Manufacturing technology for runner of impulse turbine

A manufacturing process and hydraulic turbine technology, which is applied in the manufacturing process of impact turbine runners, can solve problems such as uneven weight distribution around the water bucket, processing costs for coupling bolt breakage, loose materials, etc., to improve material performance and overall strength, Reduced processing costs and fast molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

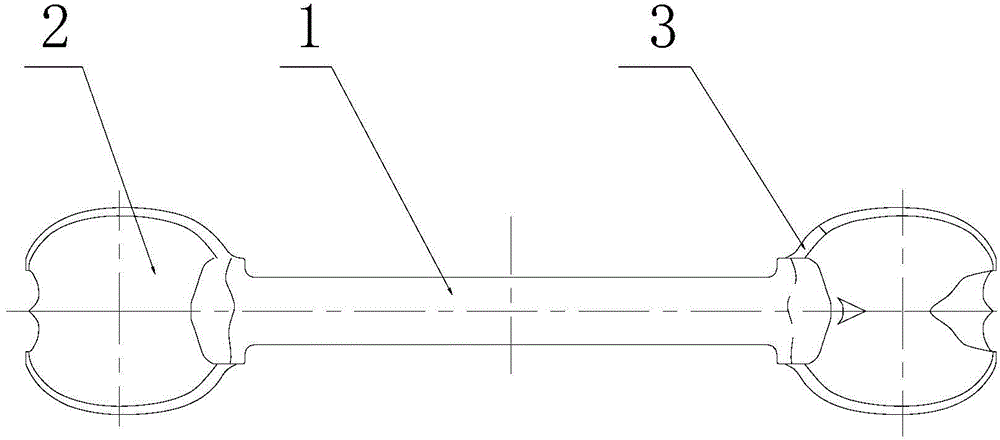

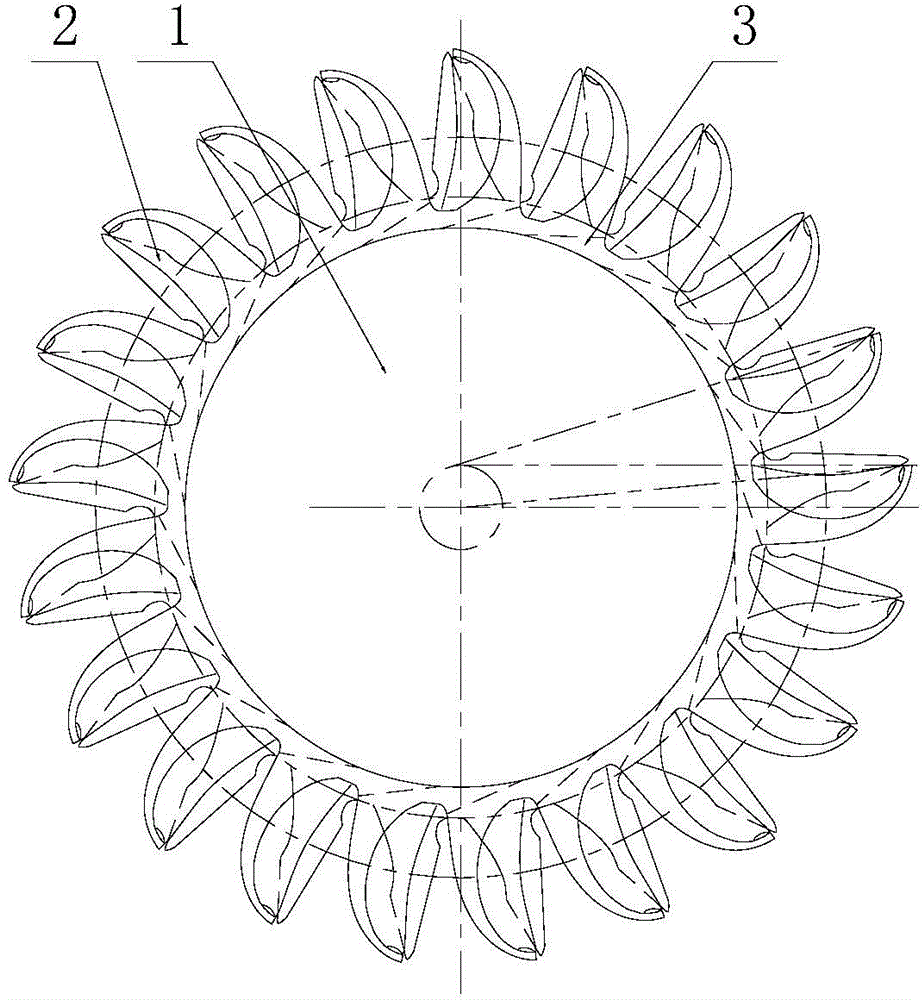

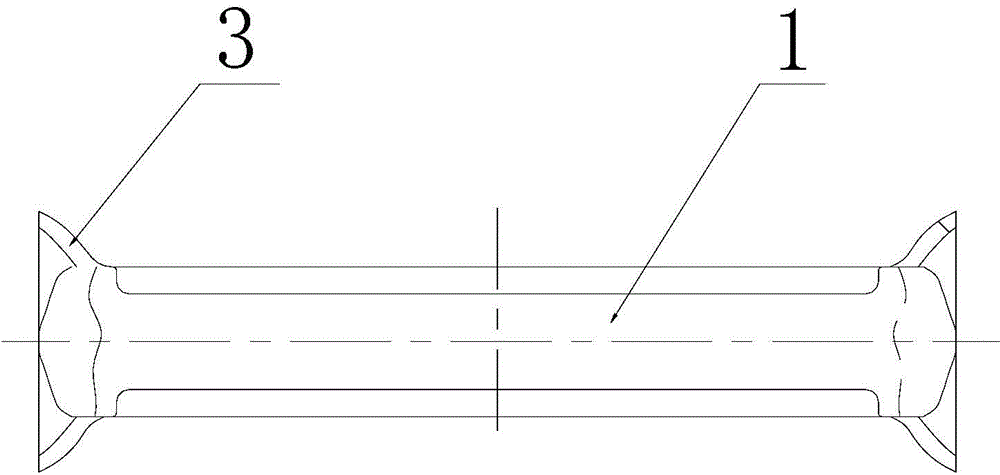

[0044] see Figure 1 to Figure 7 , is a preferred embodiment of the manufacturing process of the impact turbine runner, and the process is carried out in the following steps:

[0045] Step 1) manufacture the forging blank of runner:

[0046] 1.1 According to the shape parameters of the runner to be manufactured, use mechanical design software (such as PRO / Engineer WildFire, UG / NX, Catia, etc.) to design the three-dimensional solid shape of the runner.

[0047]1.2 Use finite element analysis technology to analyze the stress, deformation and distribution of the runner during the high-speed rotation of the runner under the impact of the jet. Stress, deformation and its distribution law, see attached image 3 , attached Figure 4 , build the solid model of the runner disc and the connection area between the disc and the water bucket, use the solid model to design the forging blank diagram, and design sufficient machining allowance on the two end faces of the forging blank.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com