Differential-temperature thermal treatment process for forged steel BD roller

A technology of differential temperature heat treatment and process method, which is applied in the direction of heat treatment furnace, heat treatment equipment, heat treatment process control, etc. It can solve the problems of insufficient impact toughness and wear resistance, so as to improve toughness, reduce scrap rate, and control grain length. a large degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

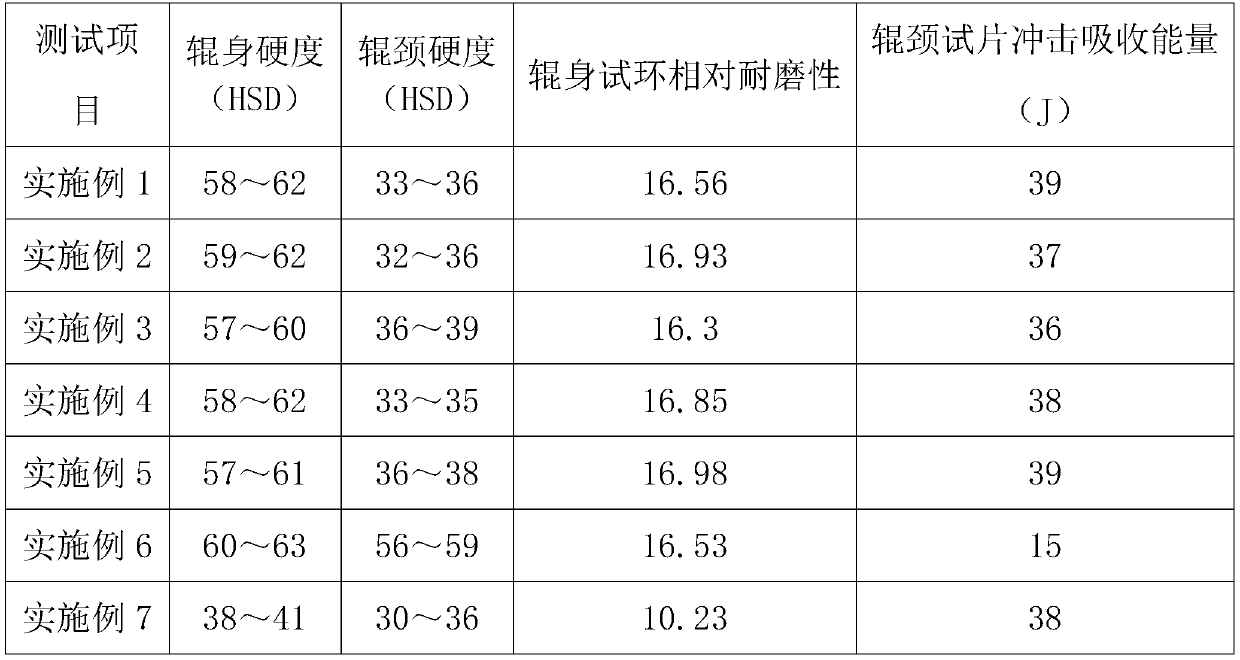

Examples

Embodiment 1

[0028] The diameter of the neck of the forged steel BD roll is 460mm, the width-to-depth ratio of the roll body is 0.9-1.2, the groove bottom radius of the roll body before heat treatment is 4mm, the groove side radius is 2mm, and the roll body length is 12mm. First heat it in a high-temperature resistance furnace to 900°C, keep it warm for 25 hours, take it out of the furnace, cool it with water for 50 minutes, and air-cool it for 25 minutes to install it in the furnace, temper it at 610°C and keep it warm for 35 hours. , The differential heating temperature is 1090°C, the holding time is 90min, the water cooling is 60min after the differential heating and holding, the air cooling is 50min, and the furnace is tempered, the tempering temperature is 530°C, and the holding time is 39h.

Embodiment 2

[0030] The diameter of the neck of the forged steel BD roll is 460mm, the width-to-depth ratio of the roll body is 0.9-1.1, the groove bottom radius of the roll body before heat treatment is 5mm, the groove side radius is 4mm, and the roll body length is 13mm. First heat in a high-temperature resistance furnace to 930°C, keep it warm for 23 hours, then heat it in a furnace for 50 minutes, then air cool it for 30 minutes, keep it at 590°C for 39 hours, cool it down to 360°C after the heat preservation, and heat it for 12 hours. , The differential heating temperature is 1070°C, the holding time is 90min, the water cooling is 60min after the differential heating and holding, the air cooling is 50min, and the furnace is tempered, the tempering temperature is 535°C, and the holding time is 39h.

Embodiment 3

[0032] The diameter of the neck of the forged steel BD roll is 430mm, the width-to-depth ratio of the roll body is 0.8-1.1, the groove bottom radius of the roll body before heat treatment is 5mm, the groove side radius is 3mm, and the length of the roll body is 15mm. First heat it in a high-temperature resistance furnace to 940°C, keep it warm for 26 hours, then put it in the furnace after cooling it in water for 55 minutes, then air cool it for 30 minutes, keep it warm at 610°C for 36 hours, cool it down to 410°C after the heat preservation is over, and heat it with a differential temperature furnace after 11 hours of heat preservation. The differential temperature heating temperature is 1060°C, the holding time is 100min, the water cooling is 58min after the differential heating and holding time, the air cooling is 56min, and the furnace is tempered, the tempering temperature is 545°C, and the holding time is 39h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com