Strengthening Method of Tooth Surface of Drive Wheel Ring Gear of Tracked Vehicle

A driving wheel and tooth surface technology, which is applied in the field of surface strengthening of parts, can solve the problems of insufficient wear resistance of the tooth surface of the driving wheel ring gear, and achieve the effect of solving the insufficient wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

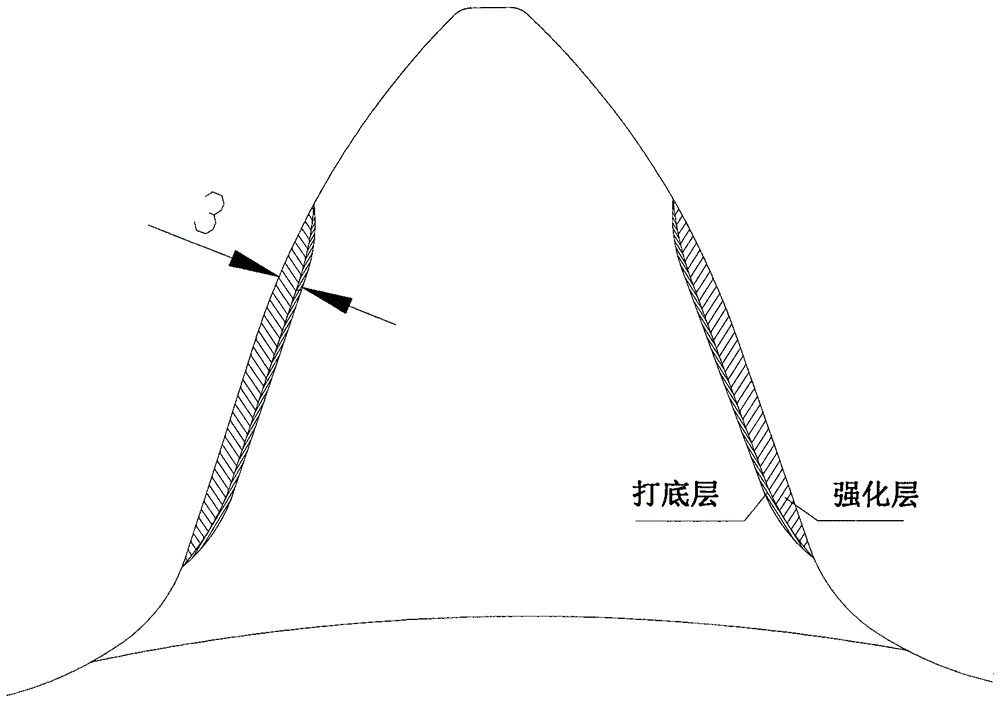

[0027] The tooth surface strengthening process of the driving wheel ring gear is implemented in the following six steps:

[0028] (1) Roughly process the ring gear in the quenched and tempered state, process and remove the 3mm base material of the tooth surface on a CNC milling machine, and inspect the processed tooth surface to ensure that there are no defects such as cracks and sand holes;

[0029] (2) Prepare T15 high speed steel rare earth modified powder and 507Mo: T15 high speed steel rare earth modified powder = 3:7 mixed powder. Before cladding, use a high-speed vibrating ball mill to perform high-speed ball milling on the alloy powder for cladding for 20 minutes to mix the powder particles evenly, and dry them in a vacuum drying oven at 80°C for 12 hours.

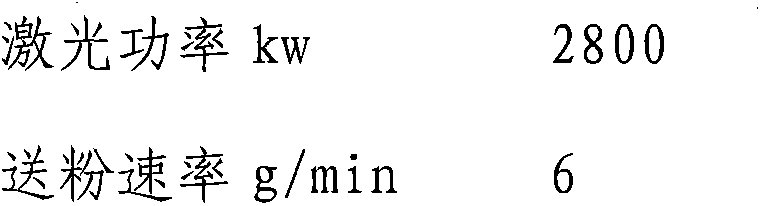

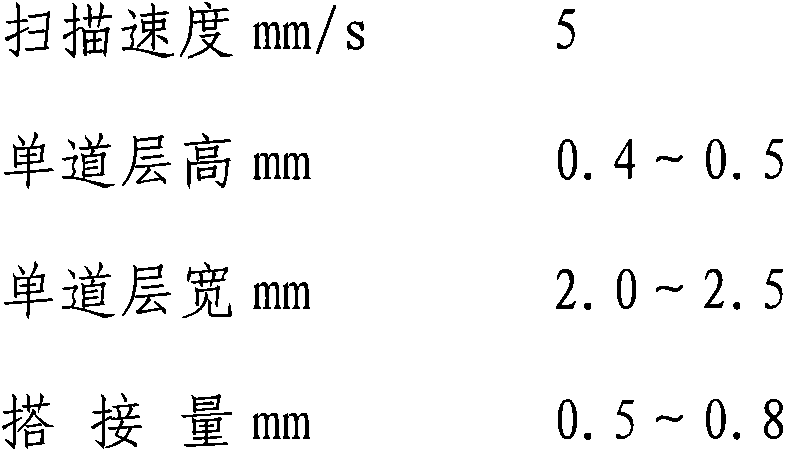

[0030] (3) According to the process parameters in Table 1, firstly, the tooth surface is clad with 507Mo: T15 high-speed steel rare earth modified powder = 3:7 mixed powder cladding, and cladding is carried out fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com