Eccentric balance mechanism

A balance mechanism and eccentric technology, applied in the field of shaft parts, can solve the problems of poor equipment working ability and failure to meet the noise standard of CNC cutting machines, and achieve the effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

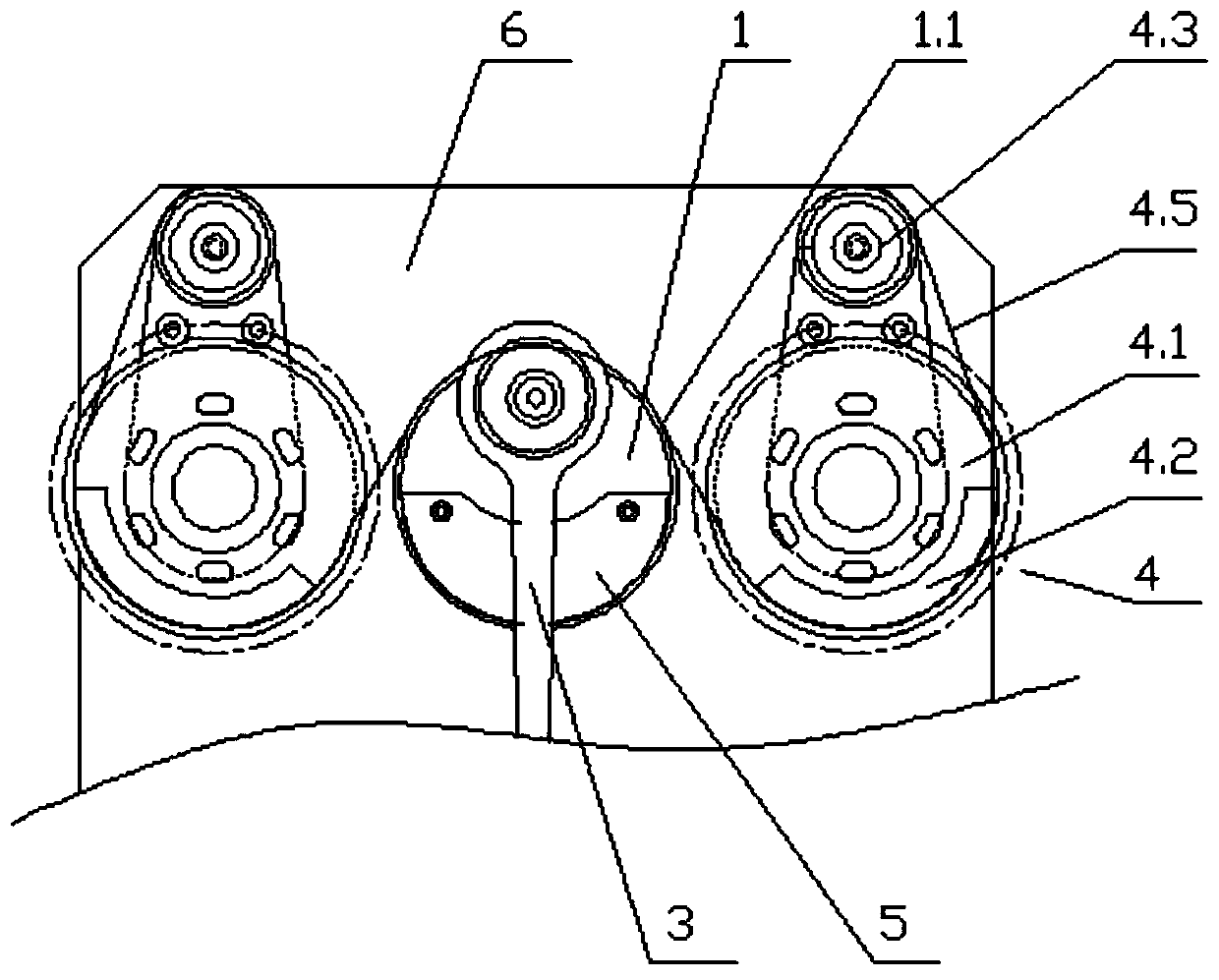

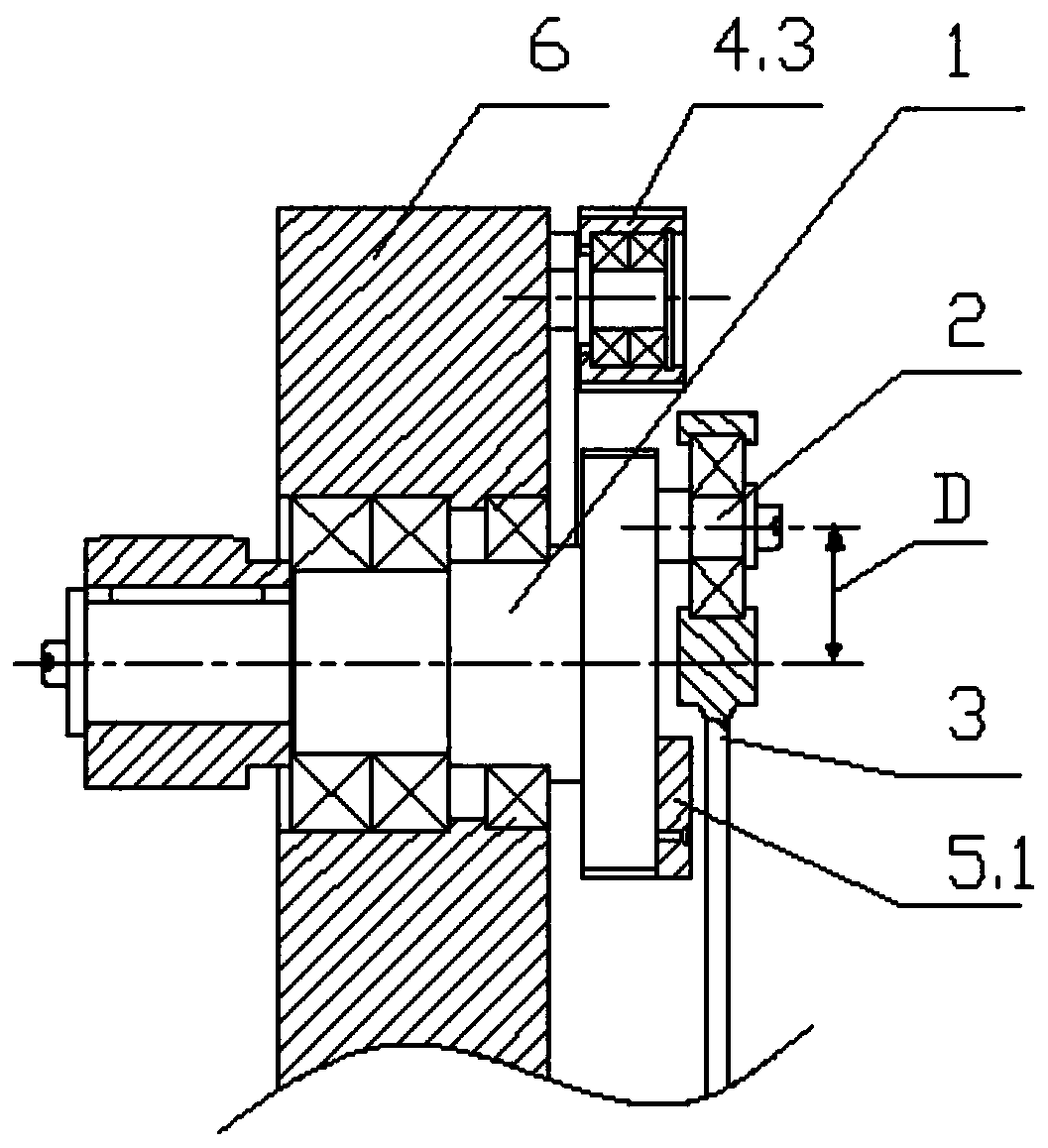

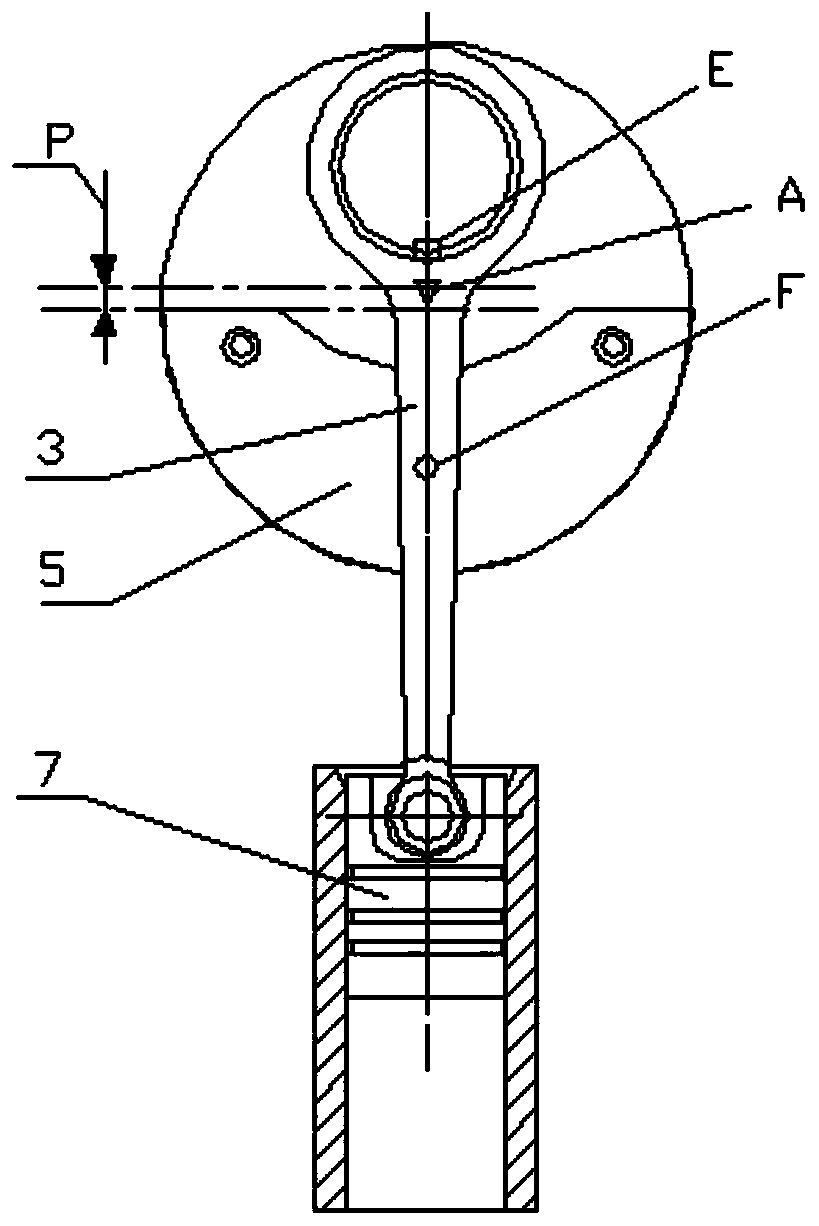

[0049] Such as Figure 1 to Figure 2 As shown, the present embodiment provides an eccentric balance mechanism, which includes an eccentric shaft with a balance weight 5 and a balance wheel device 4, and the balance wheel device 4 is in drive connection with the eccentric shaft.

[0050] The eccentric shaft includes an eccentric main shaft 1, and the eccentric main shaft 1 is fixed on the eccentric main shaft supporting seat 6 through a bearing, and the power output end of the eccentric main shaft 1 is connected with a power mechanism (such as a servo motor) by transmission; An eccentric inertial shaft 2 is provided for socketing the connecting rod assembly 3. One end of the socketing connecting rod assembly 3 is socketed on the eccentric inertial shaft 2, and one end pushes the piston 7 to perform reciprocating linear motion; the eccentric main shaft 1 is provided with an eccentric The end face of the inertial shaft 2 is also provided with the balance weight 5; the eccentricit...

Embodiment 2

[0056] Such as Figure 5 As shown, the present embodiment provides an eccentric balance mechanism, which includes an eccentric shaft with a balance weight 5 and a balance wheel device 4, and the balance wheel device 4 is in drive connection with the eccentric shaft.

[0057] The eccentric shaft includes an eccentric main shaft 1, and the eccentric main shaft 1 is fixed on the eccentric main shaft supporting seat 6 through a bearing, and the power output end of the eccentric main shaft 1 is connected with a power mechanism (such as a servo motor) by transmission; An eccentric inertial shaft 2 is provided for socketing the connecting rod assembly 3. One end of the socketing connecting rod assembly 3 is socketed on the eccentric inertial shaft 2, and one end pushes the piston 7 to perform reciprocating linear motion; the eccentric main shaft 1 is provided with an eccentric The end face of the inertial shaft 2 is also provided with the balance weight 5; the eccentricity D between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com