Method for designing forming dies for low-double-curvature sheet metal parts

A technology of forming molds and design methods, applied in calculation, special data processing applications, instruments, etc., can solve the problems of difficult positioning of blanks, uneven springback, and low production efficiency, so as to shorten the design cycle, reduce workload, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

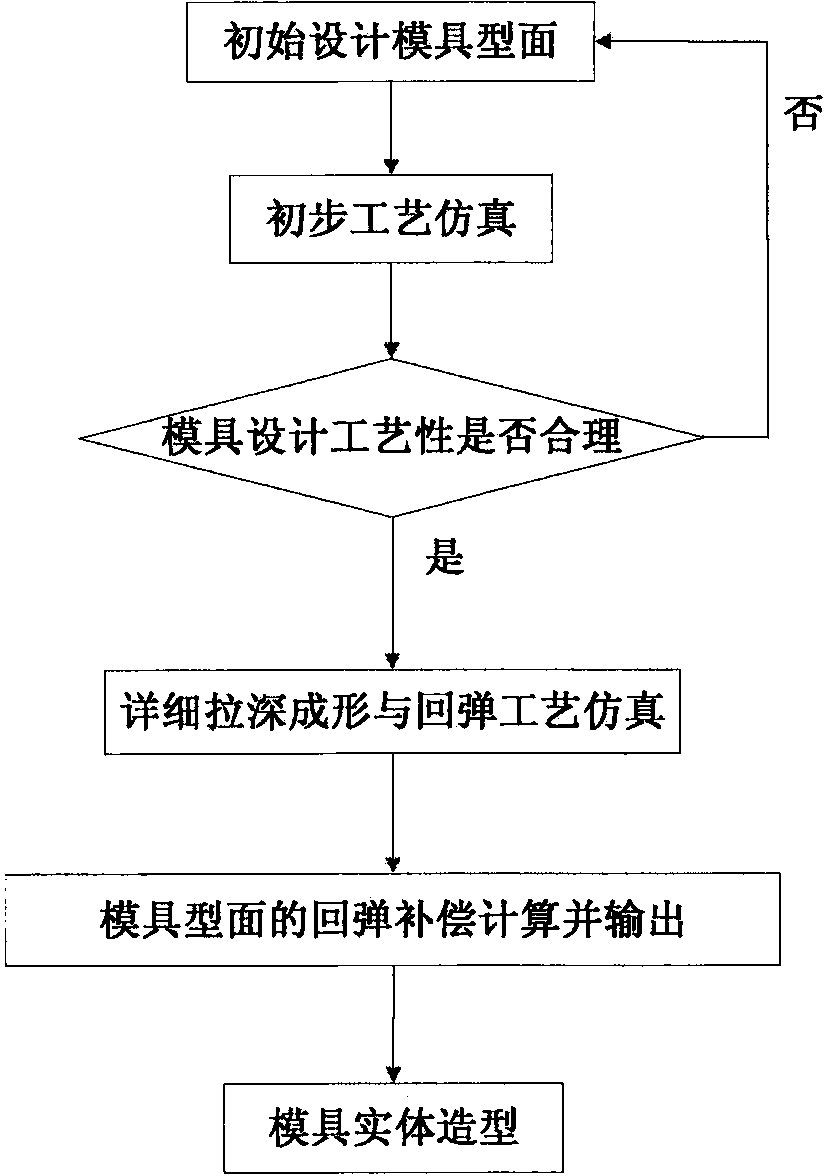

[0024] A forming die design method for small hyperbolic sheet metal parts, such as figure 1 shown, including the following steps:

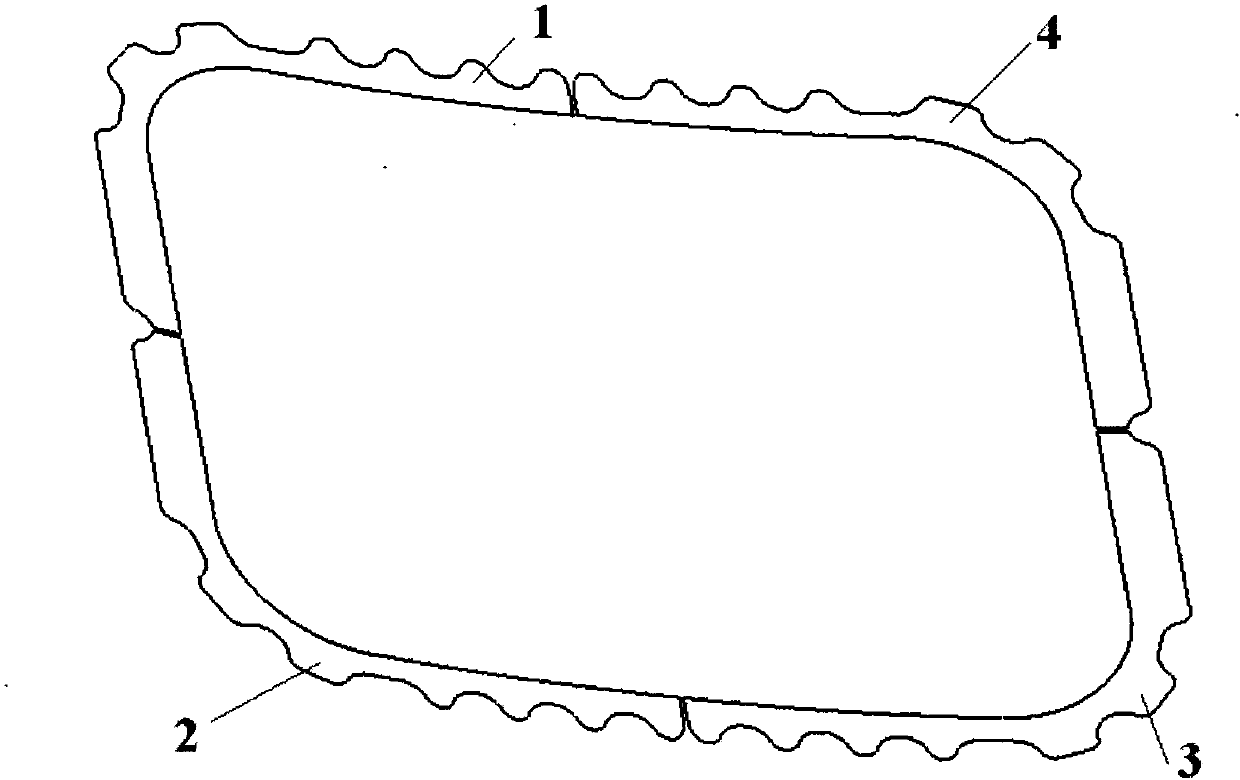

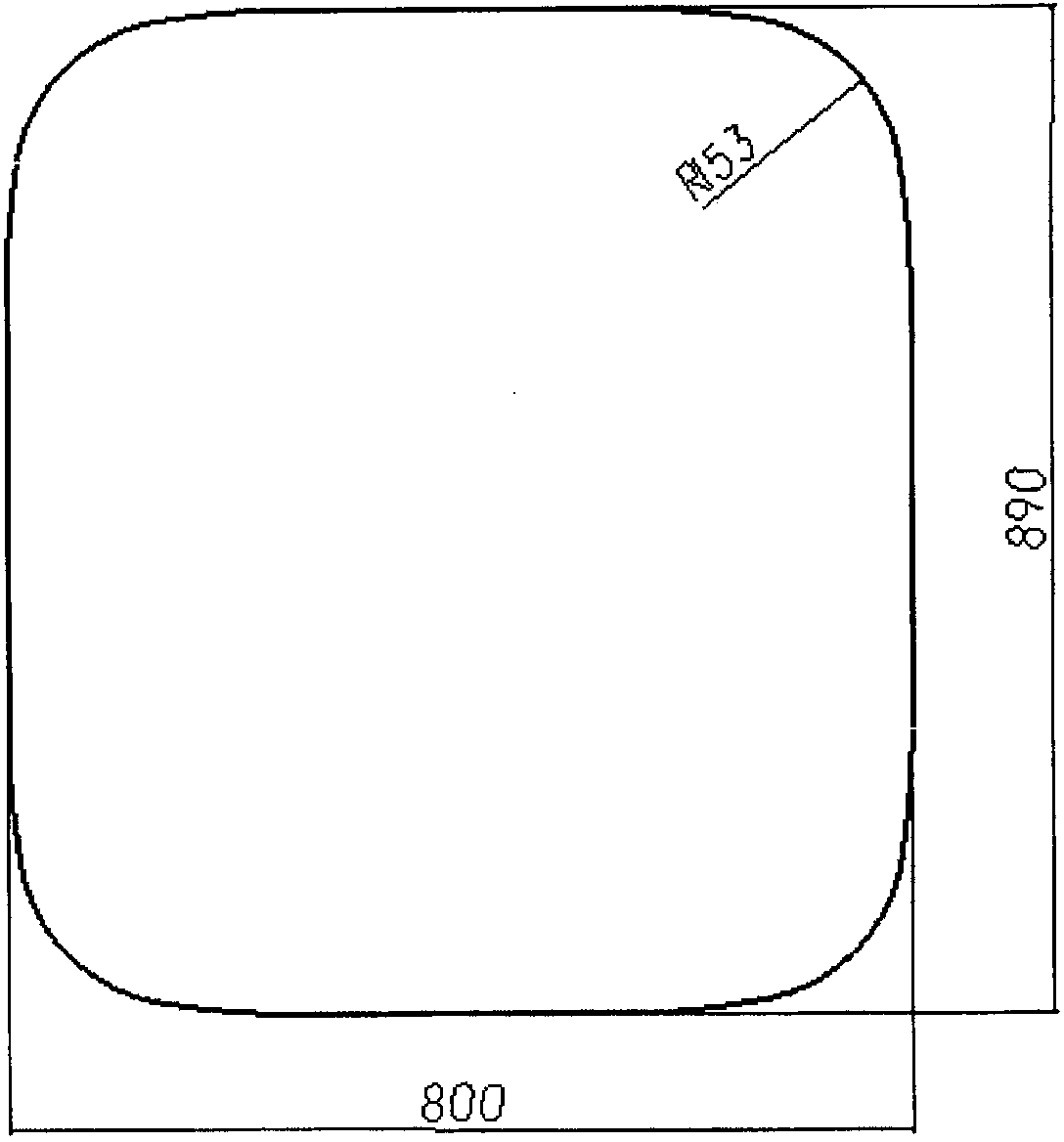

[0025] 1) Initial design of the mold surface: the 3D design software used in this example is CATIA V5, which will be as follows figure 2 The four small hypercurvature sheet metal parts shown are combined according to the assembly relationship. The material is aluminum alloy 2B06, O state, and the thickness is δ1mm. The assembly relationship of the four parts is located on the same large hypercurvature surface; the hypercurvature The surface is used for drawing forming dies, and as the bottom surface of the drawing die, that is, the four-piece curved surface is used as the bottom of a box-shaped part, and the outer edge of the bottom is the process margin, and the bottom of the box-shaped part is thinned sharply The position of the part is controlled within the range of process allowance, and the effective part of the part shall not be affected; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com