A method for detecting dynamic balance faults of multi-disk shafting of rotating machinery without test weight

A technology for rotating machinery and balancing faults, which is applied in static/dynamic balance testing, measuring devices, and testing of machine/structural components. It can solve difficult problems, achieve high accuracy, reduce the risk of dynamic balance tests, and improve The effect of dynamic balance test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Below, the present invention will be described in further detail in conjunction with the accompanying drawings and embodiments.

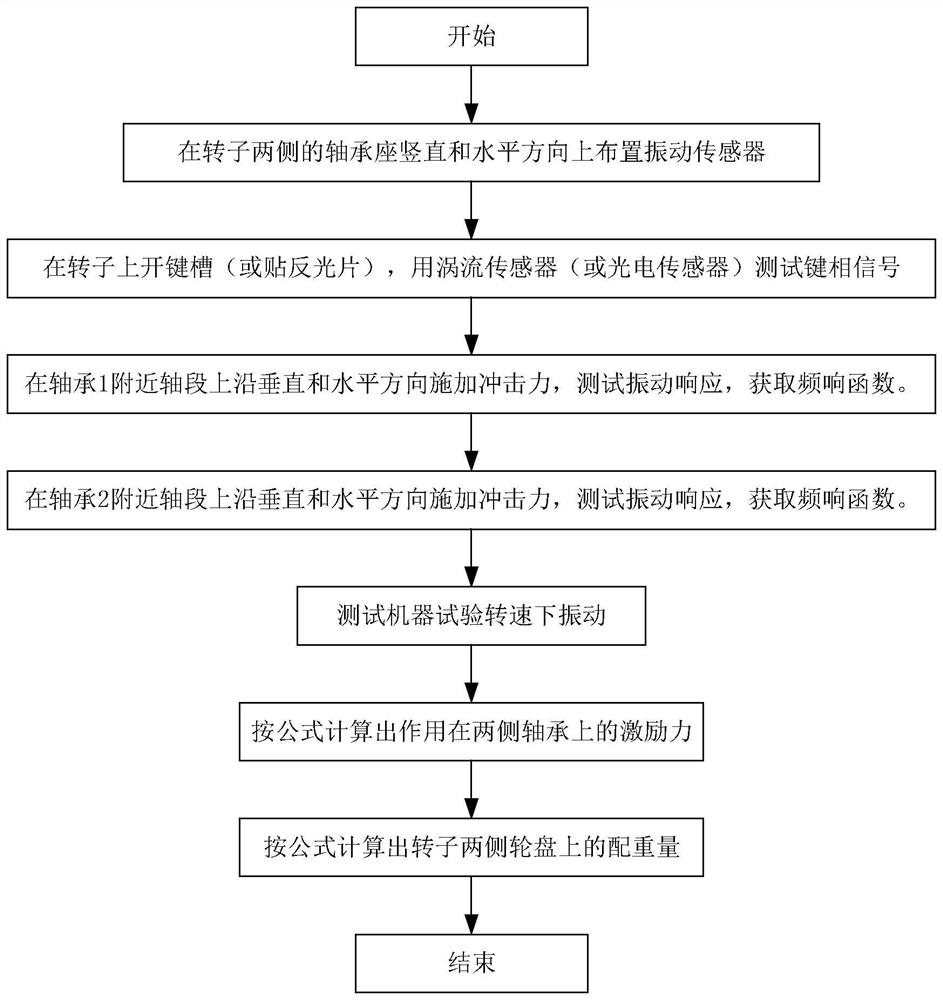

[0066] Such as figure 1 As shown, in this embodiment, the dynamic balance fault of the rotating machine is detected by the method for detecting the dynamic balance fault of the multi-disc shafting of the rotating machine without a test weight according to the present invention, and the details are as follows:

[0067] Carry out the dynamic balance test after the complete rotating machinery is assembled or under the real state of actual installation on site.

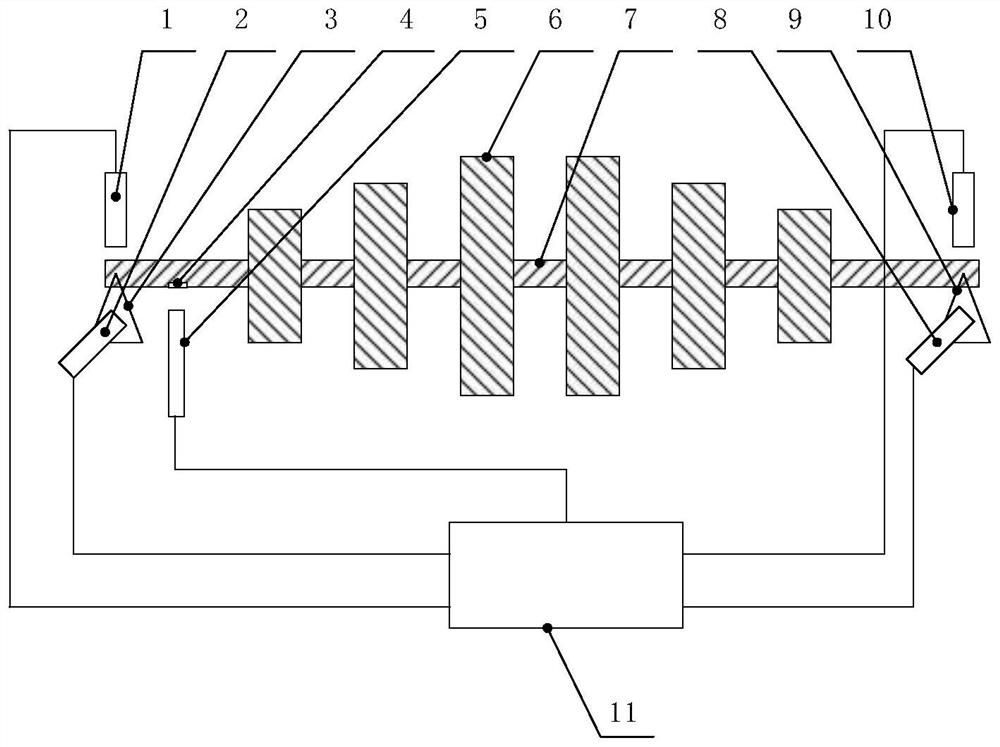

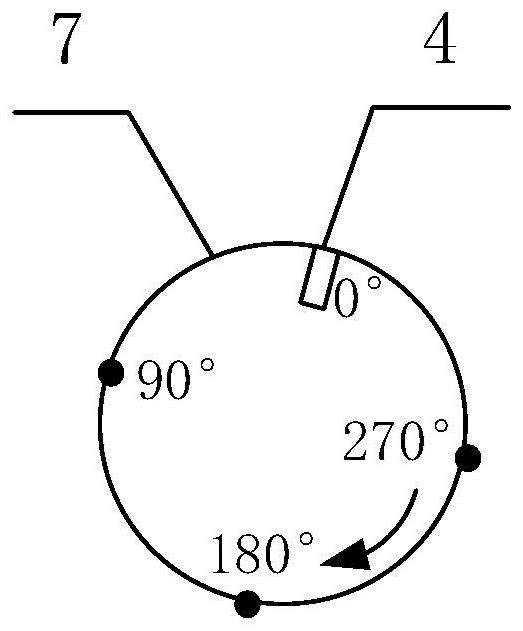

[0068] Such as figure 2 and image 3 As shown, the vibration sensors are arranged in the vertical and horizontal directions of the bearing seats on both sides of the rotor containing multiple discs, a total of 4 vibration sensors. Open the key phase groove (or paste reflective sheet) on the rotating shaft as the 0° mark on the rotating shaft, and define the angle of the reverse rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com