Patents

Literature

65results about How to "High wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

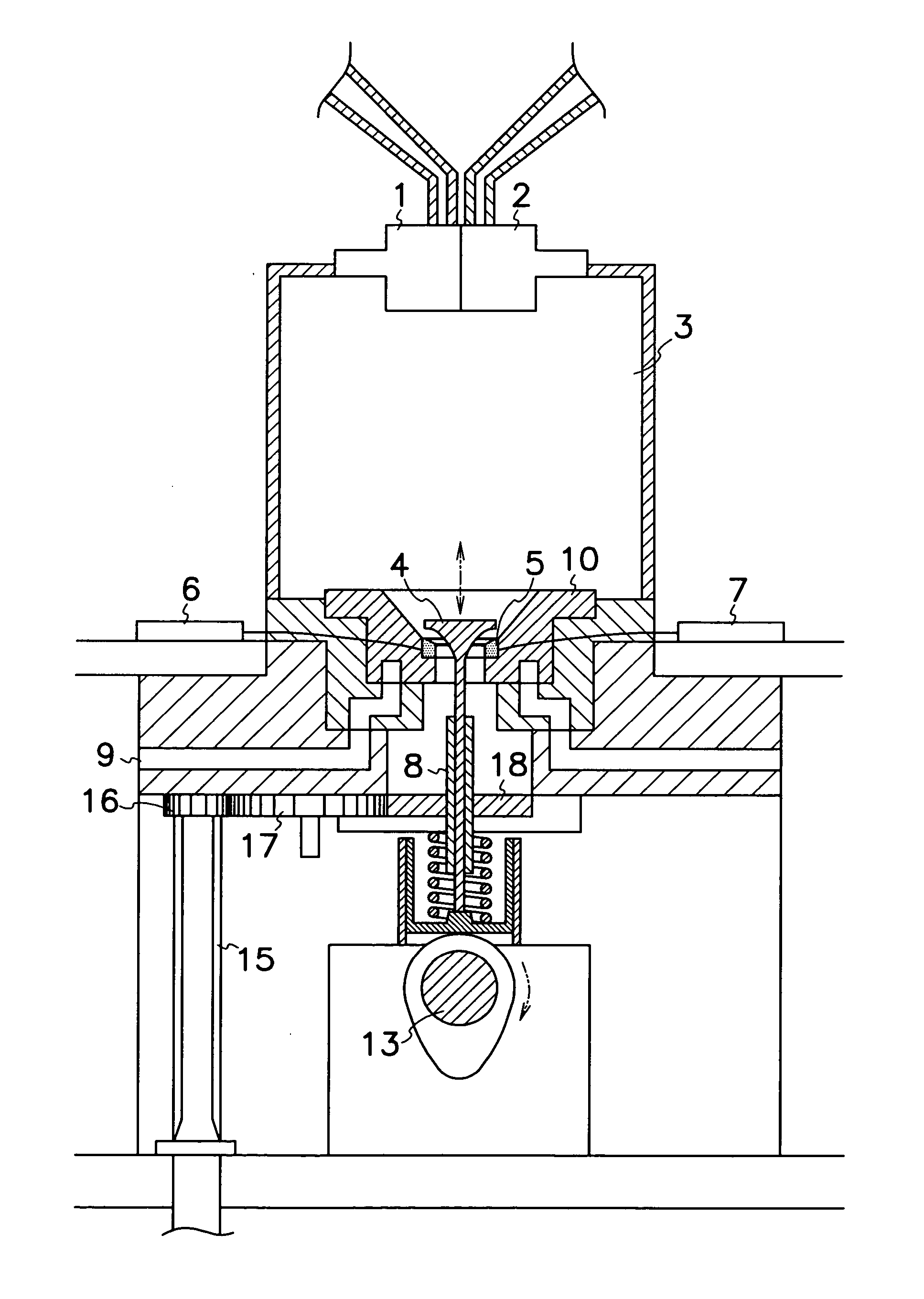

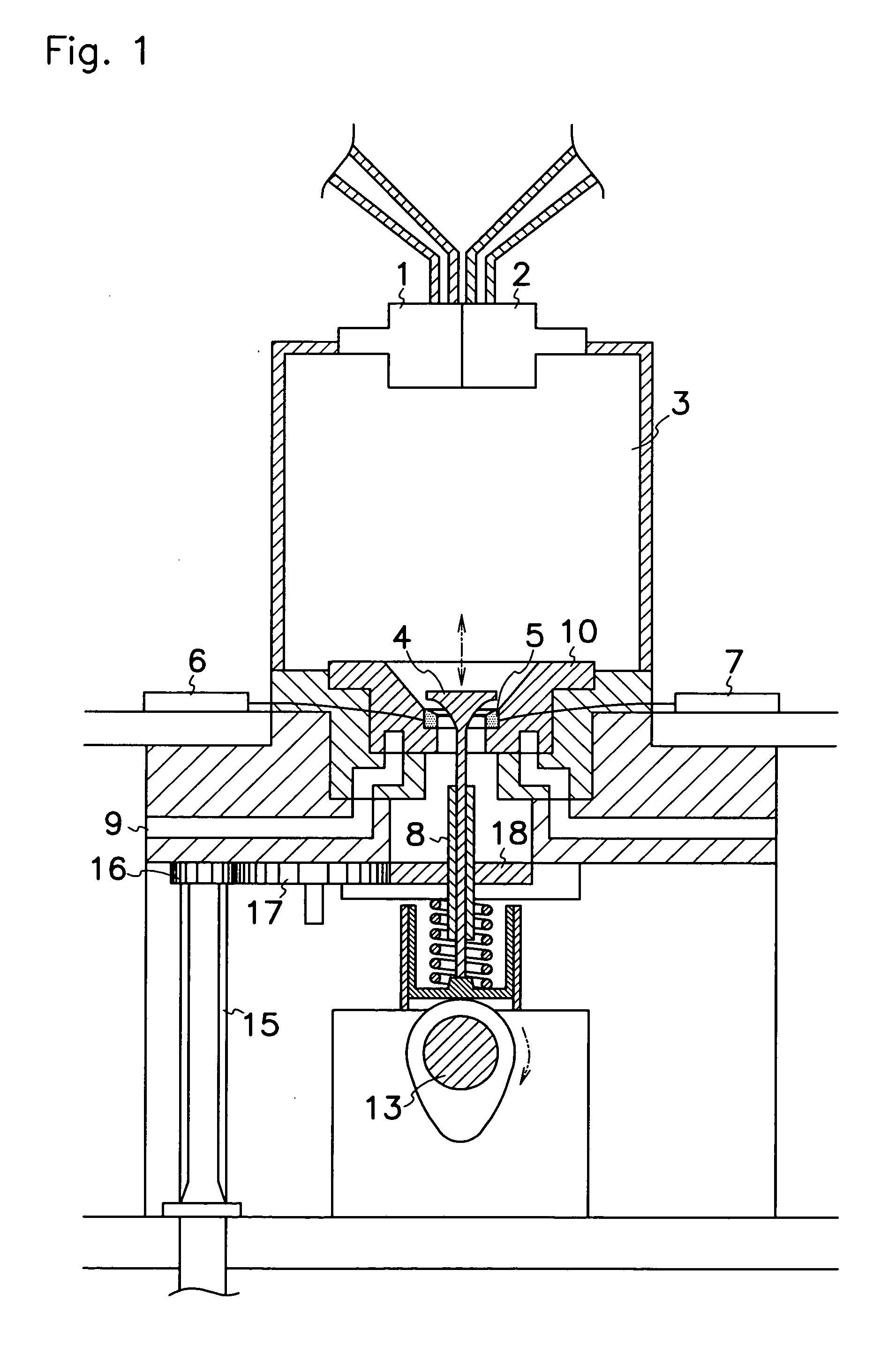

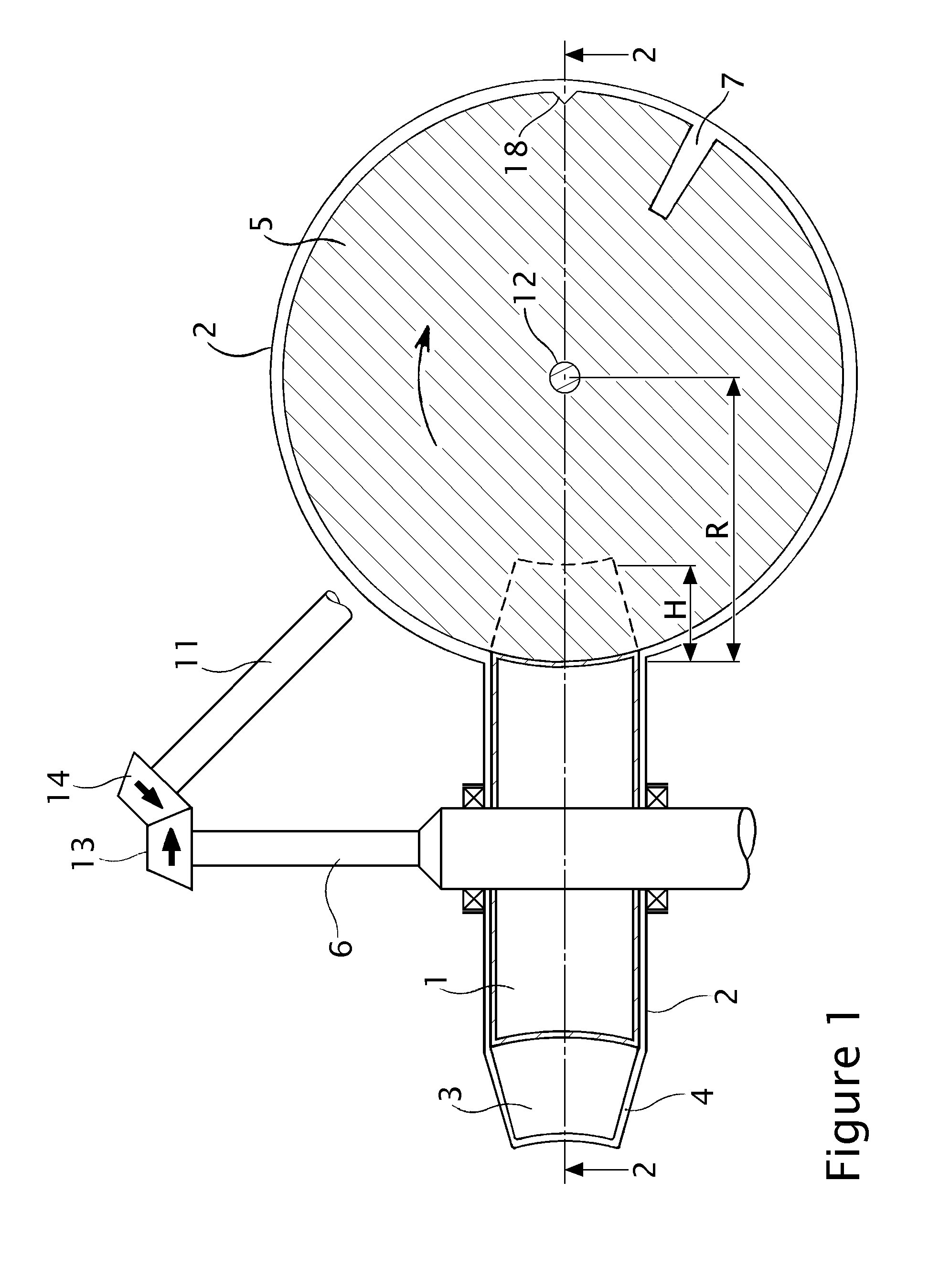

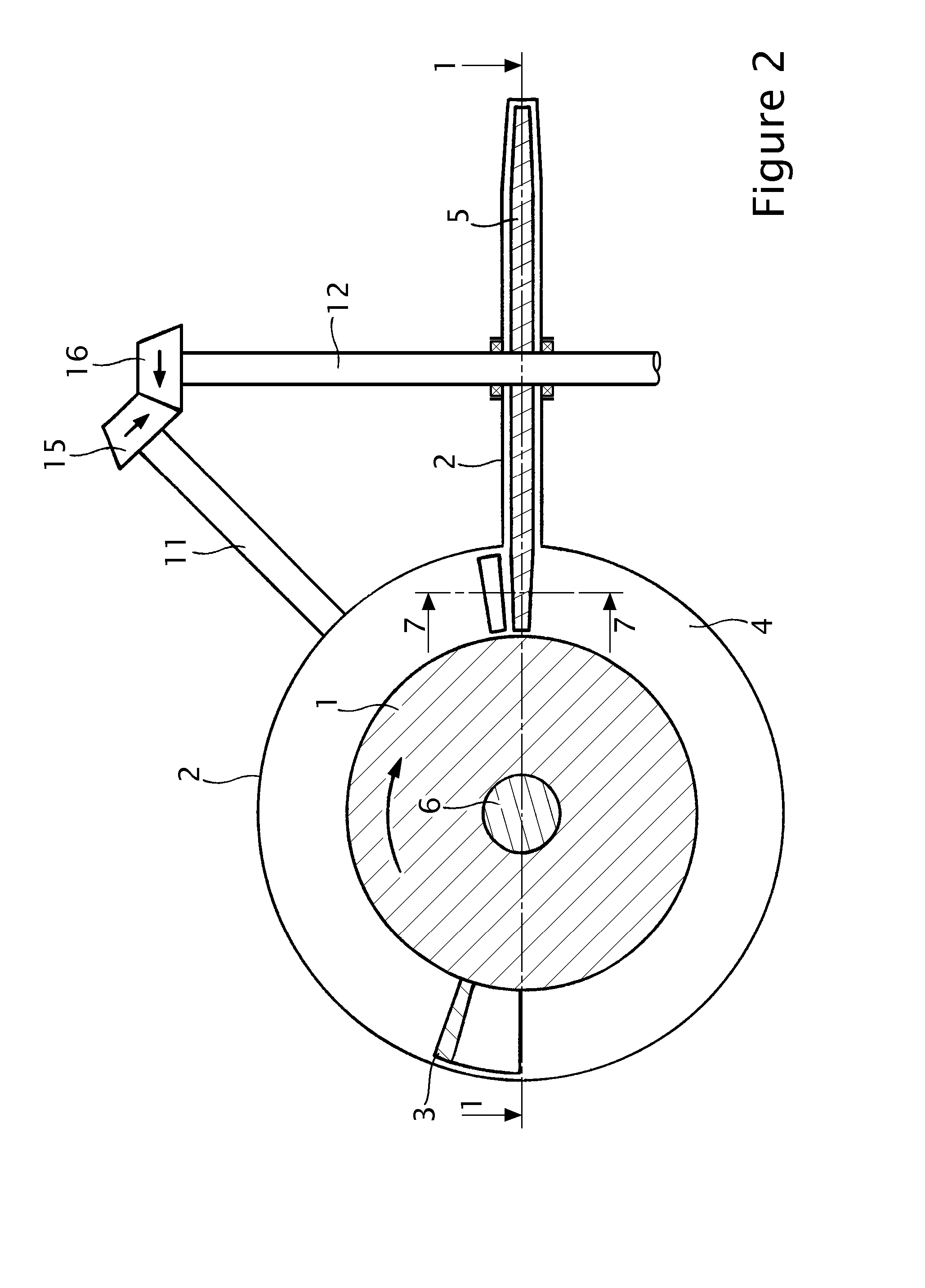

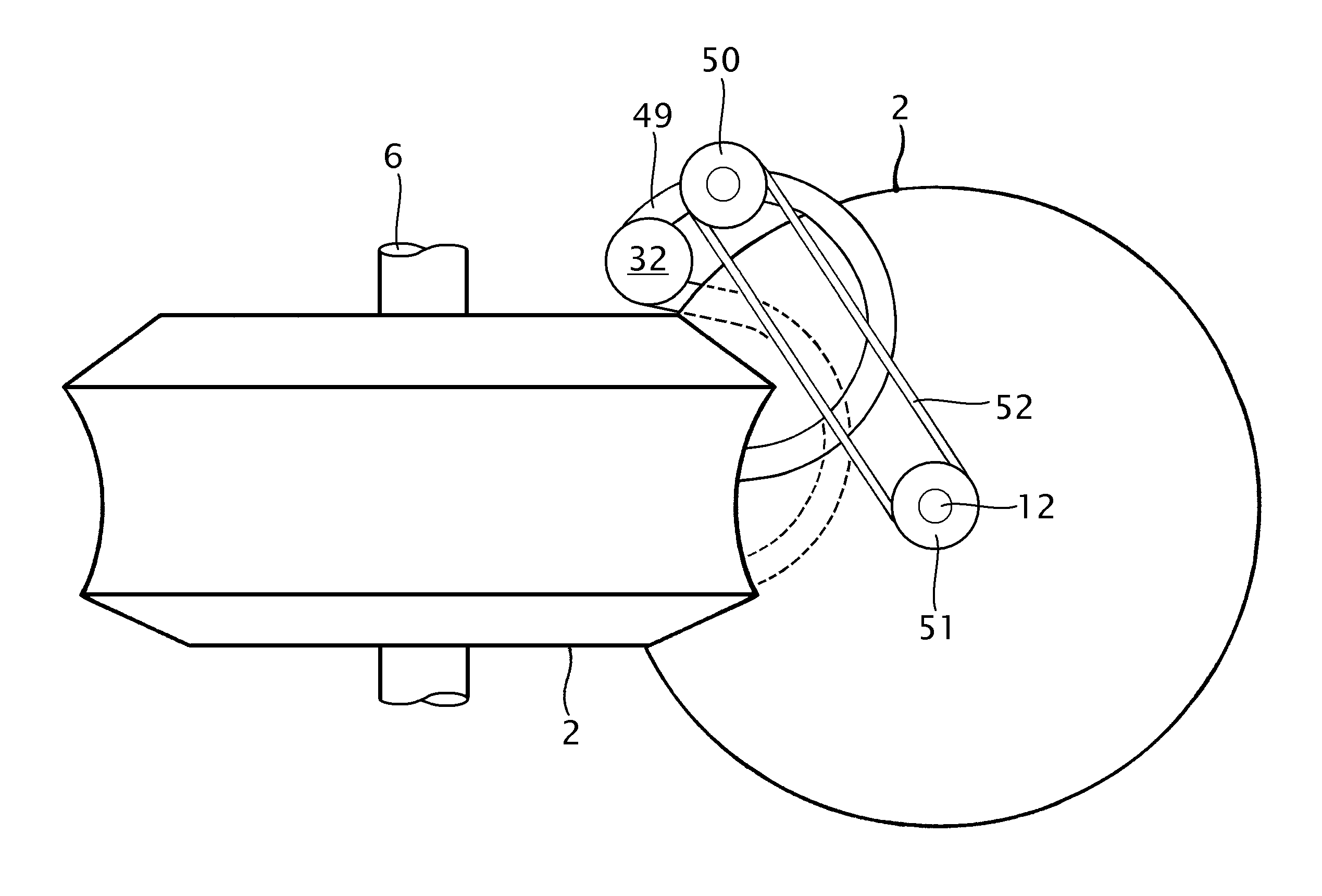

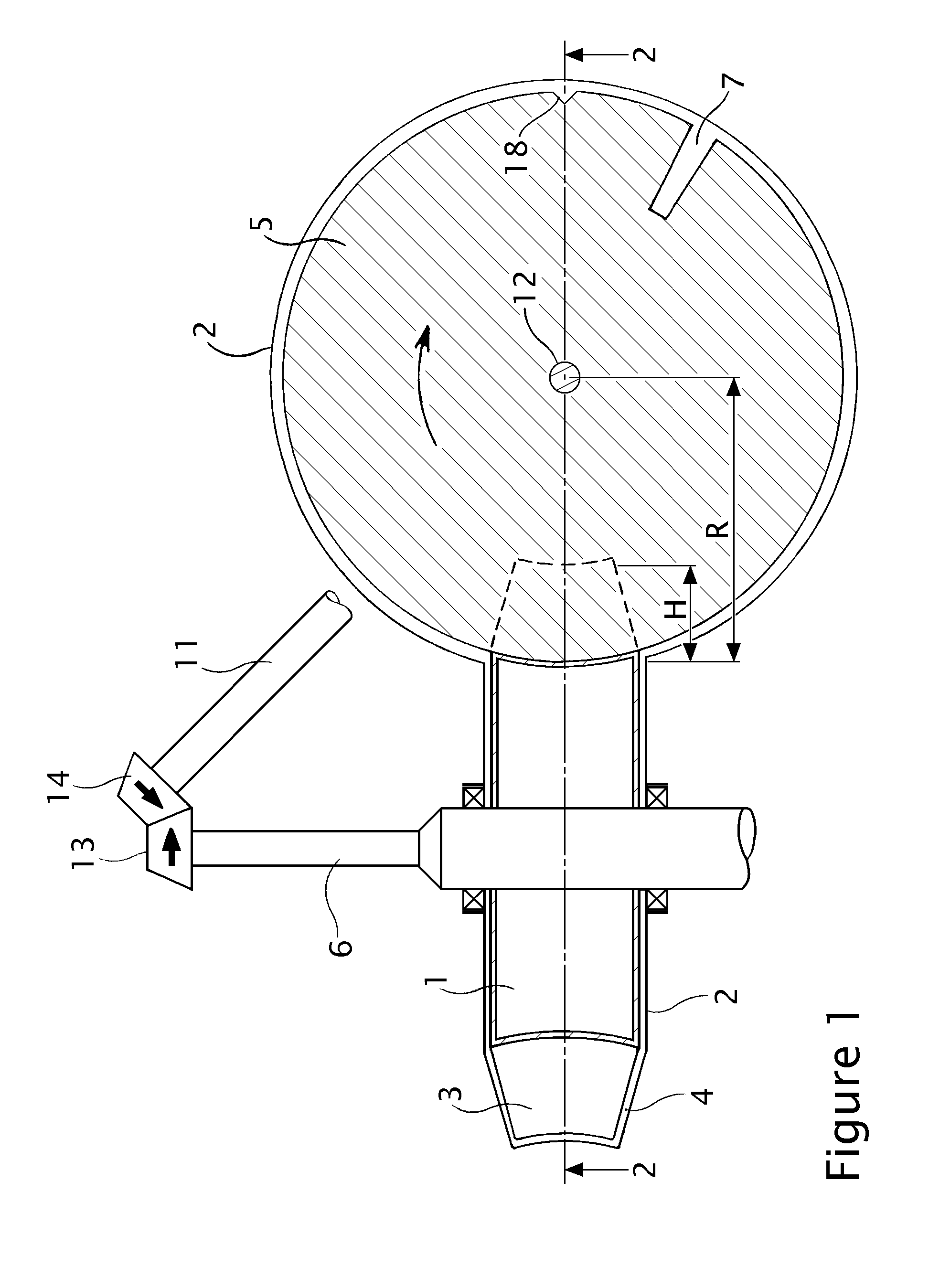

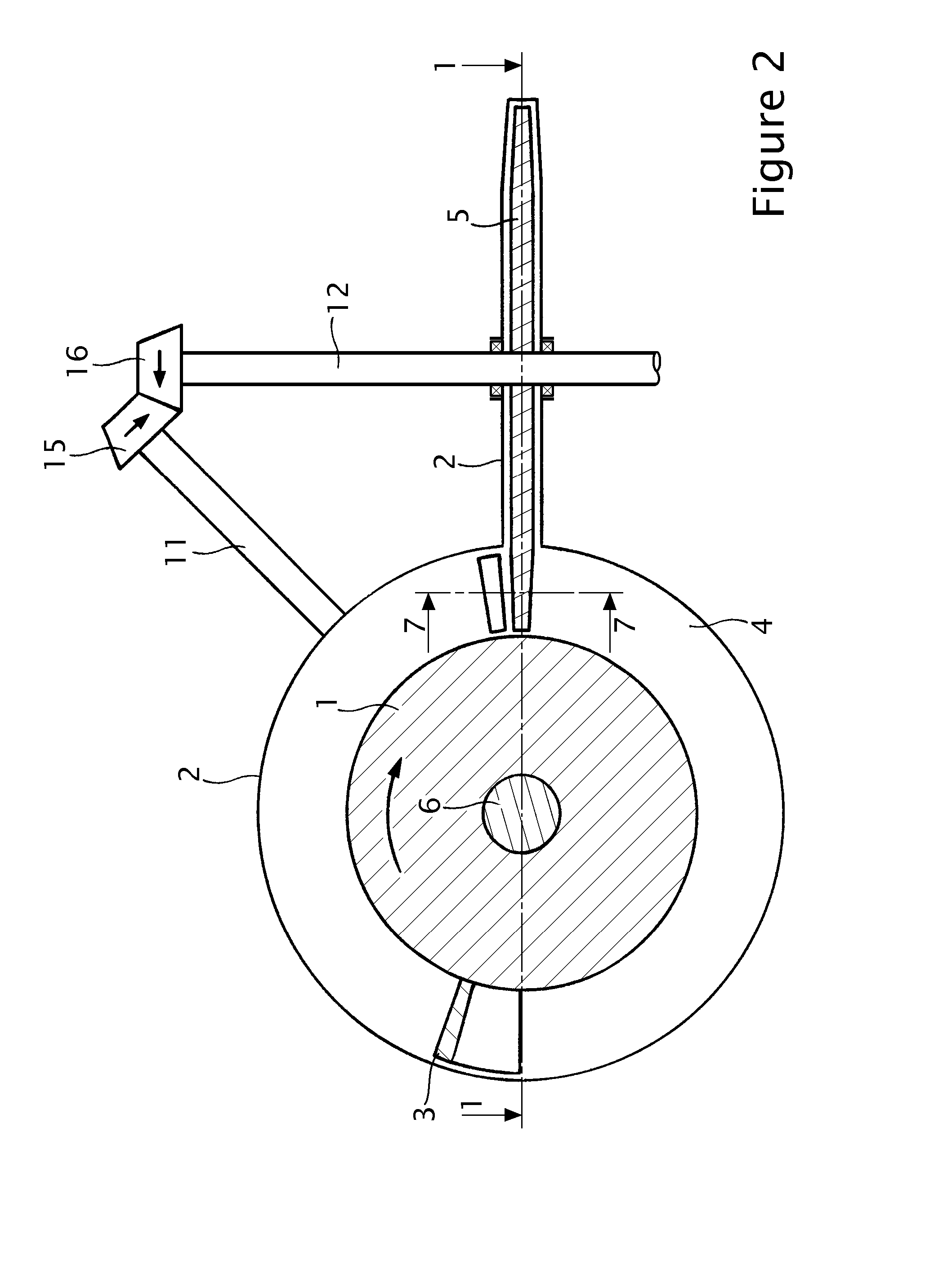

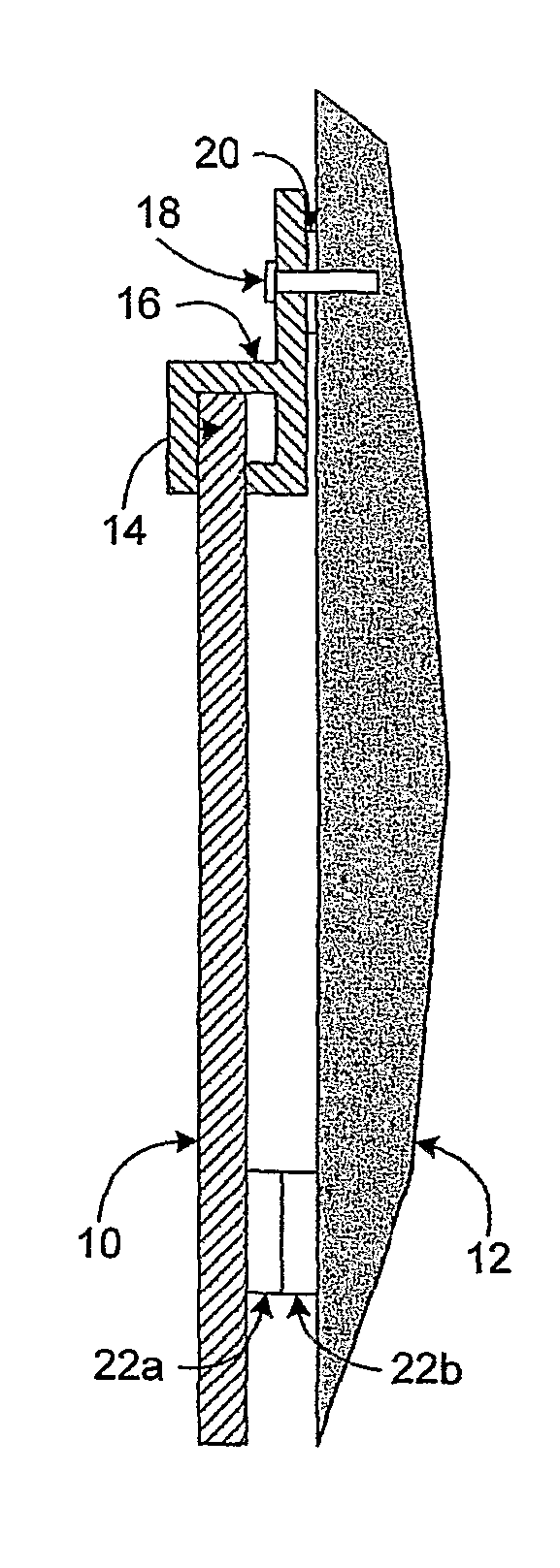

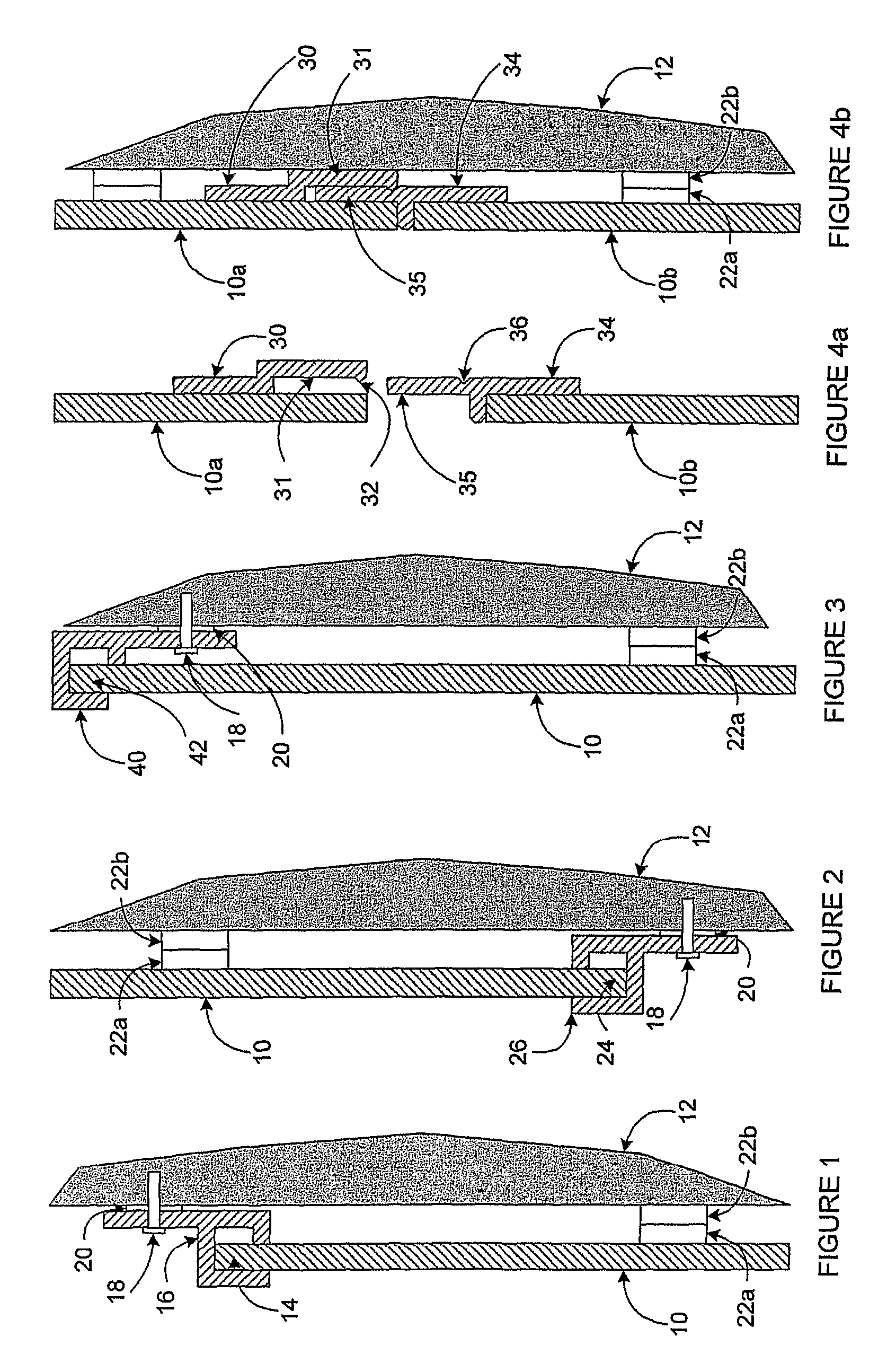

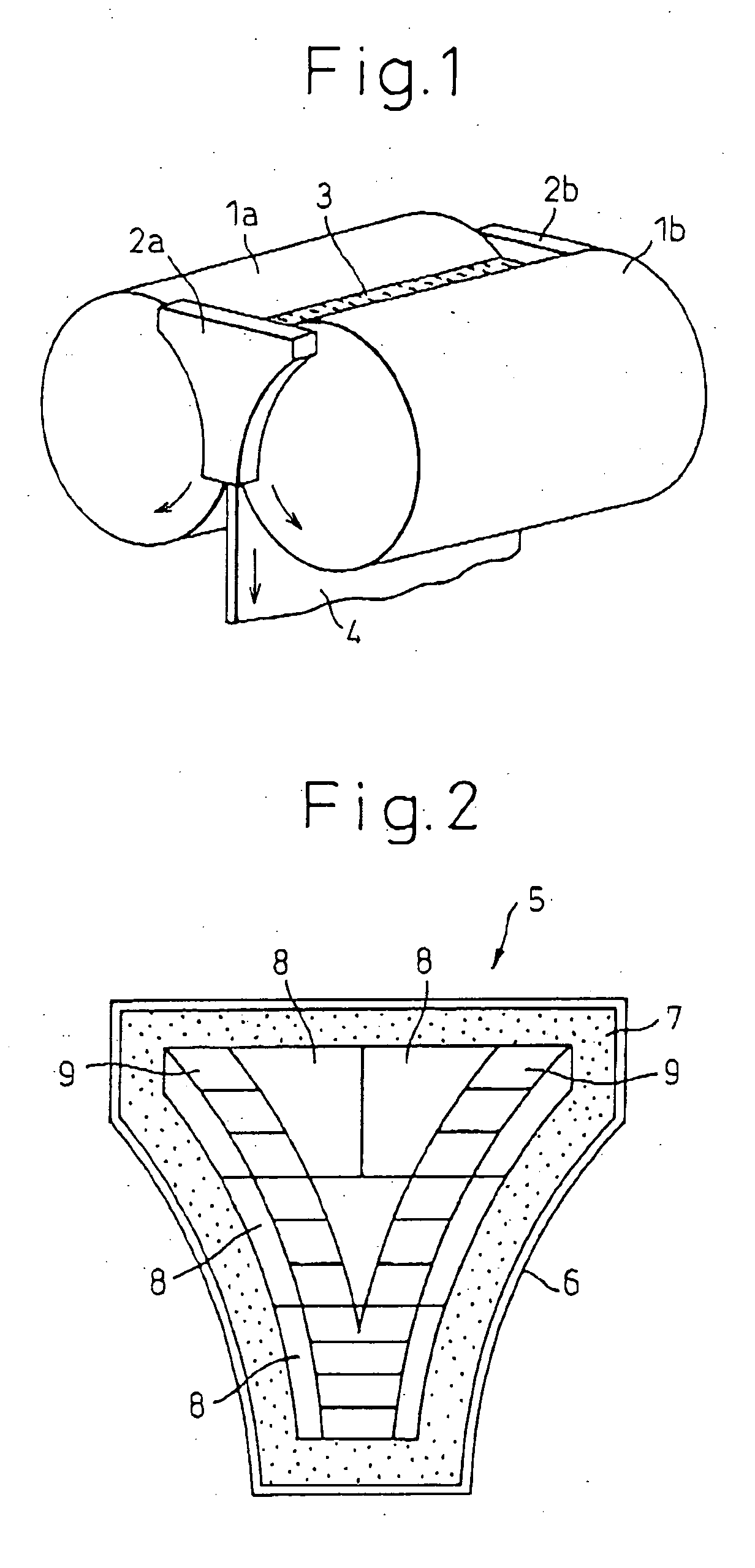

Ocean bottom seismic cable recording apparatus

ActiveUS8675446B2Avoid bendingPrevent twistingPipe laying and repairSeismology for water-covered areasOcean bottomAcoustics

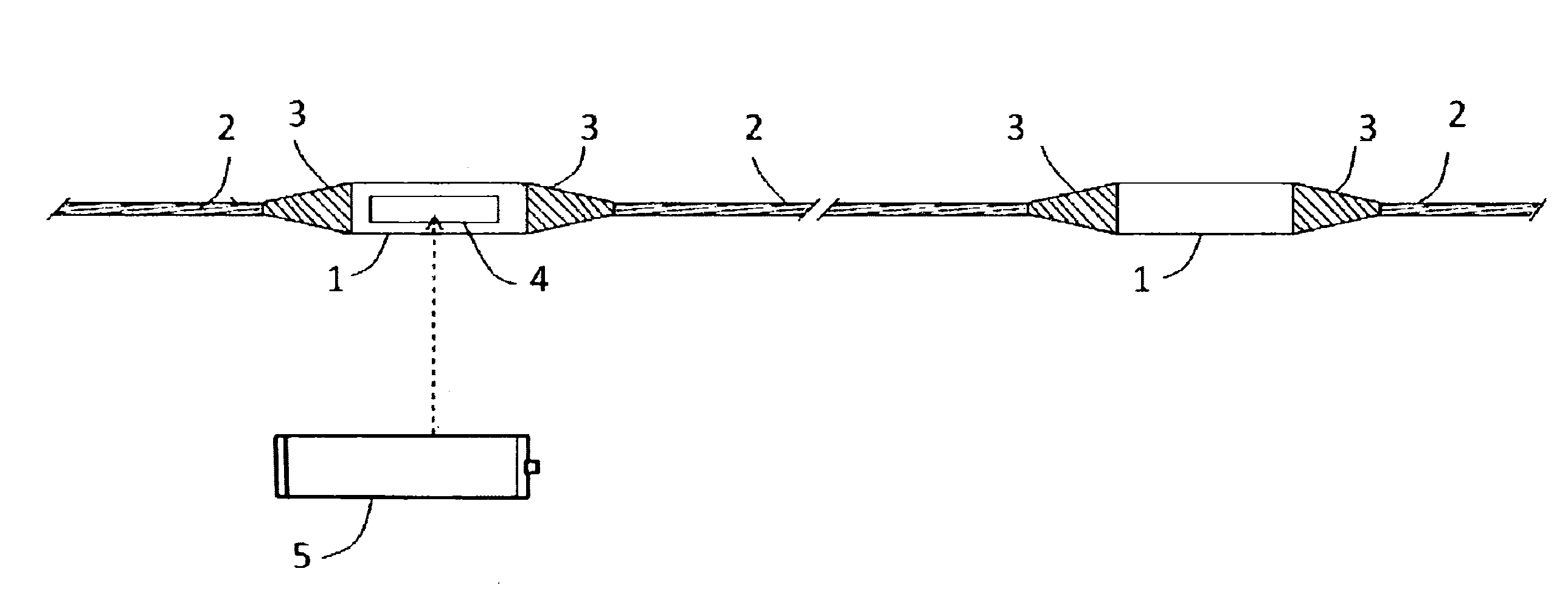

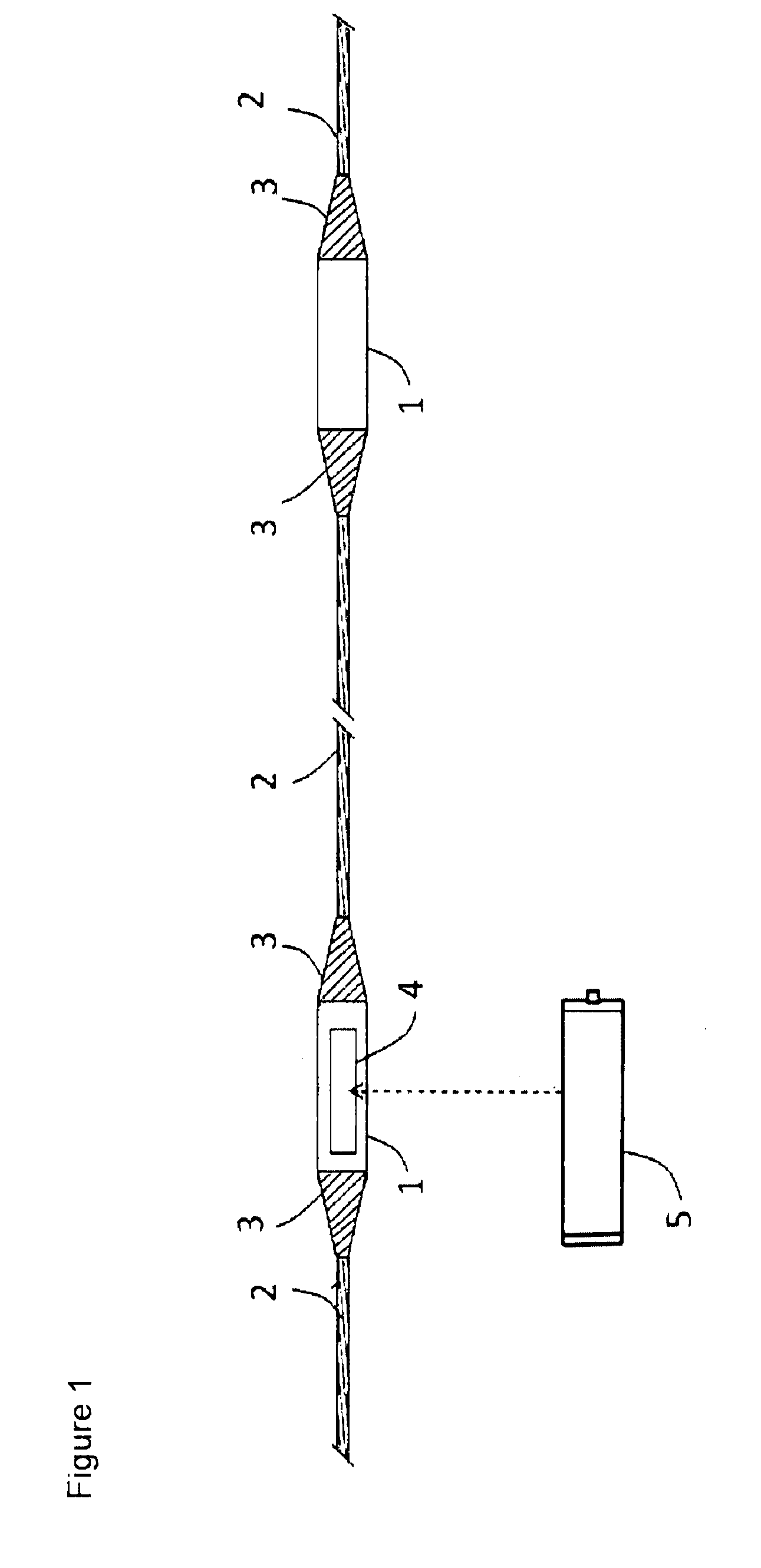

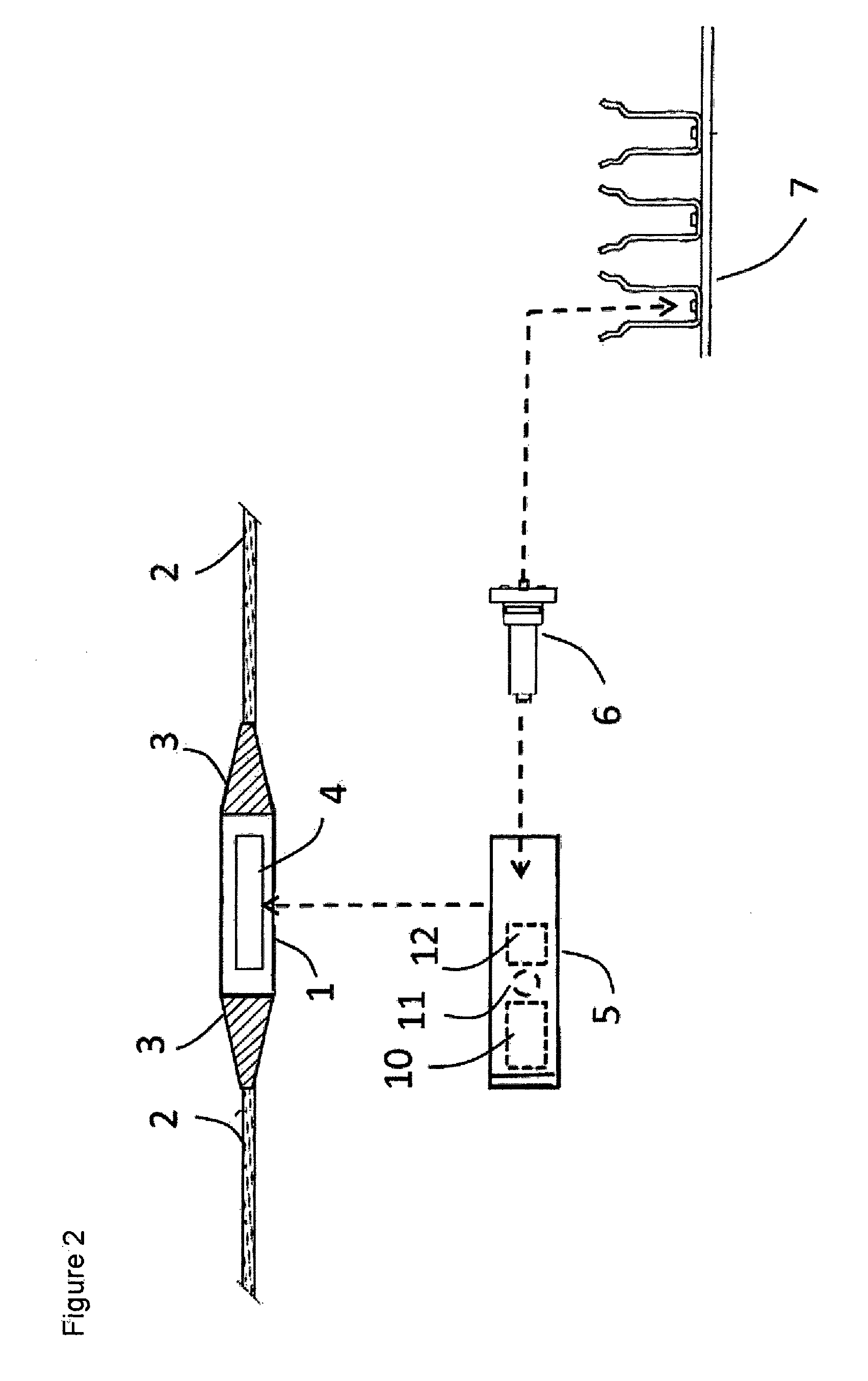

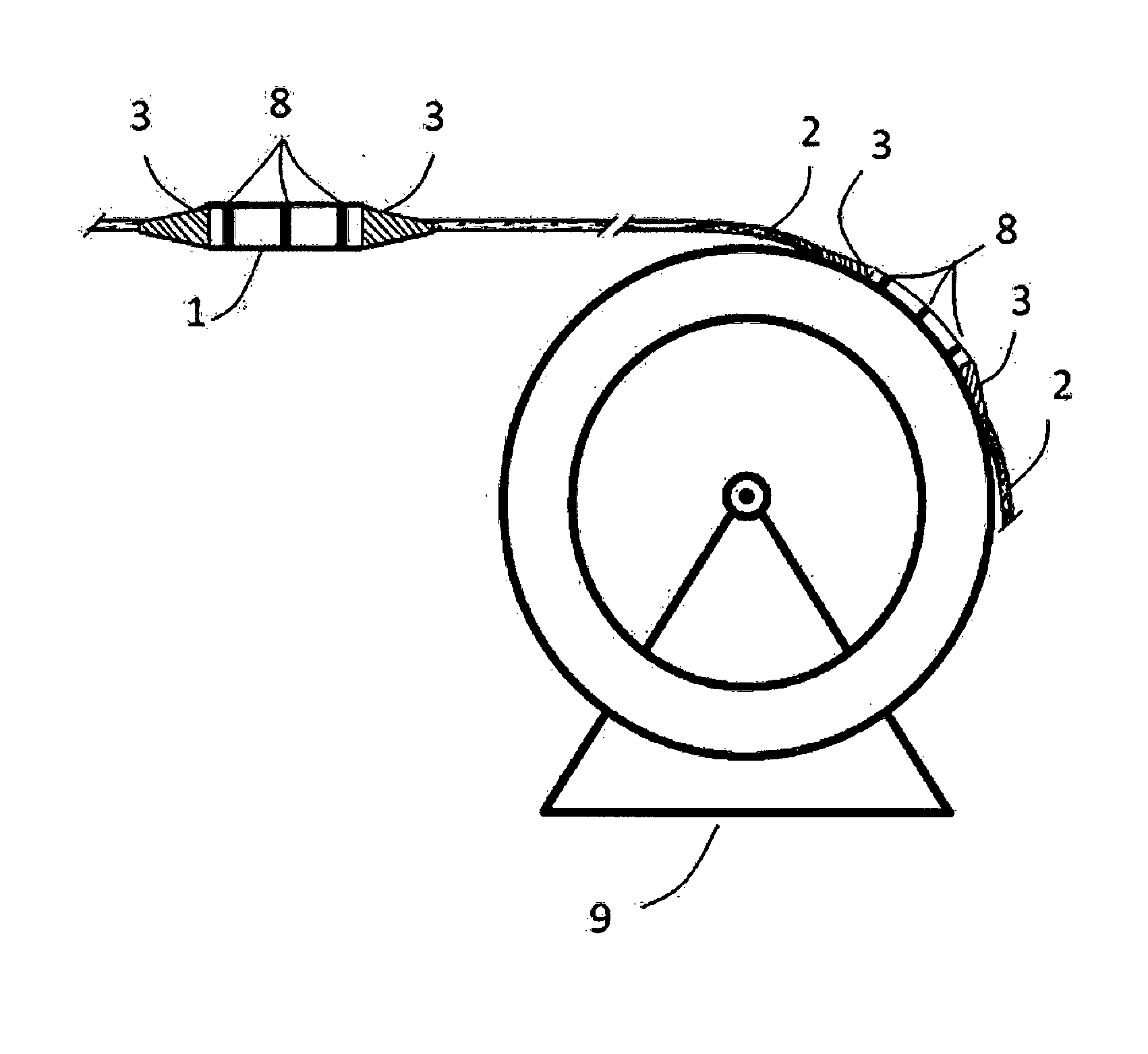

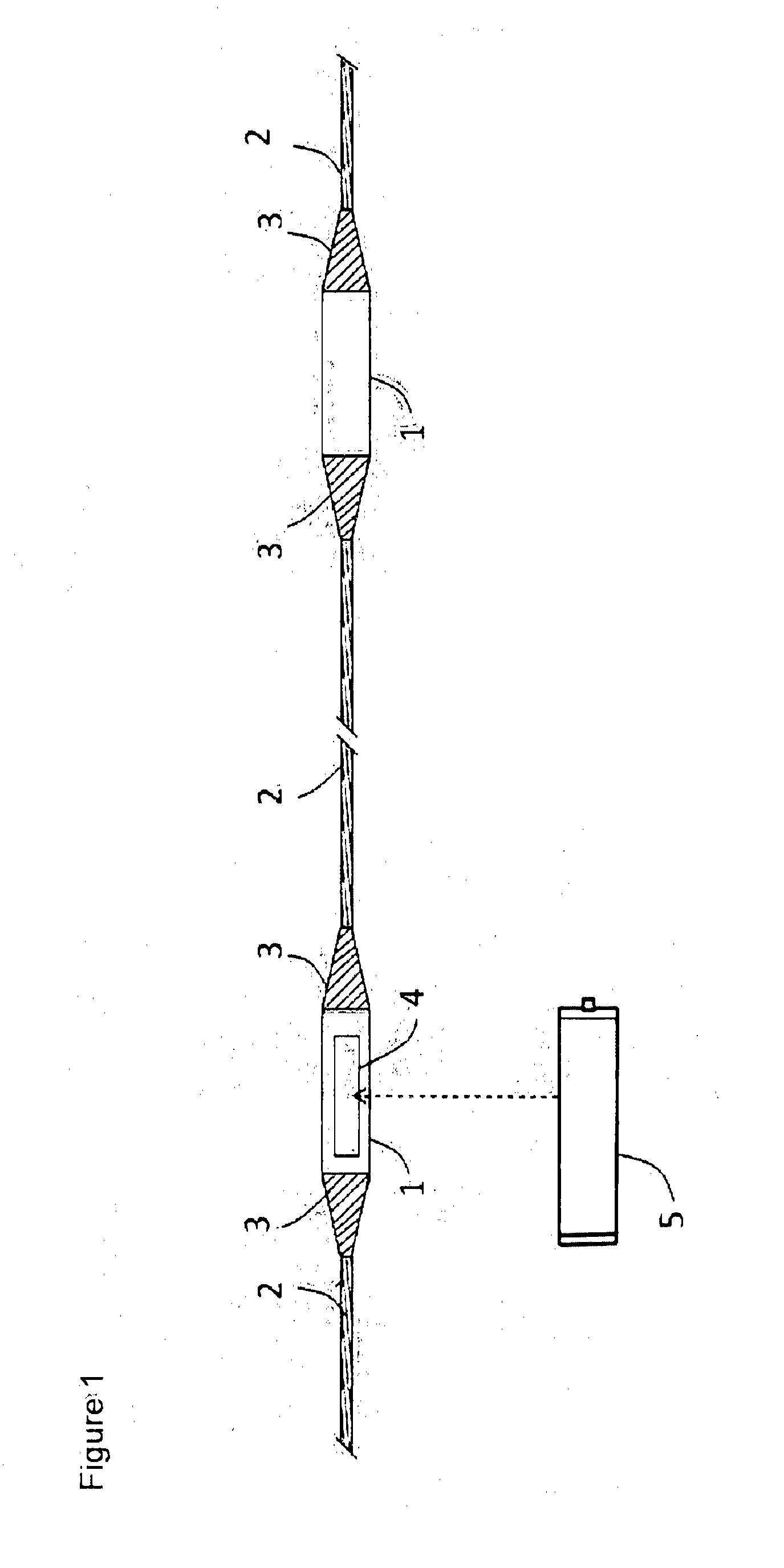

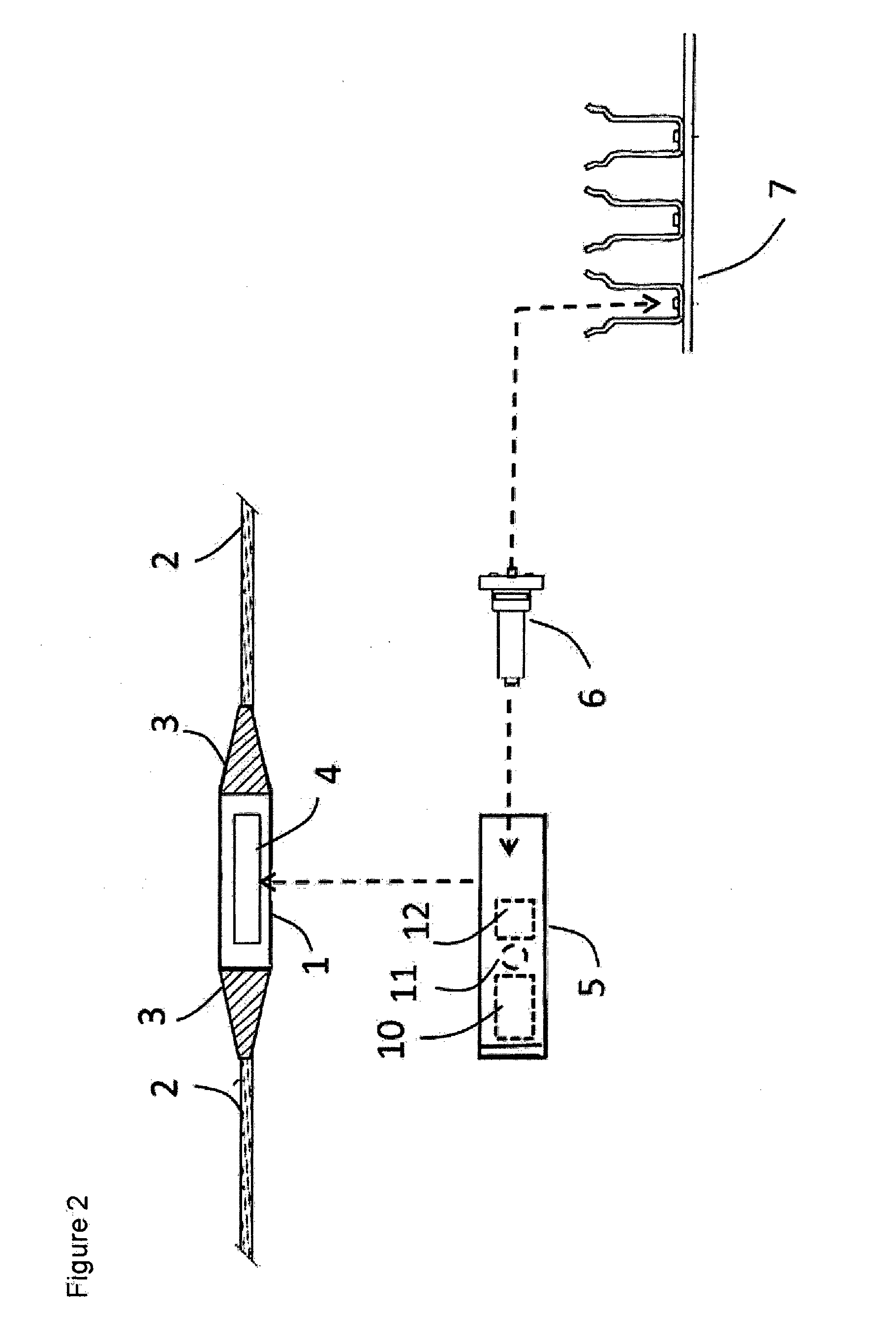

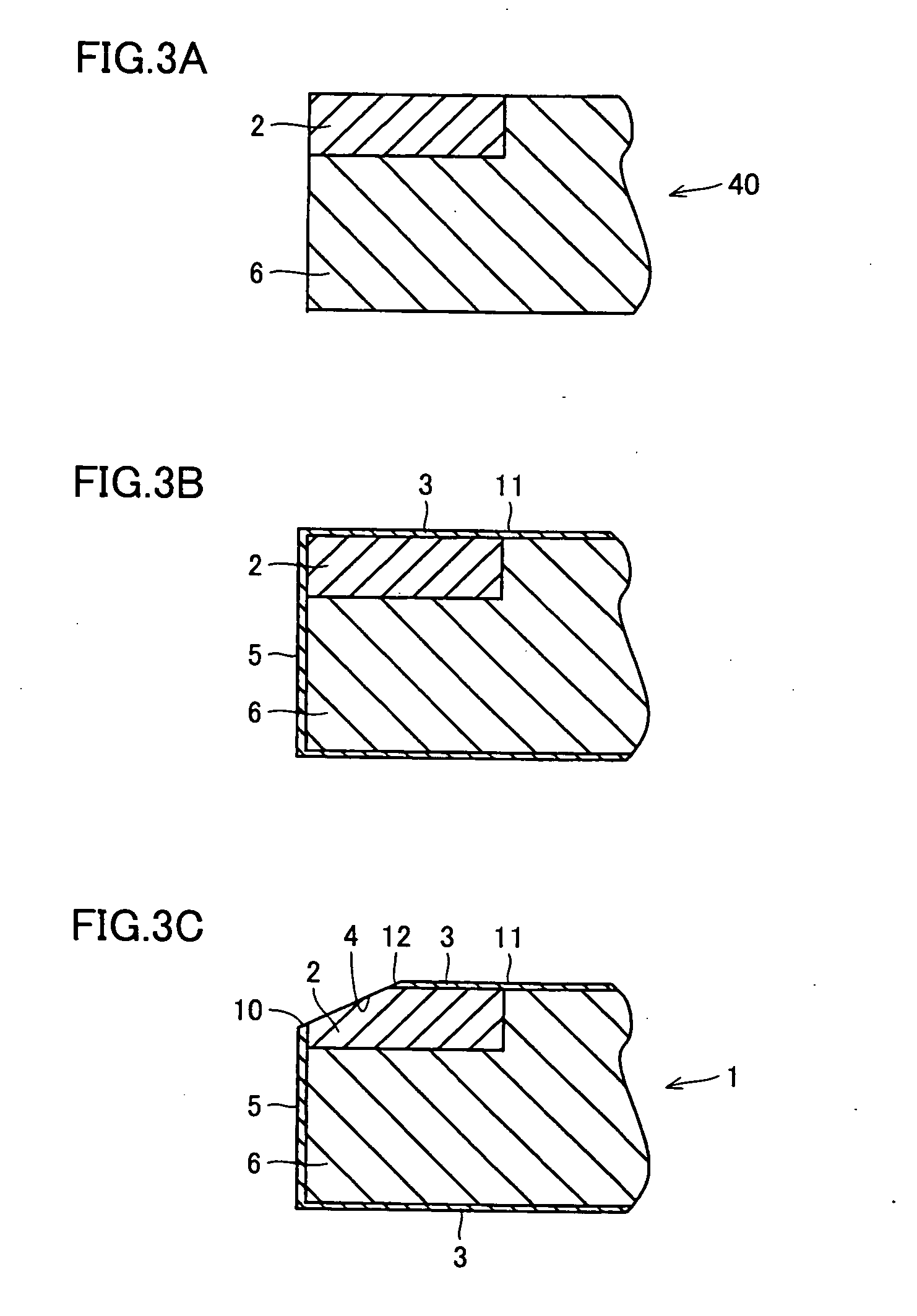

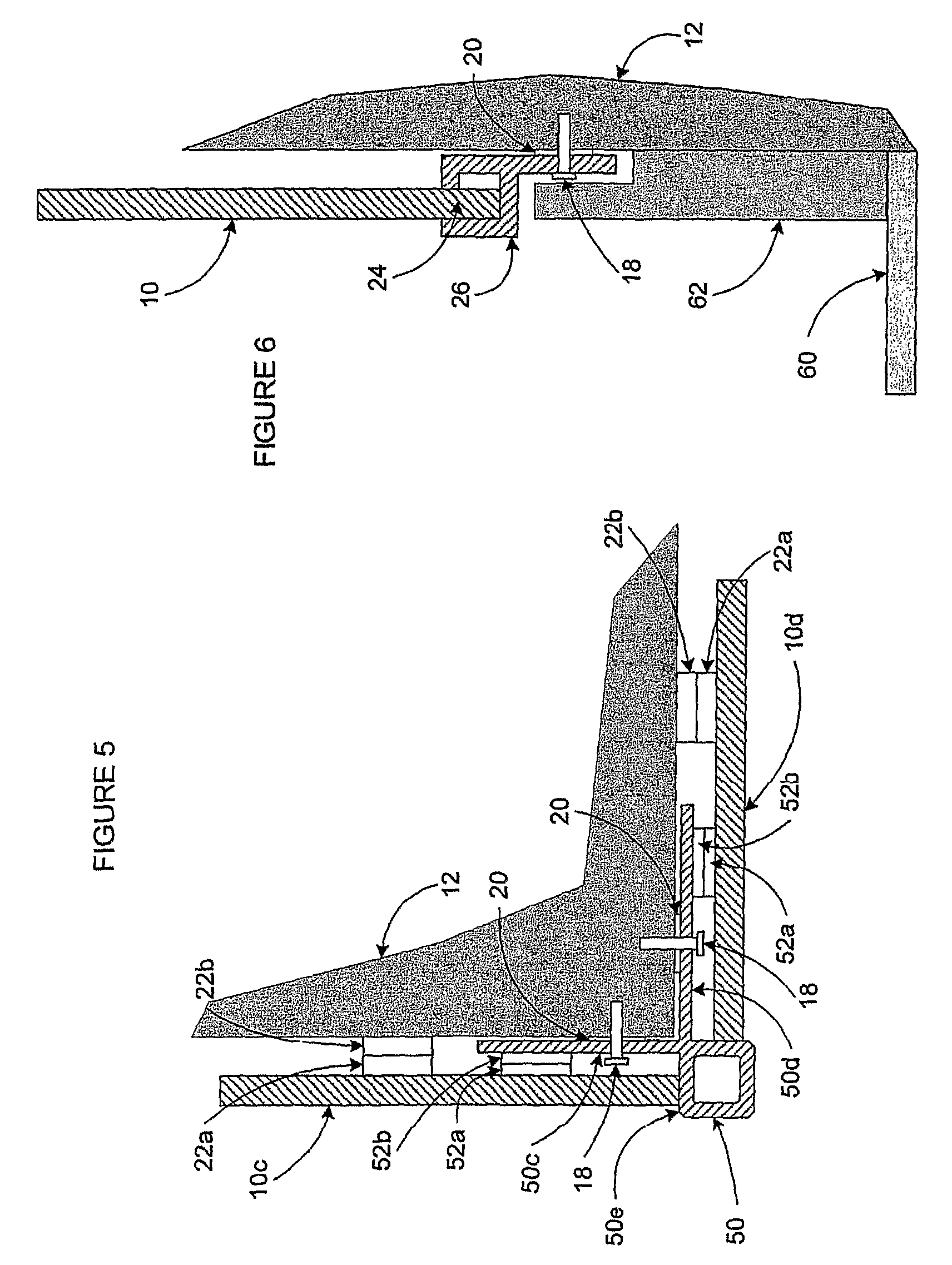

An ocean bottom seismic cable recording apparatus comprising a plurality of seismic node casings (1), said node casings being separated from each other by separate stress member sections (2), each stress member section having acoustic decoupling arrangements (3) at each end connecting to said seismic node casings (1), and where each seismic node casing comprising an autonomous sensor capsule (5) for sensing and recording seismic data, and wherein the autonomous sensor capsule (5) is removable from said seismic node casing (1), and wherein each seismic node casing (1) further comprising an inner compartment (4) accommodating the autonomous sensor capsule (5).

Owner:MAGSEIS FAIRFIELD ASA

Ocean bottom seismic cable recording apparatus

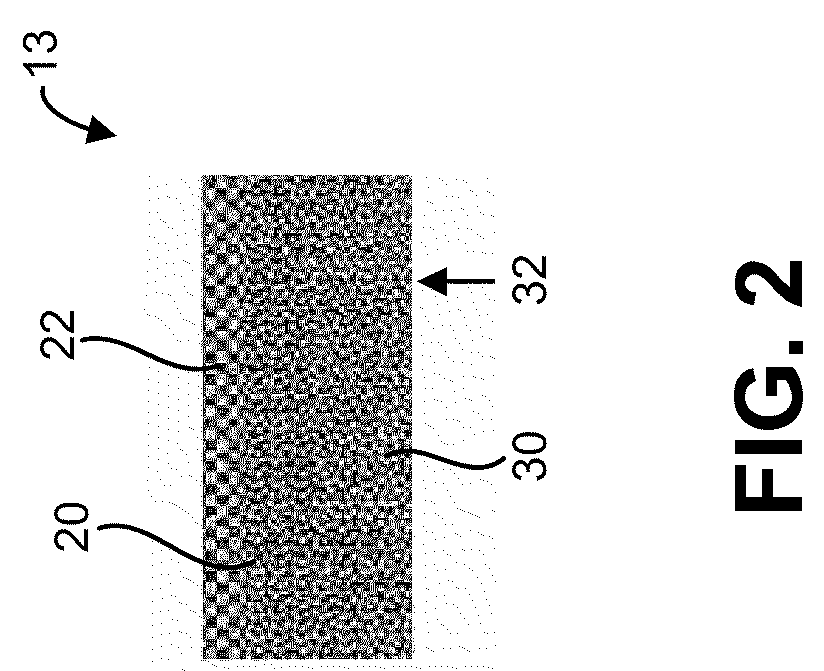

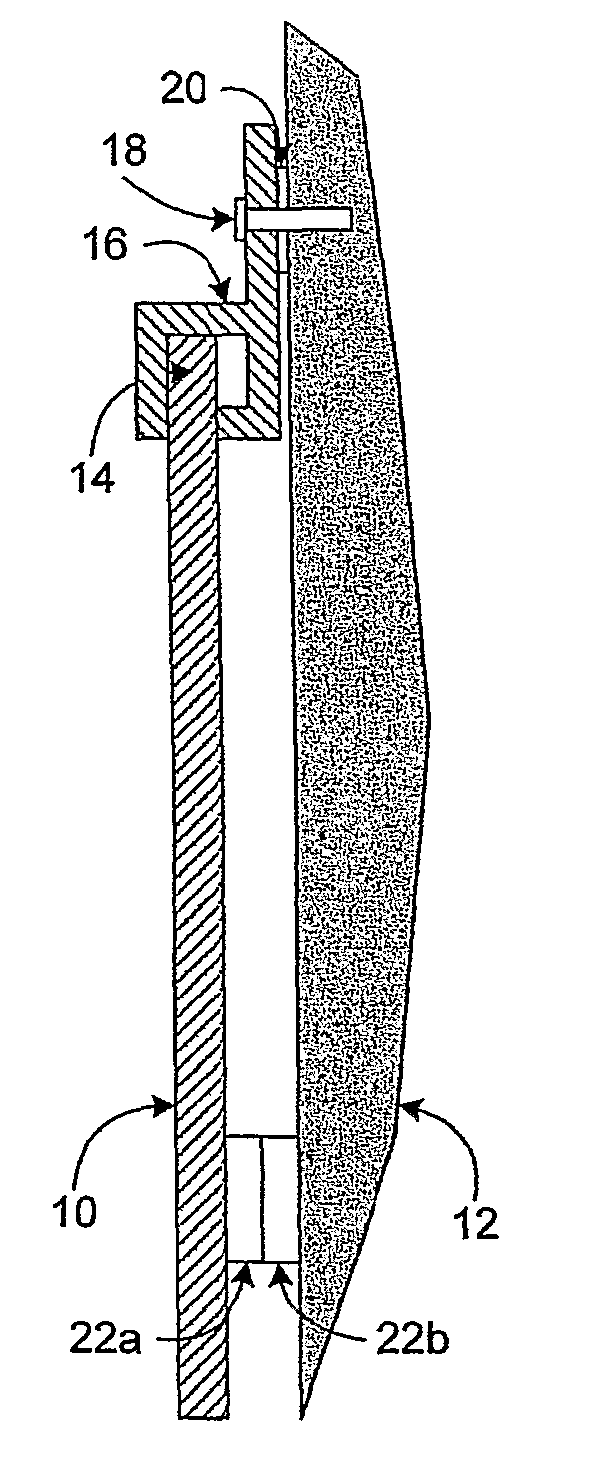

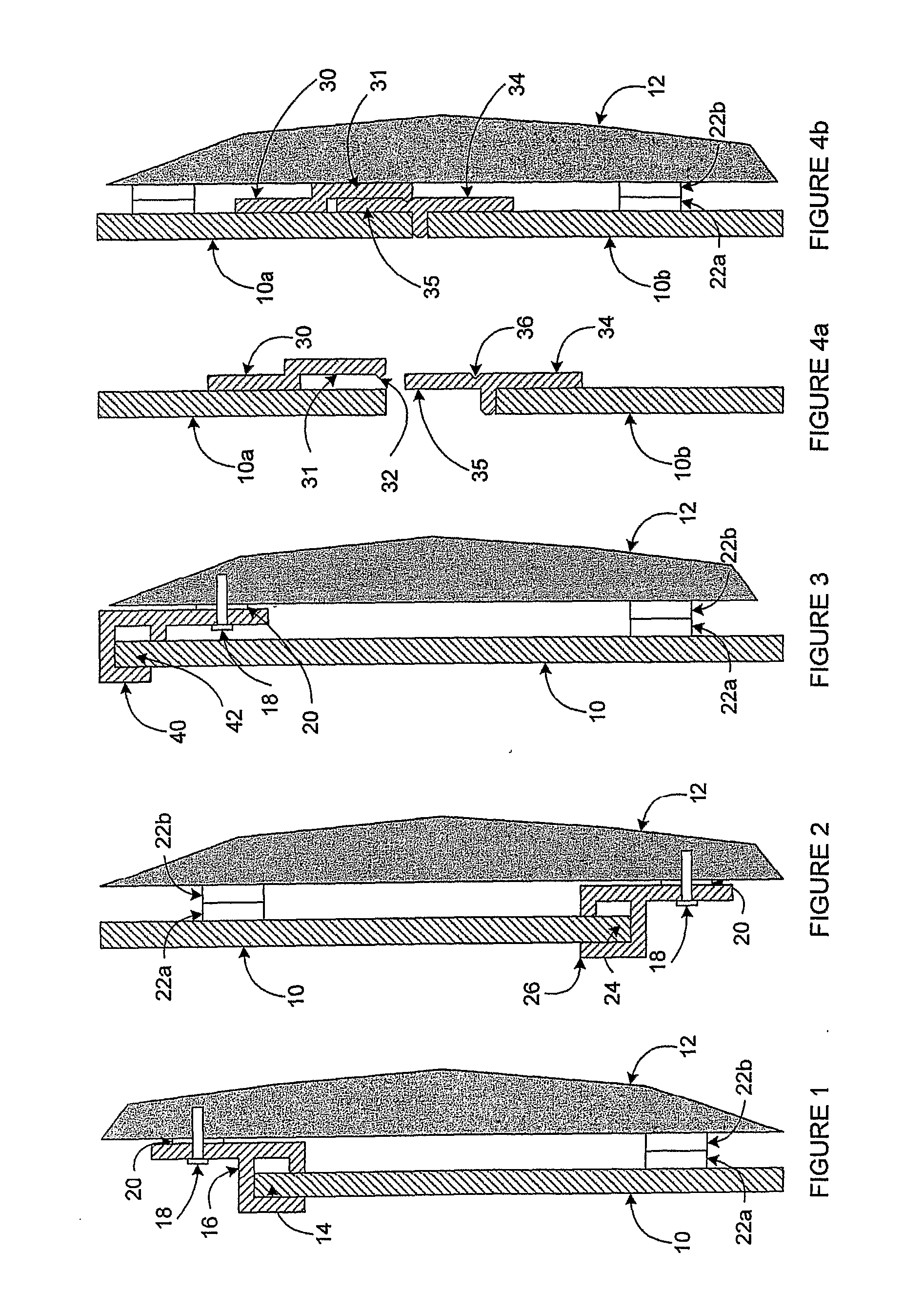

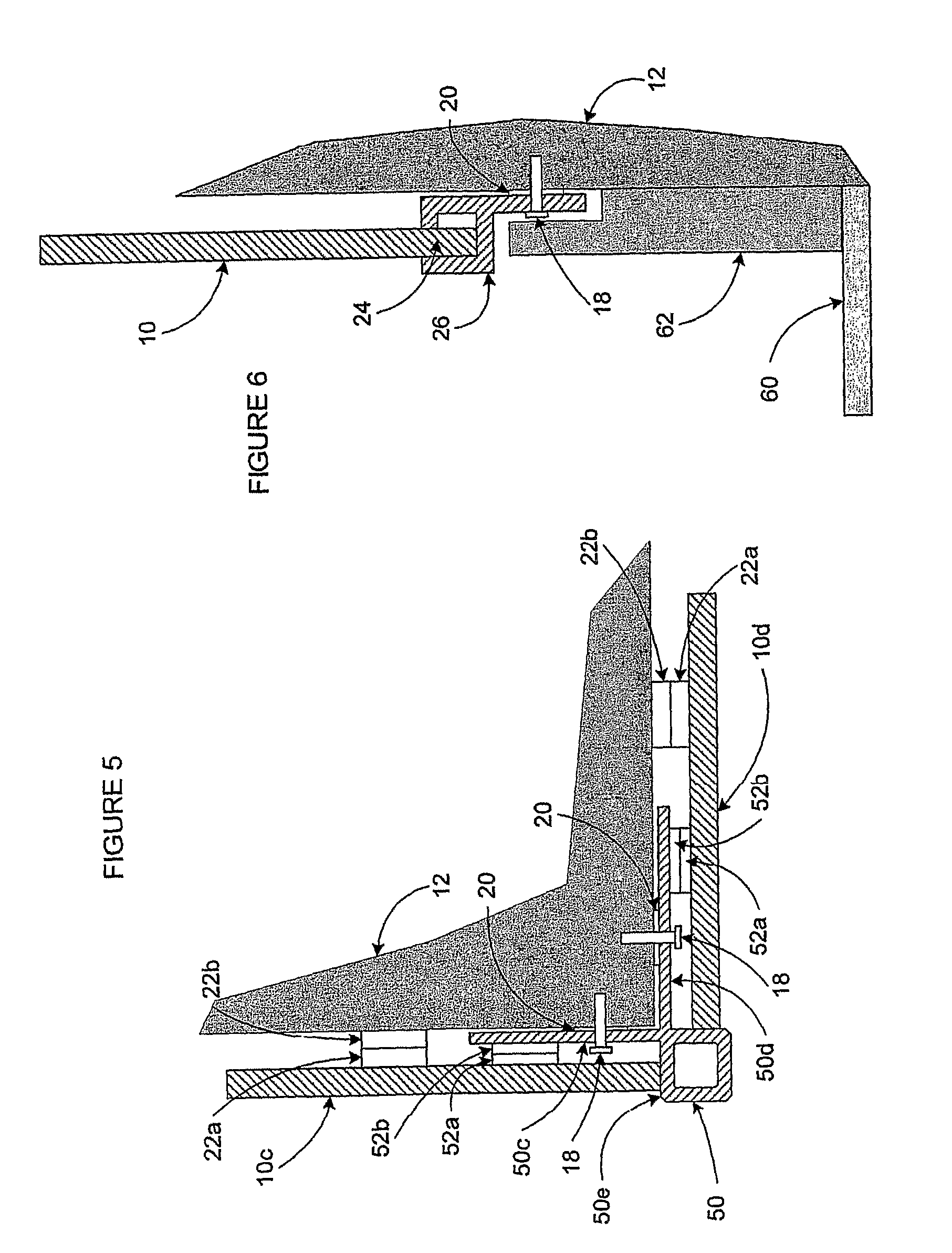

ActiveUS20130058192A1Increase speedHigh mechanical wearPipe laying and repairSeismic signal receiversOcean bottomEngineering

An ocean bottom seismic cable recording apparatus comprising a plurality of seismic node casings (1), said node casings being separated from each other by separate stress member sections (2), each stress member section having acoustic decoupling arrangements (3) at each end connecting to said seismic node casings (1), and where each seismic node casing comprising an autonomous sensor capsule (5) for sensing and recording seismic data, and wherein the autonomous sensor capsule (5) is removable from said seismic node casing (1), and wherein each seismic node casing (1) further comprising an inner compartment (4) accommodating the autonomous sensor capsule (5).

Owner:MAGSEIS FAIRFIELD ASA

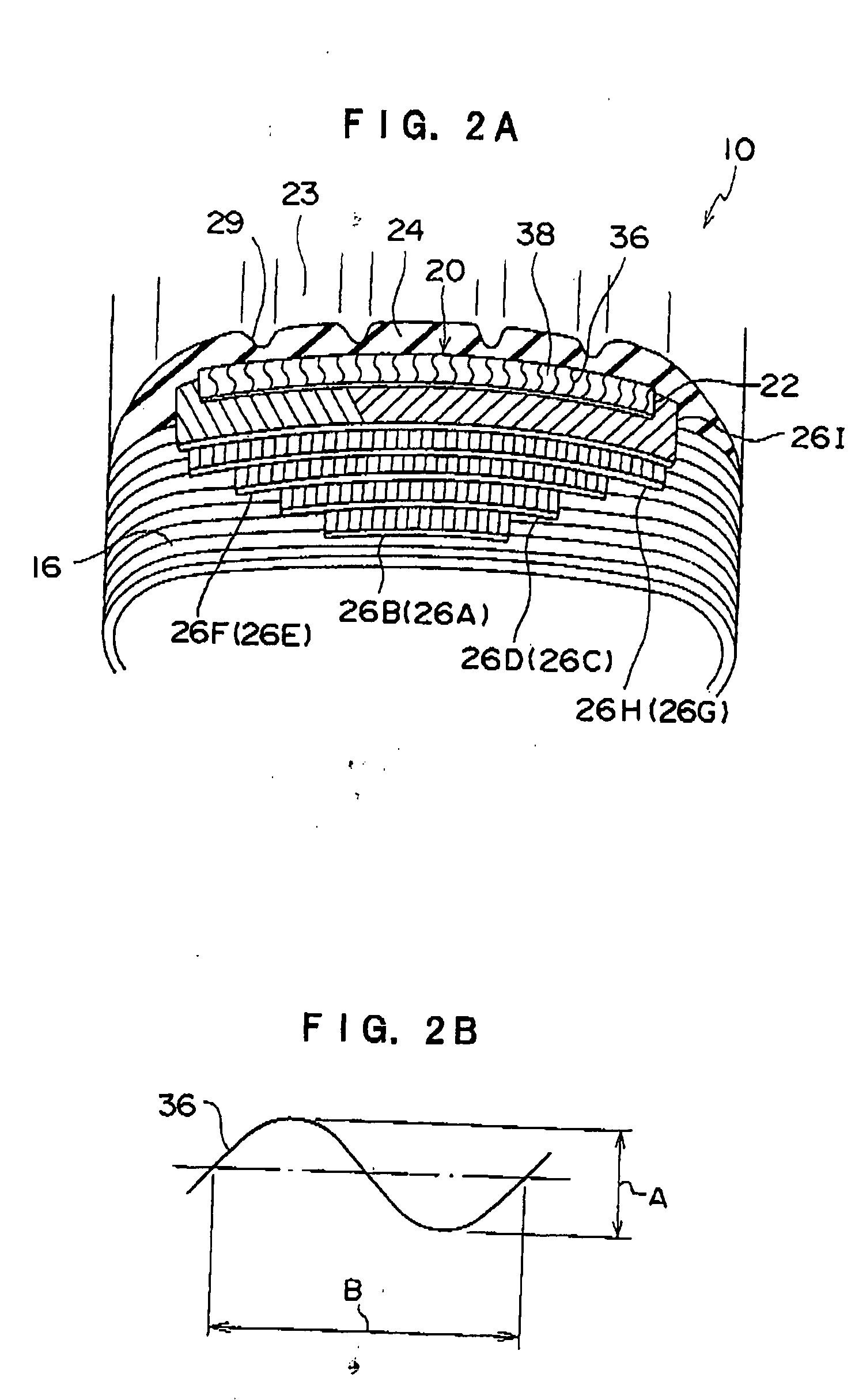

Pneumatic Radial Tire

InactiveUS20080277037A1Excellent durabilityIncreased durabilityPneumatic tyre reinforcementsTyre tread bands/patternsAirplaneInternal pressure

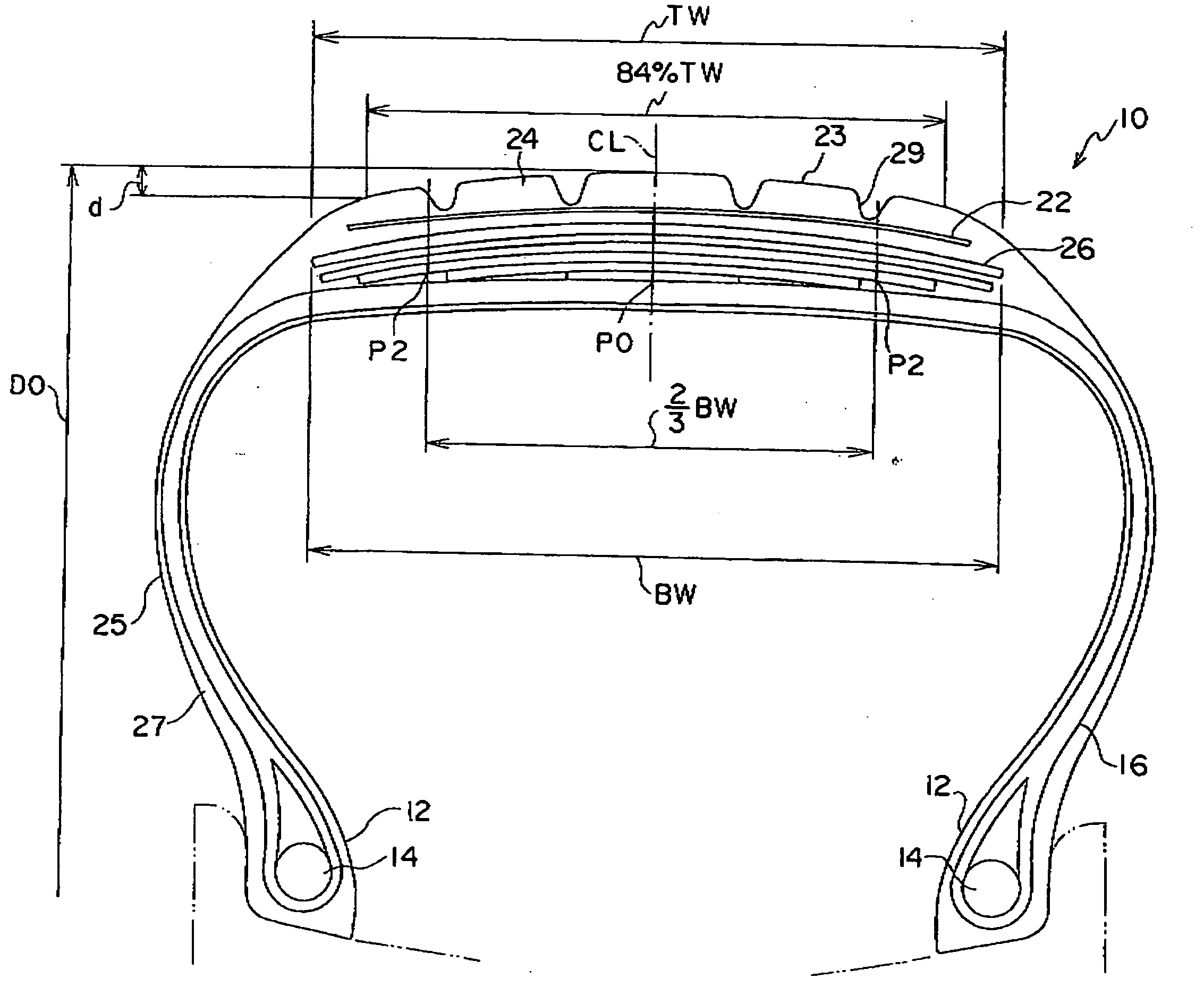

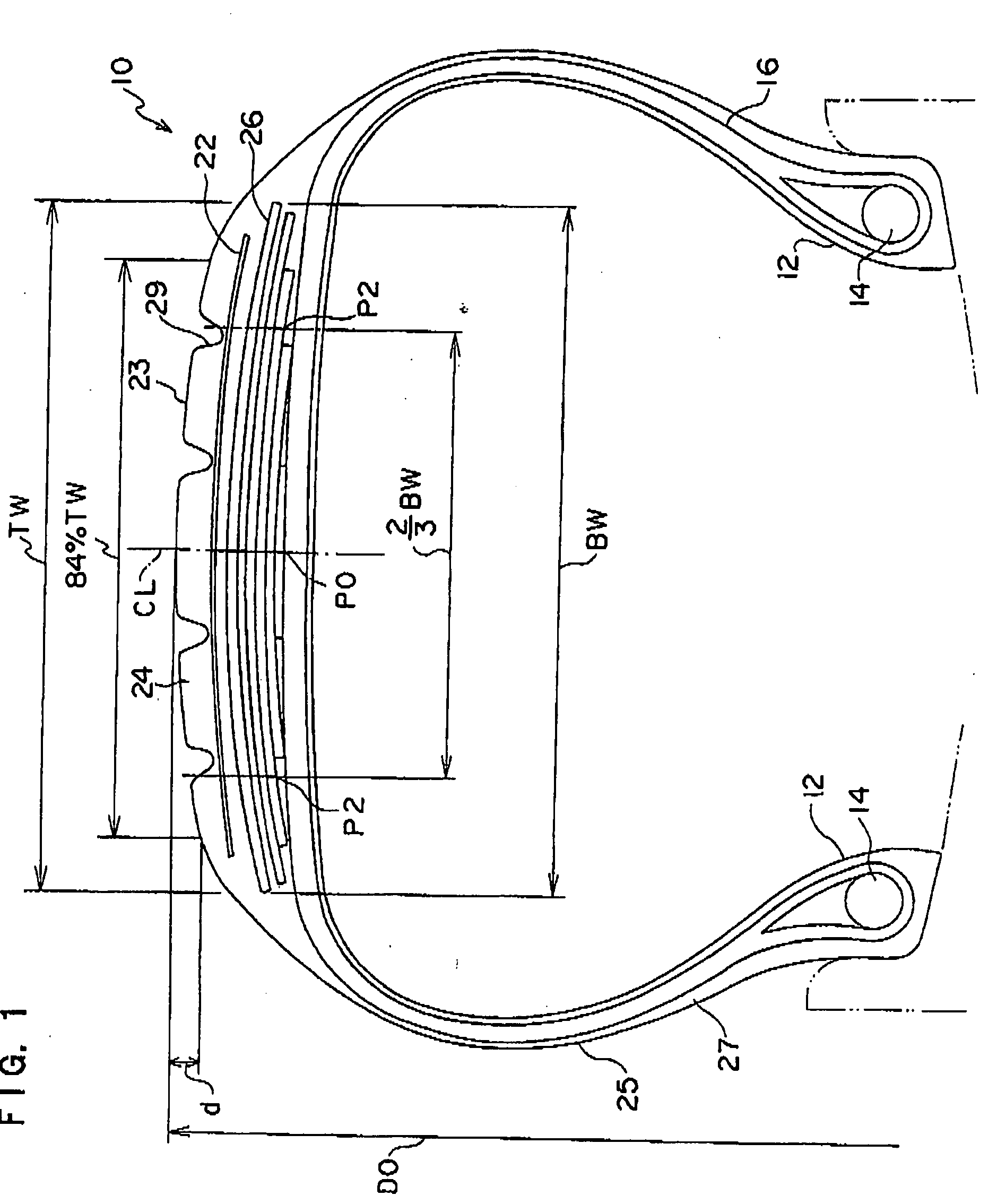

A pneumatic tire for airplanes that assures a good high-speed durability and wear characteristics without its excellent durability against foreign object being impaired is provided. The number of plies of the main belt layer 26 is substantially continuously decreased from the crown center part P0 to the shoulder part, and if the circumferential rigidity in the crown center part P0 of the main belt layer 26 and the circumferential rigidity of the main belt layer 26 at the position P2 which provides ⅔ of the width of the main belt layer 26 are M0 and M2, respectively, the ratio M2 / M0 between both is set at a value greater than 0.2 and smaller than 0.8, whereby, while the quantity of materials used for the main belt layer 26 being minimized, the amount of the tread rubber circumferential elongation in the tread central region at the time of air filling to a prescribed internal pressure and at the time of high speed revolution can be efficiently suppressed for suppressing the radial growth of the tire. Because the amount of circumferential elongation of the tread rubber layer 24 is suppressed, and thus the degree of tension of the tread rubber layer 24 is lowered, the resistance to penetration of a foreign object is increased, and even if a foreign object should stick into the tire, the growth of the crack can be suppressed.

Owner:BRIDGESTONE CORP

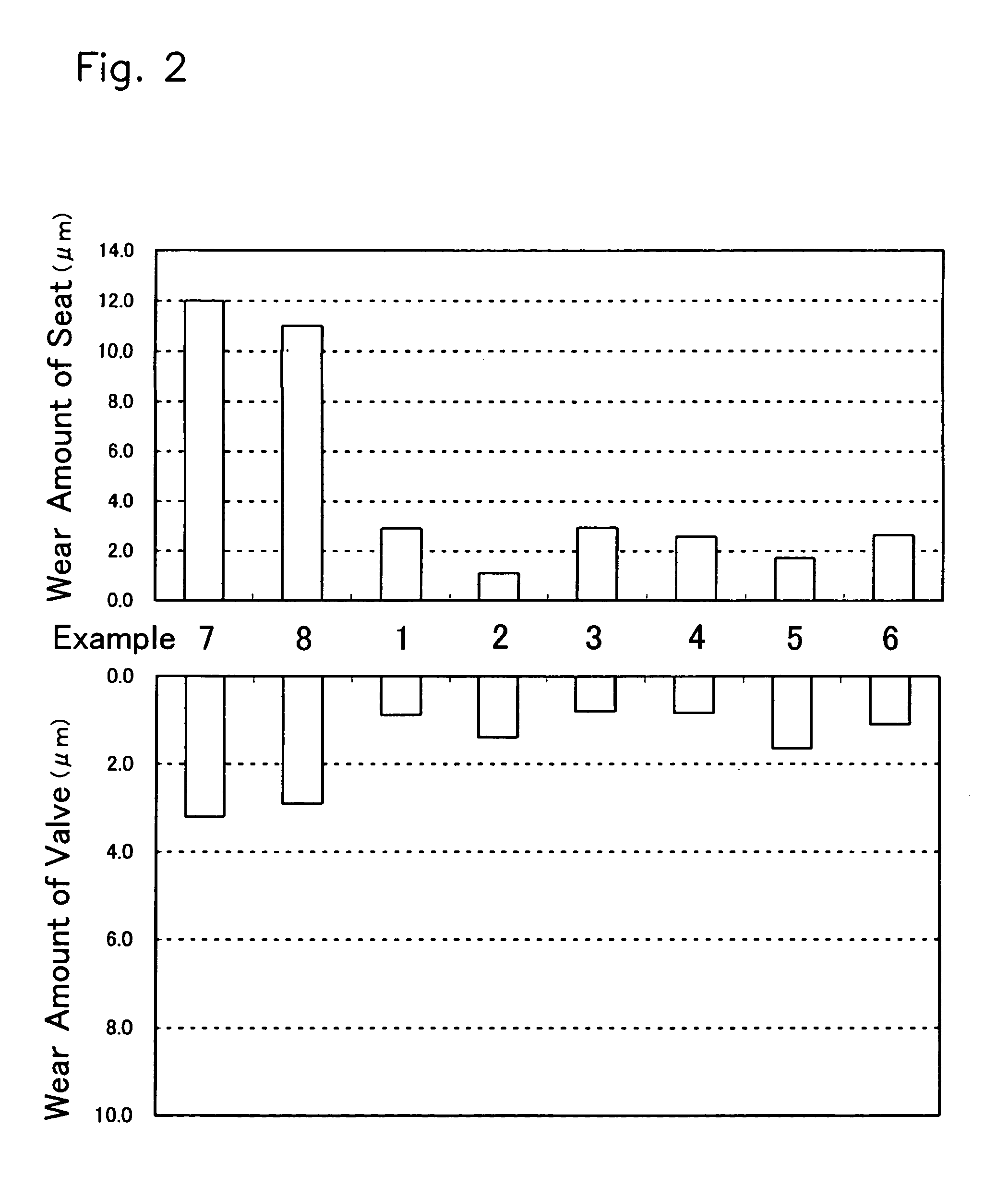

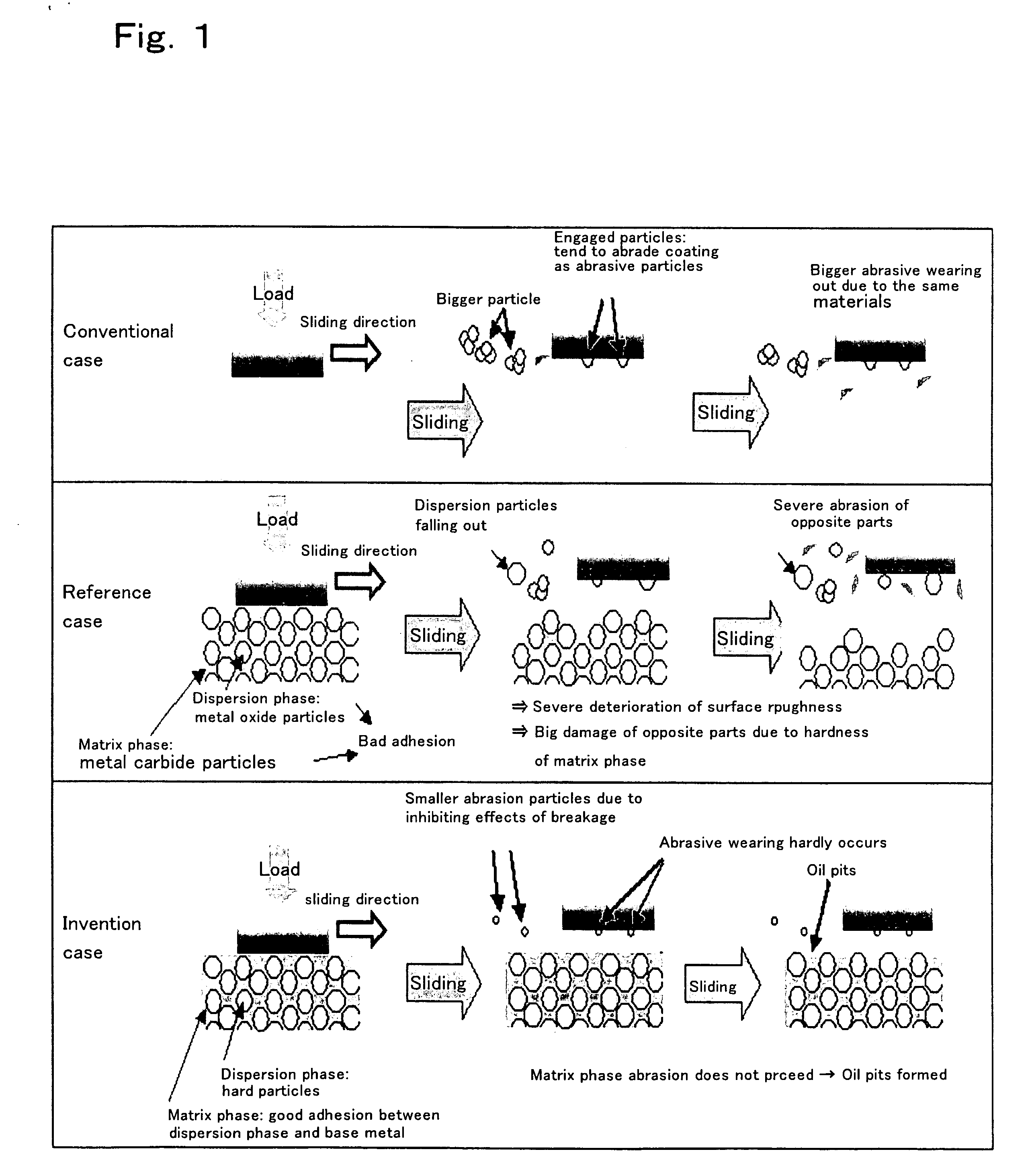

Iron-based sintered alloy with dispersed hard particles

An iron-based sintered alloy having improved thermal and mechanical strength is provided. The iron-based sintered alloy with dispersed hard particles comprises: a matrix comprising, by weight, 0.4 to 2% silicon (Si), 2 to 12% nickel (Ni), 3 to 12% molybdenum (Mo), 0.5 to 5% chromium (Cr), 0.6 to 4% vanadium (V), 0.1 to 3% niobium (Nb), 0.5 to 2% carbon (C), and the reminder of iron (Fe); and hard particles comprising 60 to 70% molybdenum (Mo), 0.3 to 1% boron (B), 0.1% or less carbon (C), and the reminder of iron (Fe). The hard particles are dispersed in the matrix in an amount in the range of 3 to 20% based on the entire alloy. They are sintered to produce the iron-based sintered alloy. Addition of boron into the ferromolybdenum hard particles enhances the wettability of the ferromolybdenum hard particles to prevent the hard particles from falling off the matrix. Thus, the adhesive property between the matrix and the hard particles is improved, thereby enhancing the thermal and mechanical strength of the iron-based sintered alloy.

Owner:RIKEN CO LTD

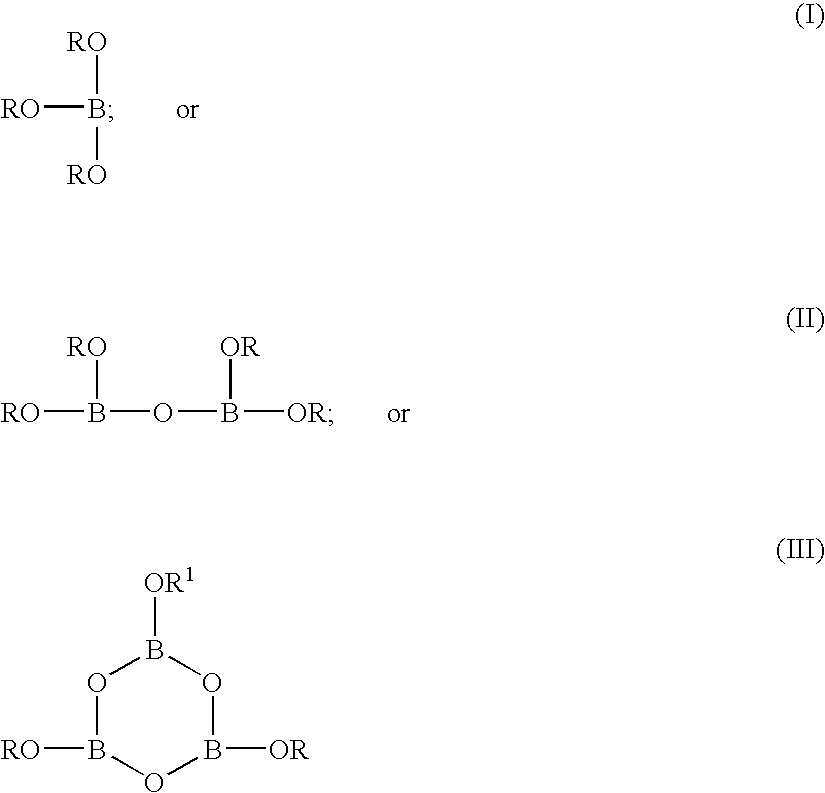

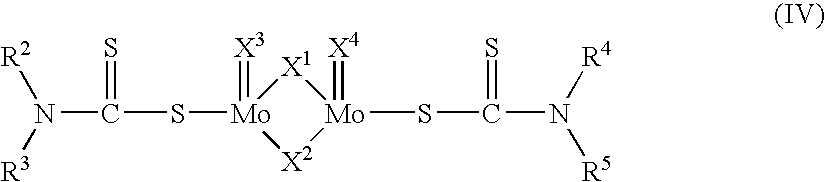

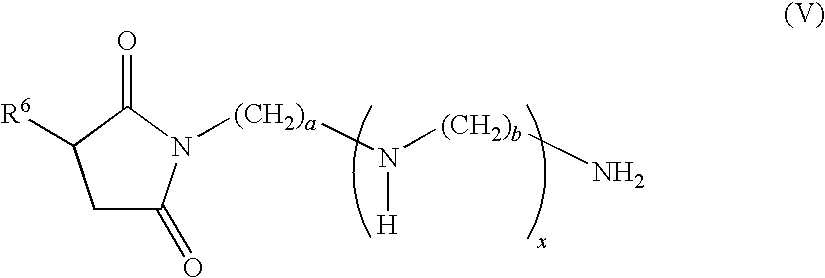

Lubricating oil compositions

InactiveUS20100152072A1High deposit reductionHigh wearBearing componentsAdditivesPhysical chemistryMolybdenum compounds

A lubricating oil composition having a sulfur content of up to about 0.4 wt. % and a sulfated ash content of up to about 0.5 wt. % as determined by ASTM D874 is disclosed which comprises (a) a major amount of an oil of lubricating viscosity; (b) at least one oil-soluble or dispersed oil-stable boron-containing compound having greater than 400 ppm of boron, based upon the total mass of the composition; and (c) at least one oil-soluble or dispersed oil-stable molybdenum-containing compound having at least about 1100 ppm of molybdenum, based upon the total mass of the composition; wherein the lubricating oil composition has a ratio of sulfur to molybdenum of less than or equal to about 4:1.

Owner:CHEVRON ORONITE CO LLC +1

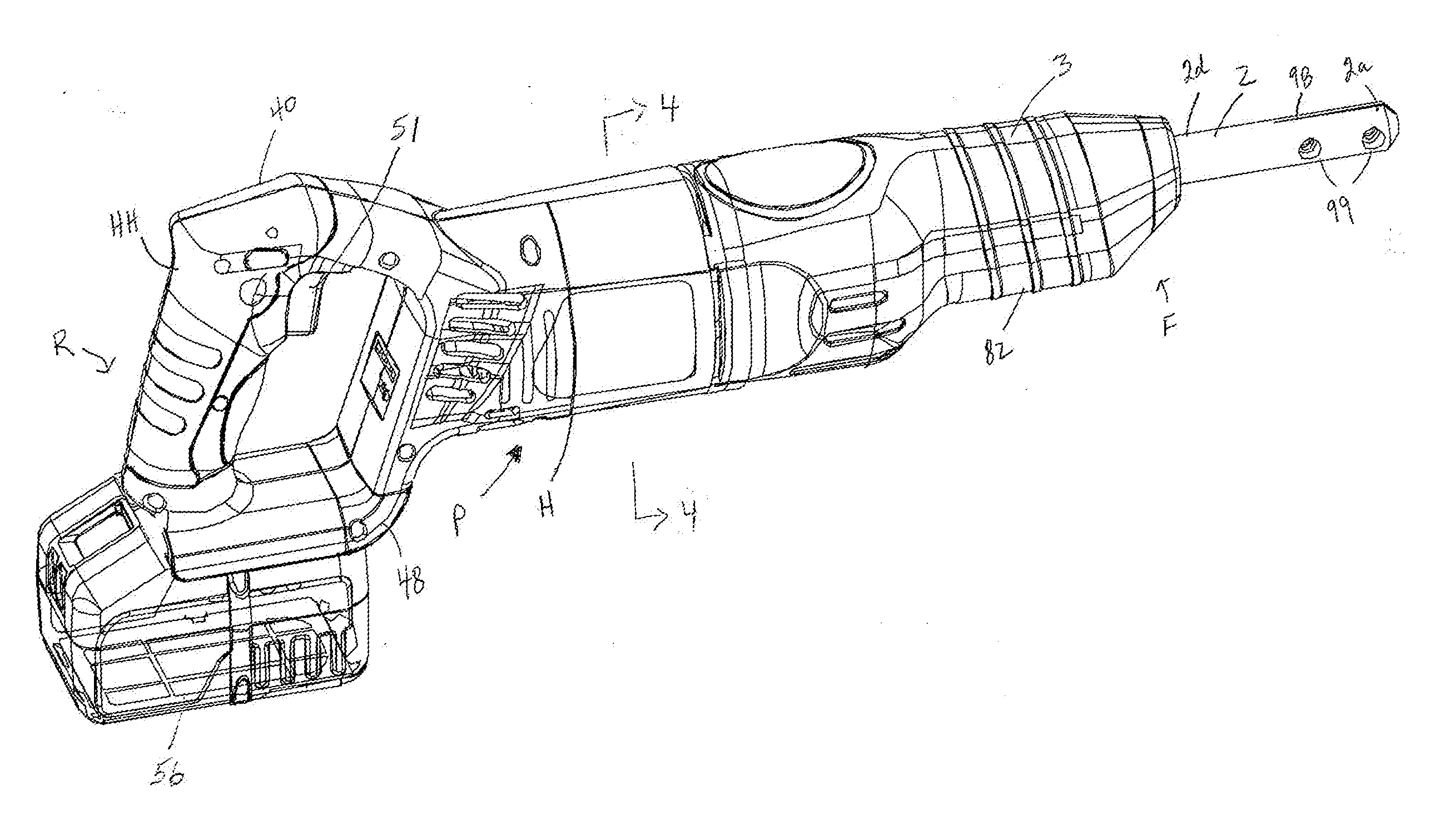

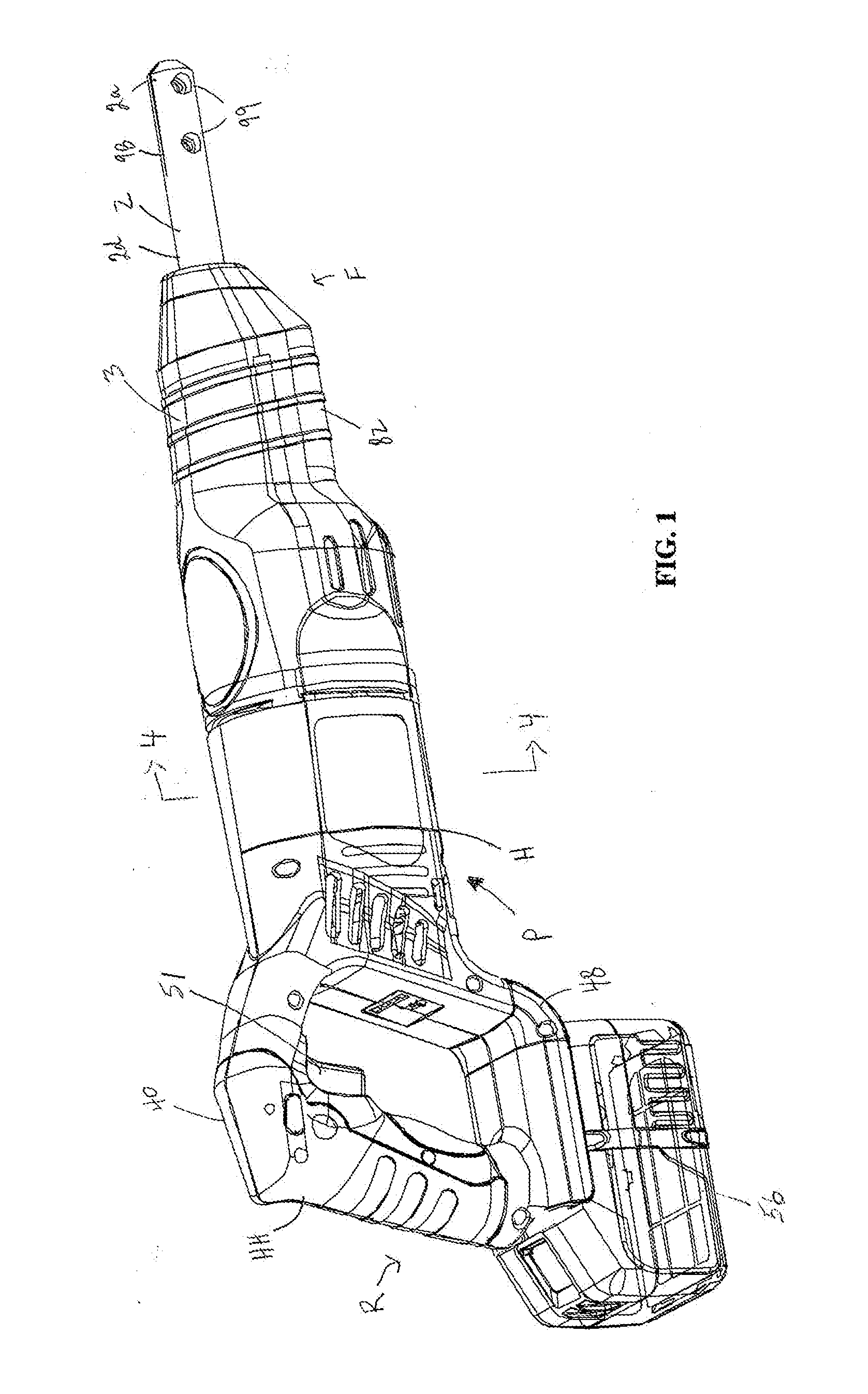

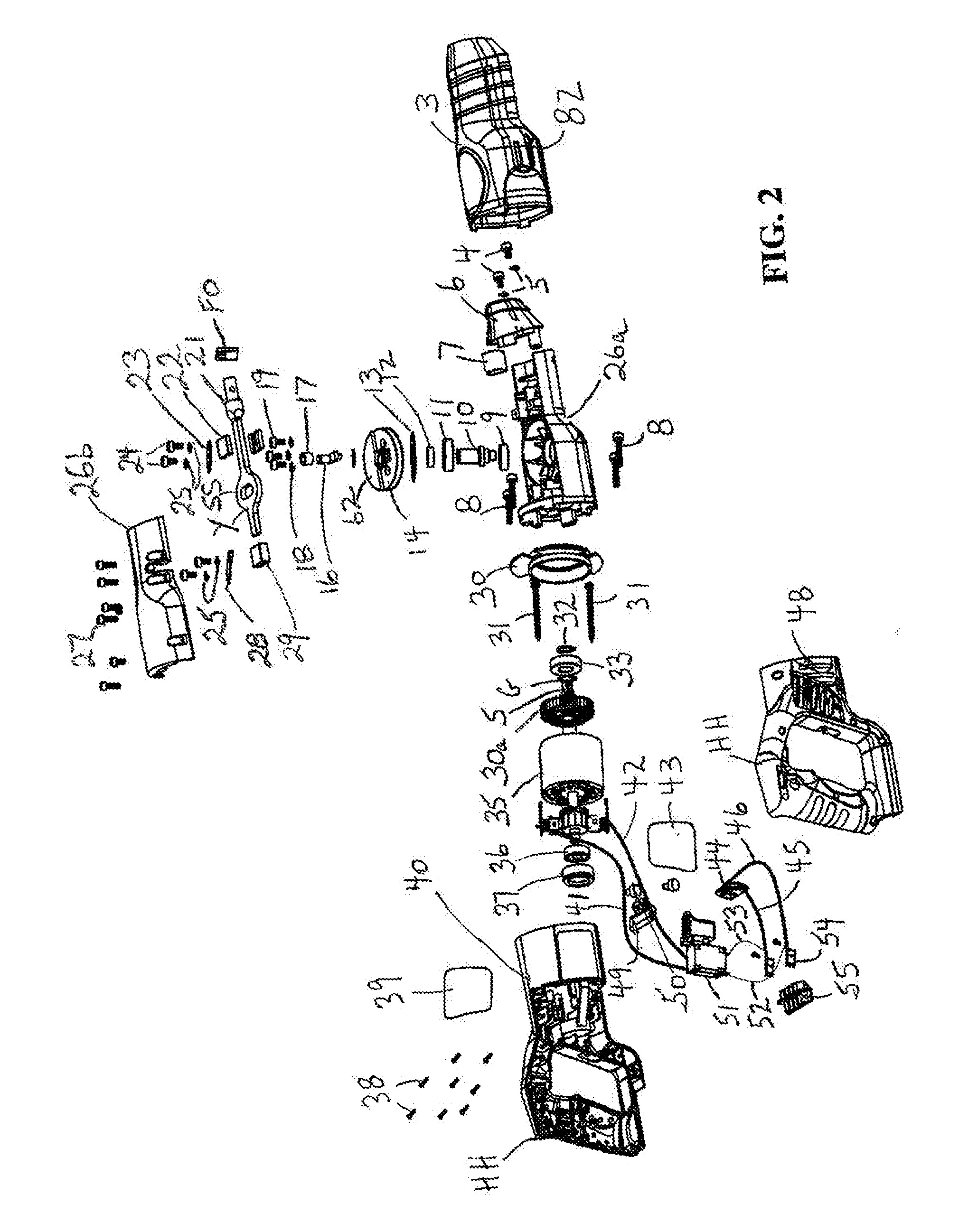

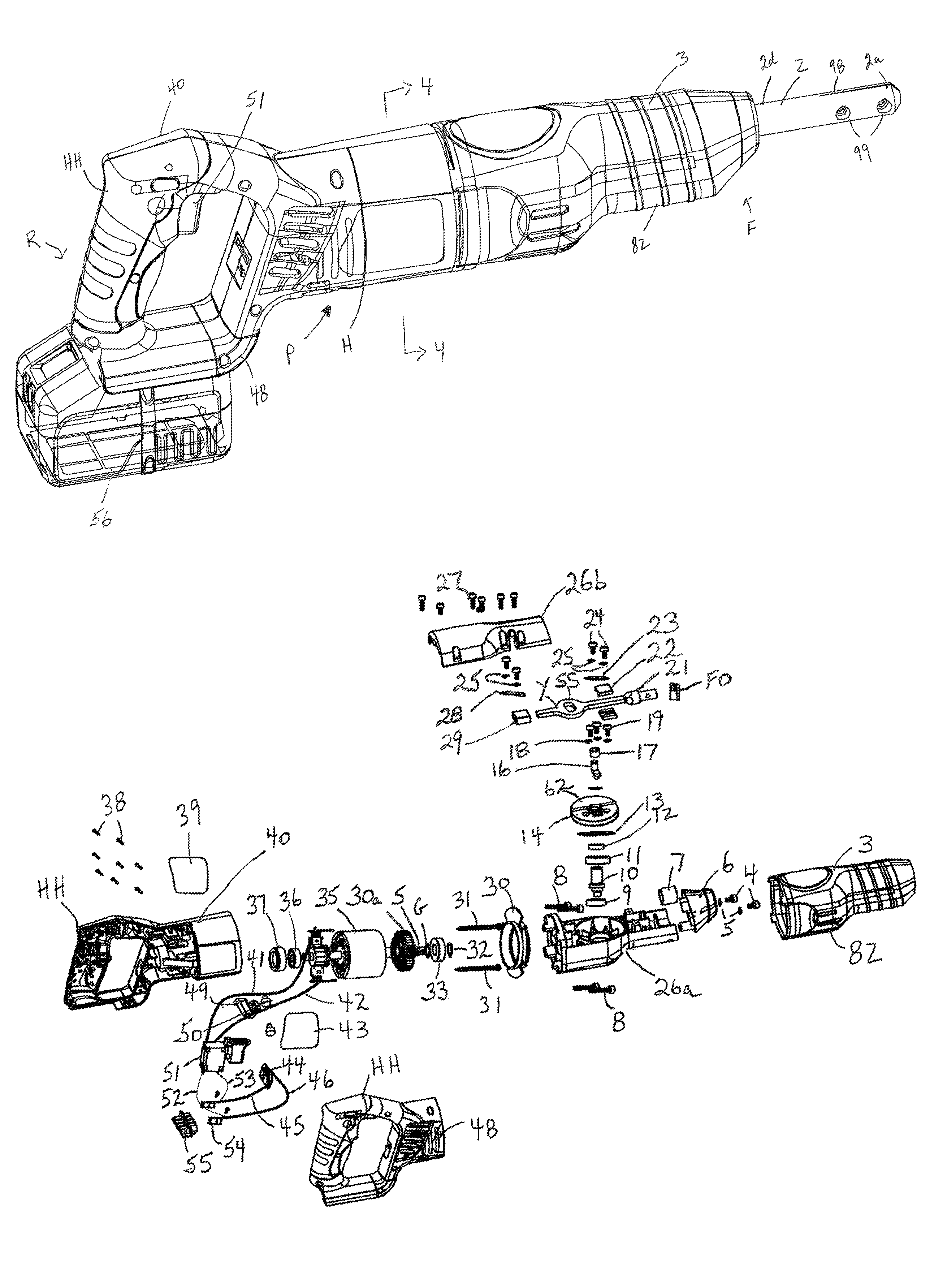

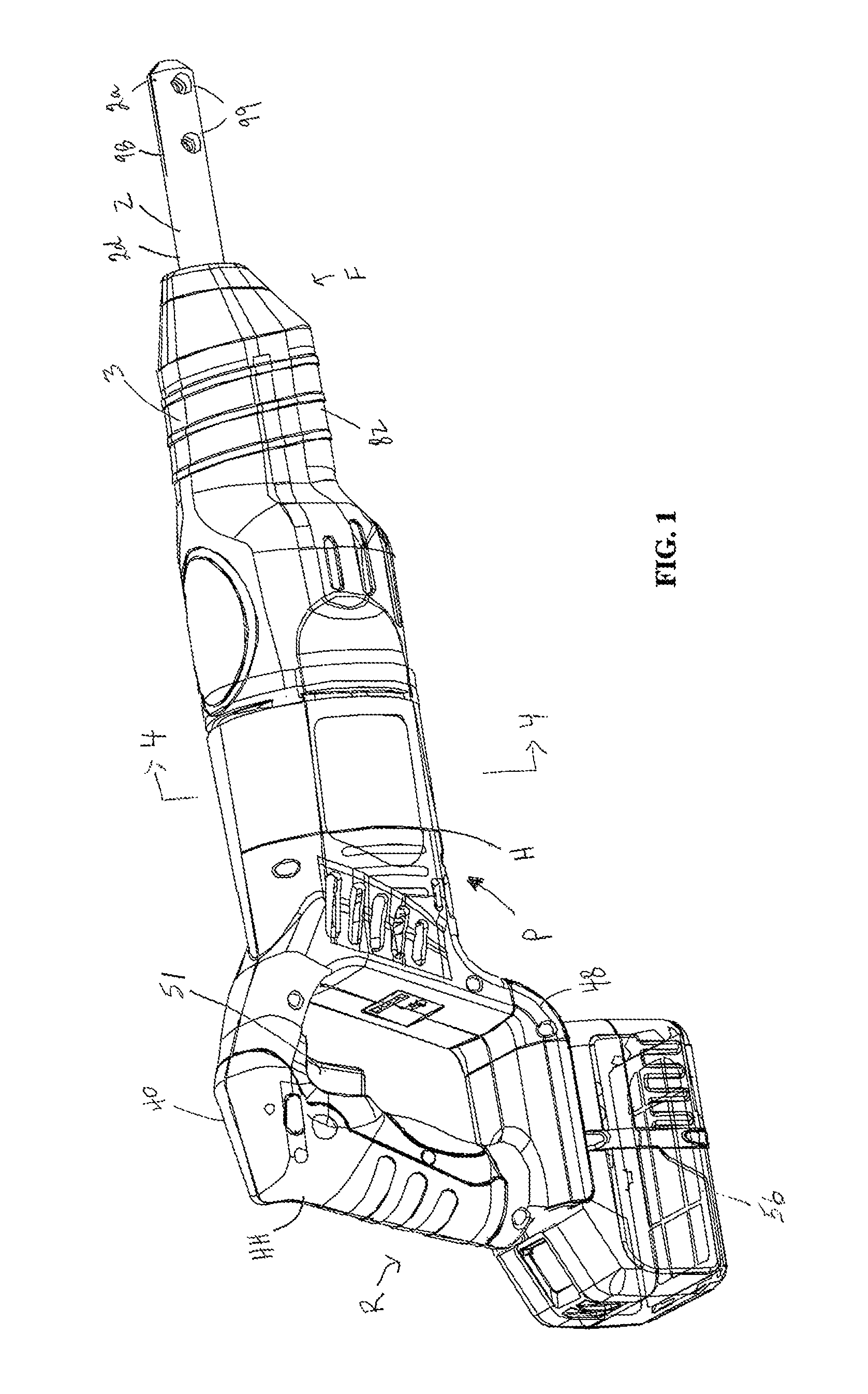

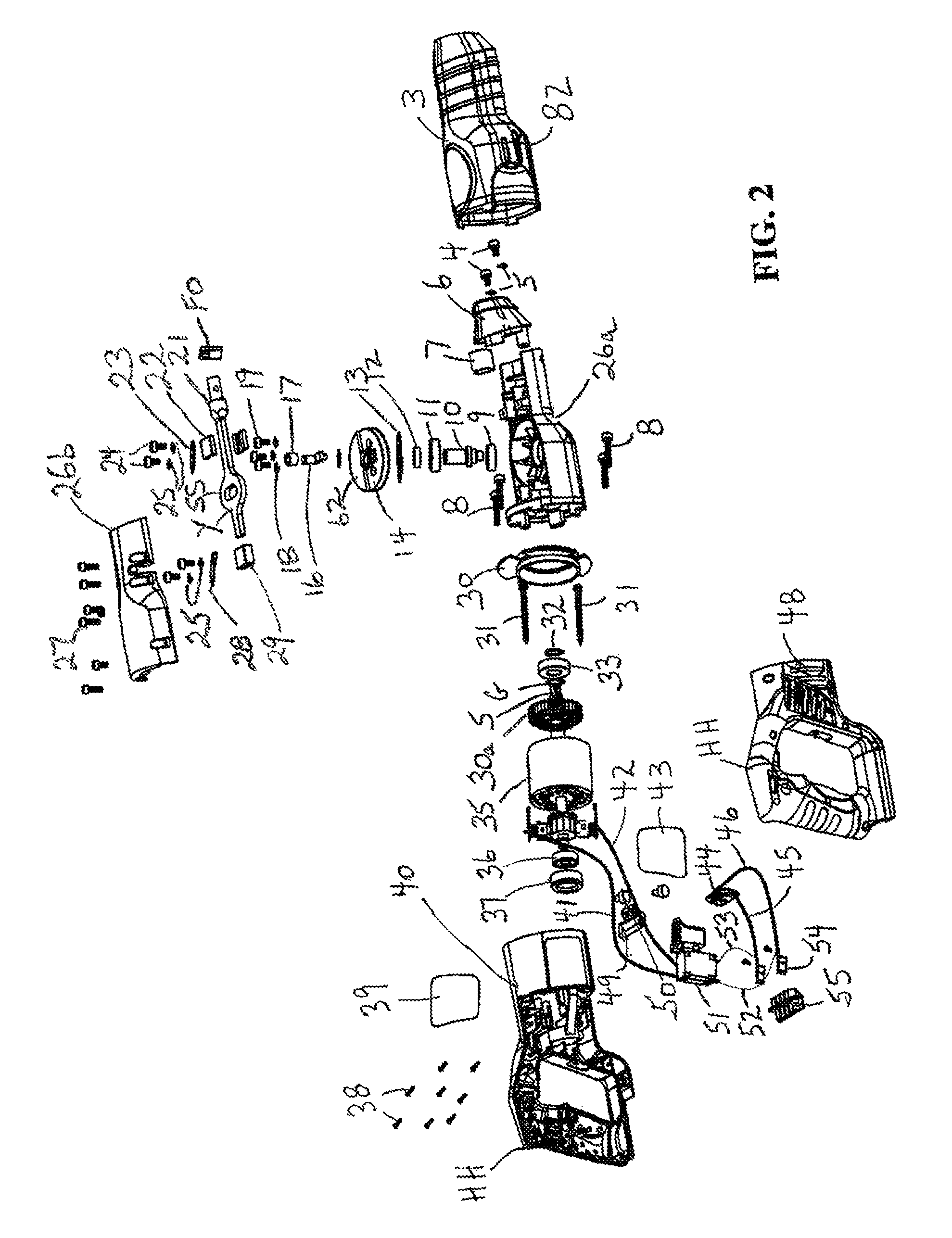

Reciprocating power tool

ActiveUS20120291294A1Reliable lockingReduce forceMetal sawing devicesOperator-supported drilling machinesReciprocating motionDrive shaft

A reciprocating power tool and drive mechanism with a drive shaft mounted for reciprocating movement relative to a housing along a center longitudinal axis of the drive shaft. The drive shaft has a front end adapted to attach to an external shaft or tool attachment, a rear end, and a slot oriented perpendicular to the center longitudinal axis of the drive shaft between the front and rear ends. A motor driven shaft imparts rotary movement to a pinion gear, which meshes with a crown gear to impart rotary motion to the crown gear about its center axis. A drive pin connected to the crown gear has an eccentric pin eccentrically offset relative to the center axis of the crown gear for engagement in the slot of the drive shaft so as to impart the reciprocating movement to the drive shaft on rotation of the crown gear.

Owner:CRYSTAL GLASS CANADA

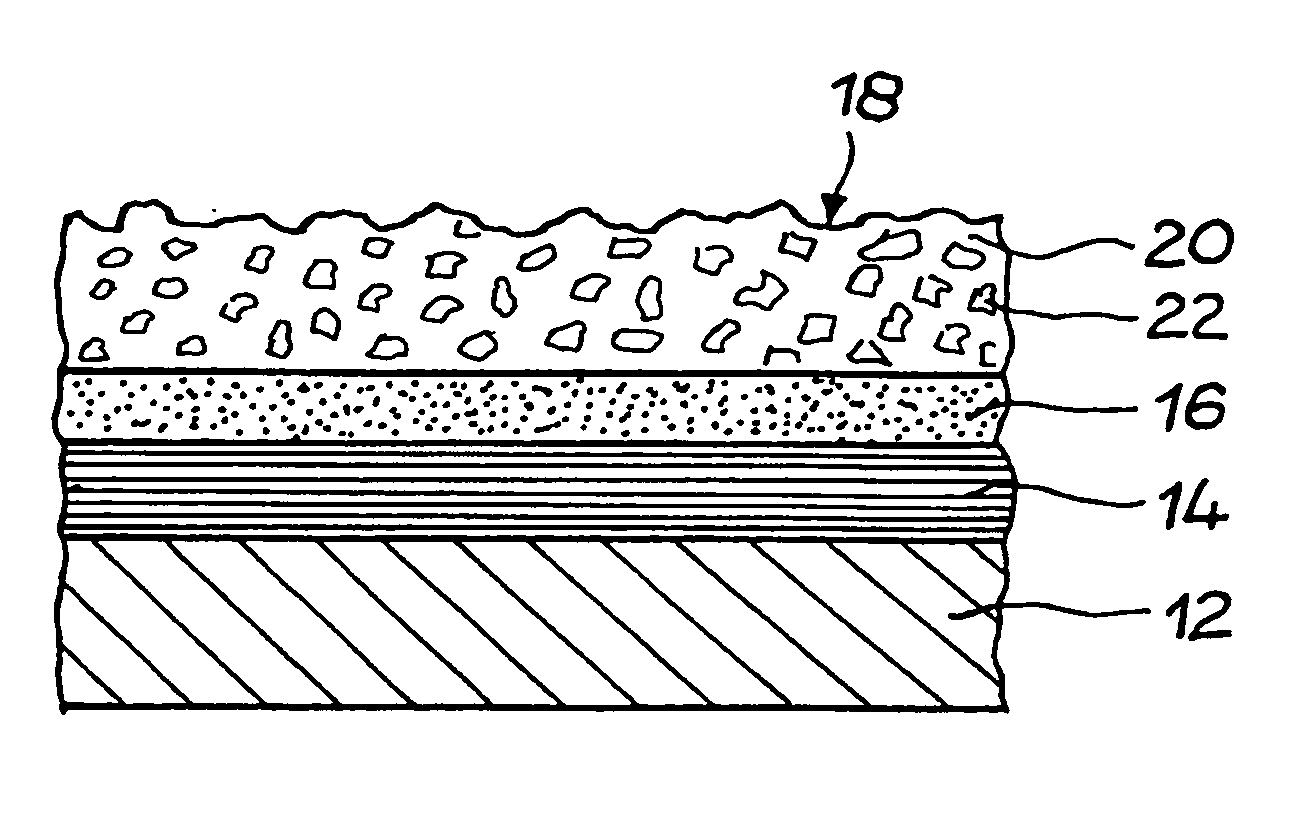

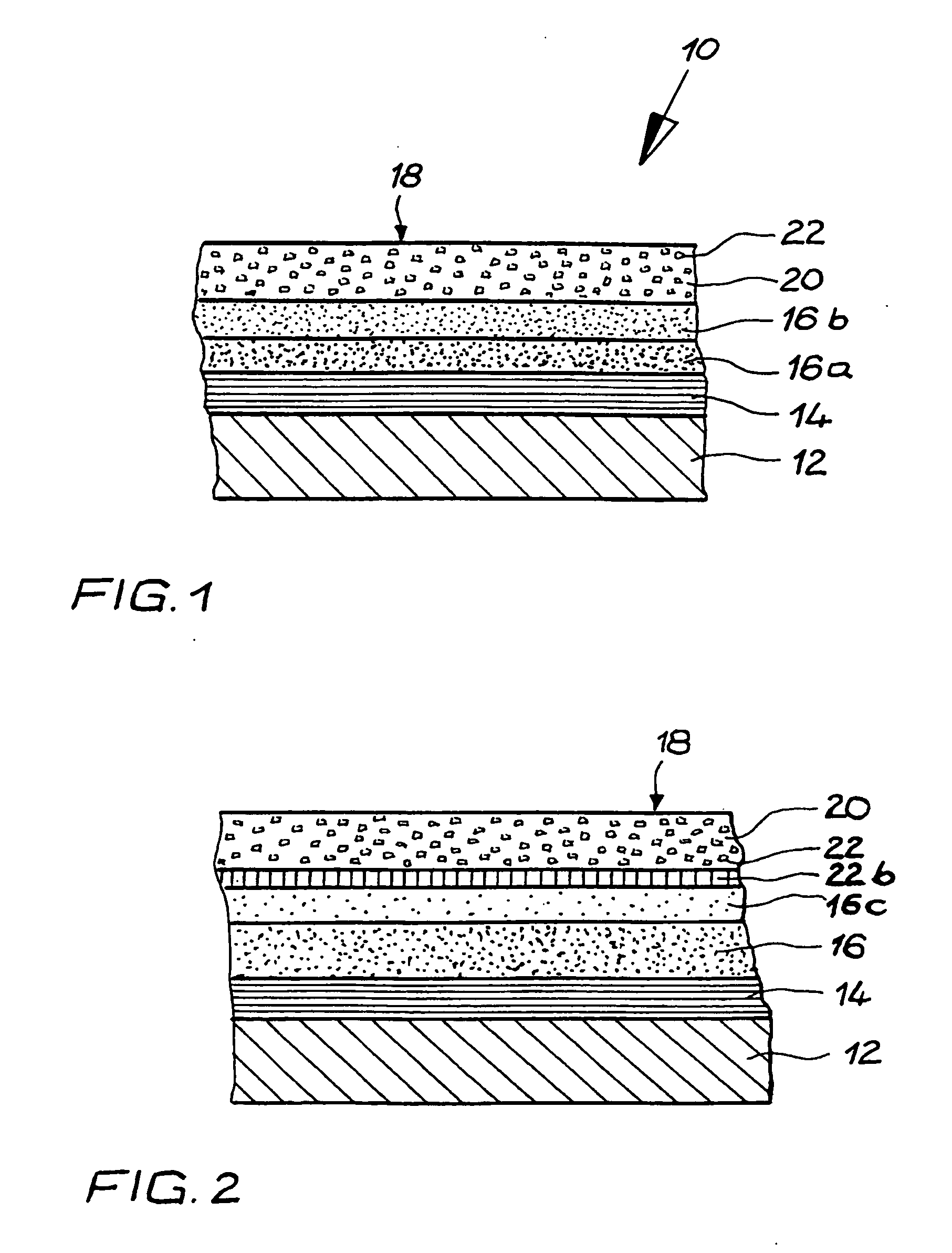

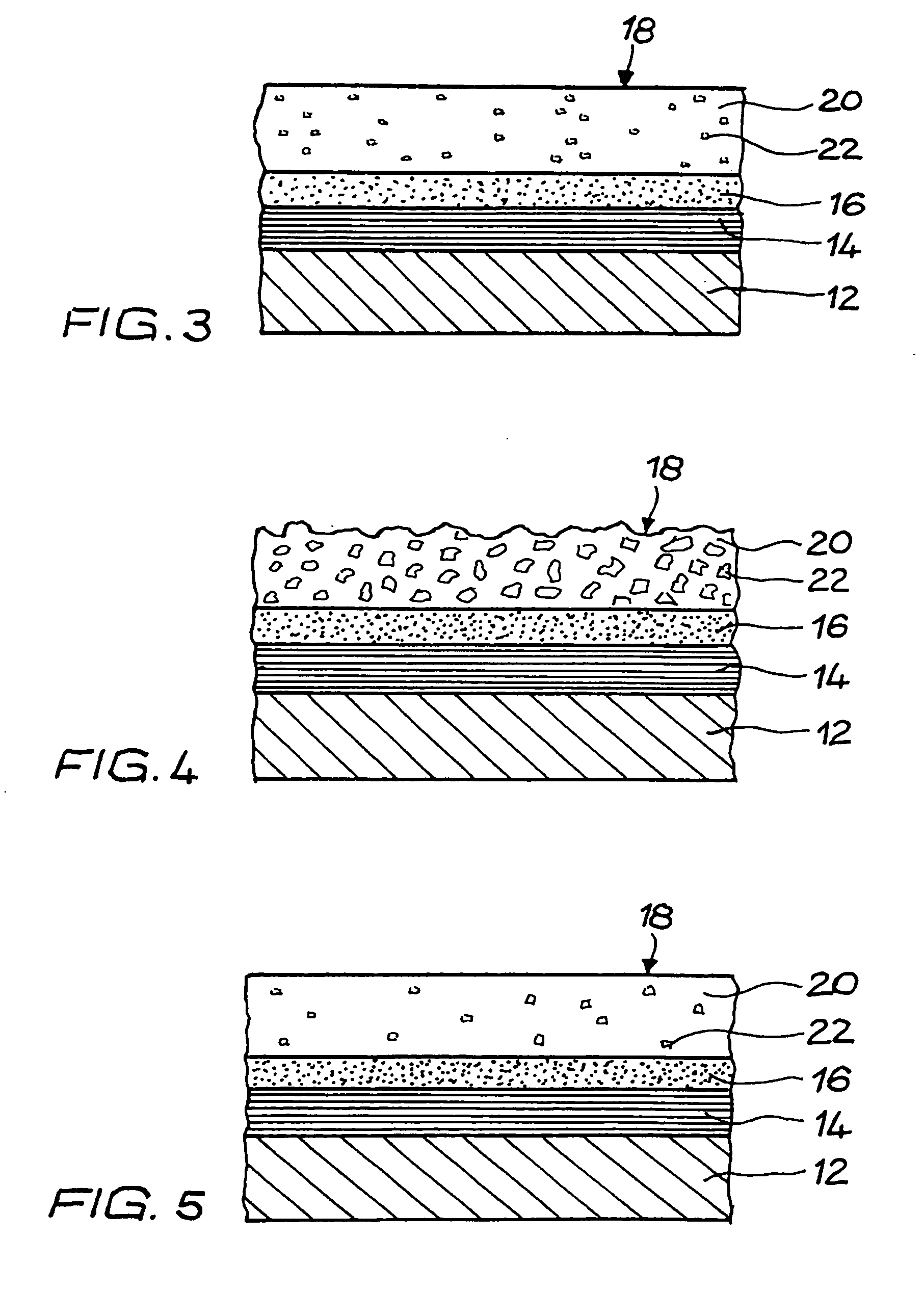

Thermal degradation and crack resistant functionally graded cemented tungsten carbide and polycrystalline diamond

InactiveUS20090226688A1Improve thermal conductivityDissipate frictional heatLamination ancillary operationsSynthetic resin layered productsPolycrystalline diamondHardness

A WC—Co material or polycrystalline diamond-Co material that has a gradient in the grain size of the particles. Specifically, the material may have a top layer that has coarse grains that is designed to dissipate the heat caused by friction (and thus prevent thermal cracking). The material will then have a bulk substrate that is made up of finer grains and provide adequate hardness for the material. The top layer is positioned on top of the bulk substrate.

Owner:UNIV OF UTAH RES FOUND

Cladding

InactiveUS20080010927A1Improve securityImprove fire resistanceCovering/liningsPublic buildingsSurface finishPanelling

There can be provided a method of cladding a surface with panelling. The method can comprise: attaching a first panel support member to the surface, the first panel support member being configured to receive at least a part of a first edge of a panel comprising a core of woven and non-woven glass impregnated with resin and a surface finish of paper and melamine resin; placing the first edge in a position of co-operative reception with the first panel support member; and placing a second edge of the panel substantially opposite the first edge in a position of co-operative reception with a second panel support member, the second panel support member being configured to be attached to the surface.

Owner:BAA IP HOLDCO

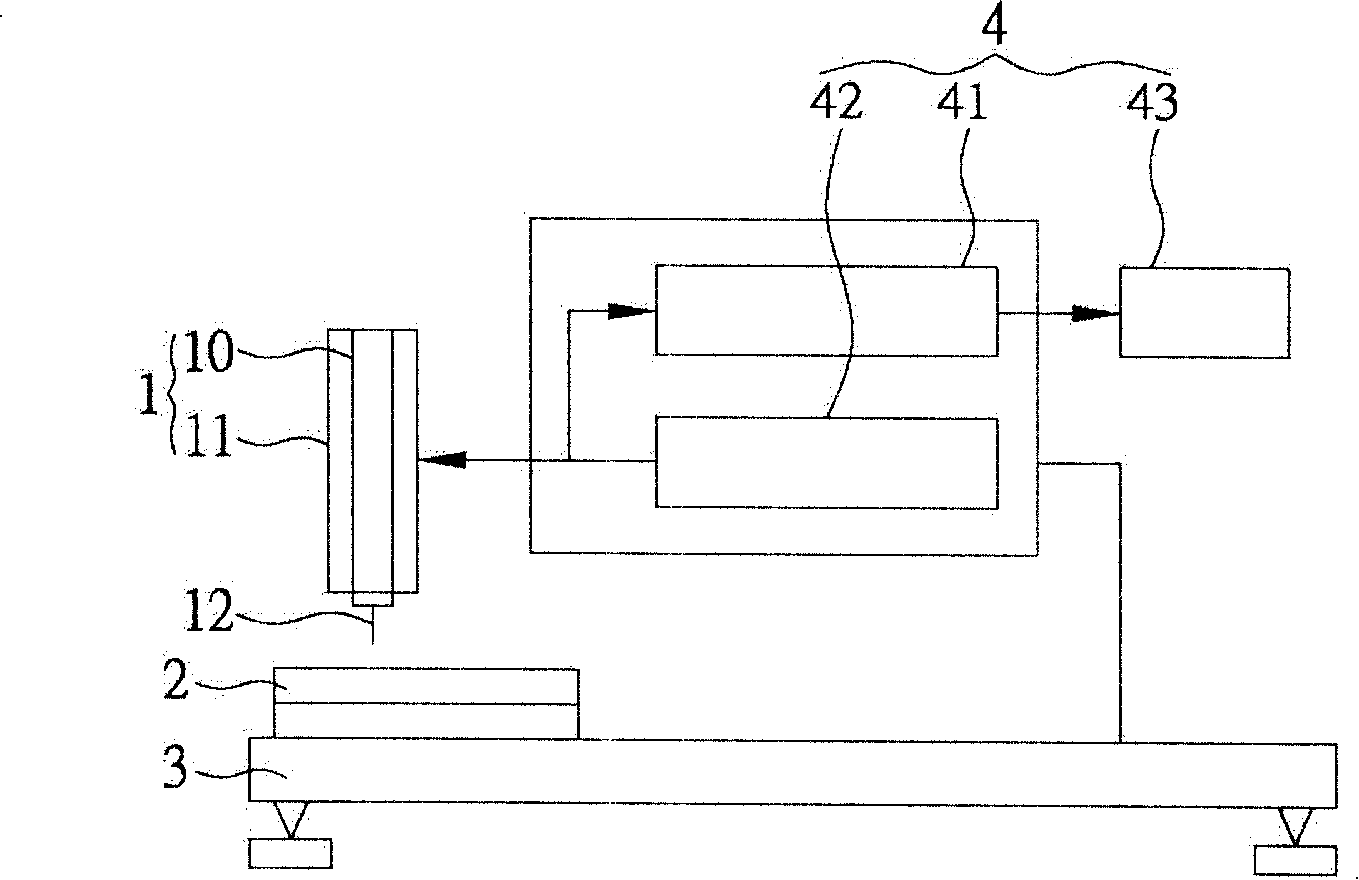

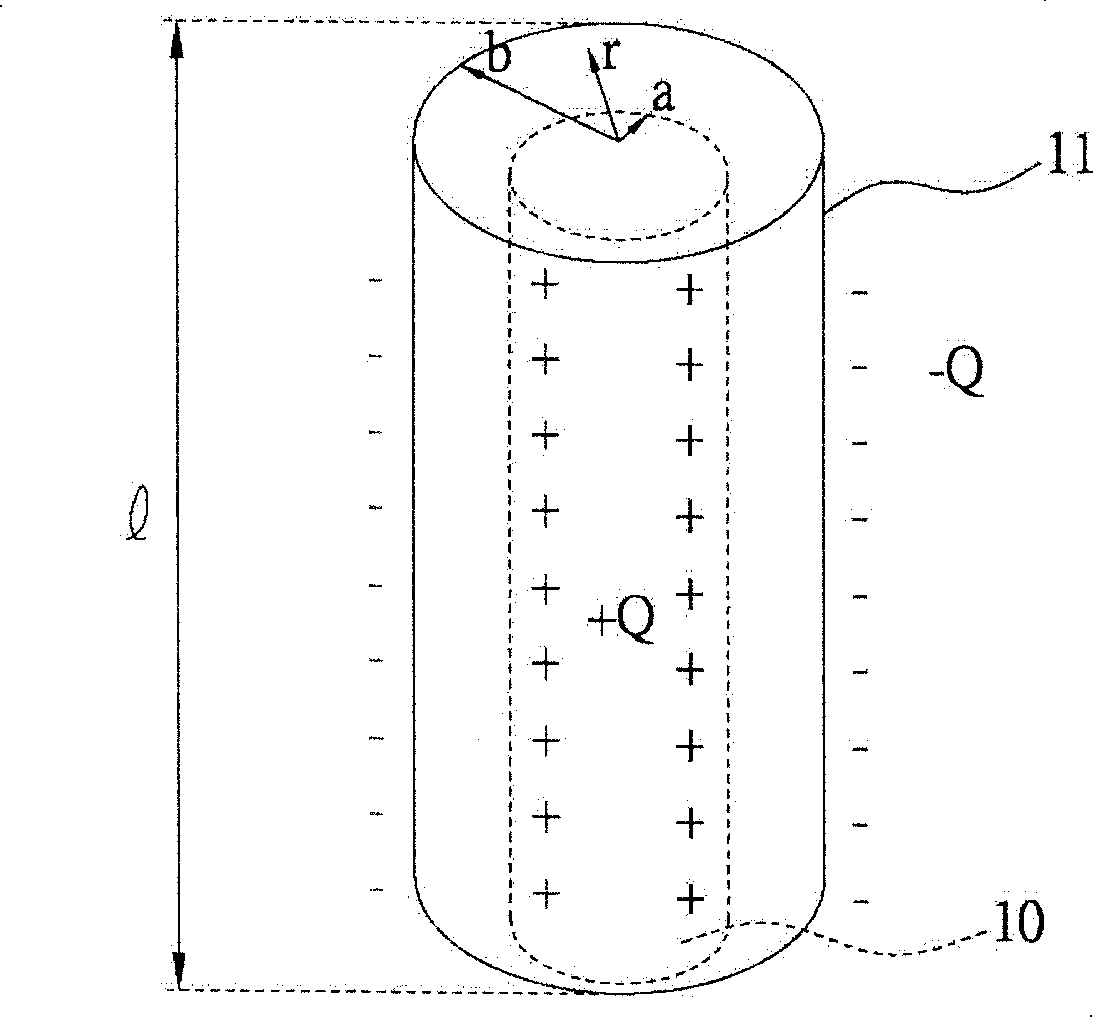

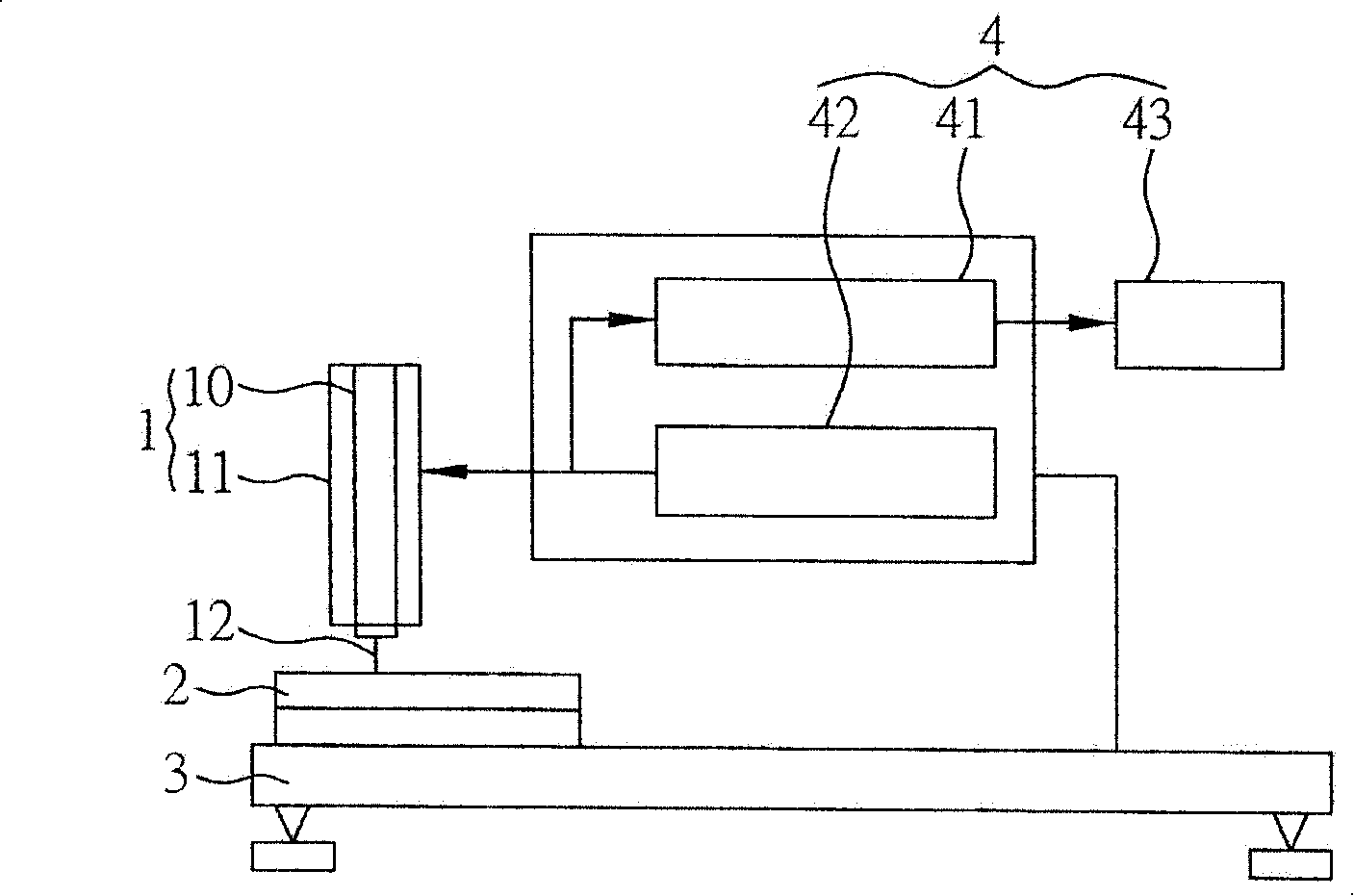

Device and method for detecting cutting tool state

InactiveCN101209530AShorten non-machining strokesDrilling speed is fastDrilling/boring measurement devicesMeasurement/indication equipmentsElectric fieldElectrical and Electronics engineering

The invention provides a cutter state detection device and a method used for detecting the state of a cutter which processes a workpiece. The workpiece is arranged on a processing machine station; the cutter is driven to rotate by a central rotor of a mainshaft motor. The central rotor of the mainshaft motor keeps insulation with a shell of the mainshaft motor; an induction electric field between the shell and the central rotor is generated mainly by an electric field signal which is acted on the shell; furthermore, the induction electric field is detected whether to exist in the processing operation. When the signal of the induction electric field disappears as the cutter is contacted with the workpiece and the processing machine station is grounded, the non-broken cutter state is detected; when the signal of the induction electric field exists continuously, the broken cutter state is detected.

Owner:IND TECH RES INST

Reciprocating power tool

ActiveUS9073563B2Reliable lockingReduce forceMetal sawing devicesOperator-supported drilling machinesMotor driveDrive shaft

Owner:CRYSTAL GLASS CANADA

Surface-Covered Cubic Boron Nitride Sintered Body Tool and Method of Manufactruing the Same

ActiveUS20080193724A1Avoid fragmentationHigh defect resistancePigmenting treatmentVacuum evaporation coatingBoron nitrideWear resistance

A surface-covered CBN sintered body tool includes a base material formed with a cubic boron nitride (CBN) sintered body and a surface covering film covering a surface of the base material, and has a nega-land exposing the CBN sintered body in at least a portion thereof and a flank having the surface covering film formed thereon. With this, the surface-covered CBN sintered body tool having high defect resistance and wear resistance can be provided. The surface covering film preferably includes a nitride or a carbonitride of a compound including at least one element selected from the group consisting of Ti, Cr, Zr, and V and at least one element selected from the group consisting of Al, Si and B, or a nitride or a carbonitride of Ti.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

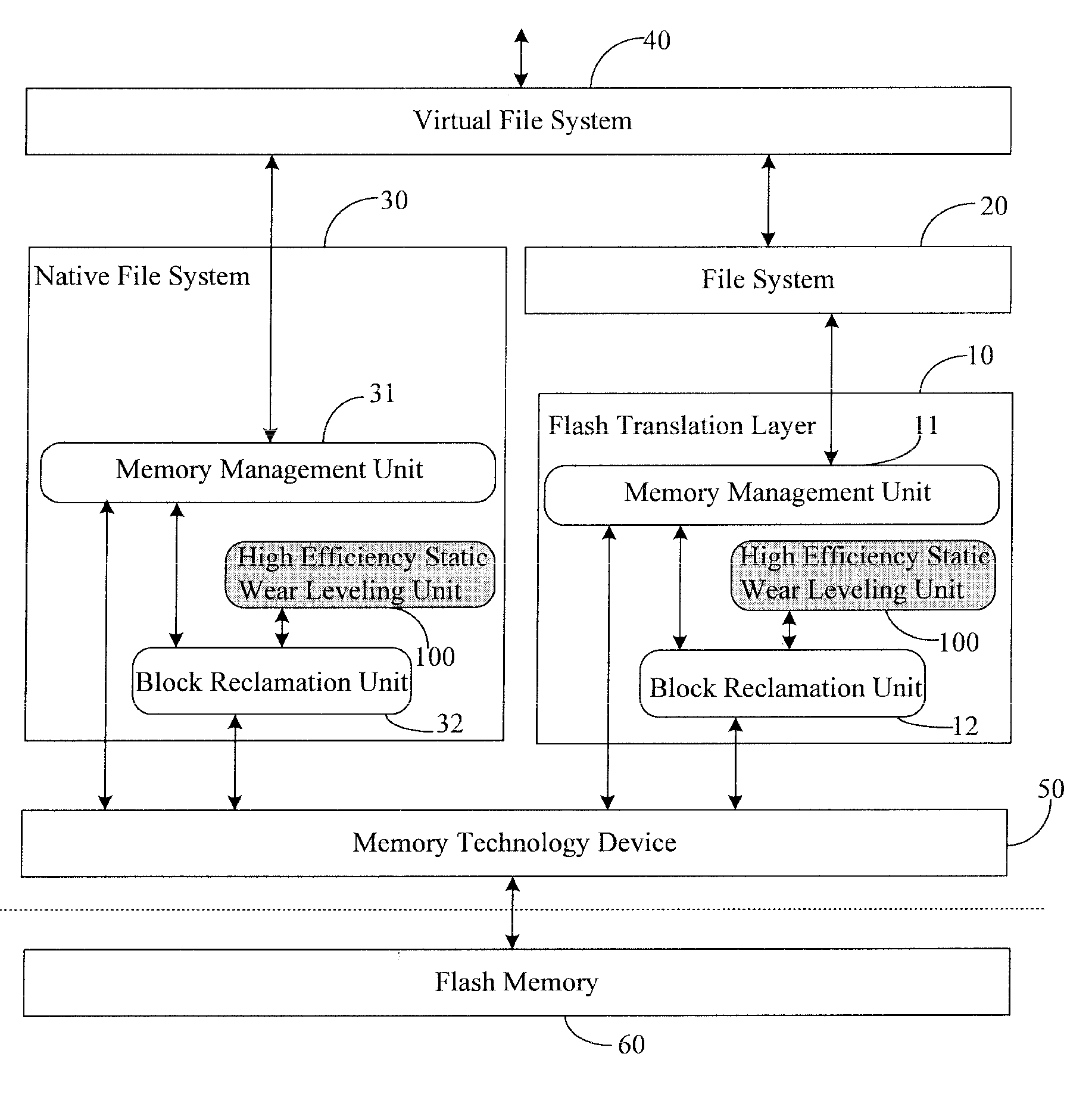

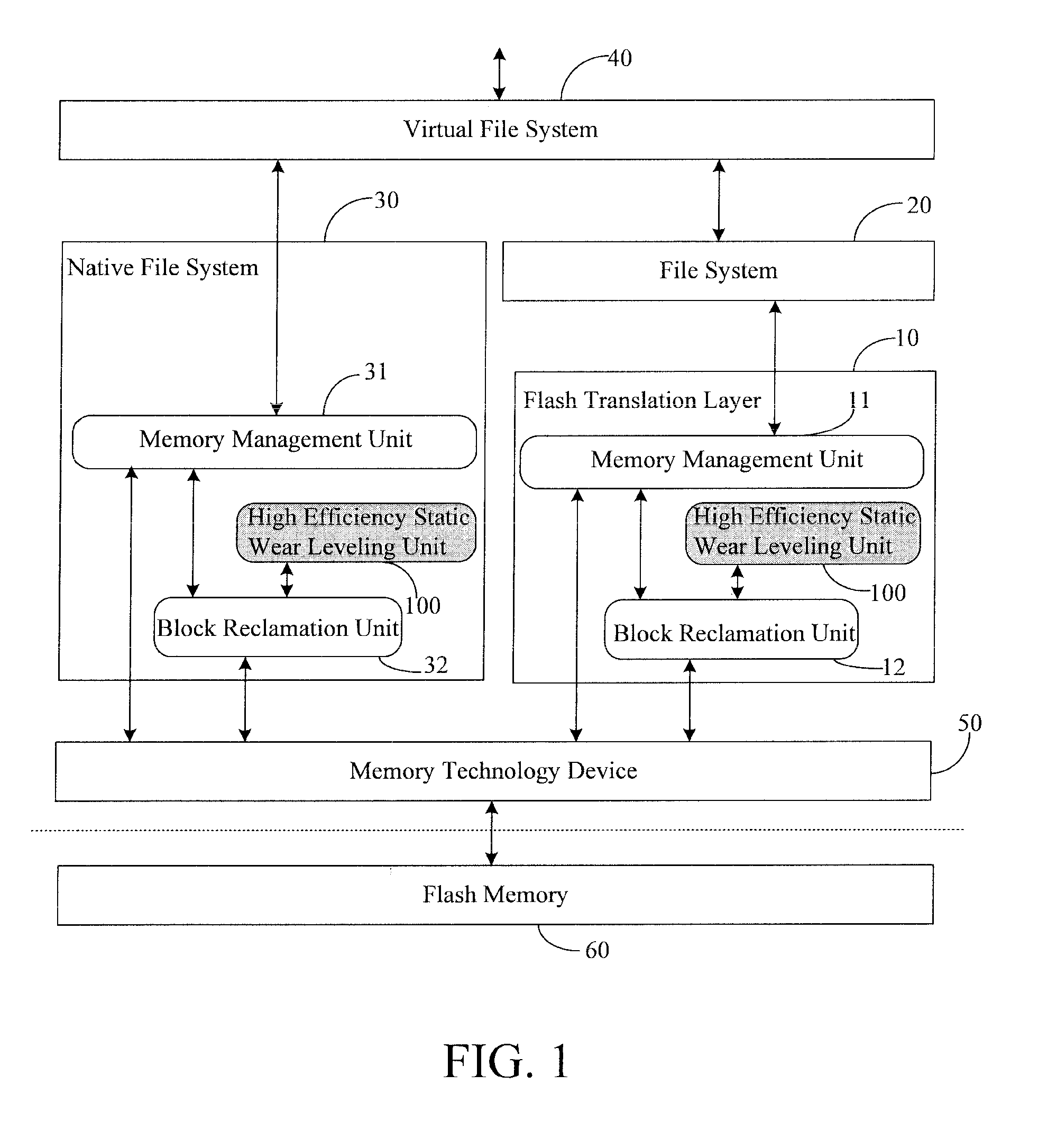

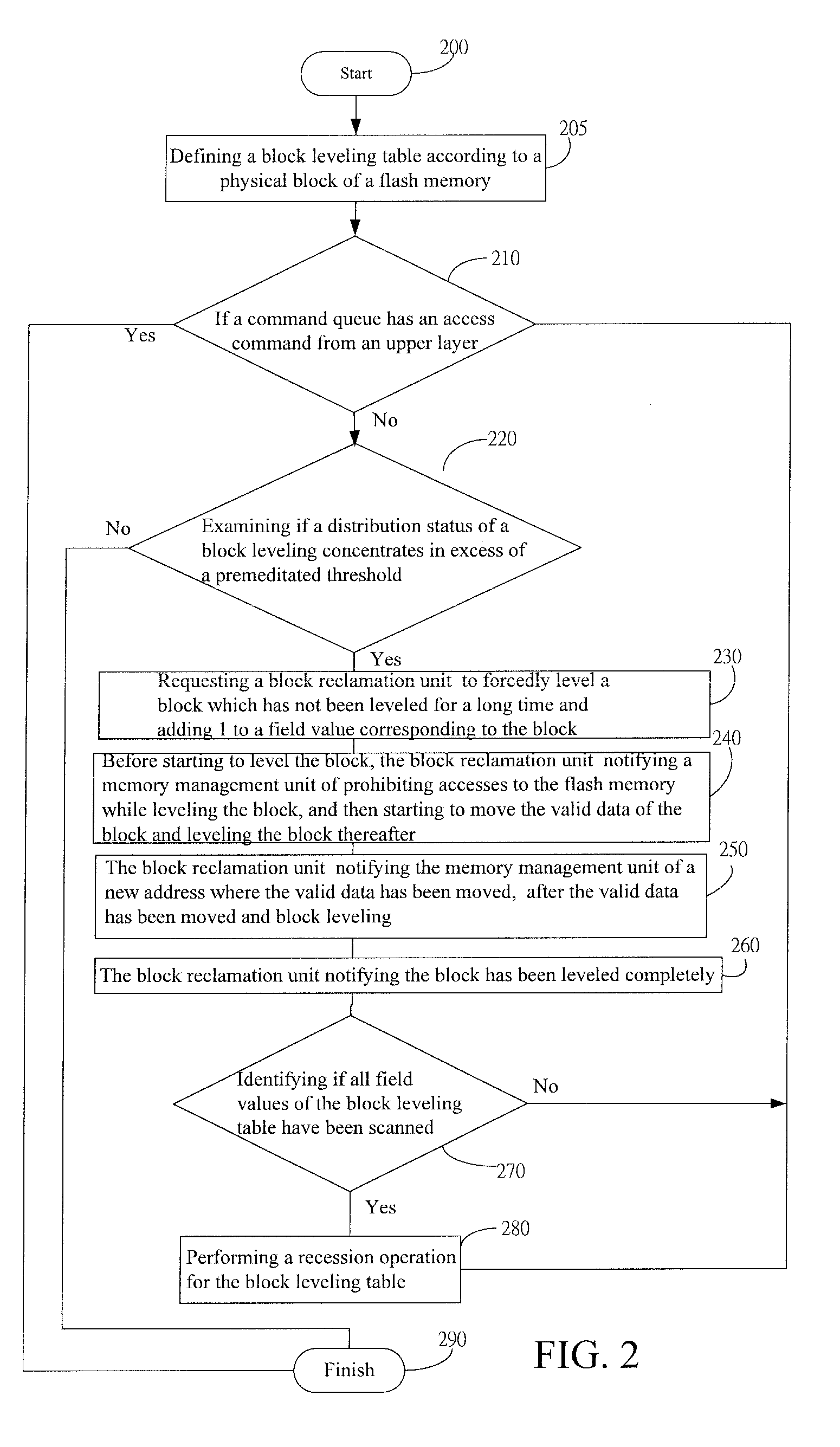

Method for performing static wear leveling on flash memory

ActiveUS20080162796A1LessLow costMemory architecture accessing/allocationMemory systemsFile systemParallel computing

A method for performing a static wear leveling on a flash memory is disclosed. Accordingly, a static wear leveling unit is disposed with a block reclamation unit of either a flash translation layer or a native file system in the flash memory, and utilizes less memory space to trace a distribution status of block leveling cycles of each physical block of the flash memory. Based on the distribution record of the block leveling cycles, the number of the leveling cycles less than a premeditated threshold would be found while the system idles. Then the static wear leveling unit requests the block reclamation unit to level the found blocks. Before leveling the found block, the rarely updated data is compelled to move from one block to another block which is leveled frequently, whereby accurate wear leveling cycles for the blocks can be averaged extremely.

Owner:GENESYS LOGIC INC

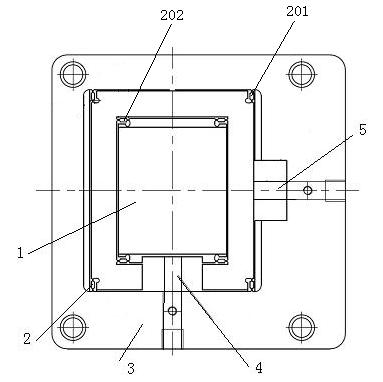

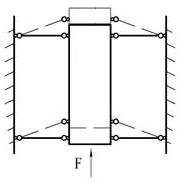

Double-parallel-flexible-hinge-based tool rest driving platform of super-precision machining lathe

InactiveCN102380788AHigh wearSmooth and continuous movementFeeding apparatusHinge anglePiezoelectric actuators

The invention relates to a double-parallel-flexible-hinge-based tool rest driving platform of a super-precision machining lathe and belongs to a tool rest driving platform of a super-precision machining lathe. A tool rest work table, a hinge group and a tool rest mounting base form an integrated structure, the free end of an X-direction piezoelectric actuator is in ejected connection with an X-direction double parallel four bar flexible hinge chain mechanism, the fixed end of the X-direction piezoelectric actuator is fixedly connected with a tool rest mounting base, the free end of a Y-direction piezoelectric actuator is in pressed connection with the tool rest work table, and the fixed end of the Y-direction piezoelectric actuator is fixedly connected with the tool rest mounting base. The double-parallel-flexible-hinge-based tool rest driving platform is a two-dimensional degree-of-freedom micro-displacement platform which is novel and simple in structure and realizes precise control.

Owner:ZHEJIANG NORMAL UNIVERSITY

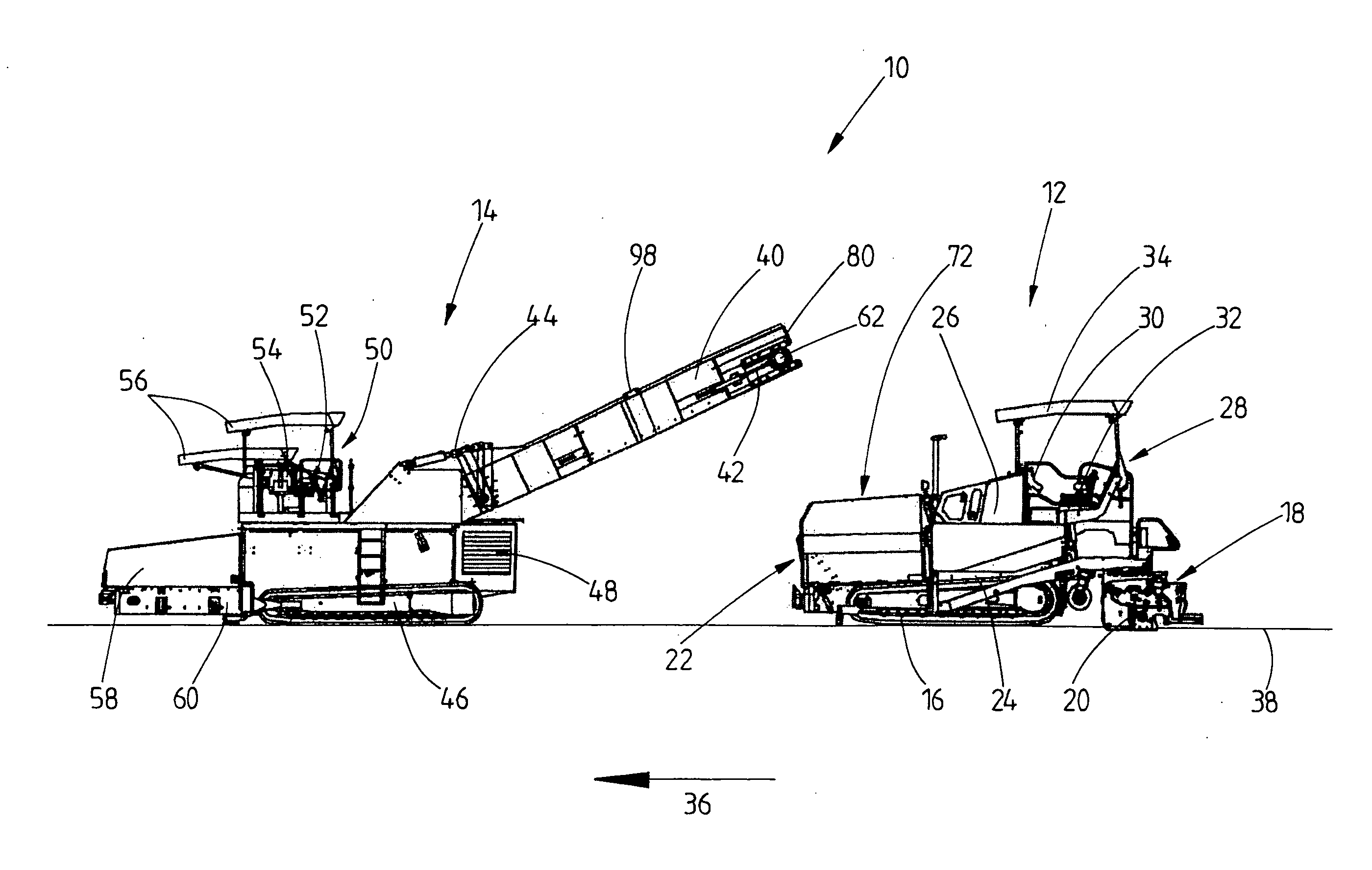

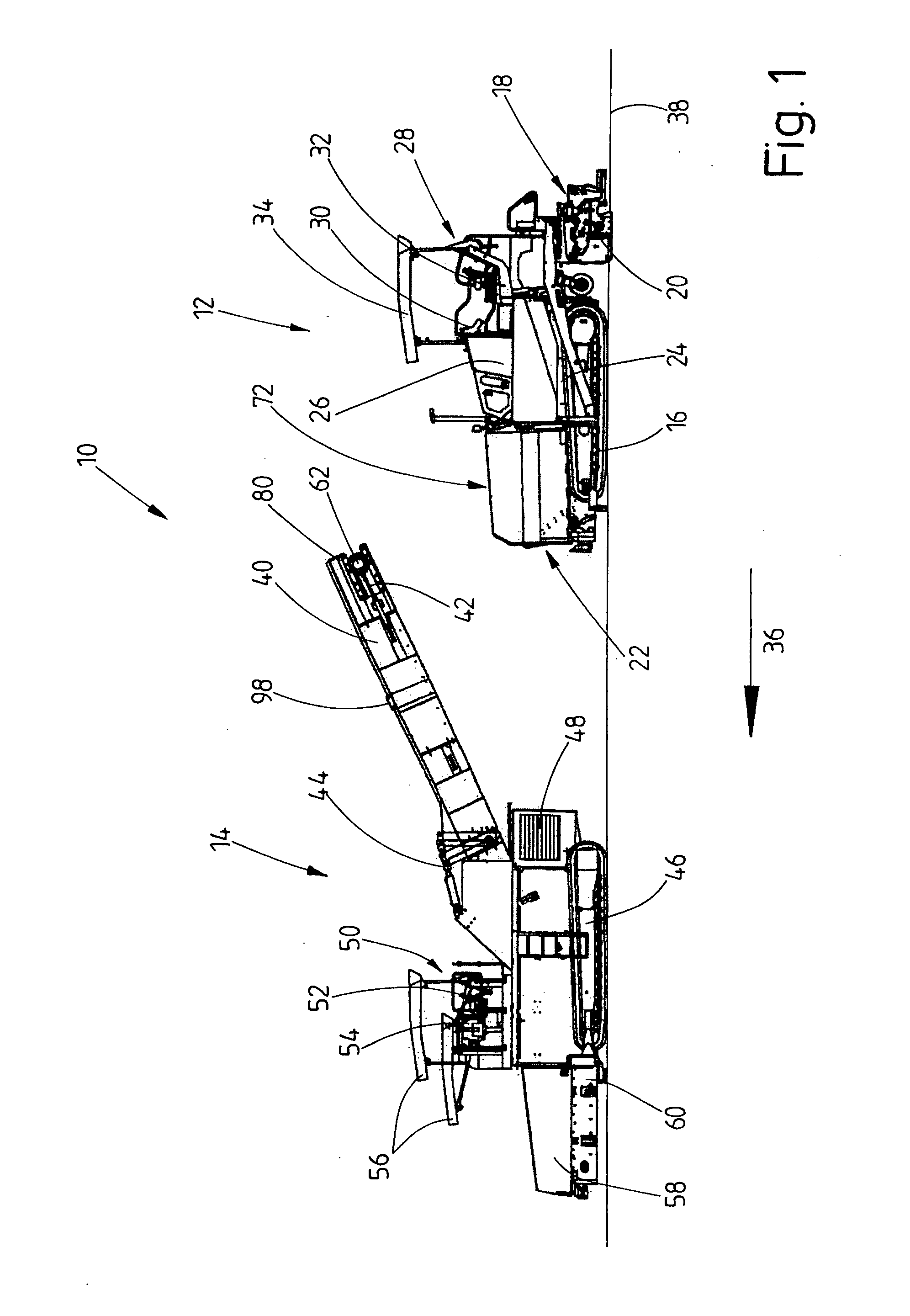

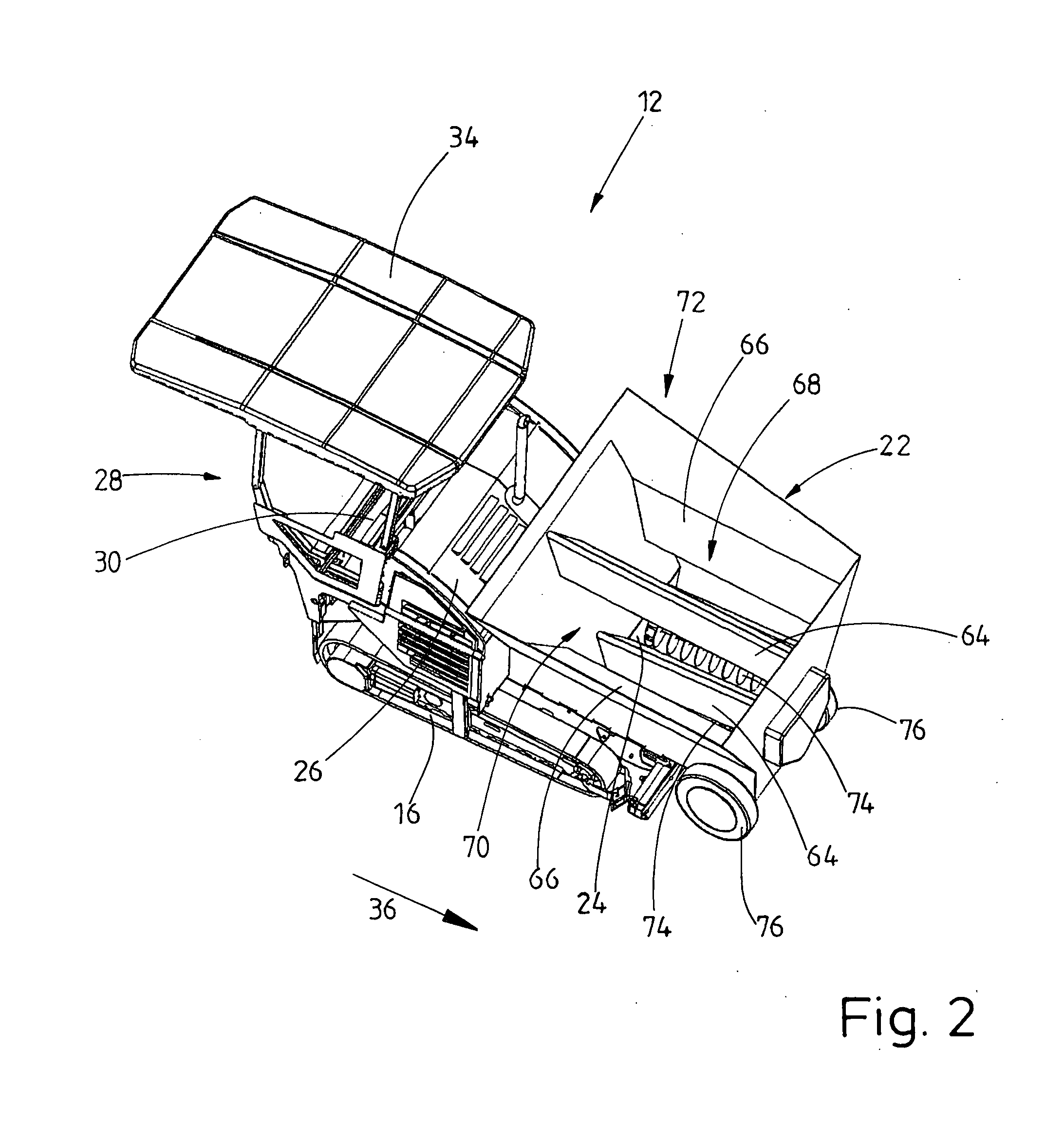

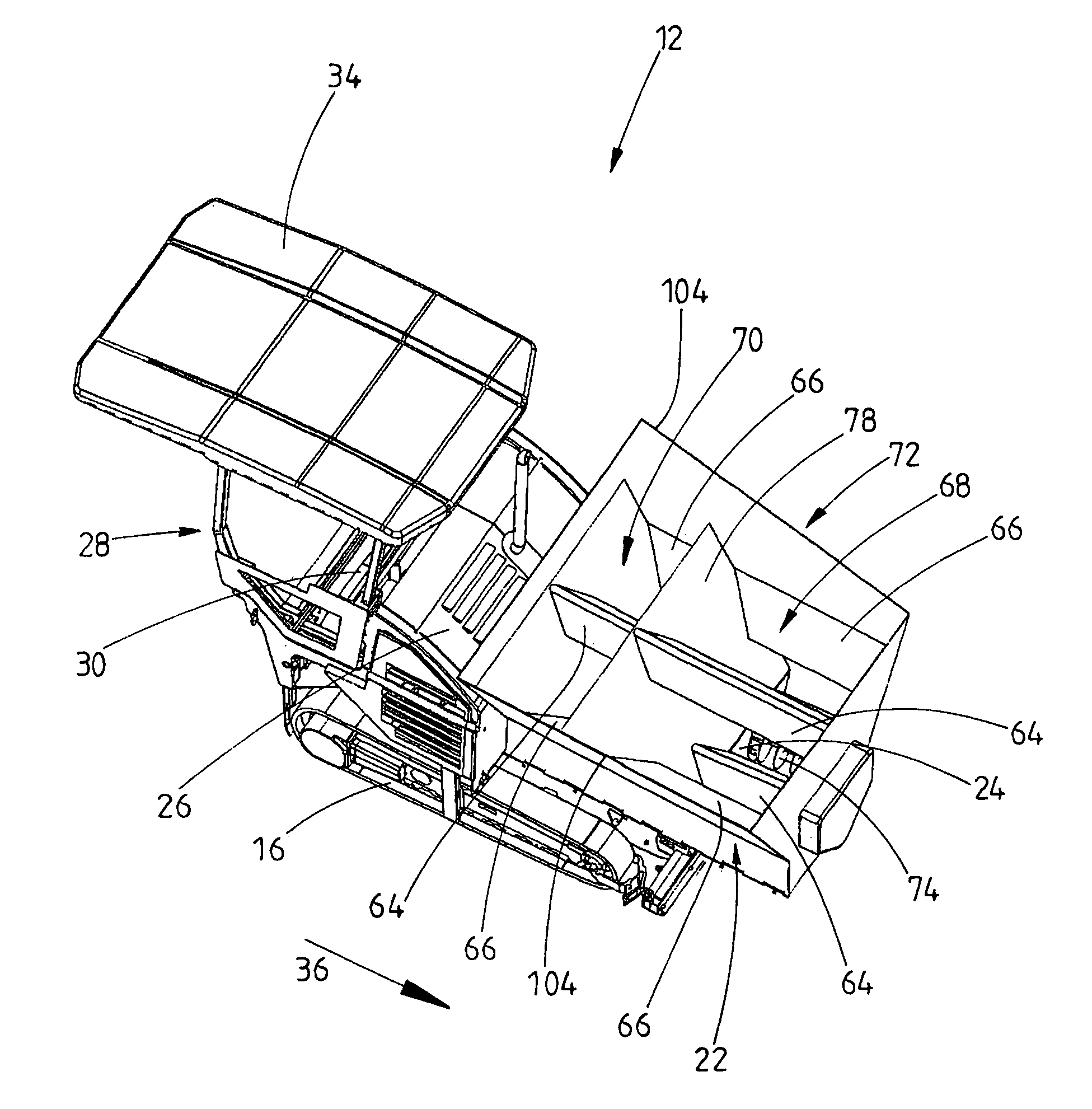

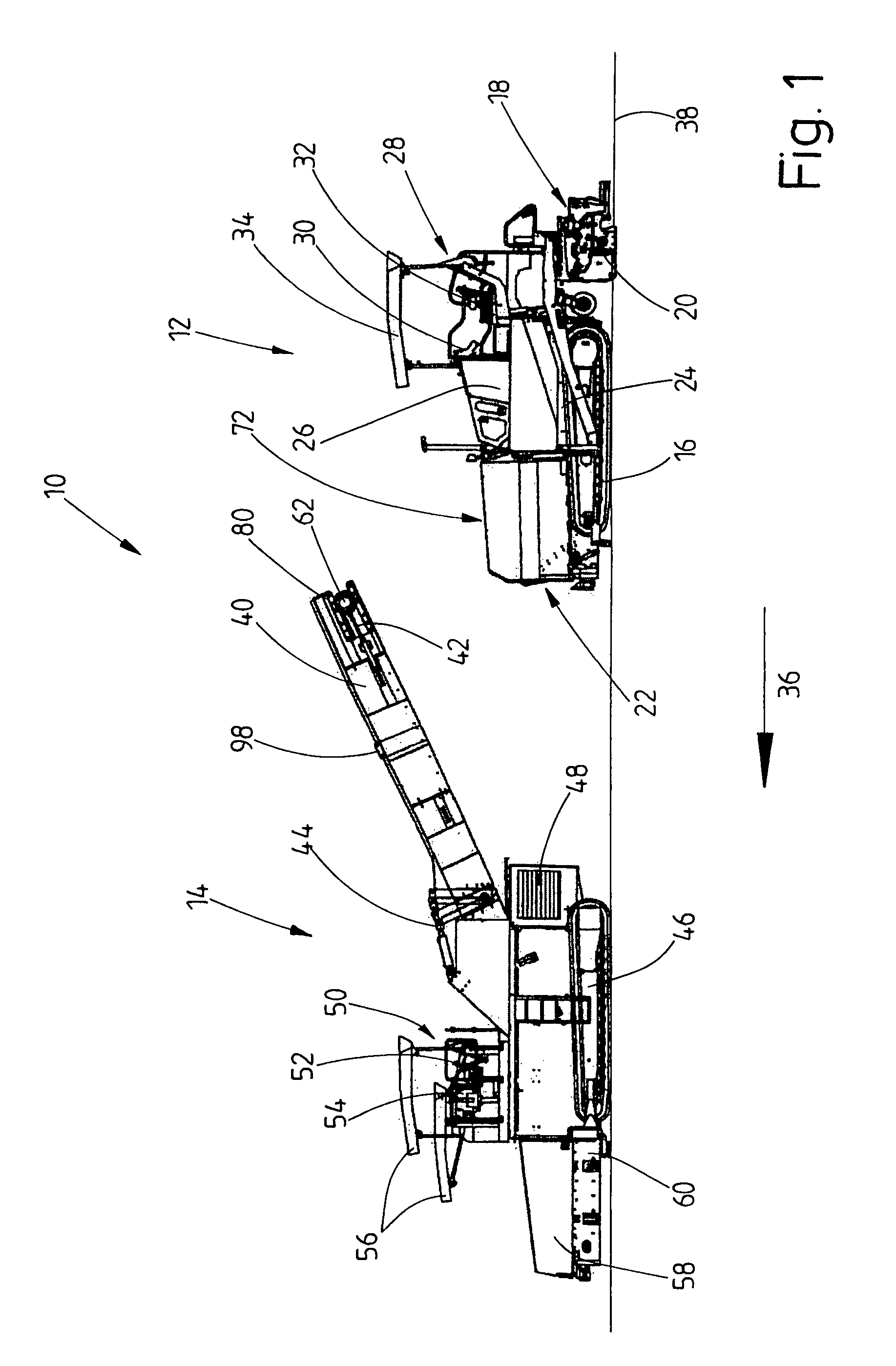

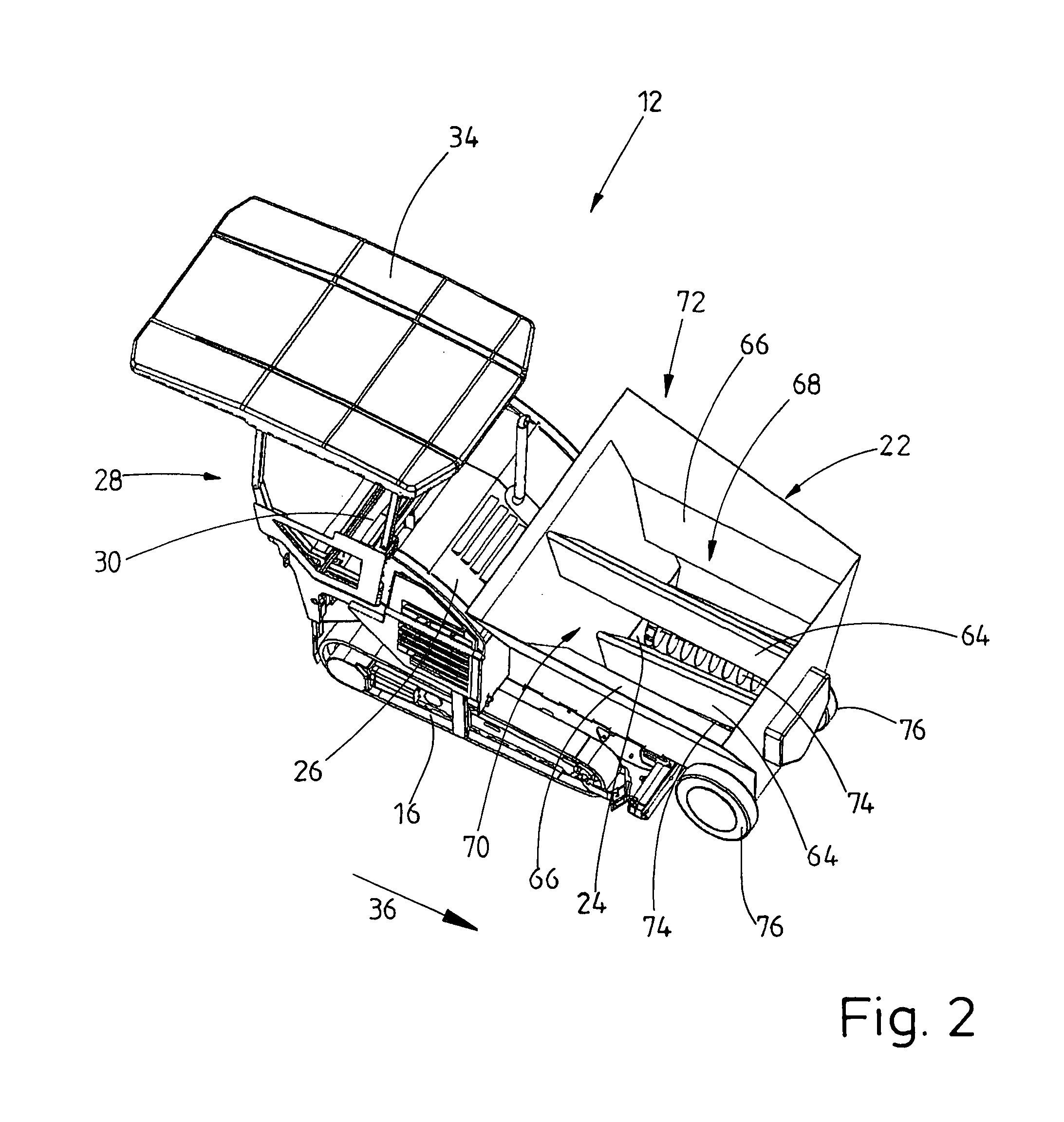

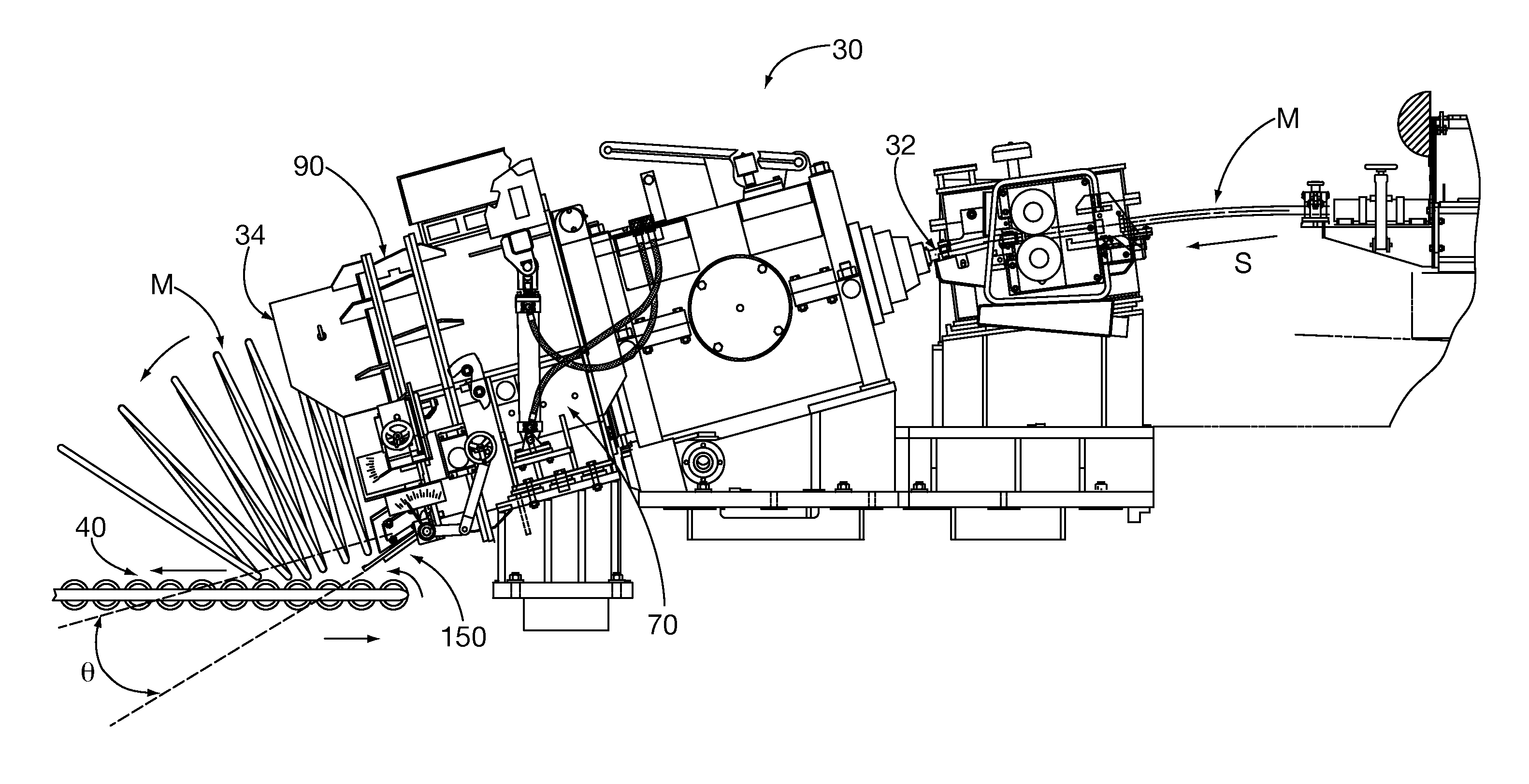

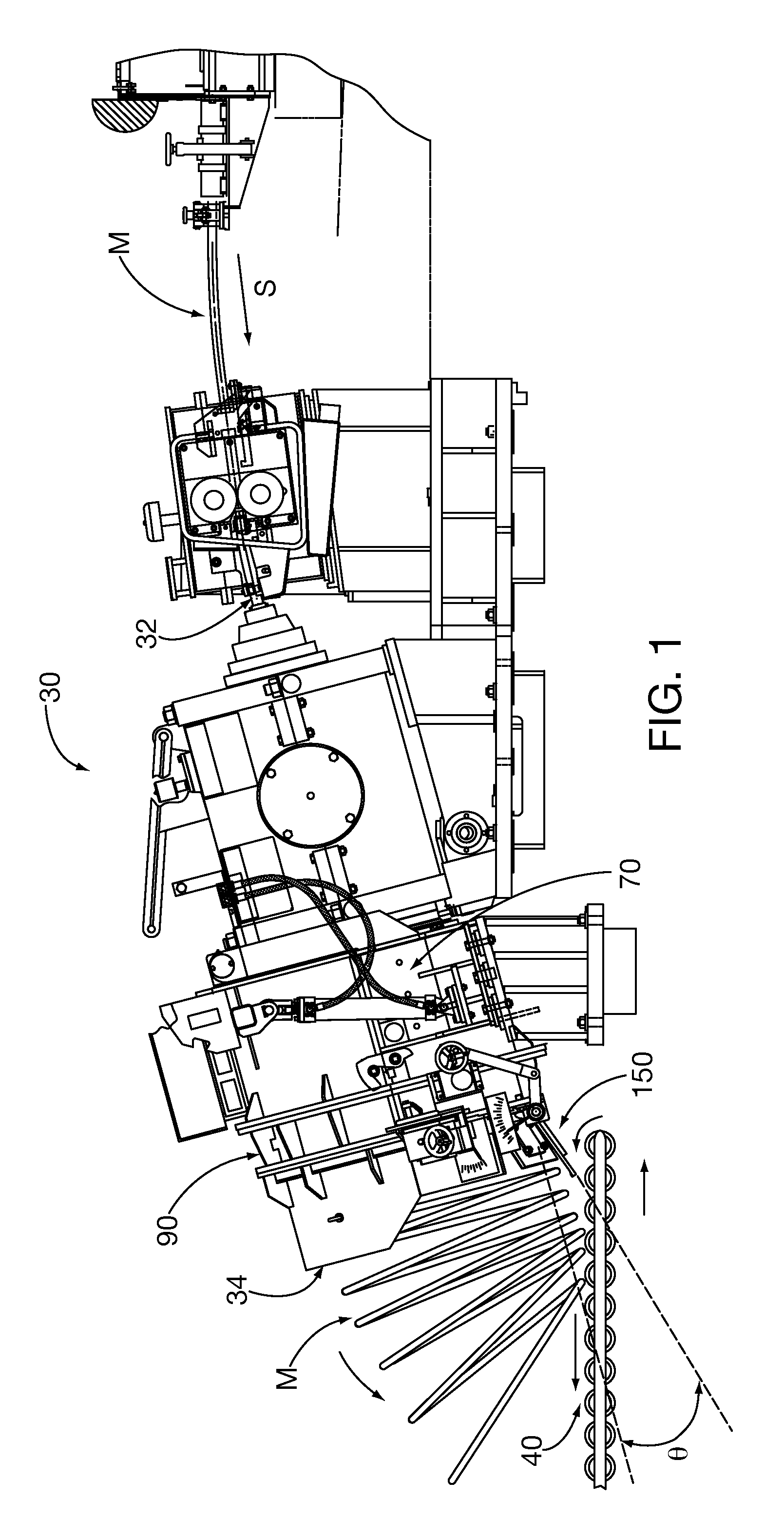

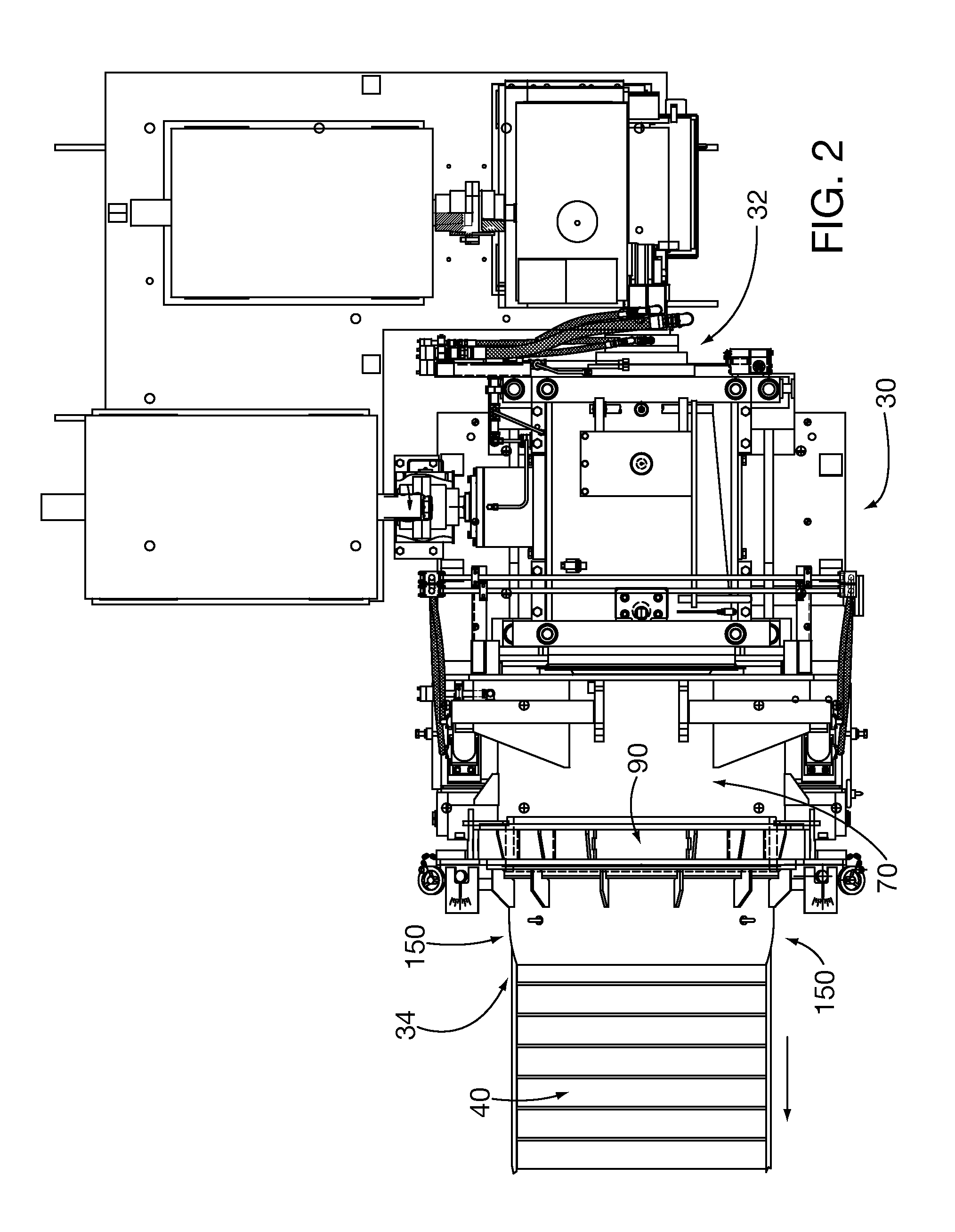

Process for producing a road covering, feeder, road paver and paving train

ActiveUS20110318102A1Quality improvementHigh consumptionPaving detailsRoads maintainenceAsphaltCivil engineering

Owner:DYNAPAC

Sliding bearing

InactiveUS20100047605A1Improve carrying capacityAccelerate transformationShaftsBearing componentsInter layerPlain bearing

The invention relates to a sliding bearing comprising a back metal layer, a bearing layer applied to the back metal layer, at least one intermediate layer applied to the bearing layer and an overlay applied to the at least one intermediate layer, wherein the overlay consists of a tin matrix and a silver-tin intermetallic phase distributed in the tin matrix, wherein the silver-tin intermetallic phase is distributed homogeneously in the tin matrix and wherein the silver-tin intermetallic phase consists of particles, most of them, preferably more than 99% of them having a particle size ≦1 micron.

Owner:MAHLE INT GMBH

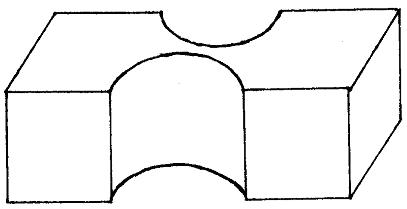

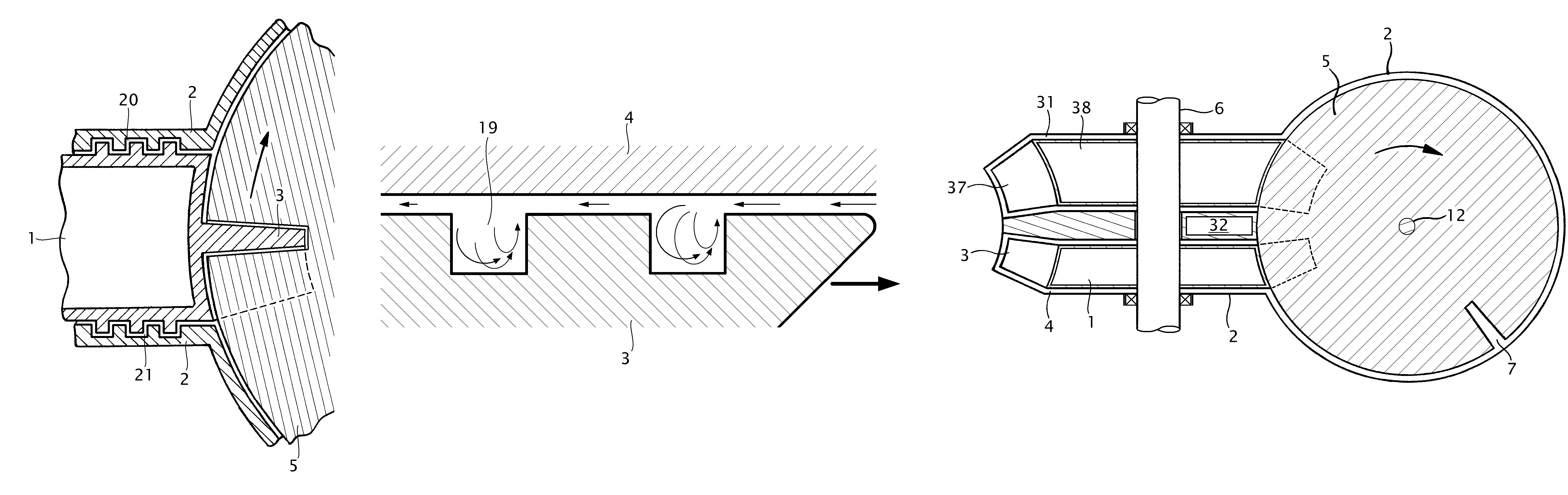

Blade-thru-slot combustion engine, compressor, pump and motor

InactiveUS7305963B2Reduced performanceIncrease frictionEngine sealsPiston ringsCombustion chamberInternal combustion engine

This is simple and efficient rotary machine that can be implemented as compressor, pump, motor and mainly as internal combustion engine. The engine comprises a housing, a rotor(s) with a radial blade(s), a chamber(s) swept by the blade(s), an intersecting planar valve(s) with slot, and a combustion chamber. Blades and slots have matching shapes that allow the traversal of the blades through the slots with negligible loss of air / gases. After traversing the slot, the blade aspires air into one side of the chamber while compresses air on the other side. Fuel is injected in the compressed stream in its way to the combustion chamber, where it is ignited. In a double-rotor implementation, combustion gases are then introduced in the second rotor chamber, just after its blade has traversed the corresponding slot. One side of this blade is pushed by the expansion while the other expels gases from the previous stroke.

Owner:ZAK JUAN

Blade-thru-slot combustion engine, compressor, pump and motor

InactiveUS20060257278A1Reduced performanceIncrease frictionEngine sealsPiston ringsCombustion chamberElectric machine

This is simple and efficient rotary machine that can be implemented as compressor, pump, motor and mainly as internal combustion engine. The engine comprises a housing, a rotor(s) with a radial blade(s), a chamber(s) swept by the blade(s), an intersecting planar valve(s) with slot, and a combustion chamber. Blades and slots have matching shapes that allow the traversal of the blades through the slots with negligible loss of air / gases. After traversing the slot, the blade aspires air into one side of the chamber while compresses air on the other side. Fuel is injected in the compressed stream in its way to the combustion chamber, where it is ignited. In a double-rotor implementation, combustion gases are then introduced in the second rotor chamber, just after its blade has traversed the corresponding slot. One side of this blade is pushed by the expansion while the other expels gases from the previous stroke.

Owner:ZAK JUAN

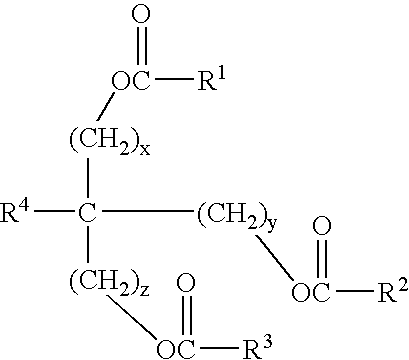

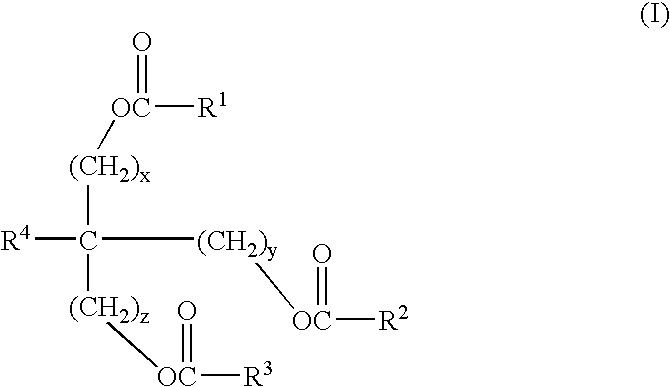

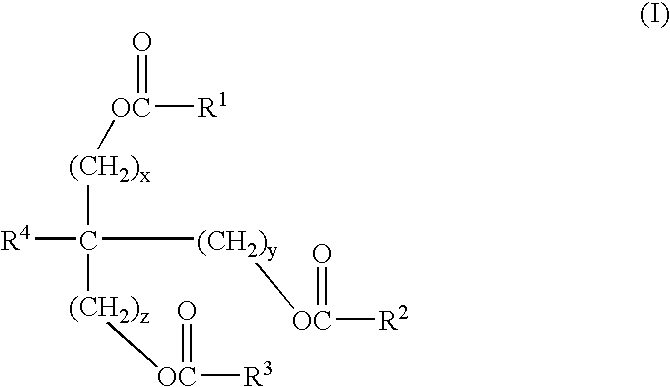

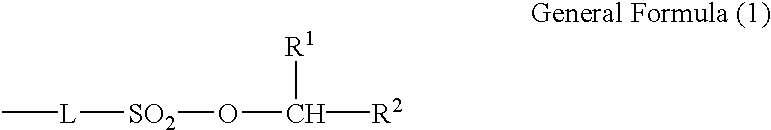

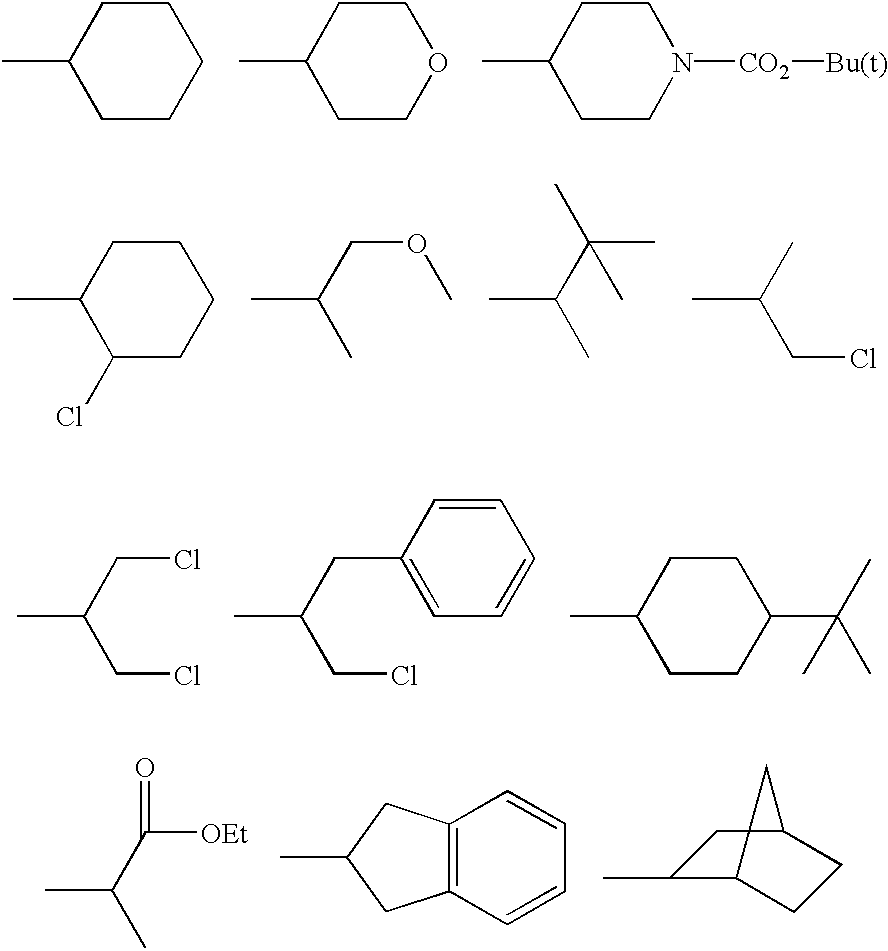

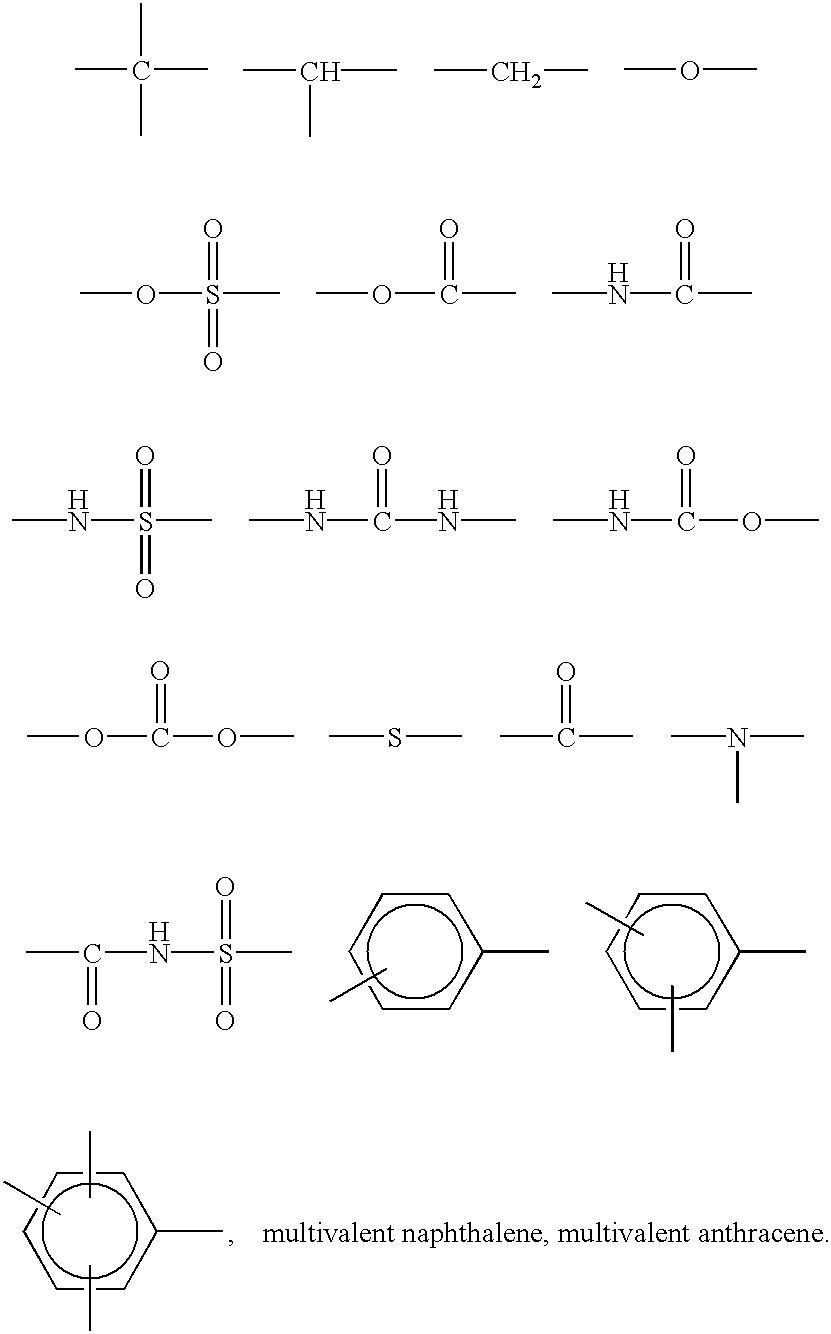

Engine oil compositions

A low phosphorous or phosphorous-free sulfur lubricating oil composition and / or low phosphorous or phosphorous-free and low sulfur or sulfur-free lubricating oil composition for internal combustion engines comprising (a) a major amount of a base oil of lubricating viscosity and (b) a minor deposit-inhibiting effective amount of at least one polyol ester of the general formula wherein R1, R2 and R3 are independently aliphatic hydrocarbyl moieties having from 4 to about 24 carbon atoms, R4 is hydrogen or an aliphatic hydrocarbyl moiety having 1 to 10 carbon atoms and x, y and z are the same or different and are integers from 1 to 6, and additive compositions and additive packages containing the foregoing polyol ester are provided.

Owner:CHEVRON ORONITE CO LLC

Process for producing a road covering, feeder, road paver and paving train

ActiveUS8562246B2Quality improvementHigh consumptionPaving detailsRoads maintainenceRoad surfaceAsphalt

Owner:DYNAPAC

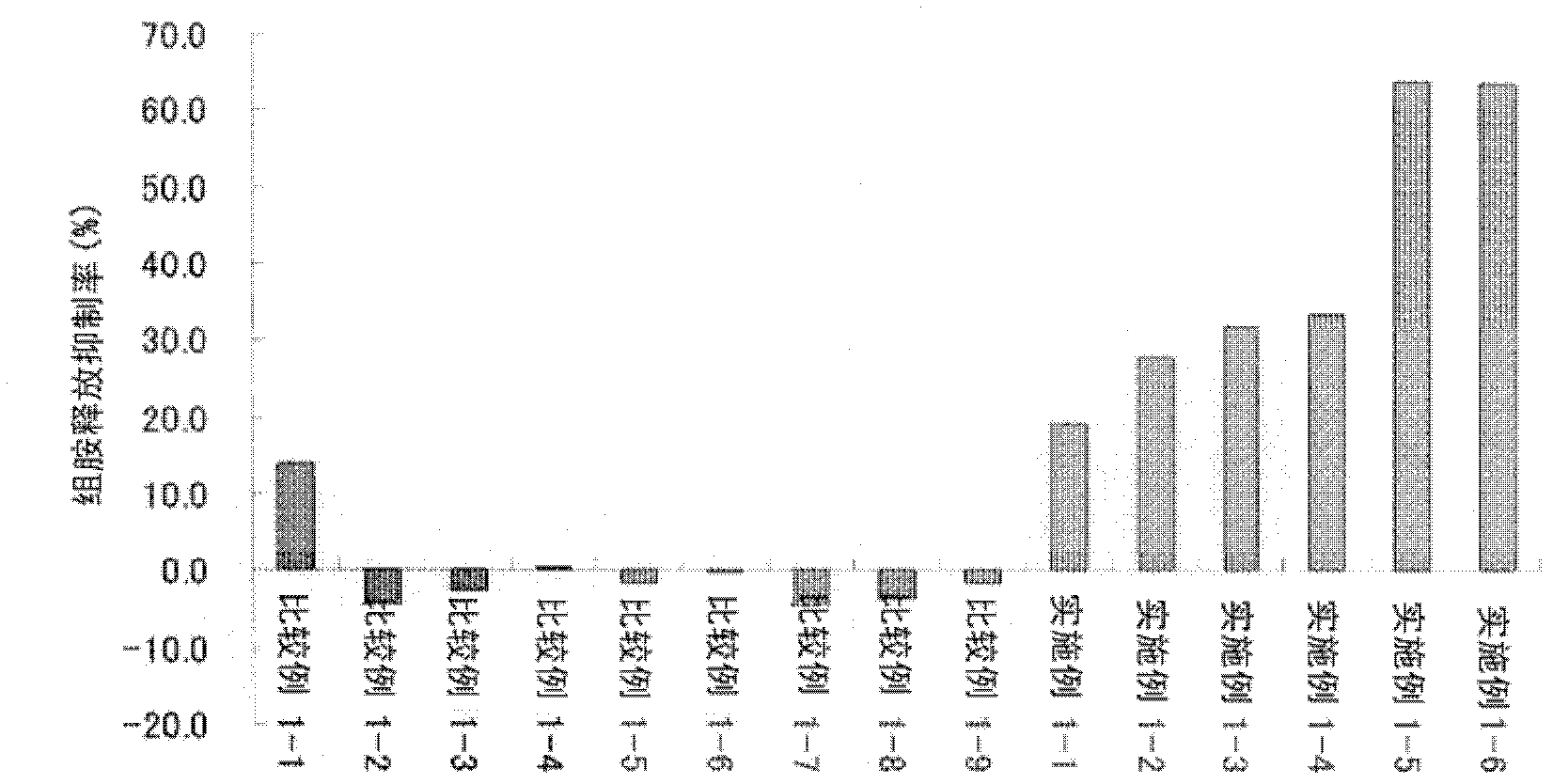

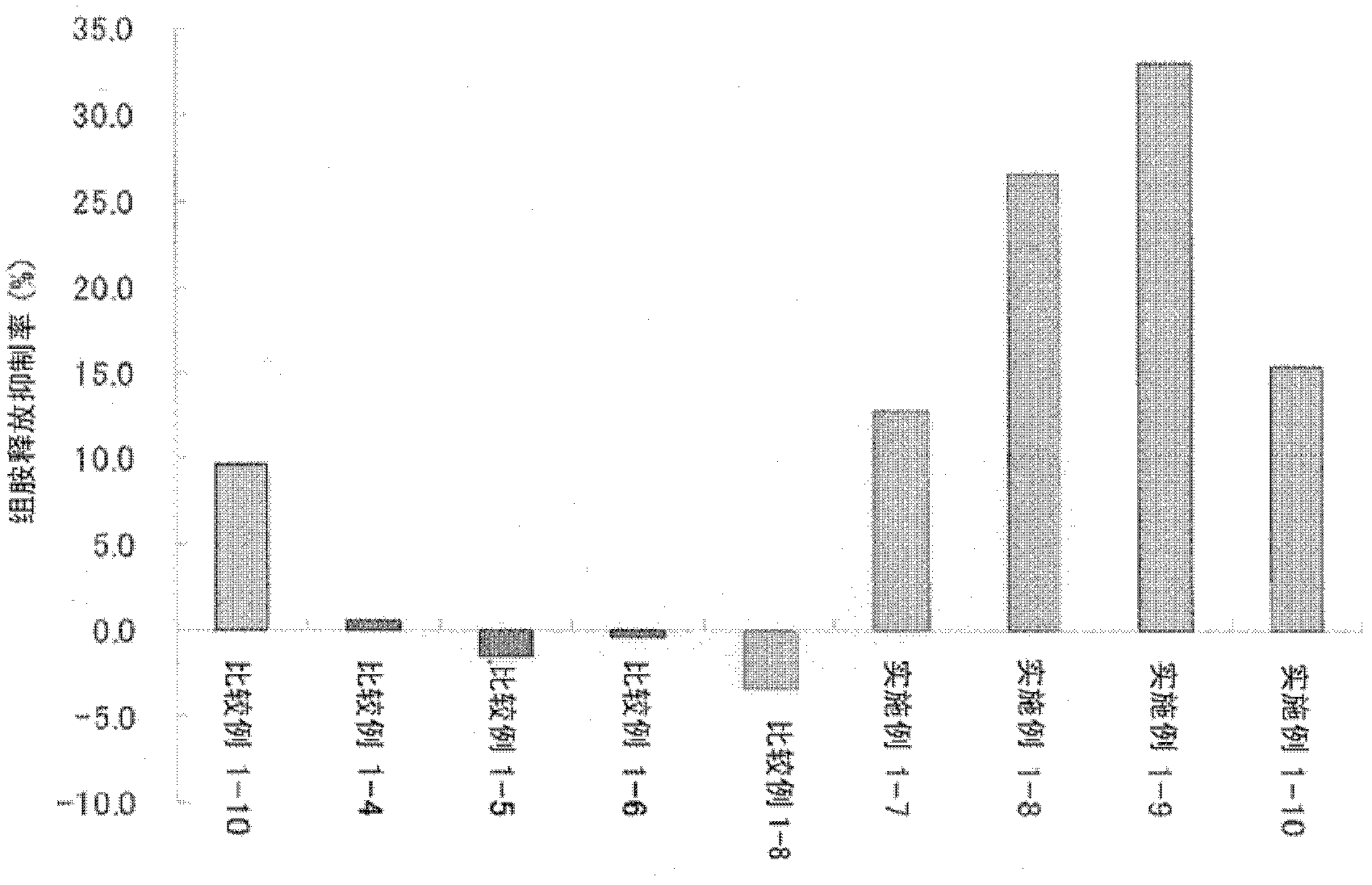

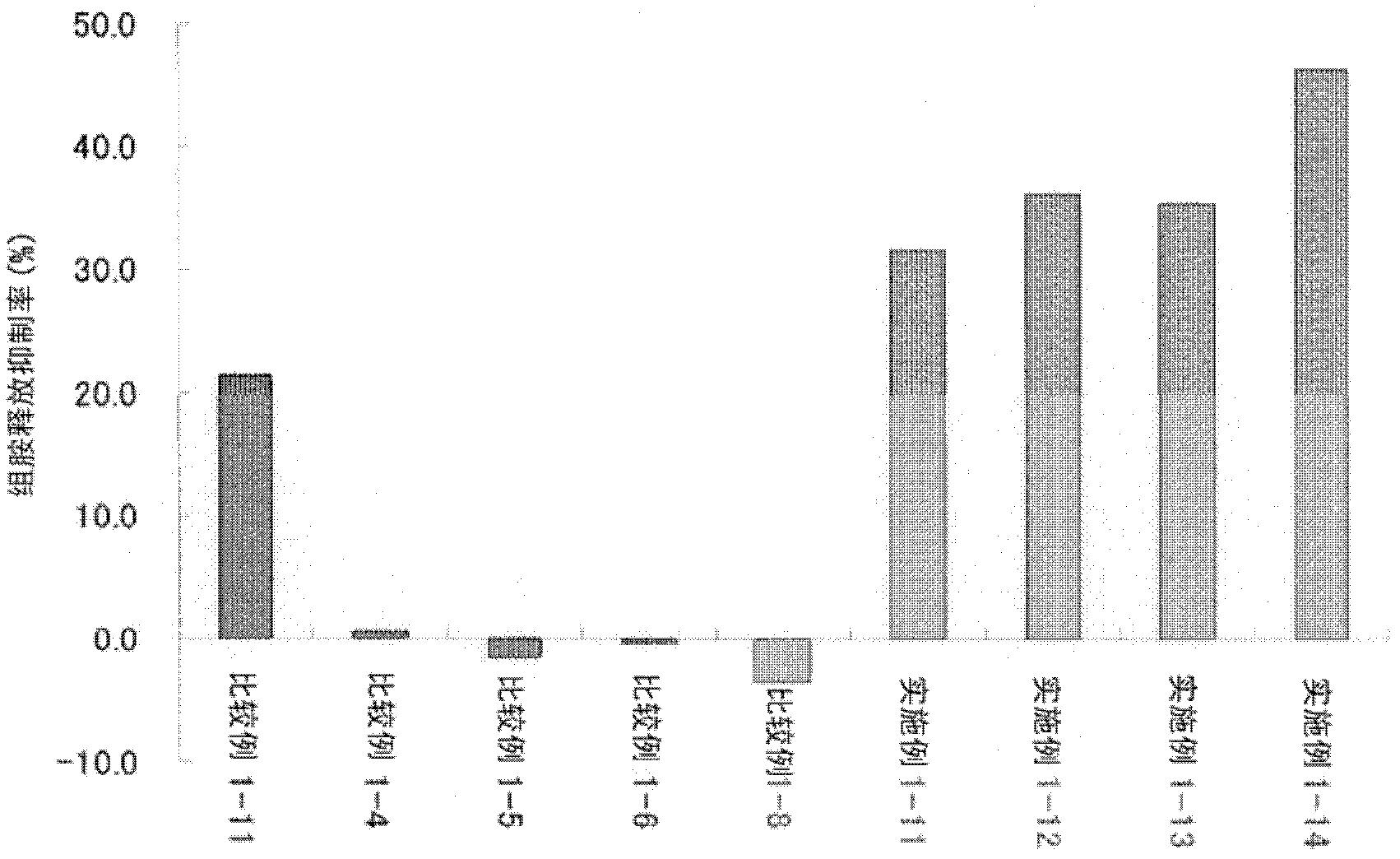

Ophthalmic composition

ActiveCN102548562AExcellent histamine release inhibitory effectSuppress discomfortAntibacterial agentsSenses disorderMentholSide chain

Disclosed are: an ophthalmic composition according to a non-conventional novel preparation, which has histamine release inhibitory action; and an ophthalmic composition for a silicone hydrogel contact lens, which is capable of suppressing adsorption of terpenoid to a silicone hydrogel contact lens. Specifically, the ophthalmic composition is prepared using (A) 0.001-2 w / v% of a polymer that has a phosphorylcholine analogous group in a side chain in combination with (B-1) 0.001-0.02 w / v% of menthol. Meanwhile, the ophthalmic composition for a silicone hydrogel contact lens is prepared using (A) a polymer that has a phosphorylcholine analogous group in a side chain in combination with (B-2) terpenoid.

Owner:ROHTO PHARM CO LTD

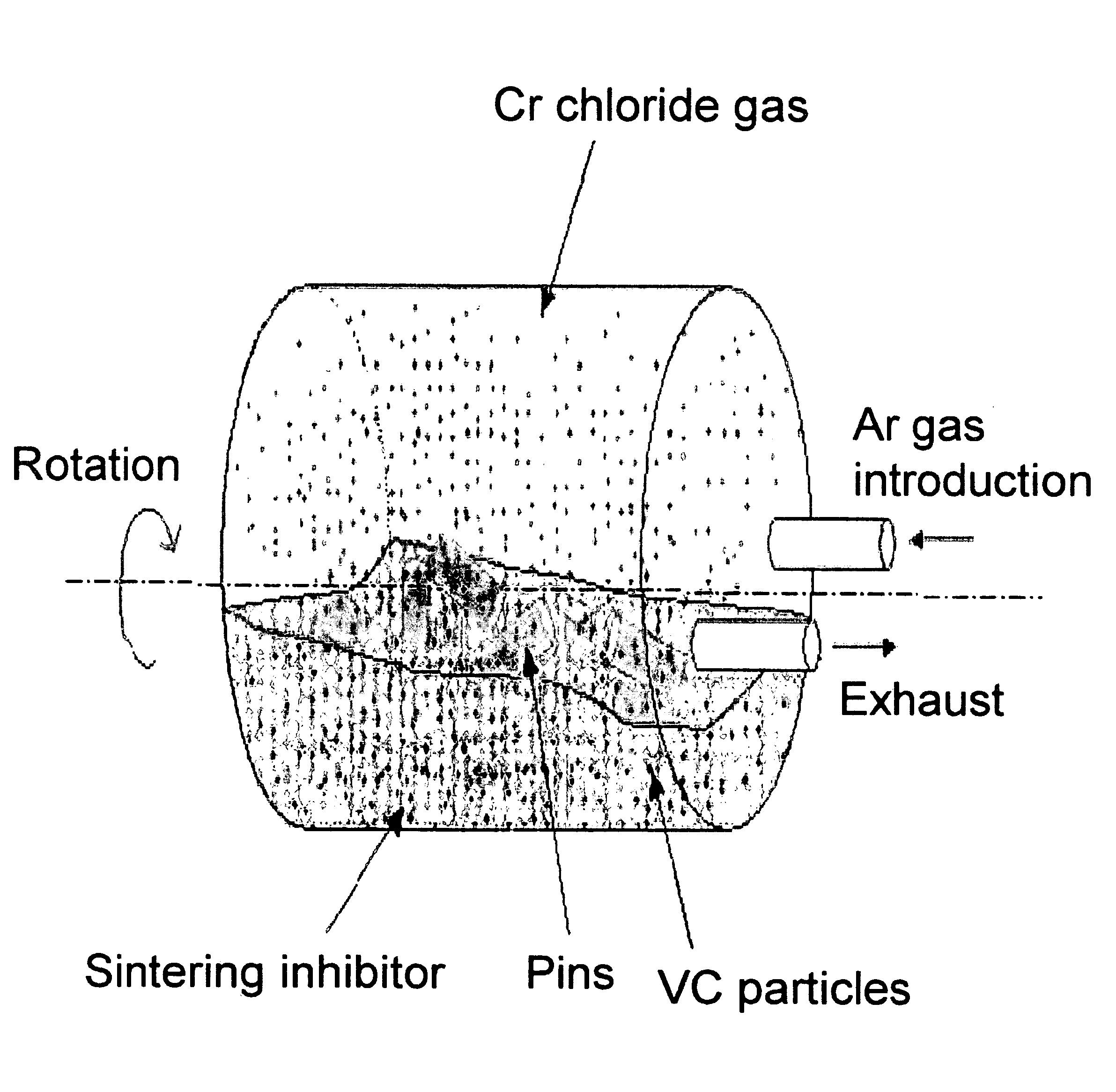

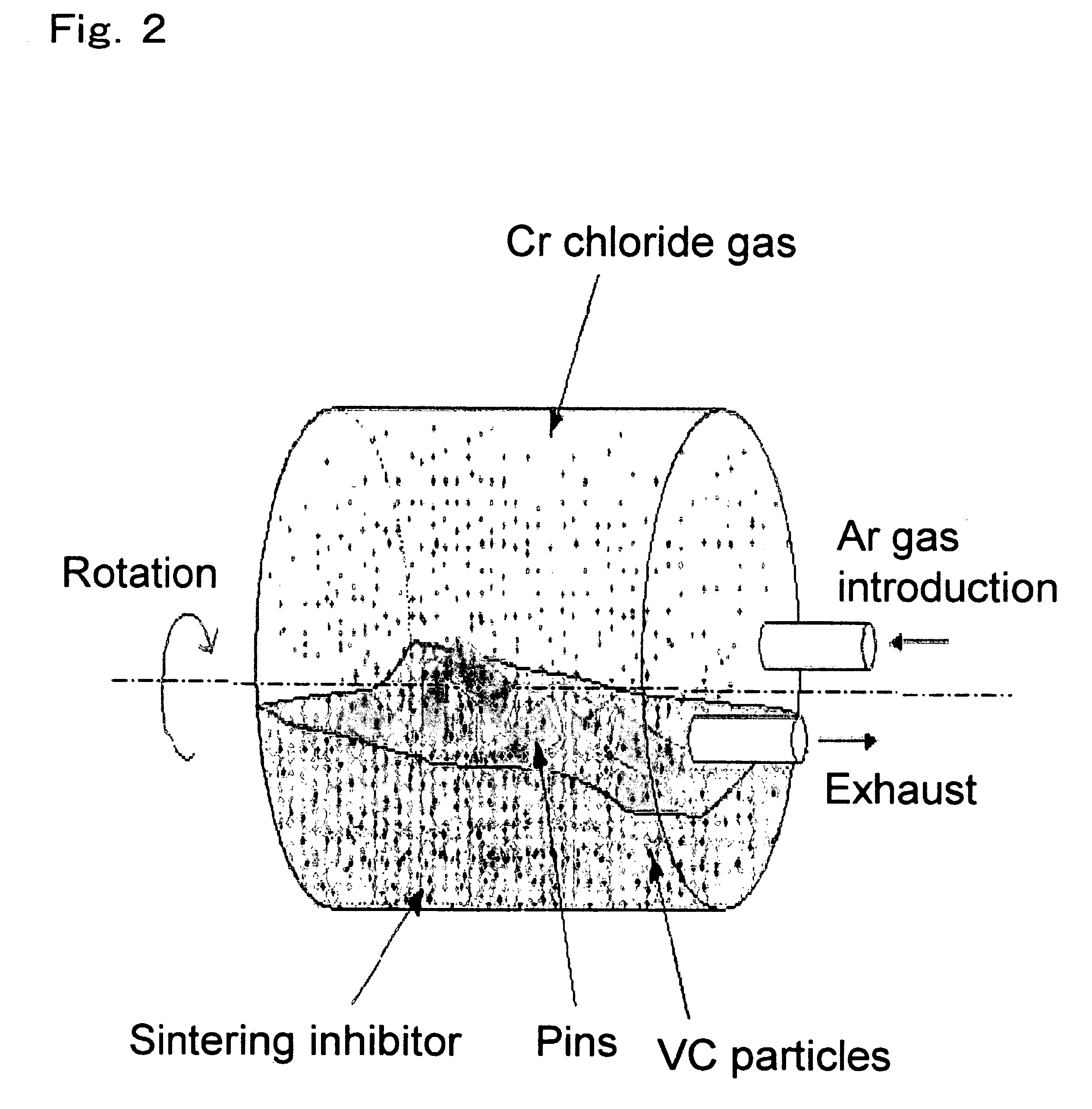

Steel parts having high wear and abrasion resistance and method for manufacturing the same

InactiveUS20060269763A1Increase resistanceHigh wearLiquid surface applicatorsCoatingsChromium carbideHafnium

A steel parts having an improved high wear and abrasion resistance is provided. The steel parts can be manufactured by a method wherein a steel parts containing 0.5 to 1.2 wt % of carbon is subjected to a chromium cementation treatment at a temperature of 1,000 to 1,100° C. with a cementing agent mainly consisting of carbide particles selected from the group consisting of Vanadium Carbide, Titanium Carbide, Niobium Carbide, Tungsten Carbide, Hafnium Carbide and Zirconium Carbide; metallic chromium and a sintering inhibitor to make an outermost surface of chromium carbide formed on the steel parts being dispersed with carbide particles selected from the group consisting of Vanadium Carbide, Titanium Carbide, Niobium Carbide, Tungsten Carbide, Hafnium Carbide and Zirconium Carbide.

Owner:HONDA MOTOR CO LTD

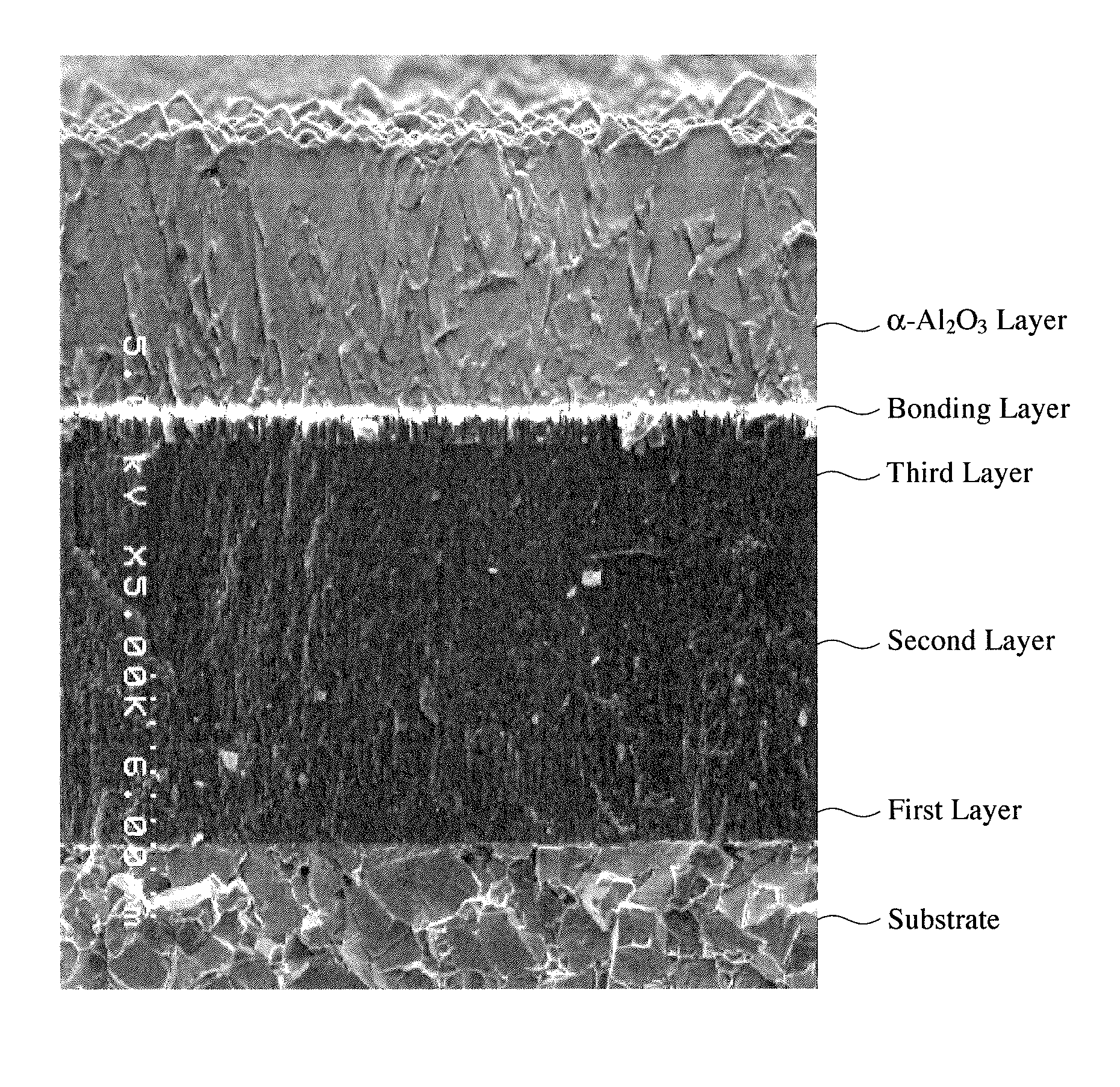

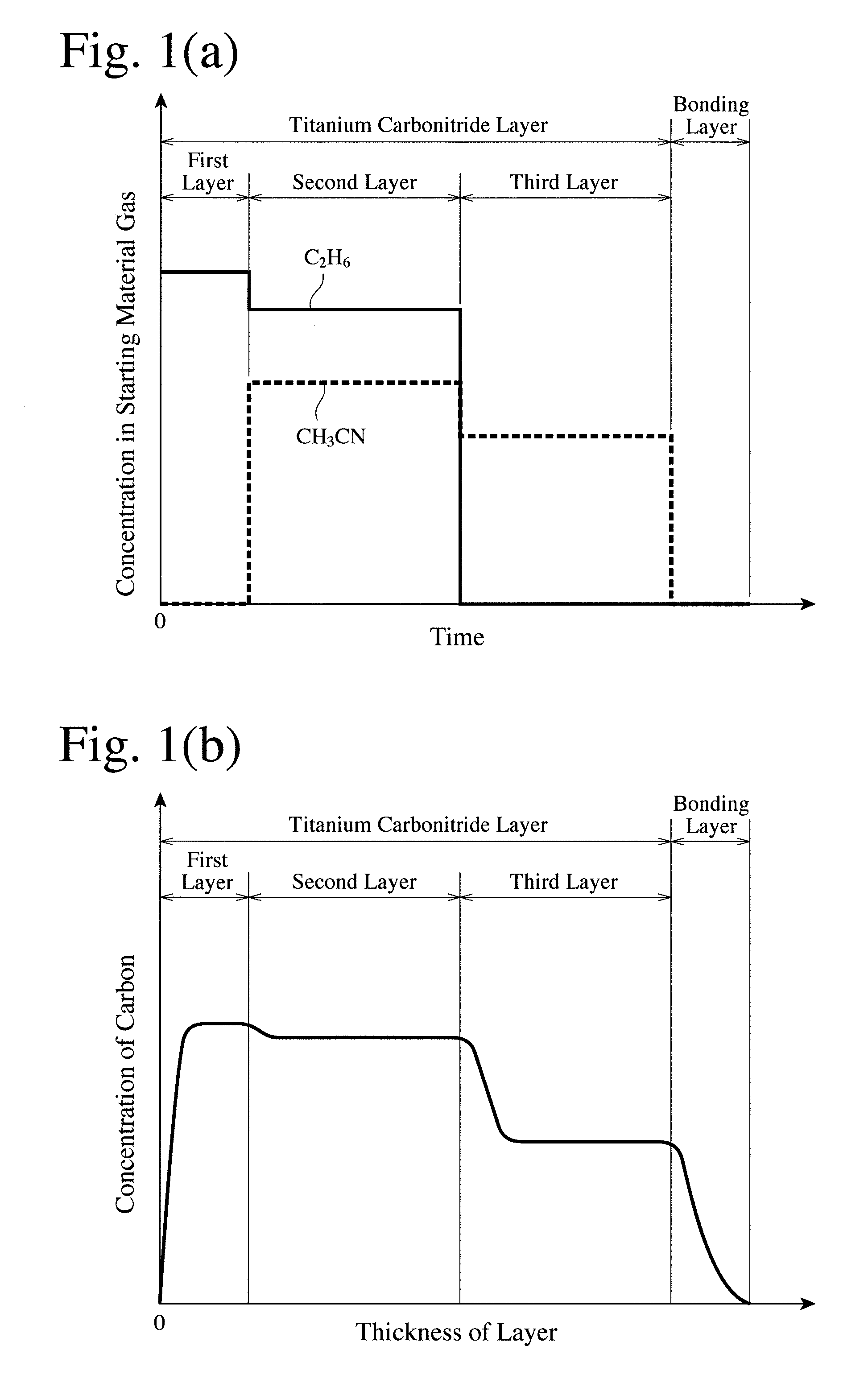

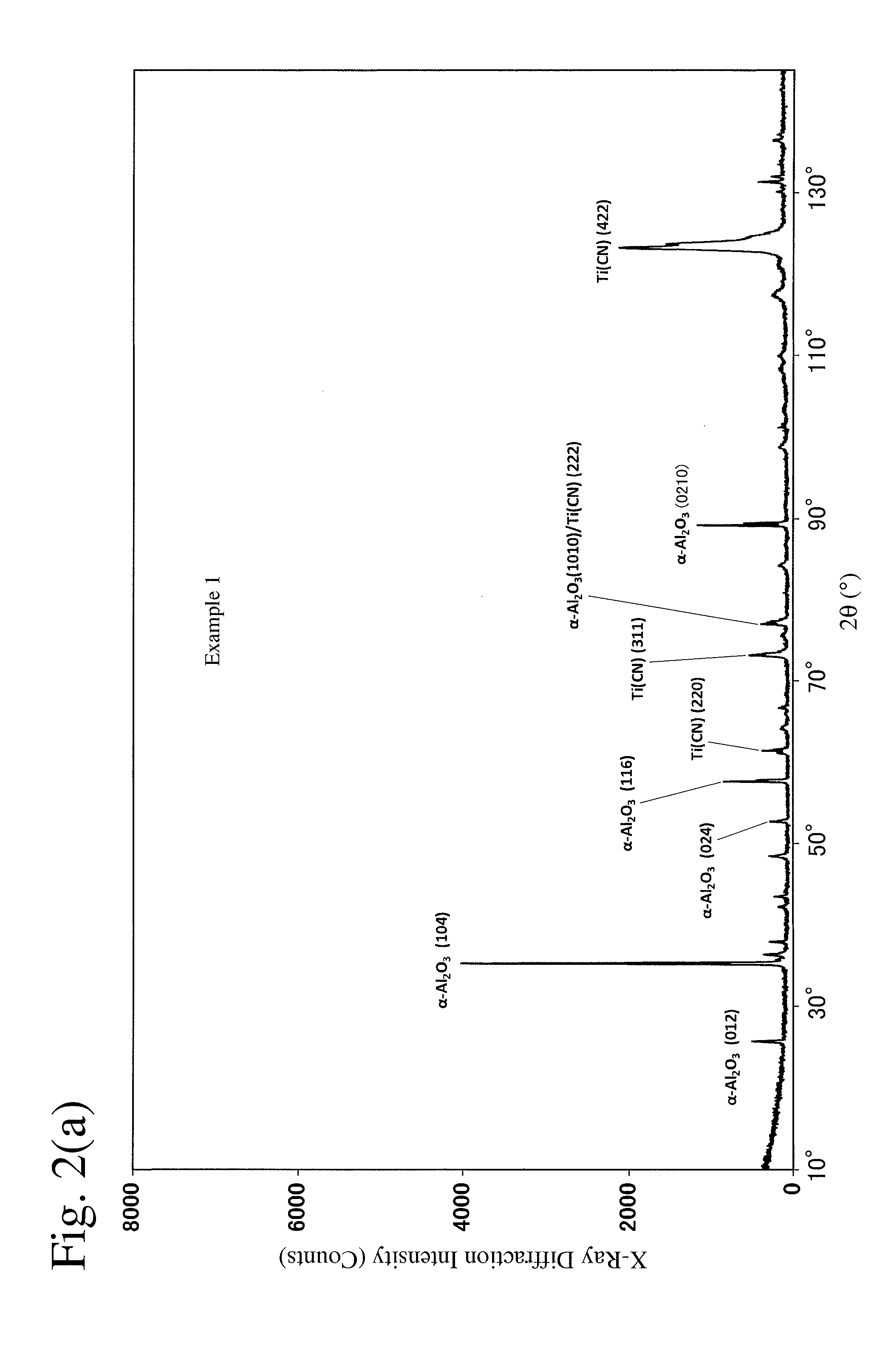

Hard-coated member and its production method, and indexable rotary tool comprising it

A hard-coated member comprising a substrate made of cemented carbide or high-speed steel and a titanium carbonitride layer formed on the substrate by a chemical vapor deposition method, the titanium carbonitride layer comprising first to third layers each having a columnar crystal structure in this order from the side of the substrate, the second layer being smaller than the first layer in carbon concentration, and the third layer being smaller than the second layer in carbon concentration, and an indexable rotary tool comprising it. The first layer is formed by using a starting material gas comprising a TiCl4 gas, an N2 gas, a C2-C5 hydrocarbon gas and an H2 gas, the second layer is formed by using a starting material gas comprising a TiCl4 gas, an N2 gas, an organic cyanide gas, a C2-C5 hydrocarbon gas, and an H2 gas, and the third layer is formed by using a starting material gas comprising a TiCl4 gas, an N2 gas, an organic cyanide gas, whose amount is smaller than in the second layer, and an H2 gas.

Owner:HITACHI TOOL ENG LTD

Cladding

InactiveUS7966783B2Improve fire resistanceEmission reductionCovering/liningsPublic buildingsSurface finishPanelling

There can be provided a method of cladding a surface with panelling. The method can comprise: attaching a first panel support member to the surface, the first panel support member being configured to receive at least a part of a first edge of a panel comprising a core of woven and non-woven glass impregnated with resin and a surface finish of paper and melamine resin; placing the first edge in a position of co-operative reception with the first panel support member; and placing a second edge of the panel substantially opposite the first edge in a position of co-operative reception with a second panel support member, the second panel support member being configured to be attached to the surface.

Owner:BAA IP HOLDCO

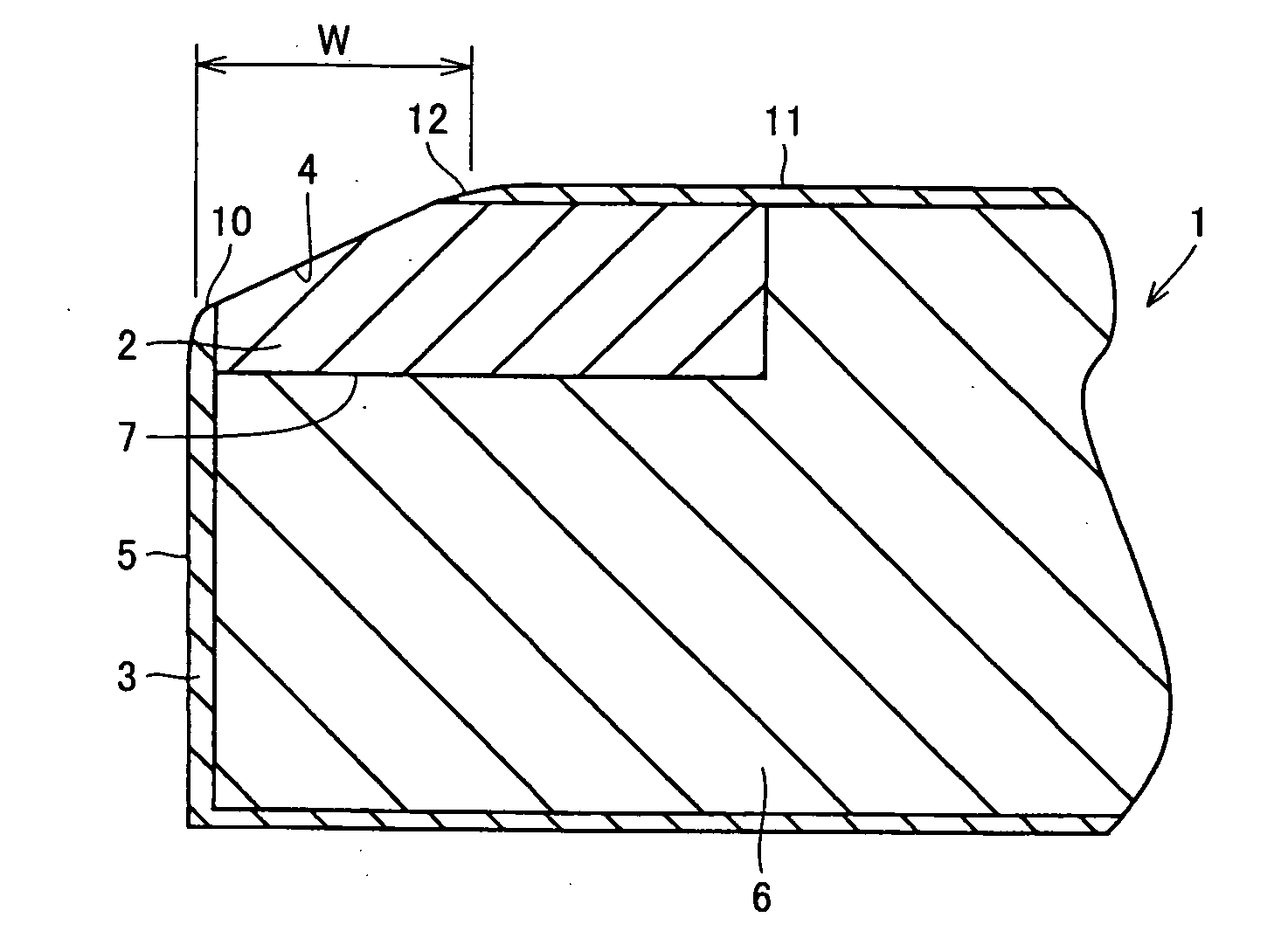

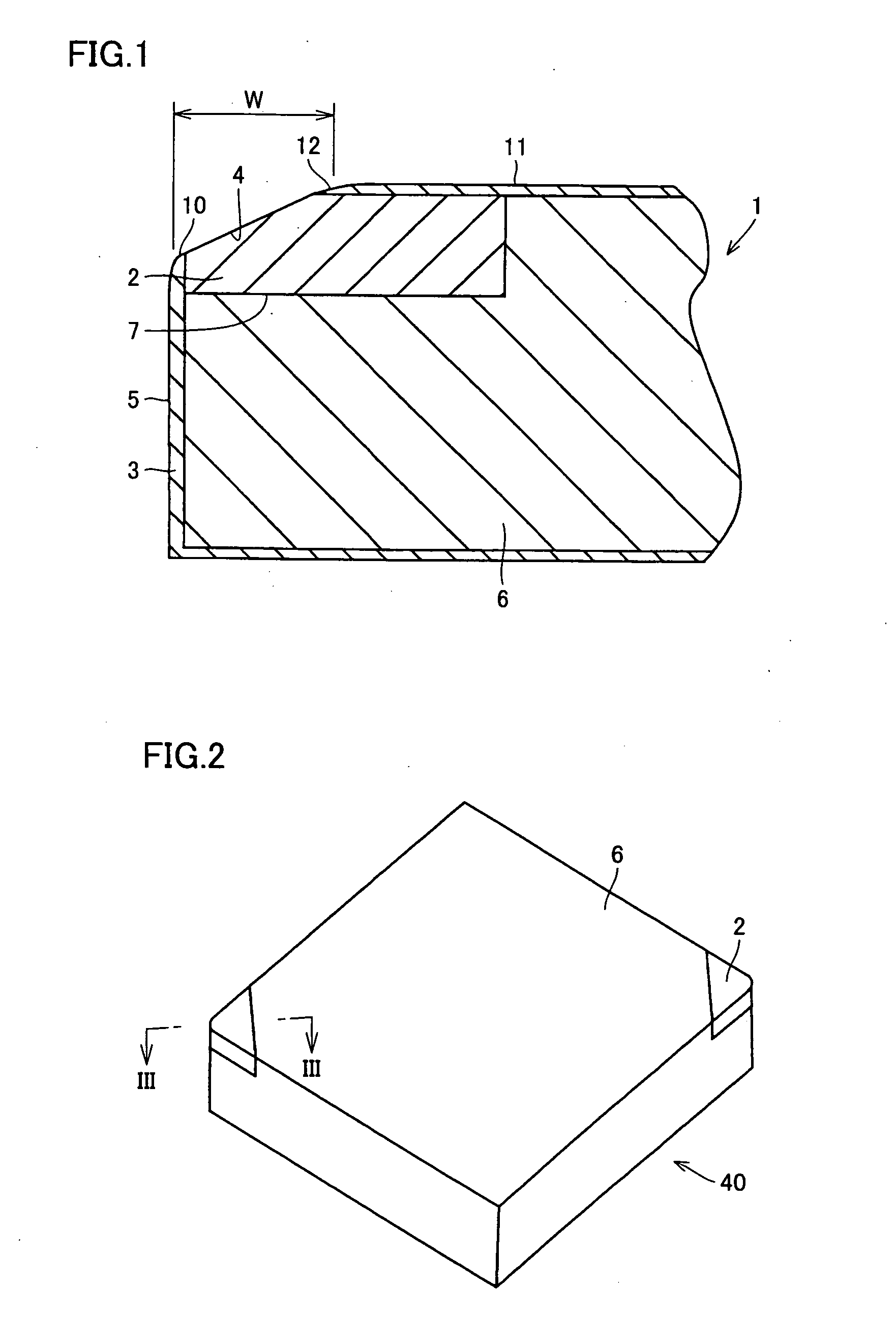

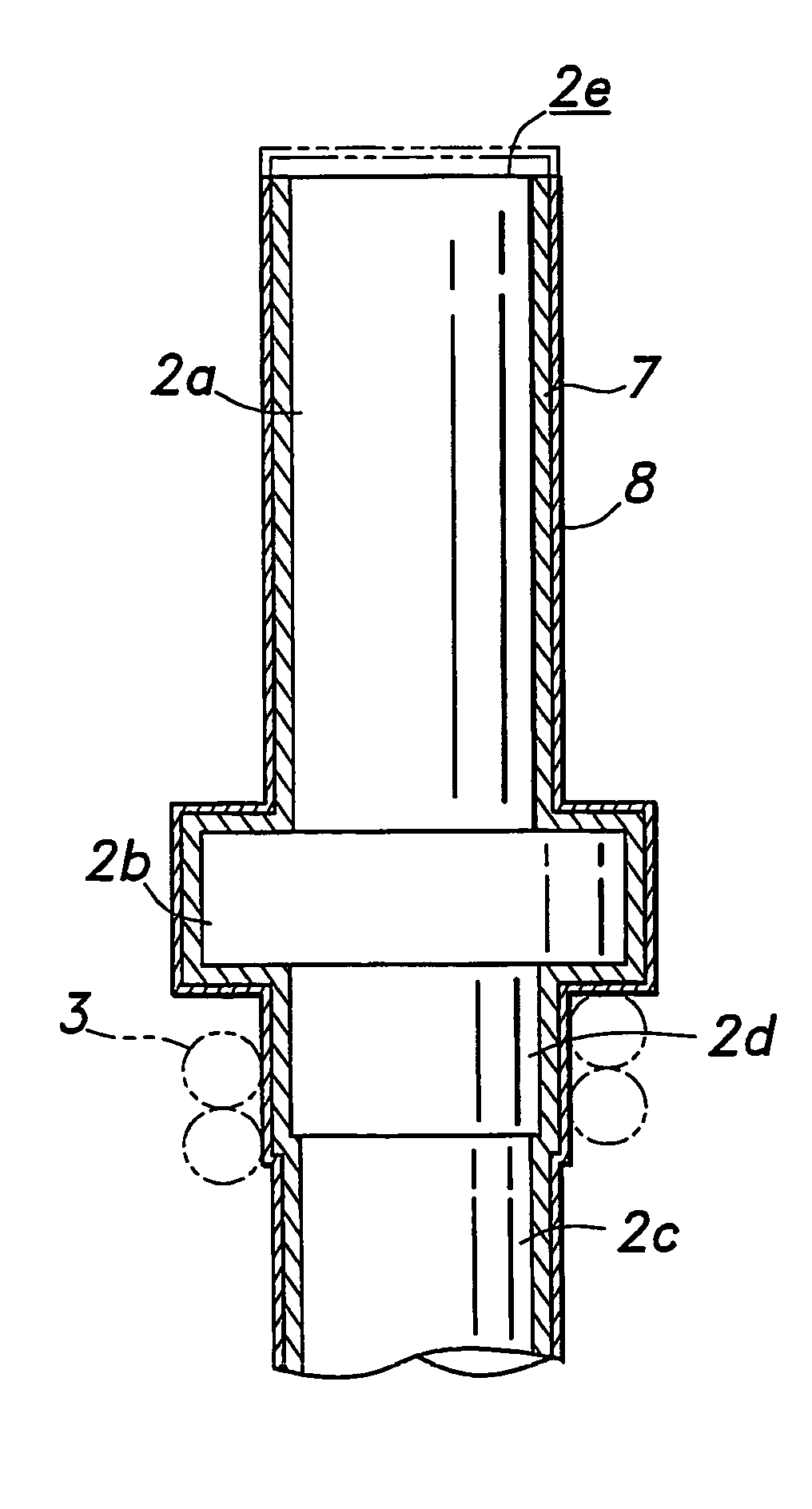

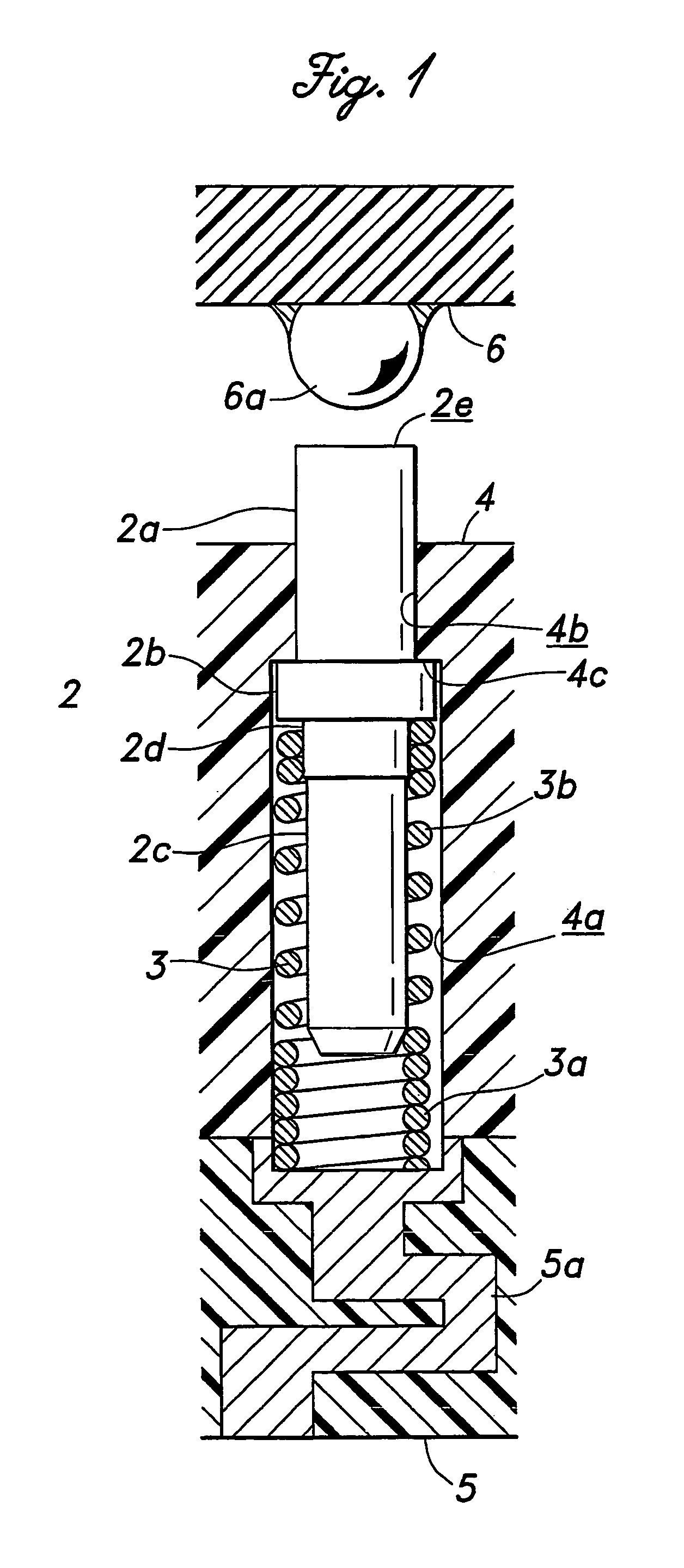

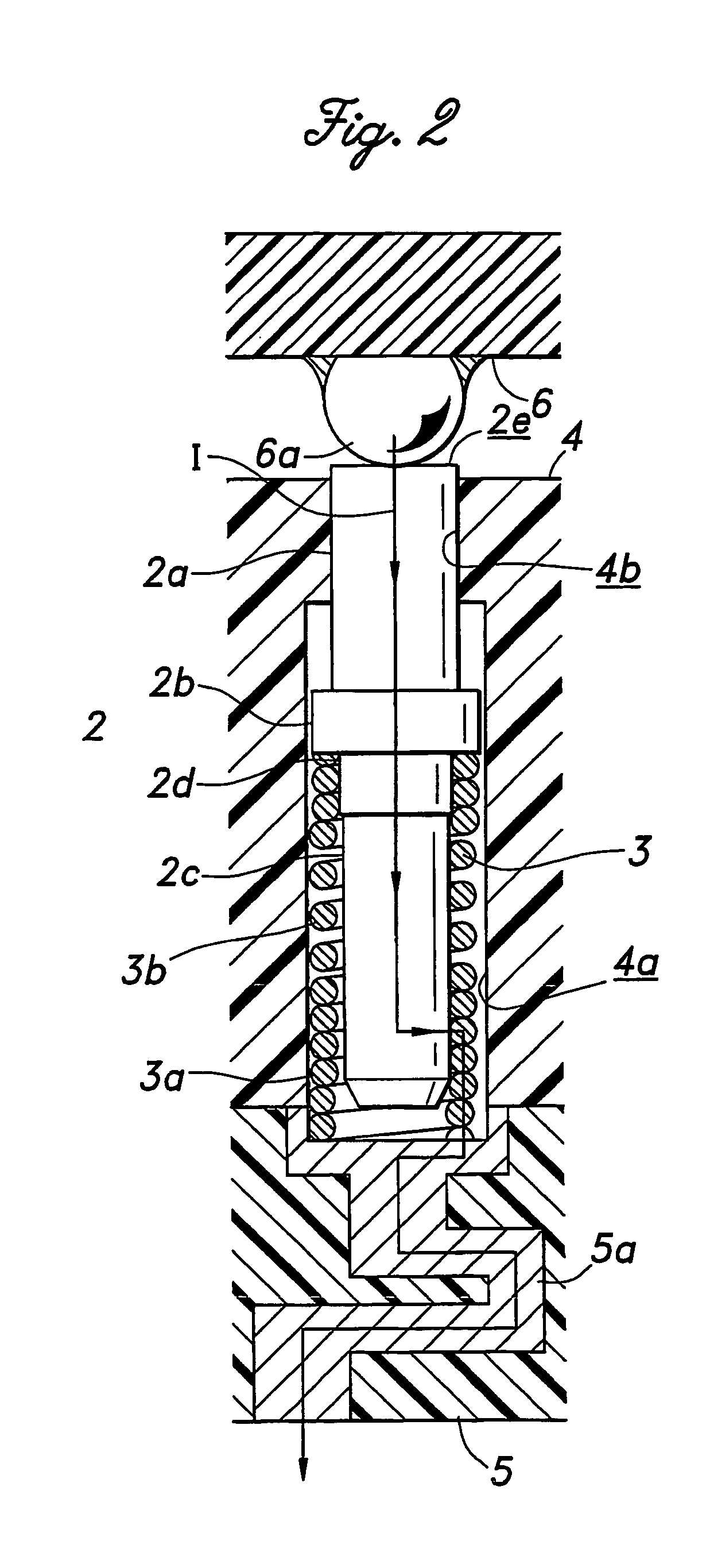

Electroconductive contact unit

InactiveUS7091734B2High hardnessHigh wear resistanceElectrical measurement instrument detailsCoupling contact membersElectrical resistance and conductanceSolder ball

In the electroconductive contact unit of the present invention, an electroconductive needle member 2 is made of a noble metal alloy having a high hardness and wear resistance, and formed with a gold plated layer 8 via a Ni under layer 7, and a flat surface 2e is formed by a tip portion thereof so as to expose the material of the needle member. Thereby, the durability of the needle member is ensured and the electroconductivity of the electric path between the needle member and coil spring is minimized on account of the gold plated layer. Even when the contact surface is soiled by solder deposition after repeated applications to contact objects such as solder balls, simply grinding the contact surface and revealing a new surface, the contact resistance between the contact surface and contact object can be kept unchanged by grinding so that the test can be conducted with the benefit of low resistance at all times.

Owner:NHK SPRING CO LTD

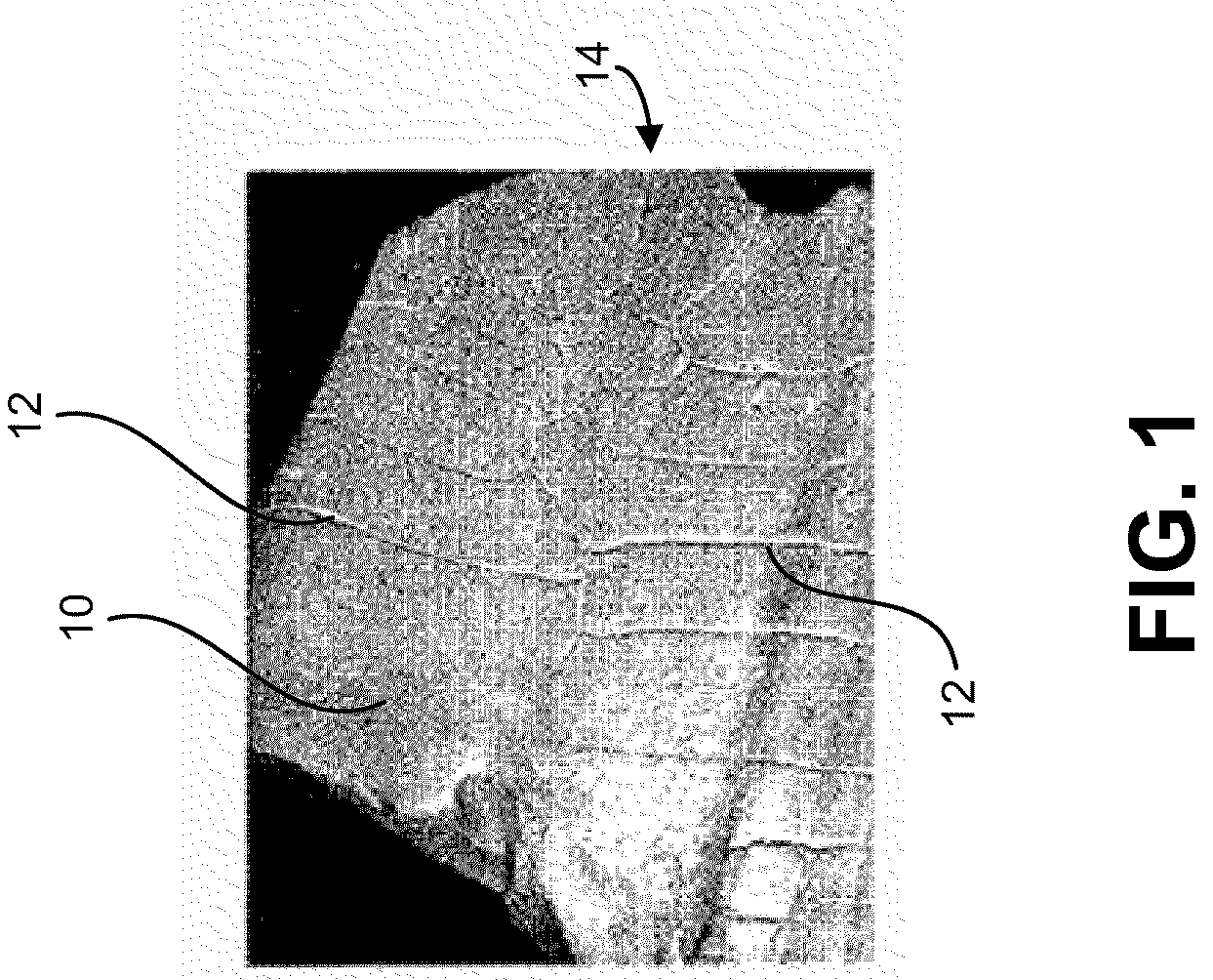

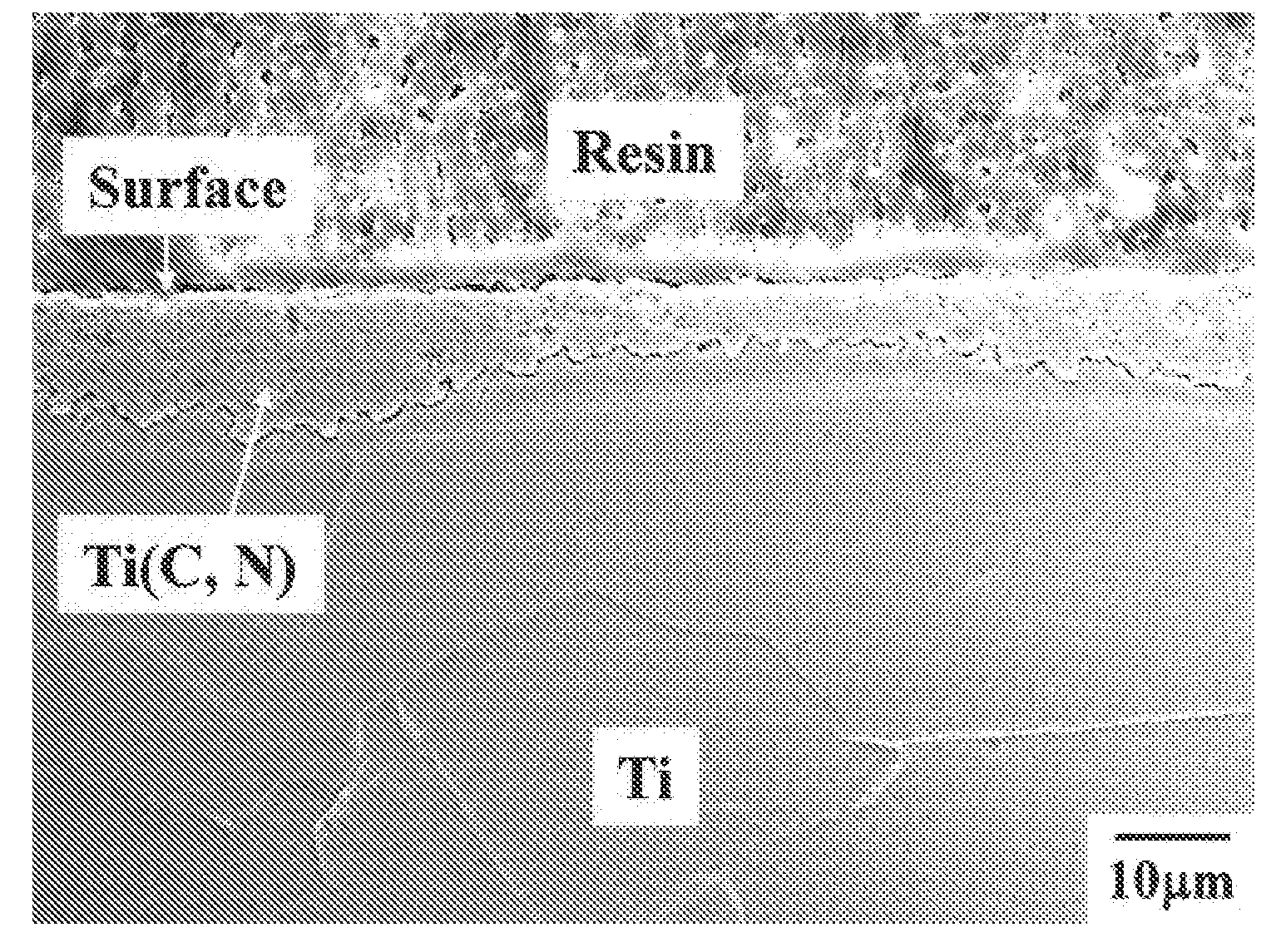

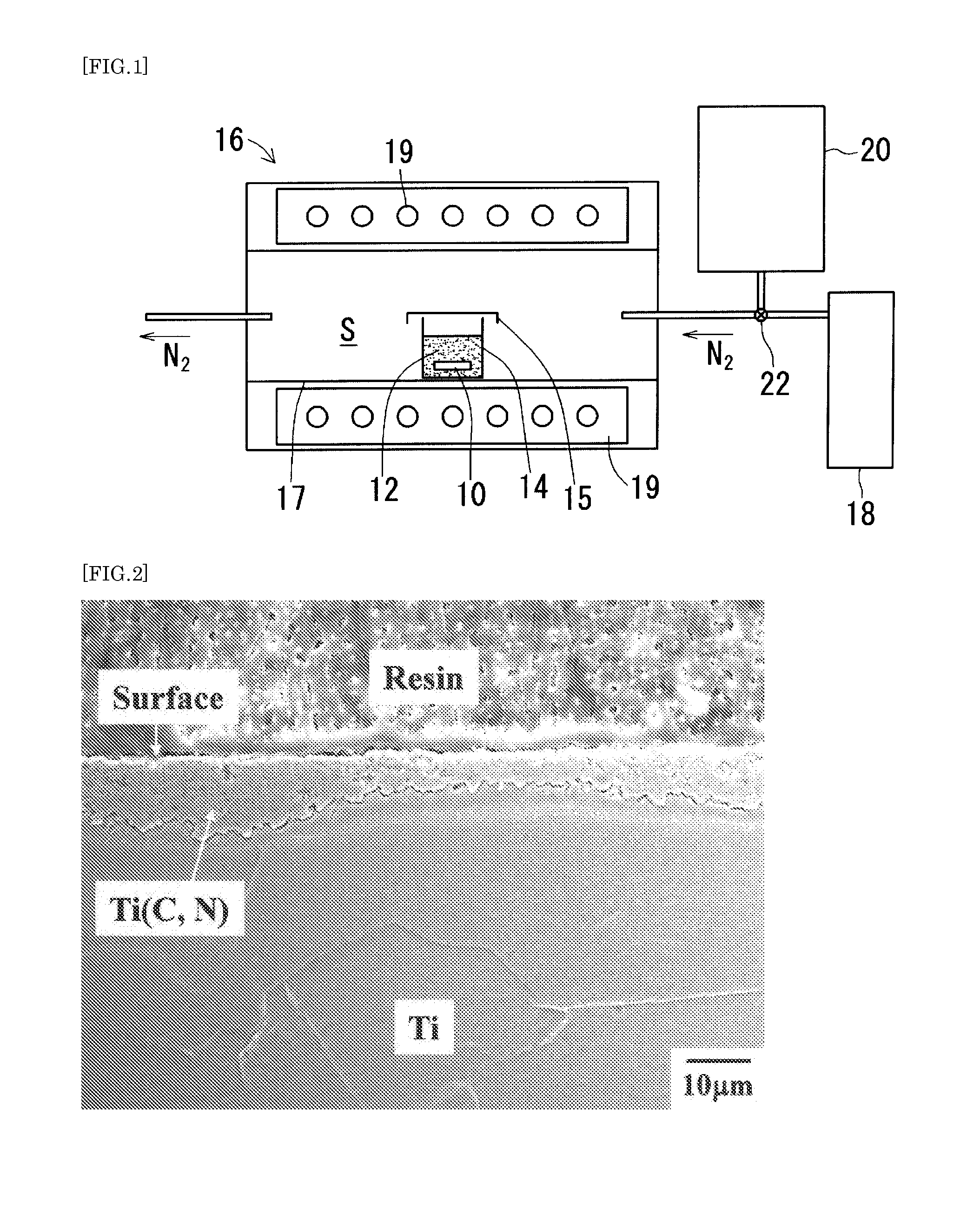

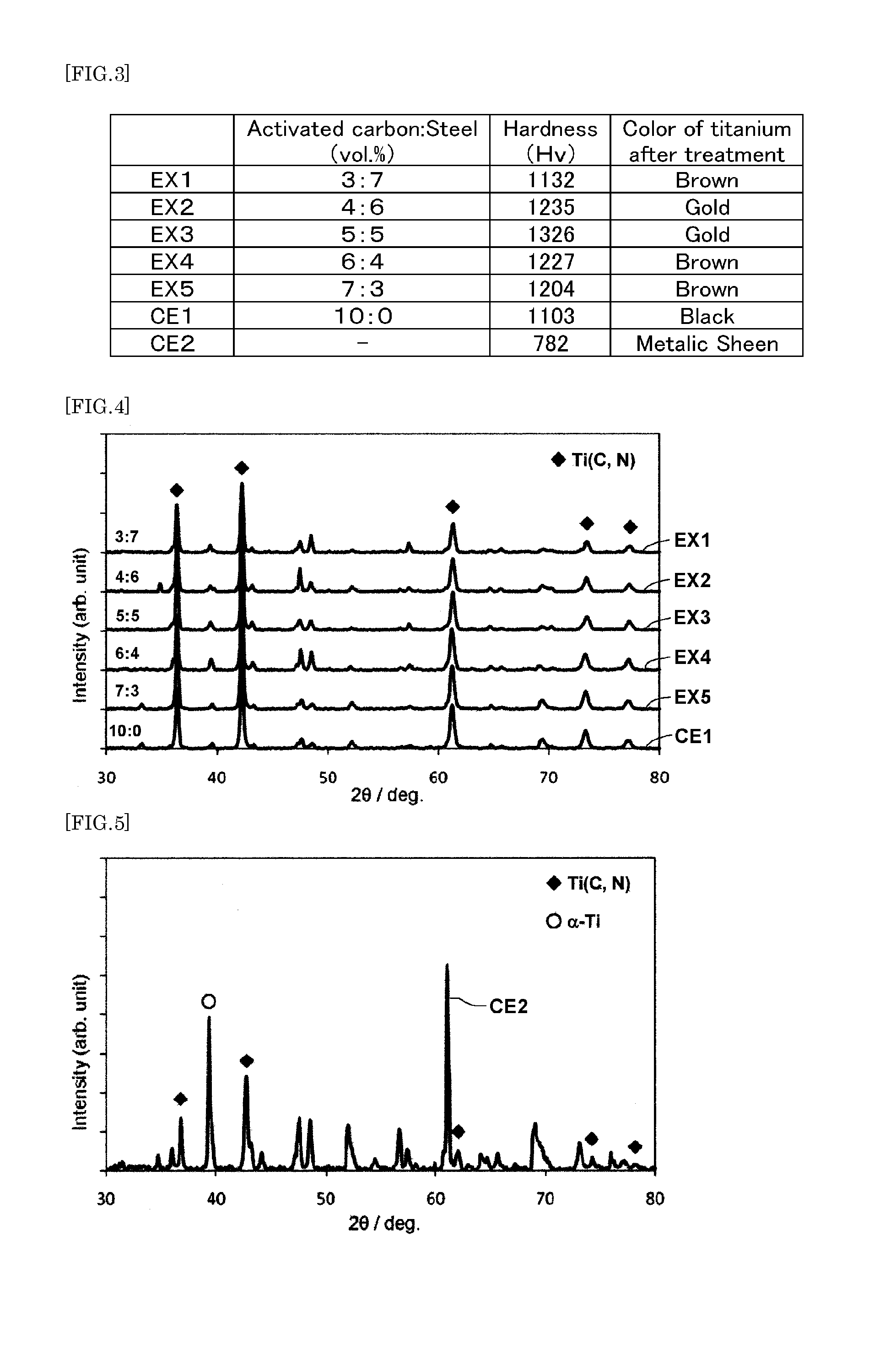

Method for treatment of metal surface, and surface-modified metal product

InactiveUS20120325373A1Improve surface propertiesLow costSolid state diffusion coatingMetal layered productsCarbon sourceNitrogen gas

Provided is a method of treating a metal surface, which can improve surface properties of a target metal, such as surface hardness and wear resistance in a simple manner and at low cost using very simple equipment alone, and which can prevent the deterioration of the metal to create high added value. The present invention is comprised of a method of treating a metal surface, characterized in that: heat-treating a target metal (10) to be surface-modified in nitrogen gas atmosphere (S), in such a state where the target metal (10) is buried in a carbon source powder (12) comprising a carbon powder and a powder of iron or an iron alloy mainly comprising iron and containing carbon, whereby the surface of the target metal (10) is at least nitrided or nitrogen-absorbed to modify the surface.

Owner:NAT UNIV CORP KUMAMOTO UNIV

Thermoplastic elastomer composition, and vibration-proof sound-proof member comprising the composition

Disclosed is a thermoplastic elastomer composition which is excellent in a vibration-proof property and a sound-proof property, and which has flexibility, wear resistance and processability at the levels required for a member (e.g., a roller) to be used in an image-forming device (e.g., a printer). The thermoplastic elastomer composition contains a butyl rubber at a ratio of 30 to 80 mass % (inclusive), and further contains 15 to 50 parts by mass (inclusive) of an olefin thermoplastic resin and 10 to 100 parts by mass (inclusive) of a hydrogenerated styrene thermoplastic elastomer relative to 100 parts by mass of the rubber component, wherein the rubber component is finely dispersed by dynamic cross-linking.

Owner:SUMITOMO RUBBER IND LTD

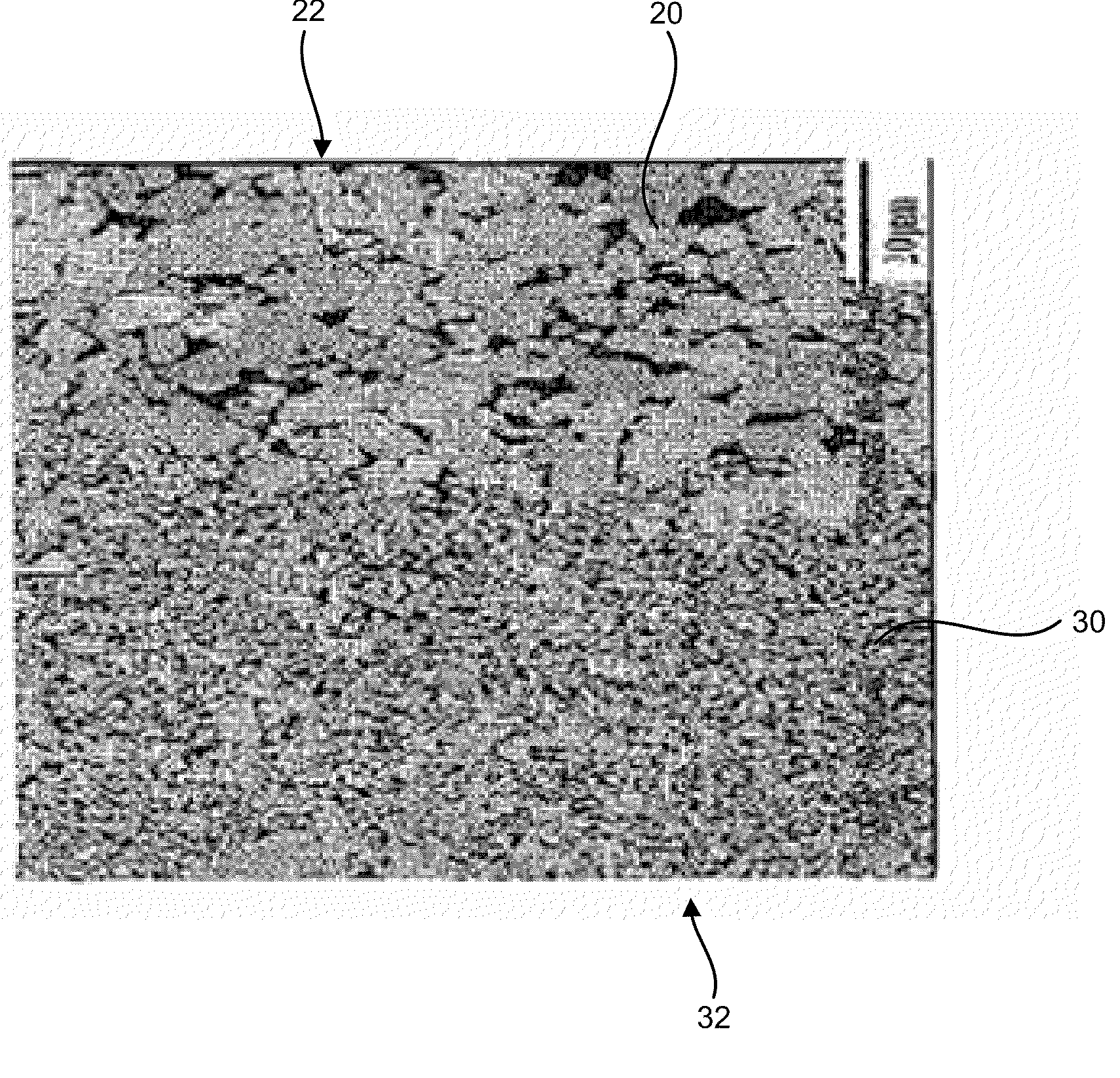

Rolling mill coil forming laying head with path or pipe having dissimilar materials composite construction

InactiveUS20130075513A1High wearLess wearAdditive manufacturing apparatusFilament handlingCurve shapeNonferrous metal

A rolling mill coil-forming apparatus includes a rotating quill that discharges elongated material into an elongated path hollow structure, such as a laying head pipe. The elongated structure is constructed of combinations of ferrous and non-ferrous dissimilar materials. Generally, non-ferrous materials are used in zones that are subject to relatively higher wear. A portion of the elongated path structure can be formed from nested, enveloping layers and / or by joining segments in axial abutting relationship. Components formed from nested layers can be constructed in many three dimensional compound curve shapes that can replicate the smooth, continuous curve elongated material transport path laying head pipes, with localized symmetrical or asymmetrical cross sections.

Owner:SIEMENS IND INC

Image forming material, color filter master plate, and color filter

InactiveUS7157193B2High sensitivityHigh resolutionPhotosensitive materialsOptical filtersImage recordingIrradiation

An image recording material provided with an image recording layer including a polymer compound which contains a functional group with a hydrophilic / hydrophobic character thereof being changeable by heat, acid, or irradiation and which is directly chemically bonded to the substrate, wherein the image recording layer is heated, treated with acid, or irradiated to change the hydrophilic / hydrophobic character of a surface of the image recording layer and organic or inorganic molecules for forming a visible image are adsorbed at regions thereof where the hydrophilic / hydrophobic character has been changed.

Owner:FUJIFILM CORP

Ceramic plate as side weir for twin drum type thin-sheet continuous casting

ActiveUS20060166808A1Accelerated corrosionHigh wearBlast furnace componentsBlast furnace detailsAluminiumThin sheet

Ceramic plates for side dams of twin-drum continuous strip casters comprising a REAG phase of 10 to 90 vol. %, a Sialon phase of 5 to 50 vol. %, a BN phase of 5 to 50 vol. % and an amorphous phase of over 0 to 20 vol. %, with the REAG phase comprising at least one rare-earth aluminum garnet phase selected from YAG, ErAG, YbAG and DyAG phases and the Sialon phase having a chemical formula, Si6-zAlzOzN8-z, wherein Z is between 0.05 and 1.9.

Owner:NIPPON STEEL CORP

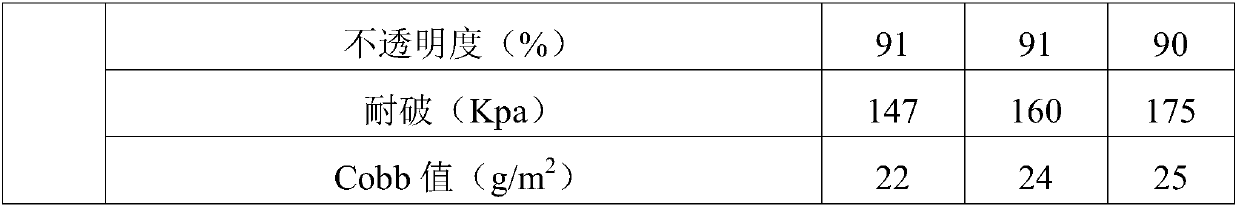

Production method of lightweight paper

InactiveCN109680536AHigh yieldHigh opacityWater-repelling agents additionChemical and mechanical pulp mixtureSulfatePaper manufacturing

The invention discloses a production method of lightweight paper. The production method comprises a wood pulp proportioning step and a mixing step. Needle BCMTP chemimechanical pulp and needle bleached chemical wood pulp are proportioned and pulped; a neutral sizing agent, cationic starch, cationic polyacrylamide and talcum powder are used; then a paper manufacturing process is performed. Importedneedle wood pulp and broadleaf wood bleached sulfate pulp are respectively pulped and blended, and various additives are added; the blend is conveyed into an approaching system for dehydration forming through a wet part and then is further dehydrated through a squeezing part; after pre-drying, semi-dry calendaring and surface sizing are performed, the product is dried through a drying part; the product is baked at low temperature, subjected to soft calendaring finishing and wound. First of all, high bulkiness is achieved, and the flatness and the tensile strength of paper are not affected, sothe production method is suitable for high-speed printing; secondly, no flourescent brightener is contained; compared with common coated paper, offset paper and lightweight paper, the lightweight paper produced according to the method is relatively dark and has a color close to the primary color of wood pulp, so that visual fatigue cannot be caused by long-time reading.

Owner:SHANDONG TIANYANG PAPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com