Gear load wireless monitoring system and interactive multi-stage gear physical simulation method finished based on same

A monitoring system and gear technology, applied in machine gear/transmission mechanism testing, electrical digital data processing, special data processing applications, etc., can solve problems such as limiting the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

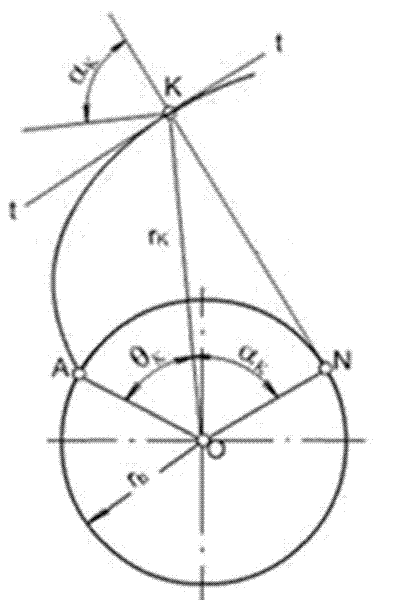

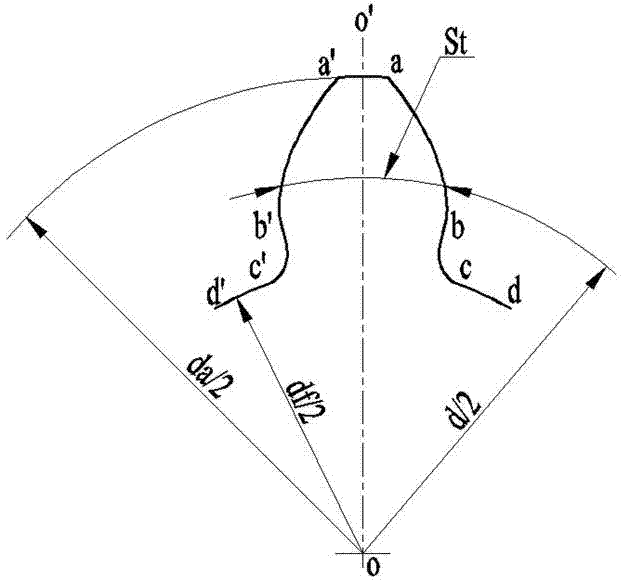

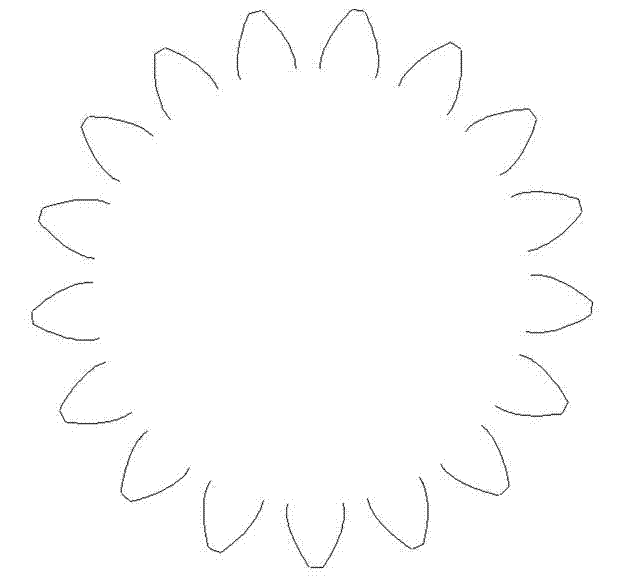

[0035] 1. CAE modeling

[0036] Based on the parametric design language, a CAE analysis-oriented parametric modeling system for the multi-stage gear mechanism of a typical mining reducer is developed to realize the parametric modeling and automatic assembly of cylindrical gears, planetary gears, and spur bevel gears. The established overall parameterized model can not only be used for CAE simulation analysis under finite element, but also can be exported to other simulation invention patents for joint simulation. Parametric design language, which provides functions of general programming language, such as parameters, macros, scalars, vector and matrix operations, branches, loops, repetitions, and access to finite element databases. Using its parametric design language in finite element, the parametric modeling of involute spur gears can be realized through variable parameters, array parameters, mathematical expressions and functions, macro files and user programs. Realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com