Double-parallel-flexible-hinge-based tool rest driving platform of super-precision machining lathe

An ultra-precision machining, flexible hinge technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of complex structure, low resolution and low precision of the drive platform, and achieve smooth and continuous movement. Sensitivity reduction, high wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

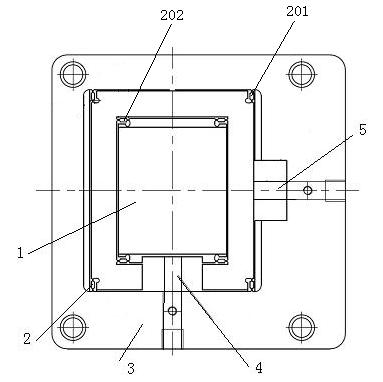

[0015] The tool rest workbench 1, the hinge group 2 and the tool rest mounting base 3 are of an integrated structure. The hinge group 2 includes an X-direction double parallel four-bar flexible hinge mechanism 201, a Y-direction double parallel four-bar flexible hinge mechanism 202, and an X-direction double parallel four-bar flexible hinge mechanism 202. The double parallel four-bar flexible hinge mechanism 201 is fixedly connected to the tool holder mounting base 3, the Y-direction double parallel four-bar flexible hinge mechanism 202 is fixedly connected to the tool holder table 1, and the free end of the X-direction piezoelectric driver 5 is connected to the X-direction double parallel four-bar flexible hinge mechanism 201. The rod flexible hinge mechanism 201 is connected to the top, the fixed end of the X-direction piezoelectric driver 5 is fixedly connected to the tool holder installation base 3, the free end of the Y-direction piezoelectric driver 5 is connected to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com