Patents

Literature

185 results about "Solid modeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid modeling (or modelling) is a consistent set of principles for mathematical and computer modeling of three-dimensional solids. Solid modeling is distinguished from related areas of geometric modeling and computer graphics by its emphasis on physical fidelity. Together, the principles of geometric and solid modeling form the foundation of 3D-computer-aided design and in general support the creation, exchange, visualization, animation, interrogation, and annotation of digital models of physical objects.

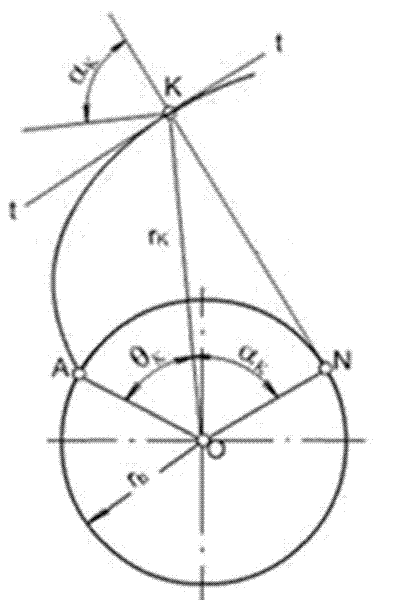

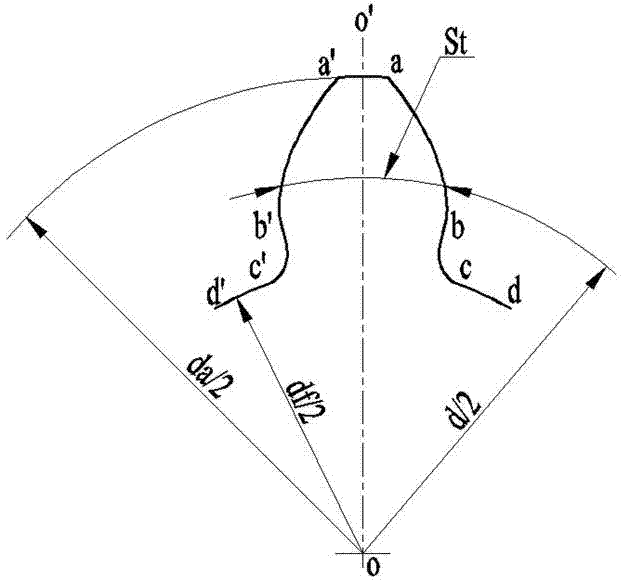

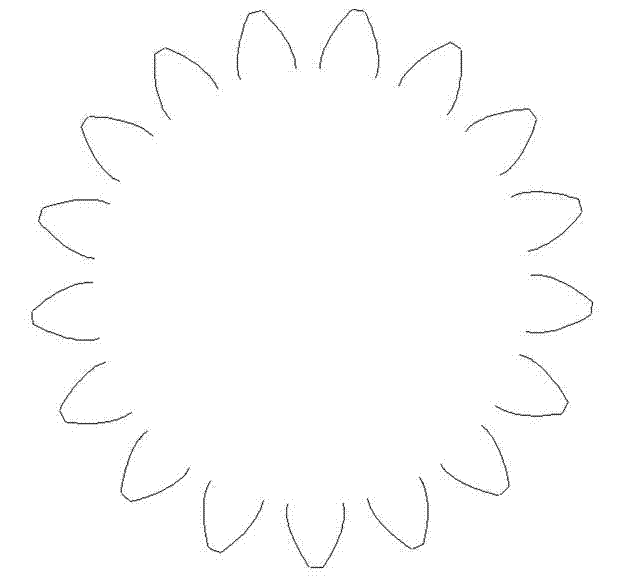

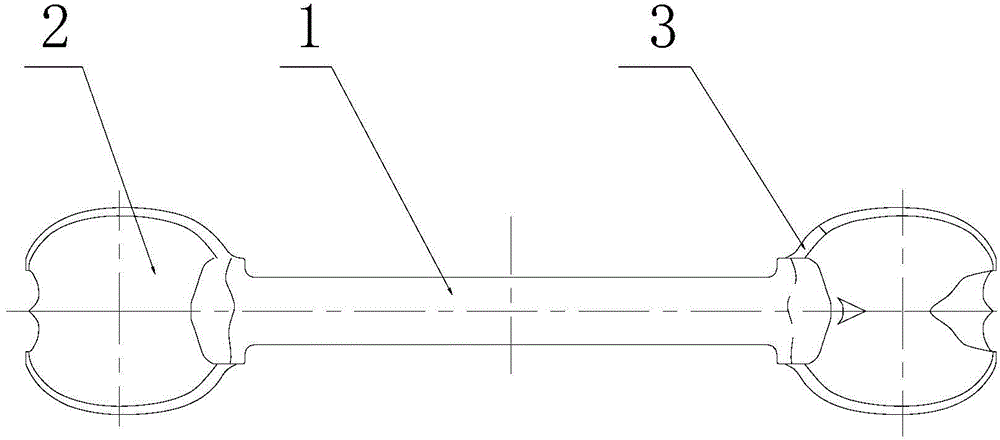

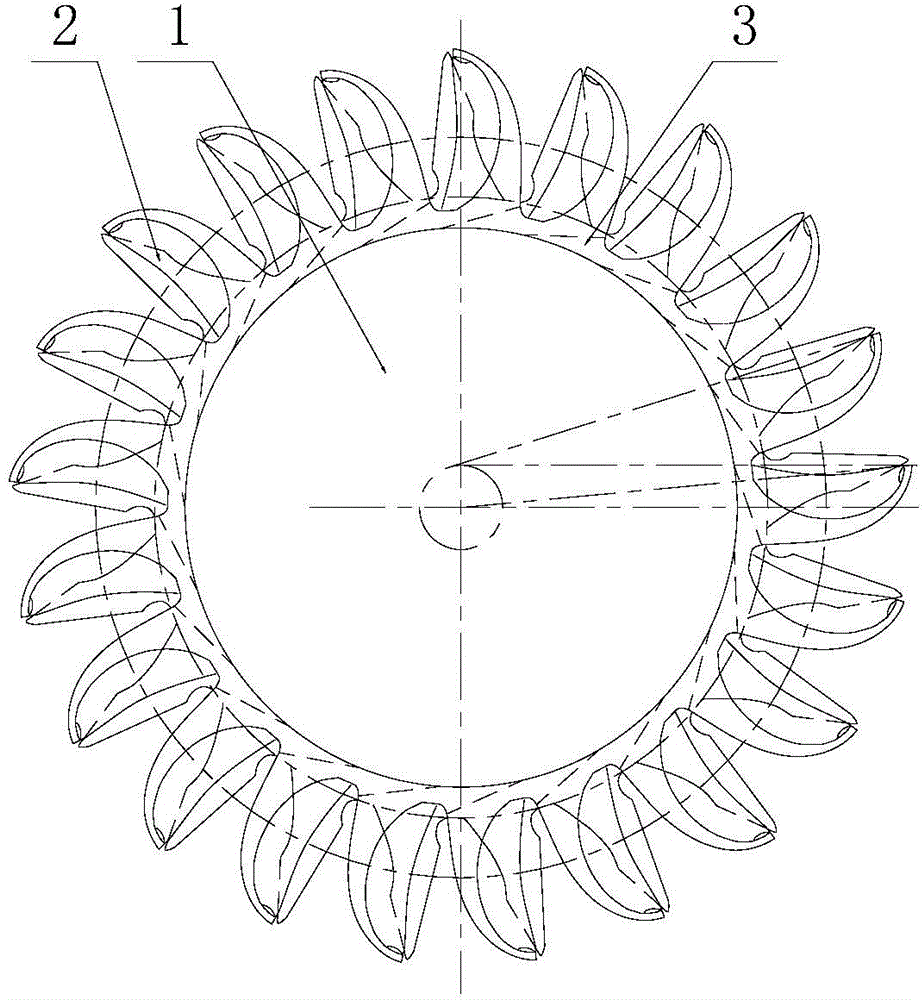

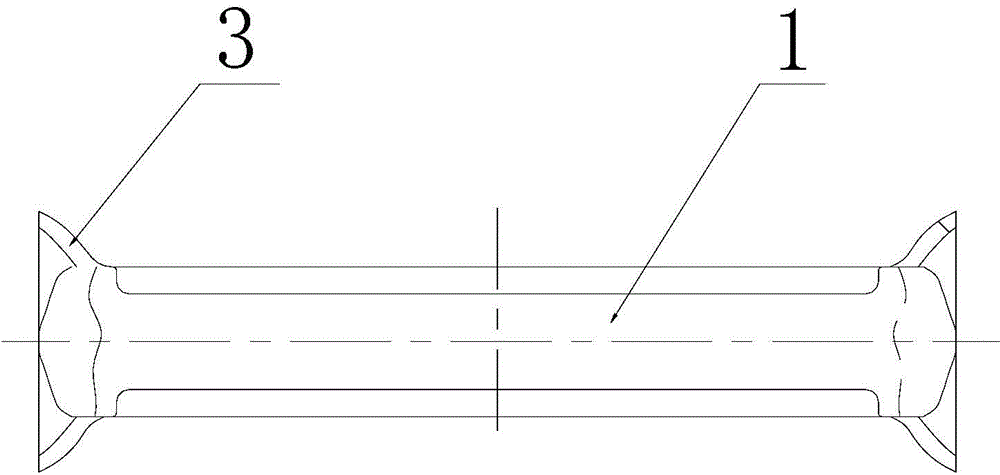

Involute straight tooth cone gear trimming method

InactiveCN101937211AExtend your lifeCompensation for deformationProgramme controlComputer controlNumerical controlStress distribution

The invention provides a technical scheme, in particular an involute straight tooth cone gear trimming method. The method comprises the following steps of: determining a tooth trimming position, a trimming quantity and a tooth profile quantity; solving for a spherical space involute Decare coordinate equation; generating a spherical involute in three-dimensional modeling software, forming a spherical involute plane through curve filling, and realizing straight tooth cone gear solid modeling on the basis of the spherical involute; forming a tooth trimming profile on the central cross section of the gear, and isometrically stretching the profile to the tooth surface to realize tooth isometric trimming; carrying out tooth top arc trimming on the tooth profile; and converting a trimming gear model into a digital control code imported into a digital control machine tool to realize the processing of the trimming cone gear. The invention better controls the stress distribution of the gear through controlling the position and the trimming quantity of the isometric trimming so as to compensate the deformation of the gear and reduces the sensitivity of a cone gear pair to errors and load changes as well as improves the transmission precision of the cone gear pair, reduces the vibration and the noise and prolongs the service life of the gear.

Owner:UNIV OF JINAN

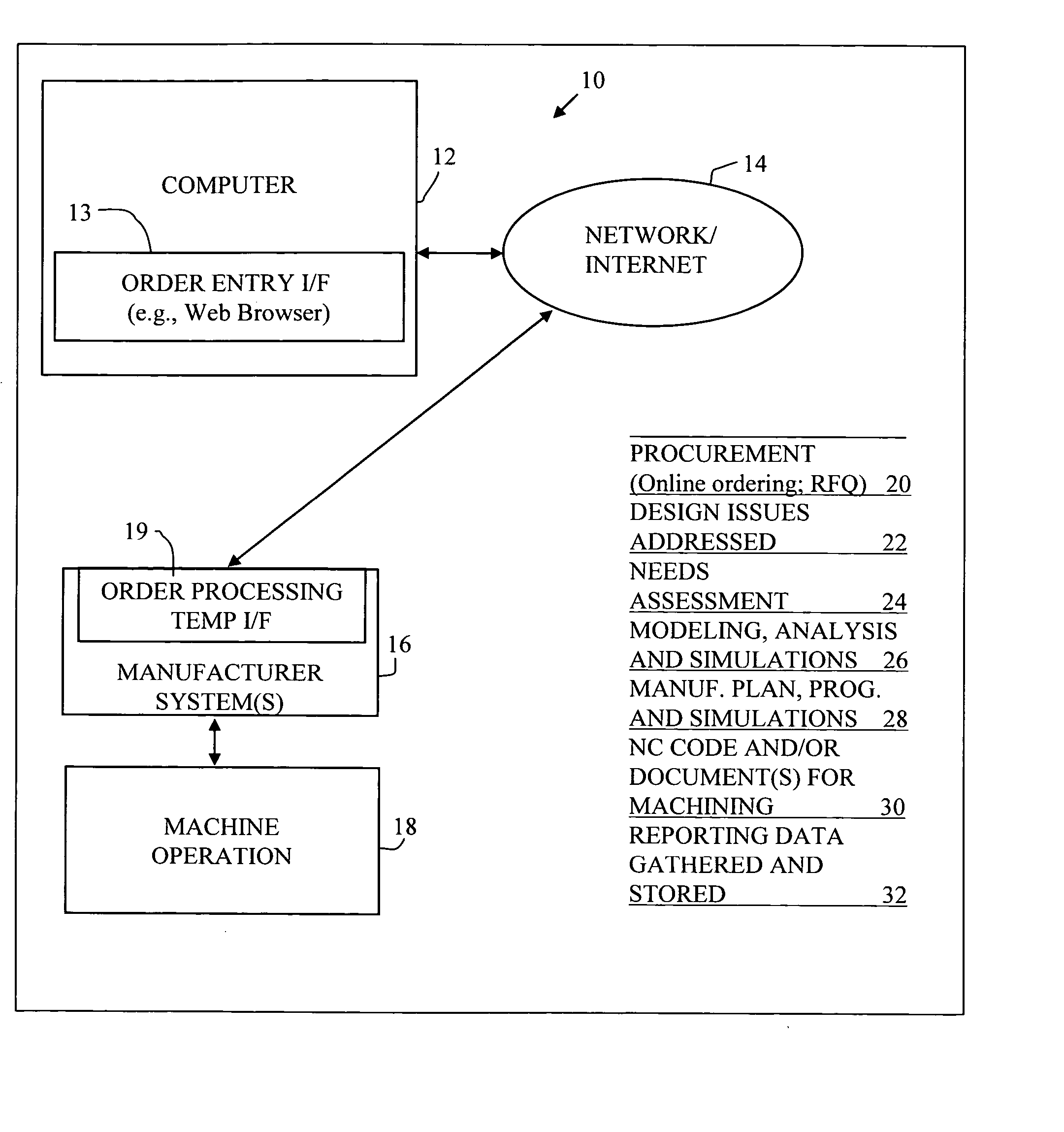

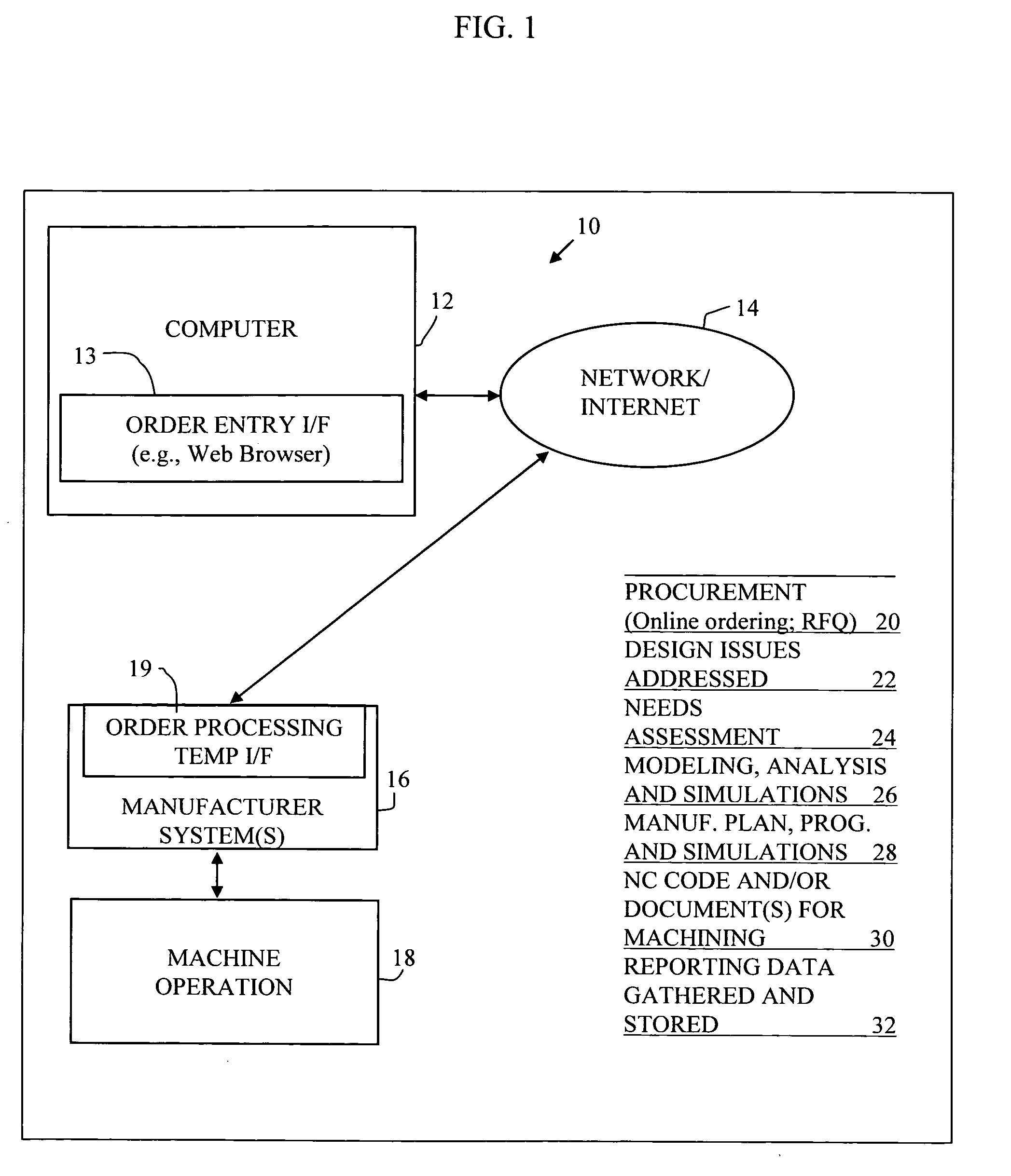

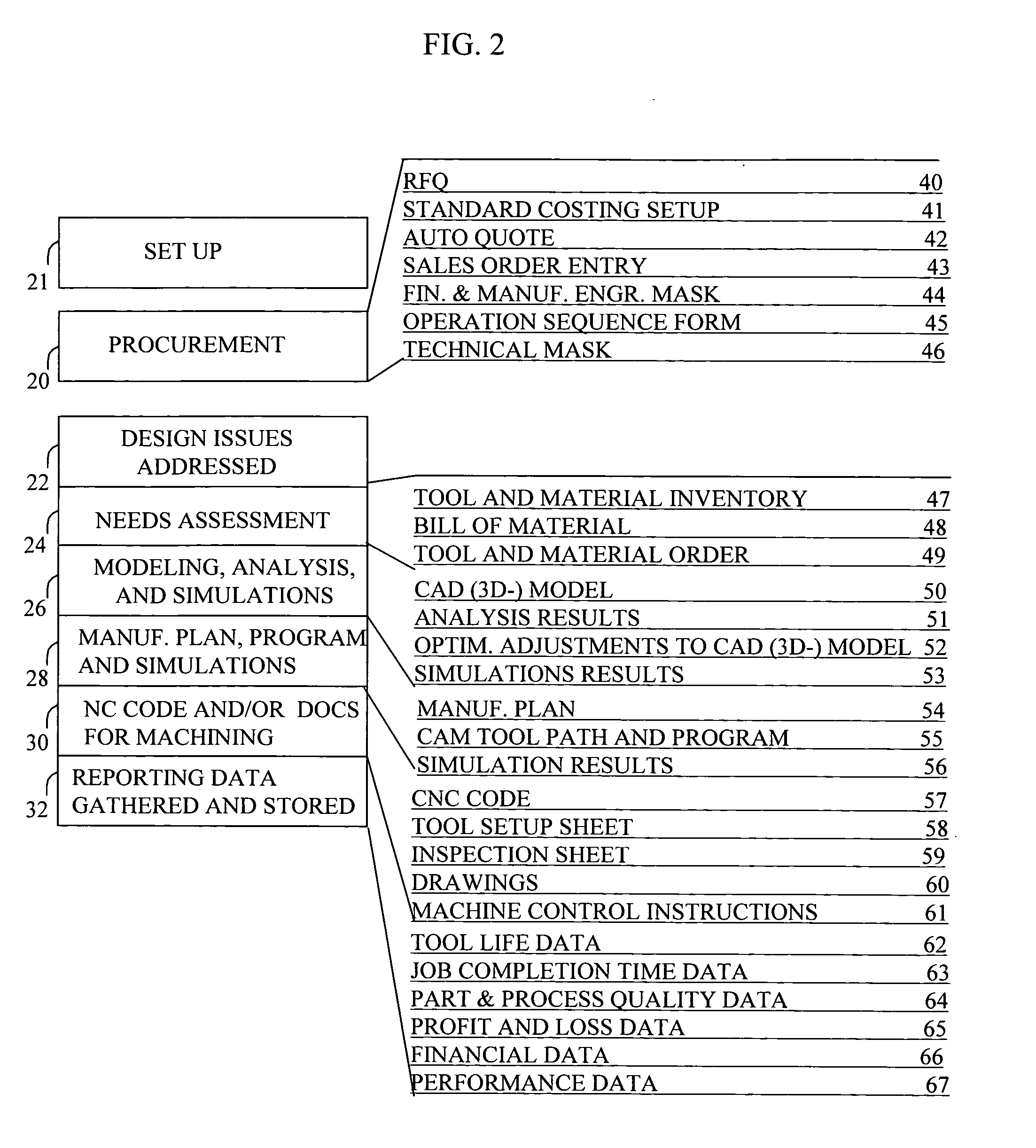

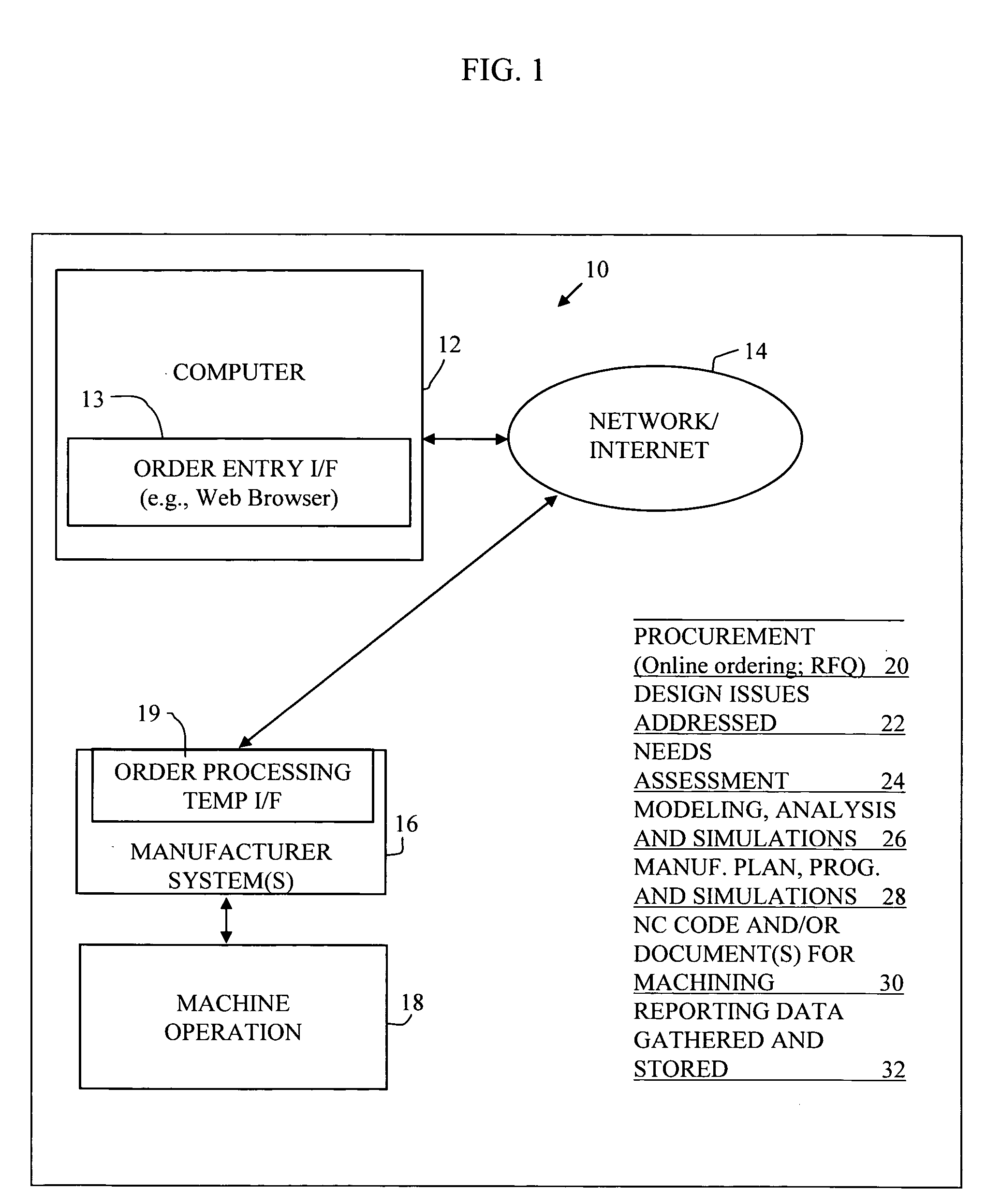

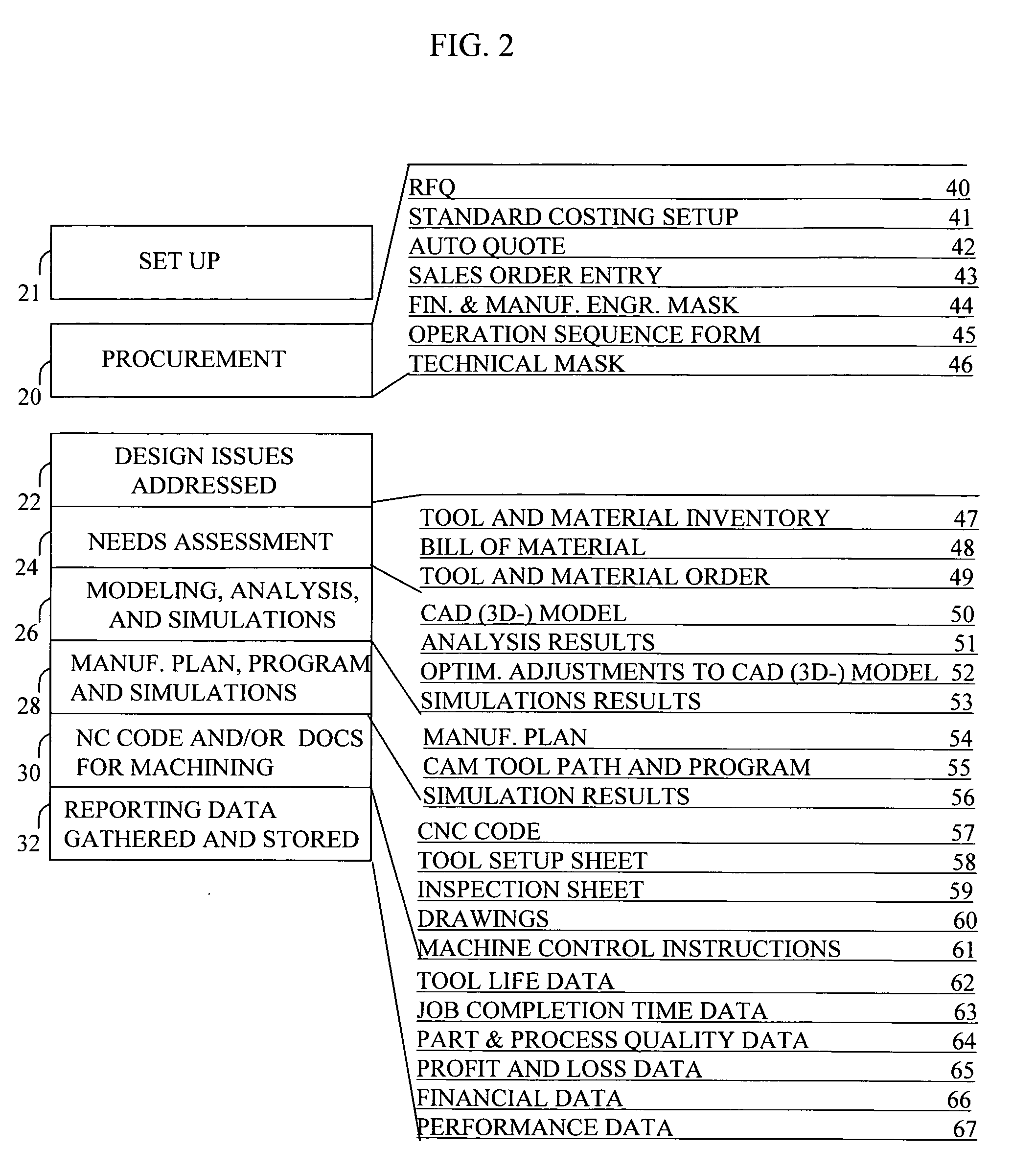

Automated planning and manufacturing systems

InactiveUS20060129462A1Increased riskImprove product qualityBuying/selling/leasing transactionsOrder formOrder processing

A system is provided for part ordering, design, and manufacturing. A manufacturer computer system is provided which comprises a parametric design mechanism to specify geometries of the part with parameters, an intelligent geometry portion, a 3D solid modeling function, and one or more simulation components. The intelligent geometry portion determines machining cycles to manufacture the part. Part-related databases are provided, and order processing components are provided. Such part-related databases and order processing components may form part of one or both of an ERP and PLM computer system. An order processing template is provided to facilitate sales and order processing, tool planning, CA parametric modeling, computer simulation, and the generation of a factory machine program. The order processing template comprises financial and manufacturing engineering planning fields and technical fields. An order template interface, or a set of order template interfaces, is provided. This interface or set of interfaces provides, for a given ordered part, from the order template, CA-specific information to the manufacturer computer system before the manufacturer computer system performs any CAD modeling or CAE calculation of the part. The interface or set of interfaces further provides, for the given ordered part, from the order template, ERP-specific information to the ERP system before the ERP system performs any scheduling of machines and resources, material reservation, or RFQ calculations.

Owner:PANKL GEROLD +1

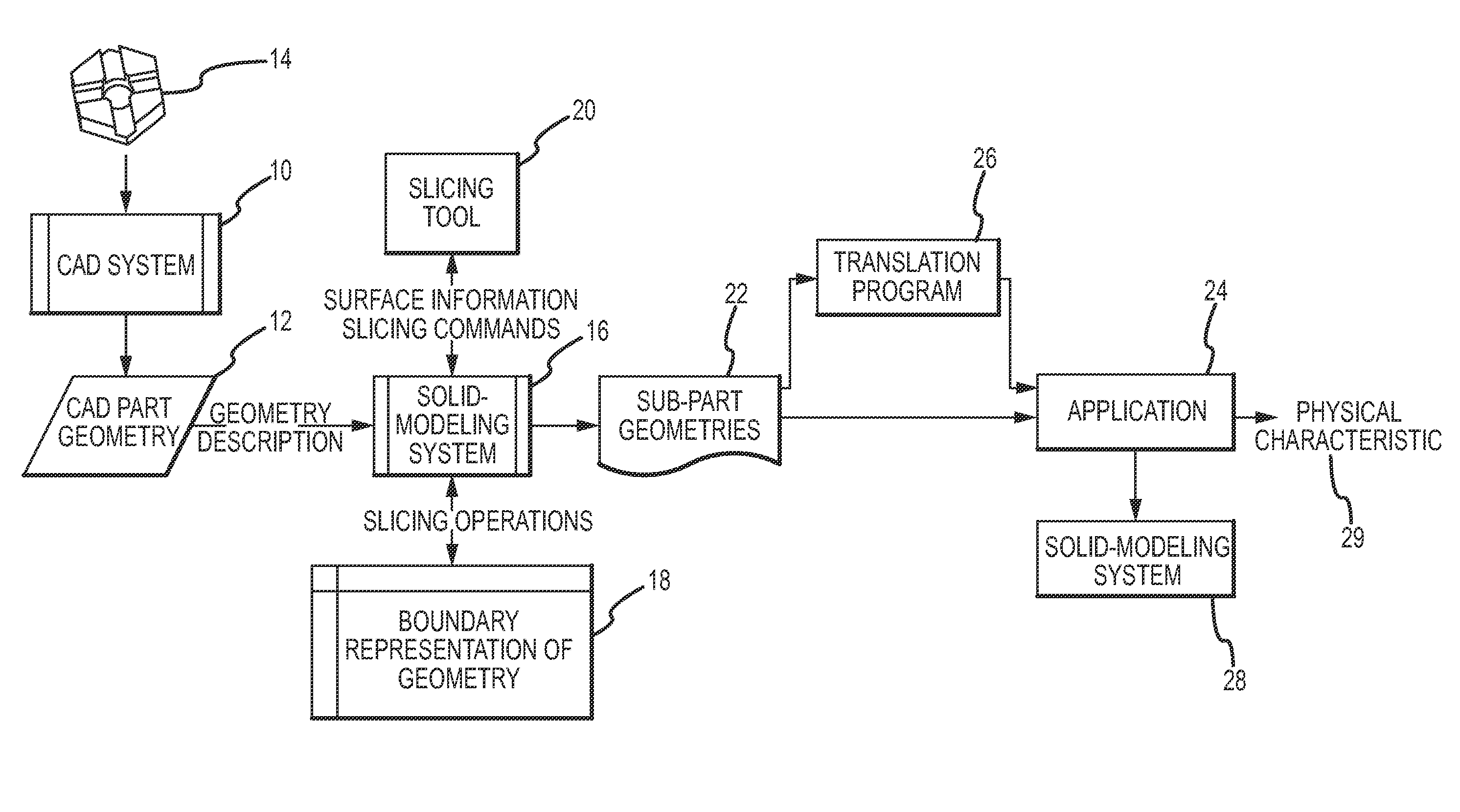

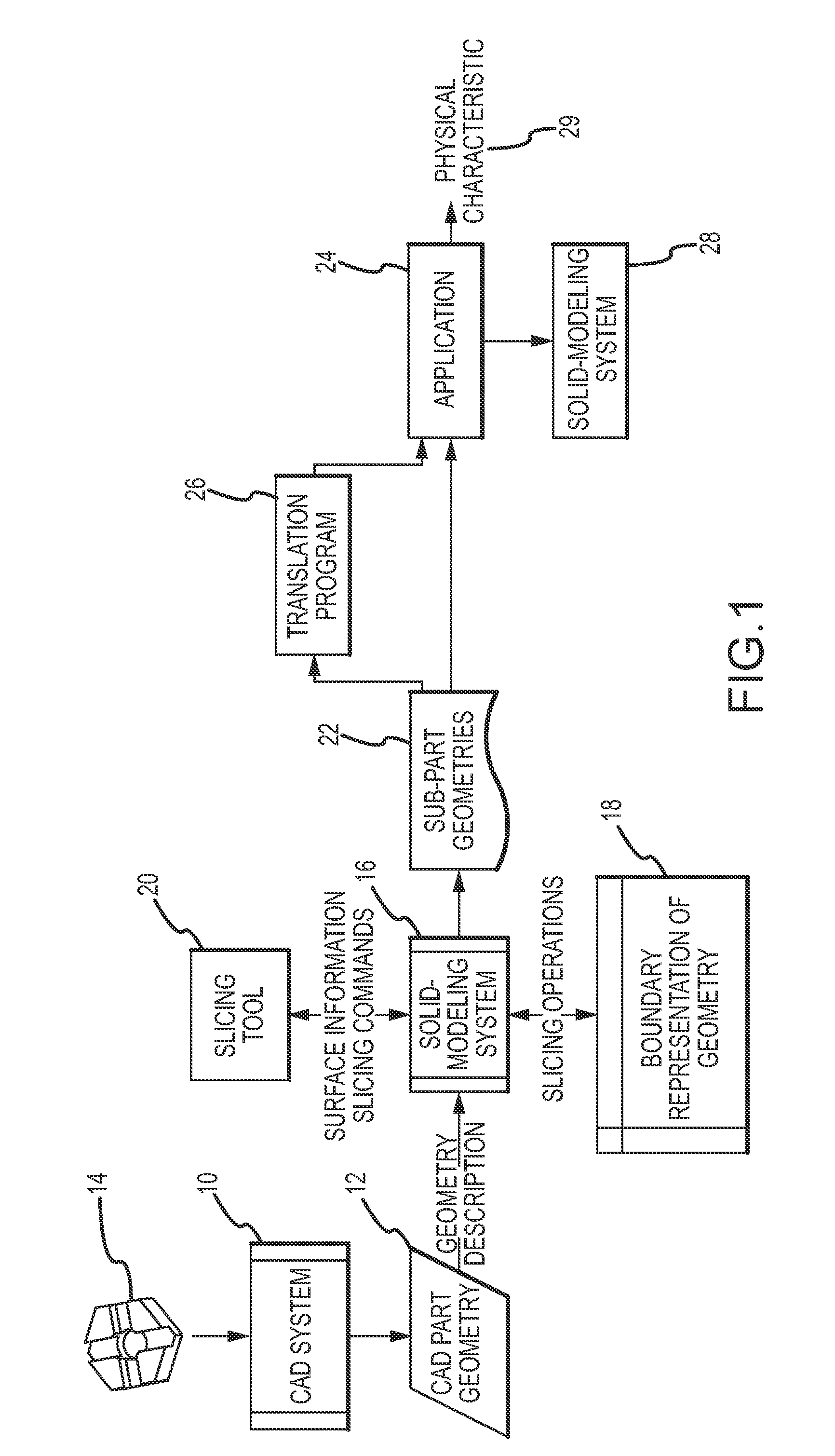

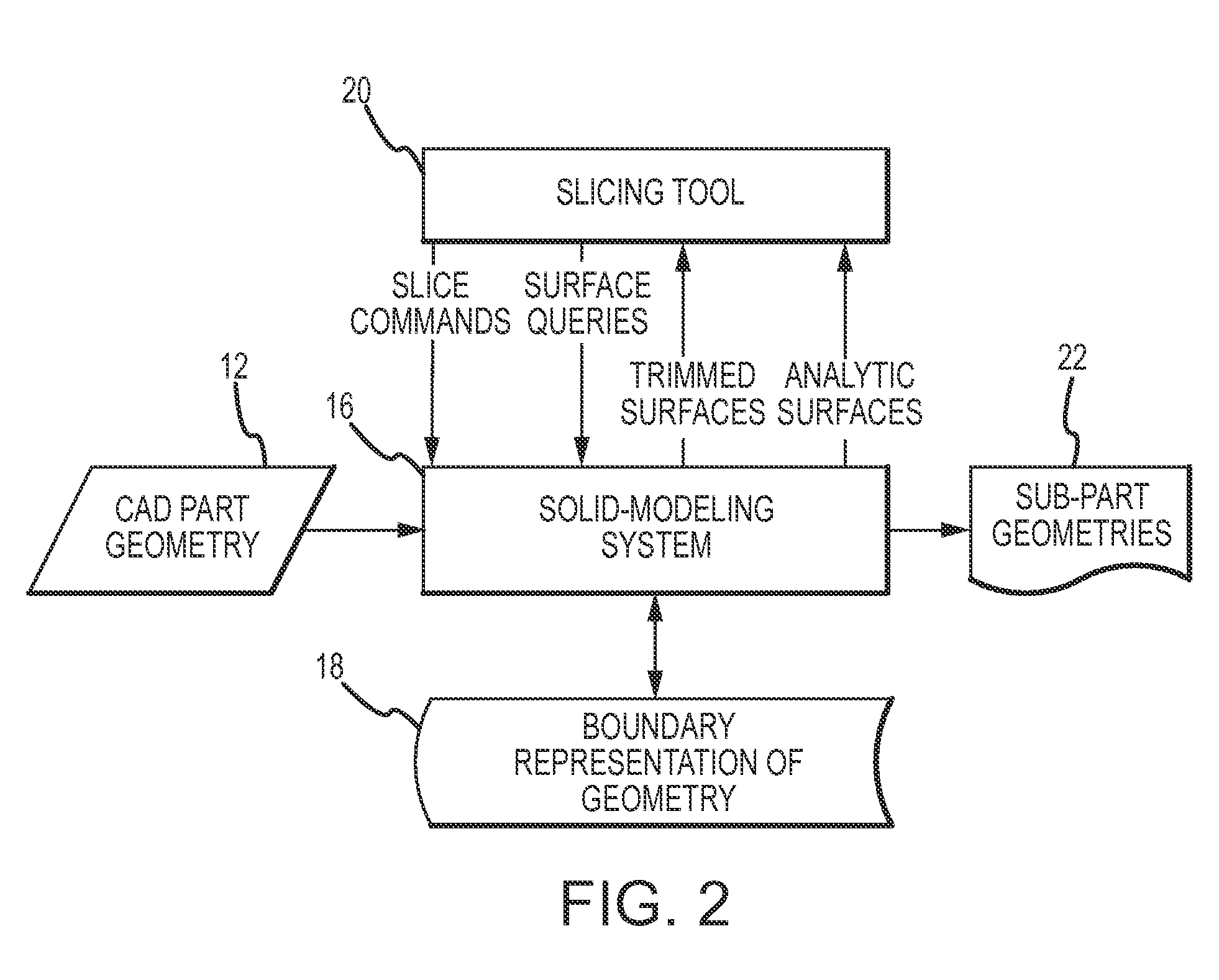

System and method for partitioning CAD models of parts into simpler sub-parts for analysis of physical characteristics of the parts

ActiveUS7733339B2Reduce complexityConstraint-based CADSpecial data processing applicationsAlgorithmTheoretical computer science

A slicing tool works with a solid modeling system to partition the geometric representation of a three-dimensional part into a series of simpler sub-parts the union of which replicates the original part in a manner that introduces a minimal number of new surfaces in each sub-part and in total. This approach uses the existing analytic surfaces that define the part geometry to partition the part and selects a partition from a quality metric based on the number of trimmed surfaces of the part being partitioned and the candidate sub-parts. This approach greatly reduces the complexity of any downstream solid modeling applications that perform combinatorial surface operations on the geometric representation of the series of sub-parts to analyze physical characteristics such as radiation, mechanical, optical, thermal, structural or biological of the original part.

Owner:RAYTHEON CO

Gear load wireless monitoring system and interactive multi-stage gear physical simulation method finished based on same

ActiveCN102542105AMaster the law of forceImprove practicalityMachine gearing/transmission testingSpecial data processing applicationsWireless transmissionElement analysis

The invention belongs to the technical field of gear detection and measurement, in particular relates to a gear load wireless monitoring system and an interactive multi-stage gear physical simulation method finished based on the same. The invention overcomes the defects and limitations of the existing gear monitoring and simulation method. The gear load wireless monitoring system comprises an upper computer and a lower computer, wherein the lower computer is internally arranged on a measured gear structure, and the lower computer with a wireless transmission function is in wireless transmission with the upper computer. The interactive multi-stage gear physical simulation method comprises the following steps of: detecting an external field; carrying out gear solid modeling, and carrying out grid partition on the gear solid model by adopting swept mapping; setting boundary conditions; carrying out finite element analysis; and verifying the data subjected to finite element analysis and actual measurement. According to the invention, wireless data transmission and load identification testing schemes are used for correcting the error of CAE (Computer Aided Engineering) analysis so as to master the stress rule of the gear, thereby providing a basis for fatigue life prediction. The system and method provided by the invention have higher practical and economic values.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

3D (three-dimensional) printing based processing technique of automobile styling concept model

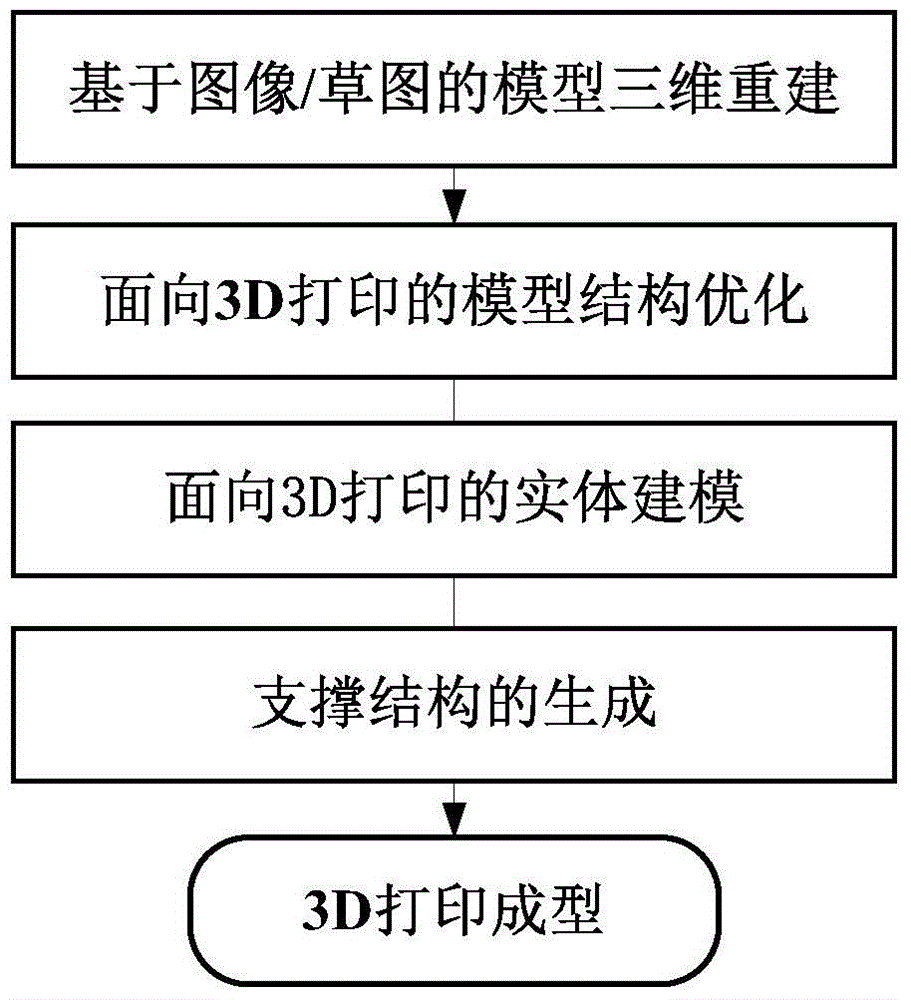

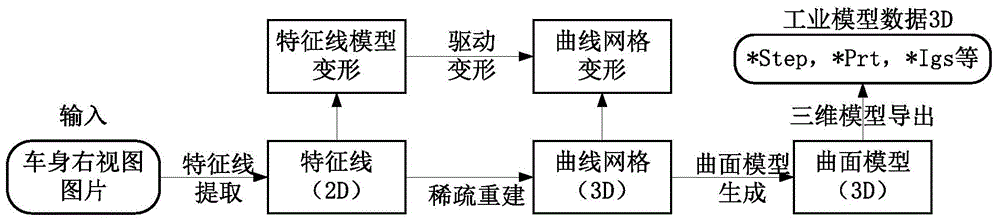

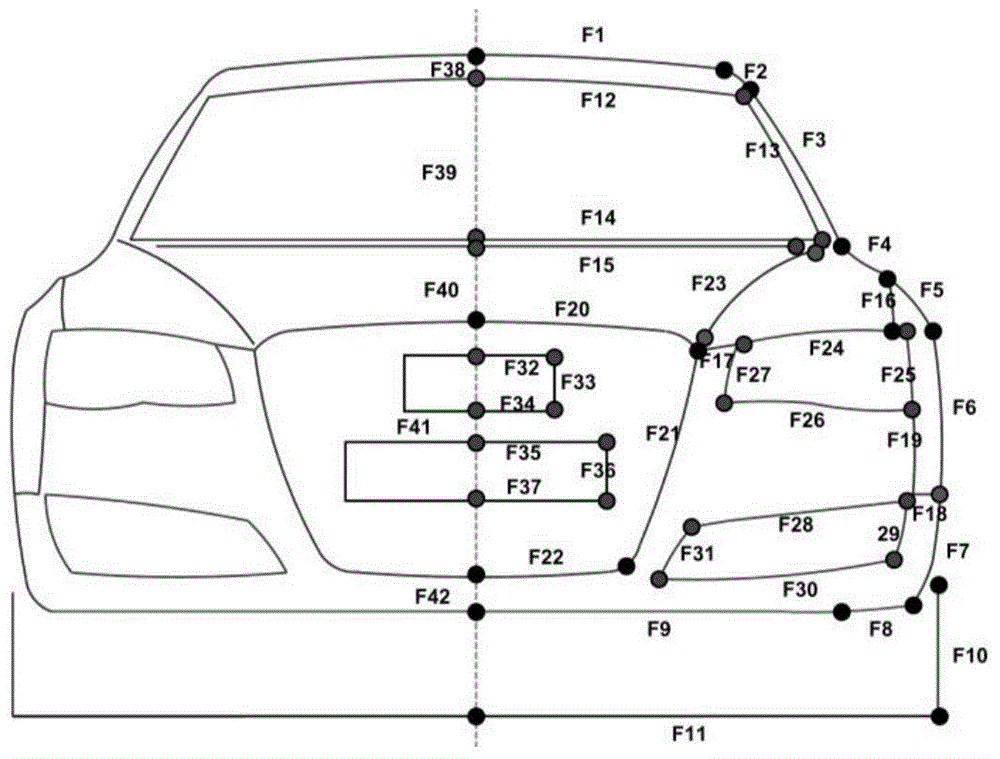

ActiveCN104881513AReduce processing costsImprove processing efficiencyAdditive manufacturing apparatusSpecial data processing applicationsDesign phaseEngineering

The invention provides a 3D (three-dimensional) printing based processing technique of an automobile styling concept model and belongs to the field of automobile styling concept design. The technique includes the steps of 1, performing three-dimensional model reconstruction based on an image / draft; 2, performing 3D printing oriented model structural optimization; 3, performing 3D printing oriented solid modeling; 4, generating a support structure; and 5, performing 3D printing. The technique has the advantages that quick expression of an automobile solid model from an automobile image / draft is achieved, model processing cost is lowered at the premise of quickly implementing a personalized solid model, processing efficiency is improved, operating is simple, and the technique is reliably applied to the automobile concept design phase for automobile styling engineers.

Owner:DALIAN UNIV OF TECH

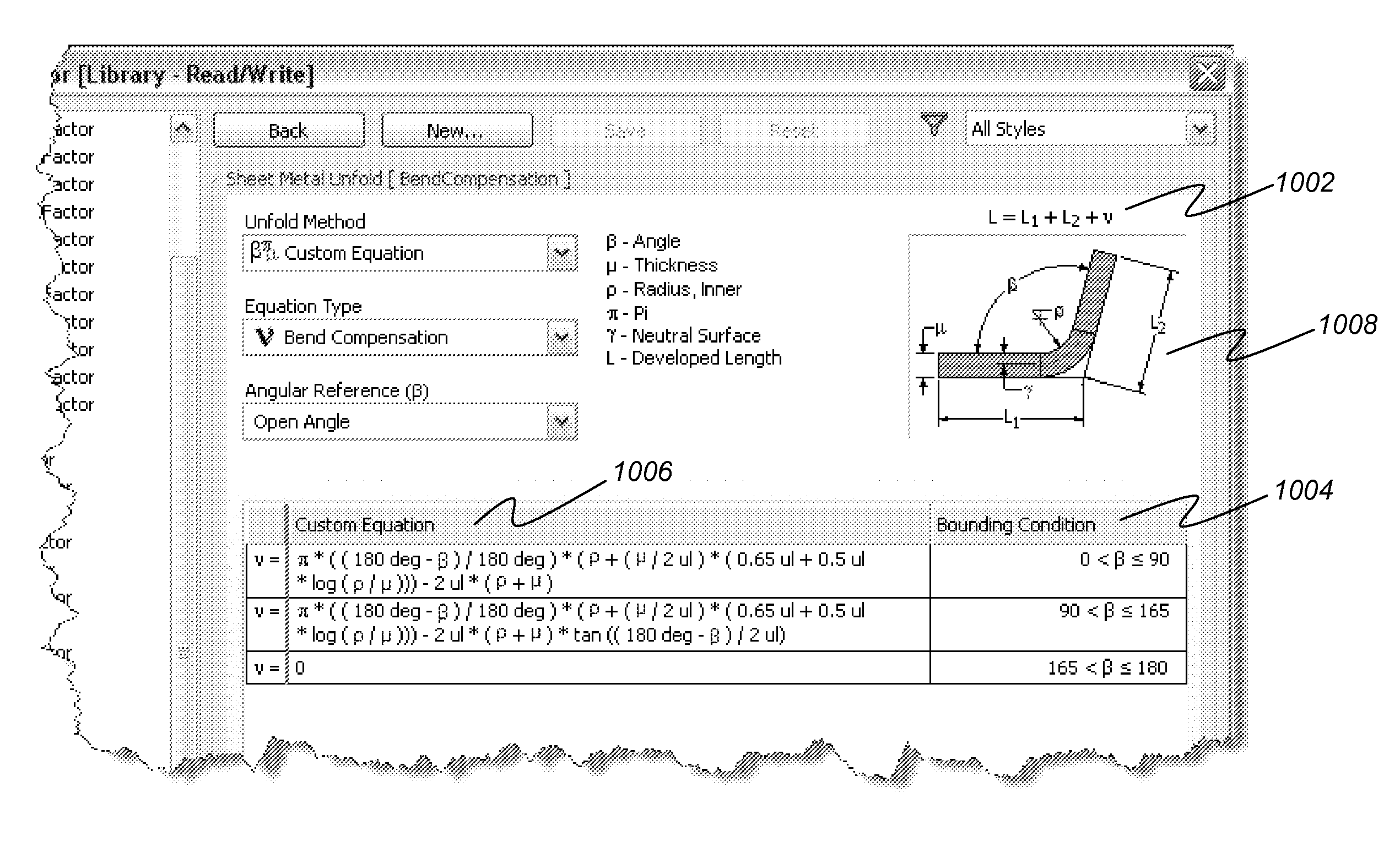

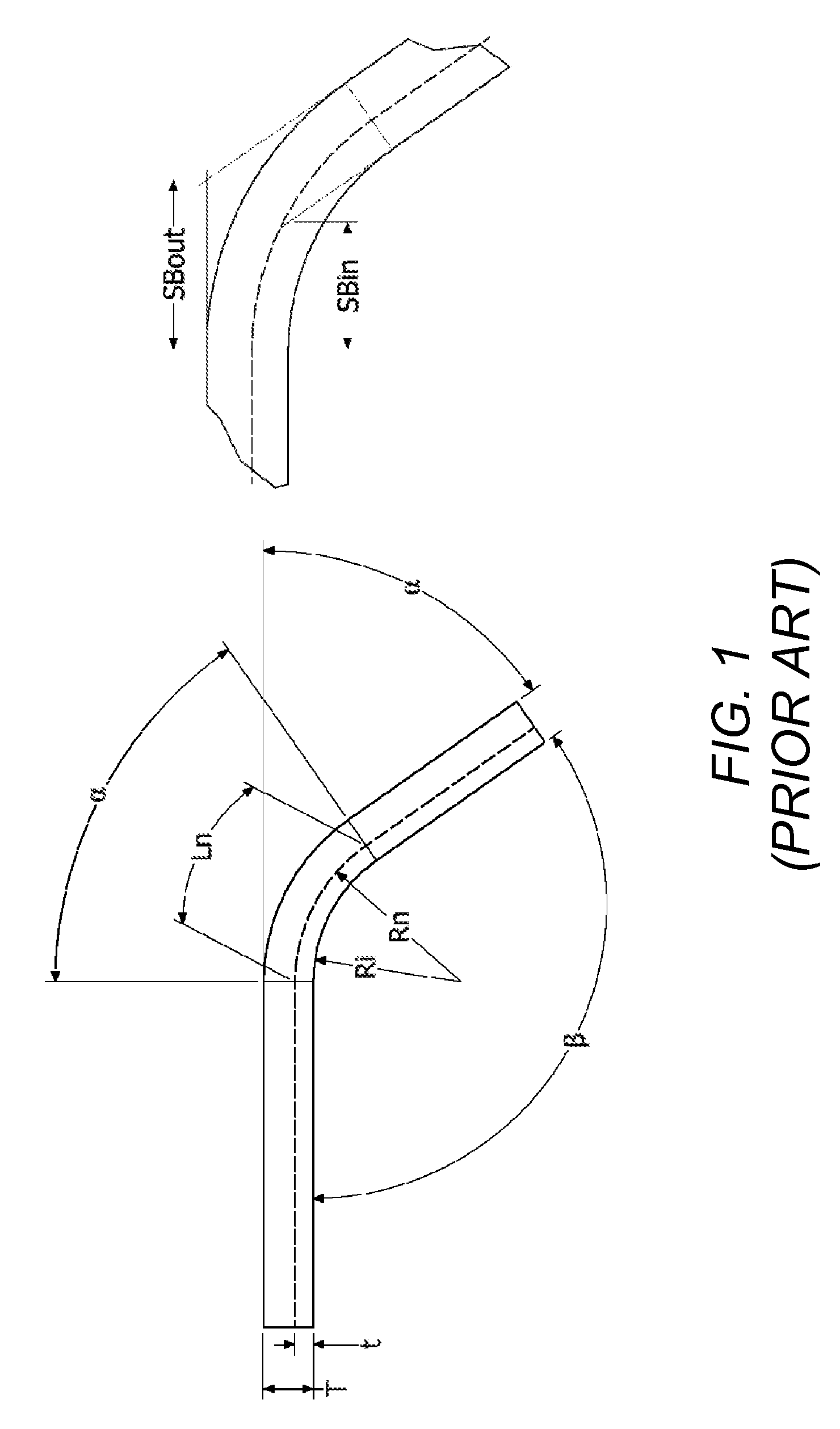

Custom equations for the unfolding of sheet metal

ActiveUS20100106463A1Easy to controlComputation using non-denominational number representationComputer aided designObject basedUser input

A computer implemented method, apparatus, and article of manufacture provide the ability to utilize custom equations for the unfolding of sheet metal in a solid modeling application. A drawing model is obtained and defines a sheet metal object in the solid modeling application. User input is accepted that defines a custom equation for a first variable that is directly used to calculate a developed length for a bend in the sheet metal object. The custom equation is converted into a standard equation that produces the developed length and is accepted by a modeling kernel of the solid modeling application. The modeling kernel dynamically displays an unfolded version of the sheet metal object based on the standard equation and the calculated developed length without exposing the standard equation to the user.

Owner:AUTODESK INC

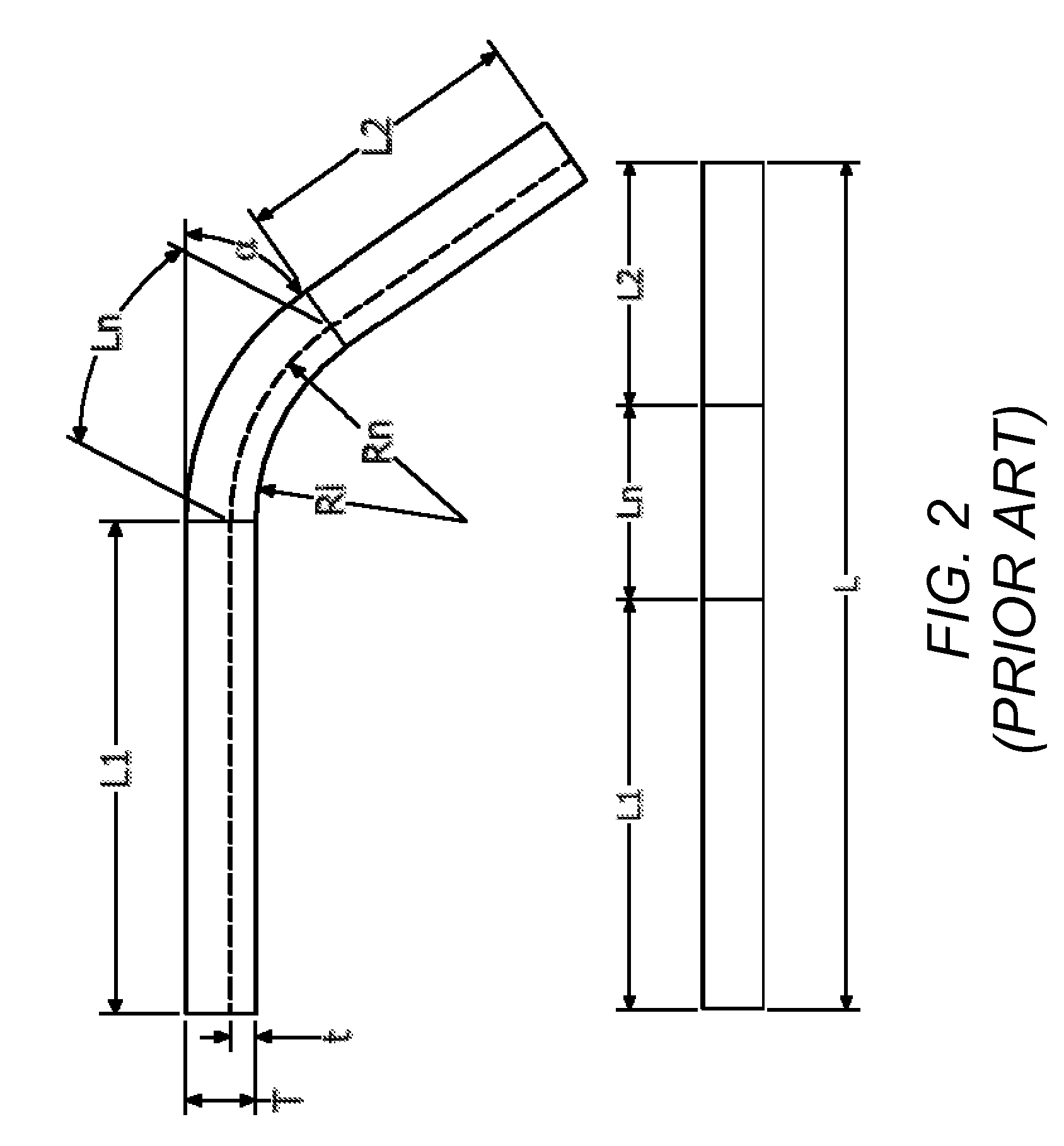

Transient temperature field simulation method based on multiple commutation failures of smoothing reactor

ActiveCN104834781ASpecial data processing applicationsSteady state temperatureFinite element software

The invention discloses a transient temperature field simulation method based on multiple commutation failures of a smoothing reactor. The method comprises the following steps that A, an oil immersed type smoothing reactor three-dimensional geometrical model is built in a solid modeling mode on the basis of ANSYS finite element software; B, an oil immersed type smoothing reactor is subjected to heat generating analysis; C, the oil immersed type smoothing reactor is subjected to heat radiation analysis; D, the boundary conditions of temperature field simulation calculation are determined; E, the steady temperature field of the smoothing reactor under the normal work condition is calculated; F, the obtained steady temperature field result is used as an initial value of a failure transient model, then, the failure current is loaded, a step-length method is adopted, the distribution of the temperature field along with time after the failure is calculated, and the transient temperature field simulation method based on multiple commutation failures of the smoothing reactor is completed. The method has the advantage that basis is provided for checking the maloperation reason of a smoothing reactor gas relay and setting the gas checking setting valve of the smoothing reactor.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

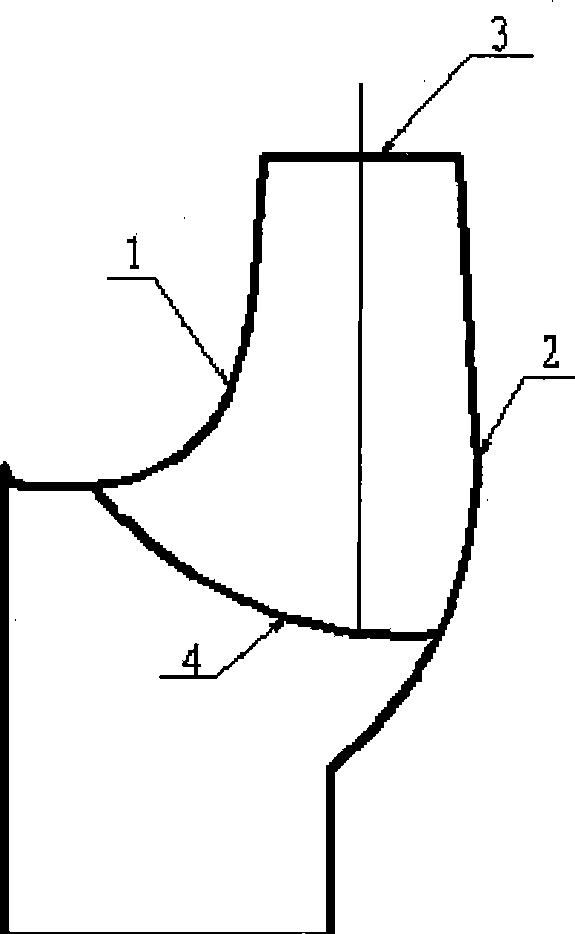

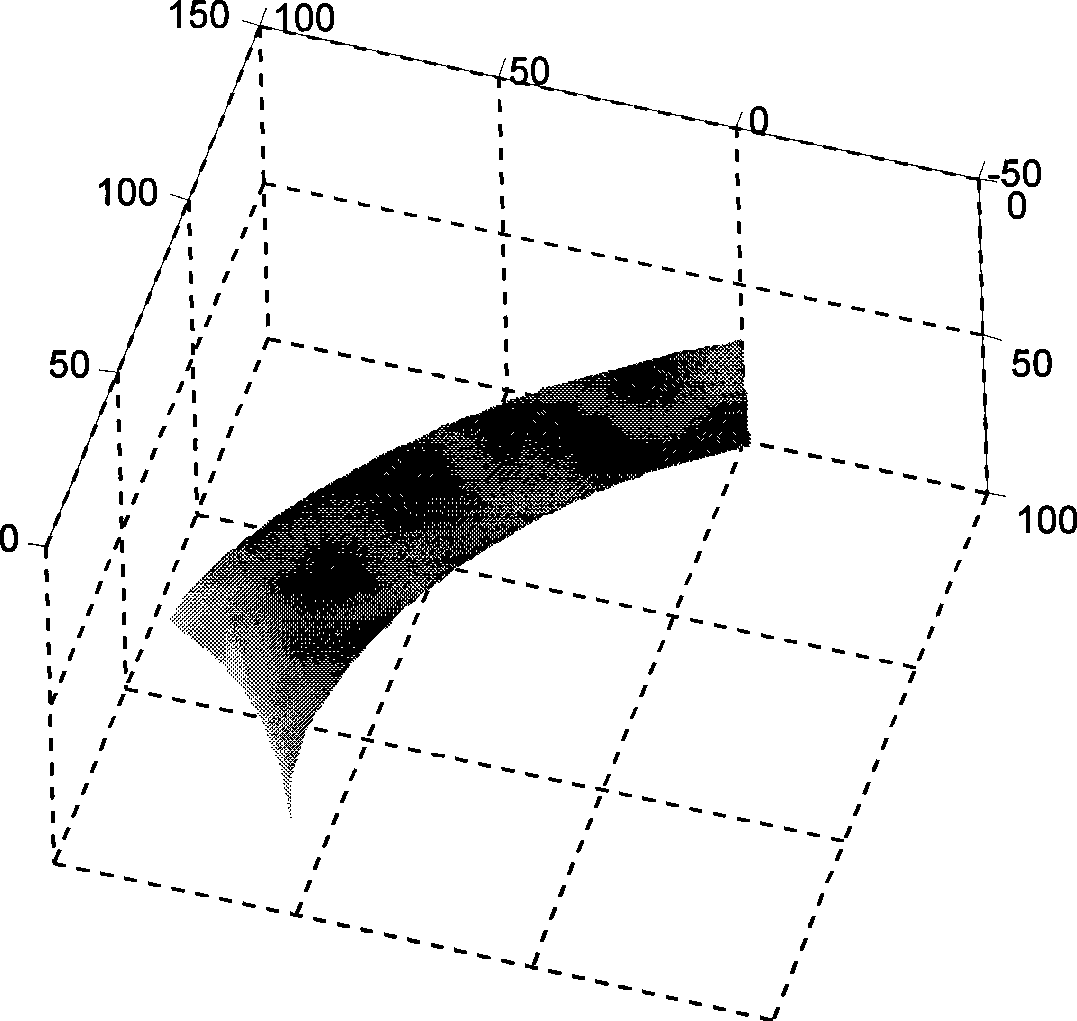

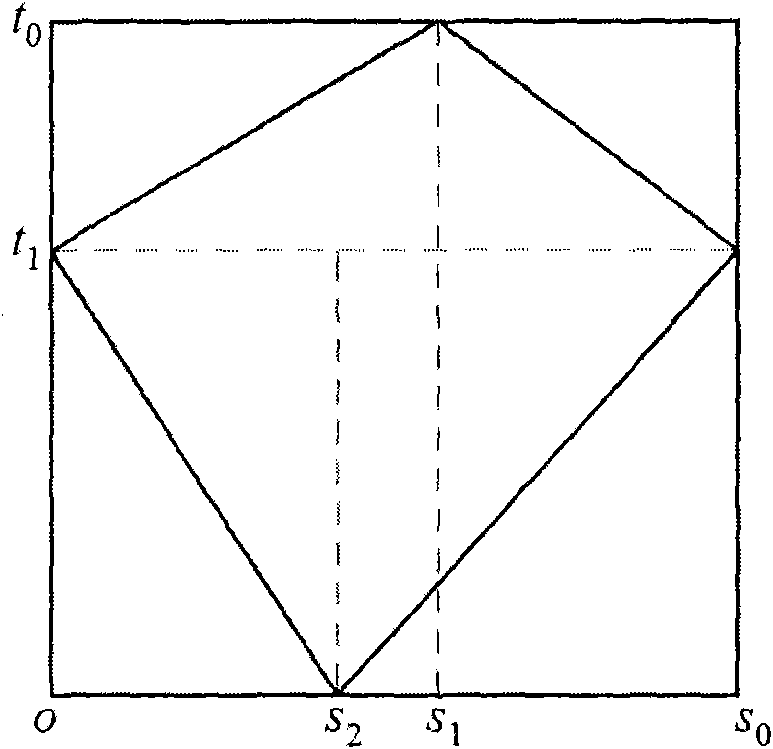

Reverse design method for impeller of centrifugal pump

InactiveCN101520052AOvercoming the Definition of GeometryOvercome many inconveniences such as modificationPump componentsPumpsBoundary value problemThree-dimensional space

The invention discloses a reverse design method for an impeller of a centrifugal pump, which comprises the following steps: according to a given impeller axial plane, a blade in a three-dimensional space can be actually expressed as X=X(z(u, v), r(u, v), theta(u, v)), the (z(u, v), r(u, v)) has been determined when a streamline of the impeller axial plane is given, and the space modeling of the blade can be determined by determining the theta(u, v) on the impeller axial plane. The reverse design method is characterized in that the reverse design method transforms a geometric design problem of the blade of the centrifugal pump into a boundary value problem of a partial differential equation to solve under the condition of the given impeller axial plane of the centrifugal pump. The reverse design method overcomes a lot of disadvantages such as the definition and modification of geometrical shape of the blade in the prior design method, can realize the parametric design of the blade, overcome the defects existing when a fussy two-dimensional form drawing is used for showing three-dimensional twisted blades in the prior method, can closely combine the hydraulic design of hydraulic machinery, three-dimensional solid modeling and the CFD analysis of flow field, and realize the quick and accurate solving of the reverse problem of the blade.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

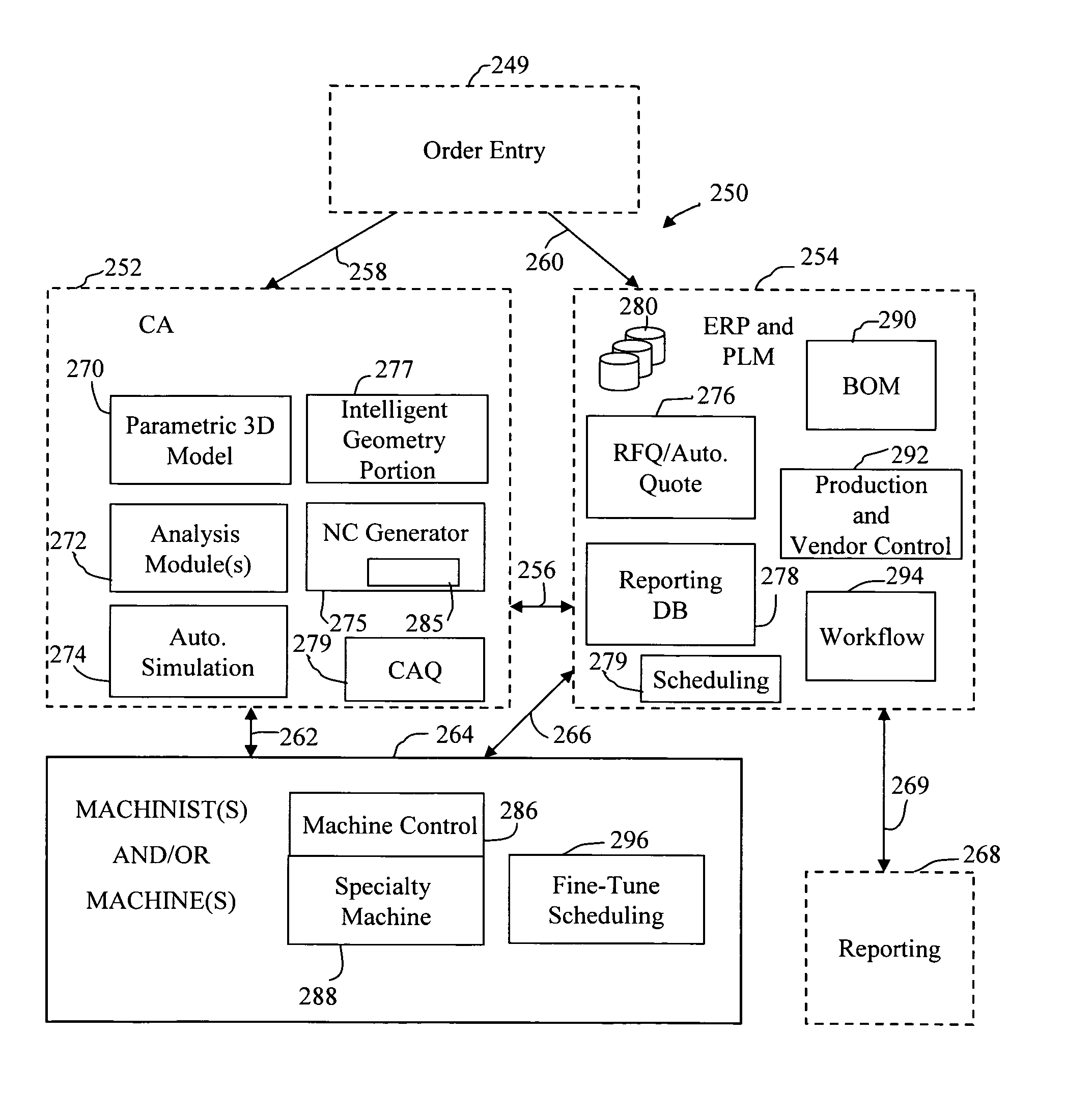

Processes and systems for creation of machine control for specialty machines requiring manual input

InactiveUS20060129270A1Increased riskImprove product qualityComputer controlSimulator controlComputer architectureMachine control

A system is provided for creating specialty machine control programs for manufacturing a part. A CA (computer aided) computer system is provided. The CA system may comprise a computer aided design and computer aided manufacture (CAD / CAM) computer system. The CA computer system may further comprise a computer aided engineering (CAE) computer system. The CA computer system may further comprise a computer aided quality (CAQ) computer system. The CA computer system comprises a parametric design mechanism to specify geometries of the part with parameters. In addition, an intelligent geometry portion is provided to determine machining cycles to manufacture the part. A 3D solid modeling function is provided, and one or more simulation components are provided. A human-readable control program generator is provided to generate from the CA computer system a human-readable control program including instructions for a human to carry out.

Owner:PANKL GEROLD +1

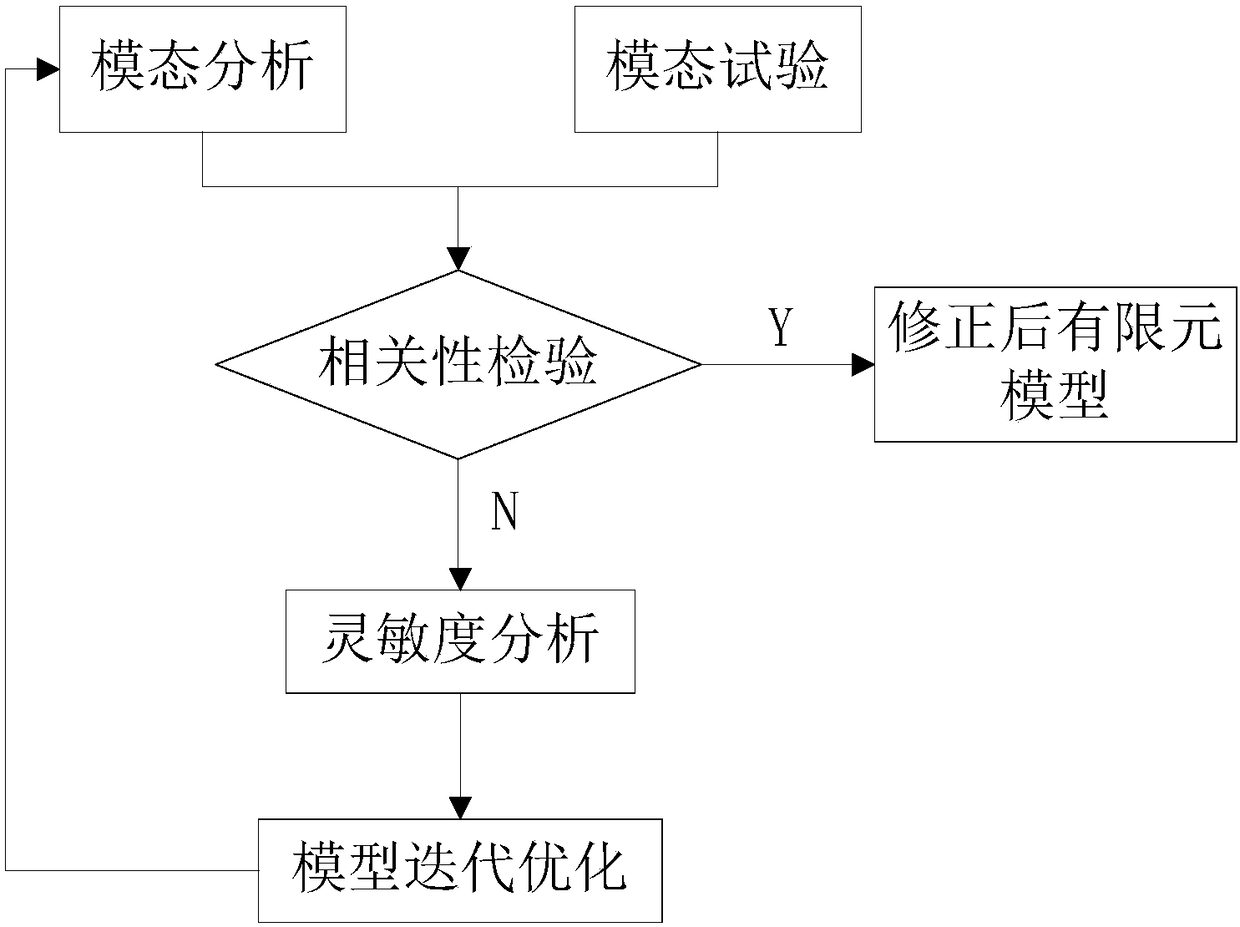

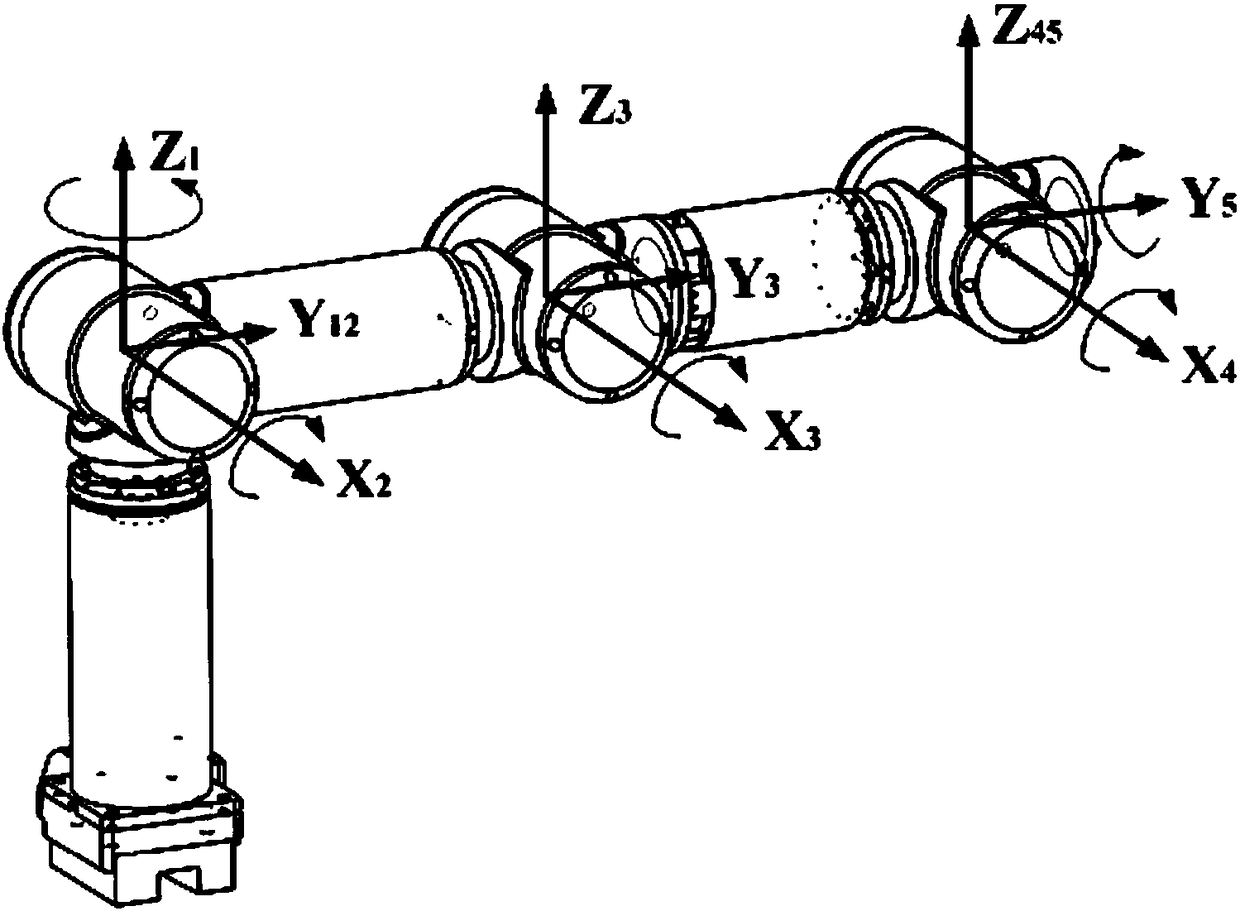

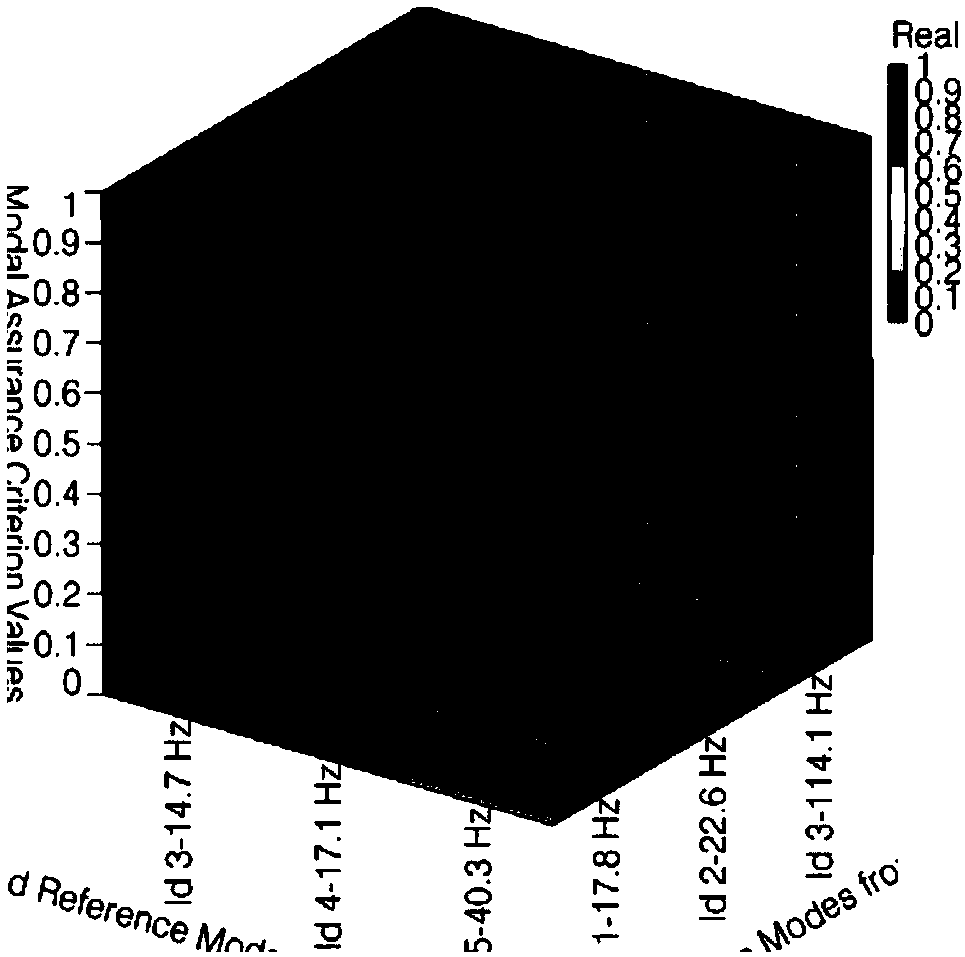

Finite element model correction method based on sensitivity analysis

InactiveCN108959686AGeometric CADDesign optimisation/simulationModal analysis using FEMElement model

The invention relates to a finite element model correction method based on sensitivity analysis. According to the method, solid modeling is performed on an assembly in three-dimensional software, a modal test is performed on an assembly model through a modal test system, an assembly finite element simulation model is established by the adoption of pre-processing software and post-processing software, modal analysis solving is performed through finite element analysis software, correlation checking is performed on a modal test result and a modal simulation analysis result through LMS.VirtualLabsimulation analysis software, modal sensitivity analysis is performed, parametric variables sensitive to modal frequency are found out, and finite element model fundamental frequency is matched withmodal test fundamental frequency through optimization iteration. Compared with a physical test, the simulation analysis technology has many advantages such as low cost and a short cycle; and within asimulation result error allowed range, the simulation analysis result can serve as a reference basis for vibration characteristic analysis, so that the method has important reference value for relevant test work.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

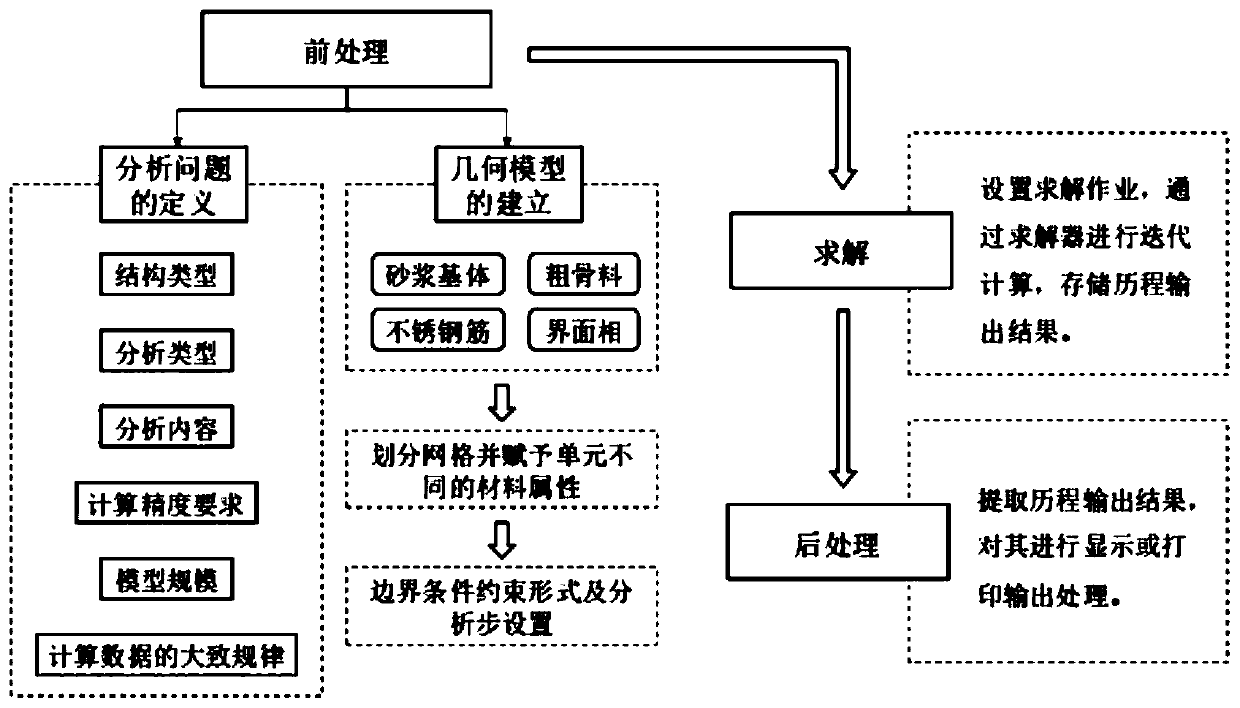

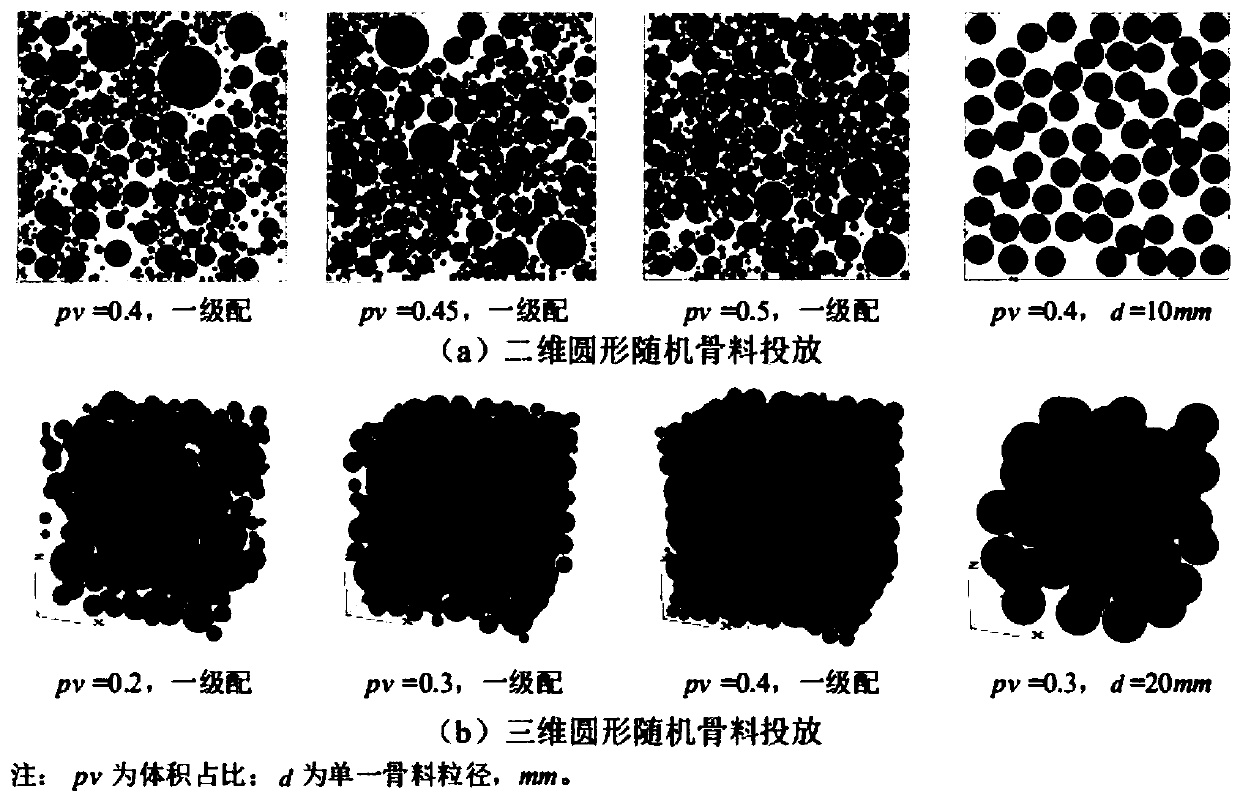

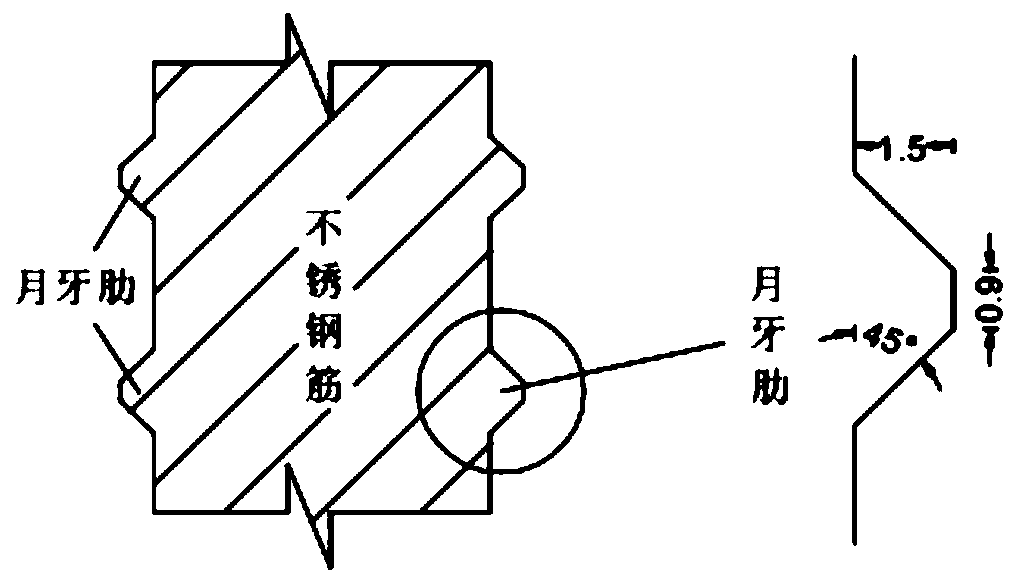

Method for establishing stainless steel bar concrete mesoscopic numerical model

ActiveCN110442922ASustainable transportationMaterial strength using tensile/compressive forcesBond interfaceElement analysis

The invention discloses a method for establishing a stainless steel bar concrete mesoscopic numerical model. The method comprises the following steps: uncertain stainless steel bar concrete mesoscopicstructure composition, model establishment of each mesoscopic structure, constitutive relation of each mesoscopic component and determination of mesoscopic material parameters. Under the condition ofdetermining the mesoscopic material parameters of the coarse aggregate, the mortar, the mortar-coarse aggregate interface and the steel bar-mortar bonding interface, mesoscopic finite element analysis is carried out on the bonding performance of the stainless steel bar concrete. According to the method, based on a mesomechanics theory, detailed expression is carried out from the aspects of mesoscopic structure composition, constitutive relations of all mesoscopic components, determination of mesoscopic parameters, setting of boundary constraints and the like. A simplified method of a stainless steel bar solid structure in two-dimensional solid modeling is proposed, a parameter assignment method of a stainless steel bar-mortar matrix bonding layer microstructure material is studied, the influence of interface performance on bonding strength is analyzed, and the recommended value range of the tensile strength of a bonding layer is determined in combination with a calculation result.

Owner:ZHENGZHOU UNIV

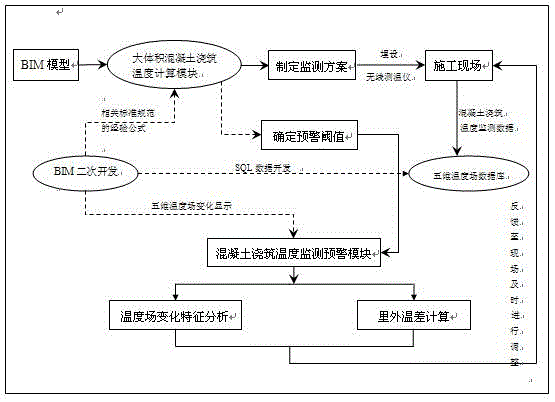

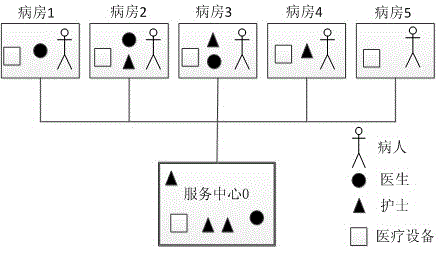

BIM (building information models)-based mass concrete real-time temperature monitoring and warning method

InactiveCN106768432AImprove pouring qualityThermometers using value differencesMeasuring instrumentComputer module

The invention discloses a BIM (building information models)-based mass concrete real-time temperature monitoring and warning method. The BIM-based mass concrete real-time temperature monitoring and warning method includes 1, carrying out BIM solid modeling on buildings according to design requirements; 2, establishing mass concrete pouring temperature field computing modules, concrete pouring temperature monitoring and warning modules and five-dimensional temperature field databases by means of BIM secondary development; 3, formulating temperature monitoring schemes; 4, arranging wireless temperature measuring instruments on sites according to the temperature monitoring schemes, transmitting five-dimensional temperature field variation of various monitoring points in real time, automatically processing transmission data by the aid of BIM and storing the transmission data in the temperature field databases; 5, retrieving concrete pouring five-dimensional temperature field data on the BIM by means of BIM secondary development; 6, automatically warning site constructors when the difference between the internal temperatures and the external temperatures of site concrete is higher than a warning threshold value and reminding the site constructors of curing the concrete. The BIM-based mass concrete real-time temperature monitoring and warning method has the advantages that temperature field variation in integral pouring procedures can be visually displayed by the aid of the BIM, and effective warning modes can be provided for timely guiding implementation of curing measures on the sites.

Owner:NANTONG SIJIAN CONSTR GRP

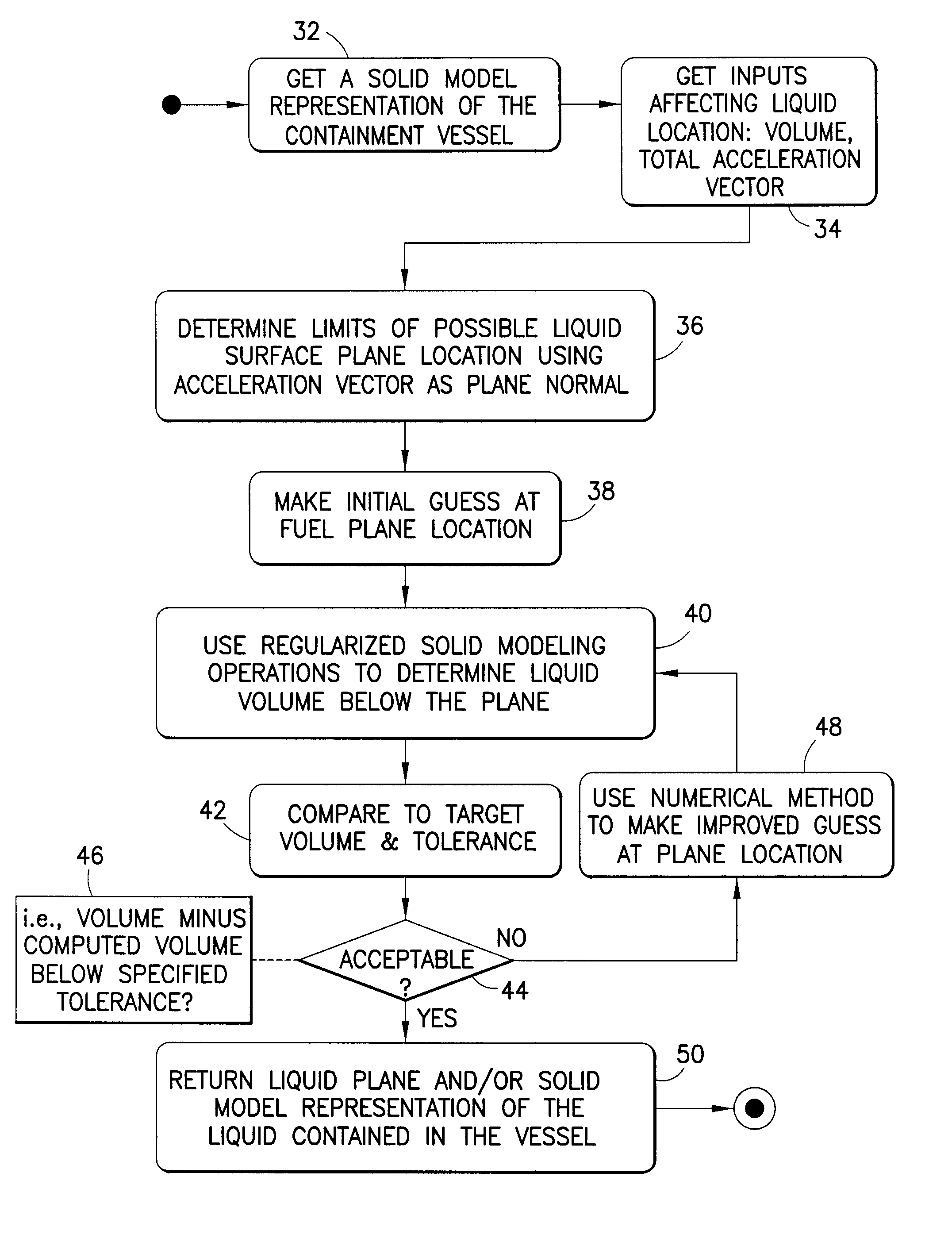

Calculating Liquid Levels in Arbitrarily Shaped Containment Vessels Using Solid Modeling

ActiveUS20120150517A1Reduce the amount requiredSimple calculationGeometric CADDesign optimisation/simulationEngineeringSolid modeling

Systems and method for simulating liquid containment behavior. The system comprises a solid modeler and a nonlinear equation solver. The nonlinear equation solver takes as input the solid model representation of the containment vessel from the solid modeler, a desired orientation in space, dynamic conditions (e.g., lateral acceleration) and an amount of liquid. To find the level of liquid in the vessel, the system solver iteratively performs successive Boolean subtractions using an infinite horizontal half-space that represents the liquid level of the vessel. The resulting sliced solid model is used to compute the volume of the liquid at that level. The iterative system solver terminates when the computed volume of the sliced containment vessel matches the specified volume of liquid (e.g., fuel) within a given tolerance. To accommodate dynamic situations, e.g., when acceleration is present, the horizontal liquid plane is replaced with a plane at an angle that corresponds to the total acceleration.

Owner:THE BOEING CO

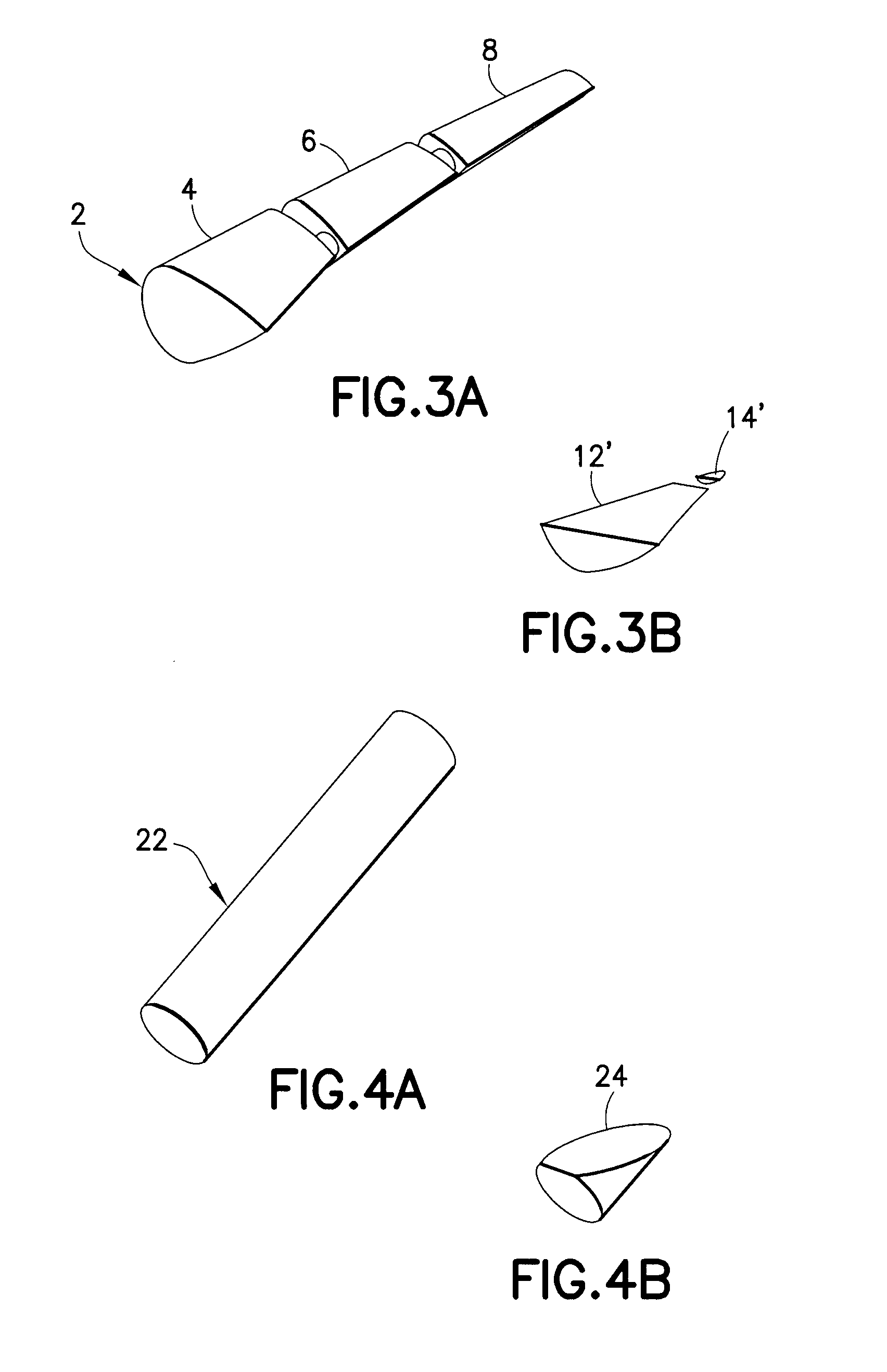

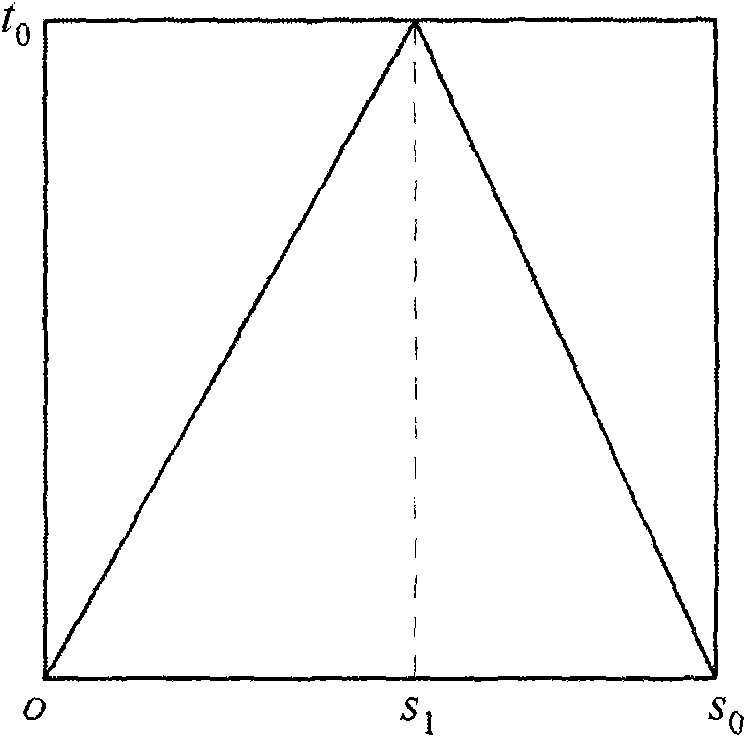

Generating method of finite element mesh in thin-wall curved surface structure

InactiveCN101840453ARealize generationSimple designSpecial data processing applicationsElement modelTopology information

The invention discloses a generating method of a finite element mesh in a thin-wall curved surface structure, aiming to solve the technical problem of great equivalent stress of a traditional design method of a finite element model in a perforated thin-wall conical curved surface structure. The technical scheme comprises the following steps of: firstly, generating a plane finite element mesh on a parameter plane by adopting a solid modeling method; then, generating network nodes in a space thin-wall curved surface structure through a parametric mapping relation by adopting a direct generating method; and generating a finite element mesh in the space thin-wall curved surface structure by utilizing corresponding unit topology information on the parameter plane. Compared with the prior art, the maximum equivalent stress of the finite element model in the perforated thin-wall conical curved surface structure in the same size is greatly reduced.

Owner:NANTONG HENGDA MACHINERY MFG +1

Manufacturing technology for runner of impulse turbine

The invention discloses a manufacturing technology for a runner of an impulse turbine. The manufacturing technology comprises the following steps that a forged blank of the runner is manufactured, wherein three-dimensional solid modeling of the runner is conducted, solid models of a runner disk and the connection area between the disk and a bucket are established, stainless steel for making the runner is refined, a steel ingot is cast, the runner disk and the connection area between the disk and the bucket are forged, normalizing and tempering are conducted, and then the forged blank is obtained; mechanical rough machining is conducted on the forged blank until the size precision and the surface roughness meet the requirements of fine machining; robot overlaying is conducted on the workpiece in the shape of a bucket; mechanical fine machining is conducted on the workpiece, and then the finished runner is obtained. By the adoption of the manufacturing technology, the material performance and the overall strength of the runner of the impulse turbine are improved, the performance of the runner of the impulse turbine is improved, the service life of the runner of the impulse turbine is prolonged, and the production cost of the runner of the impulse turbine is reduced.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

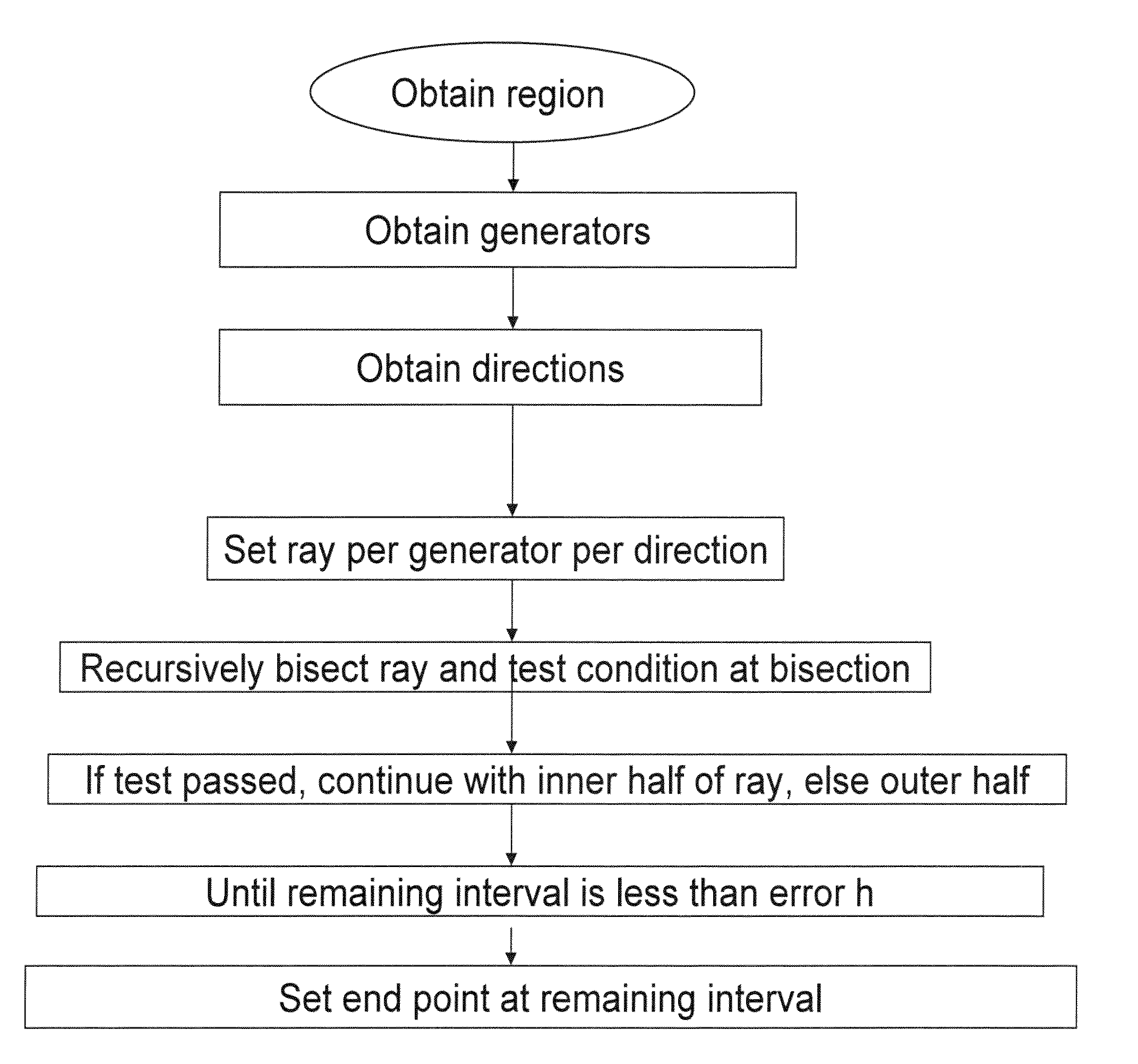

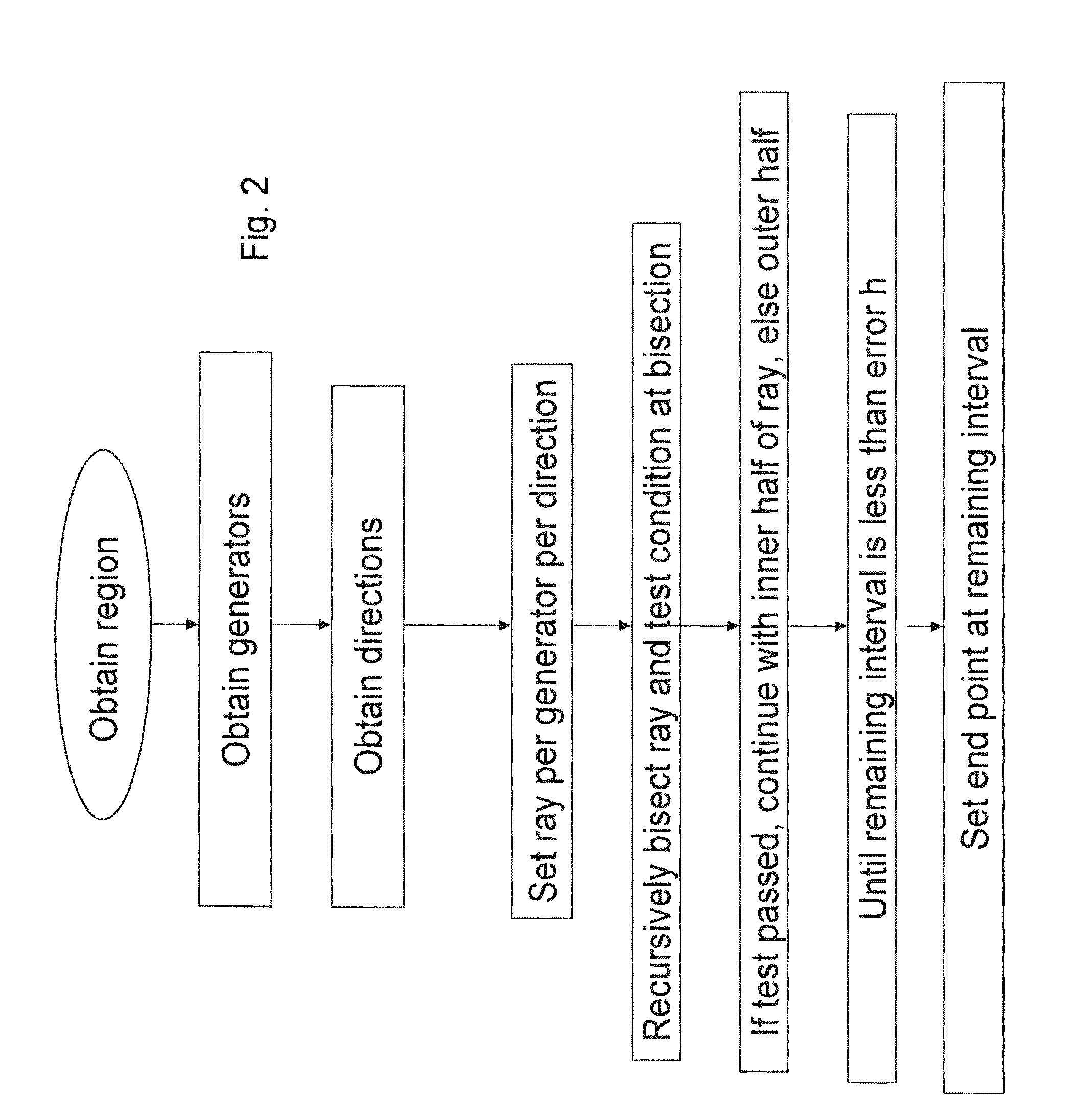

Efficient computation of Voronoi diagrams of general generators in general spaces and uses thereof

InactiveUS20100036647A1Character and pattern recognitionComputation using non-denominational number representationData compressionCollision detection

A computerized method of computing the Voronoi diagram has applications including communications networks, robotics, three-dimensional networks, materials science, searching image processing, data clustering, data compression, control of a groups of methods for image processing and the like, design of electronic circuits, geographic information systems, solutions of the efficient location problem, face recognition, mesh generation and re-meshing, curve and surface generation / reconstruction, solid modeling, collision detection, controlling motion of vehicles, navigation, accident prevention, data clustering and data processing, proximity operations, nearest neighbor search, numerical simulations, weather prediction, analyzing and modeling proteins and other biological structures, designing drugs, finding shortest paths, pattern recognition and as an artistic tool. The Voronoi diagram is a decomposed region X made into cells, the decomposition being induced by a set of generators (Pk)k-K, and a distance function, and involves finding for each generator Pk a cell, which is a set of all the points in X satisfying the condition that the distance to the current generator P=Pk is not greater than the distance thereof to the union A of the other generators, The method comprising: for each generator, and for each point p in this generator, selecting a set of directions, then for each direction recursively testing a ray in that direction, until a certain interval on the ray is of length less than or equal to a given error parameter. A point corresponding to the interval on the ray is then selected as an end point, the cells are defined from the end points, thus forming the Voronoi diagram.

Owner:REICH SIMEON +1

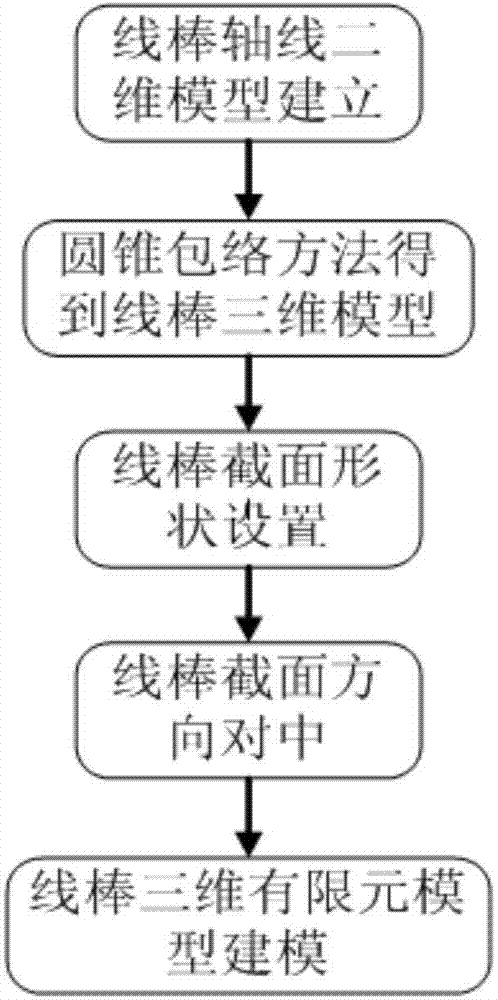

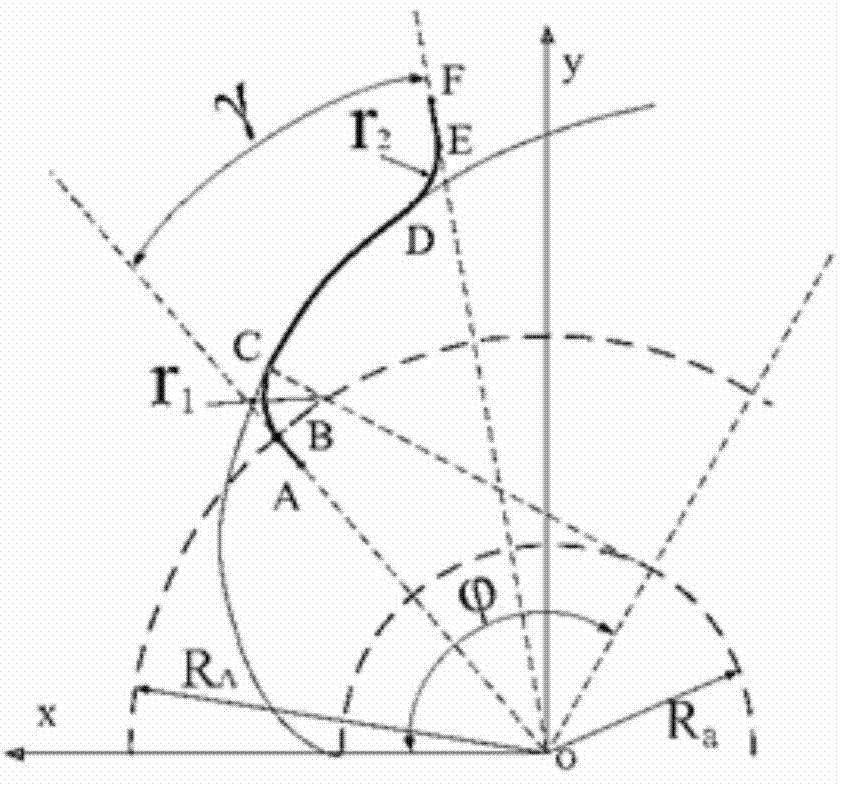

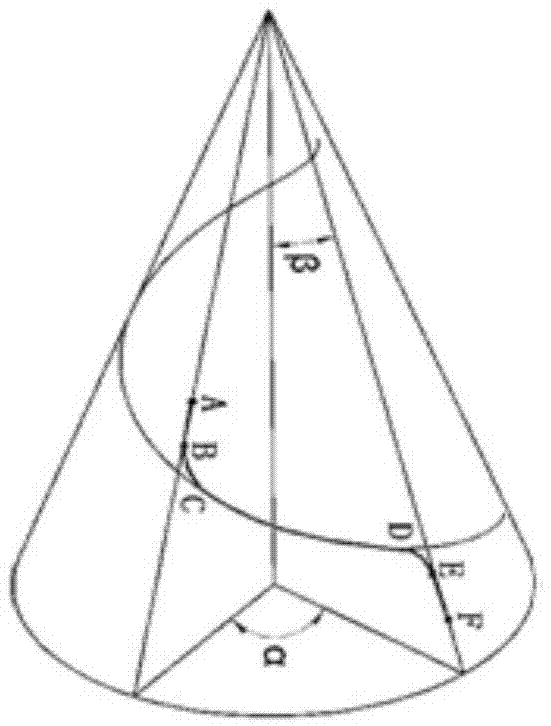

Finite element precise modeling method for stator bar of large turbine generator

ActiveCN103577654AEasy to modifyEasy loadingSpecial data processing applicationsElement modelSimulation

The invention discloses a finite element precise modeling method for a stator bar of a large turbine generator. The method includes the following steps: 1) obtaining a two-dimensional model of the bar axis according to the dimension requirements of a drawing; 2) building a three-dimensional geometrical model of the bar axis by using the cone enveloping method; 3) dividing the section into a plurality of small rectangles according to the location of each material in the bar and the geometrical shape of each layer structure, and centering the section direction; 4) after a section in the accurate direction is generated at each key point of a space three-dimensional curve, connecting in sequence the corresponding nodes on adjacent sections and generating a hexahedral element, so as to form a complete three-dimensional finite element model of the bar. The three-dimensional finite element modeling method for the bar is based on finite element software and the cone enveloping algorithm, so as to dispense with three-dimensional solid modeling and simplify the analysis steps; the three-dimensional finite element modeling method for the stator bar of the large turbine generator provided by the invention has the advantages of high efficiency and precision.

Owner:SHANGHAI ELECTRICGROUP CORP

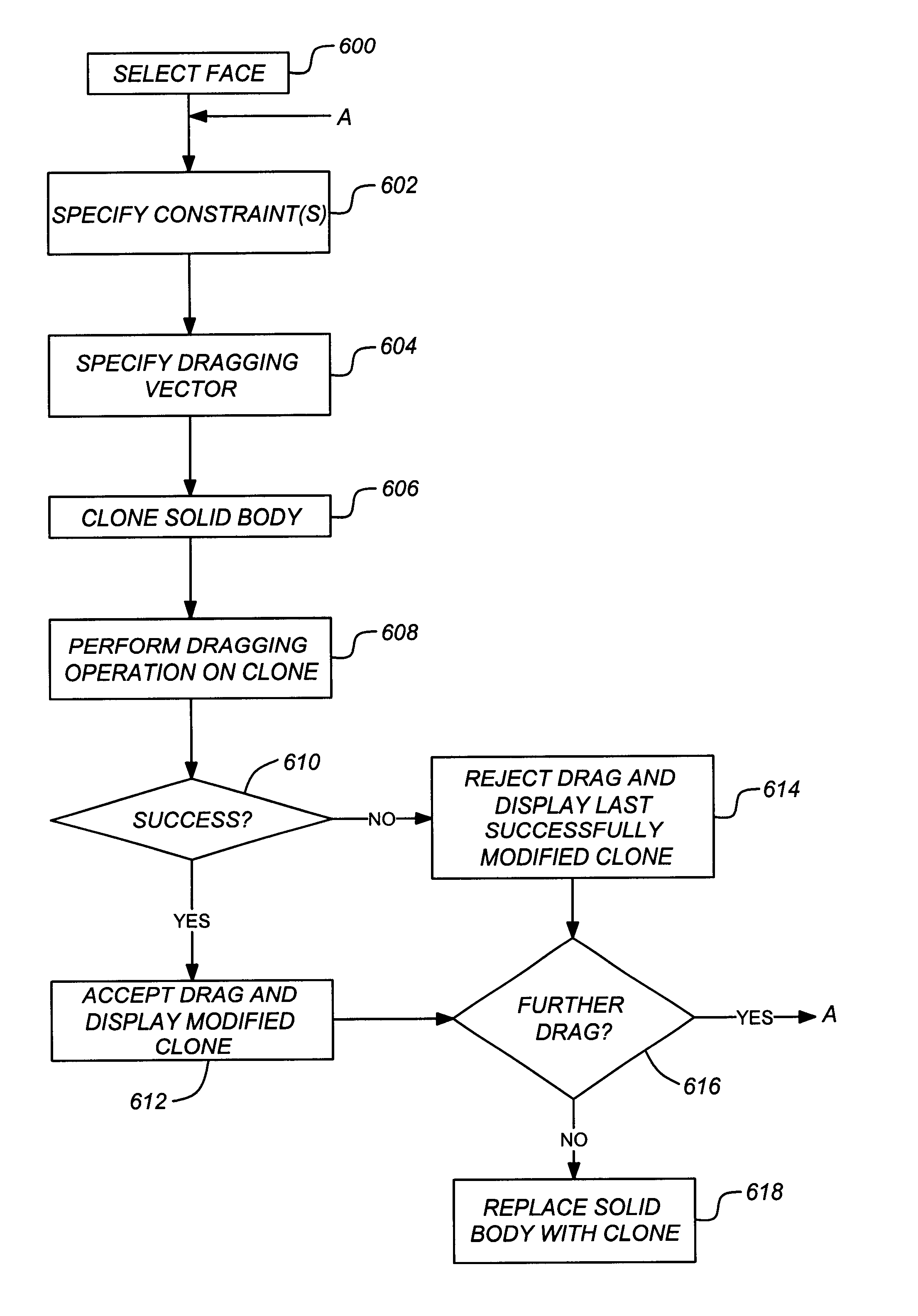

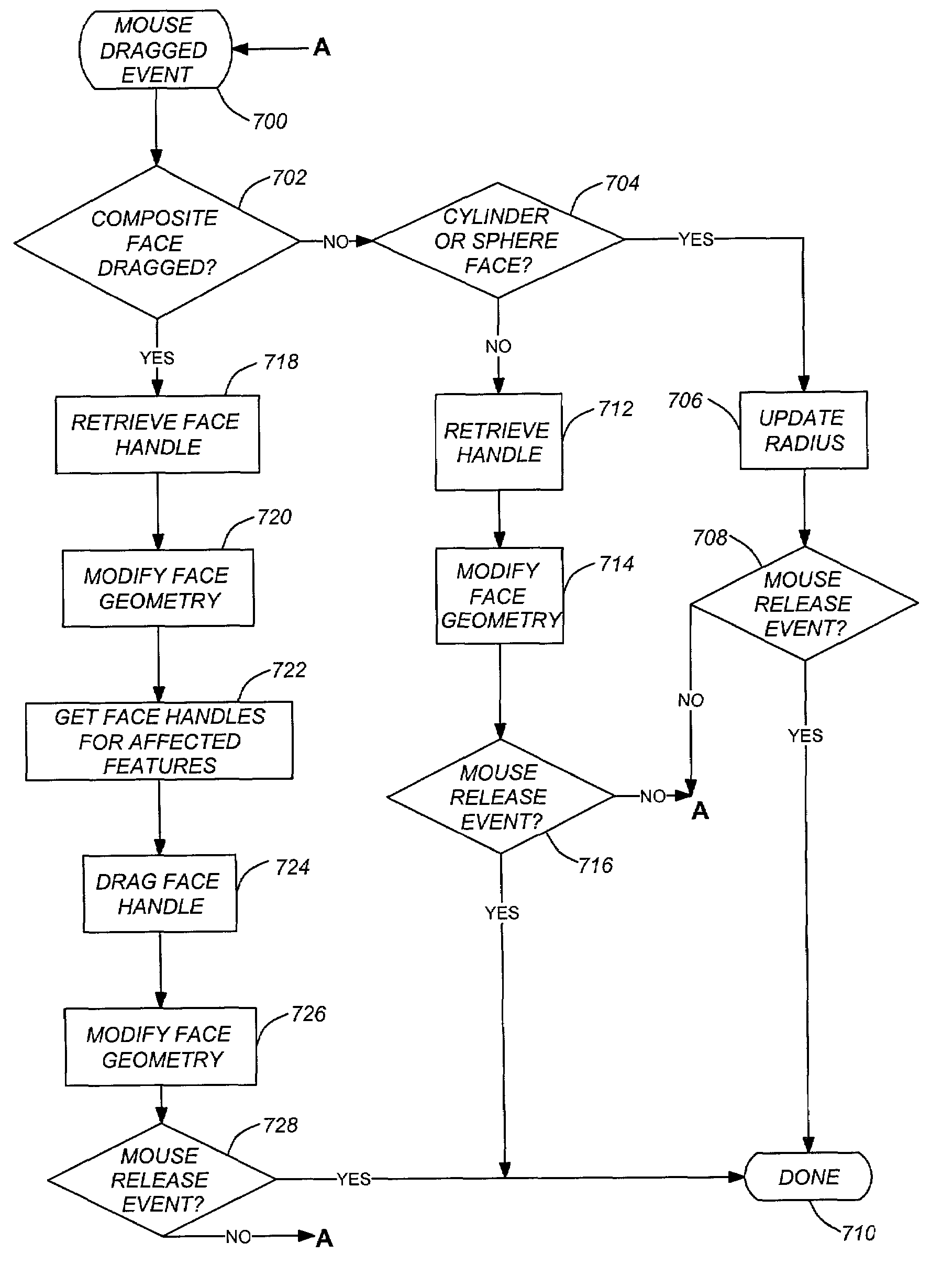

Controlled face dragging in solid models

One or more embodiments of the invention provide a method, apparatus, and article of manufacture for modifying a three-dimensional model. A three-dimensional model is displayed in a computer implemented solid modeling system. A first face of the three-dimensional model is then selected. A first constraint that controls a behavior of a repositioning operation for the first face is specified. Once the face and constraint have been selected / specified, the three-dimensional model is modified by repositioning the selected first face, wherein the repositioning operation is constrained in accordance with the specified first constraint.

Owner:AUTODESK INC

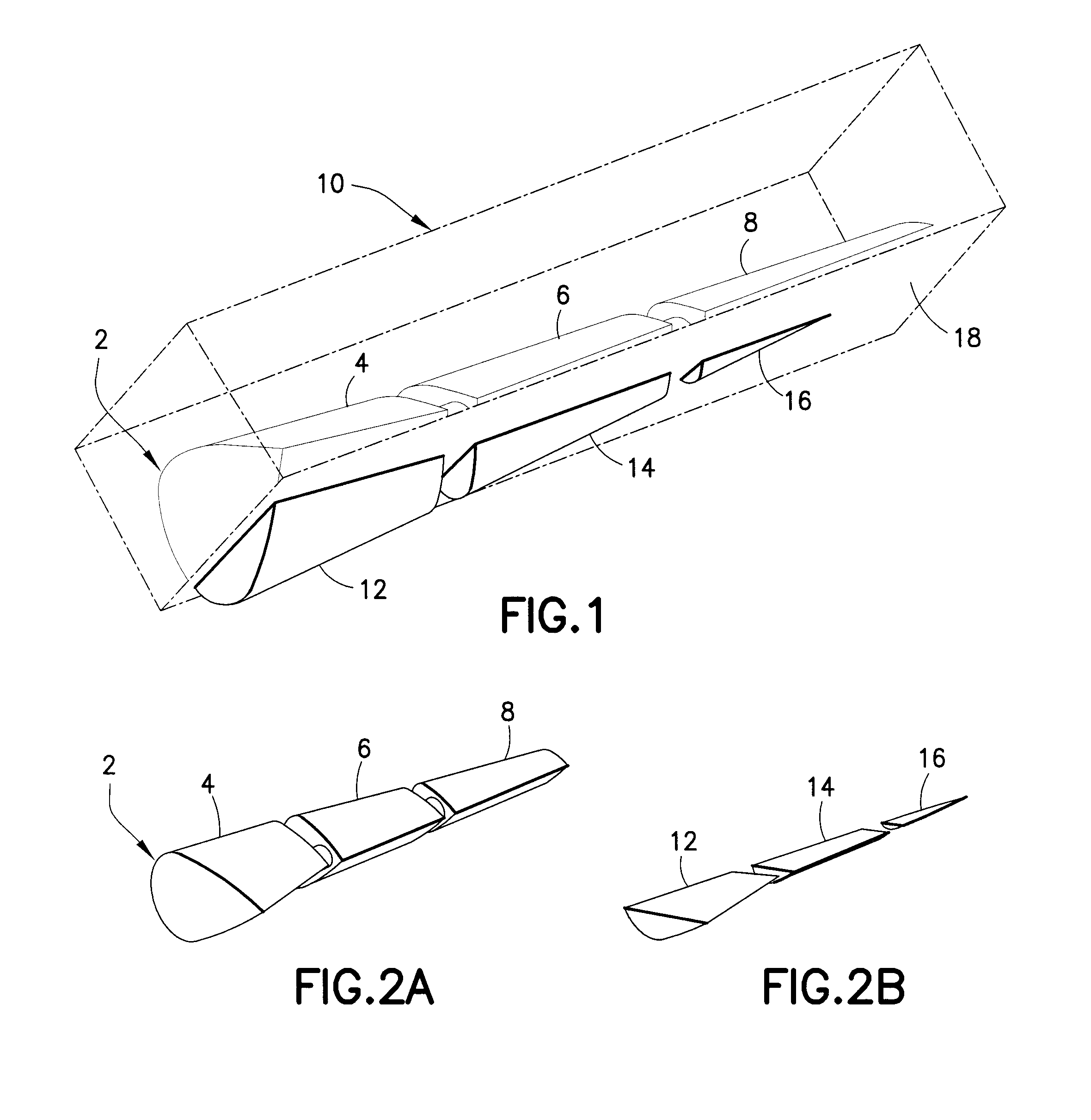

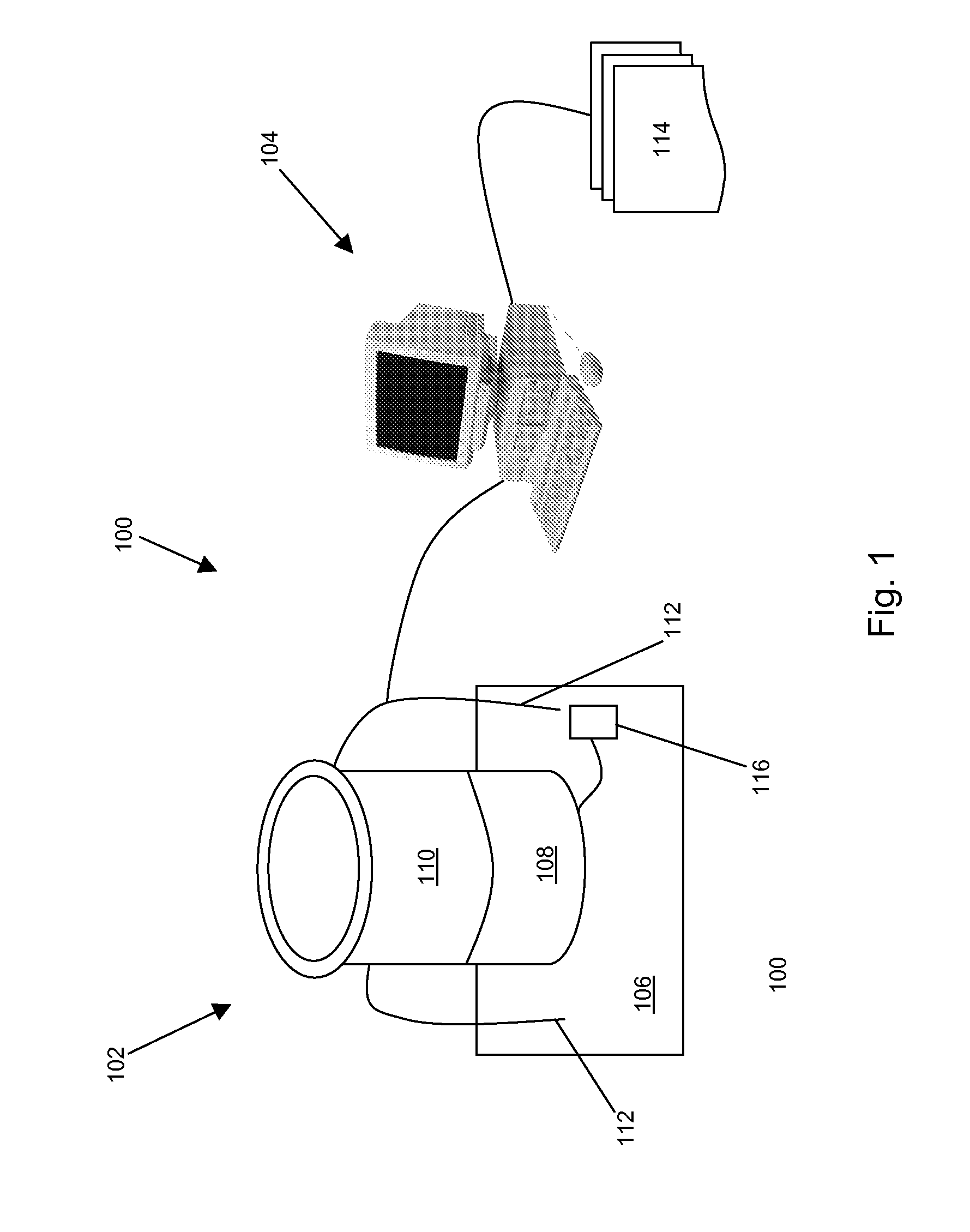

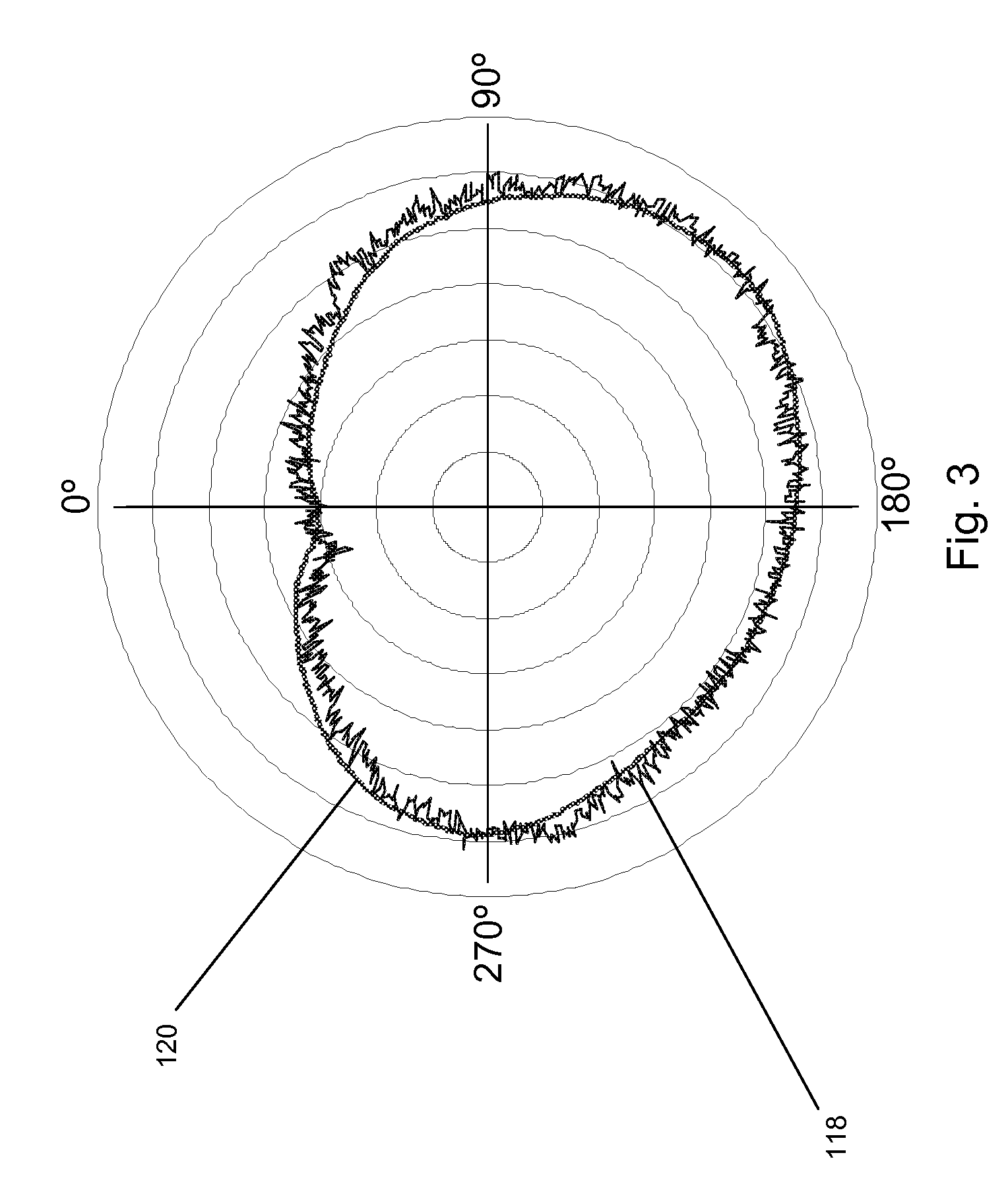

Rotor Assembly System and Method

A system for assembling a rotor stack having a plurality of rotor disks may include a measurement system for measuring characteristics of the rotor disks, a computer electronically connected to the measurement system for capturing data from the measurement system, and solid modeling software for creating a virtual stack of the rotor disks optimized for concentricity.

Owner:GENERAL ELECTRIC CO

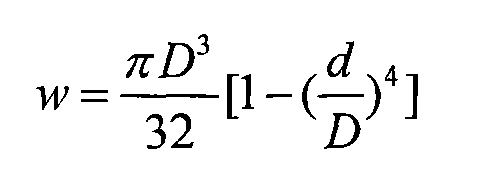

Composite electrical cross arm and design method of structure thereof

ActiveCN101906895AMeet strength requirementsReduce structural weightTowersGlass fiberAnalogue computation

The invention relates to a composite electrical cross arm and a design method of a structure thereof, belonging to the design field of assorted structural parts of transmission poles. The electrical cross arm is of cylindrical solid structure and comprises an inner core layer, a middle layer and an outer layer from inside to outside in a radial direction. The middle layer is the base and is a composite hollow pipe, the core of the pipe is filled with foaming polyurethane material to form the inner core layer, and the outer surface of the pipe is wound with glass fiber polymer matrix composite material to form the outer layer. The design method comprises the steps of: carrying out solid modeling, meshing, load applying and analog computation by utilizing the operation order of an ANSYS and confirming the structure setting, optimization of outer winding thickness and direction angle of the cross arm so that the cross arm meet the requirements of a design safety coefficient value and deflection. The cross arm produced by the design method has the advantages of light weight, good insulation performance, convenient installation and high section bending resistance index, and can effectively improve a safety margin when being applied to an actual circuit, can reduce the cost and is beneficial for popularization and application.

Owner:北玻电力复合材料有限公司

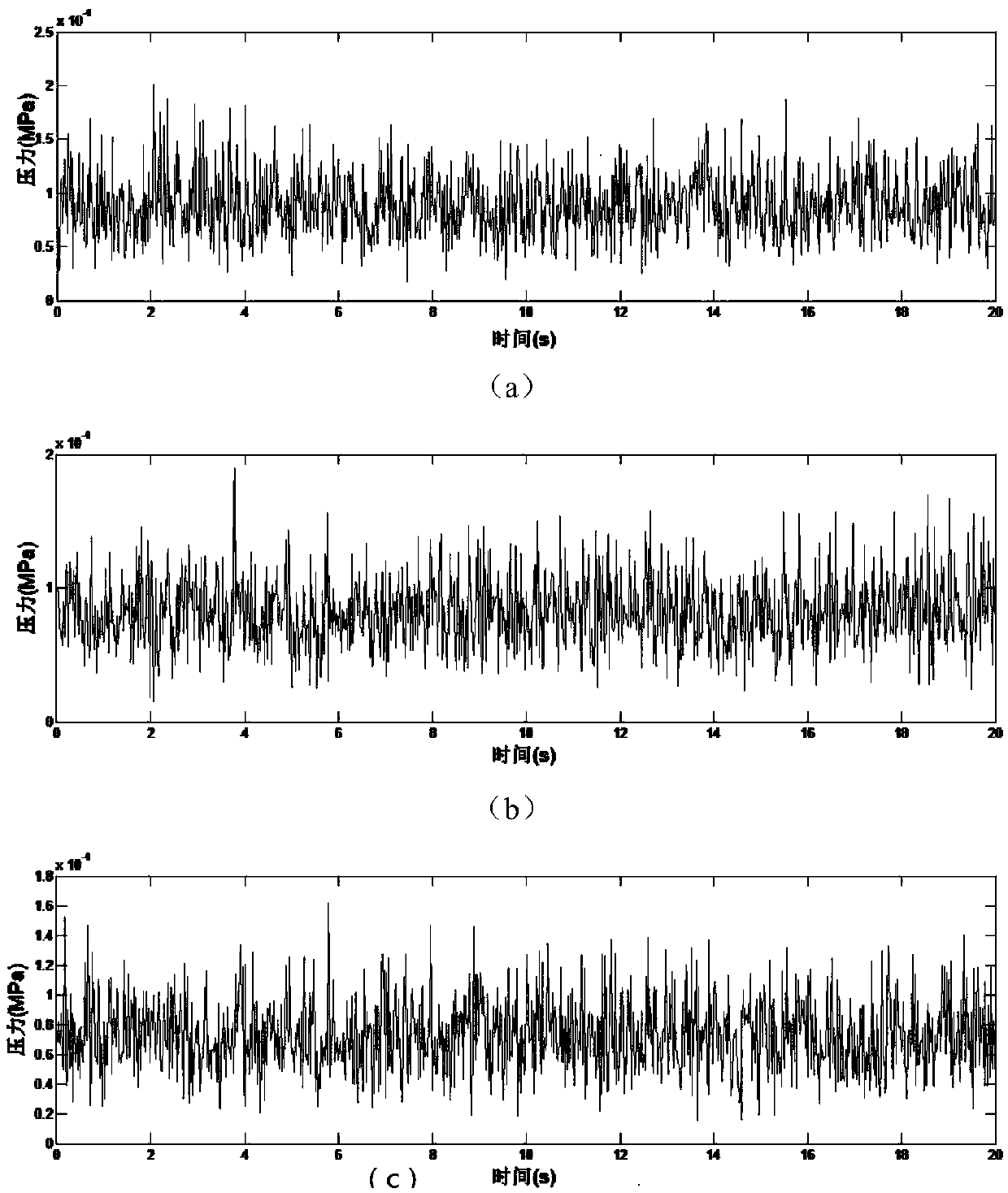

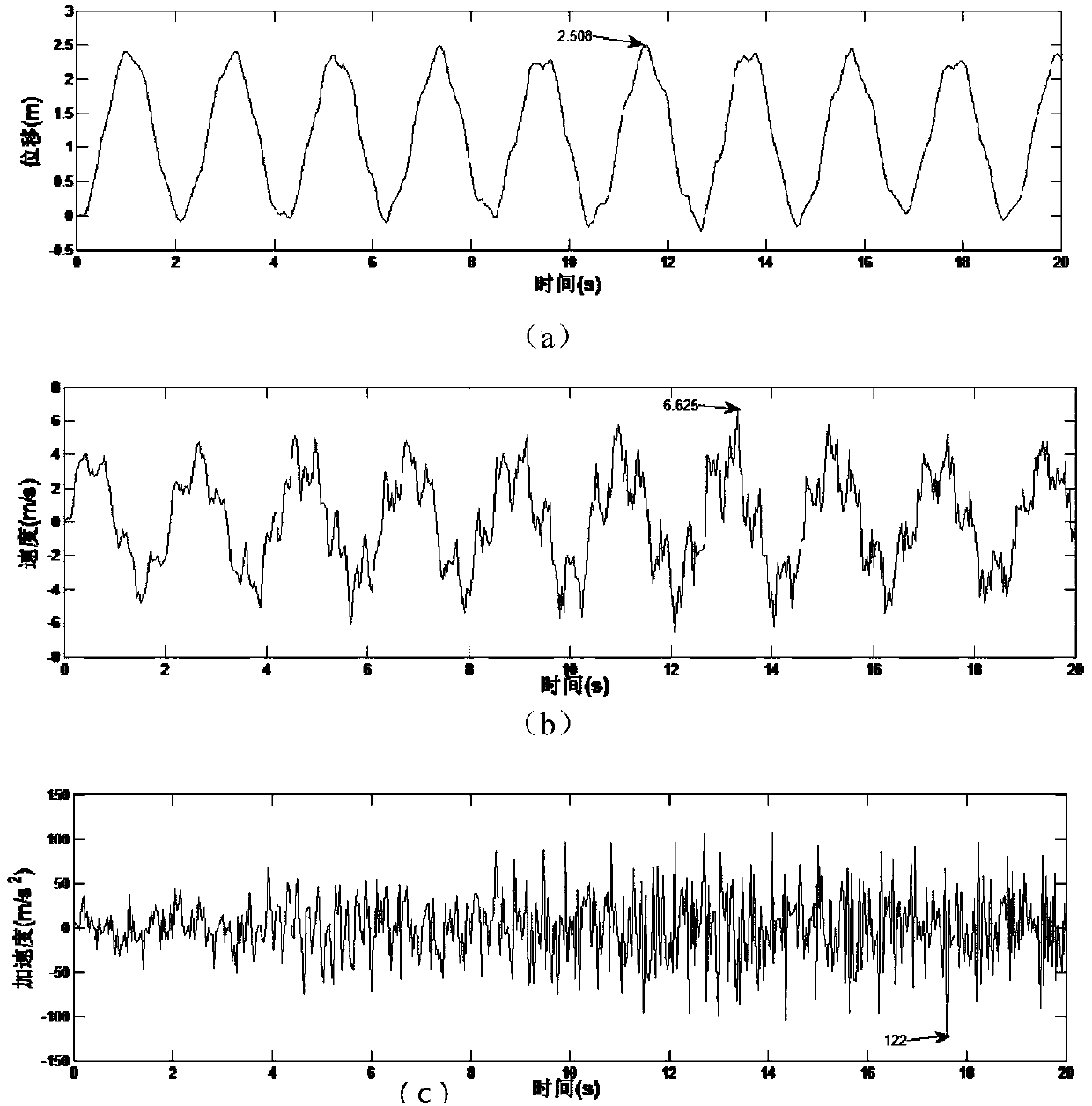

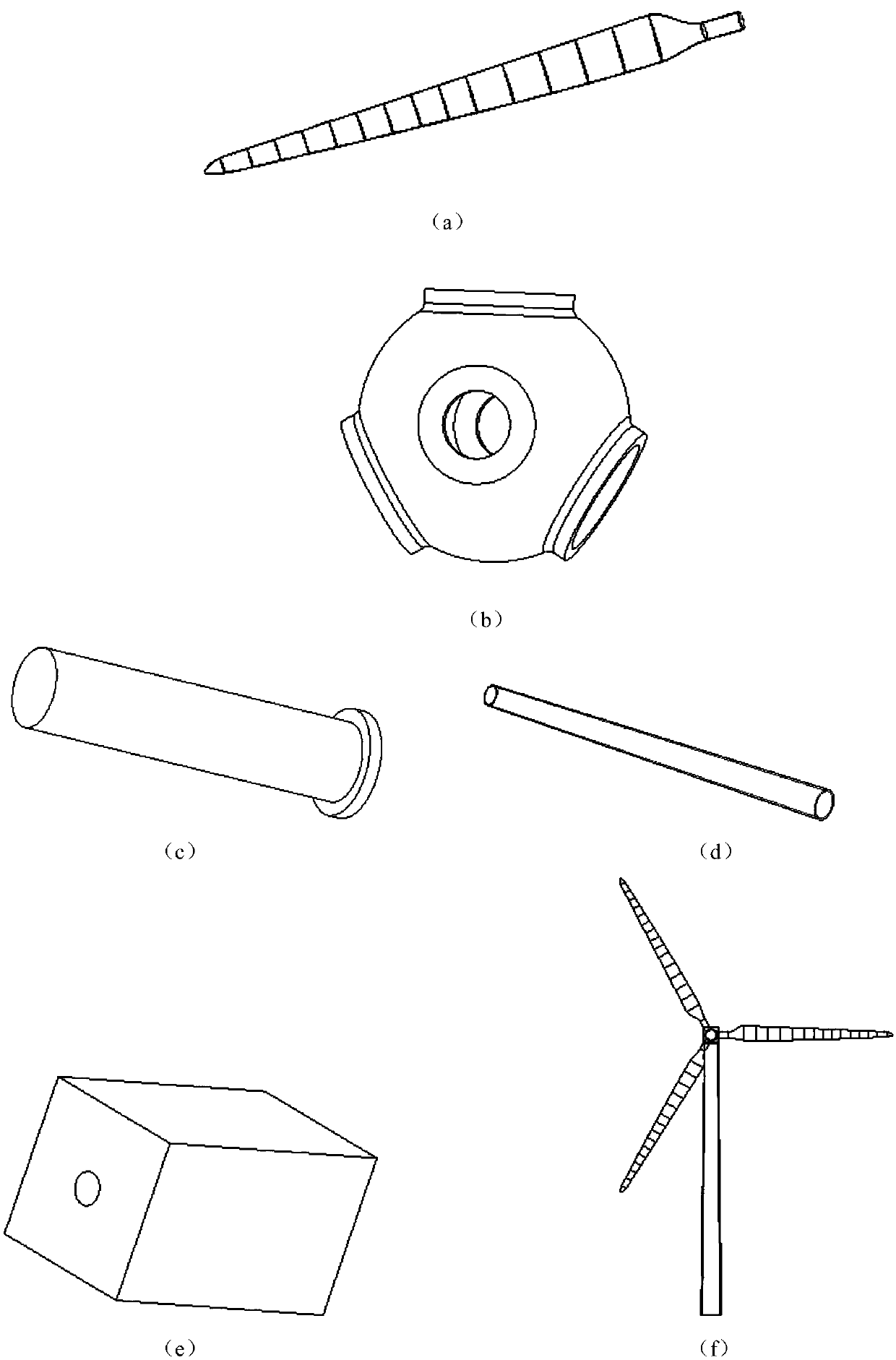

Wind turbine generator dynamic response analysis method based on multi-platform co-simulation

InactiveCN108694277ASimple structural designUncovering Coupled Operating CharacteristicsEngine fuctionsMachines/enginesElement modelMulti platform

The invention discloses a wind turbine generator dynamic response analysis method based on multi-platform co-simulation, and belongs to the technical field of wind turbine generators. Aiming at structural components of a wind turbine generator, 3D solid modeling is completed through a Creo platform, and a Creo model is imported into an ABAQUS finite element platform. According to the actual working conditions, the correct constraint relationship of each part of a finite element model of a whole unit in the ABAQUS is set, and simulation is conducted to obtain the intrinsic frequency and mode shape of an impeller assembly and the whole unit. Coupling response between the inside of the unit, that is, between an impeller and a tower, is discussed through response simulation, the natural vibration characteristics of key components and the whole unit are studied by using a finite element simulation method, the dynamic response characteristics of the wind turbine generator are obtained by using time-varying wind pressure distribution as the main excitation load, the wind turbine generator dynamic response analysis method based on multi-platform co-simulation has significances to improvingthe structure design of the unit and formulating effective diagnosis strategies.

Owner:BEIJING UNIV OF TECH

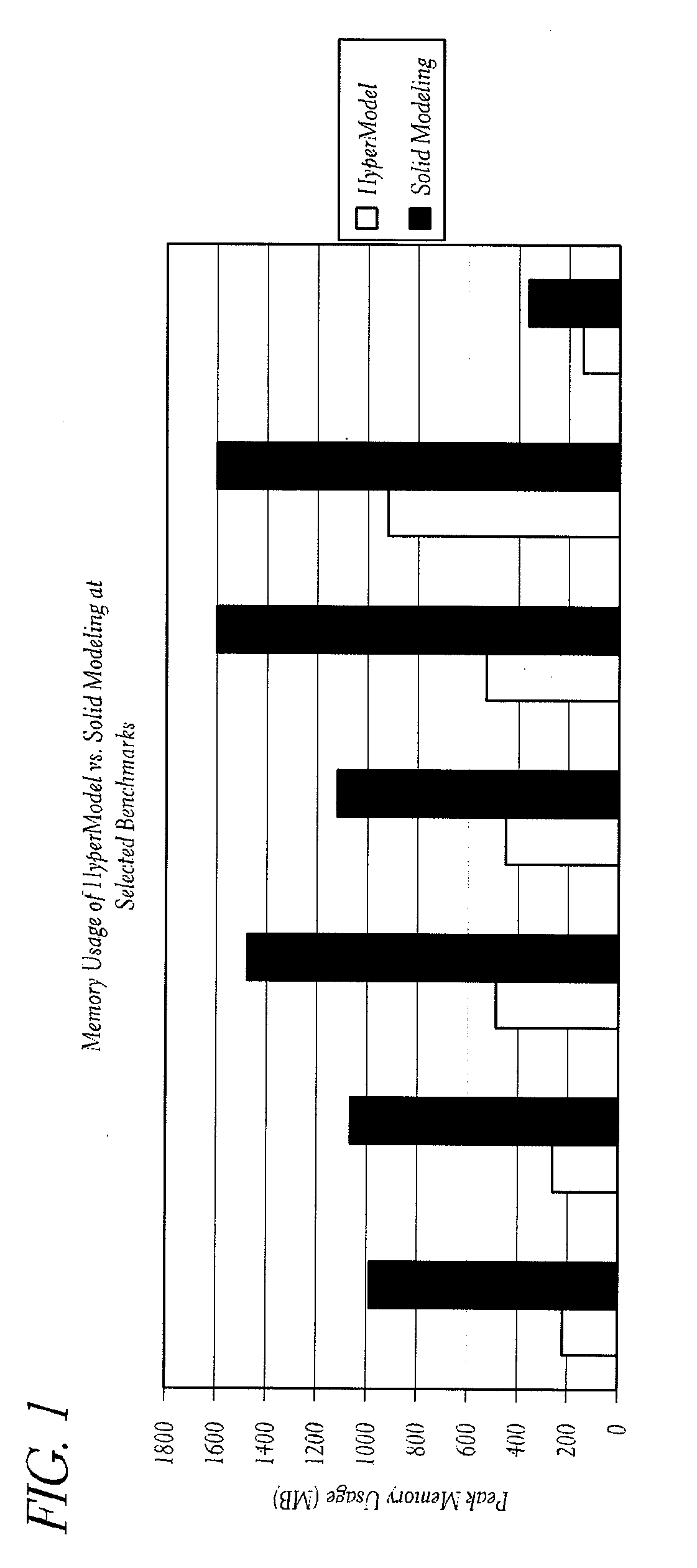

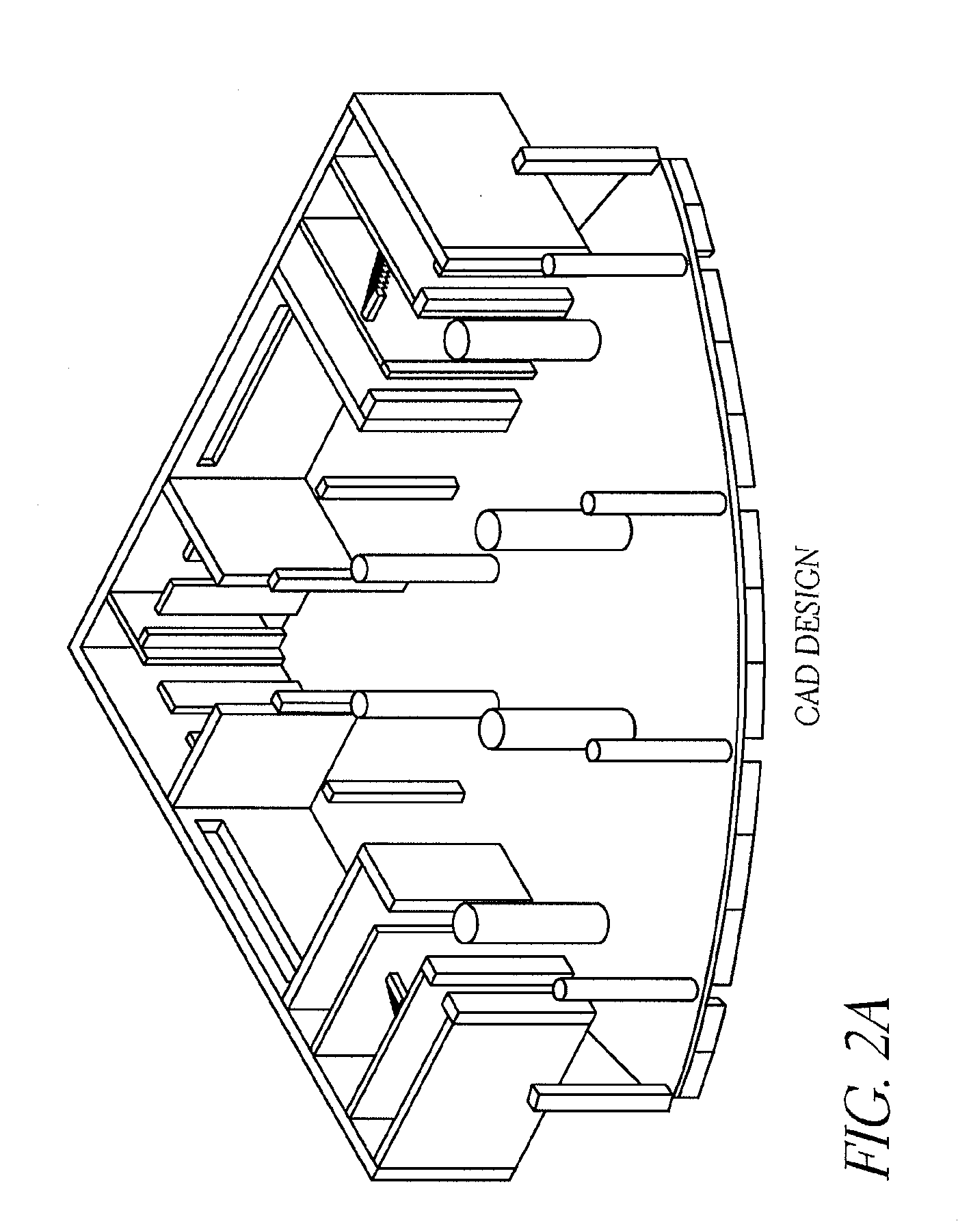

System and method for hybrid solid and surface modeling for computer-aided design environments

Systems and methods for modeling computer-aided design (CAD) environments and objects are disclosed. The systems and methods provided herein comprise a hybrid between solid modeling and surface modeling. The methods and systems are directed to structures that represent objects and rendering of the objects. The hybrid solution combines the modeling features and rules of solid modeling and the performance abilities provided by surface modeling. This provides efficient memory usage and advantageous run time performance.

Owner:CCT INT

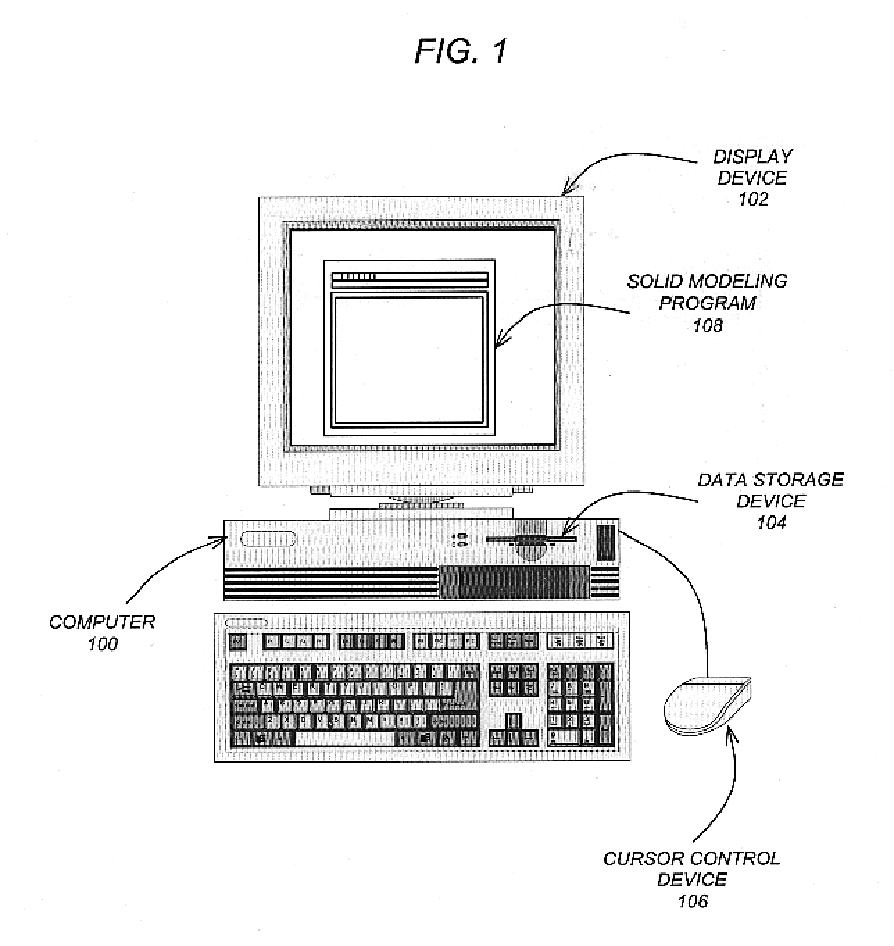

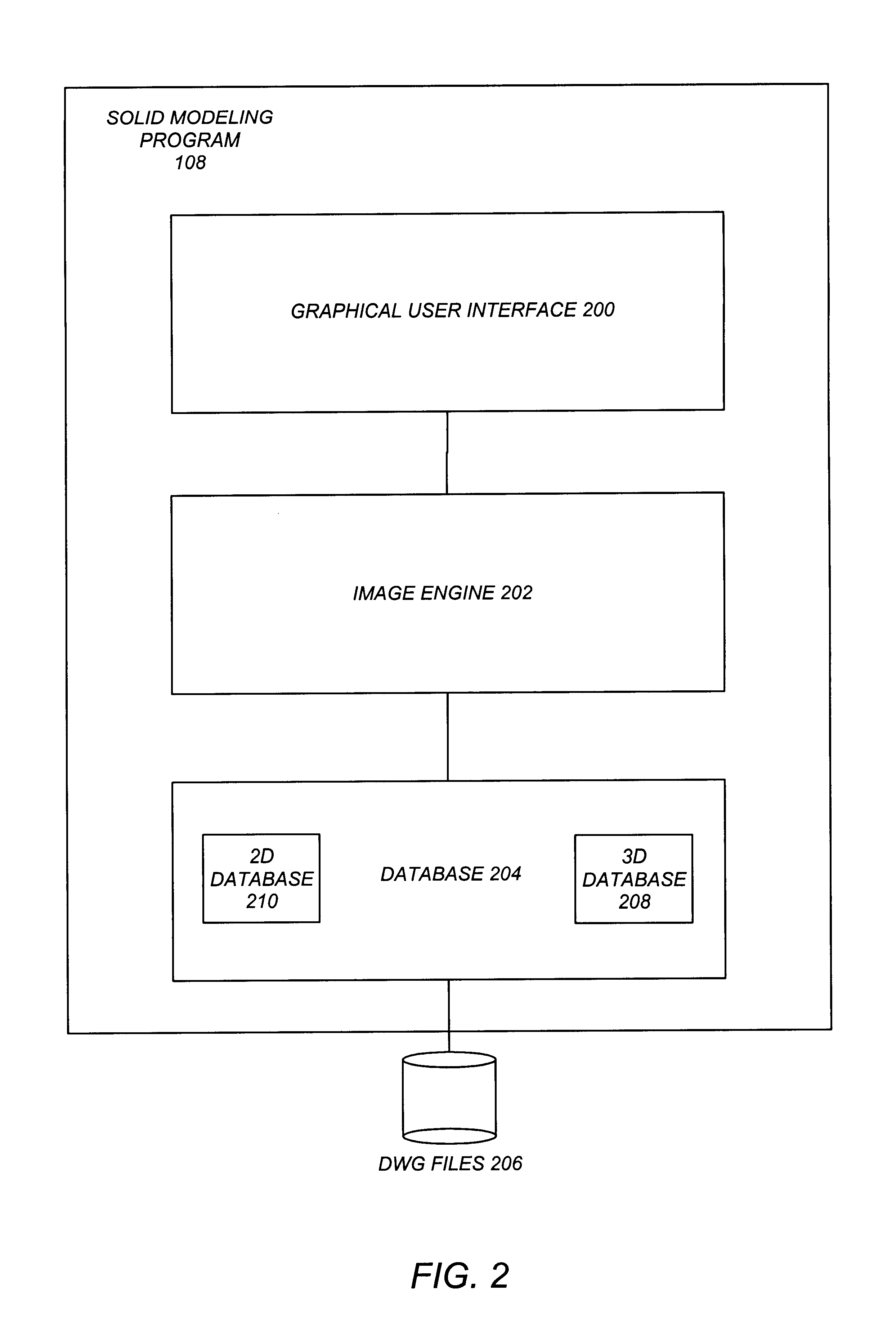

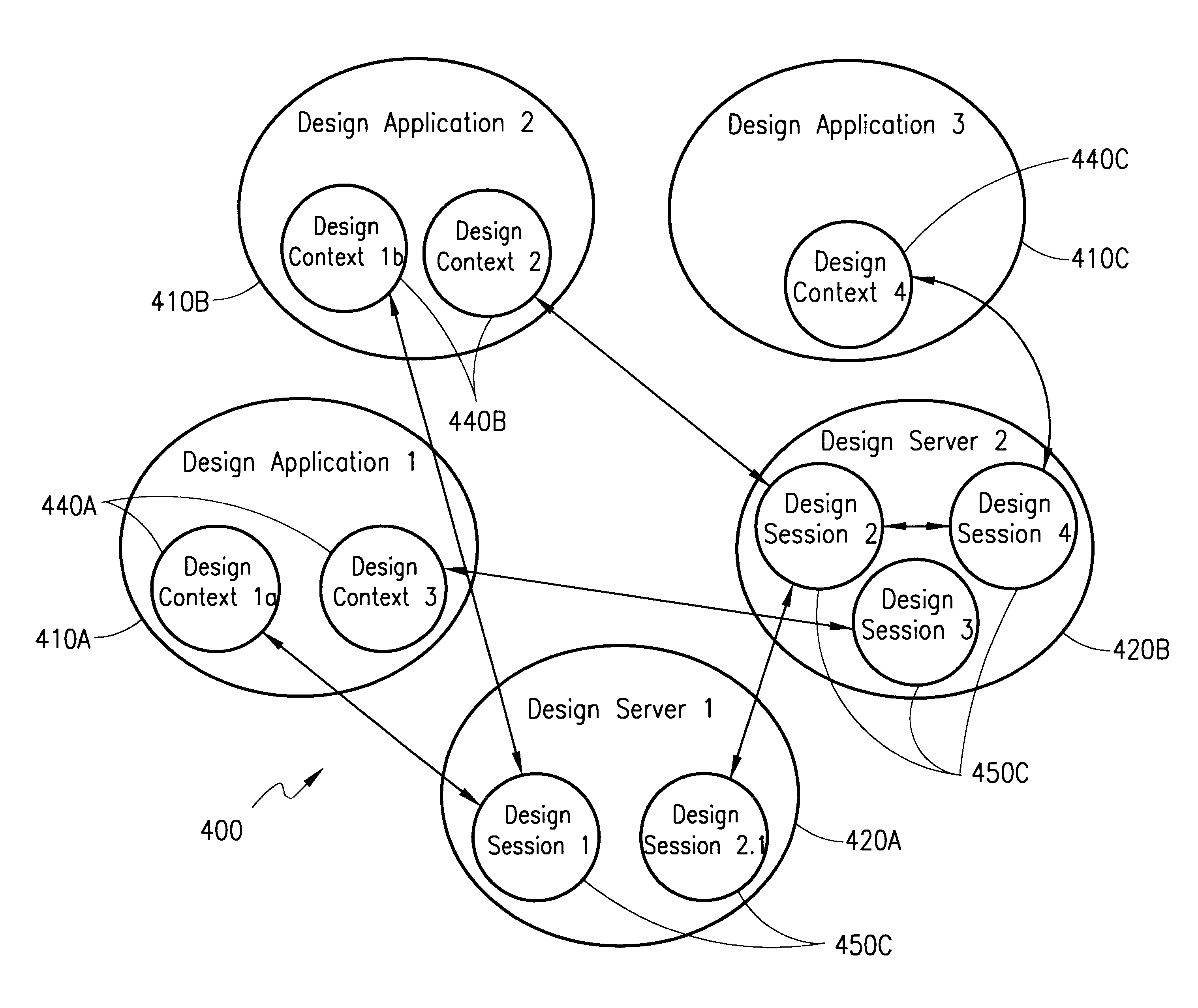

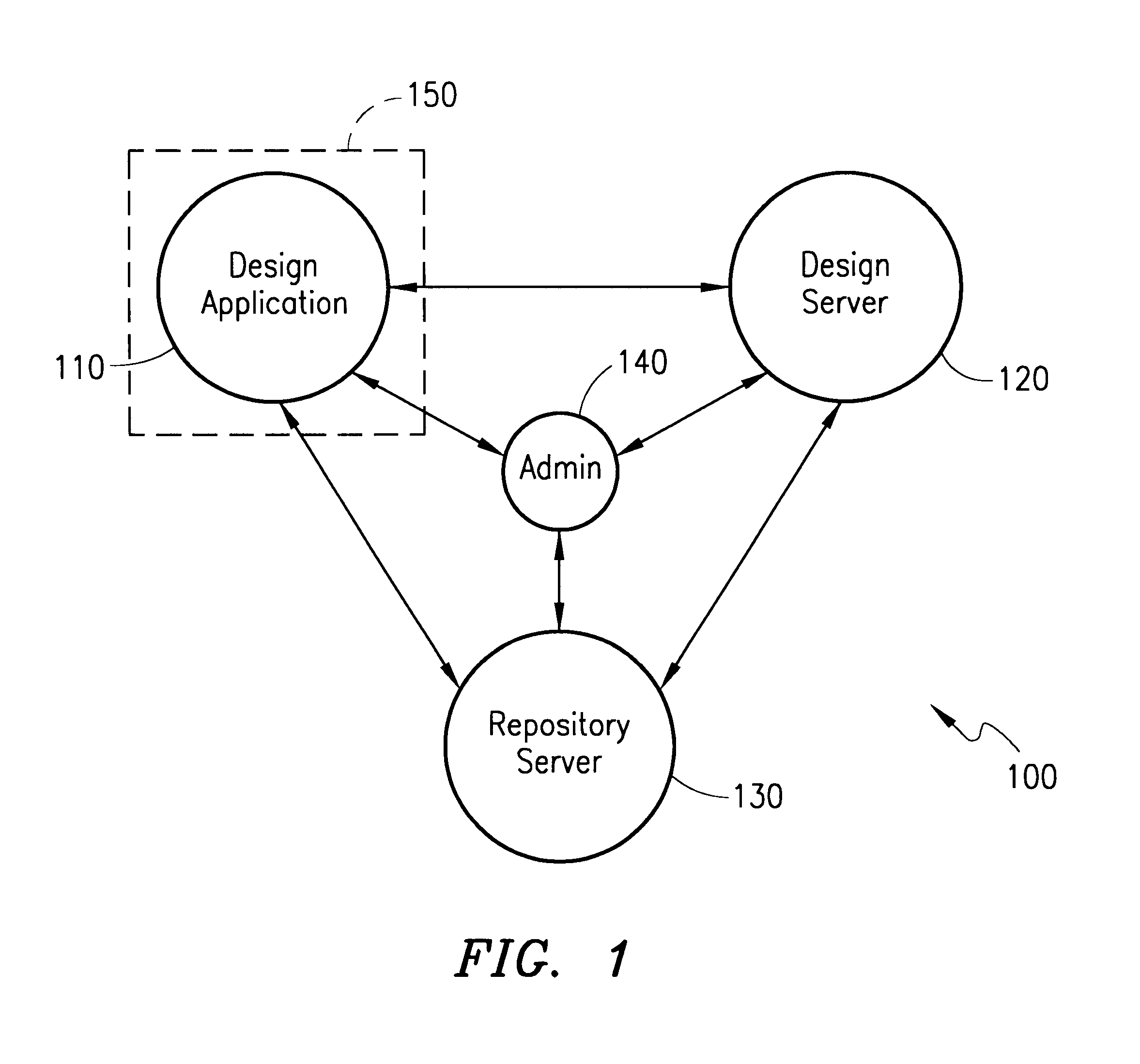

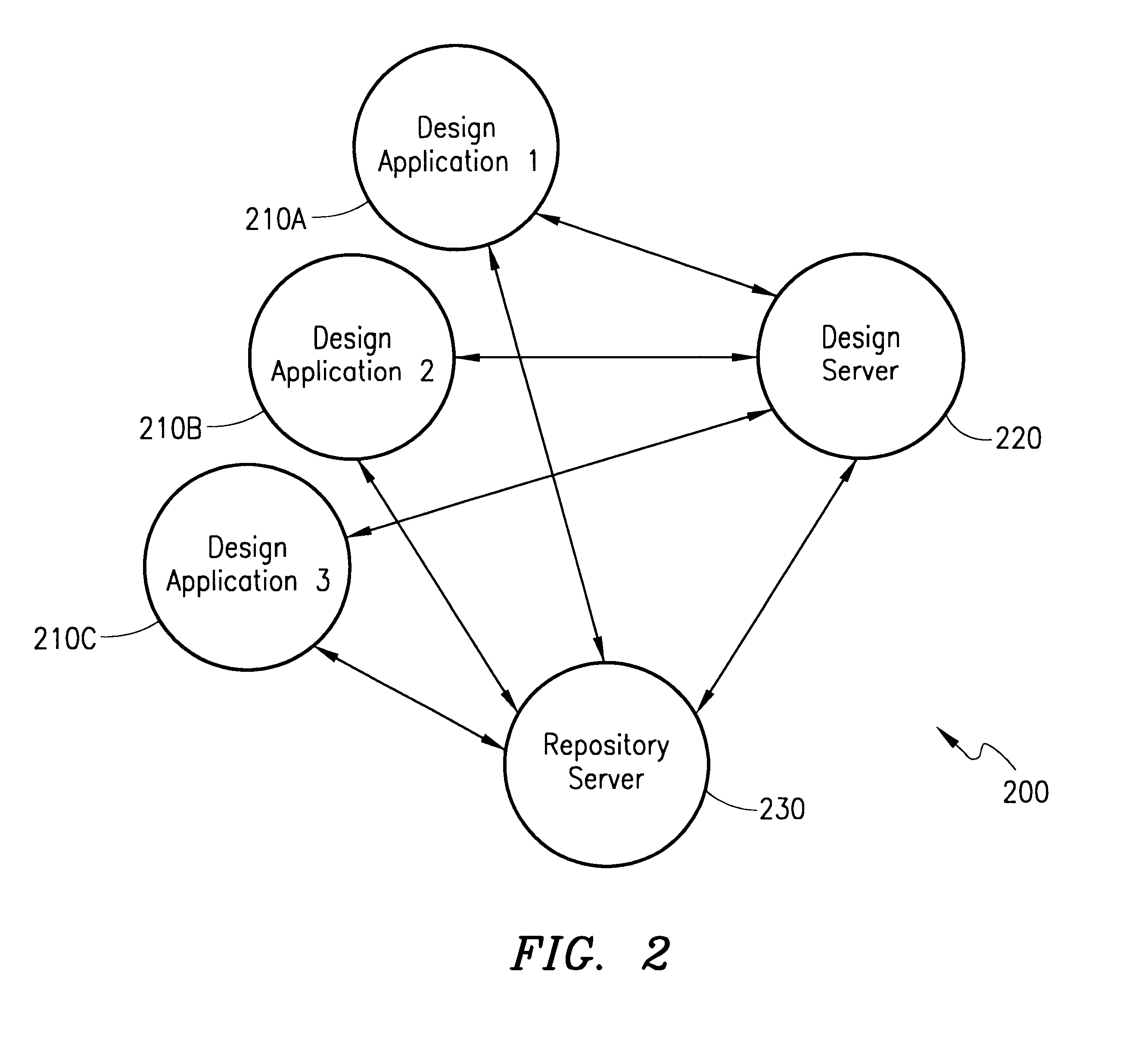

System and method for solid modeling

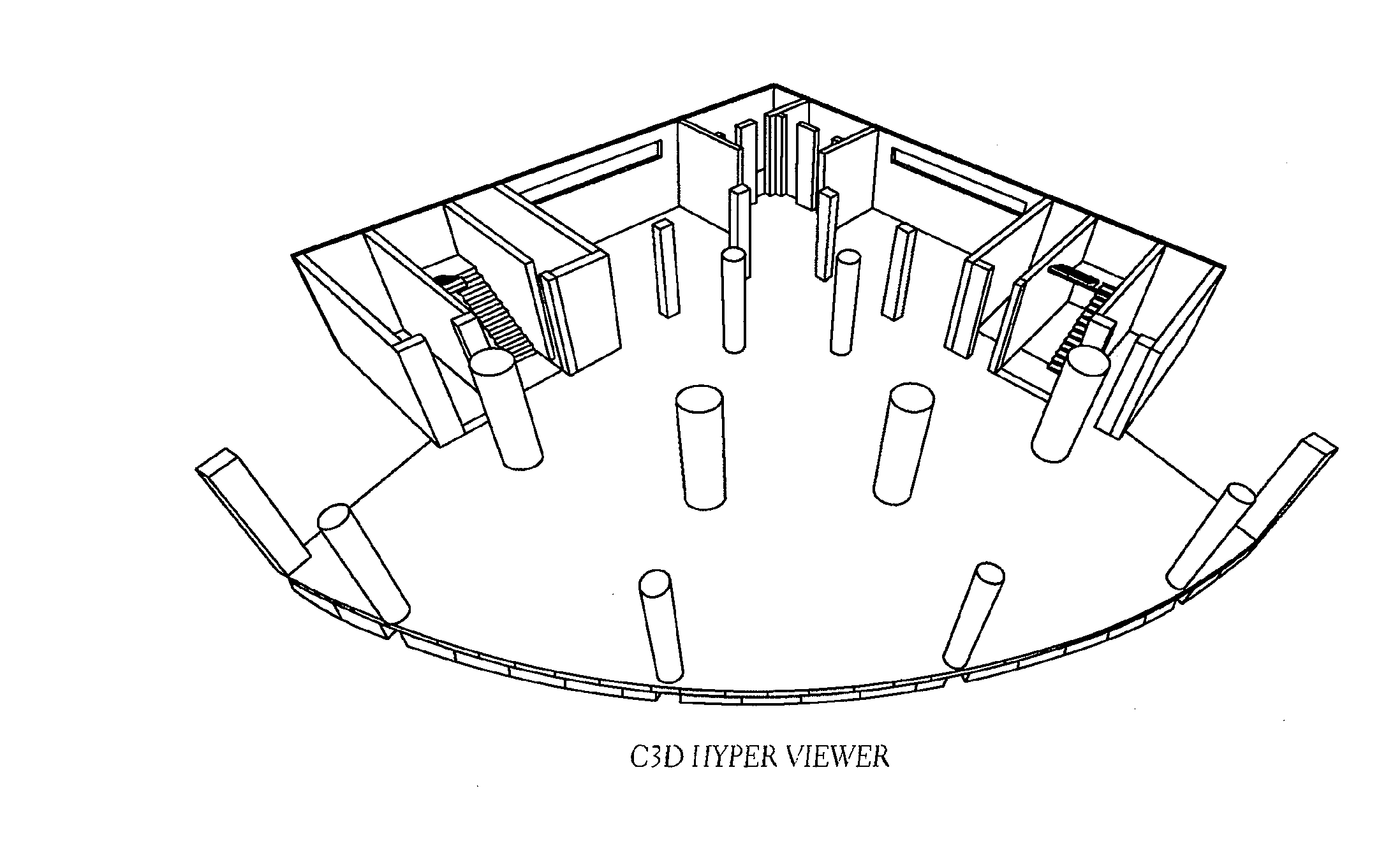

InactiveUS6748419B2Improve processing efficiencyAdd optionsMultiple digital computer combinationsAerodynamics improvementData storeUser interface

Modeling three-dimensional objects on a computer system via a high bandwidth distributed network, facilitating the computing of intensive computer-aided design (CAD) tasks to take place on a series of servers. A multi-tiered distributed processing architecture, which separates client user interface, multiple application servers and database servers is employed, resulting in the separation of server computing and data storage from the client control device. Computing for CAD tasks is directed to the client device or to an application server, as is appropriate for the complexity of tasks being performed.

Owner:ALIBRE

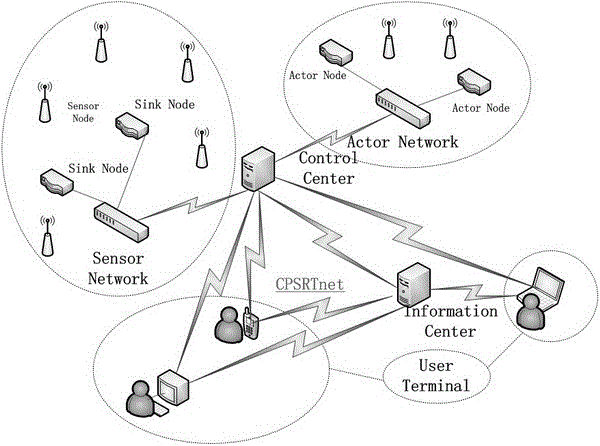

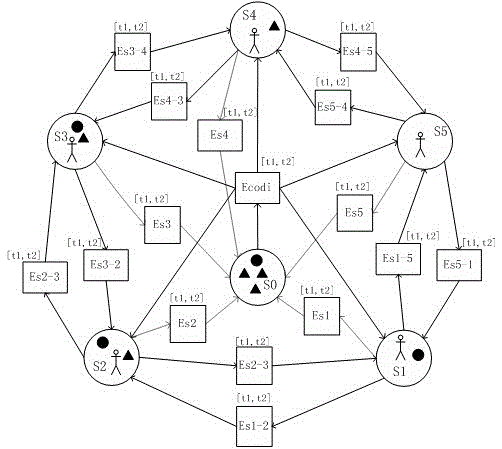

CPS physical solid formalized modeling method based on blend space-time Petri net model

InactiveCN105653577AGuaranteed real-timeRelational databasesSpecial data processing applicationsPhysical entityPetri net

The invention provides a CPS physical solid formalized modeling method based on blend space-time Petri net model. First, a rational system structure map is provided after Cyber-physical System (CPS) features are analyzed; a new event presentation is designed for space-time features of the CPS event message and physical solid dynamic changes; space-time factors and continuous variables are introduced on the basis of the Petri net to construct a blend space-time Petri net model; physical solid logic and time hierarchal behaviors can be described and state changes due to changes of physical solid position changes can be described. The CPS physical solid formalized modeling method based on a blend space-time Petri net model can be applied to real-time event CPS model design, so a new CPS physical solid modeling method can be achieved. Consistency between real-time property and space-time can be achieved for the CPS by the use of the method; continuous variables are introduced in consideration of physical environment dynamic property, so the method is suitable for all environments; and foundation is laid for the development of CPS.

Owner:NANCHANG HANGKONG UNIVERSITY

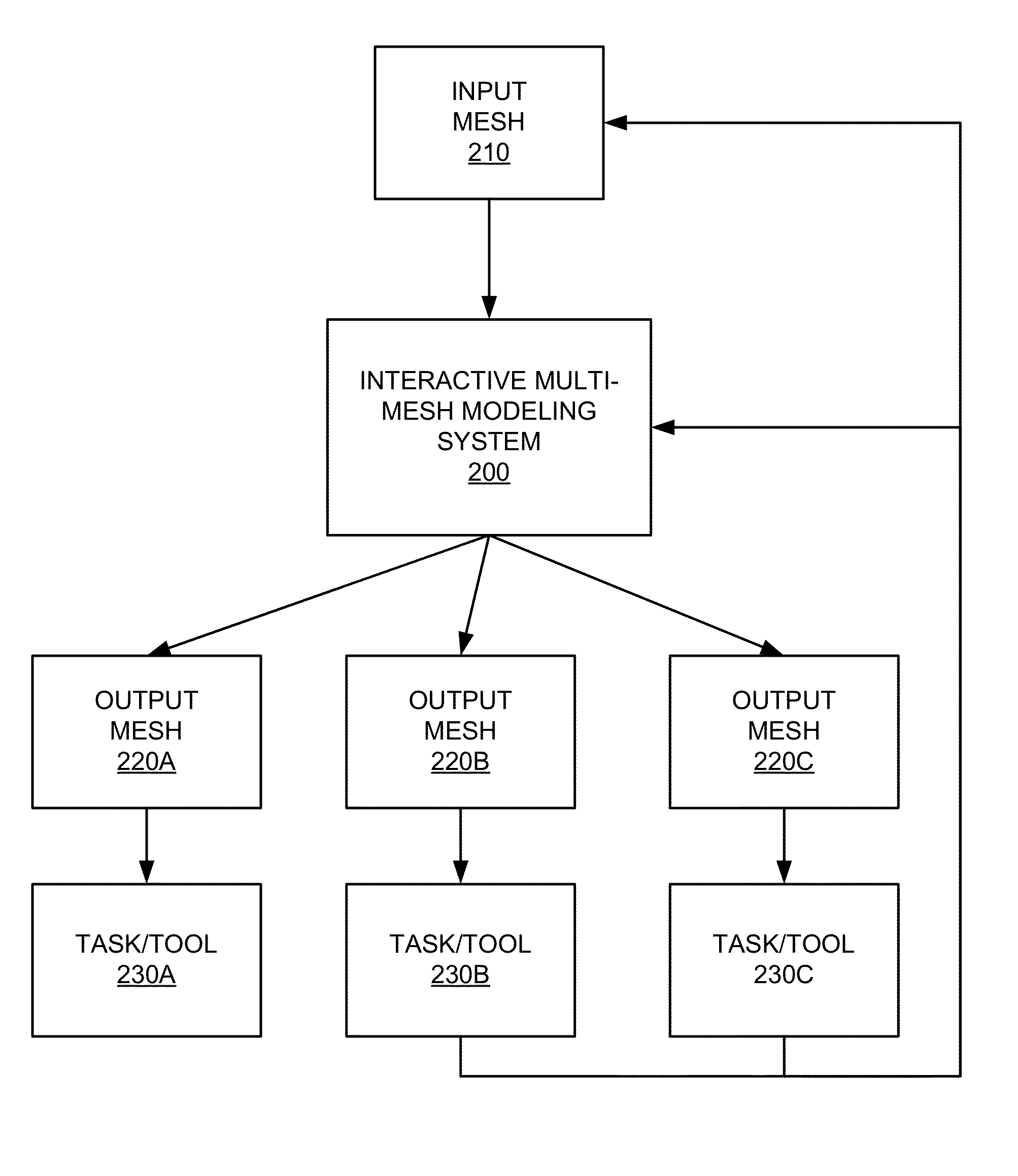

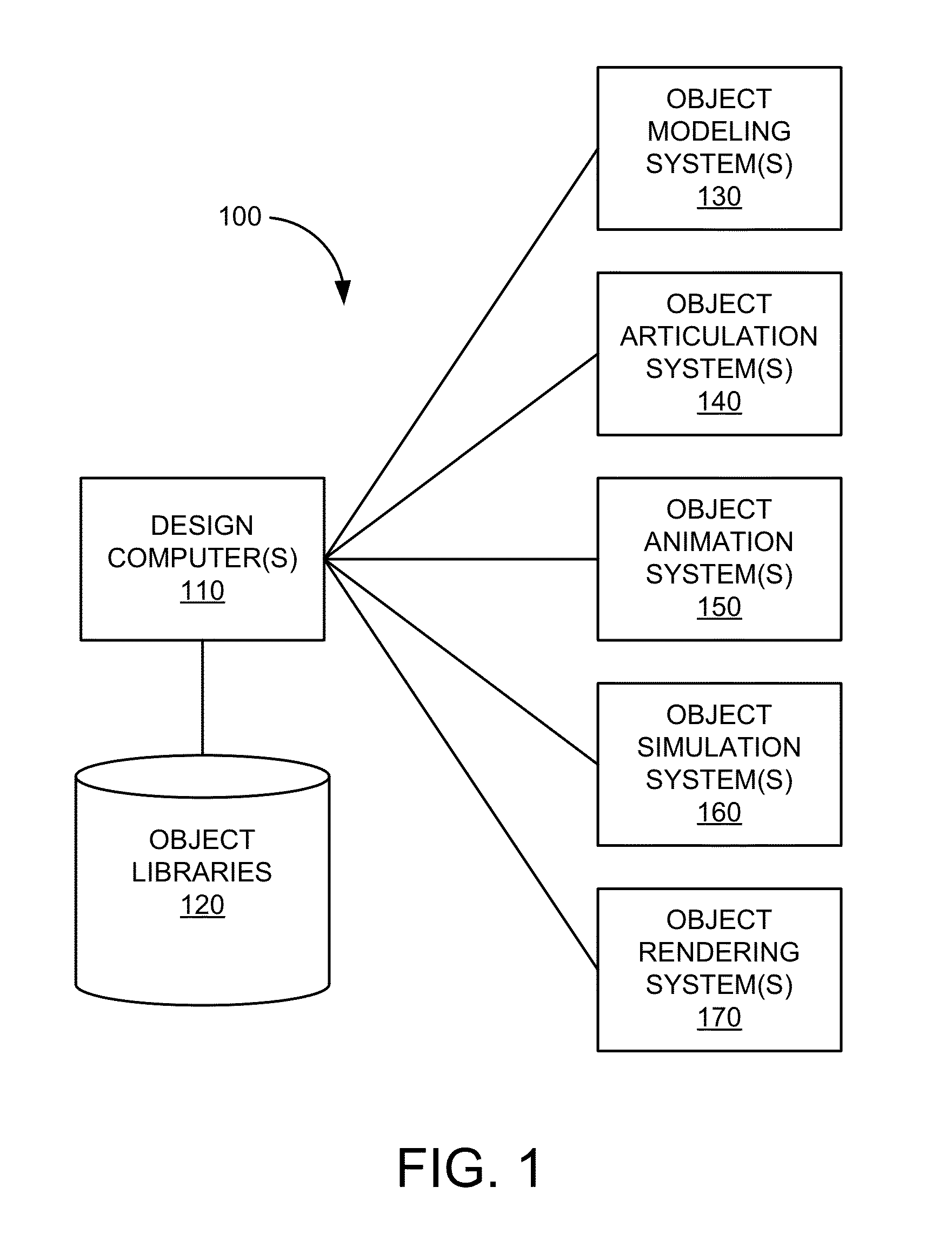

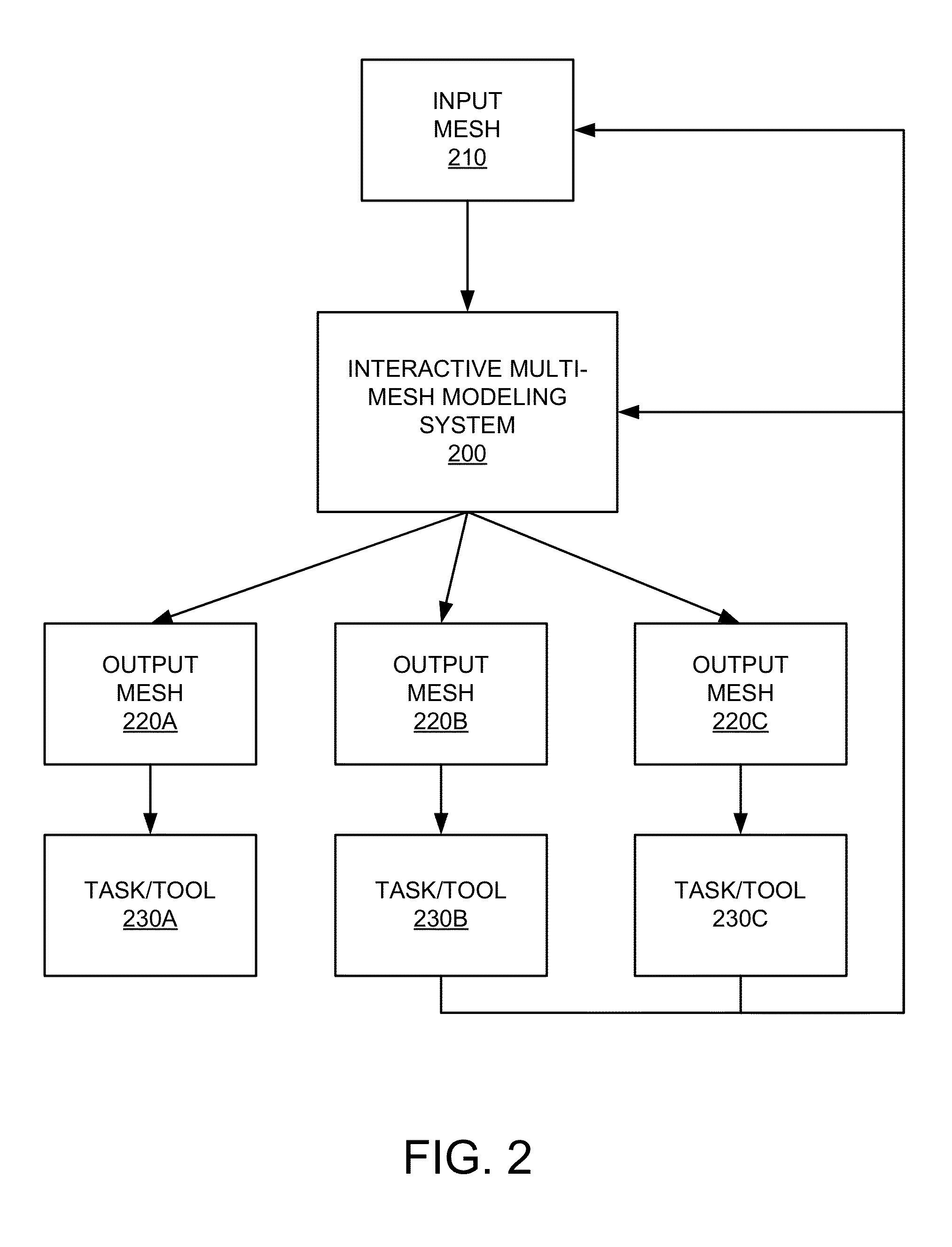

Interactive multi-mesh modeling system

An interactive multi-mesh modeling system allows users to employ a variety of modeling techniques to interactively create objects for a variety of different tasks or tools. Some of these different tasks or tools can have requirements for computer-generated representations of objects on which they operate. These requirements may differ from how some computer-generated representations were originally created (e.g., 3D solid objects output using solid modeling techniques vs. 2D flat “panel constructed” objects required for some computer simulations). Thus, the interactive multi-mesh modeling system may further employ a variety of techniques for taking a source computer-generated representation of an object and providing the automatic creation, management, and maintenance of instances or versions of the source. The interactive multi-mesh modeling system may further employ a variety of techniques for the automatic management and transfer of information defined thereon or associated with these meshes.

Owner:PIXAR ANIMATION

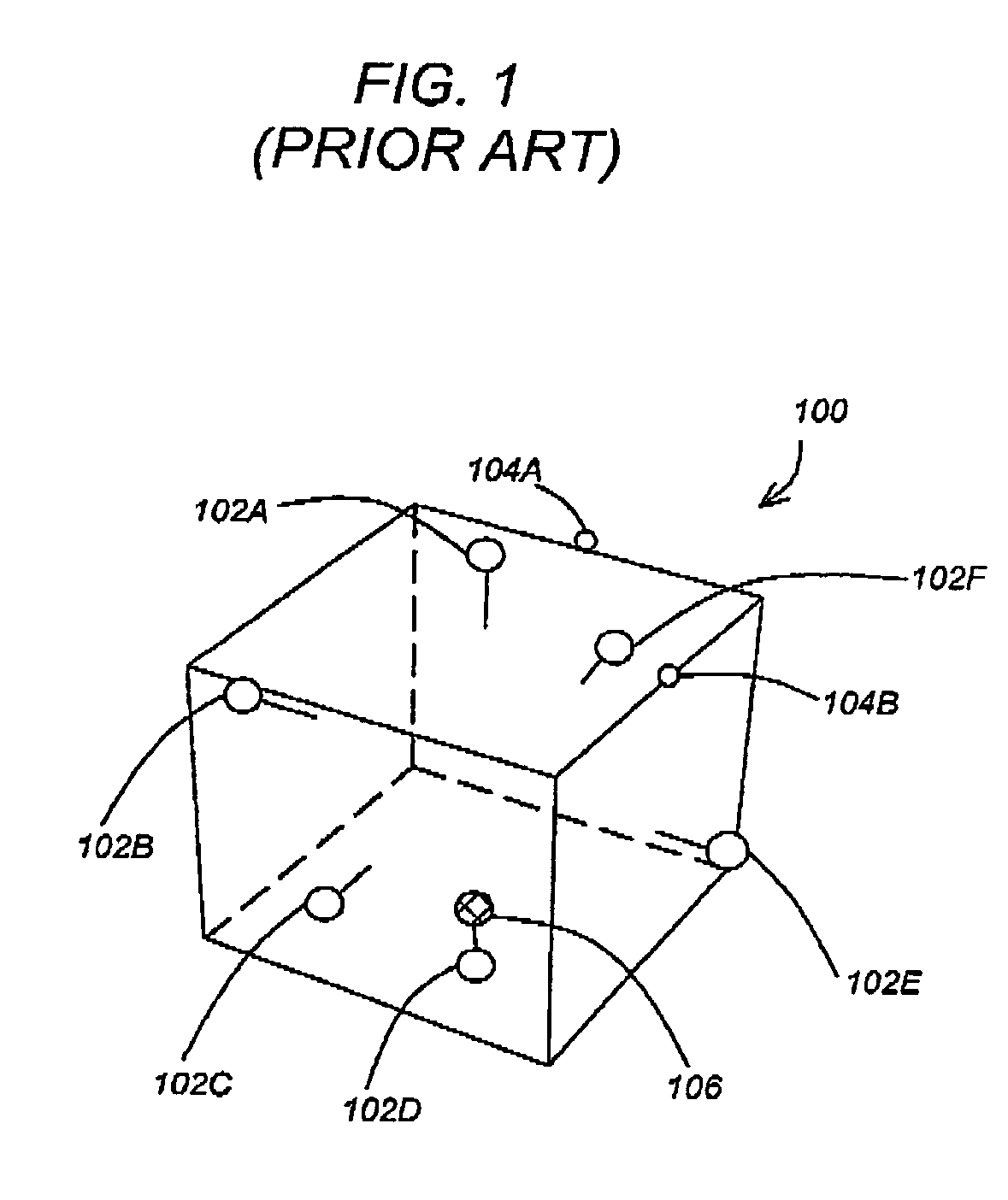

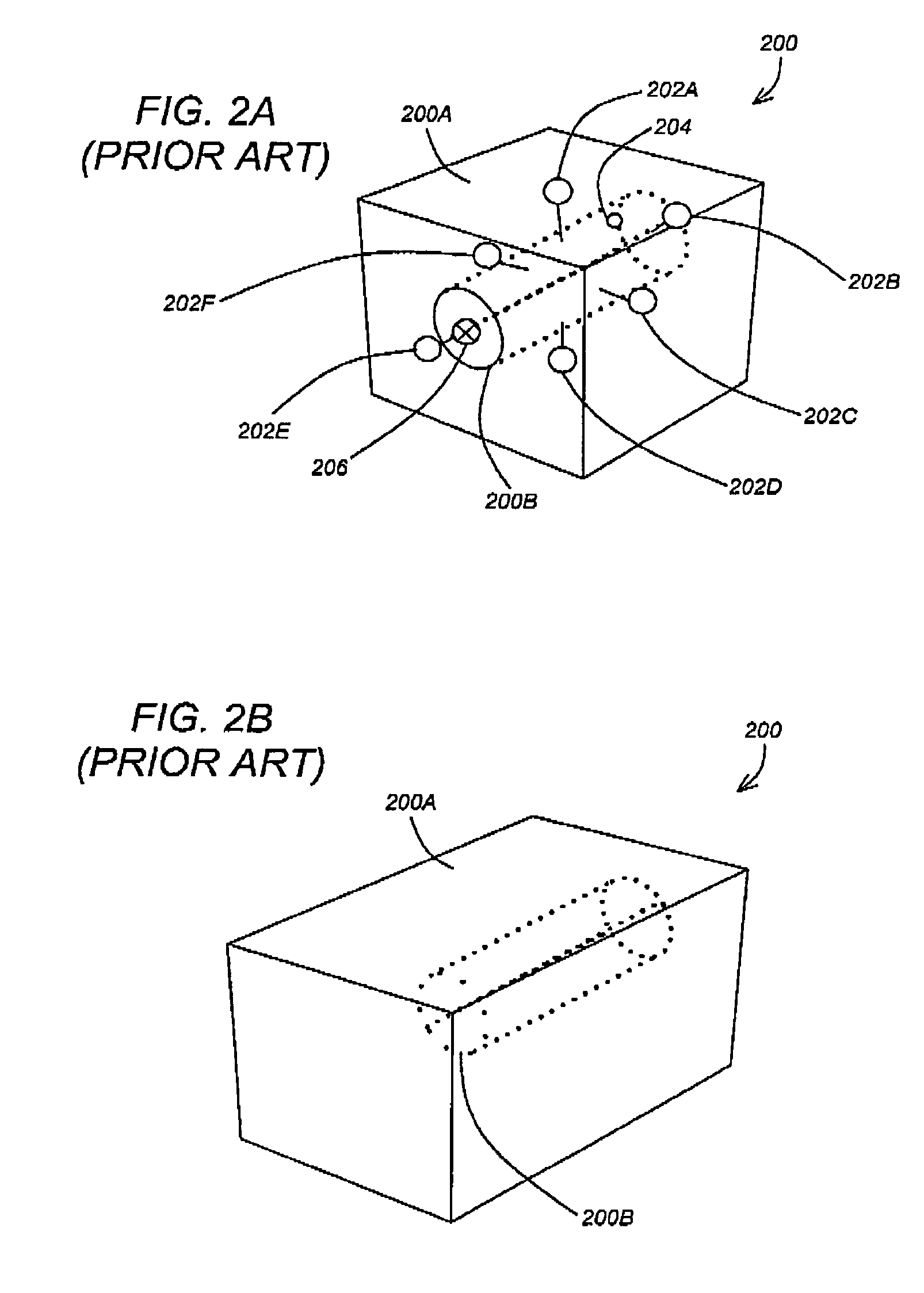

Face modification tool

ActiveUS7092859B2Avoiding adding new operationComputation using non-denominational number representationInput/output processes for data processingComputational scienceBoundary representation

One or more embodiments of the invention provide a method, apparatus, system, and article of manufacture for modifying a three-dimensional model. A composite three-dimensional model is displayed in a computer implemented solid modeling system. The composite model comprises a first primitive and a second primitive. A first face of the first primitive is selected. Once selected, a first boundary representation of the first primitive is modified using the selected first face. Thereafter, a second boundary representation of the second primitive is automatically modified based on the modification to the first boundary representation.

Owner:AUTODESK INC

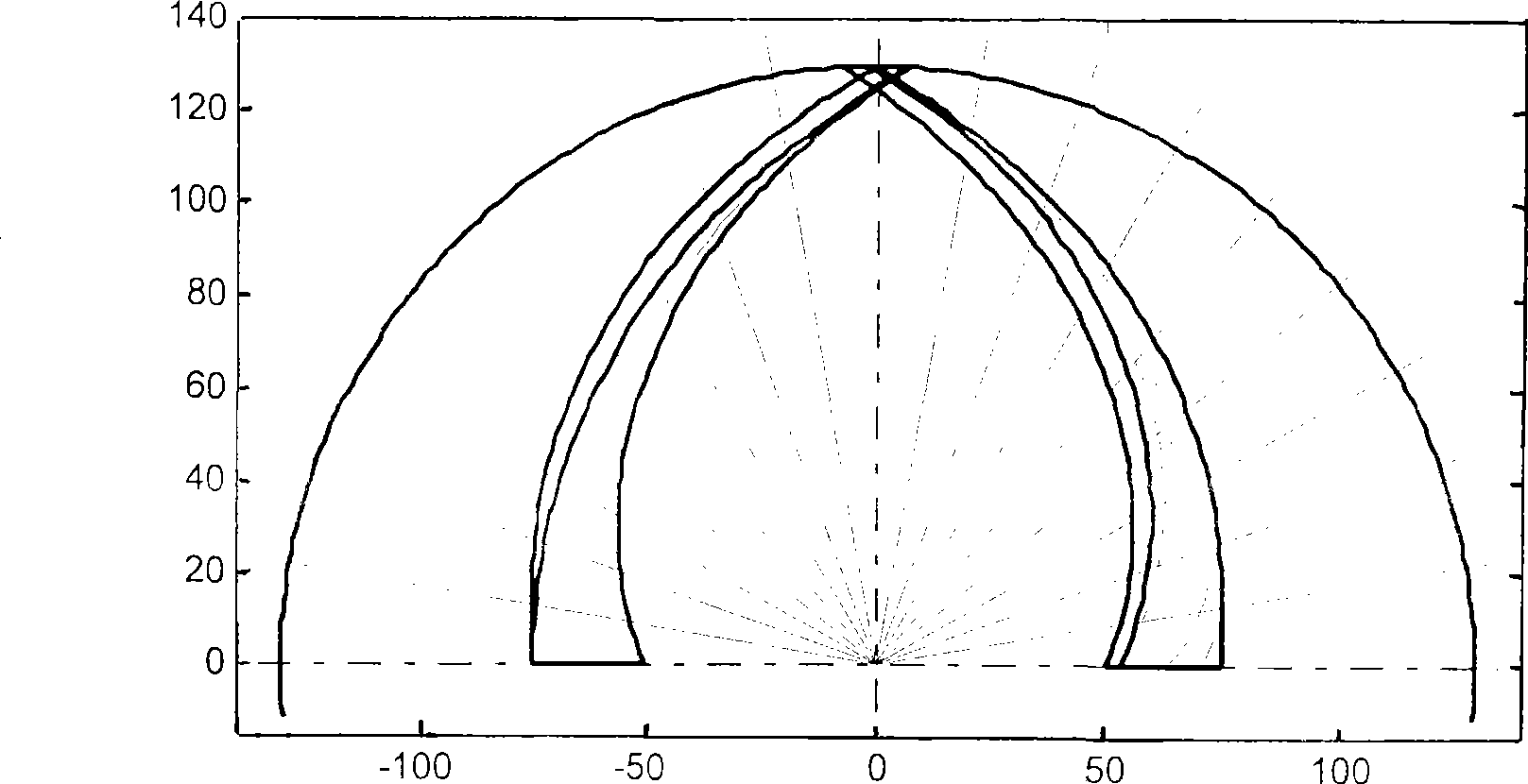

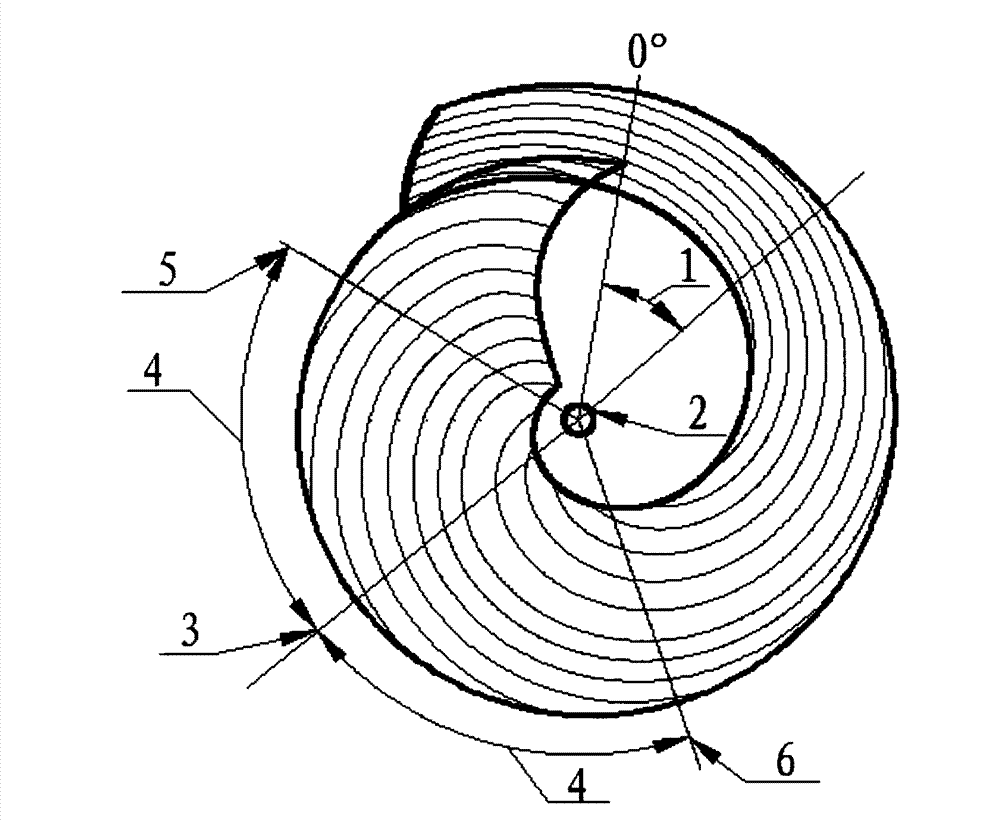

Method for eliminating unbalanced force of single-blade pump impeller

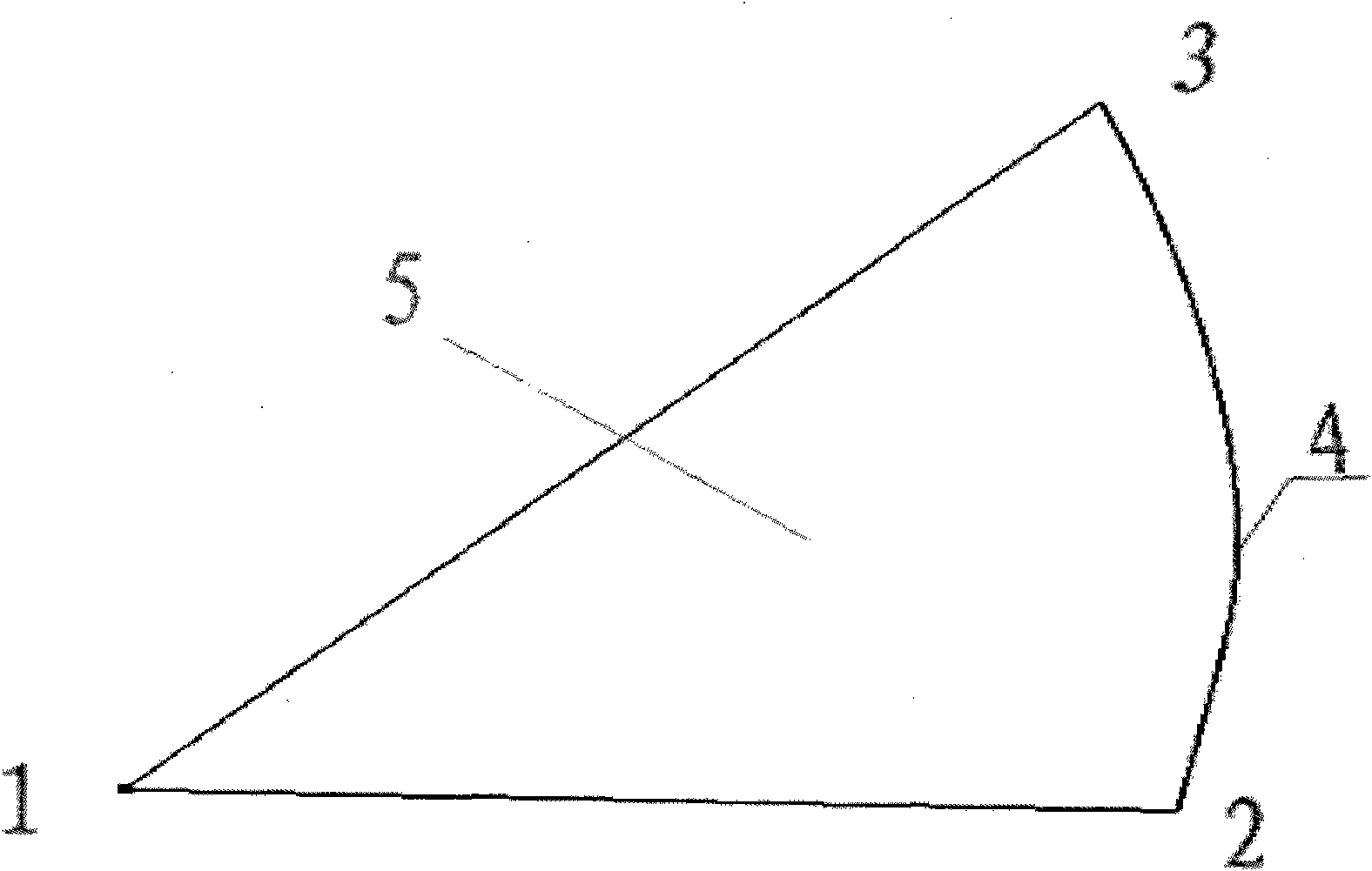

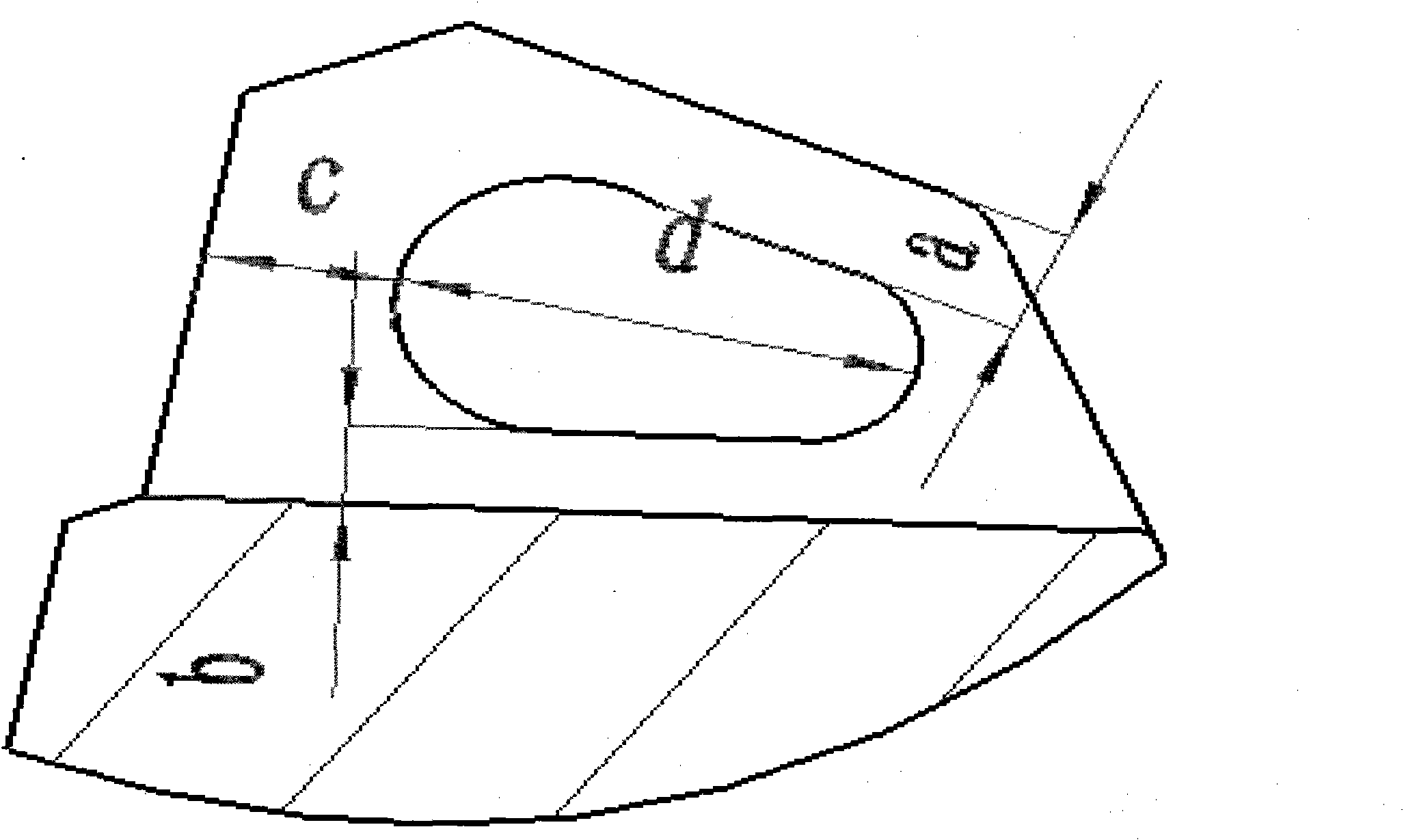

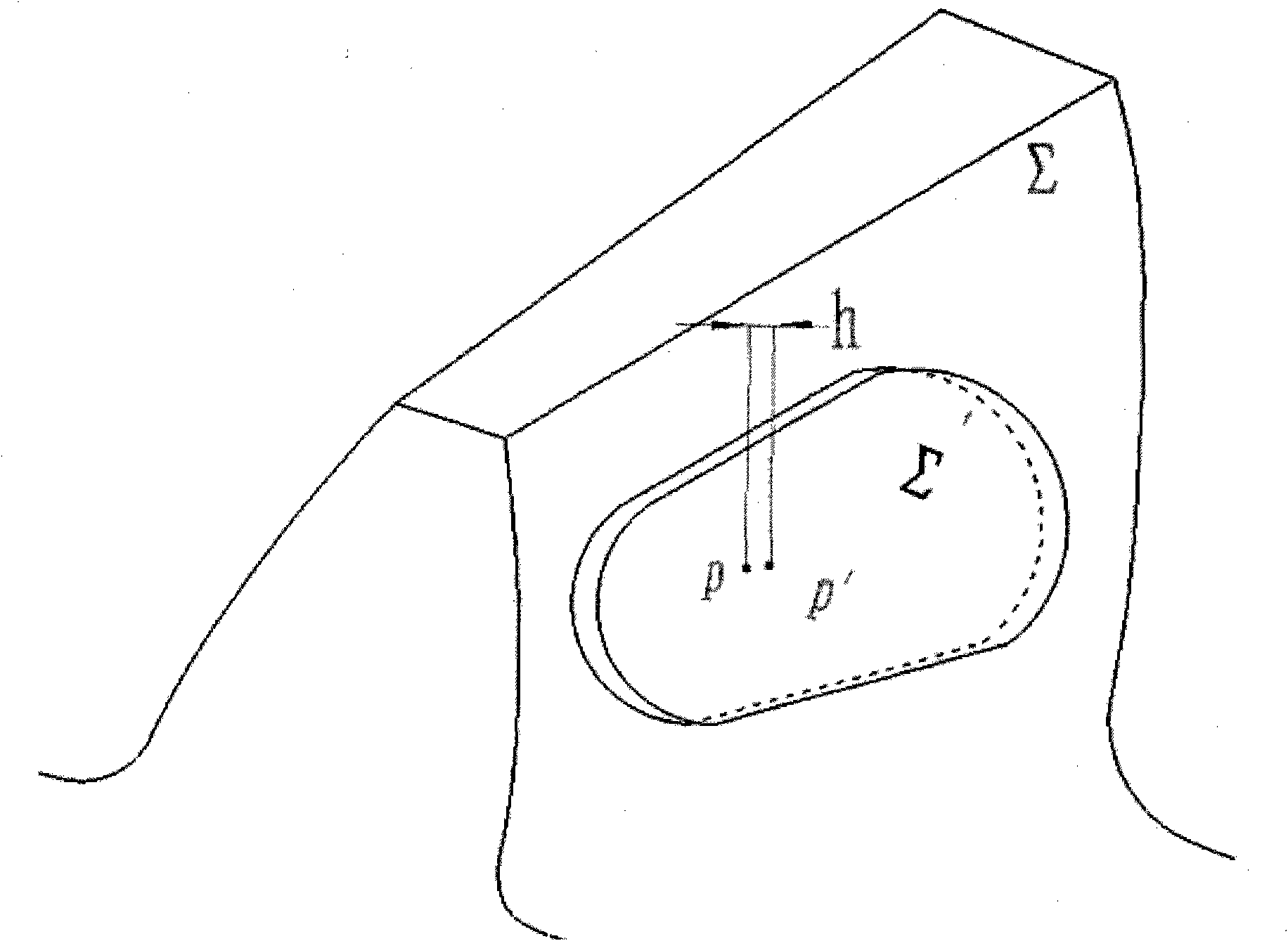

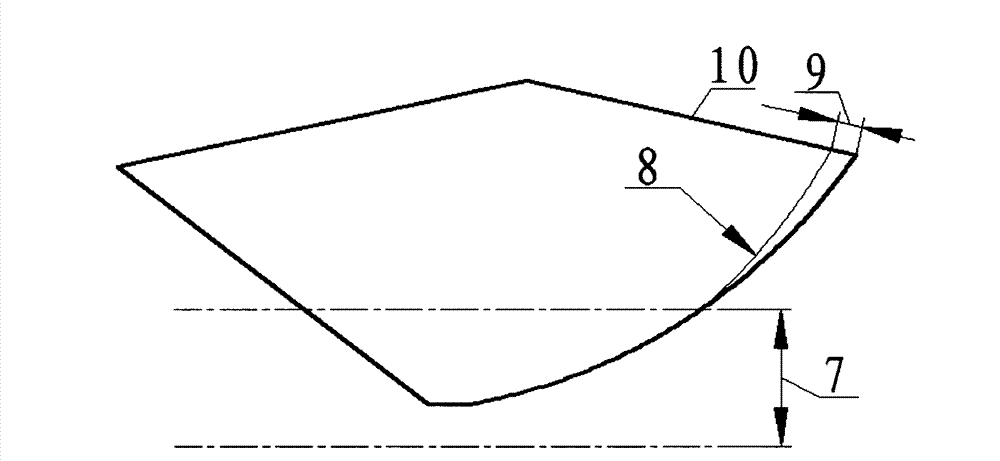

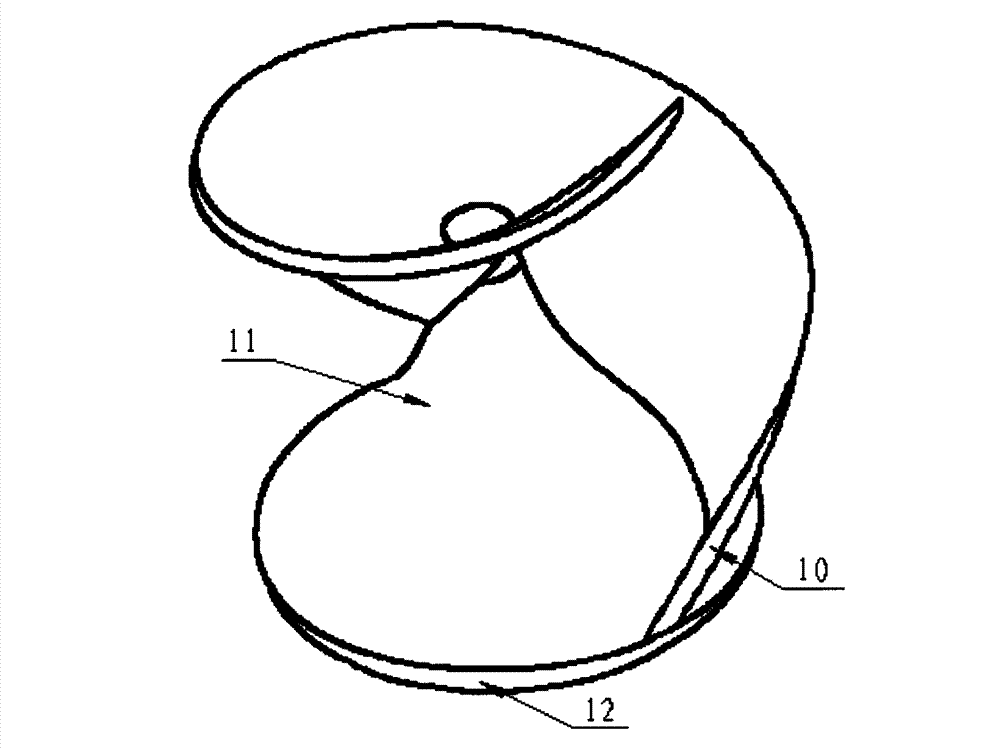

ActiveCN102734232AEliminate unbalanced forcesImprove performancePump componentsPumpsImpellerGravity center

The invention relates to a method for eliminating unbalanced force of a single-blade pump impeller. The method is characterized by comprising a step of determining a blade gravity shifting angle (1), non-thickening gravity position (2), a thickening central line (3), a single side thickening range (4), a thickening starting line (5), a thickening ending line (6), a thickening radius starting point derivation axes distance (7), a hub thickening radius (8) and a hub thickening thickness (9). Based on a key point, when the blade is designed, unbalance of the single-blade pump impeller is considered; solid modeling is performed to the blade by a three-dimensional modeling software PROE; a gravity position is found in the software so as to count a derivation angle; the hub is thickened or the blade is thickened on a position opposite to the gravity position; by dint of a pre-accentuation method, weighted quality can be estimated; data is fed back to an impeller mould; therefore, the impeller achieves quality balance initially.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

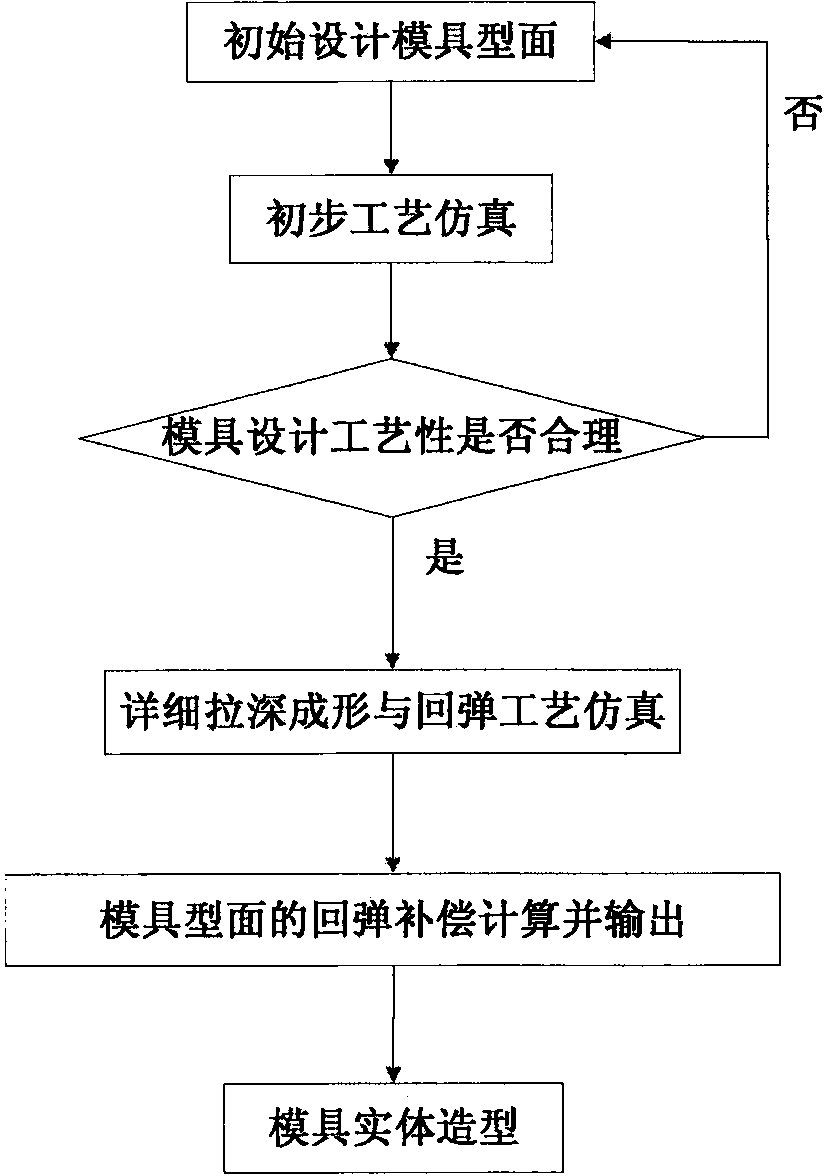

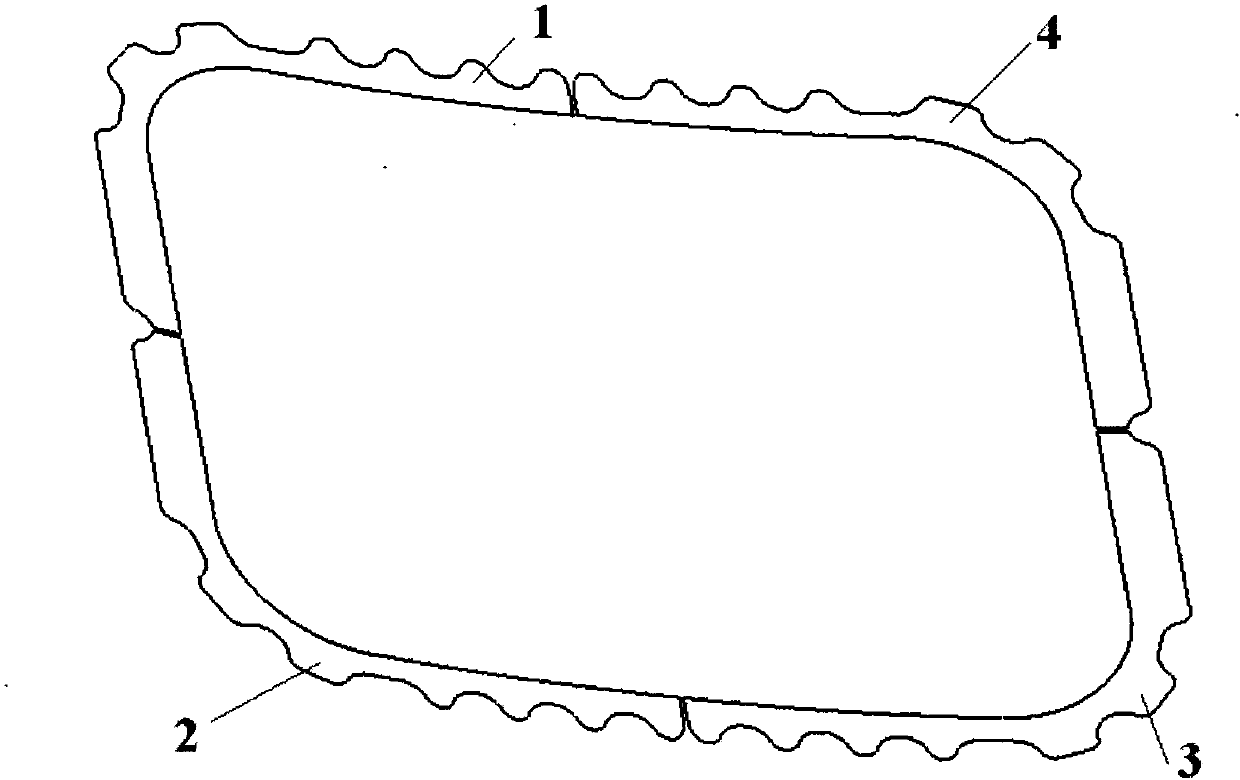

Method for designing forming dies for low-double-curvature sheet metal parts

ActiveCN104200037APrecise positioningLarge plastic deformationSpecial data processing applicationsDesign softwareEngineering

The invention relates to a method for designing forming dies for low-double-curvature sheet metal parts. The method includes steps of 1), initially designing four-piece integrated forming die profiles; 2), preliminarily simulating deep drawing forming technologies; 3), judging the rationality of die design technologies; 4), simulating deep drawing forming and spring-back technologies in detail; 5), computing and outputting spring-back compensation on the die profiles; 6), performing solid modeling on the dies in three-dimensional design software. The method has the advantages that all the four-piece double-curvature parts can be formed at one step by the aid of a deep drawing forming process, accordingly, the forming efficiency can be improved, the parts are low in spring-back rate, and the quality of the parts can be guaranteed.

Owner:SHENYANG AIRCRAFT CORP

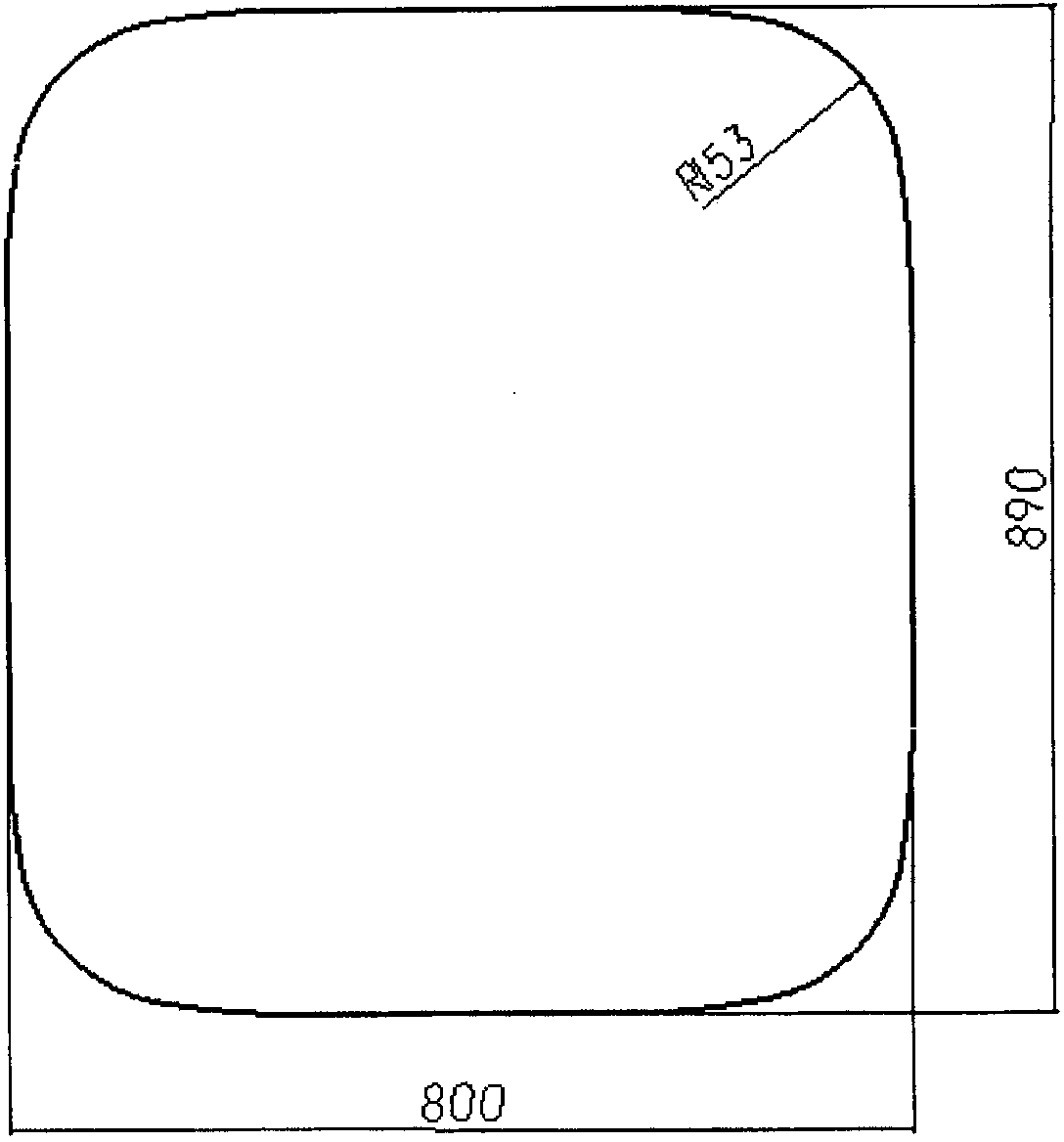

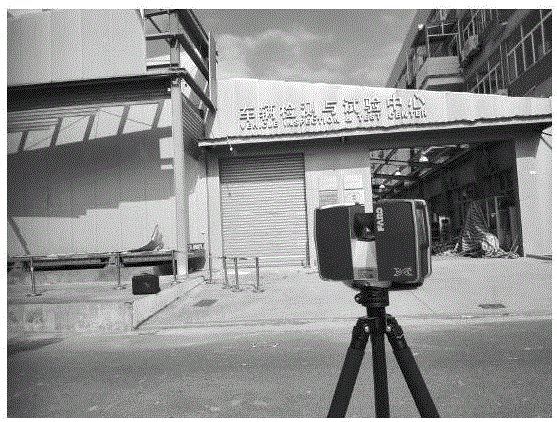

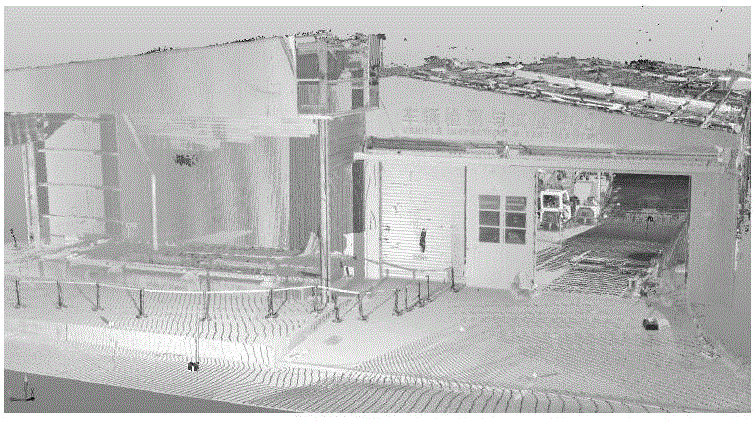

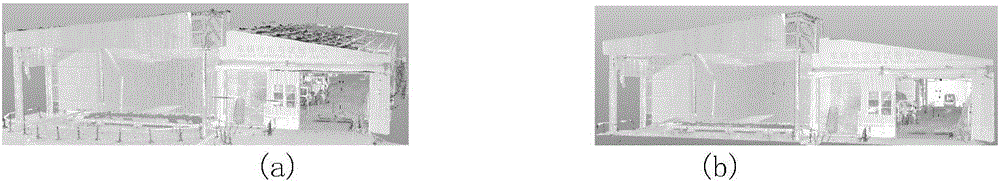

Method for enhancing typhoon protection capacity of buildings

ActiveCN106844983AEasy accessEfficient acquisitionGeometric CADDesign optimisation/simulationPoint cloudComputer science

The invention discloses a method for enhancing typhoon protection capacity of buildings. The method includes the following steps: firstly, structuring a two-dimensional line drawing and a three-dimensional model of a typhoon damaged building; to be more specific, a, acquiring laser point cloud data of the disaster damaged building; b, performing registration and splicing on the point cloud data so as to obtain the two-dimensional line drawing; c, performing solid modeling through the two-dimensional line drawing matching with the point cloud data so as to obtain the three-dimensional model of the building; secondly, computing disaster damage according to the two-dimensional line drawing of the building, judging disaster damage types of the building structure according to the three-dimensional model, and adopting different design schemes on different structures of the building according to the disaster damage types. Through the method, the three-dimensional model of the typhoon damaged building can be structured, and theoretical guidance is provided for the anti-typhoon structure of the buildings according to the three-dimensional model.

Owner:XIAMEN UNIV OF TECH

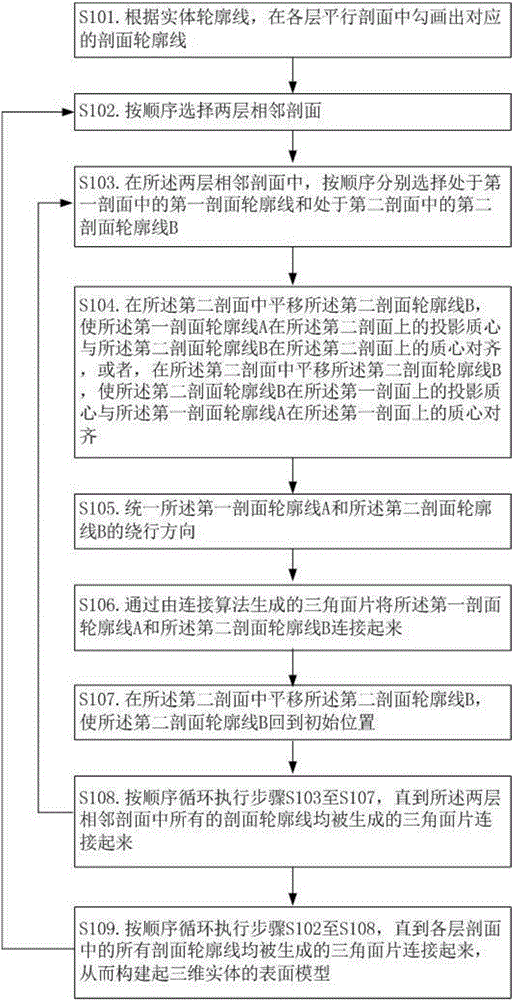

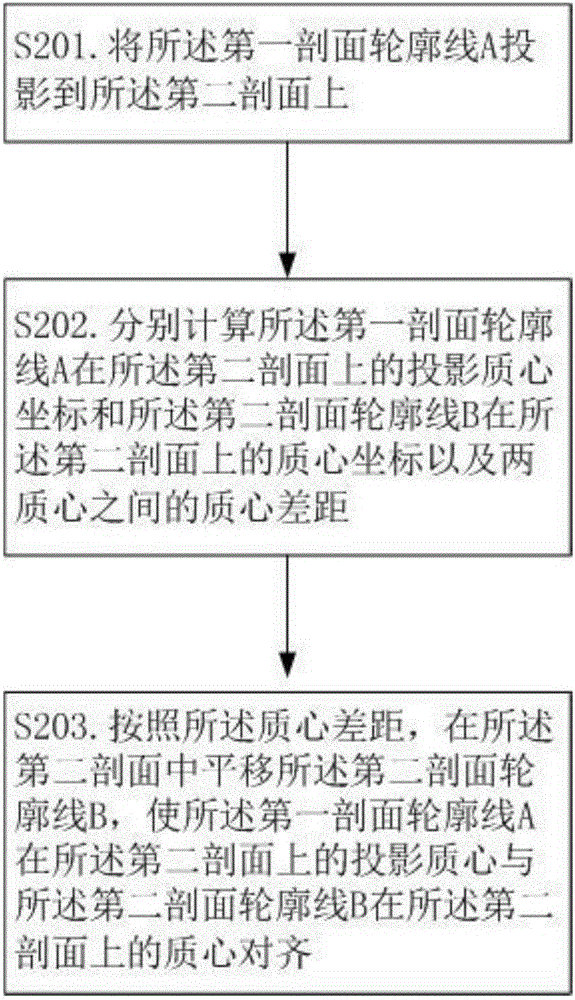

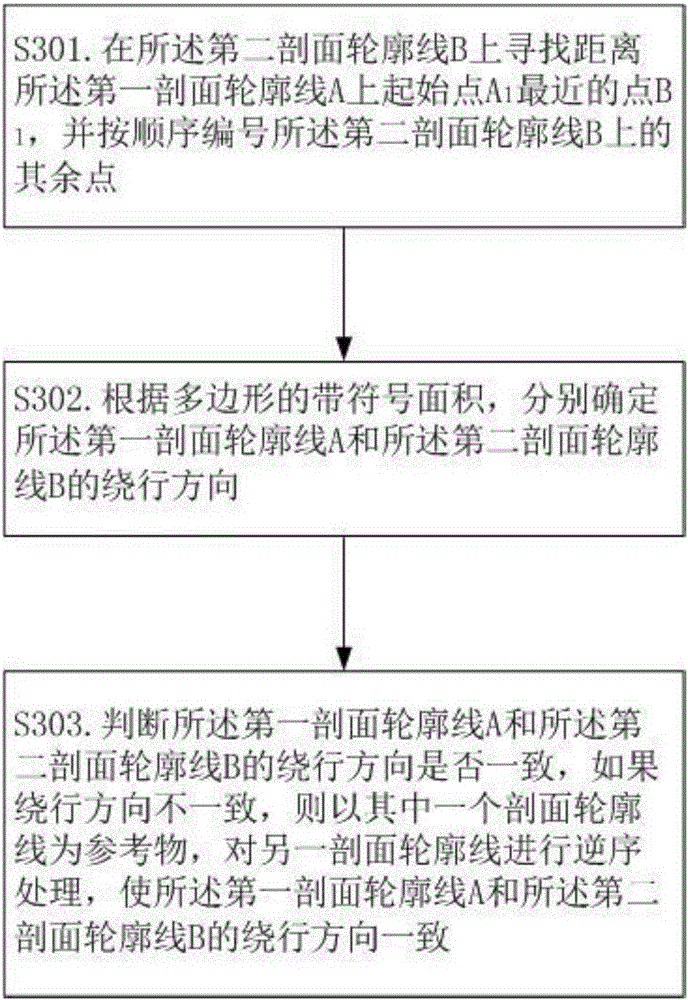

Three-dimensional solid modeling method based on multi-contour-line triangularization network reconstruction

The present invention relates to the technical field of three-dimensional geological modeling and discloses a three-dimensional solid modeling method based on multi-contour-line triangularization network reconstruction. According to the three-dimensional solid modeling method, a triangular sheet surface can be constructed between multiple pairs of mutually paralleled cross-sectional contour lines in pairs of adjacent cross sections by using a multi-contour triangular network reconstruction based algorithm that contains a cross sectional contour line mass center alignment technology, a cross sectional contour line directional consistency technology and a cross sectional contour line curved surface reconstruction technology, so that a surface model of a three-dimensional solid body is completed. Therefore the three-dimensional solid modeling method can synthesize advantages of a surface model modeling method and a body model modeling method to make up for the defects of the method and perform comprehensive expression on solid bodies such as a geological object in a three-dimensional space so as to facilitate space analysis, and meanwhile has the advantages of a simple structure, a small computational amount and less possibility of errors, so that highly precise three-dimensional modeling can be rapidly implemented, and the method has higher practicality.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com