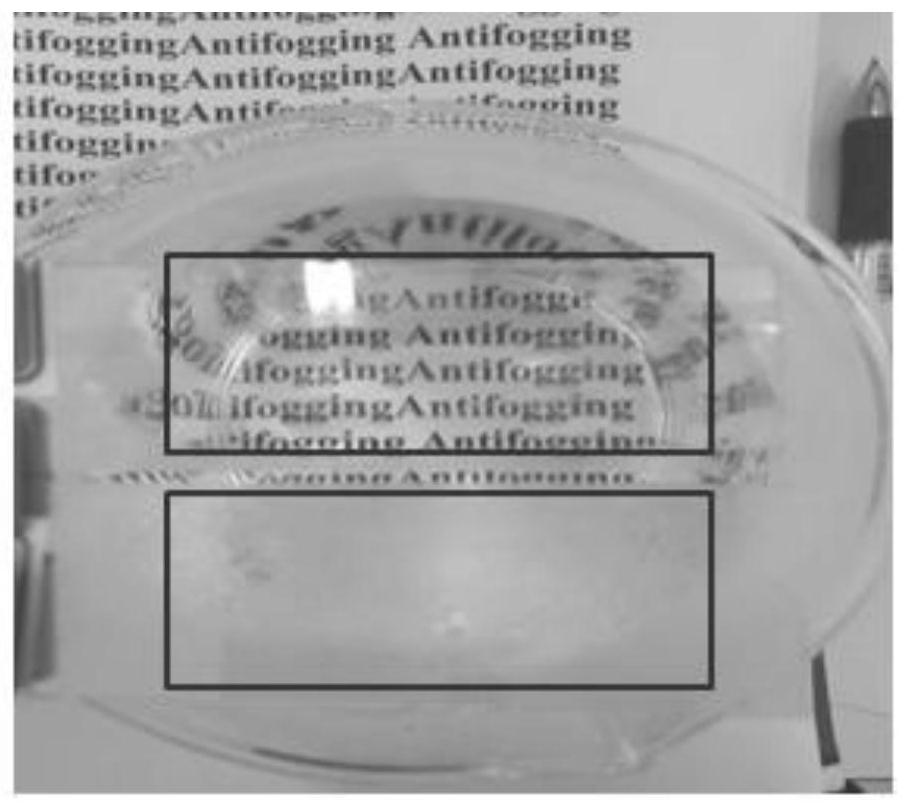

[0031] 2 g of polyvinyl alcohol (PVA) was dissolved in 98 g of hot water, heated and stirred until completely dissolved, and then cooled to room temperature to obtain a 2% polyvinyl alcohol aqueous solution A. Mix 300g of absolute ethanol, 5g of ammonia, and 20g of water and stir for 30 minutes, then add 6g of ethyl orthosilicate, keep at 60°C, and stir for 20 hours. Then 1 g of triaminopropyltriethoxysilane was added to obtain organosilane-modified SiO 2 Sol B. The A and B solutions were left to stand for 7 days, and 2 g of the B solution was slowly added to 10 g of the A solution under stirring conditions to obtain a transparent antifogging agent C solution. After cleaning the glass, apply C solution, dry at 80°C for 5 minutes, put the glass on a beaker filled with 80°C hot water, observe that the glass has a good anti-fog effect, and its anti-fog effect lasts for half a year , rinsing with water and wiping with a rag has no effect on this.

Embodiment 2

[0033] Dissolve 3 g of polyvinyl alcohol (PVA) in 97 g of hot water, heat and stir until completely dissolved, and then cool to room temperature to obtain a 3% polyvinyl alcohol aqueous solution A. Mix 300g of absolute ethanol, 5g of ammonia, and 20g of water and stir for 30 minutes, then add 8g of ethyl orthosilicate, keep at 60°C, and stir for 20 hours. Then 1 g of N-(2-aminoethyl)-3-aminopropyltrimethoxysilane was added to obtain organosilane-modified SiO 2Sol B. The A and B solutions were left to stand for 7 days, and 2 g of the B solution was slowly added to 10 g of the A solution under stirring conditions to obtain a transparent antifogging agent C solution. After cleaning the glass, apply C solution, dry at 80°C for 5 minutes, put the glass on a beaker filled with hot water at 80°C, and observe that the glass has a good anti-fog effect, and its anti-fog effect lasts for half a year. , rinsing with water and wiping with a rag has no effect on this.

Embodiment 3

[0035] 4g of polyvinyl alcohol (PVA) was dissolved in 96g of hot water, heated and stirred until completely dissolved, and then cooled to room temperature to obtain a 4% polyvinyl alcohol aqueous solution A. Mix 300g of absolute ethanol, 5g of ammonia water, and 20g of water and stir for 30min, then add 7g of ethyl orthosilicate, keep at 60°C, and stir for 20h. Then 1 g of 3-(trihydroxysilyl)-propanesulfonic acid was added to obtain organosilane-modified SiO 2 Sol B. The A and B solutions were left to stand for 7 days, and 2 g of the B solution was slowly added to 10 g of the A solution under stirring conditions to obtain a transparent antifogging agent C solution. After cleaning the glass, apply C solution, dry at 80°C for 5 minutes, put the glass on a beaker filled with hot water at 80°C, and observe that the glass has a good anti-fog effect, and its anti-fog effect lasts for half a year. , rinsing with water and wiping with a rag has no effect on this.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com