Finite element model correction method based on sensitivity analysis

A technology of sensitivity analysis and model correction, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inaccurate finite element modeling and simulation

Inactive Publication Date: 2018-12-07

SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

View PDF5 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the deficiencies of the prior art, the present invention provides a finite element model correction method based on sensitivity analysis, which uses a small amount of data obtained from structural tests to correct the finite element model to obtain a more accurate finite element model and solves the problem of finite element Inaccurate problem of modeling and simulation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

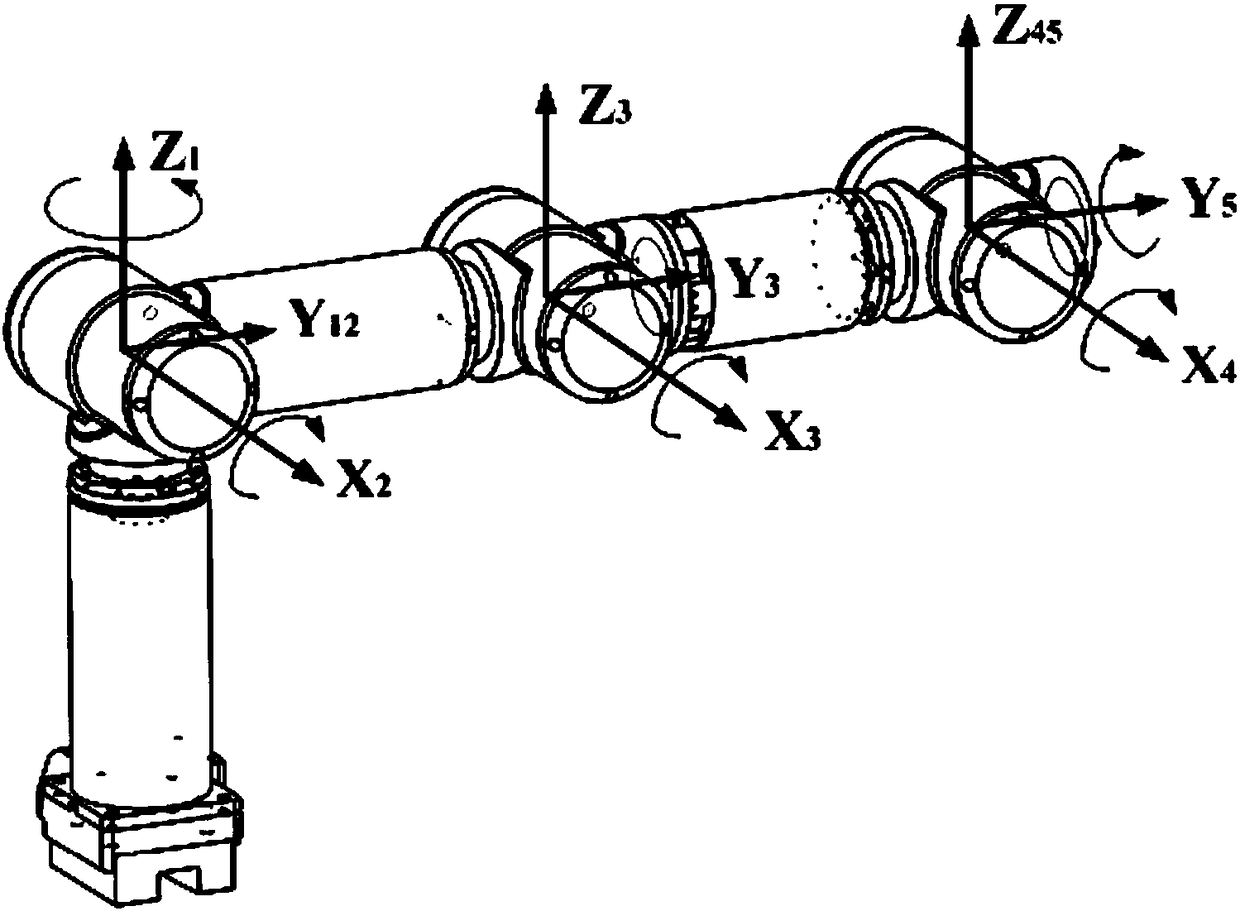

[0040] The invention corrects the finite element model based on the sensitivity analysis for the structure of the five-joint mechanical arm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

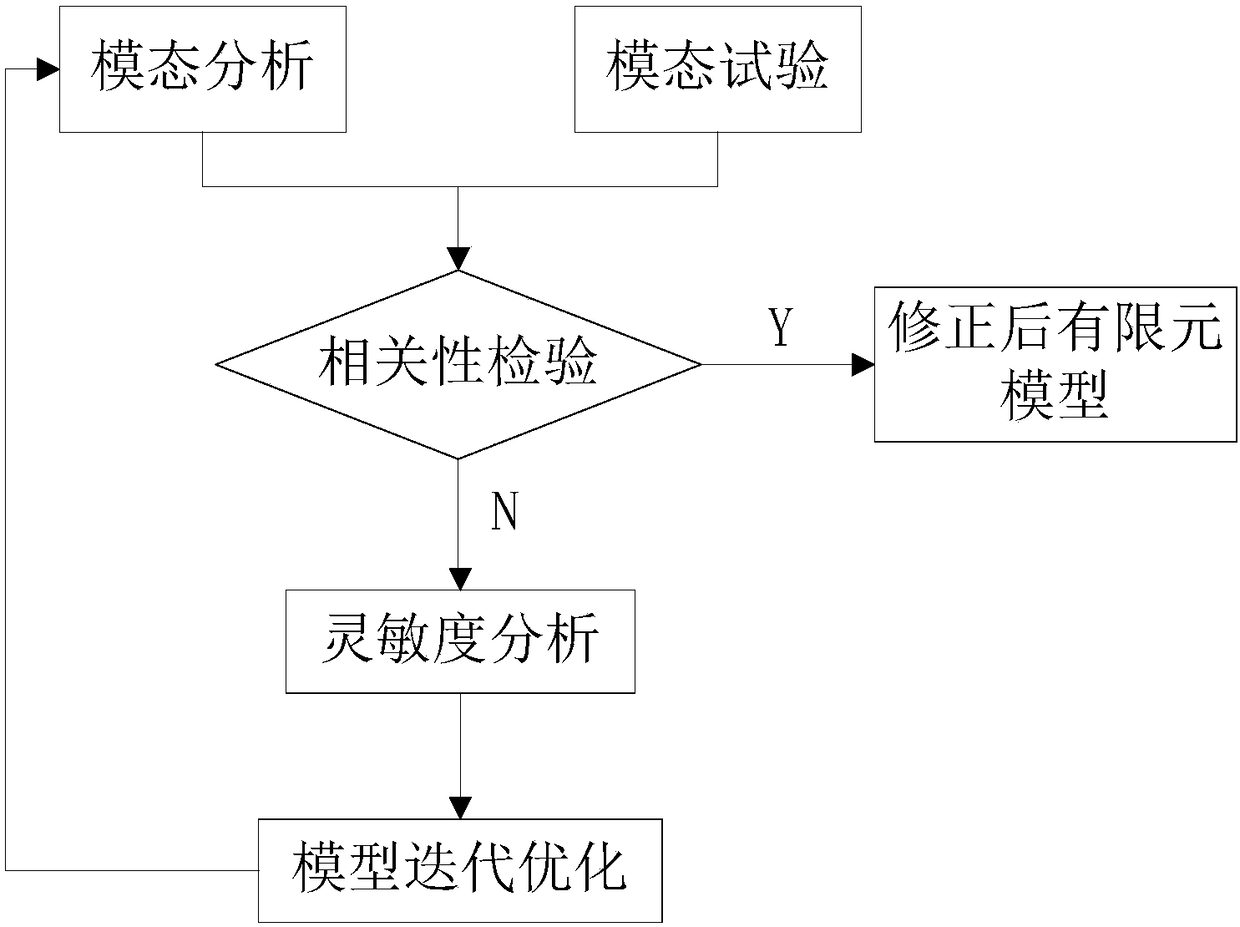

The invention relates to a finite element model correction method based on sensitivity analysis. According to the method, solid modeling is performed on an assembly in three-dimensional software, a modal test is performed on an assembly model through a modal test system, an assembly finite element simulation model is established by the adoption of pre-processing software and post-processing software, modal analysis solving is performed through finite element analysis software, correlation checking is performed on a modal test result and a modal simulation analysis result through LMS.VirtualLabsimulation analysis software, modal sensitivity analysis is performed, parametric variables sensitive to modal frequency are found out, and finite element model fundamental frequency is matched withmodal test fundamental frequency through optimization iteration. Compared with a physical test, the simulation analysis technology has many advantages such as low cost and a short cycle; and within asimulation result error allowed range, the simulation analysis result can serve as a reference basis for vibration characteristic analysis, so that the method has important reference value for relevant test work.

Description

technical field [0001] The invention relates to the field of finite element model correction of complex assemblies, in particular to a finite element model correction method based on sensitivity analysis. Background technique [0002] With the rapid development of CAE technology in the field of industrial manufacturing, through finite element simulation analysis, the vibration characteristics of the mechanism are studied, the weak parts in the structural design are pointed out, and the optimization scheme can be proposed to avoid the occurrence of resonance in the mechanism during work. At the same time, finite element analysis is the most widely used numerical analysis method in the field of modern engineering, and its reliability has been widely verified. Through finite element simulation analysis, the number of physical tests can be reduced to achieve the purpose of saving costs, evaluating the rationality of configuration, reducing risks, improving product quality, and s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F17/50G01M7/00

CPCG01M7/00G06F30/17G06F30/23

Inventor 富佳骆海涛刘广明轿利闯

Owner SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com