Wave-shaped lip oil seal with backflow stripes at lip opening and three-dimensional modeling method

A technology of reflow pattern and lip, which is applied in the field of corrugated lip oil seal and 3D modeling, and can solve problems such as not widely used, easy to wear, complex structure of the lip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

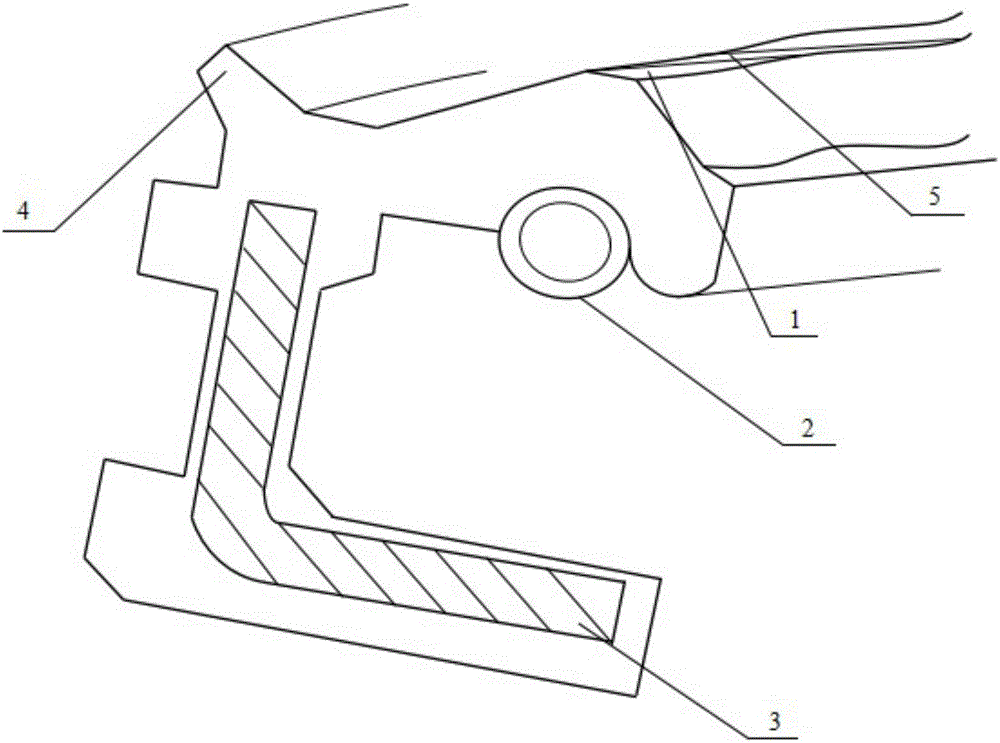

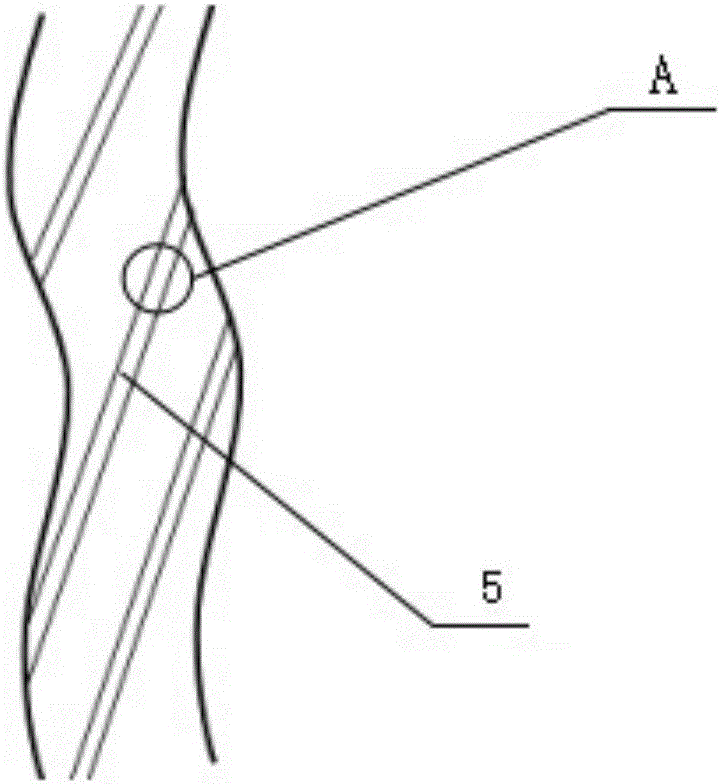

[0056] Such as Figure 1 to Figure 4 As shown, this embodiment provides a corrugated lip oil seal with reflow lines on the lip. The corrugated lip oil seal includes a rubber body, a metal frame 3, a sealing lip 1 with reflow lines, a spring 2 and a dust-proof lip 4; The surface of the lip 1 includes an air side lip side 13, a lip surface and an oil side lip side 15, and a reflow pattern 5 is arranged on the lip surface, and the lip surface is mainly composed of the lip base surface 14 and the lip surface. The base surface 14 is composed of a reflow cylinder surface, wherein the lip base surface 14 is a ruled surface surrounded by two closed sinusoidal curves of the same shape on the same cylindrical surface, the air side lip side 13 and the oil The side lip side surfaces 15 are ruled surfaces formed by two boundary sinusoidal curves of the lip base surface 14 and closed sinusoidal curves with equal period, phase and amplitude on the other two cylindrical surfaces.

[0057] Wh...

Embodiment 2

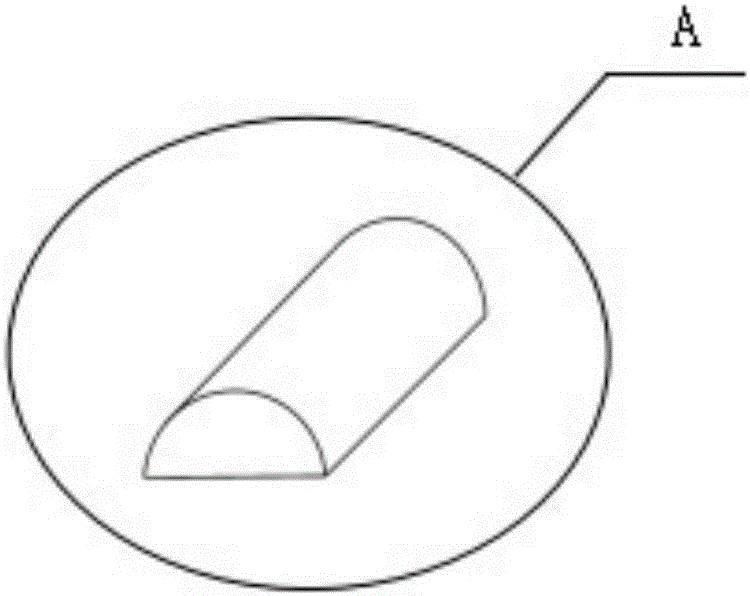

[0061] A corrugated lip oil seal with reflow lines on the lip, the structure is as described in Example 1, the difference is that: the helical angle of the outwardly convex reflow lines 5 is 5°, and the normal cross section of the outwardly convex reflow lines 5 is an arc Shaped surface, the height is 0.1mm, and the groove width between adjacent convex reflow lines is 0.35mm.

[0062] Wherein, the width of the lip base surface 14 is 0.6 mm, that is, the axial distance between the two closed sinusoidal curves constituting the lip base surface is 0.6 mm.

Embodiment 3

[0064] Such as Figure 4 to Figure 7 As shown, a three-dimensional modeling method of a corrugated lip oil seal with reflow lines on the lip as described in Example 1, the corrugated lip oil seal is mainly composed of air side cylinder 12, air side lip side 13, lip base surface 14. The oil side lip side 15, the oil side cylindrical surface 16 and other simple curved surfaces (cylindrical surface, torus) constituting the oil seal, wherein the lip base surface 14 is composed of a cylindrical sine curve a9 and a cylindrical sine curve b8 The oil side lip side 15 is surrounded by the cylindrical sine curve b8 and the cylindrical sine curve c7, the oil side cylinder 16 is surrounded by the cylindrical sine curve c7 and the circle d6, and the air side lip side 13 is surrounded by the cylindrical The sinusoidal curve a9 is surrounded by the cylindrical sinusoidal curve f10, and the air-side cylinder 12 is surrounded by the cylindrical sinusoidal curve f10 and the circle e11.

[0065...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Helix angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com