Connected box-shaped laminating heat exchanger

A heat exchanger and combined box technology, which is applied in the field of combined box-shaped stacked heat exchangers, can solve the problems of inability to resist the impact of refrigerant working pressure, limited pressure bearing capacity of aluminum heat exchange plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Further description will be made below in conjunction with embodiments and illustrations.

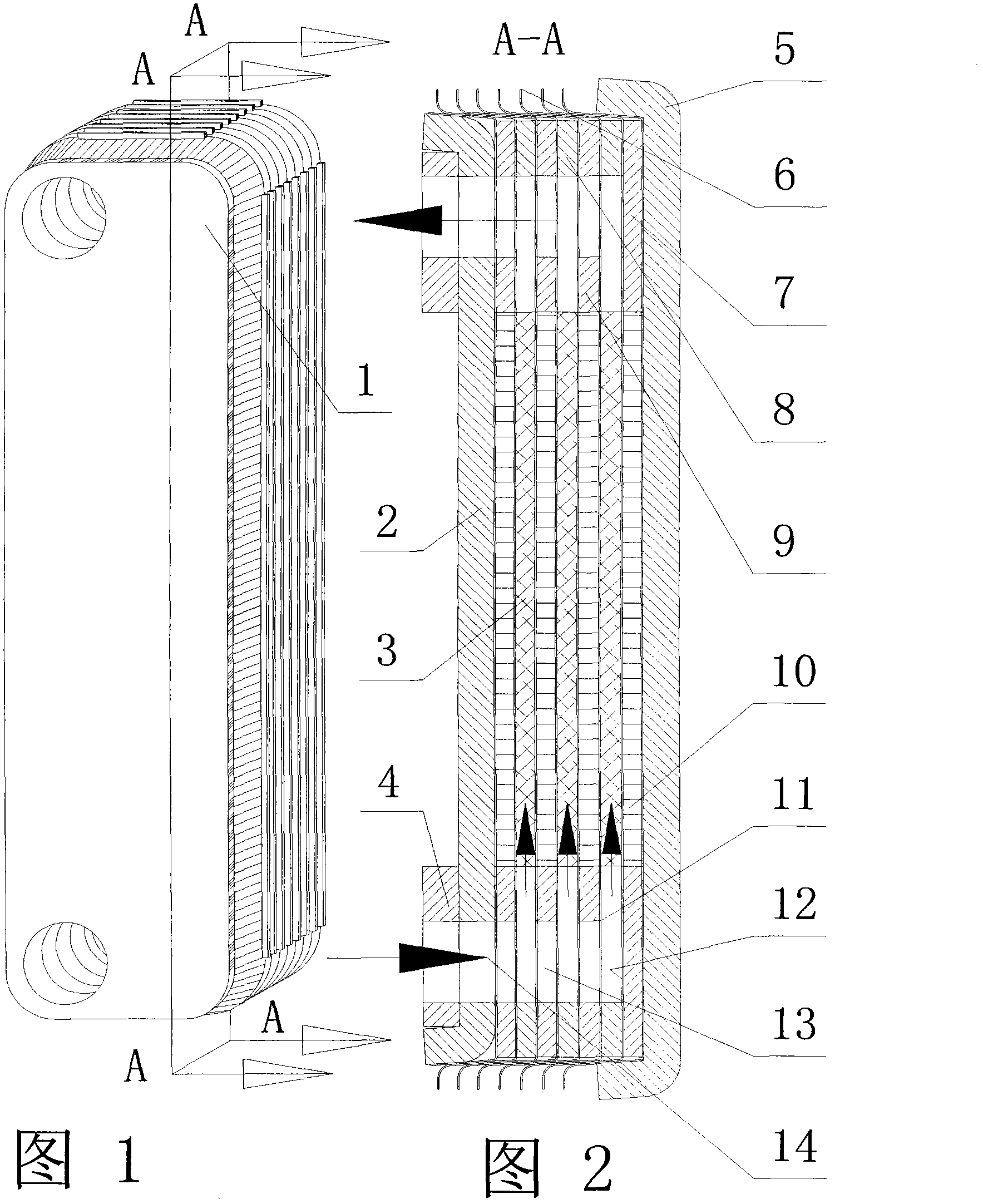

[0028] figure 1 The 1 in the figure represents a single box-shaped laminated heat exchanger. The heat exchange medium inside the heat exchanger adopts the heat exchange mode of the same side flow. It can be seen from the surface of the three-dimensional heat exchanger that the left side of the front baffle There are two through holes and pipes on the upper and lower sides. This pipe can be considered as a through hole and pipe through which a certain heat exchange medium enters and exits the heat exchanger, and another kind of heat exchange that is opposite to it. The circulation duct of the medium Y is behind the front baffle, and there is no corresponding through hole on the front baffle. For this reason, the section A-A is set up to illustrate the pipeline behind the front baffle.

[0029] figure 2 expressed figure 1 The A-A section of , where 2 represents the rear baffle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com