Method for eliminating unbalanced force of single-blade pump impeller

A technology of pump impeller and balancing force, which is applied to the components, pumps and pump components of the pumping device for elastic fluid, can solve the problems of shortening the service life, affecting the performance of the pump, wear or loosening, etc., so as to prolong the service life. , the effect of eliminating unbalanced force and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

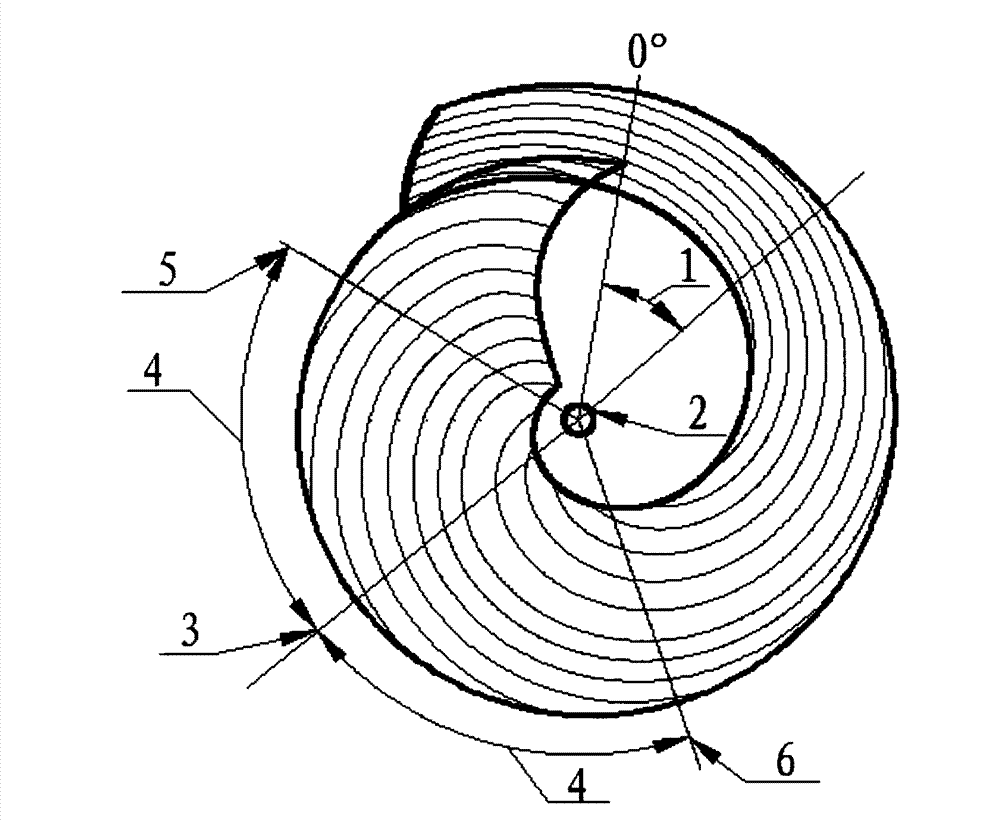

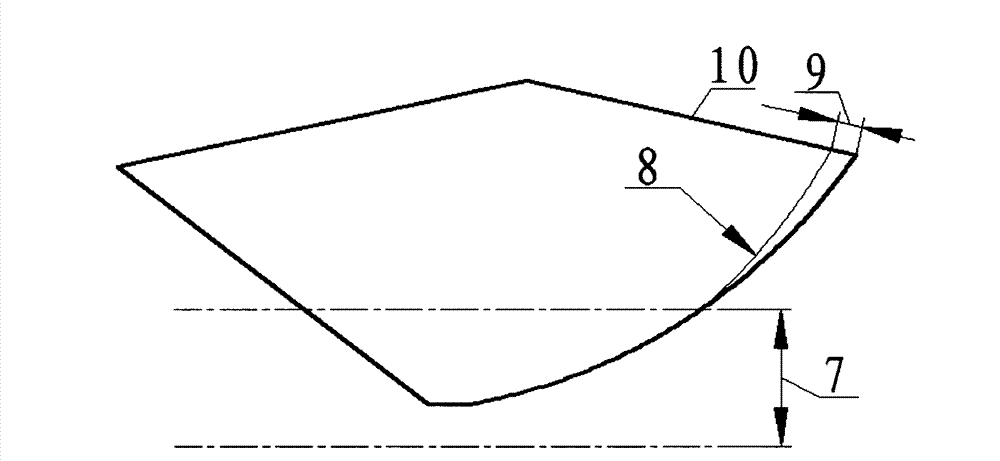

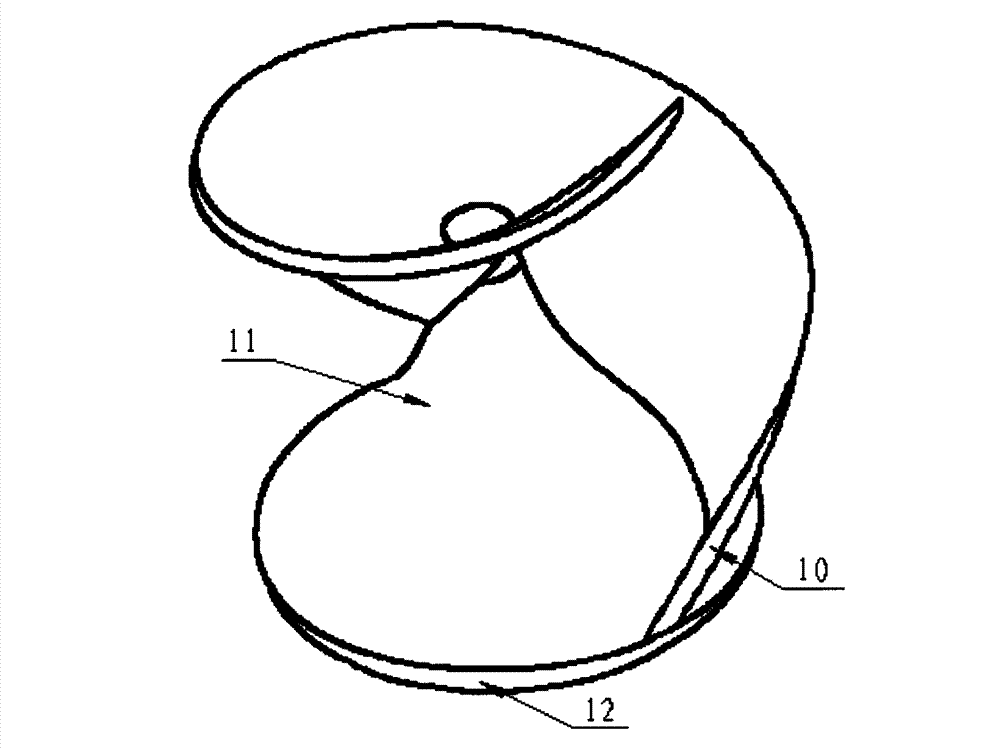

[0018] figure 1 , figure 2 and image 3 The thickening position and thickness of the single vane pump impeller of this embodiment are jointly determined. The specific implementation steps are as follows: first determine the offset angle of the center of gravity of the blade (1), find the position of the center of gravity of the impeller before thickening (2) and the thickening centerline (3) through three-dimensional PROE modeling, and then in PROE every 10 °Create a plane, estimate the unilateral thickening range (4), find the thickening starting line (5) and thickening end line (6), and draw the section of the impeller hub (11) into the plane, and create by scanning and mixing impeller hub (11). The principle of thickening is not to affect the flow path of the impeller, and after each section is thickened, the transition is as smooth as possible, until the distance between the center of gravity and the axis reaches the allowable range, and the unbalance at this time is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com