Composite electrical cross arm and design method of structure thereof

A composite material and cross-arm technology, applied in building types, buildings, towers, etc., can solve the problems of low strength, material consumption, poor insulation performance of cross-arms, etc., achieve stable elastic modulus, increase safety margin, and reduce structure effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0050] Such as figure 1 , figure 2 As shown, the composite cross-arm structure of the present invention consists of a winding structure layer 1, a pultruded composite material hollow tube 2, and a foamed polyurethane foam filling layer 3; wherein, the winding structure layer 1 is formed by a mature winding molding process; There are 9 layers of glass fiber cloth. Whether the stress and deflection of the cross-arm structure between each two layers of glass fiber cloth can meet the requirements of the working conditions can be determined by thickening the thickness of the winding structure layer 1.

[0051] The specific operation is:

[0052] 1) The cylindrical cross-arm structure is designed into a three-layer structure from the radial inside to the outside, which are the inner core, the middle layer and the outer layer; the middle layer is a pultruded composite hollow tube, and the Based on a composite material hollow tube, the core of the hollow tube is filled with polyure...

example 2

[0068] The basic design method is the same as Example 1, the difference lies in:

[0069] Determine the ratio of the resin-based raw material used in the outer layer of the cross-arm and the winding thickness of the outer layer; wherein, the resin-based raw material consists of 90 parts of vinyl ester resin, 1 part of curing agent, 0.2 parts of accelerator, and 1 part of anti-aging agent , mixed with 1 part of color paste; the thickness of the outer layer winding is 7mm;

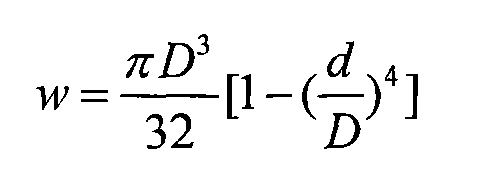

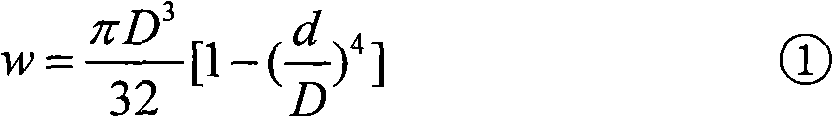

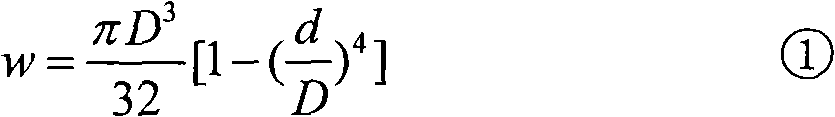

[0070] The composite material hollow tube used in the middle layer of the cross arm has an inner diameter d of 80 mm and an outer diameter D of 100 mm; substituting the inner diameter d and the outer diameter D into formula ①, the bending section coefficient W of the cross arm is 0.579×10 -4 ;

[0071] w = π D 3 32 [ 1 - ( d ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com