Device and method for detecting cutting tool state

A state detection device and state detection technology are applied in manufacturing tools, measuring/indicating equipment, positioning measurement in boring machines/drilling machines, etc., which can solve problems such as increasing non-processing strokes and affecting drilling speed, and achieve faster drilling speed , The effect of shortening the non-processing stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The implementation of the present invention will be described through specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

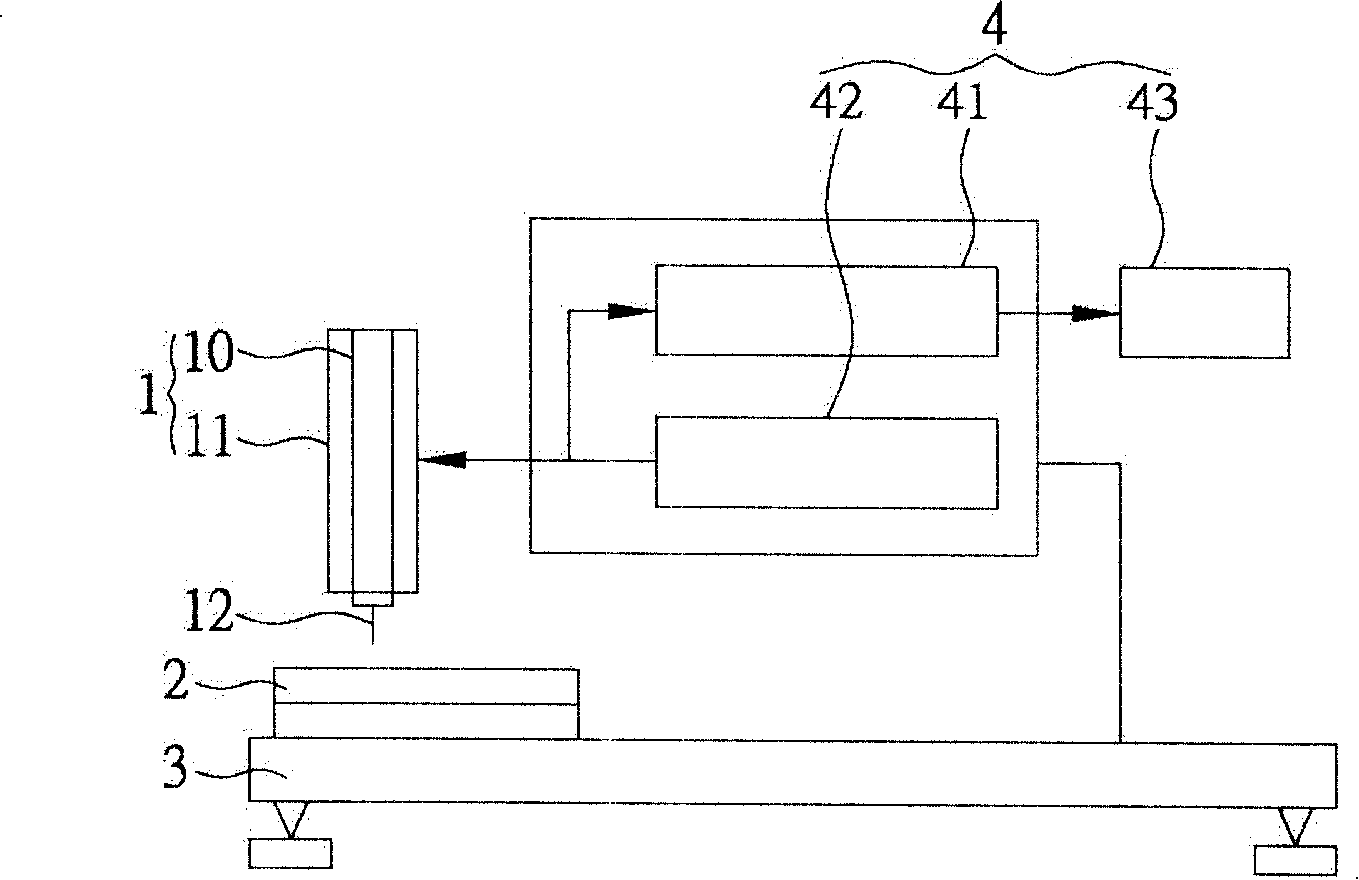

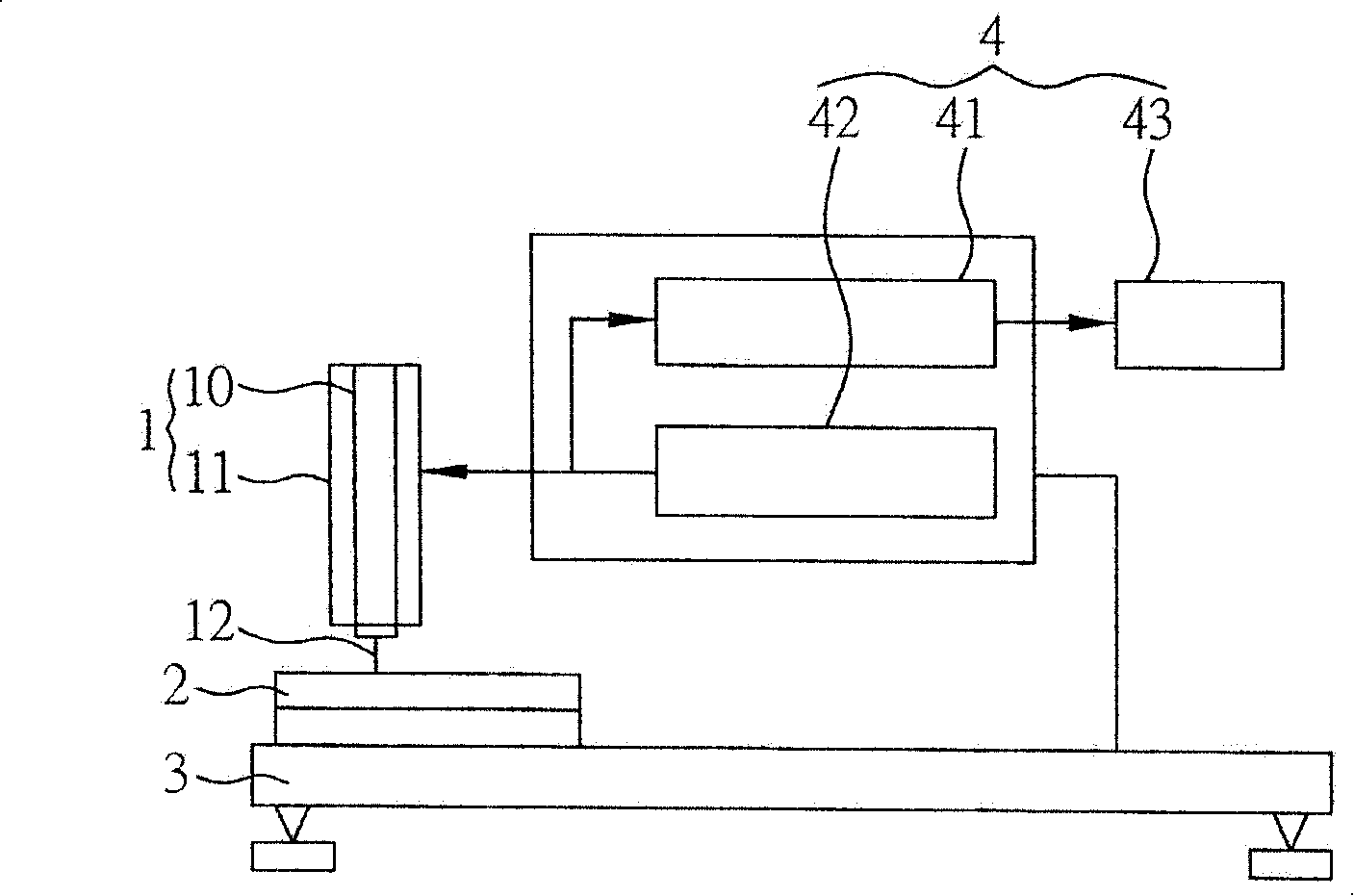

[0050] see Figure 1 to Figure 3 , is a specific embodiment of the tool state detection device and method of the present invention. In this embodiment, the application to the drilling operation is taken as an example, so the drill pin is used to represent the tool, but those skilled in the art can understand that the present invention is not limited to the application in the drilling operation, and the tool referred to is not a drill pin limit.

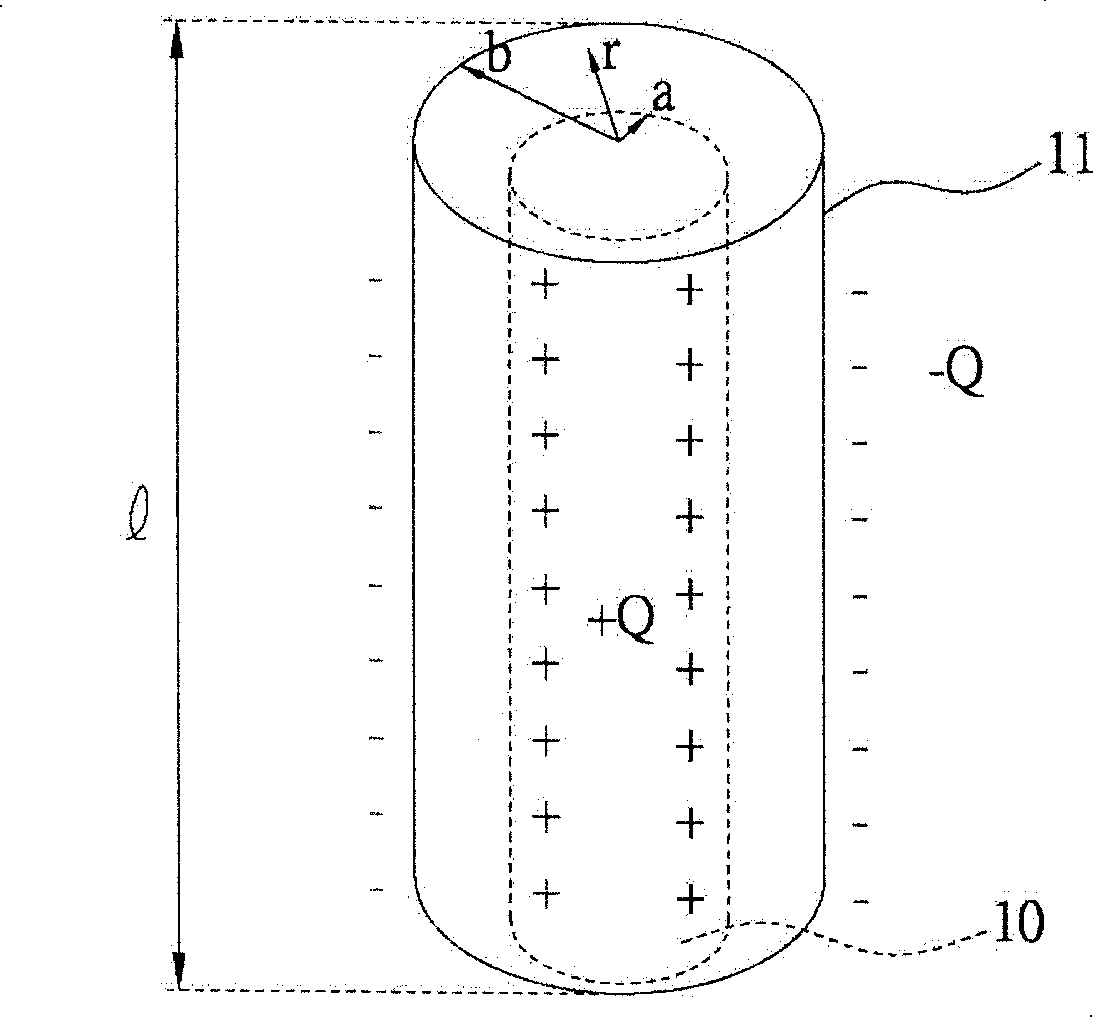

[0051] Such as figure 1 As shown, the spindle motor 1 has a central rotor 10 and a housing 11 surrounding the central rotor 10 . When the center rotor 10 is running, the spindle motor 1 introduces air between the center rotor 10 and the housing 11 to insulate the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com