Reverse design method for impeller of centrifugal pump

A centrifugal pump impeller and reverse design technology, which is applied to components, pumps, and pump components of a pumping device for elastic fluids, can solve problems such as large workload, long design cycle, and complicated design steps, and achieve accurate solutions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

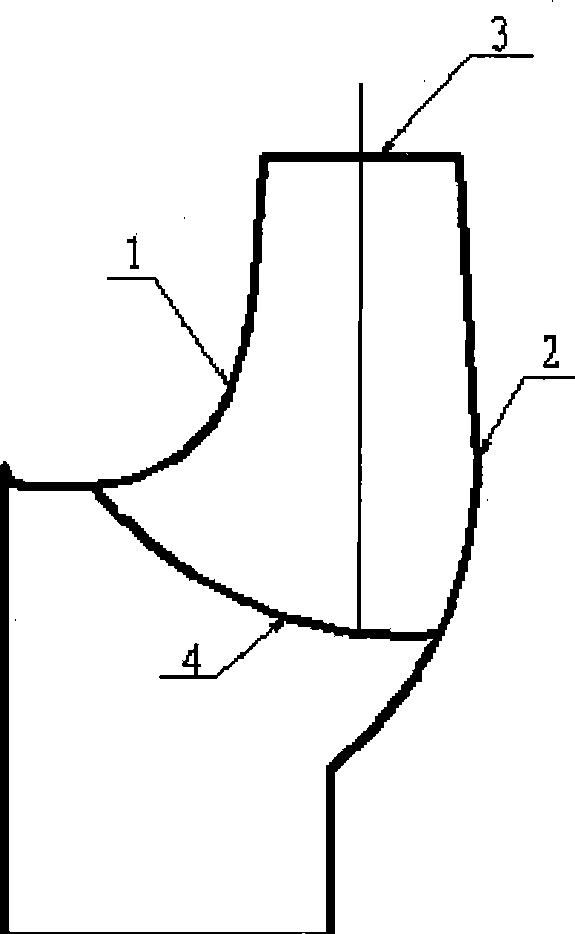

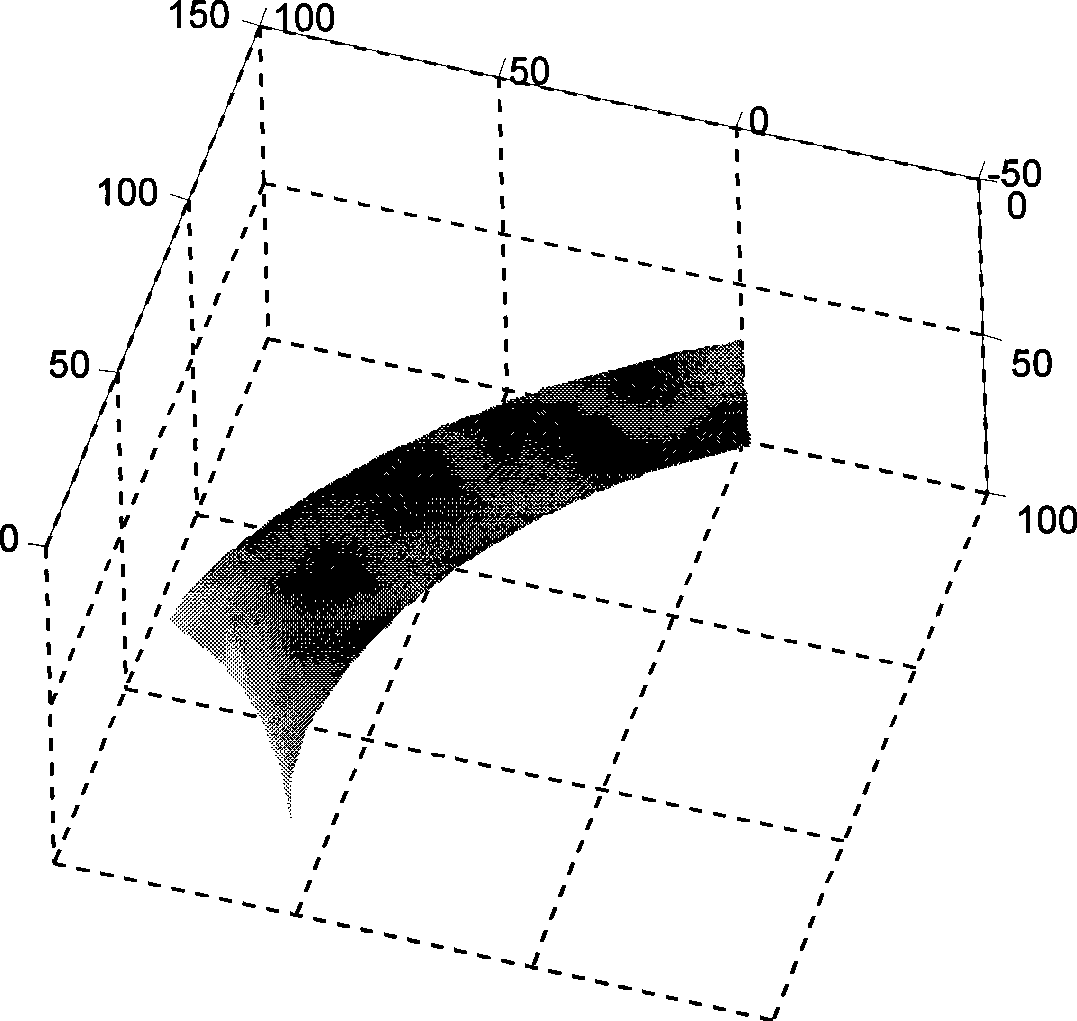

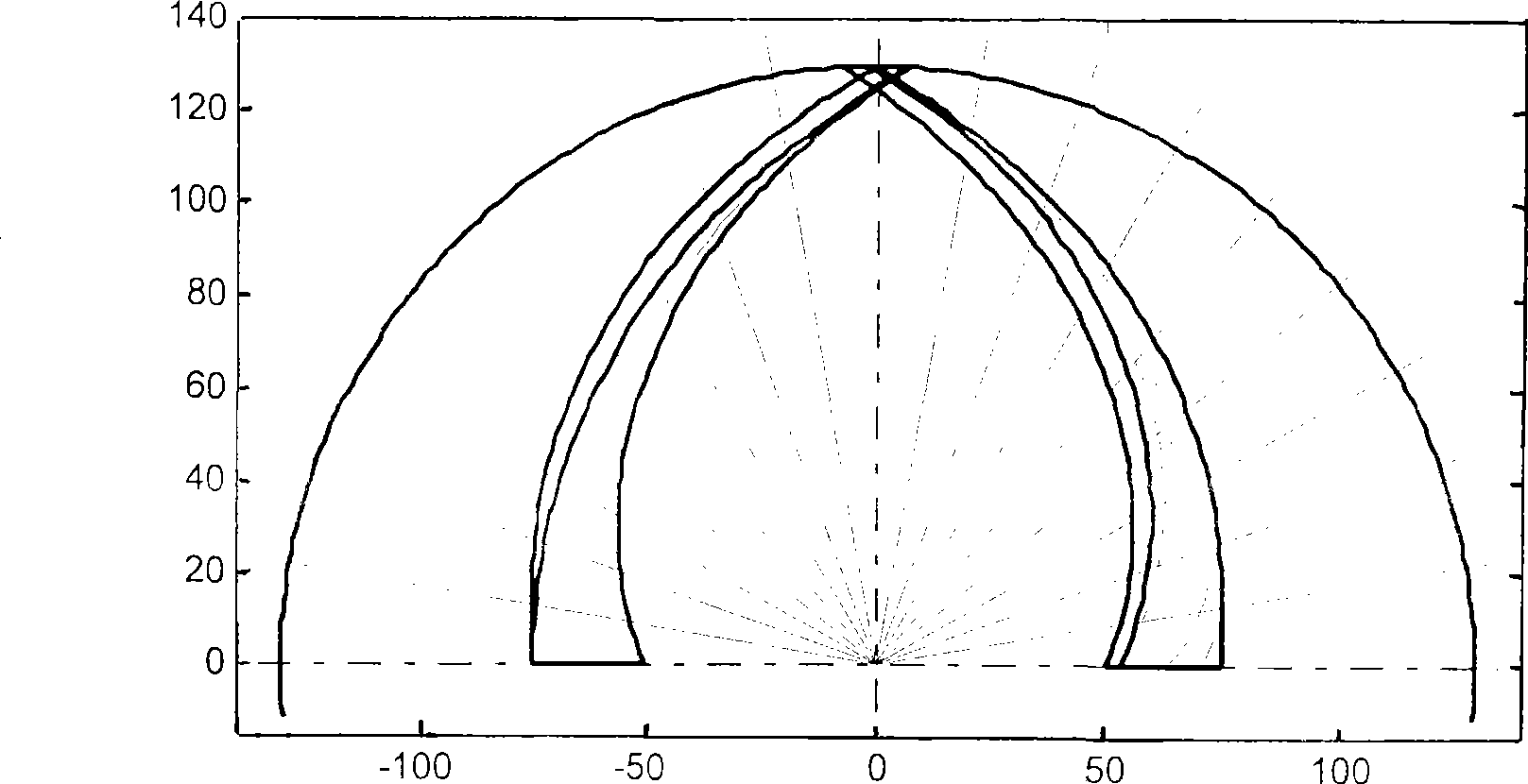

[0017] Such as figure 1 As shown, in the reverse design method of a centrifugal pump impeller, according to the given impeller axial surface, the blades in three-dimensional space can actually be expressed as X=X(z(u, v), r(u , v), θ(u, v)), when the streamline on the axial surface of the impeller is given, (z(u, v), r(u, v)) has been determined, by determining θ(u, v) on the axial surface of the impeller , v) can determine the spatial shape of the blade; its characteristic is that under the given condition of the axial surface of the impeller of the centrifugal pump, the distribution of the blade placement angle β on the front and rear cover plates is based on the following formula:

[0018] β i = β 1 + ( β 2 - β 1 ) [ P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com