Patents

Literature

53results about How to "Meet heat transfer requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

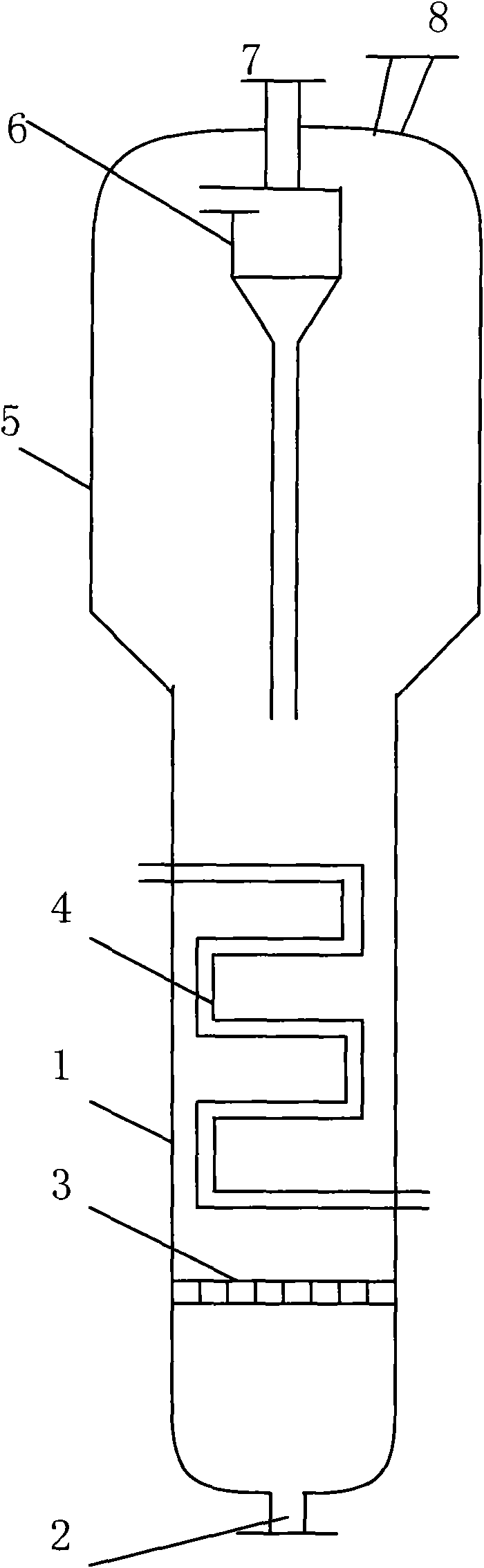

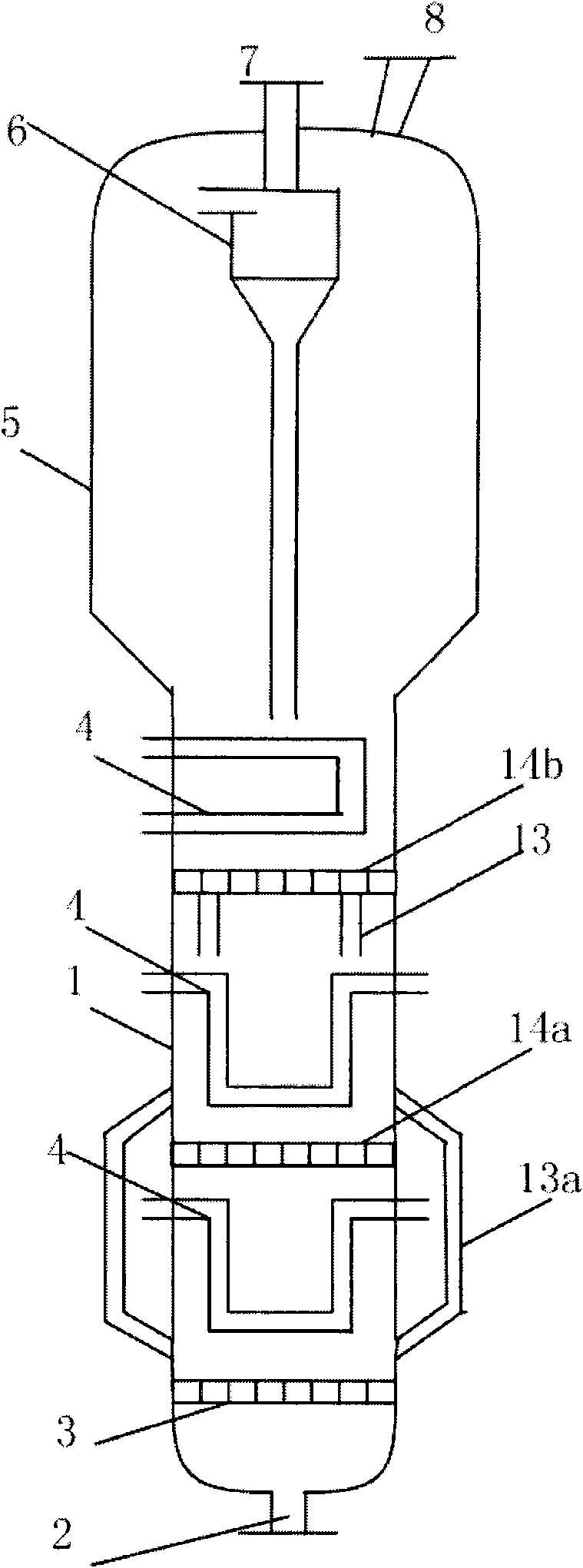

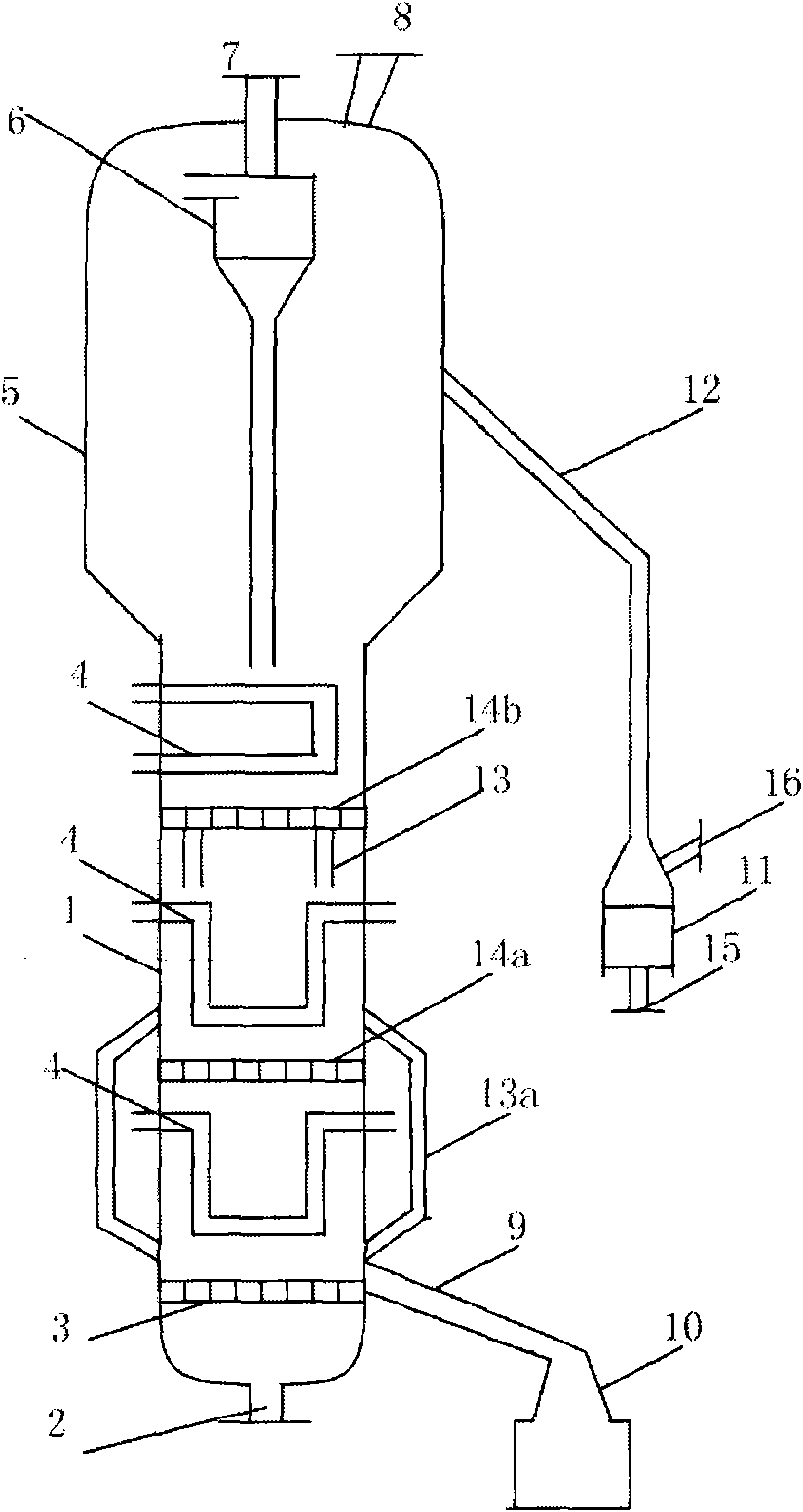

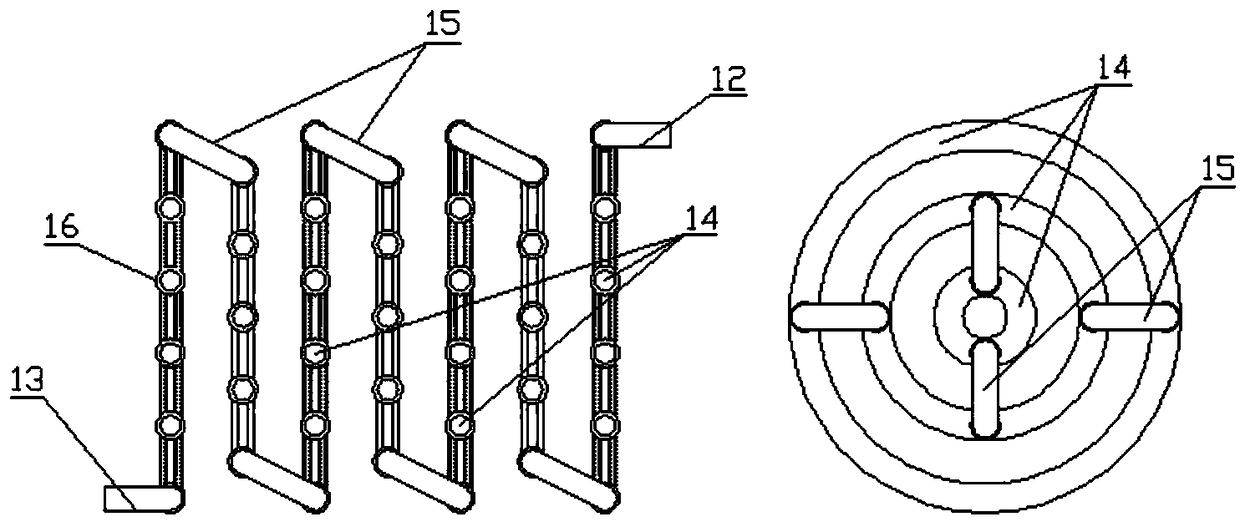

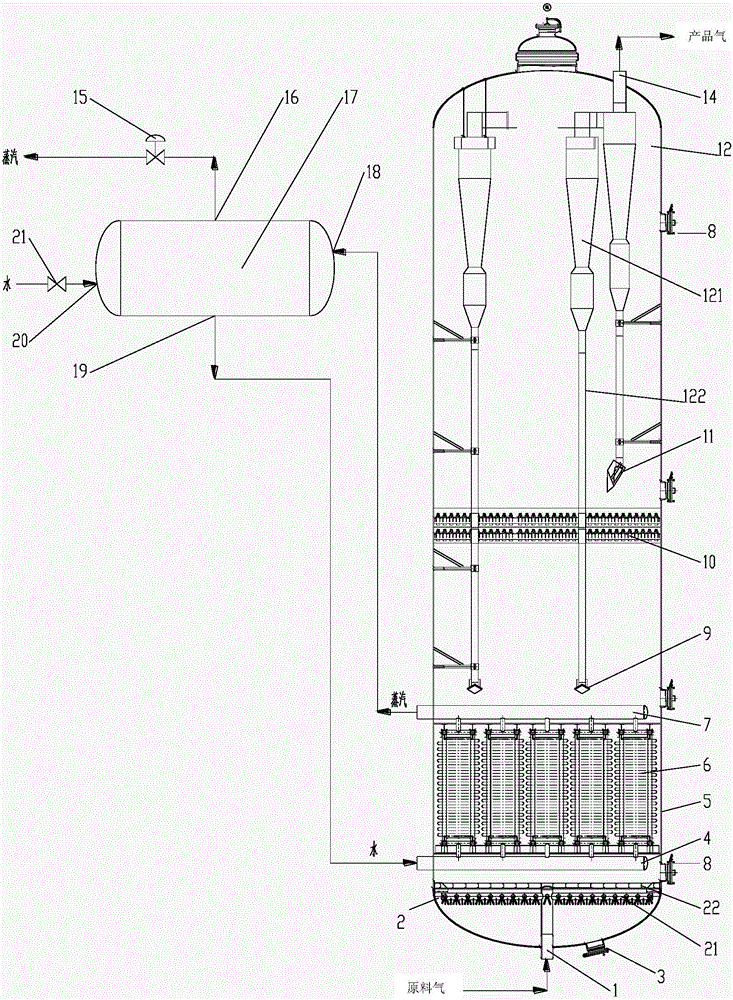

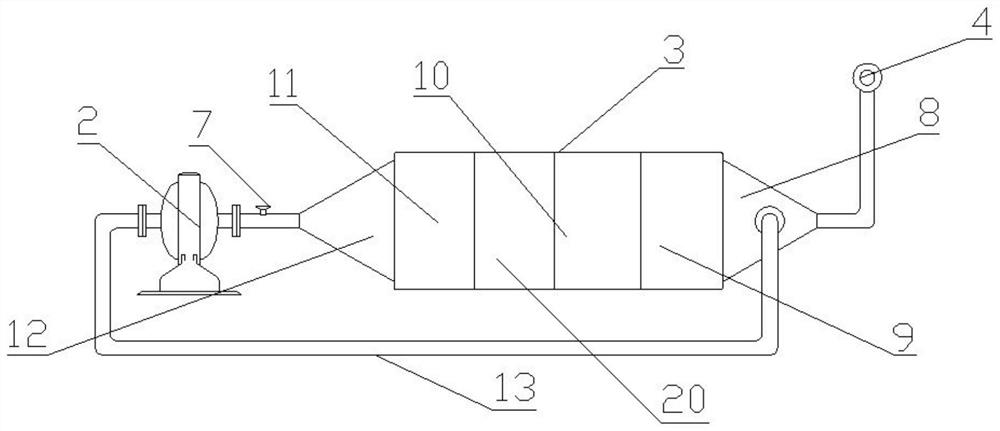

Fluidized bed process and device for preparing methane by synthetic gas

InactiveCN101665395AExpand technical routeRemarkable ability to remove heatHydrocarbon from carbon oxidesChemical/physical processesChemical industryFluidized bed

The invention relates to fluidized bed process and device for preparing methane by a synthetic gas, belonging to the field of chemical industry technologies and equipment. The process comprises the following steps: adding catalyst and diluent into a fluidized bed reaction vessel; heating and reducing the catalyst; charging the synthetic gas into the fluidized bed reaction vessel; charging a cooling medium into a reaction vessel heat exchange component to remove reaction heat; separating to obtain a methane product; and selectively containing the online replacement of the catalyst according tothe service life of the catalyst. The fluidized bed device comprises a reaction vessel simplified body, a raw gas inlet, a gas distributor, a heat exchange component, an expanding section, a cyclone separator, a catalyst feed opening and a gas outlet and selectively comprises a catalyst recovering machine and a gas stripping machine, and the reaction vessel can be divided into at least two stages.The invention has the advantages of good heat removing ability, uniform bed layer temperature, online replacement of the catalyst, high conversion rate and selectivity, long continuous running time of the catalyst, and the like.

Owner:TSINGHUA UNIV

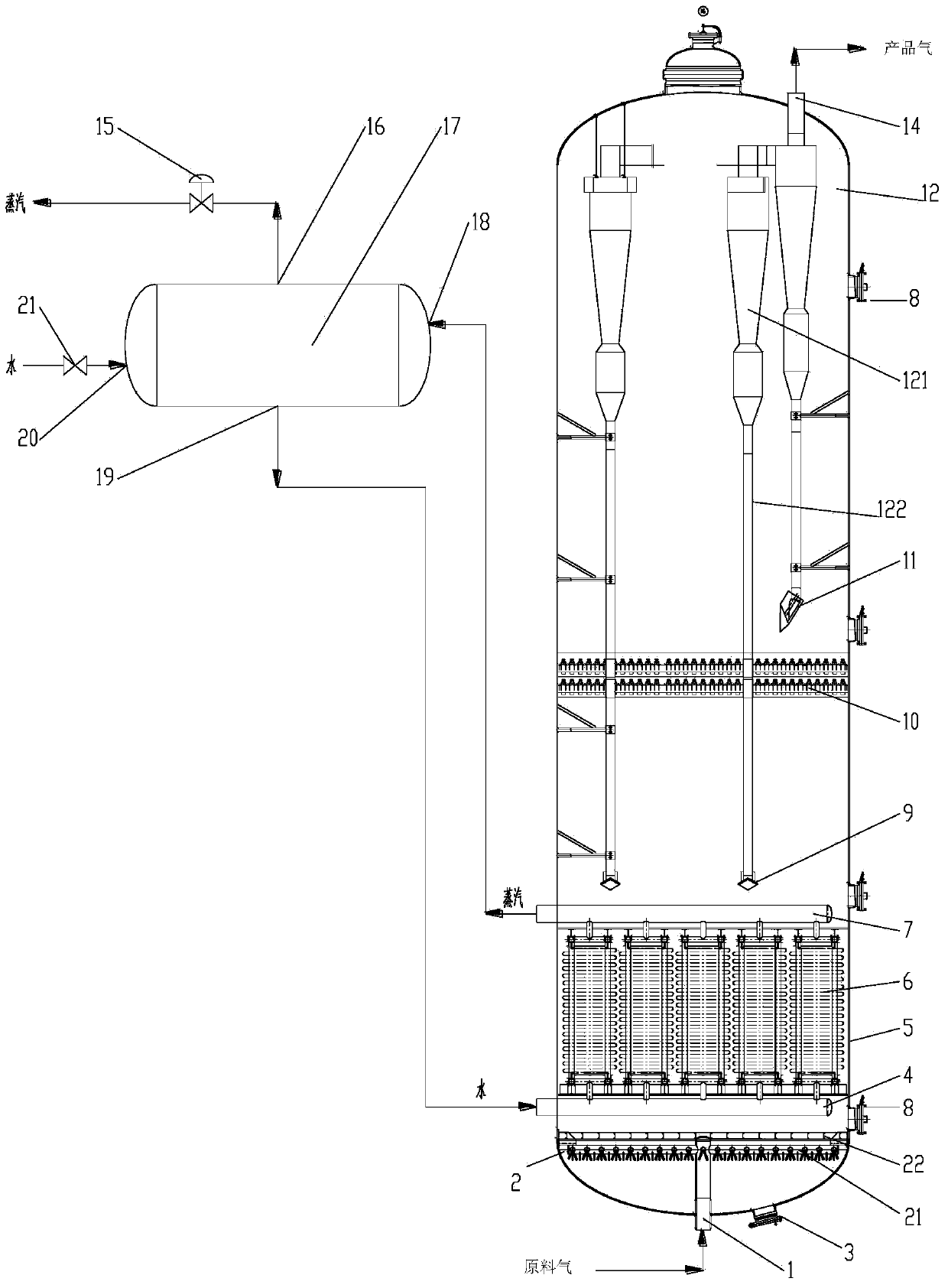

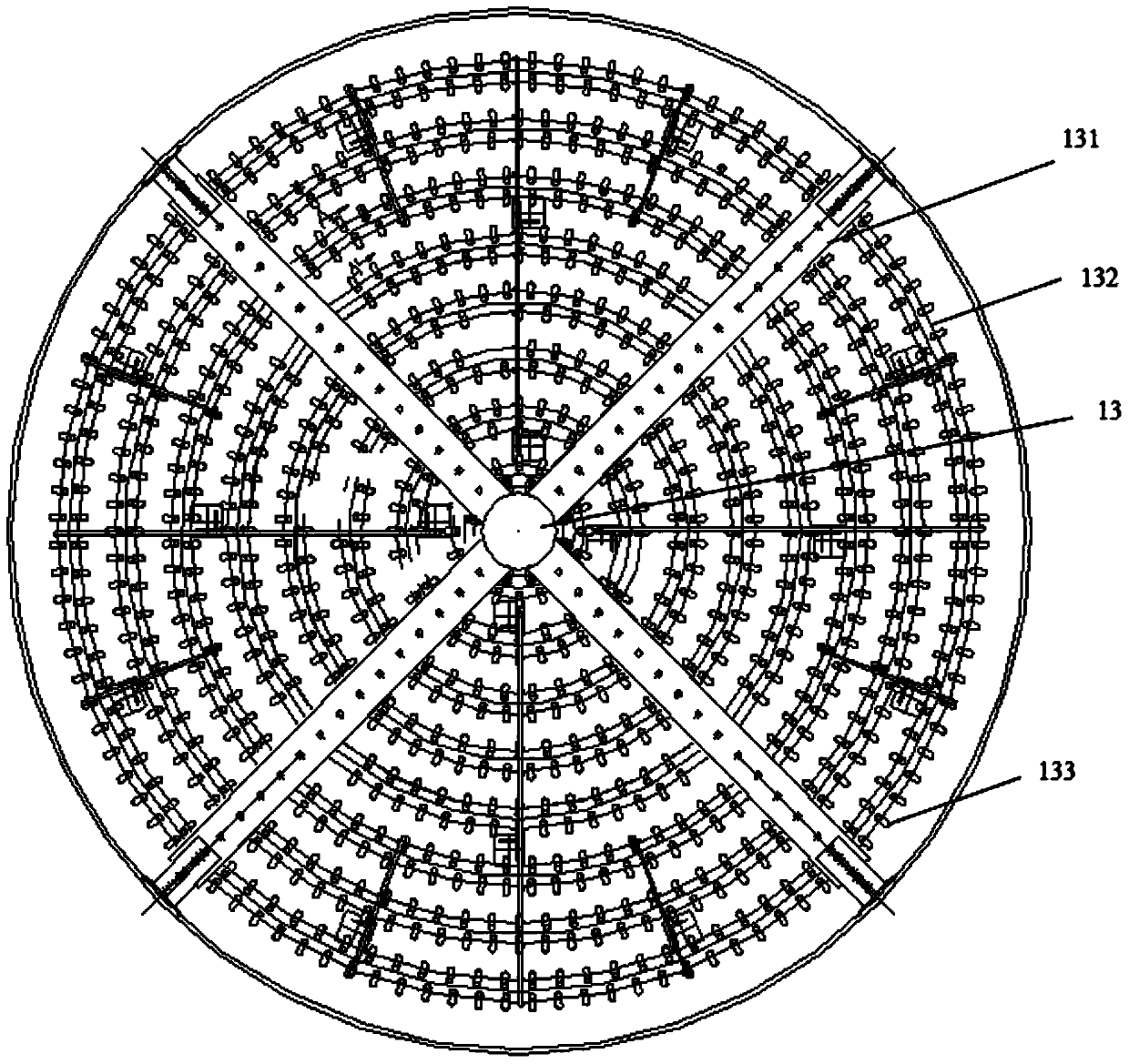

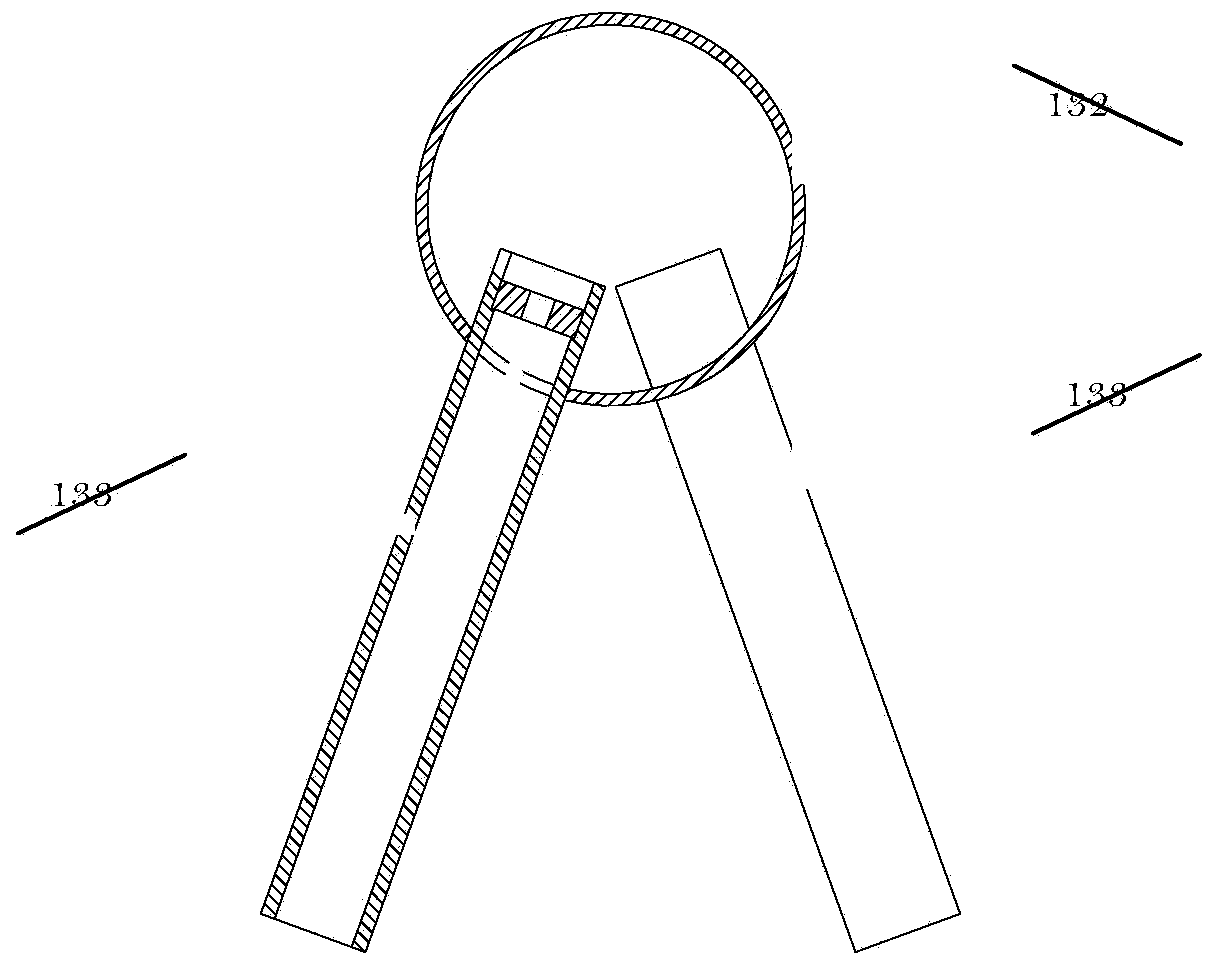

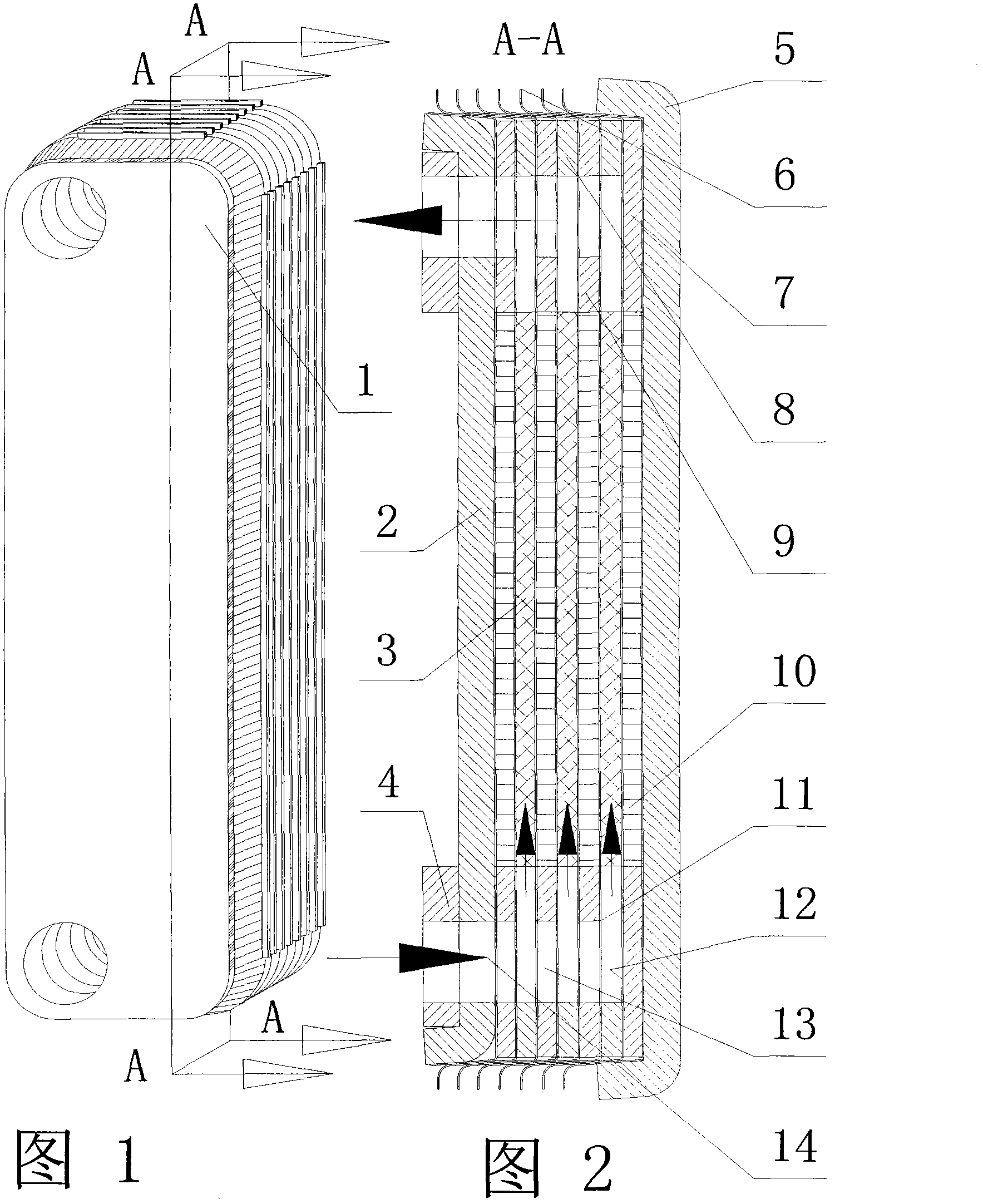

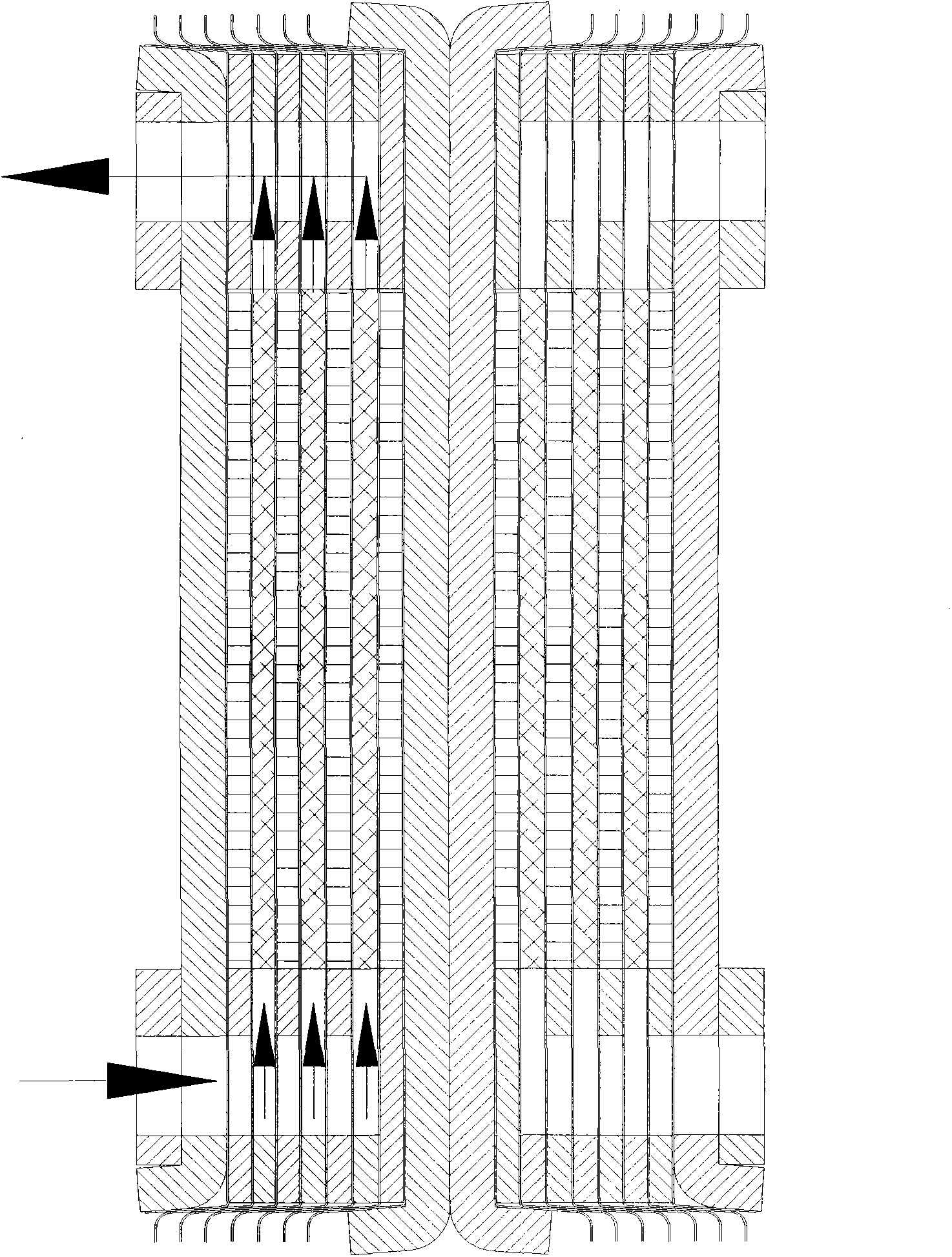

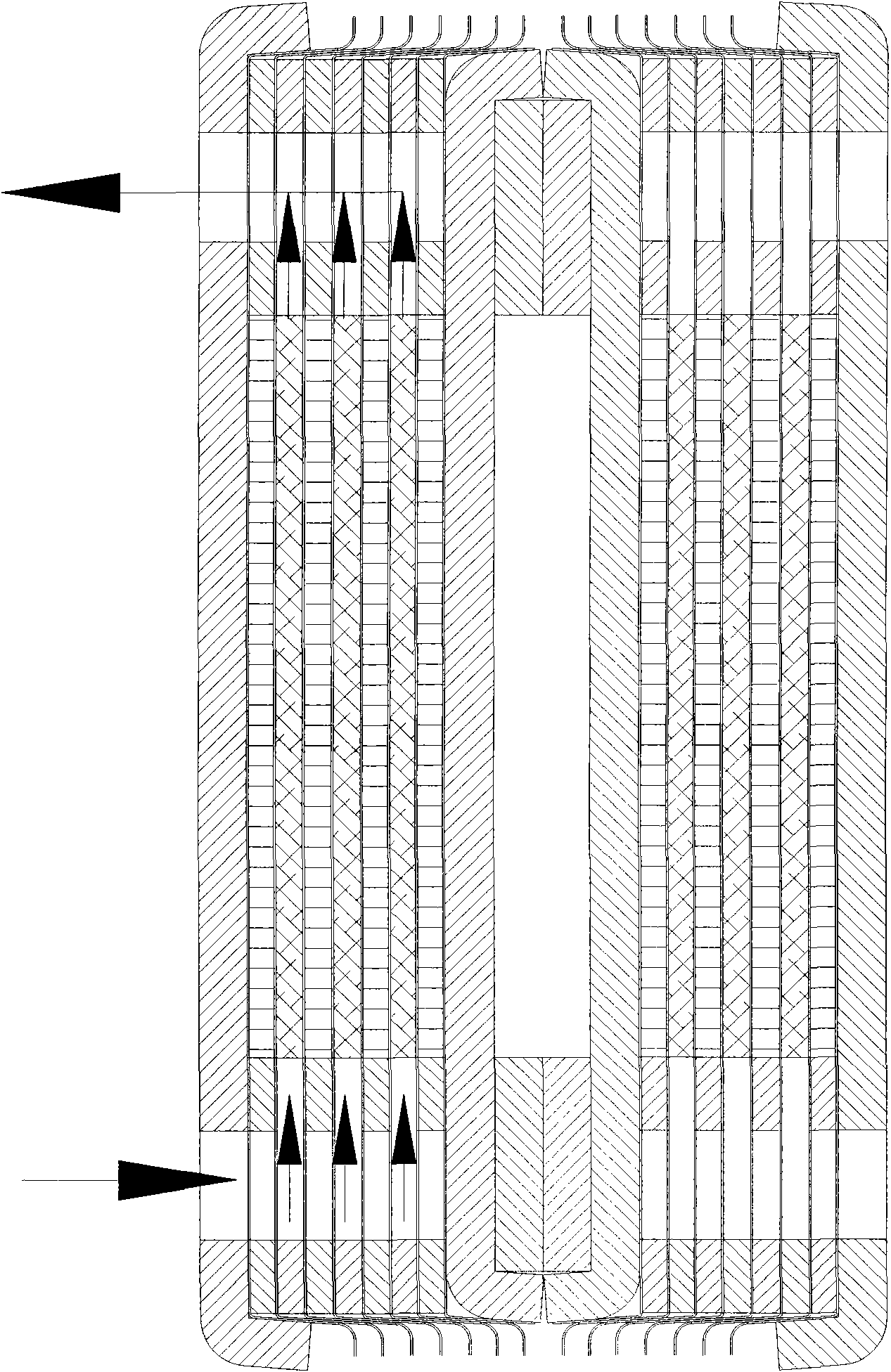

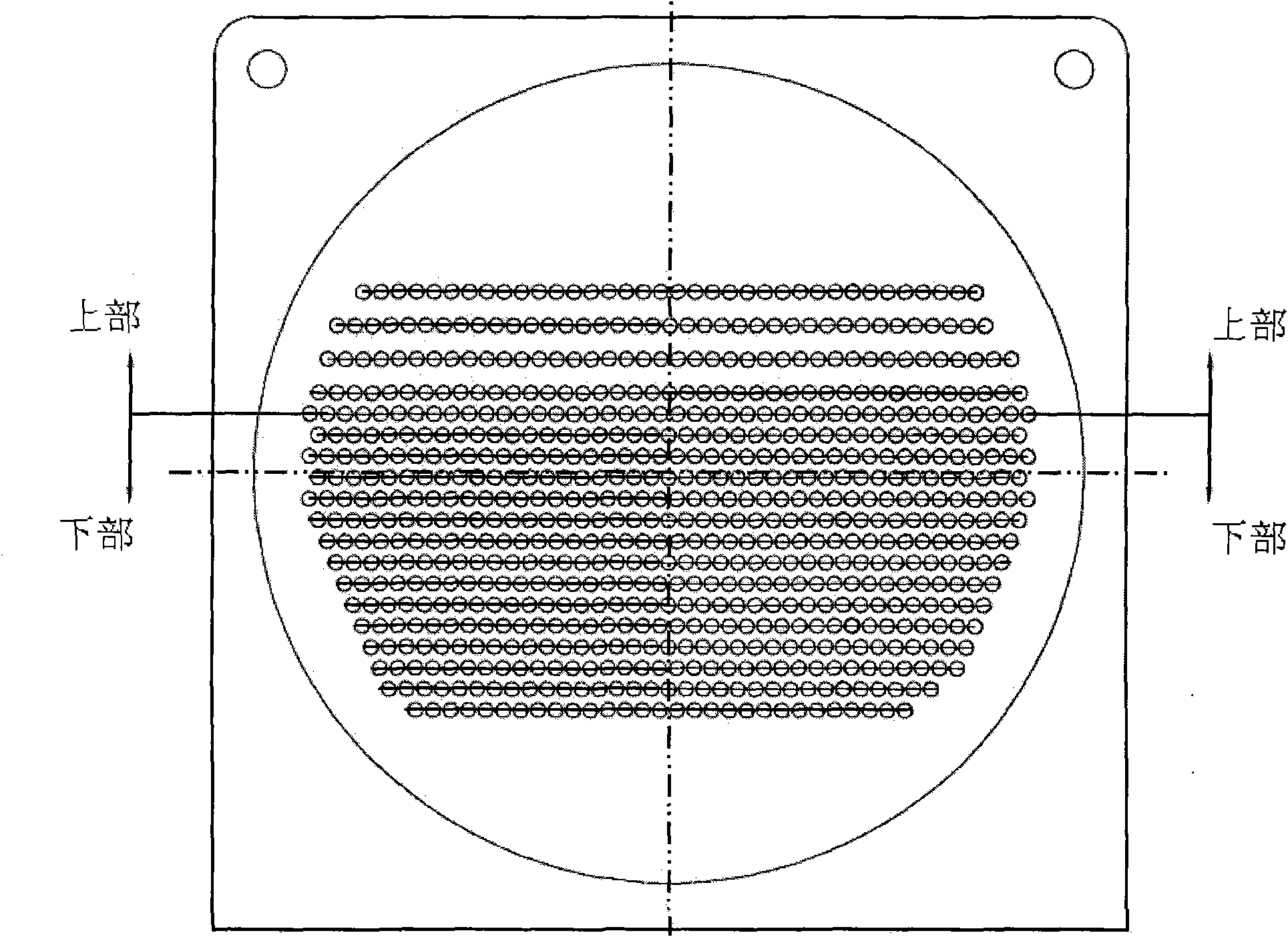

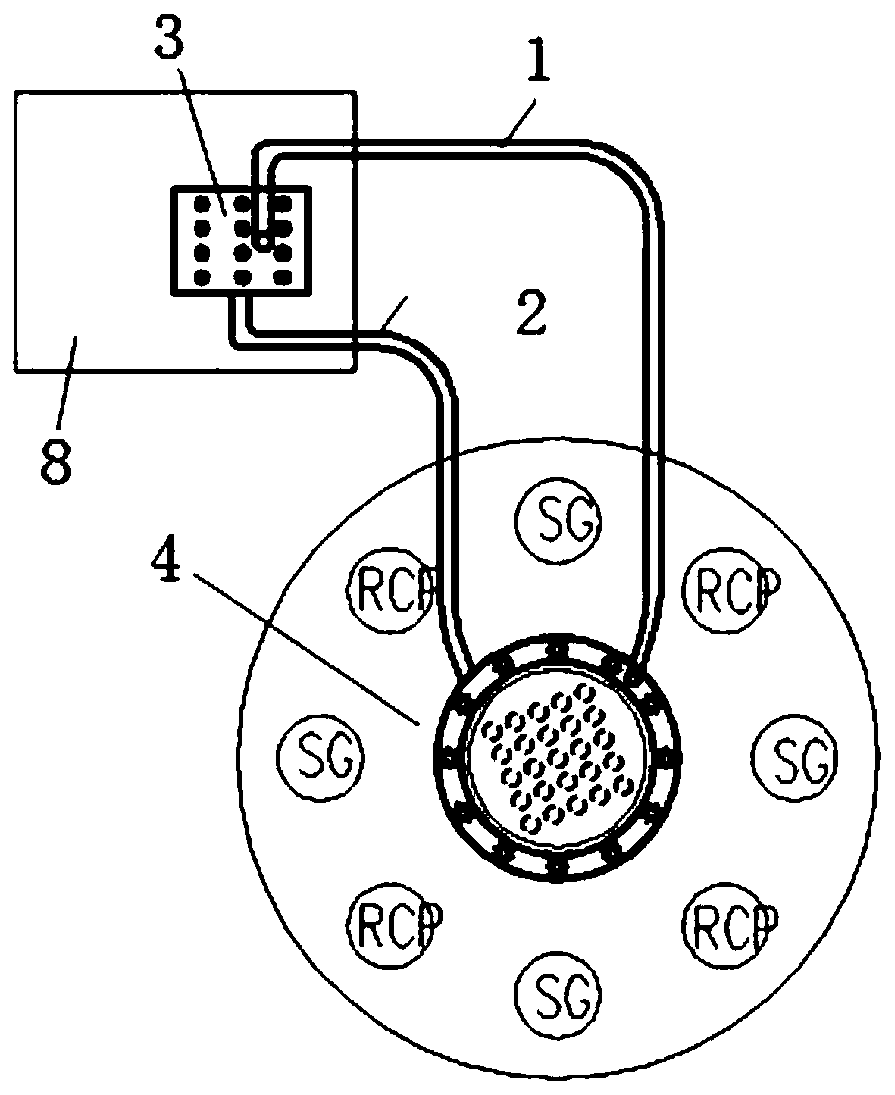

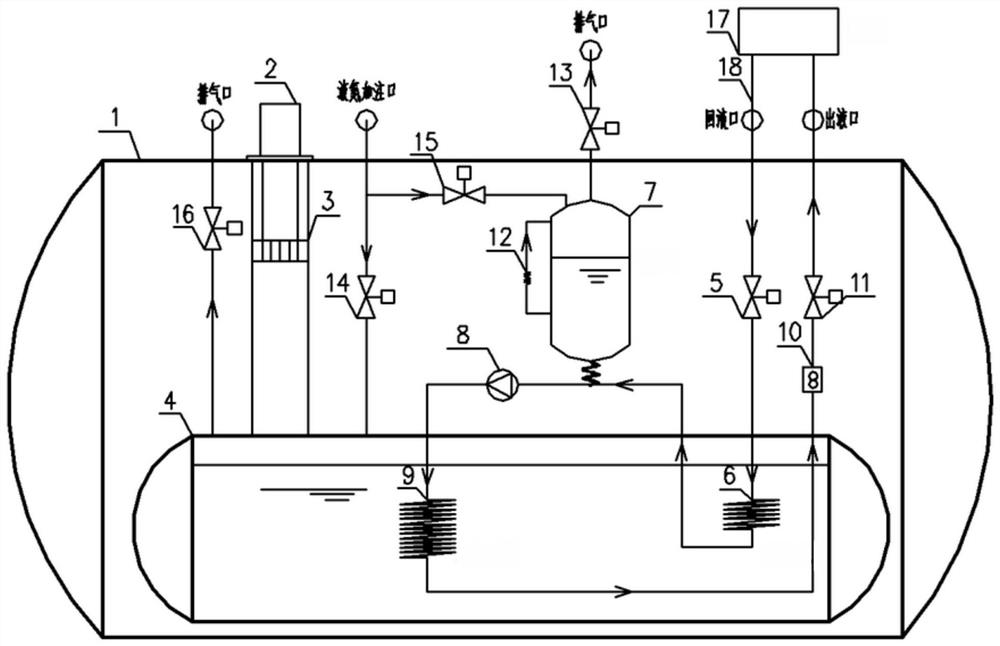

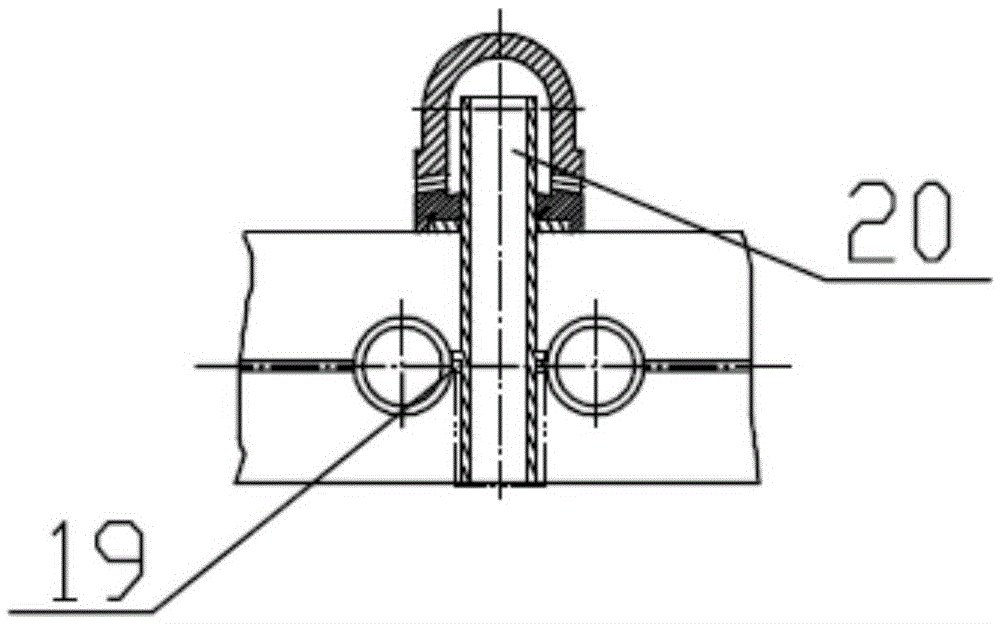

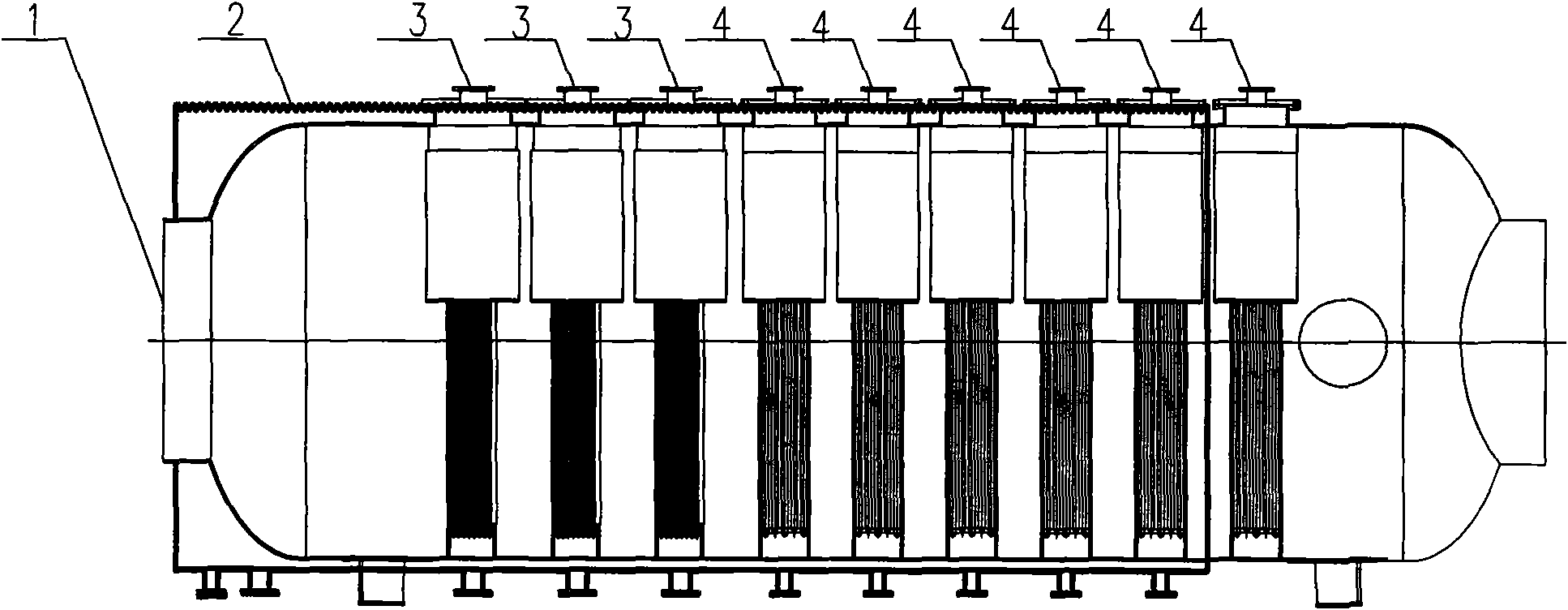

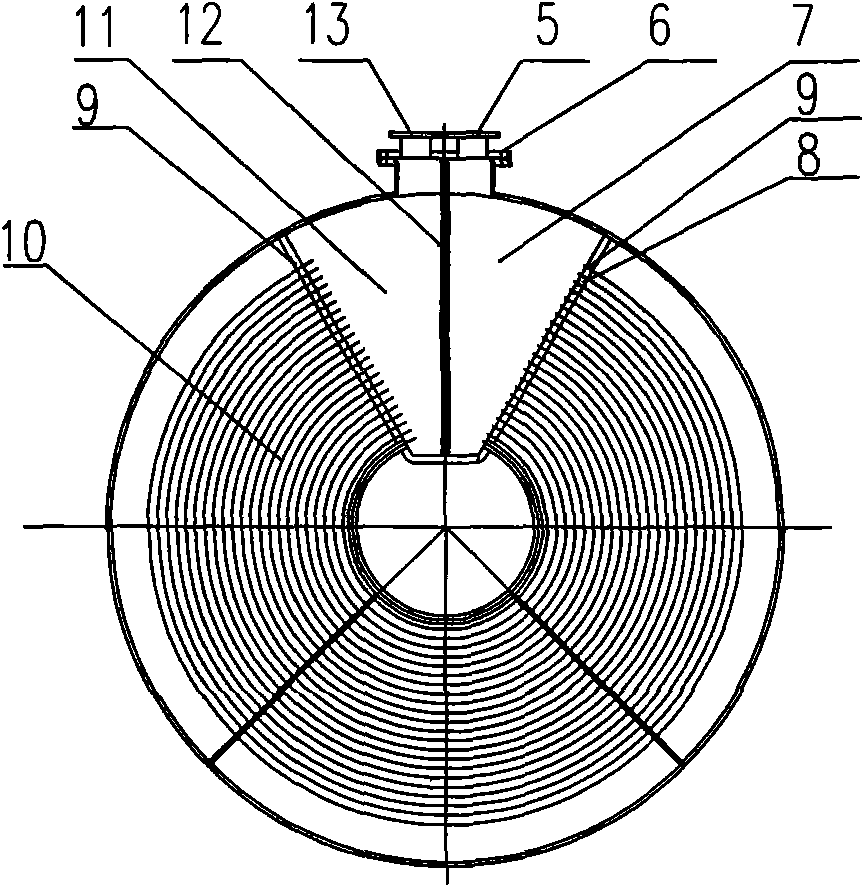

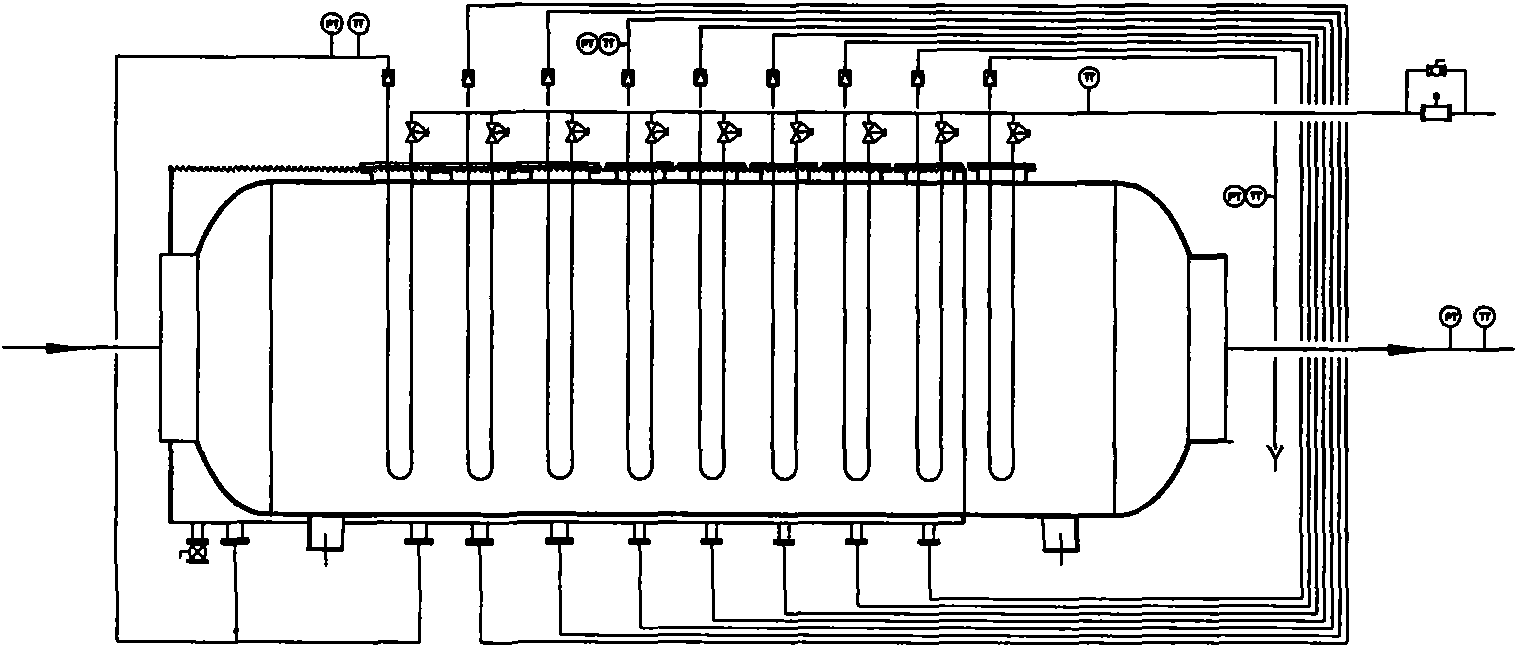

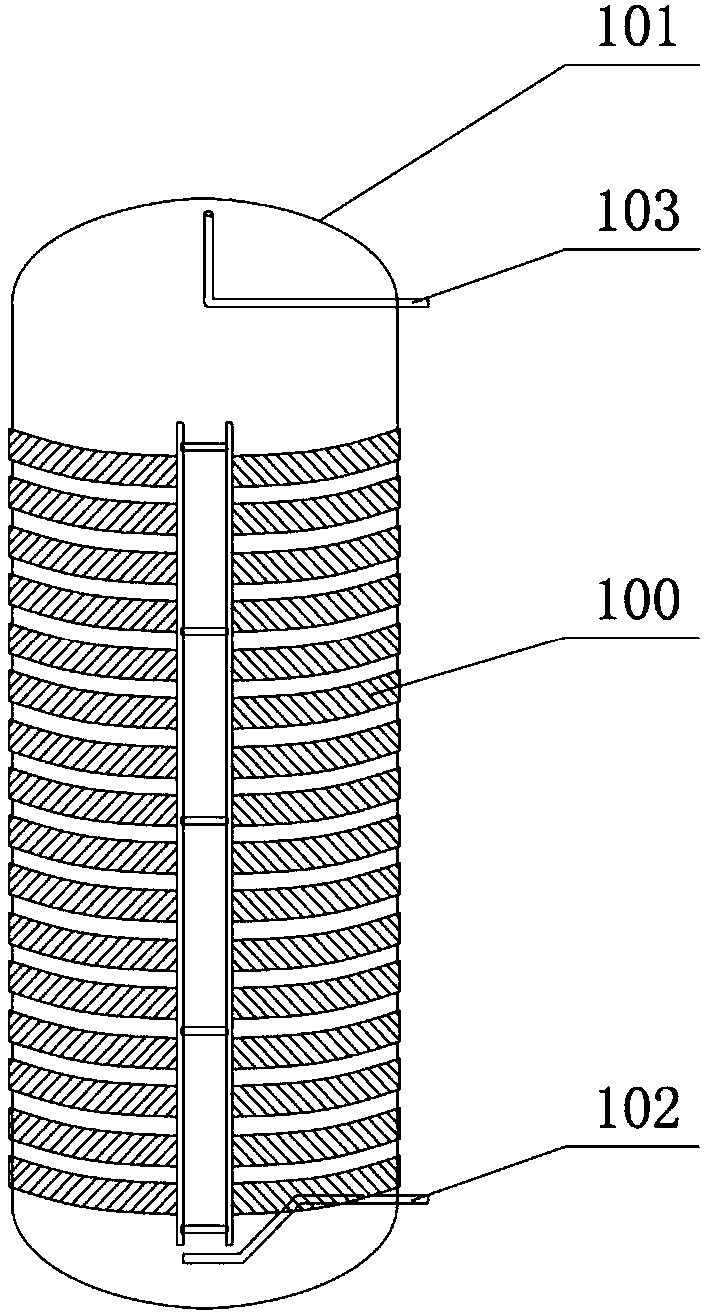

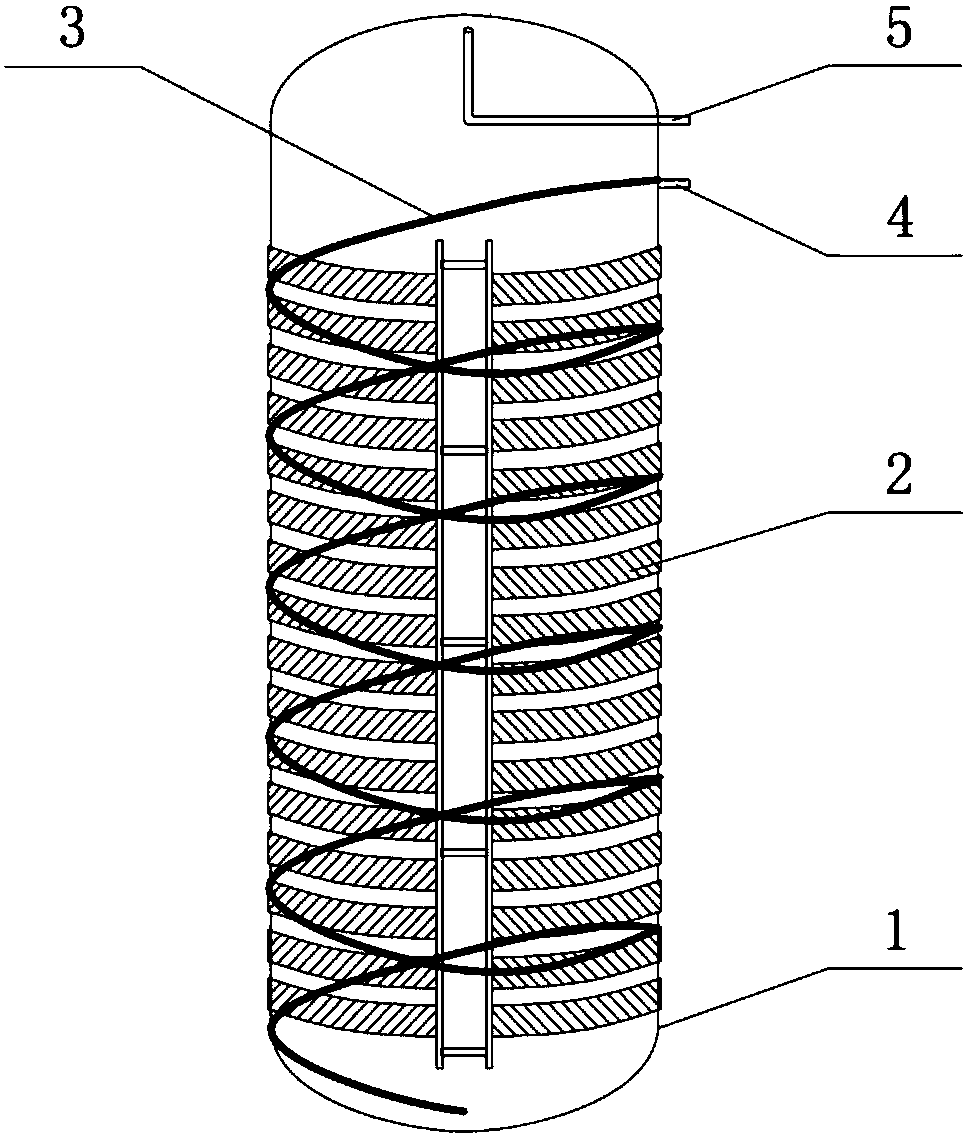

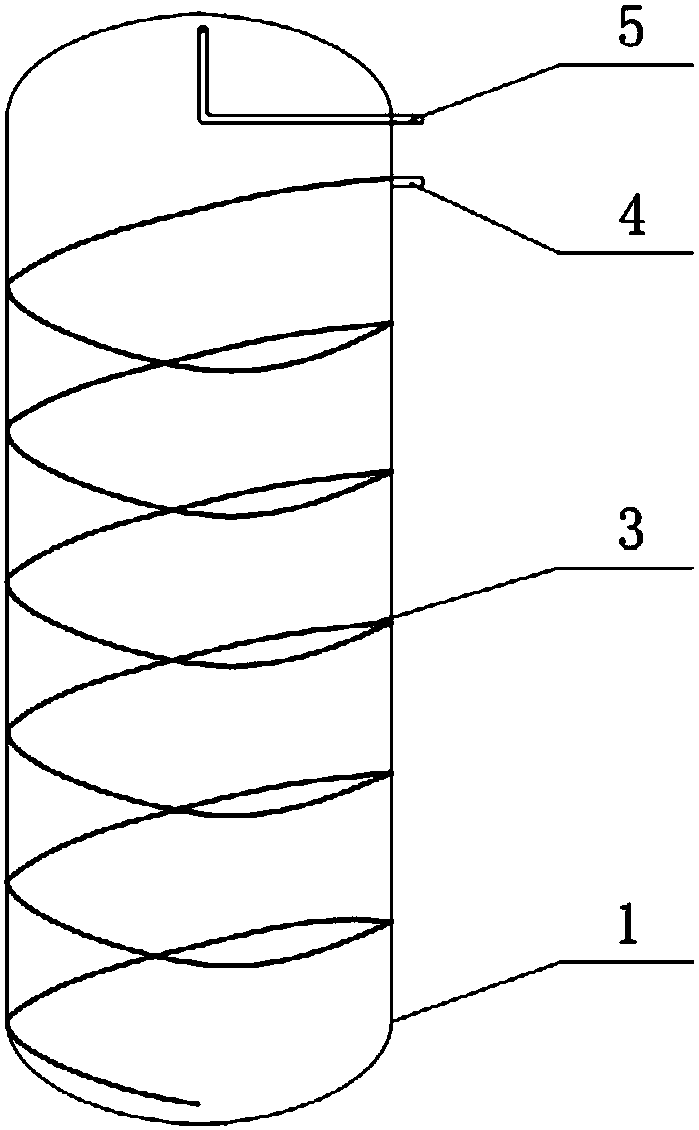

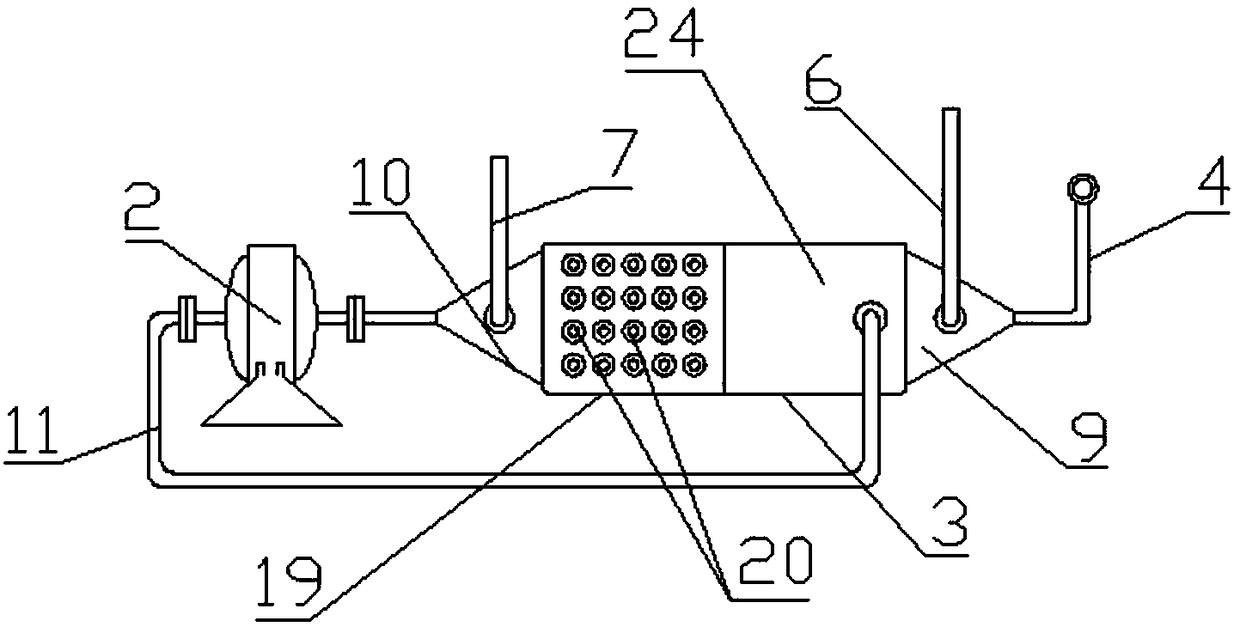

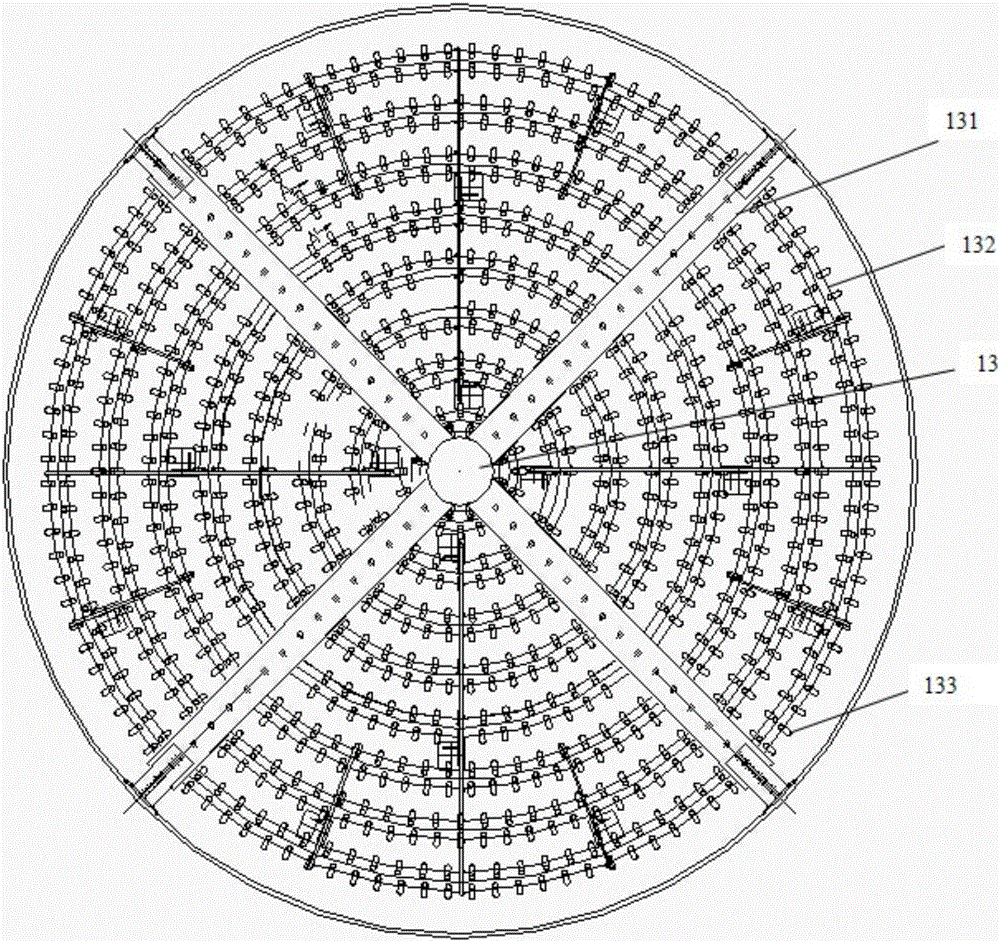

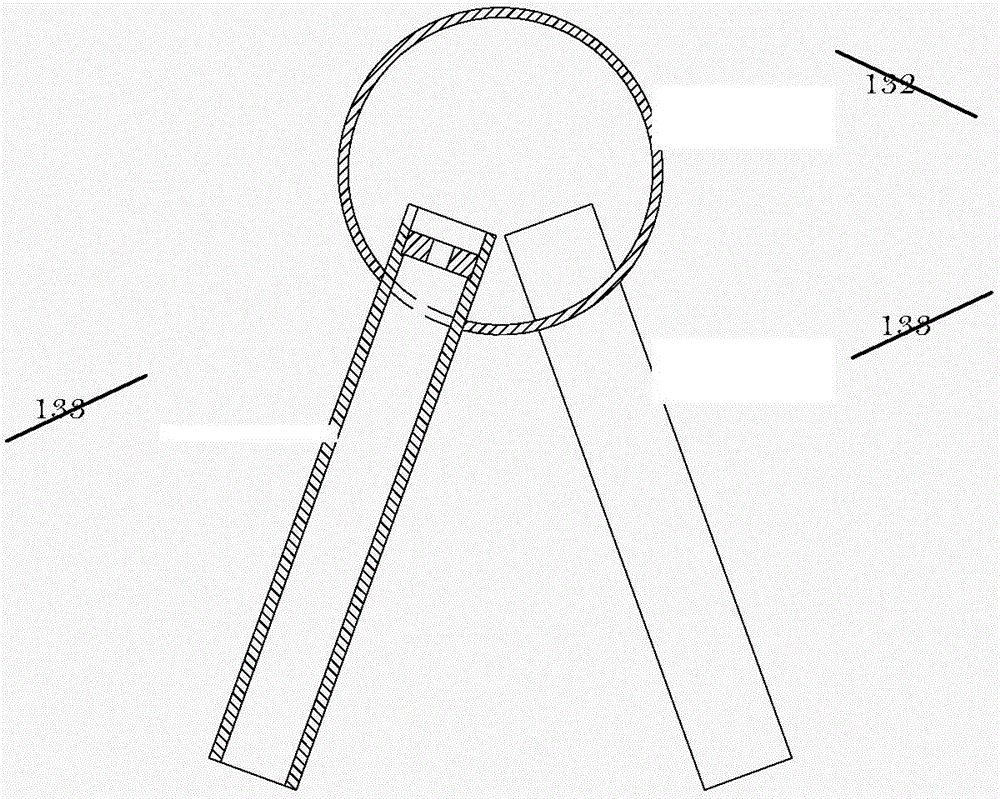

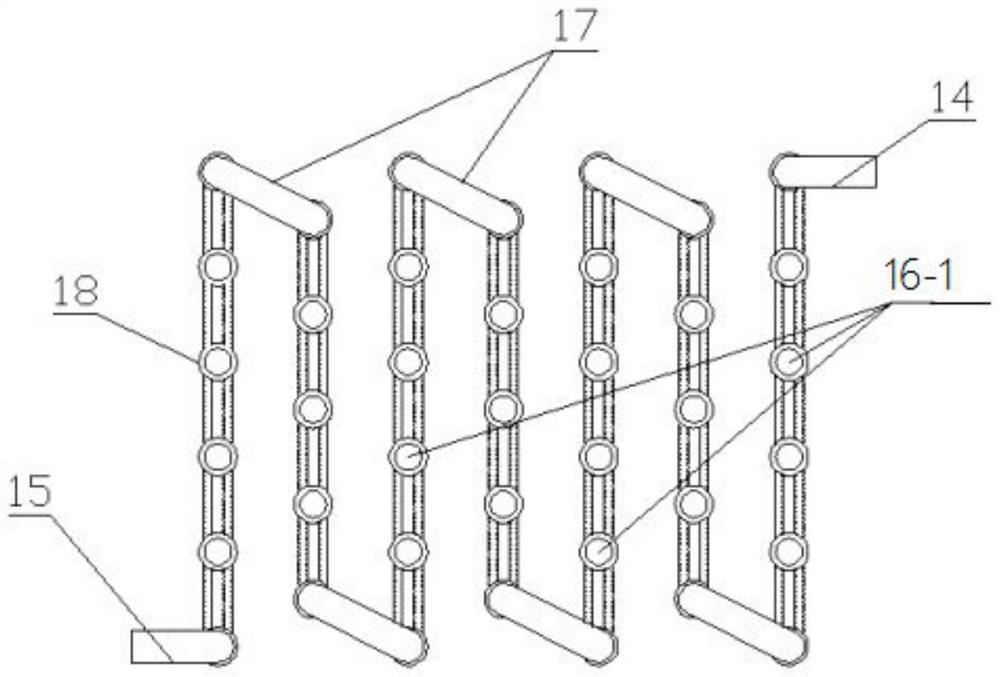

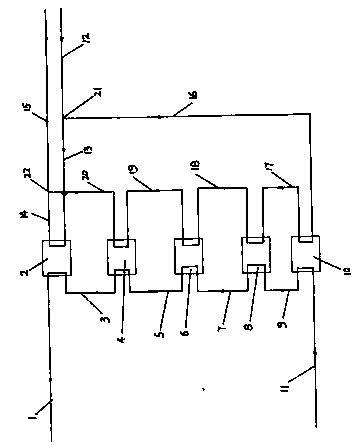

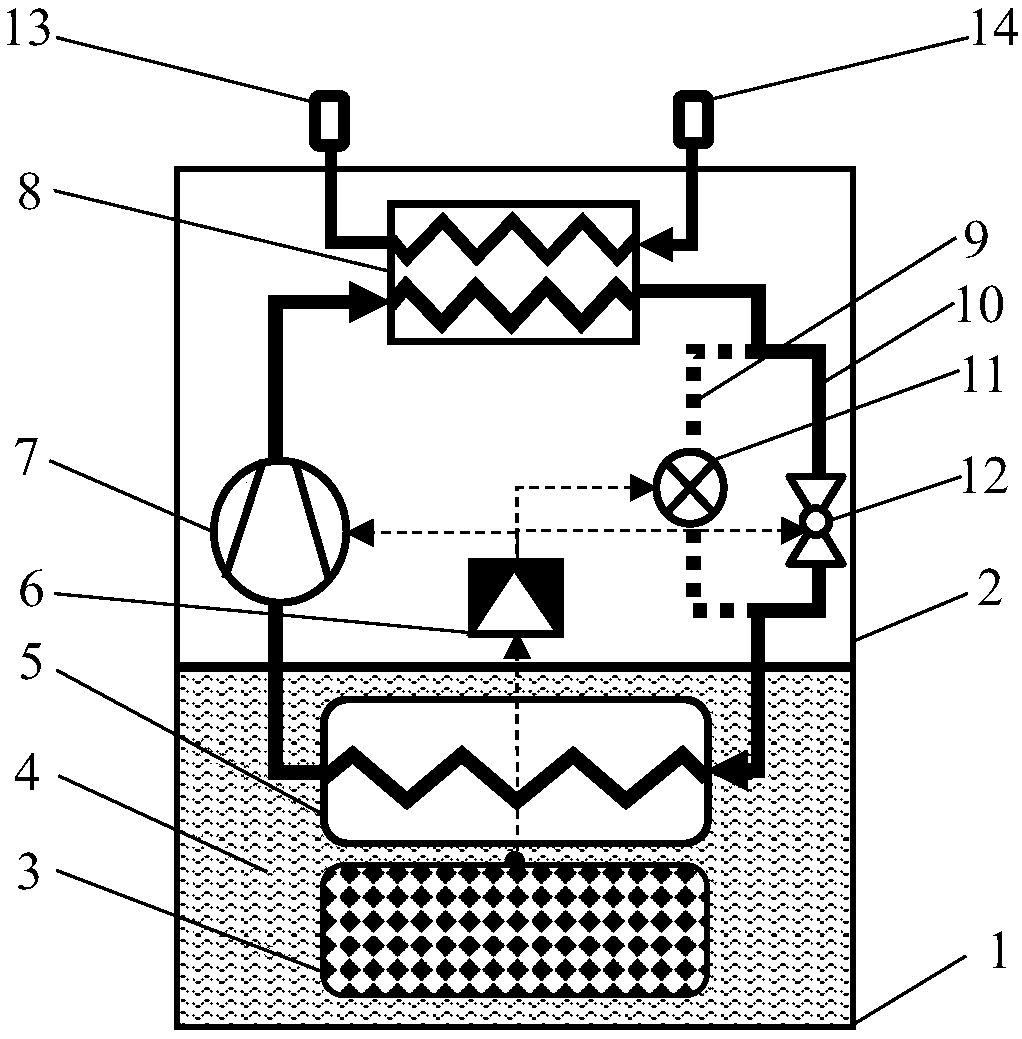

Methanation fluidized bed reactor

ActiveCN104001457AGuaranteed uptimeReduce consumptionGaseous fuelsChemical/physical processesFluidized bedMethanation

The invention provides a methanation fluidized bed reactor which is equipment for performing reaction on CO and H2 to generate methane and water and performing reaction on CO2 and H2 to generate methane and water at a certain constant low temperature. The methanation fluidized bed reactor comprises a cylindrical shell and inner parts, wherein a primary gas distributor and a secondary gas distributor are arranged at the bottom, and a catalyst is filled to form a catalyst bed; a heat exchange device consisting of a plurality of groups of heat exchange tubes is arranged in the catalyst bed; the lower ends of the heat exchange tubes in each group are communicated with a water inlet header pipe which is communicated with a water outlet of a steam drum, and the upper ends of the heat exchange tubes in each group are communicated with a steam outlet header pipe which is communicated with a steam inlet of the steam drum. According to the methanation fluidized bed reactor, heat continuously released during methanation reaction can be timely transferred through another medium, and the reaction can be performed at the constant low temperature.

Owner:尹明大

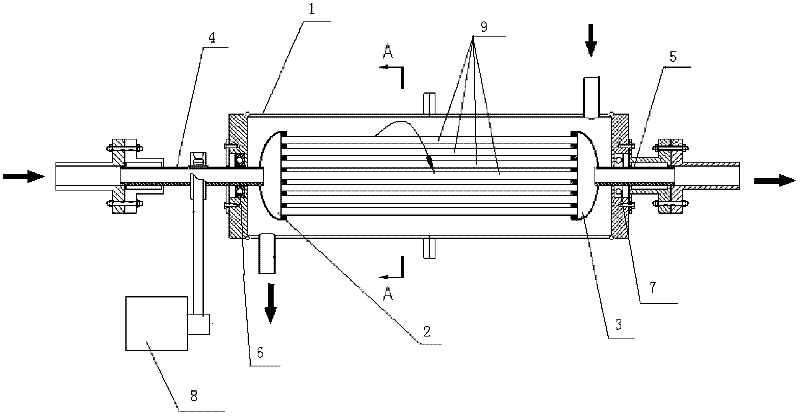

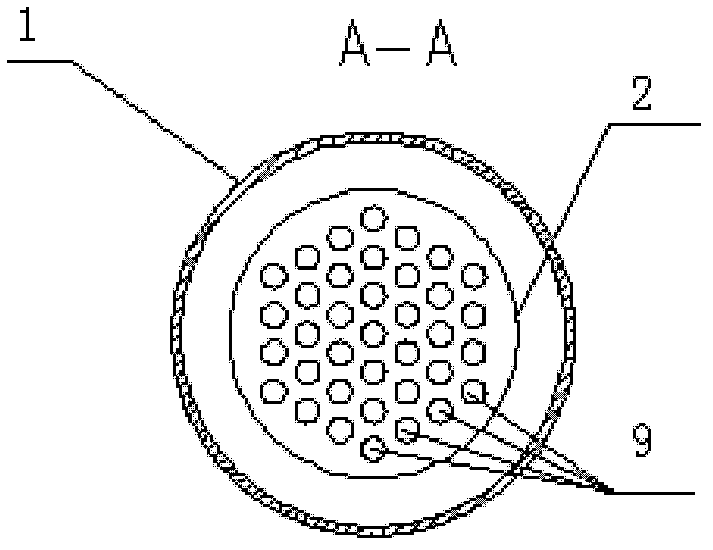

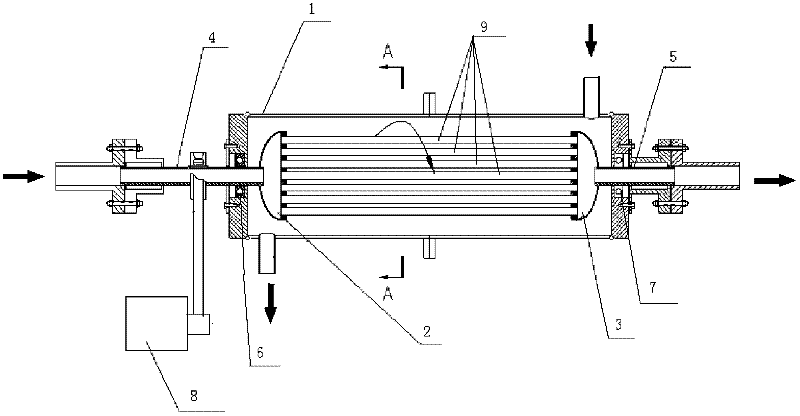

Rotary tube bundle heat exchanger

InactiveCN102538515AImprove heat transfer coefficientReduce volumeStationary tubular conduit assembliesHeat exchange apparatusEngineeringExchange coefficient

The invention belongs to the technical field of machinery, and relates to a rotary heat exchanger, in particular to a rotary tube bundle heat exchanger, which comprises a shell, a left tube plate, a right tube plate, a tube nest bundle, a motor, a rotating pipeline a, a rotating pipeline b, a bearing a and a bearing b. A fluid inlet and a fluid outlet are arranged at the upper end and the lower end of the shell respectively, through holes are arranged at the left end and the right end of the shell, annular grooves are arranged on the through holes, the left tube plate and the right tube plate are hemispherical, and the axis of the tube nest bundle is parallel to that of the shell. As the heat exchange coefficient of the rotary tube bundle heat exchanger is obtained without increasing the flow velocity of media, both a heat exchange medium a in an inner cylinder and a heat exchange medium b between the inner cylinder and an outer cylinder can enter the heat exchanger at a low speed, fluid resistance is greatly reduced, power needed for conveying fluids is remarkably decreased, and energy is saved.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

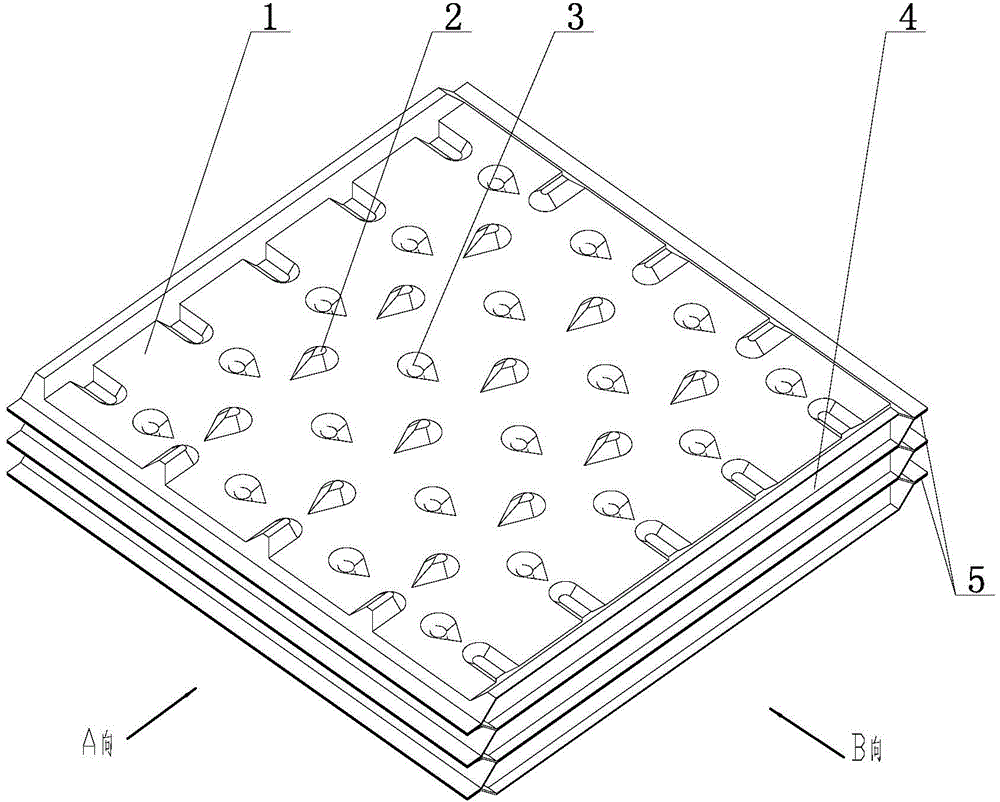

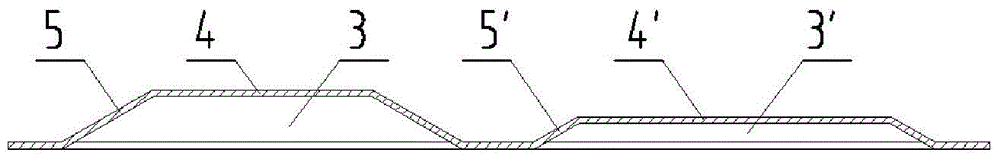

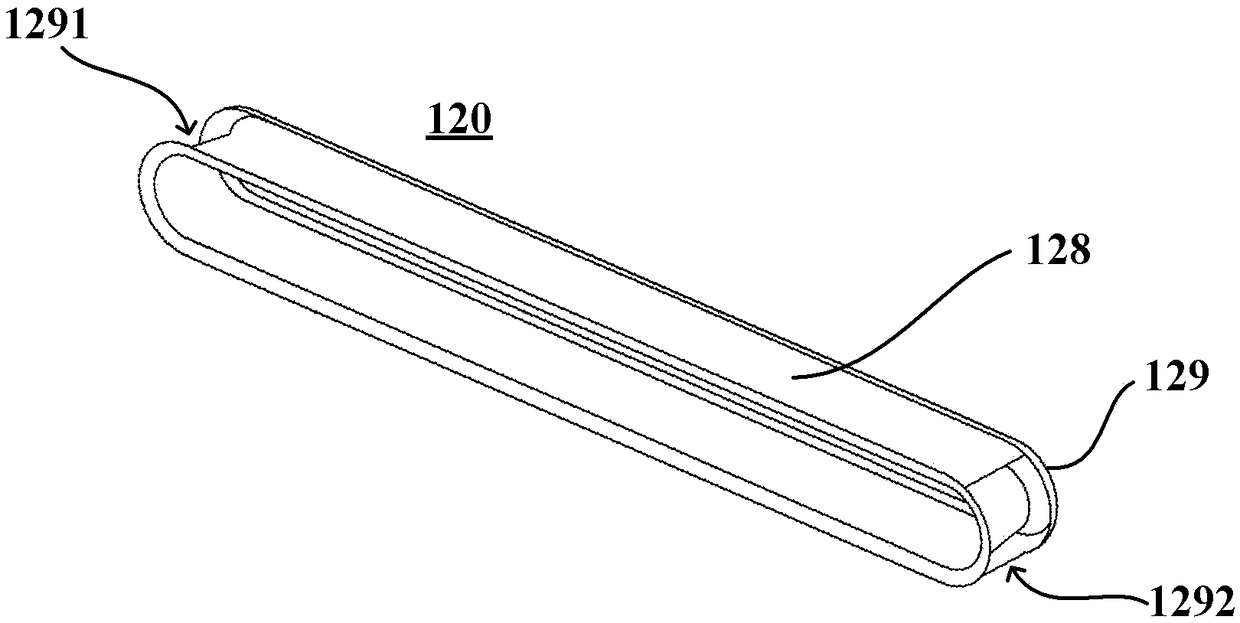

Self-supporting wide gap heat exchanging element

ActiveCN104696983ASelf-supportingReduce manufacturing costCombustion processIndirect carbon-dioxide mitigationFlue gasWide gap

The invention is applicable to the field of air cold medium pre-heating and particularly relates to a self-supporting wide gap heat exchanging element. The self-supporting wide gap heat exchanging element comprises a plurality of plate pairs which are overlapped layer by layer; each plat pair comprises upper and lower plate sheets which are arranged oppositely; a plurality of rows of convex ripples and concave ripples are distributed on the upper surfaces of the plate sheets along the same axis direction; the convex ripples and concave ripples are obtained by upwards and downwards pressing and molding the plate sheets; the convex ripples and concave ripples are distributed at intervals; the positions of the convex ripples and concave ripples on the upper plate sheets in the plate pairs correspond to the positions of the convex ripples and concave ripples on the lower plate sheets in the plate pairs; one group of opposite edges of the plate sheets are upwards folded and are transited into planes; the other group of opposite edges of the plate sheets are downwards folded and are transited into planes; the two adjacent folding edges in each plate pair are welded to form an air channel; the two adjacent plate pairs are symmetrical up and down, and the adjacent folding edges between the two adjacent plate pairs are welded to form a flue gas channel. The self-supporting wide gap heat exchanging element has the advantages that a wide gap channel can be combined, dirt and dust are not easy to deposit, the resistance fall also can be reduced and the heat exchanging efficiency is sufficiently improved.

Owner:SHANDONG WINTECH TECH CO LTD

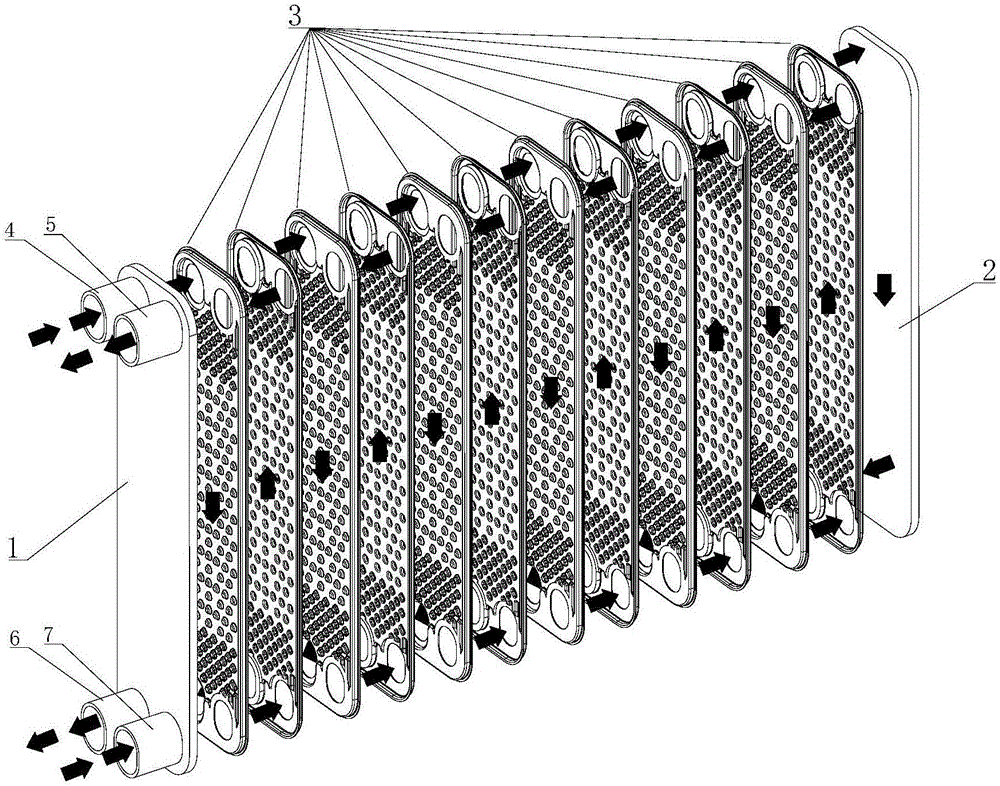

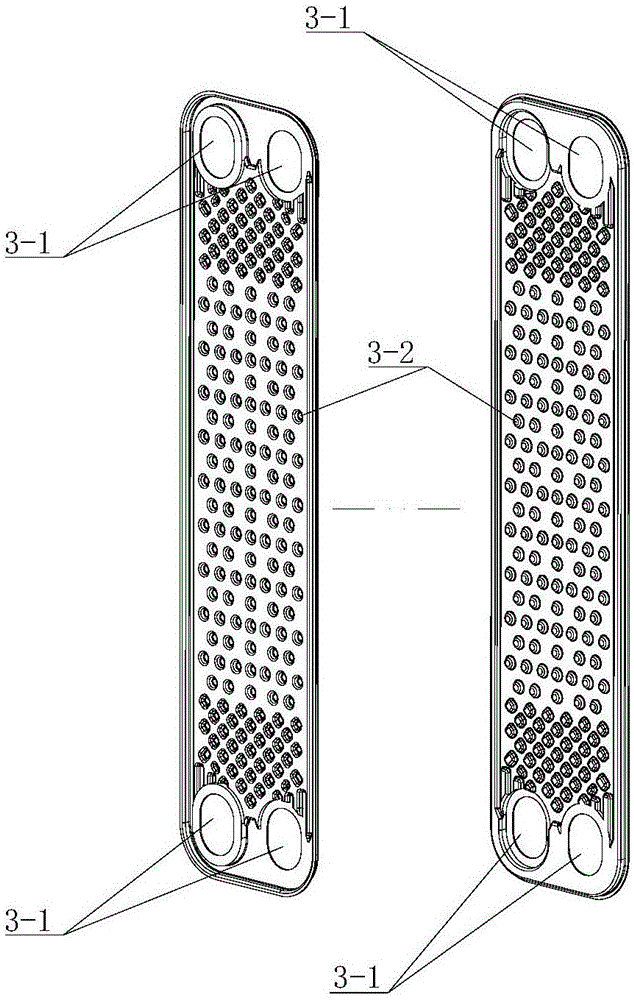

Full aluminum type plate heat exchanger for cooling heating part on electric vehicle

InactiveCN106197091ALight in massReduce weightHeat exchanger casingsCoatingsPlate heat exchangerEngineering

The invention relates to a full aluminum type plate heat exchanger for cooling a heating part on an electric vehicle. The full aluminum type plate heat exchanger is of an overall brazing structure, and comprises a front end plate, a back end plate and a plurality of heat exchange plate sheets arranged between the two end plates; a cold fluid inlet connecting pipe and a hot fluid outlet connecting pipe are arranged at the positions of two corner pores in the upper portion of the front end plate, and a cold fluid outlet connecting pipe and a hot fluid inlet connecting pipe are arranged at the positions of two corner pores in the lower portion of the front end plate; flow via through holes in the four positions of each heat exchange plate sheet are sequentially connected front and back to form a cold fluid input channel, a hot fluid output channel, a cold fluid output channel and a hot fluid input channel; a clamping cavity inside the heat exchanger forms hot fluid runner cavities and cold fluid runner cavities which are alternatively arranged in sequence; and protrusions arranged on the two heat exchange plate sheets corresponding to each cold fluid runner cavity are in one-to-one contact in the cold fluid runner cavity, brazed connection is achieved, multiple cold fluid flowing channels are formed in the cold fluid runner cavity, and an overall channel cavity structure is formed by the hot fluid runner cavities. The full aluminum type plate heat exchanger is small in weight and high in heat exchange efficiency.

Owner:TIANJIN SANDEN AUTO AIR CONDITIONING

Spray type shell-and-tube heat exchanger adopting nonmetal heat exchange tubes

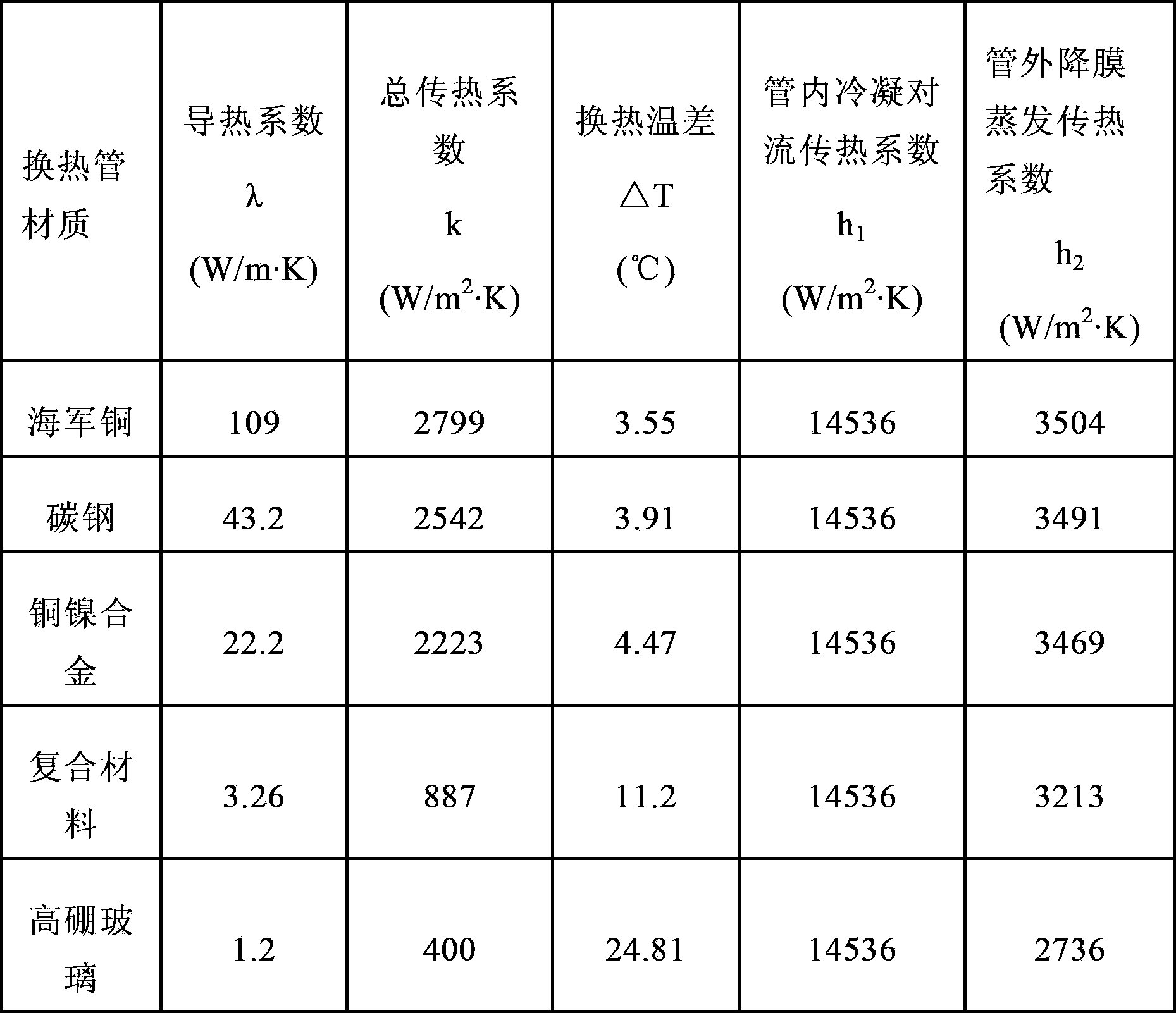

InactiveCN103837015ASmall diameterMeet heat transfer requirementsStationary conduit assembliesHeat exchange apparatusShell and tube heat exchangerDistillation

The invention relates to the technical field of shell-and-tube heat exchange, and discloses a spray type shell-and-tube heat exchanger adopting nonmetal heat exchange tubes. The heat exchanger comprises a shell, a sprayer, the heat exchange tubes arranged in parallel in the shell, a supporting plate for supporting the heat exchange tubes and a tube plate connected with the heat exchange tubes, wherein the heat exchange tubes are made of nonmetal material with the heat conductivity coefficient of 0.5 W / m*K-10 W / m*K, and the outer diameter of the heat exchange tubes is 5 mm-15mm. The corrosion prevention problem of heat exchange tubes in low-temperature multi-effect distillation sea water desalting equipment and a lithium bromide absorption refrigerator can be solved, and the spray type shell-and-tube heat exchanger has the advantages of being low in heat transfer temperature difference and cost and the like.

Owner:BLUELAGOON TECH

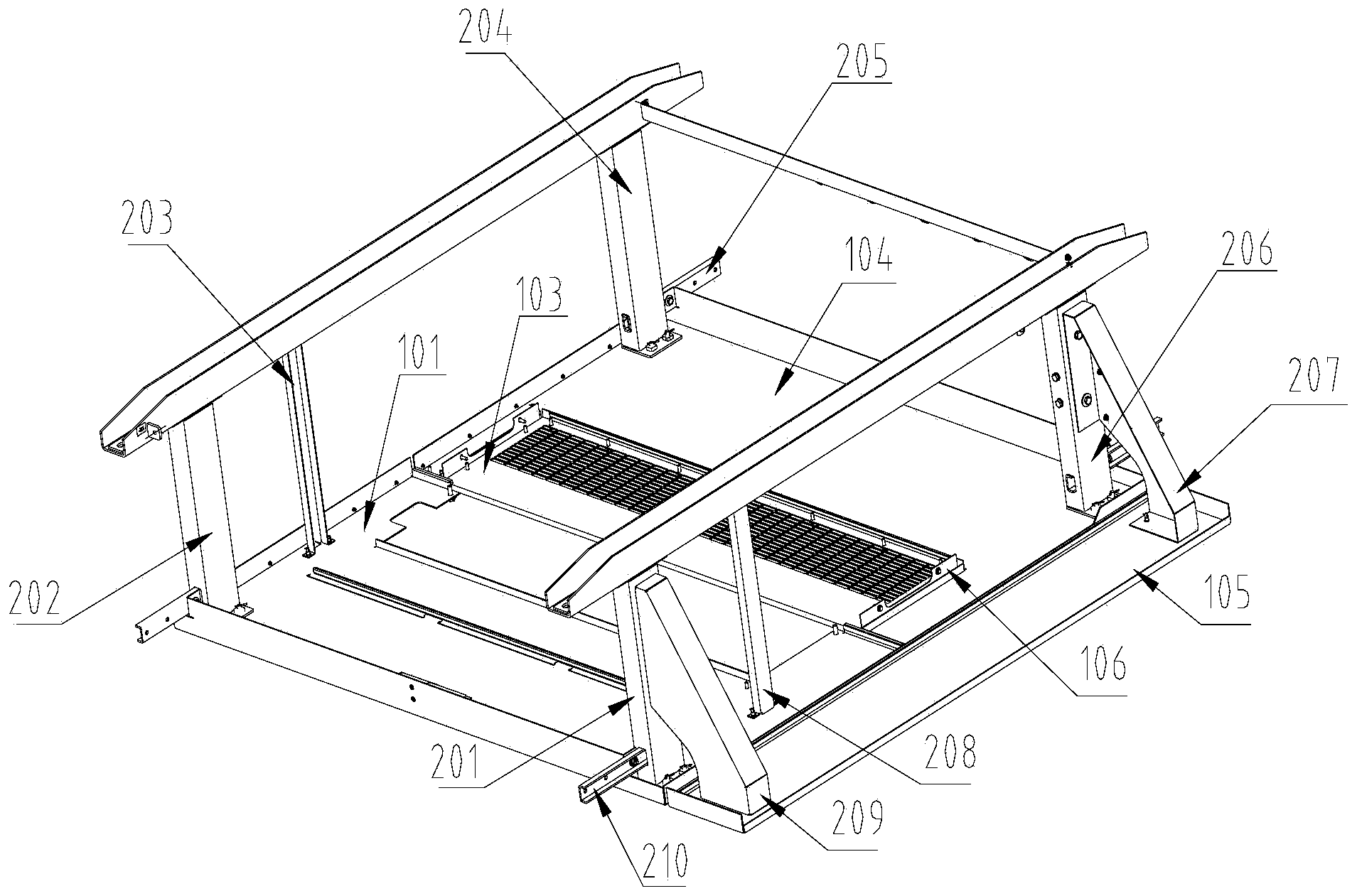

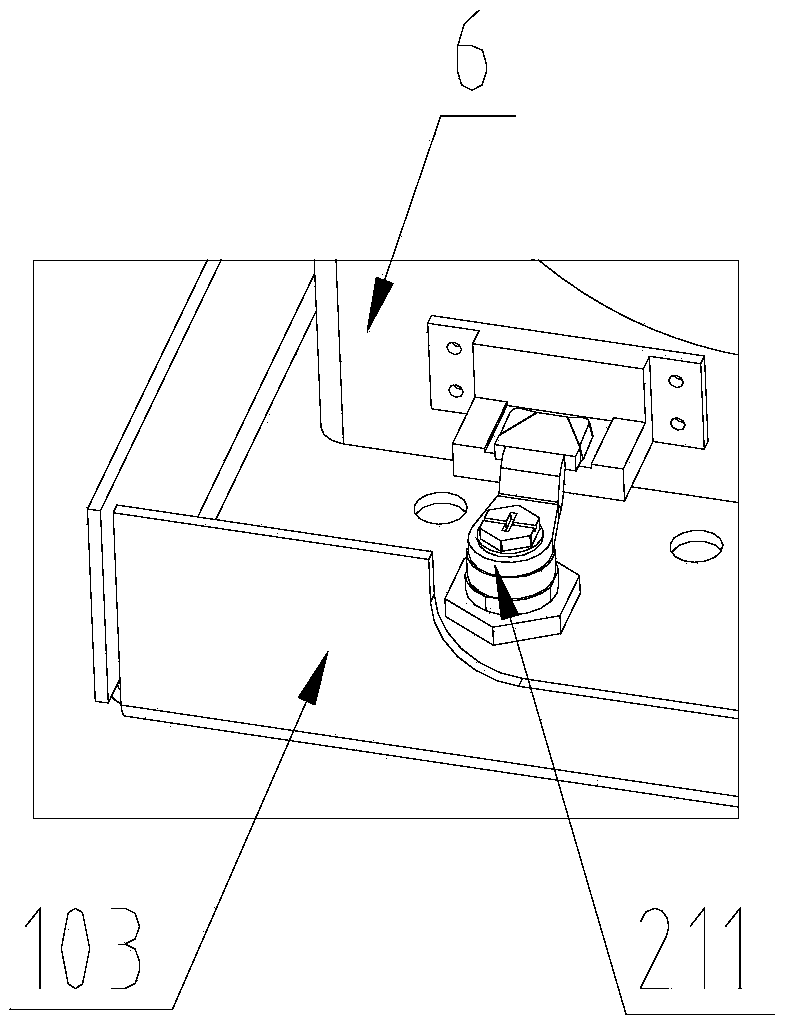

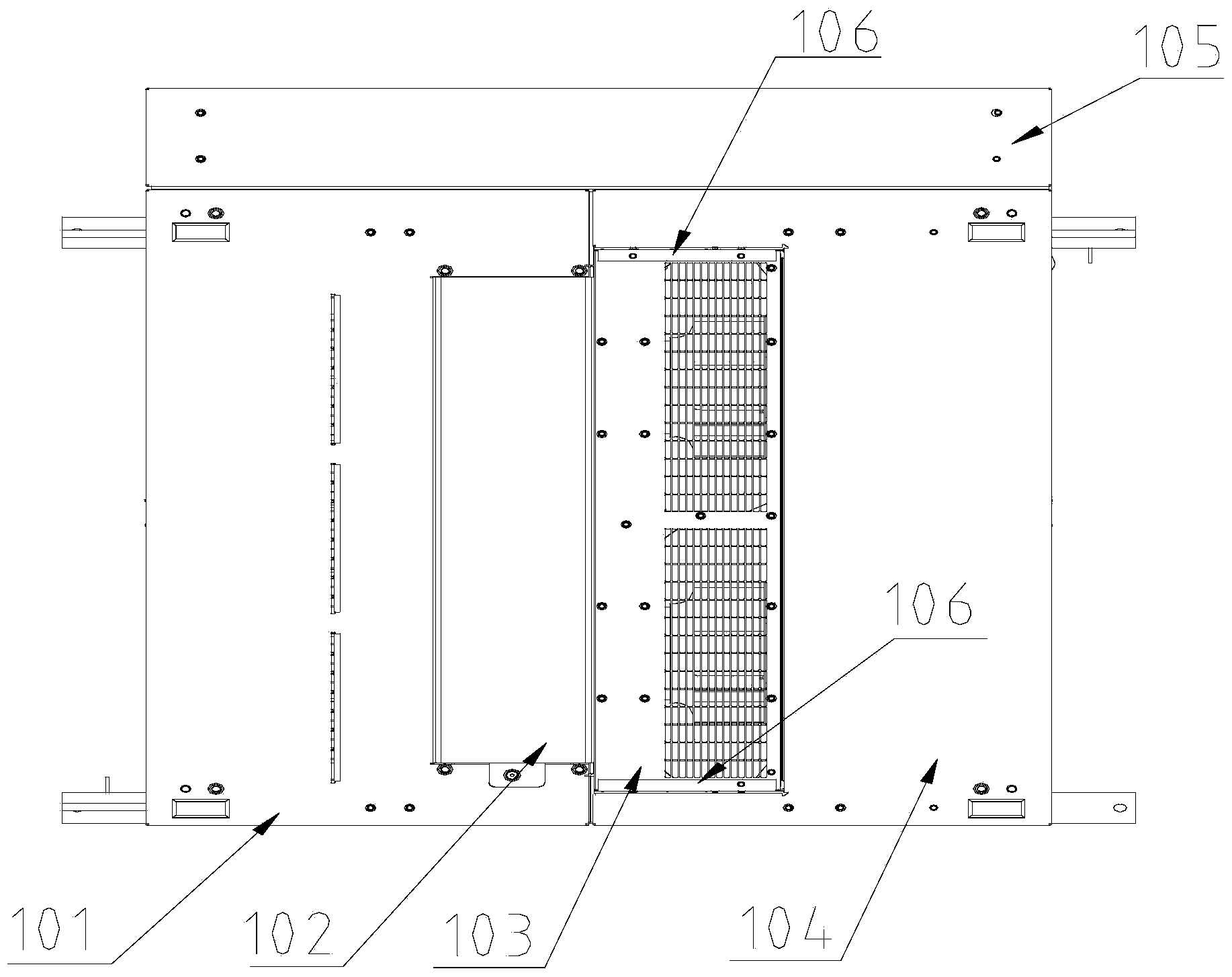

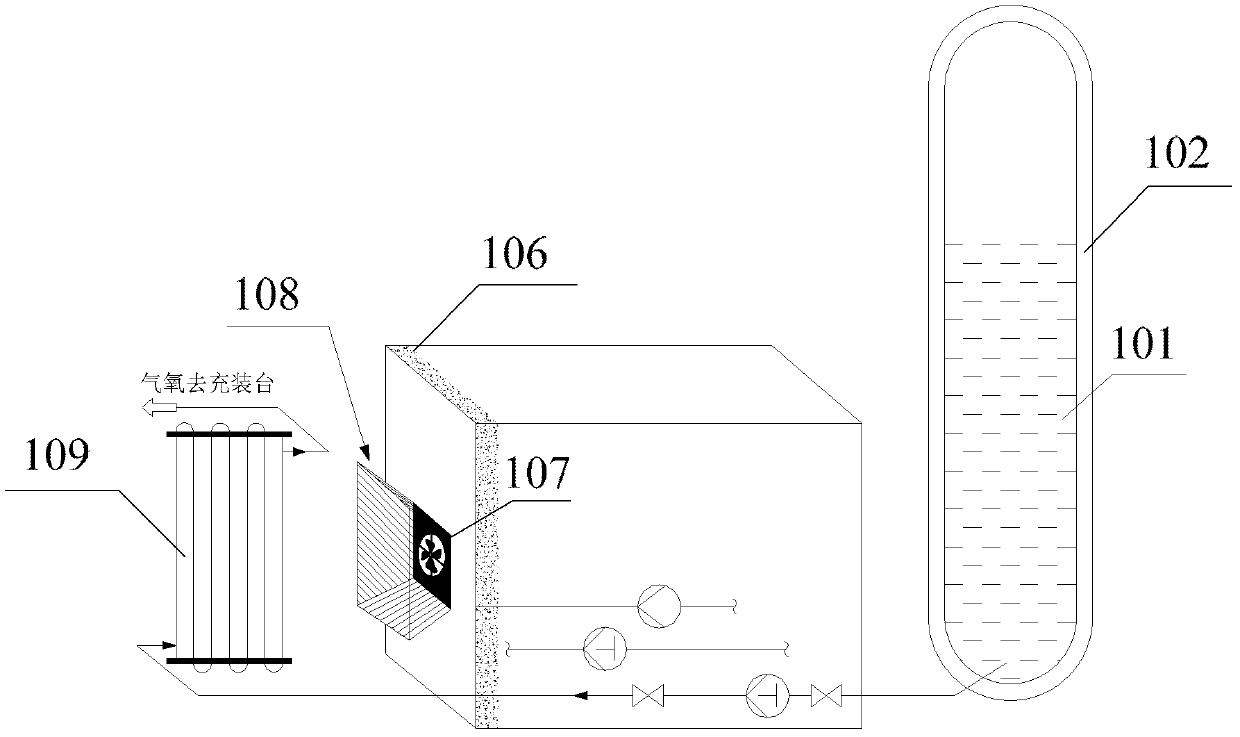

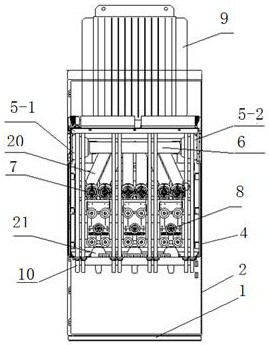

Cooling unit for traction converter

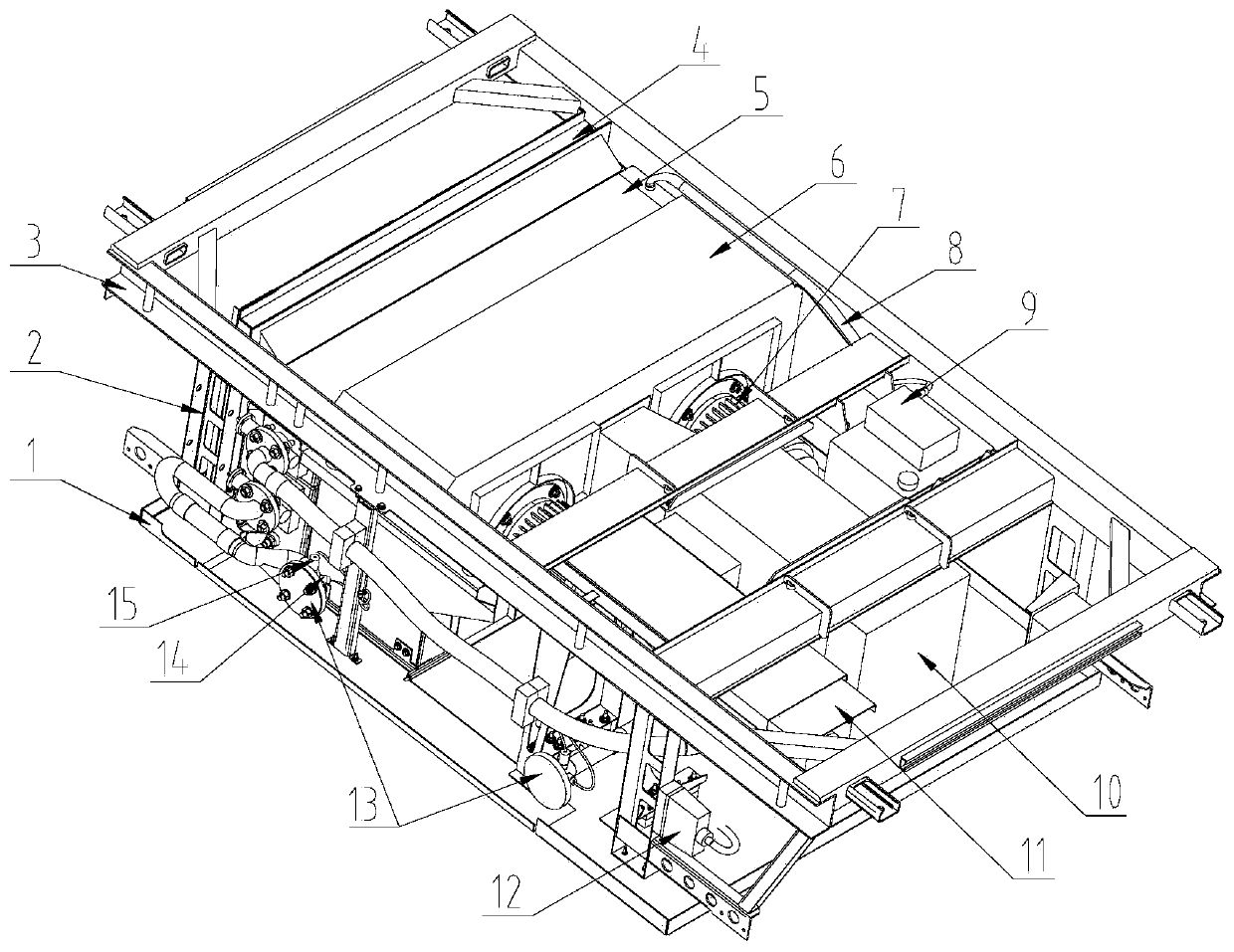

ActiveCN104201901AQuick changeLow maintenanceAc-ac conversionCooling/ventilation/heating modificationsFiltrationAir filter

The invention discloses a cooling unit for a traction converter. According to the cooling unit, by carrying out the simulated analysis on the flow behavior of cooling air and the flow behavior of water, the resistance property of an air filter, a radiator, a blower case body and other components is determined; by the adoption of the matching technology, a blower of a cooling air system is guaranteed to work in a high-efficiency working area, and a cooling water system is guaranteed to work in a water pump high-efficiency working area, so that the optimized matching among heat exchange capability, auxiliary power consumption and noise is realized. On the given working condition, the heat exchange requirement of the cooling systems is satisfied; the dust filtration and water filtration efficiency of a filter is improved, and air resistance is lowered simultaneously, so that auxiliary power consumption is reduced; the adopted security measures can prevent a baseplate of the cooling unit from dropping off so as to improve both reliability and security; the cooling unit is suitable for a motor train unit at the speed of 300-350 kilometers per hour, and can further be suitable for the motor train unit in other speed grades by variant design.

Owner:CRRC DALIAN INST CO LTD

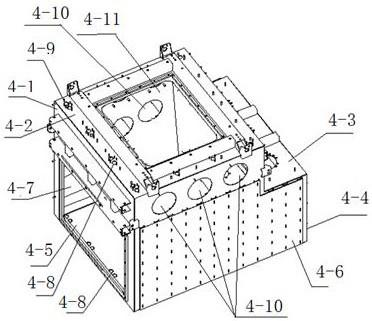

Connected box-shaped laminating heat exchanger

ActiveCN103471435AMeet heat transfer requirementsLaminated elementsStationary plate conduit assembliesEngineeringPlate fin heat exchanger

The invention discloses a connected box-shaped laminating heat exchanger. Each single box-shaped laminating heat exchanger consists of a plurality of heat exchange plate fins which are in the shape of an inclined edge box and can be laminated together, wherein angular holes through which a heat exchange medium can flow and heat exchange devices which can perform inter-wall heat exchange are arranged in each single box-shaped laminating heat exchanger; the angular holes in the heat exchangers are distributed in the two ends of each heat exchange plate fin; the heat exchange devices are positioned on the middle parts of the heat exchange plate fins; a front baffle plate, a rear baffle plate and a rear reinforcing plate which are hermetically linked with each single box-shaped laminating heat exchanger are arranged on the single box-shaped laminating heat exchanger; the materials of the front baffle plate, the rear baffle plate and the rear reinforcing plate are much thicker than the material of the heat exchange plate fins. The connected box-shaped laminating heat exchanger is characterized in that the single box-shaped laminating heat exchangers with the front baffle plates, the rear baffle plates and the rear reinforcing plates are hermetically linked together, and a linked wall plate with enough thickness is formed at the end of a heat exchange medium passage in a hermetical linkage form.

Owner:缪志先

Tube row arrangement and tube type selecting optimization method for horizontal shell-and-tube cooler

InactiveCN101793451ALess consumablesGive full play to the advantages of heat exchangeEvaporators/condensersFully developedEngineering

The invention discloses a tube row arrangement and tube type selecting optimization method for a horizontal shell-and-tube cooler. An upper heat transfer tube of the tube row of the horizontal shell-and-tube cooler is a three-dimensional reinforcing heat transfer tube, while a lower heat transfer tube is a low-rib tube, and the upper and lower heat transfer tubes are arranged in different row distances. Compared with the arrangement mode of the conventional tube row, the method is characterized in that 1), different heat transfer tube types are adopted at different positions to fit for the different heat transfer tubes to play different roles in heat transfer; 2), the different tube types adopt different arrangement heights to fully develop the advantages of the different reinforcing heat transfer tubes; and 3), the different tube types are arranged in different distances comprising transverse distance and longitudinal distances to reduce the sensitivities of the different heat transfer tubes to the tube row heights. The method replaces the primary heat exchanger by only adopting a transverse and longitudinal tube row distance based on the shell side size of the primary heat exchanger; and the consumption of a copper material is saved by nearly 1 / 5 compared with the past by the method purely adopting the heat transfer tube, and the heat exchange amount is slightly improved based on the primary heat exchange amount requirement.

Owner:XI AN JIAOTONG UNIV

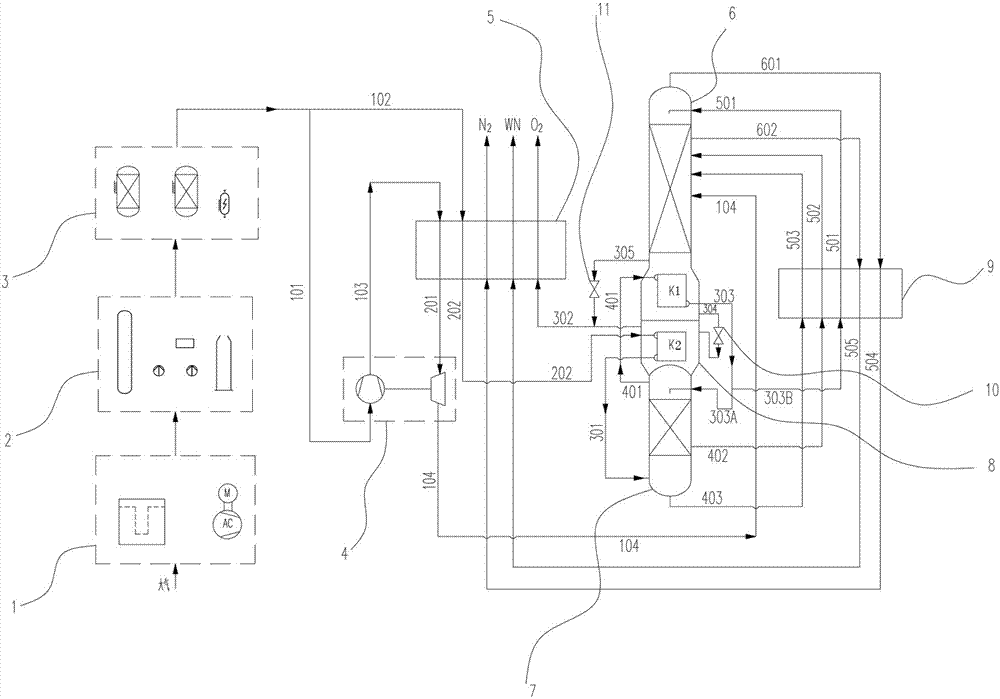

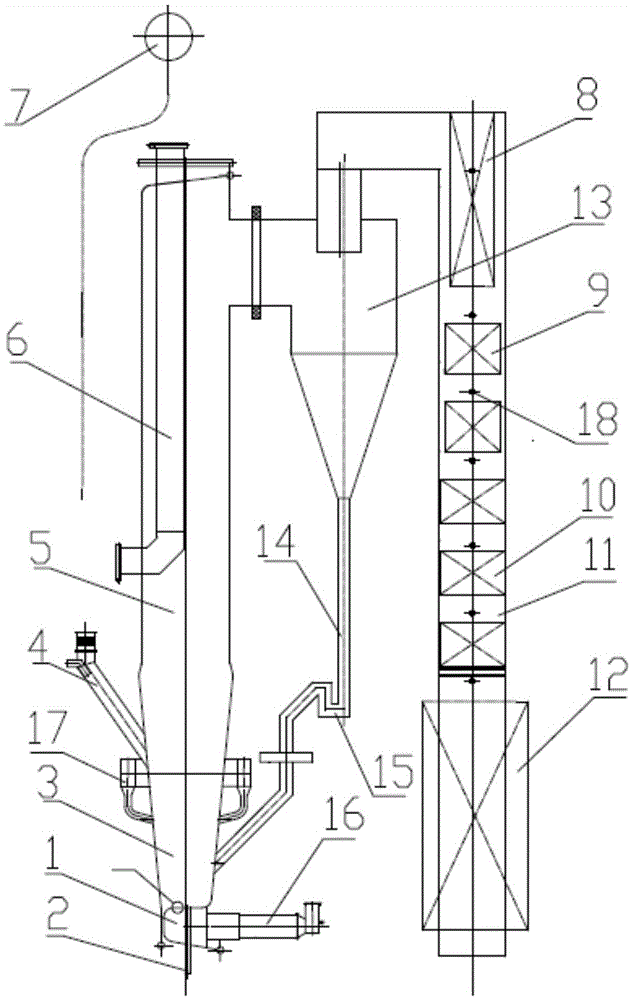

Low-energy-consumption device and method capable of producing oxygen-enriched gas and high-purity nitrogen simultaneously

PendingCN106989567AReduce output pressureMeet heat transfer requirementsSolidificationLiquefactionAir compressionMolecular sieve

The invention provides a device capable of producing oxygen-enriched gas and high-purity nitrogen simultaneously. The device comprises an air compression system, an air precooling system, a molecular sieve purification system, a booster expansion turbine, a main heat exchanger, a rectifying column and a supercooler. All the devices communicate with one another through corresponding pipelines. The invention further provides a method capable of producing the oxygen-enriched gas and the high-purity nitrogen simultaneously. In specific, air in the atmosphere is divided into two paths after being filtered, compressed and purified; one path of the air enters the booster expansion turbine and then enters an upper column body for rectification separation after passing through the main heat exchanger; and the other path of the air directly enters the main heat exchanger to be cooled and then enters a lower-layer main condensing evaporator and a lower column body in sequence, primary rectification separation is carried out in the lower column body, and then the air enters the upper column body to conduct final rectification separation. By the adoption of the device and method, the oxygen-enriched gas of different purities can be produced while the high-purity nitrogen is produced, the oxygen-enriched gas can be directly used by follow-on production, repeated construction and investment of equipment are reduced, and the production cost is also reduced.

Owner:HENAN KAIYUAN AIR SEPARATION GRP CO LTD

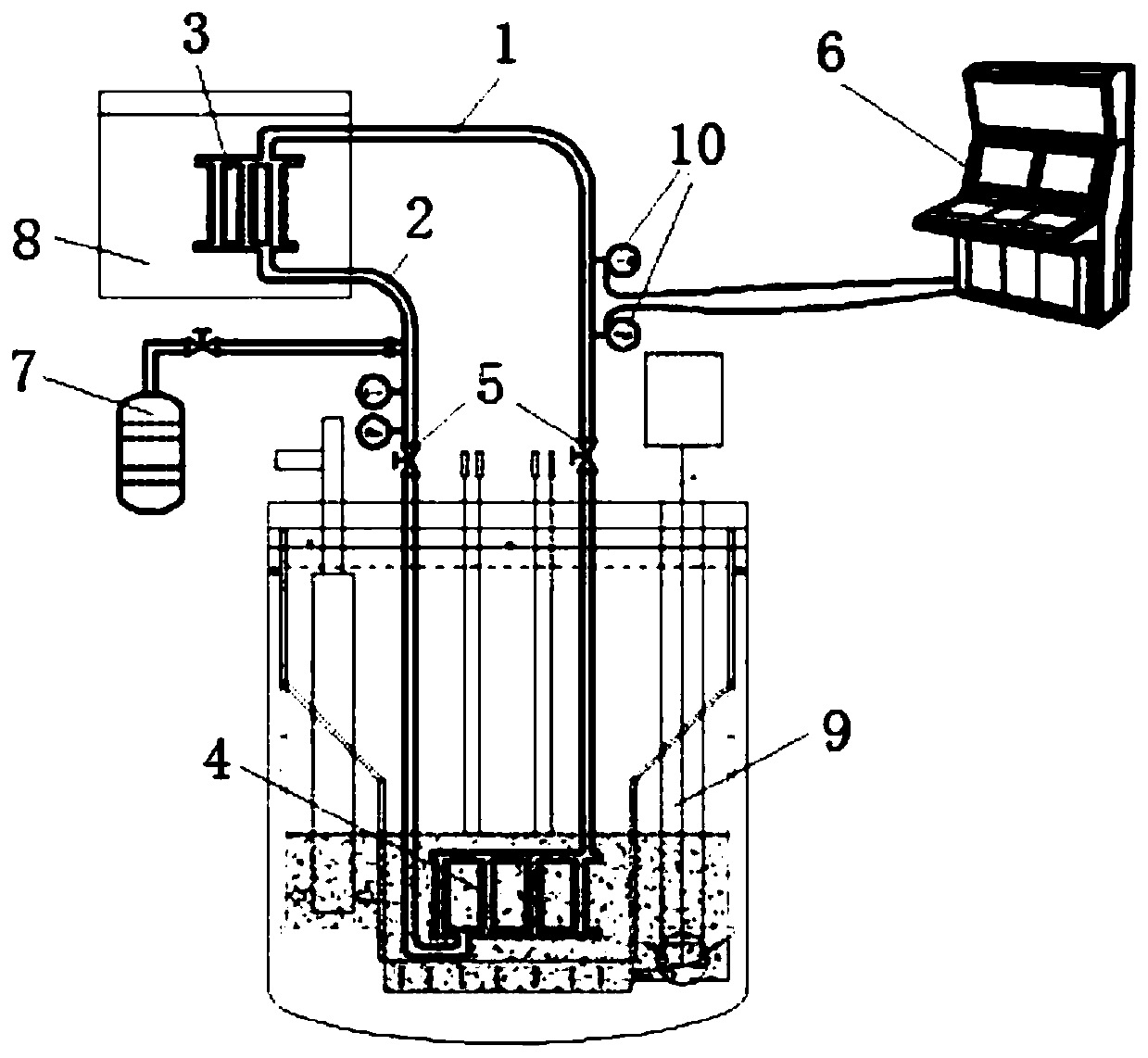

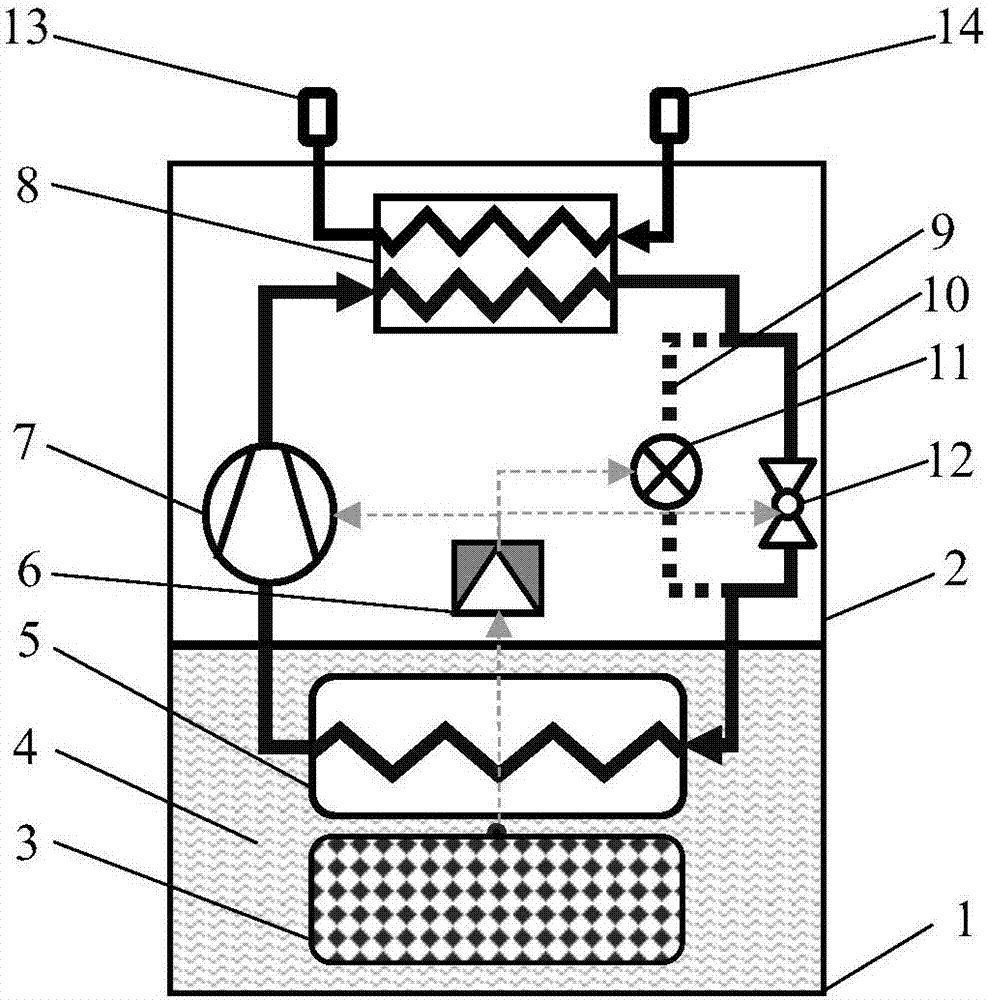

Marine heat-pipe-type lead-bismuth reactor waste heat discharge system

PendingCN110211711AImprove thermal conductivityFast thermal responseNuclear energy generationCooling arrangementLead bismuthEngineering

The invention discloses a marine heat-pipe-type lead-bismuth reactor waste heat discharge system. The system comprises a hot-end heat exchanger, a cold-end heat exchanger and a cooling water pool, a lead-bismuth reactor is internally provided with a lead-bismuth coolant, the hot-end heat exchanger is immersed in the lead-bismuth coolant, an outlet of the hot-end heat exchanger is communicated withan inlet of the cold-end heat exchanger through a hot gas pipe, the cold-end heat exchanger is arranged in the cooling water pool above the hot-end heat exchanger, and an outlet of the cold-end heatexchanger is communicated with an inlet of the hot-end heat exchanger through a return pipe; a heat exchange medium circulates between the cold-end heat exchanger and the hot-end heat exchanger through the hot gas pipe and the return pipe. The system has the advantages that the hot-end heat exchanger and the cold-end heat exchanger are adopted, the two heat exchangers are communicated with each other through the hot gas pipe and the return pipe respectively; the separated heat-pipe-type structure can ensure that when the distance between a cold source and a hot source is large, heat pipe circulation can also be established, and when a reactor is stopped, the decay heat of a reactor core, the latent heat of the coolant and the accumulation heat of equipment are discharged.

Owner:CHINA SHIP DEV & DESIGN CENT

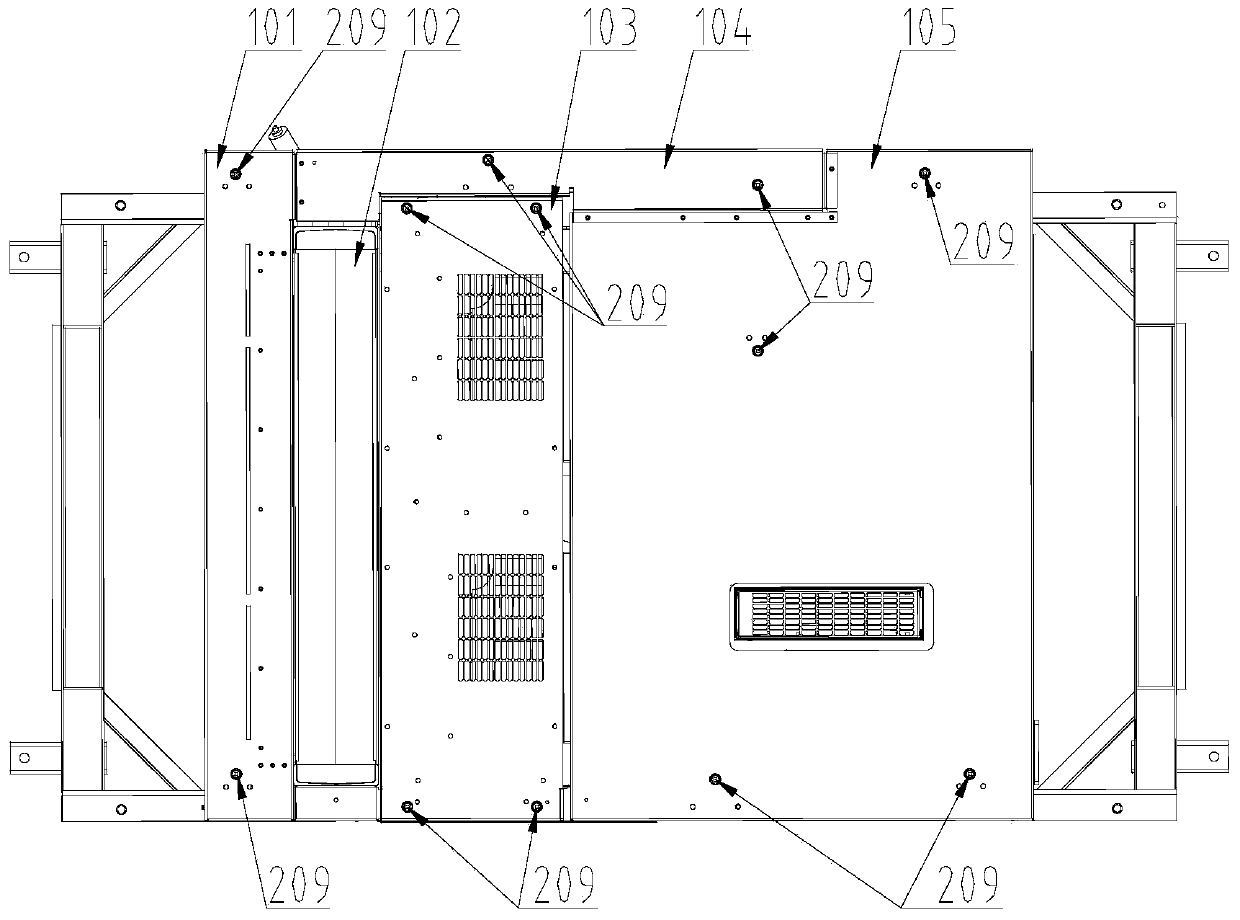

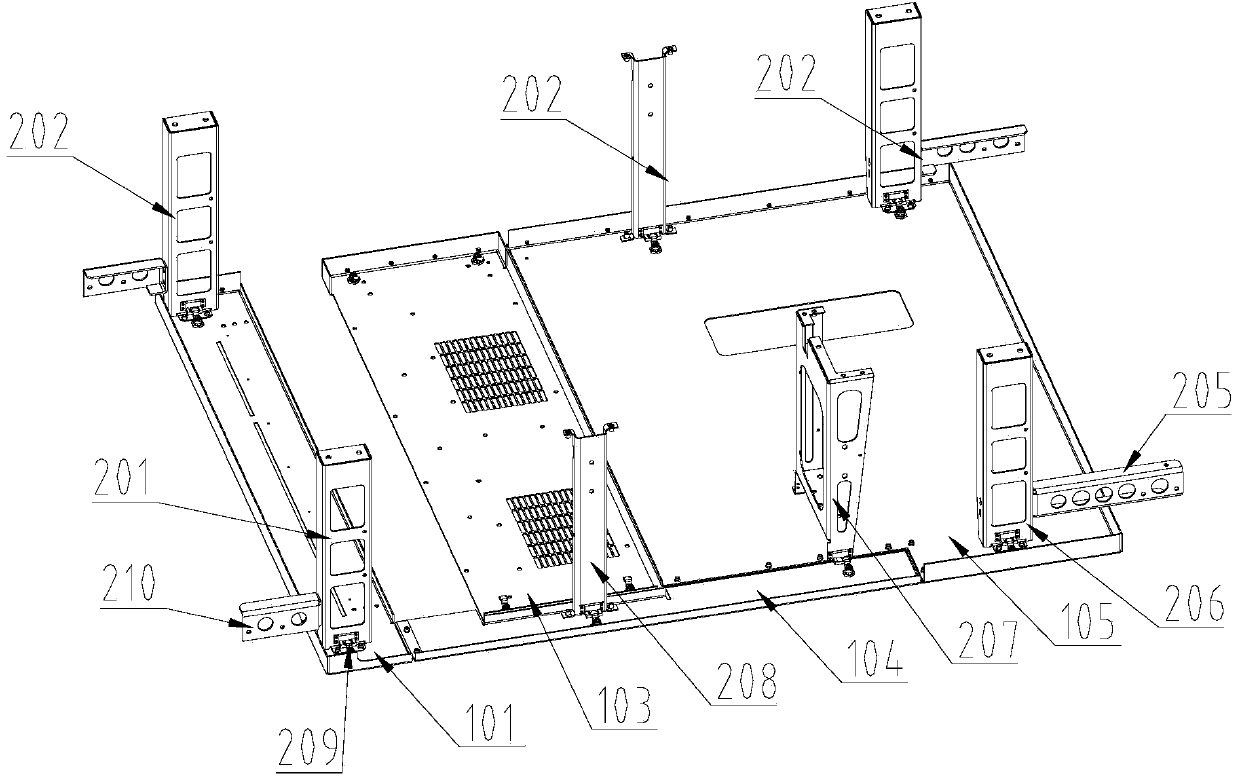

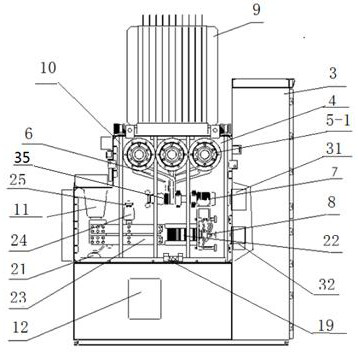

Cooling unit for traction transformers

ActiveCN104252946ARealize heat exchangeAchieving Auxiliary Power ConsumptionTransformers/inductances coolingDistribution transformerEngineering

The invention discloses a cooling unit for traction transformers of motor train units. The cooling unit has the advantages that matching technologies are optimized, so that fans of a cooling air system can assuredly work in high-efficient working areas, the heat exchange capacity, auxiliary power consumption and noise can be optimally matched with one another, the cooling unit is applicable to the motor train units with the speeds per hour of 300-350 kilometers, and requirements on the heat dissipation performance of the cooling unit can be met without increasing the weight of the cooling unit under the conditions of 380V and 50Hz or 440V and 60Hz three-phase alternating currents; the structural strength of the cooling unit can be reinforced by the aid of safety measures, and bottom plates can be prevented from falling off; the noise of the cooling unit can be lowered by the aid of comprehensive noise reduction measures.

Owner:CRRC DALIAN INST CO LTD

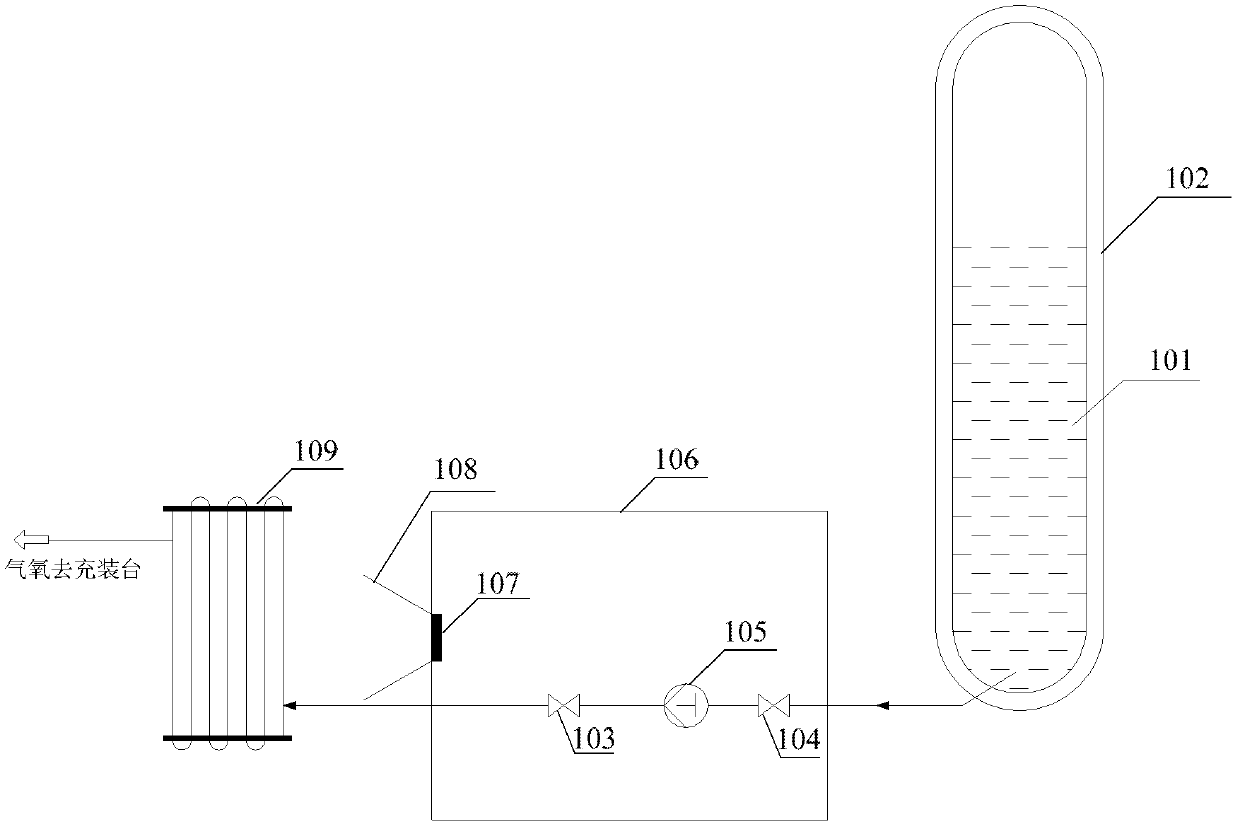

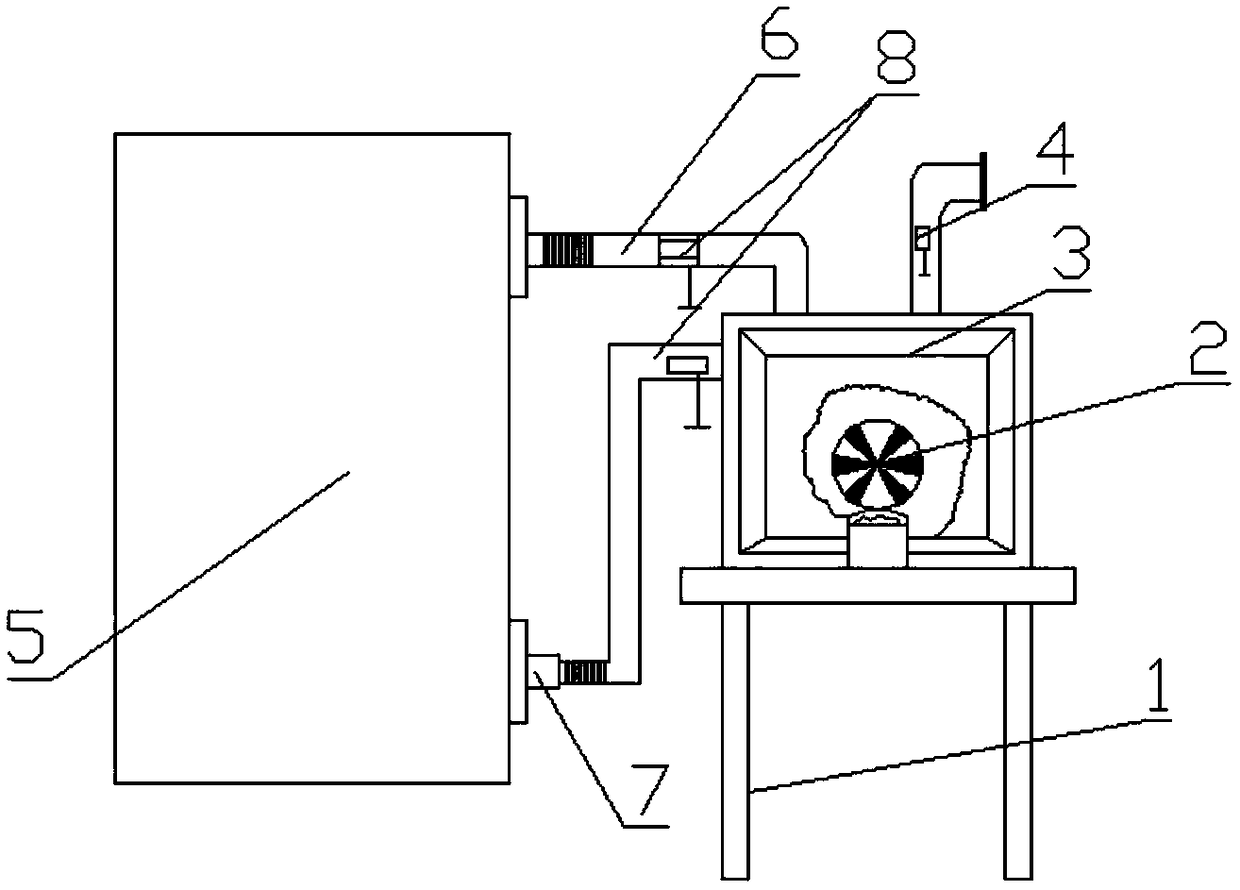

Liquid oxygen system

InactiveCN103292153AMeet heat transfer requirementsAvoiding Damage to Air Bath VaporizersPressure vesselsIce removalEngineeringTemperature difference

The invention discloses a liquid oxygen system, comprising a liquid oxygen storage tank, a liquid oxygen pump and an air shower-type evaporator, which are sequentially connected, The liquid oxygen system also comprises an air flue and a fan for extracting hot air; the fan blows the hot air to the outer surface of the air shower-type evaporator through the air flue. The fan for extracting the hot air is added, so that full heat exchange on the hot air and the air shower-type evaporator is achieved; the conducting and heat-transfer temperature difference at the surface of a radiator fin of the air shower-type evaporator is increased, so that the temperature and blast capacity of the hot air blown to the air shower-type evaporator are appropriate; the heat exchange demands of the air shower-type evaporator are achieved; the situations that the air shower-type evaporator bears a large temperature difference due to the fact that the steam is directly utilized to heat, and the air shower-type evaporator is damaged because of direct striking of thick ice are avoided; furthermore, by adopting the liquid oxygen system provided by the invention, the air flow velocity of heat exchange of the air shower-type evaporator is greatly increased under the common effect of the fan and the air flue; the outer wall of the air shower-type evaporator is prevented from being frozen; normal operation of the system is ensured.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM

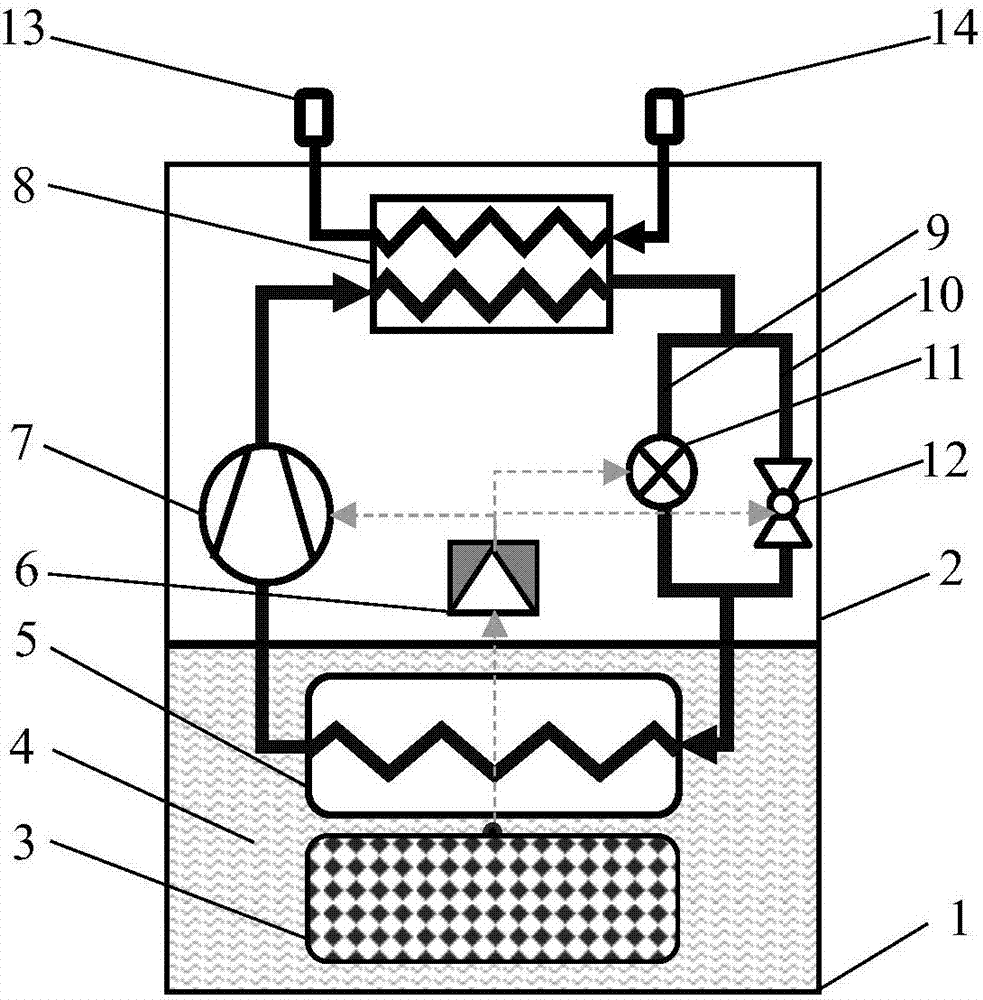

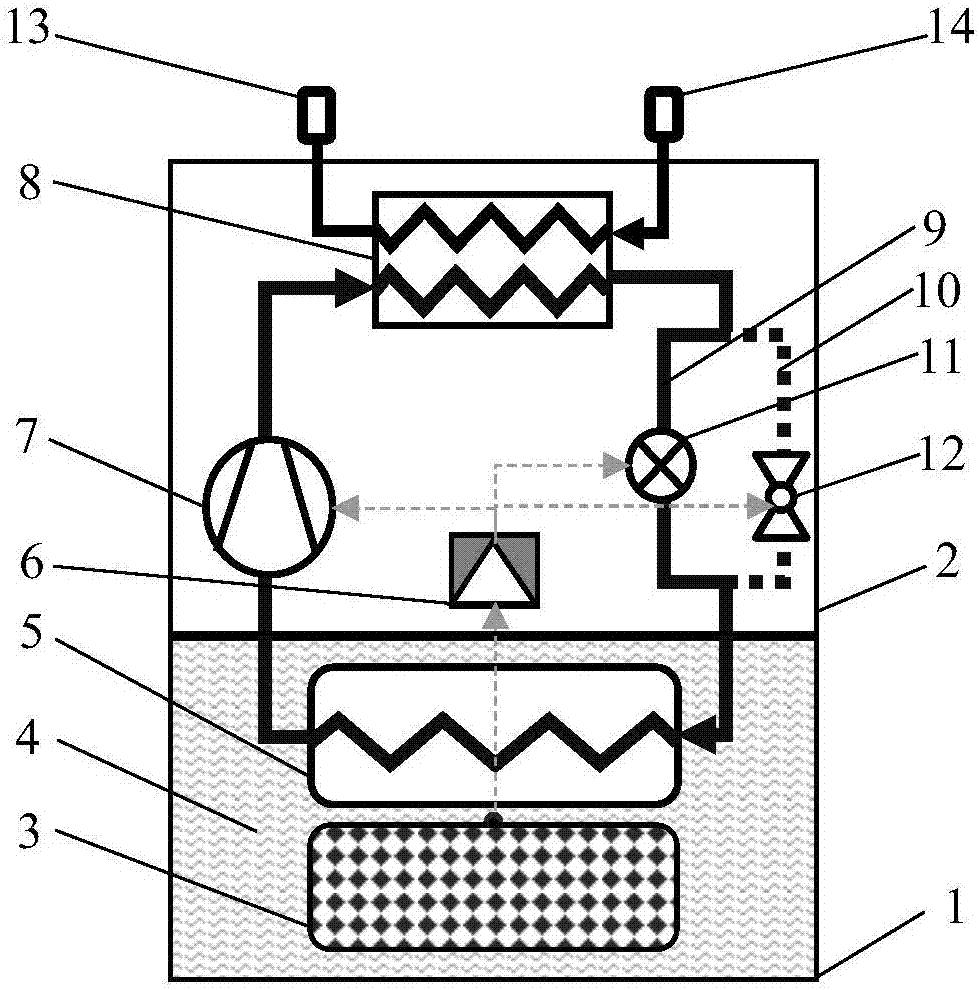

Supercooling liquid nitrogen circulating system based on GM refrigerating machine

PendingCN114111082AHigh fault toleranceMeet heat transfer requirementsCompression machinesGas cycle refrigeration machinesSubcoolingEngineering

The invention discloses a supercooled liquid nitrogen circulating system based on GM refrigerating machines, which comprises a plurality of GM refrigerating machines which are independently mounted in parallel and are used as system cold sources; each GM refrigerator comprises an independent vacuum cavity and a cold head heat exchanger; the supercooling liquid nitrogen pool and the surge tank are arranged in the vacuum cover, and a main heat exchanger and a precooling heat exchanger are soaked in the supercooling liquid nitrogen pool; the liquid nitrogen pump is connected between the supercooled liquid nitrogen pool and the surge tank; the pre-cooling heat exchanger is located in front of an inlet of the liquid nitrogen pump and used for improving the degree of supercooling when liquid nitrogen enters the liquid nitrogen pump, and the main heat exchanger is located behind an outlet of the liquid nitrogen pump and used for cooling the liquid nitrogen; and the supercooled liquid nitrogen pool is connected with a thermal load at a liquid return port and a liquid outlet through vacuum heat insulation pipes to form a closed liquid nitrogen circulation loop. The long-time stable operation of the liquid nitrogen circulating system can be ensured.

Owner:SHENZHEN POWER SUPPLY BUREAU

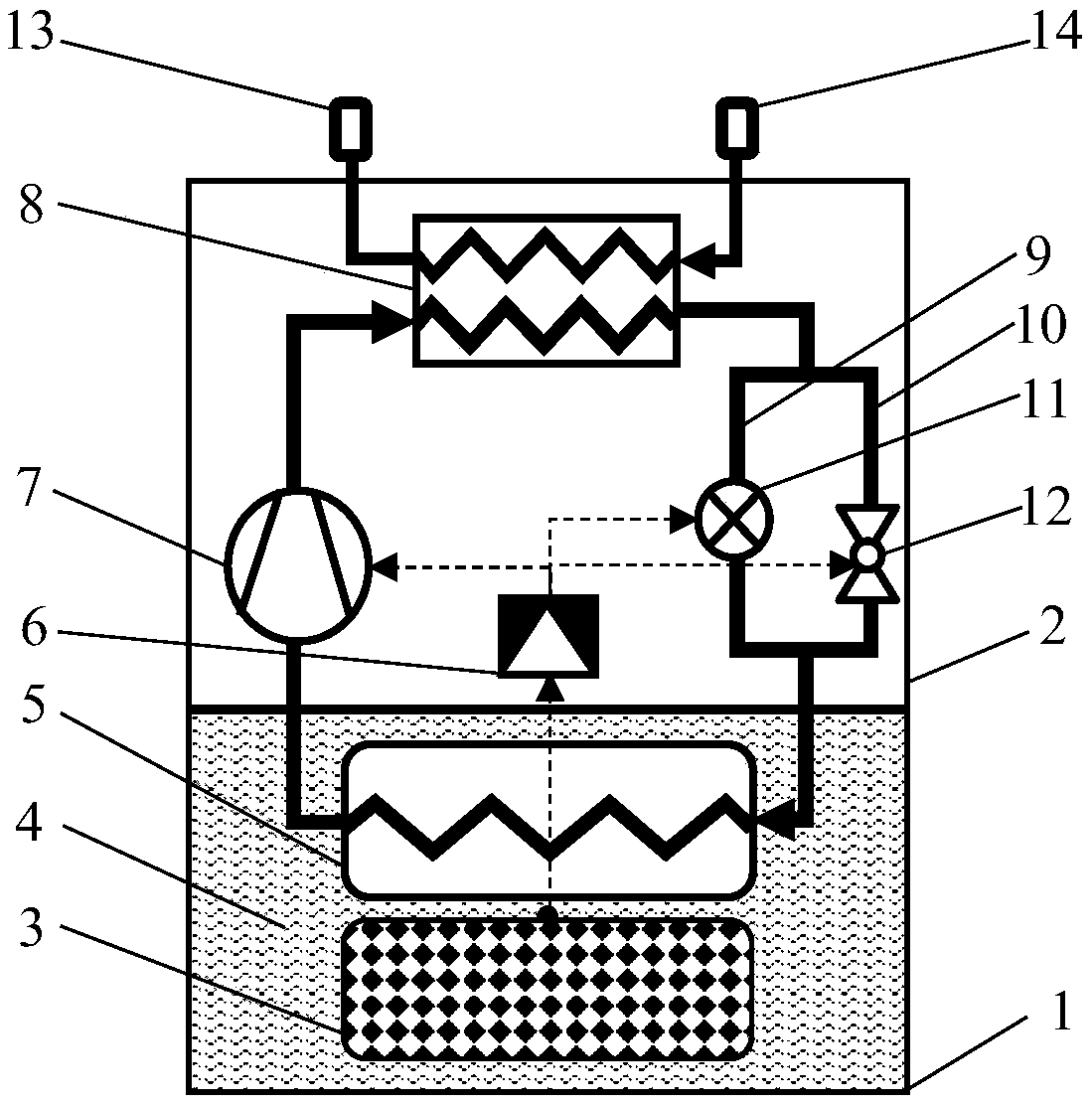

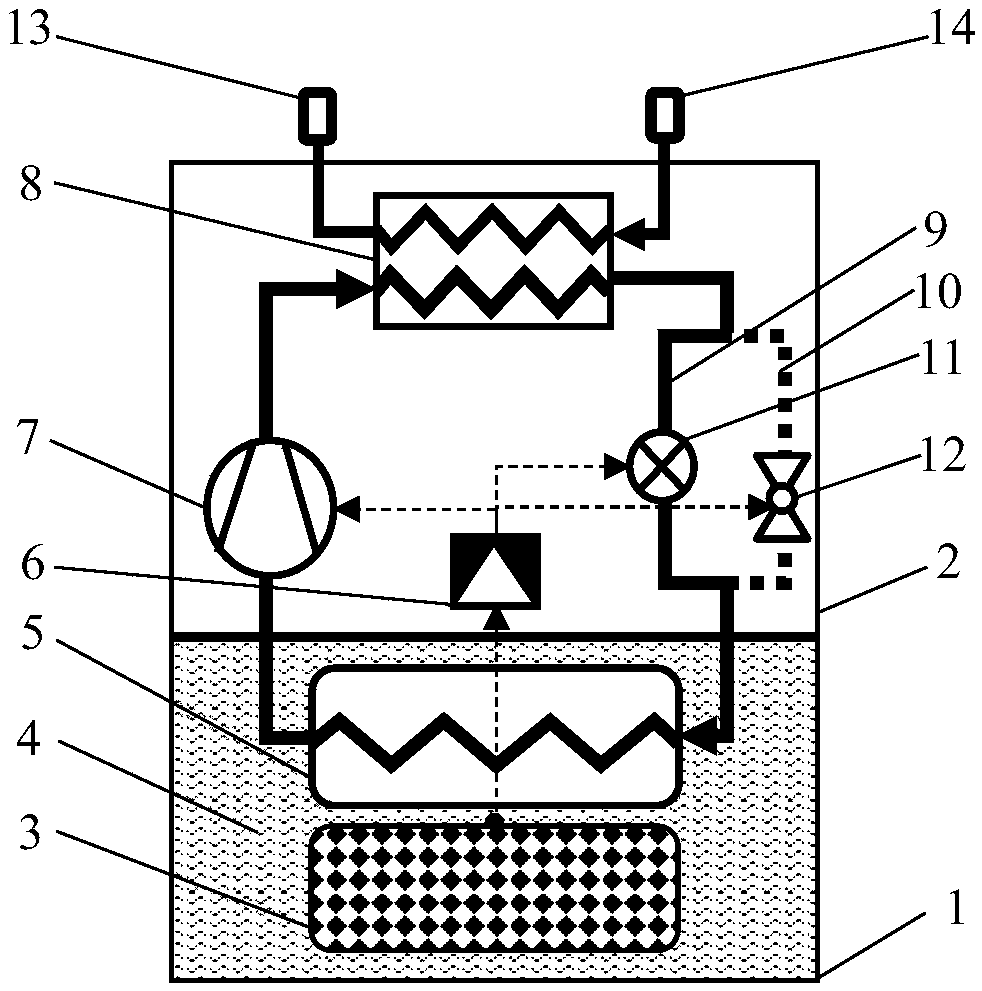

Modular compound type high-energy weapon cooling system and control method thereof

ActiveCN107152890ASimple and smooth designMeet thermal requirementsMechanical apparatusCompression machines with non-reversible cycleHigh energyPhase change

The invention discloses a modular compound type high-energy weapon cooling system and a control method thereof. The modular compound type high-energy weapon cooling system is composed of a high-energy weapon cabin and a cooling equipment cabin. A high-energy weapon and an evaporator are arranged in the high-energy weapon cabin. The periphery of the high-energy weapon and the periphery of the evaporator are filled with phase change materials. A compressor, a condenser, a throttling branch, a bypass branch, a controller, a condenser fluid inlet and a condenser fluid outlet are arranged in the cooling equipment cabin. The evaporator is connected with the compressor, the condenser and the throttling branch in sequence through a refrigerant pipeline. The throttling branch and the bypass branch are arranged in parallel. A throttling device is arranged on the throttling branch, and a bypass valve is arranged on the throttling branch. Under different cooling fluid and high-energy weapon equipment load conditions, two work modes can be achieved in the system according to the periphery temperature of the high-energy weapon. The system has two refrigerating modes, work can be done as long as cooling fluid is provided by an external platform, and flexibility, maneuverability and transportability of the high-energy weapon are greatly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

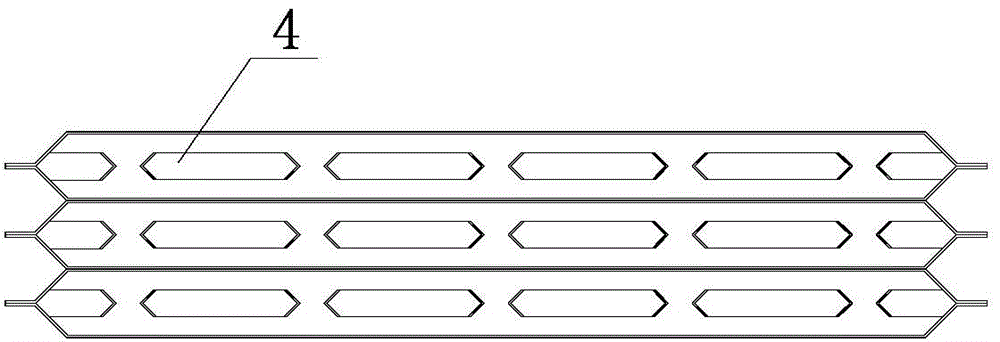

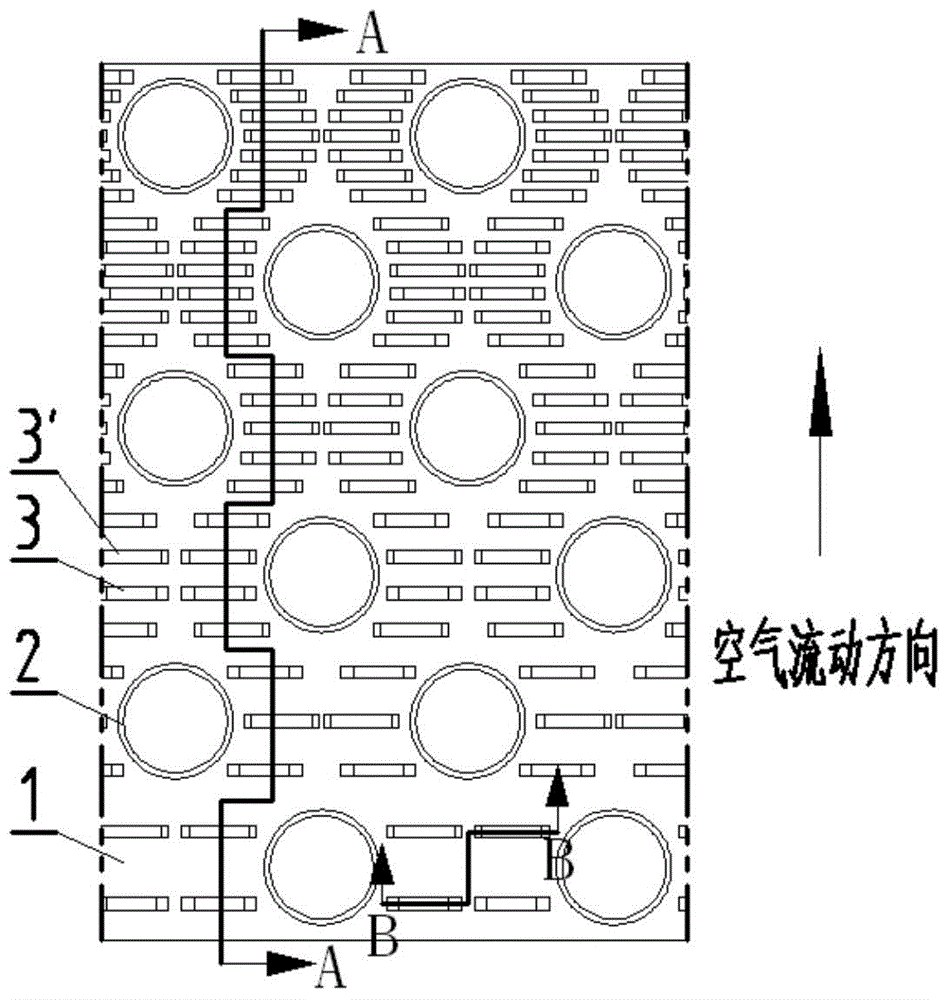

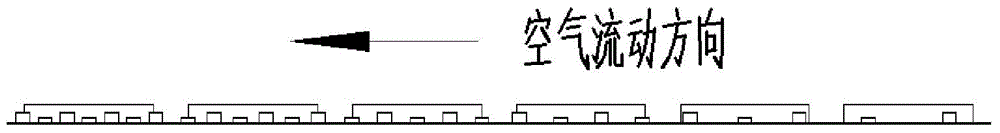

Heat exchanger for indirect air-cooling system of millions of units of power station

ActiveCN104142084AImprove heat transfer effectMeet heat transfer requirementsTubular elementsPower stationEngineering

The invention provides a heat exchanger for an indirect air-cooling system of millions of units of a power station. A heat sink comprises a cooling base body and cooling fins, wherein the cooling fins are arranged on the cooling base body. The heat exchanger is characterized in that multiple rows of parallel heat exchange base tube penetrating installation holes are formed in the cooling fins, a bridge-shaped protrusion is arranged between every two adjacent heat exchange base tube penetrating installation holes in each row, and the two ends of each bridge-shaped protrusion are connected with a fin body of the corresponding cooling fin so that a face which forms an angle smaller than or equal to 90 degrees together with the fin body can be formed. The heat exchanger has the advantages that all parts of the heat sink can exchange heat in a balanced mode, and overall heat exchange performance can be effectively enhanced without largely increasing overall resistance of the fins.

Owner:BEIJING SHOUHANG IHW RESOURCES SAVING TECH CO LTD

12kV/4000A high-current gas-insulated metal-enclosed switchgear

PendingCN113363860ADoes not take up internal spaceReduce heating powerBus-bar/wiring layoutsSwitchgear arrangementsElectrical conductorNatural convection

A 12kV / 4000A high-current gas-insulated metal-enclosed switchgear overcomes the problems of complex structure, large size and low heat dissipation efficiency in the prior art, and is characterized in that a heat dissipation pipe is mounted on a gas tank shell to form a natural convection heat exchange structure, a top heat dissipation box is mounted at the top of the gas tank shell, and a top heat dissipation box is mounted at the bottom of the gas tank shell; the lower end of the main bus in the gas tank shell is connected with a direct-acting three-station double-set disconnecting switch, and the lower part of the direct-acting three-station double-set disconnecting switch is connected with an arc extinguish chamber moving end flexible connector. The beneficial effects of the utility model are that through the heat dissipation structure design of a plurality of components with large heat productivity, the temperature in the air chamber is reduced through natural convection in the closed air chamber, and the problem of large-current temperature rise is solved; the conductive contact area is multiplied through the plurality of flexible connection conductors, and the through-current capability is improved; the size of a single conductive part is reduced through double sets of isolating switches of each phase, and the requirement of 12 kV / 4000 A large-current gas insulated metal-enclosed switchgear for the through-current capability is met.

Owner:SHENYANG HUADE HIGH TECH ELECTRIC CO LTD

Circulating fluidized bed boiler for purely burning furfural residues

InactiveCN105627301AAvoid troubleAnti-channelingFluidized bed combustionApparatus for fluidised bed combustionAir preheaterCombustion chamber

The invention belongs to the technical field of fluidized bed boilers and particularly relates to a circulating fluidized bed boiler for purely burning furfural residues. According to the circulating fluidized bed boiler for purely burning the furfural residues, a high-temperature platen superheater is arranged in a hearth; a fluidized bed combustion chamber is arranged on the lower portion of the interior of the hearth; a wind distribution plate is arranged at the bottom of the fluidized bed combustion chamber; a wind cap is arranged on the wind distribution plate; a wind chamber is arranged below the wind distribution plate; a residue discharge pipe is arranged in the wind chamber; an ignition device is arranged on the wind chamber; the upper portion of a separator communicates with an outlet in the upper portion of the hearth; a lower vertical pipe of the separator is connected with the upper portion of a material return system; the lower portion of the material return system communicates with the fluidized bed combustion chamber; a low-energy-consumption self-balancing material return valve is mounted on a vertical pipe of the material return system; an inlet of a vertical shaft flue communicates with an outlet tube in the center of the upper portion of the separator; an evaporation pipe bundle, low-temperature superheaters, economizers and an air preheater are all arranged in the vertical shaft flue; and the vertical shaft flue is further provided with soot blowing points.

Owner:TAIYUAN BOILER GROUP

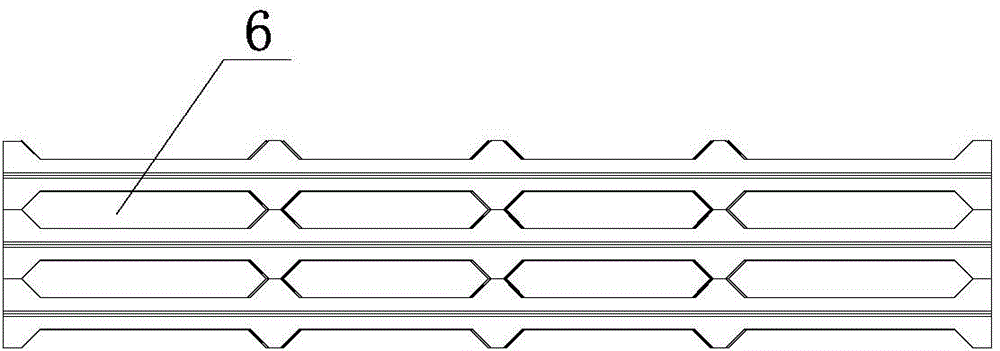

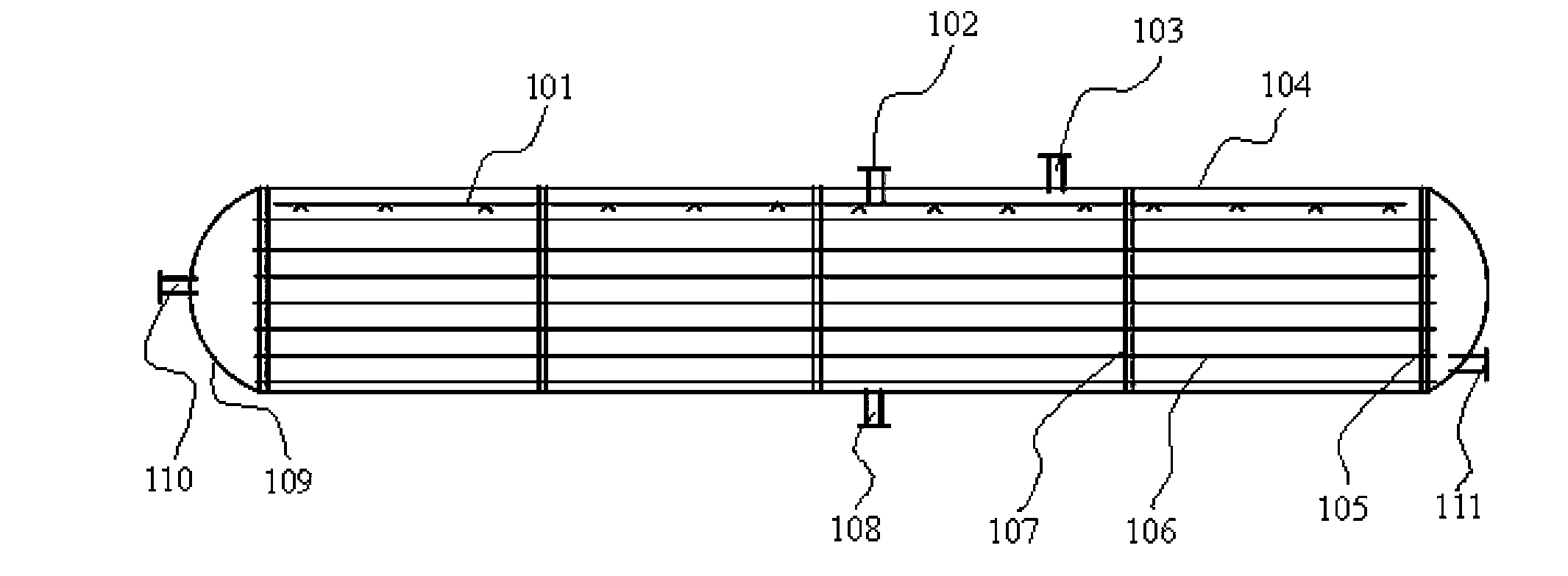

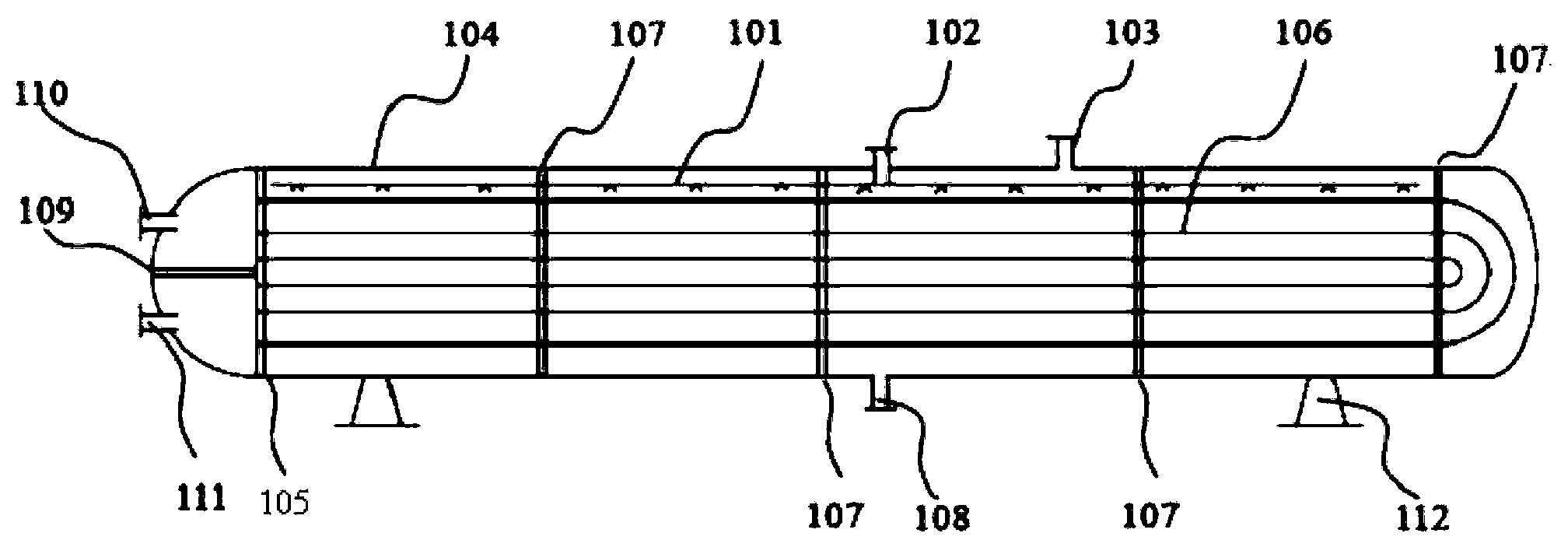

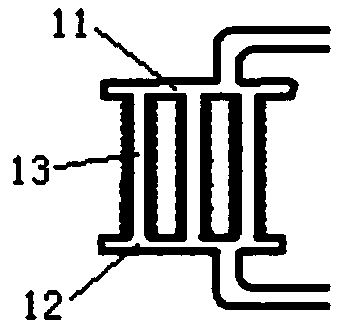

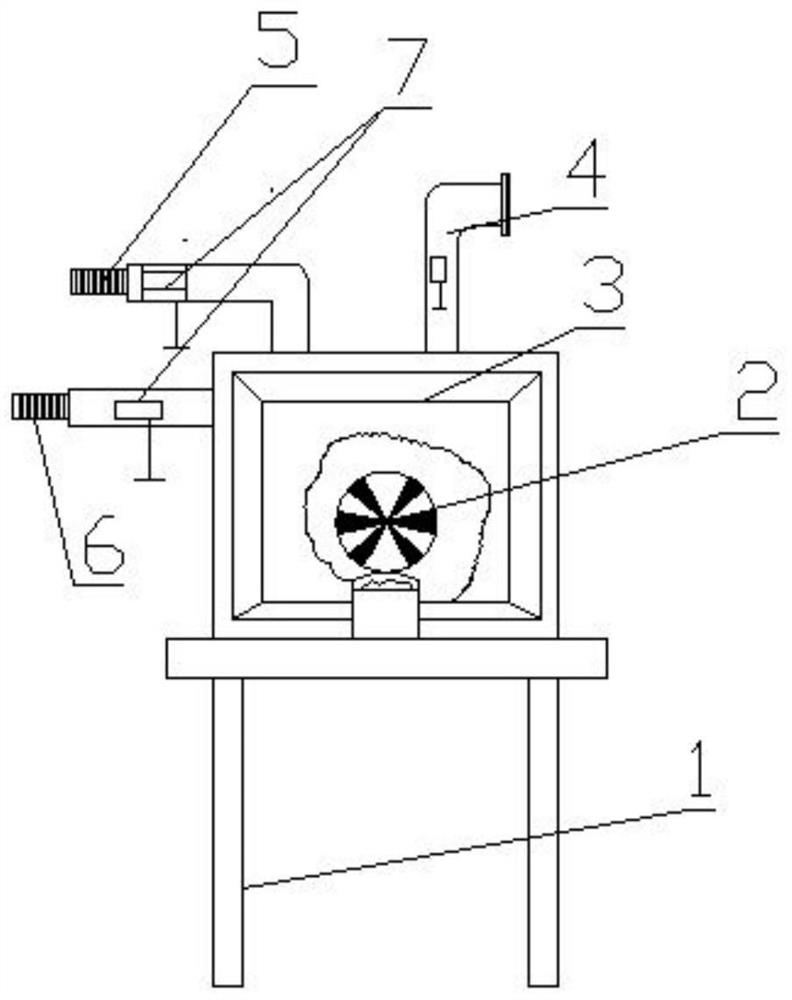

Temperature reduction method for hot gas and device thereof

ActiveCN101655325ASolving Stress ProblemsAvoid thermal expansionHeat exchanger casingsStationary tubular conduit assembliesEngineeringThermal efficiency

The invention relates to the technique for cooling hot gas, particularly to a temperature reduction method for hot gas and a device thereof. At present, the method for reducing temperature by sprayingis used widely, which not only increase the composition of hot gas and the volume flow, but also increase the investment of system, with low heat exchange efficiency and difficulty to control the process. The invention comprises a tube bundle heat exchanger canister, an outer jacket of a tube bundle cooler, a light tube heat exchange unit, and a finned tube heat exchange unit. The light tube heatexchange unit and the finned tube heat exchange unit are orderly disposed inside of the tube bundle heat exchanger canister. The outer jacket of a tube bundle cooler is fixedly disposed on the outerwall of the tube bundle heat exchanger canister. The hot gas is cooled by air exchanging heat with recycled cooling water by entering the tube bundle heat exchanger. By adopting the tube bundle heat exchanger, with the outer jacket opening, the invention can efficiently decrease the temperature of the tube bundle heat exchanger, decrease the load of canister, reduce the thickness of the canister,and lower the investment.

Owner:西安航天华威化工生物工程有限公司

Water tank and heat pump water heater

PendingCN110307644AImprove heat transfer effectImprove heat transfer efficiencyFluid heatersEngineeringOuter coil

The invention belongs to the technical field of water heaters, and discloses a water tank. The water tank comprises an inner container, the outer wall of the inner container is wrapped with an outer coil pipe heat exchanger, the inner wall of the inner container is provided with a spiral water inlet pipe in an attaching manner, and water enters the water tank, passes through the spiral water inletpipe and then is led into the inner container. The spiral water inlet pipe is arranged on the inner wall of the inner container of the water tank in the attaching manner, after the water enters the water tank, and enters through an inlet of the spiral water inlet pipe, under the water supplementing pressure effect, the ware and the outer coil pipe heat exchanger are subjected to forced convectionheat exchange, the heat exchange coefficient and the heat exchange efficiency are improved, cold water entering the spiral water inlet pipe directly exchanges heat with the outer coil pipe heat exchanger, the temperature of a refrigerant medium in the outer coil pipe heat exchanger does not need to be very high, the heat exchange needs can be met, the energy consumption is effectively reduced, the heat exchange property is improved, and the burdens on a heat pump water heater compressor are reduced.

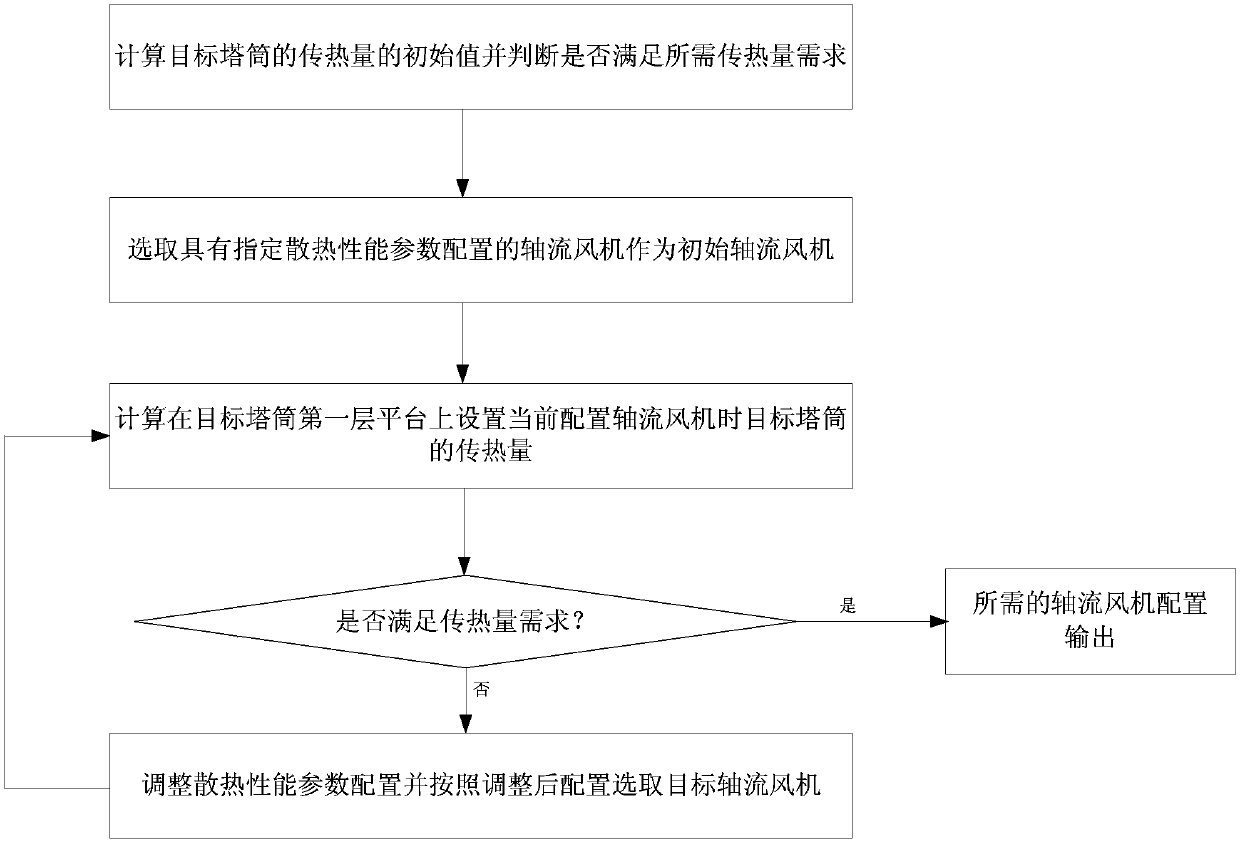

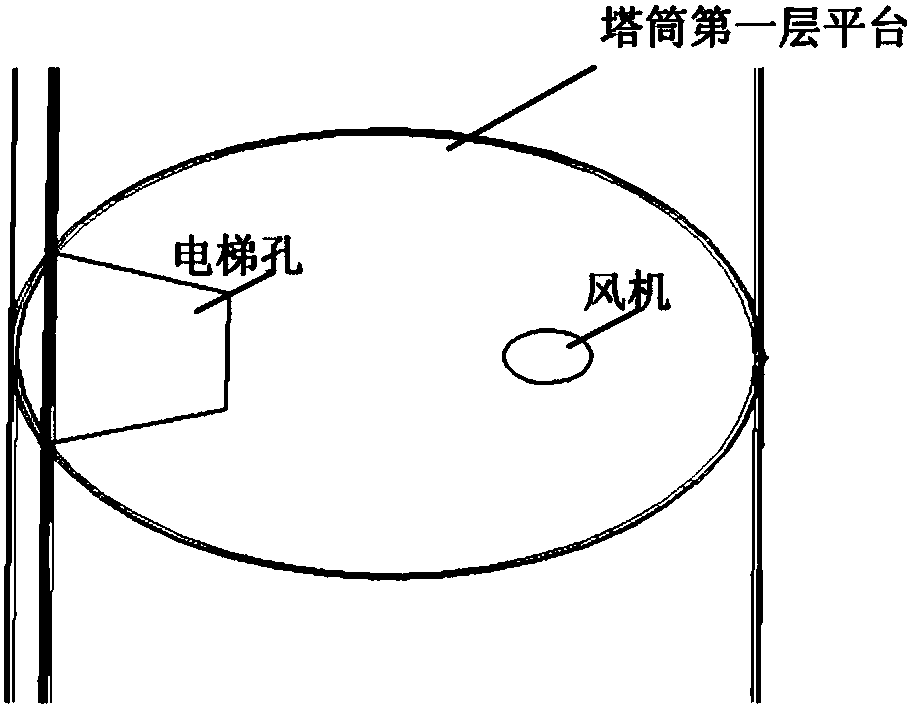

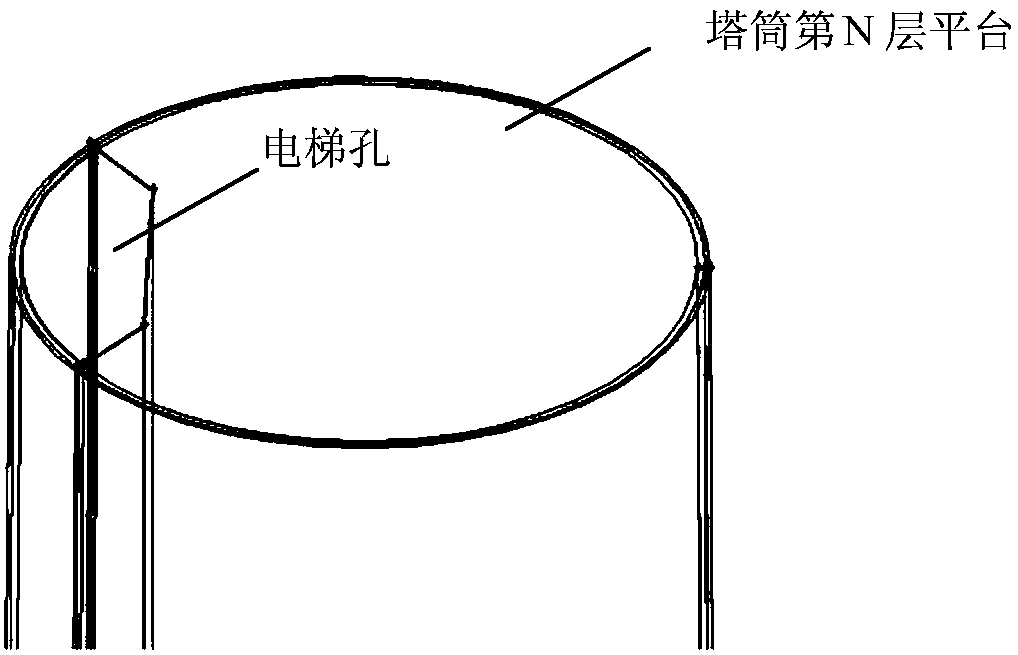

High tower tube ventilation cooling performance setting method and device and tower tube

ActiveCN109869289AEffective ventilation and heat dissipationImprove efficiencyMachines/enginesWind energy generationEngineeringTower

The invention discloses a high tower tube ventilation cooling performance setting method and device and a tower tube. The method comprises the steps that S1, an initial value of the heat transfer amount of the target tower tube is calculated, and whether the heat transfer amount meets the required heat transfer amount demand or not is judged, and if not, the process goes to step S2; S2, an axial flow fan with specified radiating performance parameter setting is selected as an initial axial flow fan; and S3, the heat transfer amount of the target tower when the axial flow fan with the current setting is arranged on a first layer of platform of the target tower tube is calculated, whether the heat transfer amount meets the required heat transfer amount demand or not is judged, if not, the radiating performance parameter setting is adjusted, and the process returns to step S3, and if yes, the required axial flow fan setting is output. The device comprises a tower tube heat transfer amountjudgment unit, a selection unit and a judgment adjustment unit. Through the method and device, optimal setting of the tower tube ventilation cooling performance can be achieved in combination with the heat transfer characteristics of the high tower tube, and the advantages of the simple implementation method, high setting efficiency, good effect and the like are achieved.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

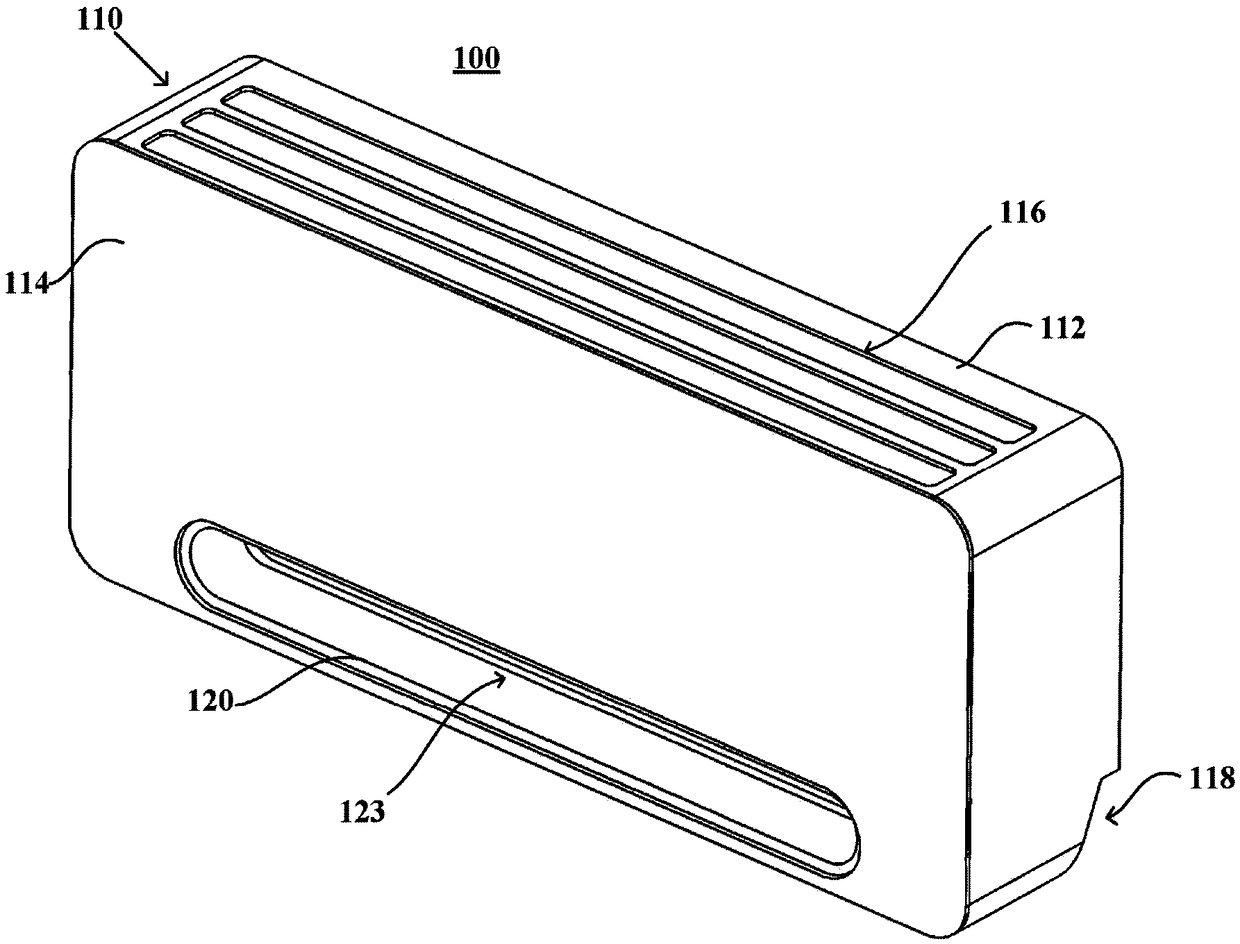

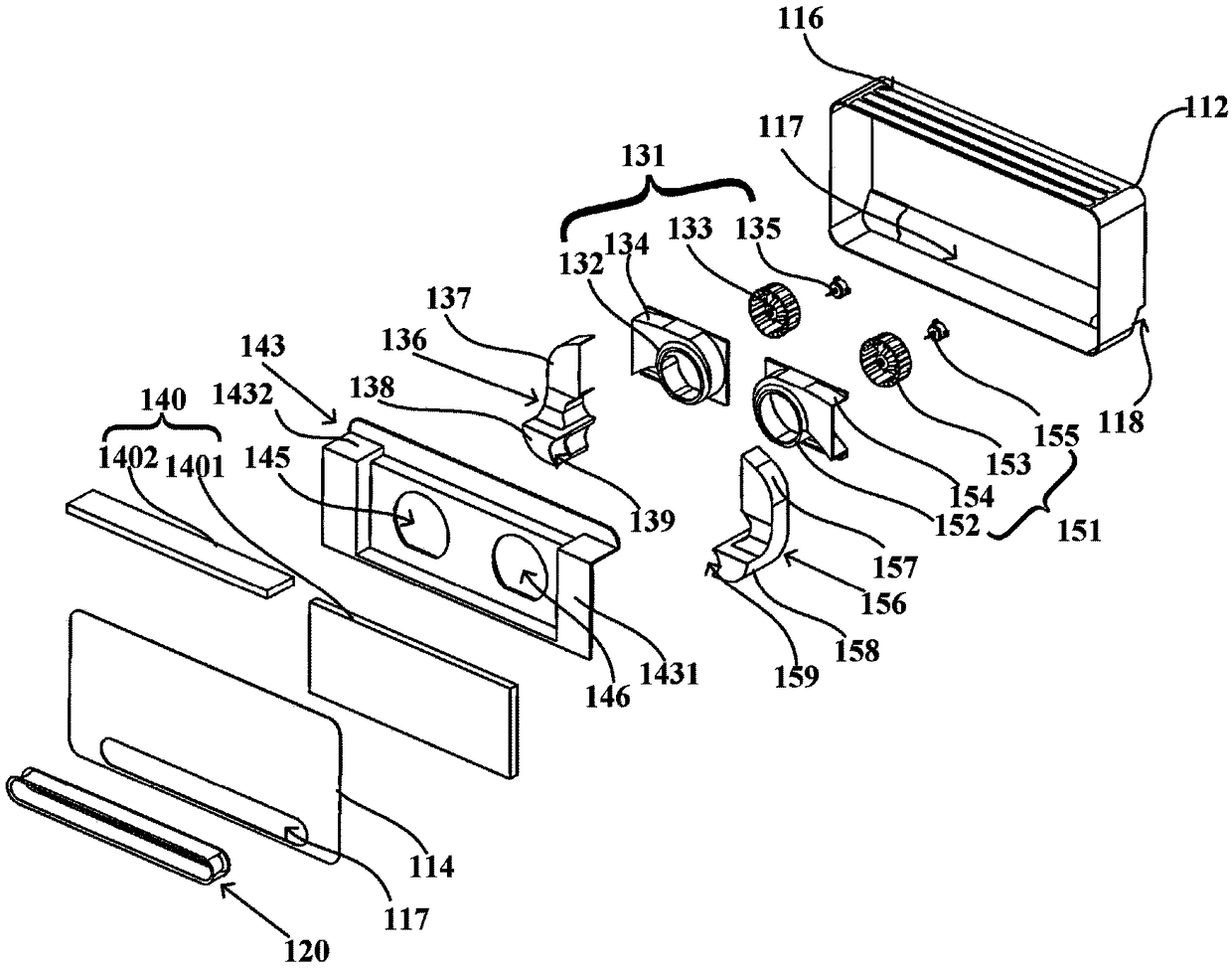

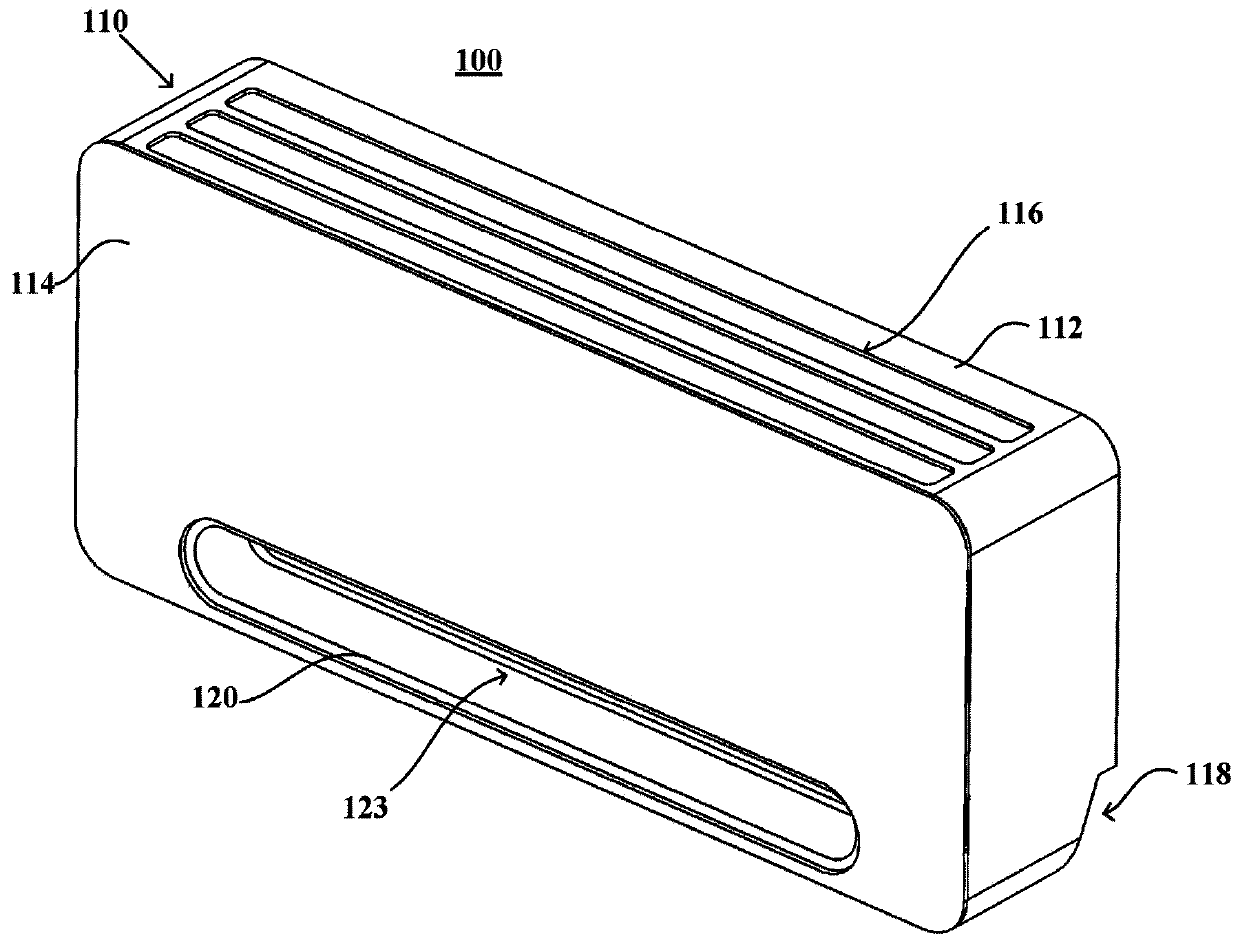

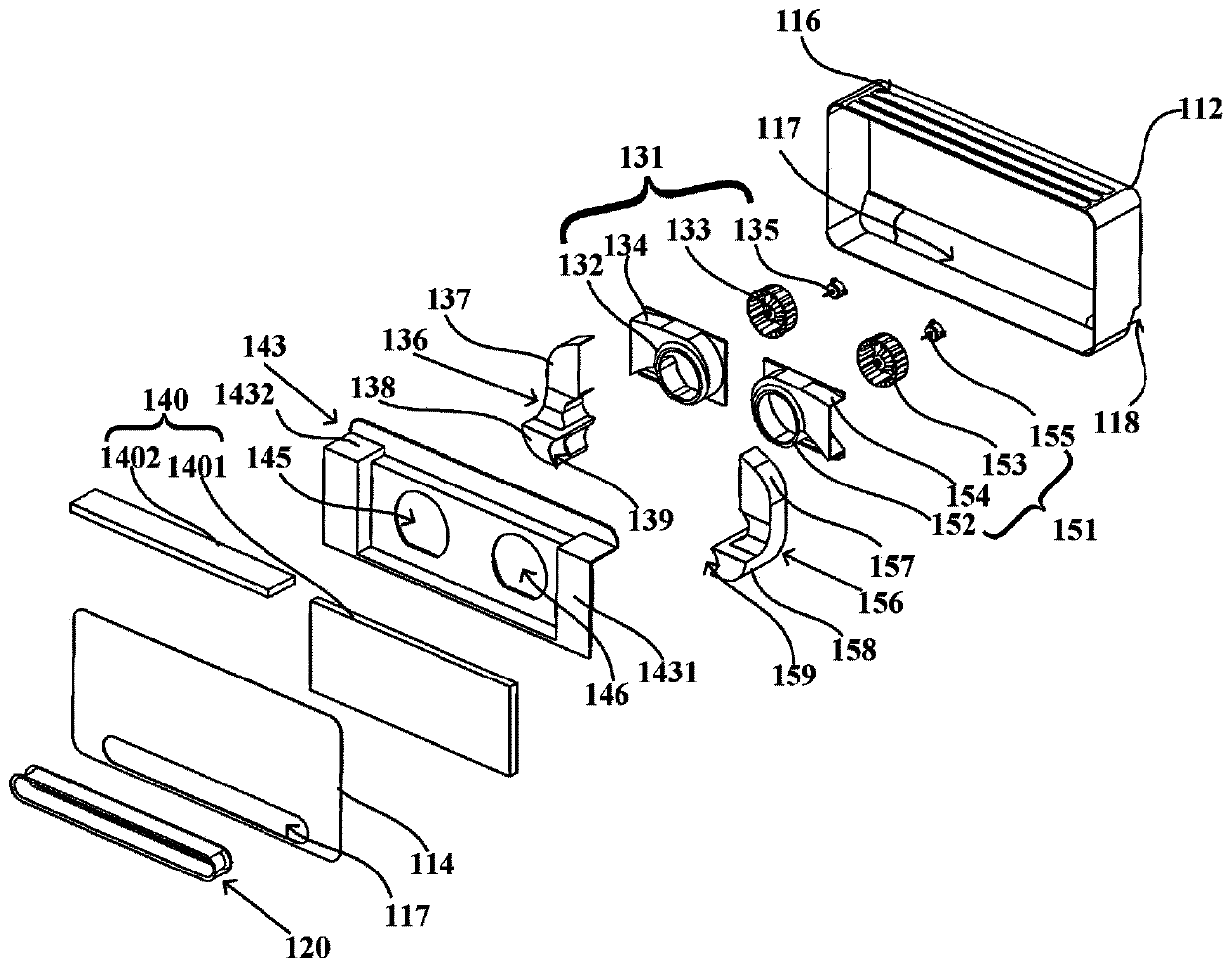

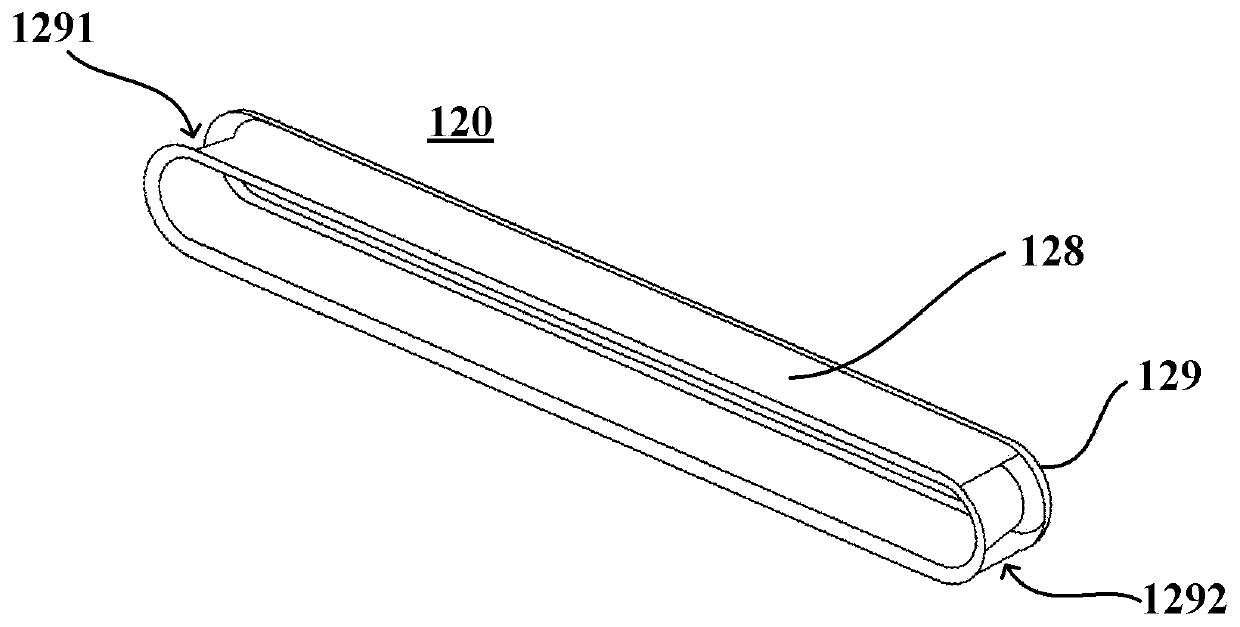

Wall-mounted air conditioner indoor unit

ActiveCN108105851ASpeed up the flowEasy to recognizeLighting and heating apparatusAir conditioning systemsEngineeringInjection air

The invention provides a wall-mounted air conditioner indoor unit. The air conditioner indoor unit comprises a shell body, a heat exchanger, an air injection part, a first air supply assembly and a second air supply assembly, wherein the shell body is provided with a housing and a front panel, air inlets are formed in the top wall of the housing, and a long circular air supply opening is formed inthe lower portion of the front panel; the heat exchanger comprises a first heat exchange section and a second heat exchange section, wherein the first heat exchange section is arranged at the position close to the front panel, and the second heat exchange section is arranged at the position tightly close to the top wall of the housing; the air injection part is arranged in the air supply openingand is used for spraying internal heat exchange airflow forwards and driving environment air to be sent out forwards; and the first air supply assembly and the second air supply assembly are transversely arranged at the rear lower part of the heat exchanger at intervals, and are correspondingly used for generating the heat exchange airflow which enters the shell body from the air inlets at the topand is supplied in from one side of the air injection part after exchanging heat with the first heat exchange section and the second heat exchange section in sequence. According to the wall-mounted air conditioner indoor unit, the air supply amount is increased, and the indoor temperature is reduced uniformly in an overall mode.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Drying heat exchange system for water-based ink printing

InactiveCN108688311AIncrease disturbanceEffective filteringDispersed particle filtrationPrinting press partsWater basedDry heat

The invention relates to a drying heat exchange system for water-based ink printing, and aims at providing a drying heat exchange system which is good in heat exchange effect and large in heat transfer temperature difference and achieves circulating backheating. The drying heat exchange system comprises a drying air box and a heat exchanger. A medium wave ultraviolet lamp tube is mounted in the drying air box, and mounted on a lamp tube rotator. A glass jalousie is arranged on the front portion of the drying air box, the downstream portion of the heat exchanger is connected with a heat exchange pump, and the heat exchanger and the heat exchange pump are connected through a heat circulating pipe. Two heat exchange areas are arranged in the drying heat exchange system, microwave heating is compounded with heat exchange tube heating, ripples are arranged in a heat exchange tube, heat and mass transfer disturbance is enlarged, heat and mass transfer is benefited, the heat exchange efficiency is improved, and fluid is subjected to circulating heating many times in the heat exchanger. Impurities in air are effectively filtered out, medium wave ultraviolet irradiation is used in the air box, and the situation that the heating temperature of heating materials is too high during shutdown, and consequently the printing materials are baked off is avoided.

Owner:广德美好包装科技股份有限公司

wall mounted air conditioner indoor unit

ActiveCN108105851BSpeed up the flowEasy to recognizeLighting and heating apparatusAir conditioning systemsAir volumeInjection air

The invention provides a wall-mounted air conditioner indoor unit. The air conditioner indoor unit comprises a shell body, a heat exchanger, an air injection part, a first air supply assembly and a second air supply assembly, wherein the shell body is provided with a housing and a front panel, air inlets are formed in the top wall of the housing, and a long circular air supply opening is formed inthe lower portion of the front panel; the heat exchanger comprises a first heat exchange section and a second heat exchange section, wherein the first heat exchange section is arranged at the position close to the front panel, and the second heat exchange section is arranged at the position tightly close to the top wall of the housing; the air injection part is arranged in the air supply openingand is used for spraying internal heat exchange airflow forwards and driving environment air to be sent out forwards; and the first air supply assembly and the second air supply assembly are transversely arranged at the rear lower part of the heat exchanger at intervals, and are correspondingly used for generating the heat exchange airflow which enters the shell body from the air inlets at the topand is supplied in from one side of the air injection part after exchanging heat with the first heat exchange section and the second heat exchange section in sequence. According to the wall-mounted air conditioner indoor unit, the air supply amount is increased, and the indoor temperature is reduced uniformly in an overall mode.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

A methanation fluidized bed reactor

ActiveCN104001457BReduce consumptionExtended service lifeGaseous fuelsChemical/physical processesFluidized bedMethanation

The invention provides a methanation fluidized bed reactor which is equipment for performing reaction on CO and H2 to generate methane and water and performing reaction on CO2 and H2 to generate methane and water at a certain constant low temperature. The methanation fluidized bed reactor comprises a cylindrical shell and inner parts, wherein a primary gas distributor and a secondary gas distributor are arranged at the bottom, and a catalyst is filled to form a catalyst bed; a heat exchange device consisting of a plurality of groups of heat exchange tubes is arranged in the catalyst bed; the lower ends of the heat exchange tubes in each group are communicated with a water inlet header pipe which is communicated with a water outlet of a steam drum, and the upper ends of the heat exchange tubes in each group are communicated with a steam outlet header pipe which is communicated with a steam inlet of the steam drum. According to the methanation fluidized bed reactor, heat continuously released during methanation reaction can be timely transferred through another medium, and the reaction can be performed at the constant low temperature.

Owner:尹明大

A heat exchange system of heat recovery exchanger

ActiveCN108613539BIncrease heat and mass transfer disturbanceIncrease disturbanceDrying gas arrangementsEngineeringHeat recirculation

The invention relates to a heat exchange system of a heat recovery exchanger, and aims to provide the heat exchange system with good heat exchange effect, high heat transfer temperature difference andcircular heat returning. A main structure of the heat exchange system is arranged as a heat exchanger; one end of the heat exchanger is connected with a heat circulating fan; a filter area is arranged at the front end of the heat exchanger; the downstream of the filter area is arranged as a plane heat exchange area; the downstream of the plane heat exchange area is arranged as a spiral heat exchange area; the downstream of the spiral heat exchange area is arranged as a disordered heat exchange area; the downstream of the disordered heat exchange area is arranged as a horn heat exchange area;and the downstream of the horn heat exchange area is arranged as a hot air flow separation area. Multiple heat exchange tubes are arranged in the heat exchange system, and ripples are arranged in theheat exchange tubes, so that the heat transfer and mass transfer disturbance is increased, the heat transfer and the mass transfer are facilitated, and the heat exchange efficiency is improved; fluidscircularly transfer heat in the heat exchanger by multiple times, so that the heat transfer temperature difference is increased, and the heat transfer requirements are met; and the system adopts semi-automatic operation, and is flexible in control, simple and practical.

Owner:广德美好包装科技股份有限公司

Electric compression heat pump combined cascade heat exchange large-temperature-difference pressure isolation unit

PendingCN111271754AMeet heat transfer requirementsLow investment costLighting and heating apparatusHot-water central heatingPlate heat exchangerEngineering

The invention discloses an electric compression heat pump combined cascade heat exchange large-temperature-difference pressure isolation unit. The problem of how to stably reduce the return water temperature of a primary network under the condition of meeting the pressure isolation function of a pressure isolation station simply and conveniently at low cost is solved; a pressure isolation heat exchange unit formed by sequentially connecting a plate heat exchanger and four electric compression heat pumps in series is arranged in the pressure isolation station between a primary pipe network anda secondary pipe network, high-temperature hot water of the primary pipe network is stably cooled to the design requirement of the return water temperature of the primary network in a stepped manner,and return water of the secondary pipe network is stably heated to the temperature close to the water supply temperature of the secondary pipe network in a stepped manner through replaced heat and issupplied out after being mixed with output water of the plate heat exchanger. According to the electric compression heat pump combined cascade heat exchange large-temperature-difference pressure isolation unit, and large-temperature-difference pressure-isolation heat exchange between the primary pipe network and the secondary pipe network is easily achieved at low cost.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST +1

A modular composite high-energy weapon cooling system and its control method

ActiveCN107152890BSimple and smooth designMeet thermal requirementsMechanical apparatusCompression machines with non-reversible cycleEngineeringRefrigeration

The invention discloses a modular composite high-energy weapon heat dissipation system and a control method thereof. It is composed of a high-energy weapon cabin and a heat dissipation equipment cabin; Variable material; compressor, condenser, throttling branch, bypass branch, controller, condenser fluid inlet and condenser fluid outlet are arranged in the heat dissipation equipment cabin; The throttling branch is connected with the throttling branch, the throttling branch and the bypass branch are arranged in parallel, the throttling device is arranged on the throttling branch, and the bypass valve is arranged on the bypass branch. Under different cooling fluids and high-energy weapon equipment load conditions, the system can realize two working modes according to the surrounding temperature of the high-energy weapon. The system of the present invention has two refrigeration modes, and the external platform can work only by providing cooling fluid, which greatly improves the flexibility, mobility and portability of high-energy weapons.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Mixed filler formula for heat transfer of ground heat exchanger

The invention relates to a mixed filler formula for heat transfer of a ground heat exchanger. The mixed filler formula comprises the following components in parts by weight: 100 parts of cement; 45-58parts of fresh water; 35-38 parts of sand; 0.5-2 parts of retarder; 4-6 parts of silicon powder; 20 parts of fly ash; 1 part of a water reducing agent; 0.01-0.02 parts of an air entraining agent; 0.5-2 parts of graphite; and 2.3 parts of a toughening fiber anti-leakage agent. The mixed filler has a relatively high heat conductivity coefficient; the heat transfer requirement of the ground heat exchanger in a geothermal well cementing filler is met; the heat transfer effect of the ground heat exchanger is improved; the water reducing agent, the air entraining agent, the graphite and the toughening fiber leakage-proof agent are added, the physical property of the mixed filler is modified and optimized, the requirement for rapid well cementation is met, when the mixed filler is used in fractured geology, the purpose of plugging cracks and pores is achieved through the friction, hanging resistance and retention effects between the mixed filler and the pores and between the mixed filler andthe walls of the cracks, the leakage phenomenon is avoided, the well cementation quality is improved, and meanwhile the well cementation cost is saved.

Owner:中国能源建设集团华北电力试验研究院有限公司

Centralized heating large temperature difference centralized combined type cascade heat exchange pressure isolation station

PendingCN110748939AMeet heat transfer requirementsBalance heat loadCentral heating with accumulated heatLighting and heating apparatusPhysicsEnvironmental geology

The invention discloses a centralized heating large temperature difference centralized combined type cascade heat exchange pressure isolation station. The effect that primary net return water temperature is stably lowered under the condition that a pressure isolation function of the pressure isolation station is met is achieved. Under the condition that the pressure isolation function of the pressure isolation station is met, the primary net return water temperature can be stably lowered as required, waste heat of a power plant can be fully utilized, heating capacity of a unit is improved, andheating energy consumption and cost are lowered. High secondary-level net water supply temperature can be provided by a cascade heating system, and heat exchange requirements of all heating stationsof a secondary-level net are met. High and low temperature heat storage water tanks and a water charging system are arranged, redundant heat of a heat source can be stored in the heat load valley period of a heating supply system and is released in the peak period, the heat supply network can be coordinated, the heat loads of the heat supply network are balanced, and heating capacity of the heating supply system is improved.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com