A heat exchange system of heat recovery exchanger

A heat exchange system and switch technology, applied in the field of heat exchange systems, can solve the problems of waste of energy resources, low heat exchange efficiency, low heat utilization rate, etc., and achieve the effects of avoiding hazards, meeting heat transfer requirements, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

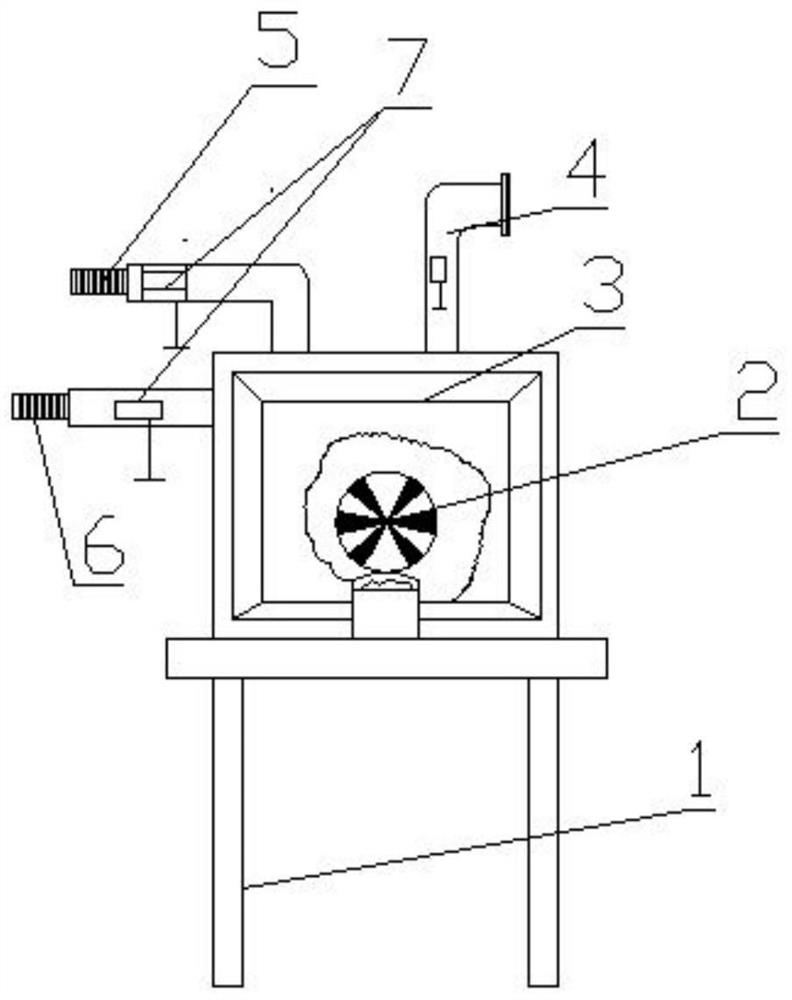

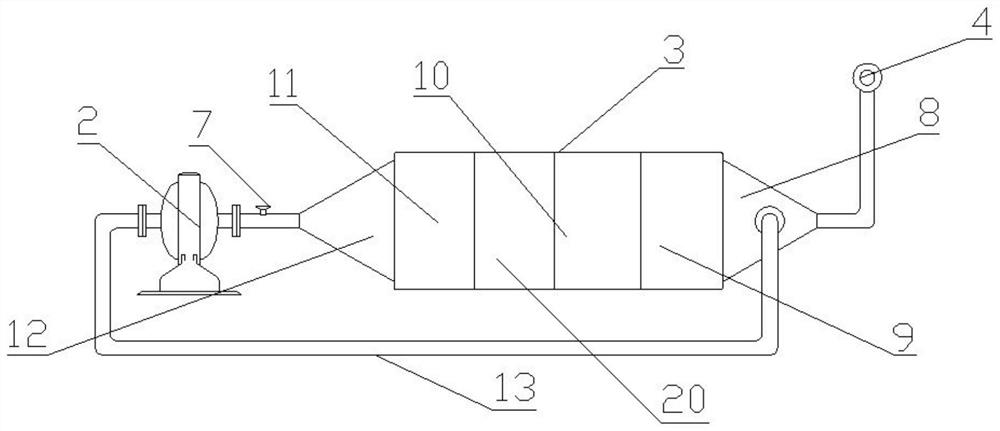

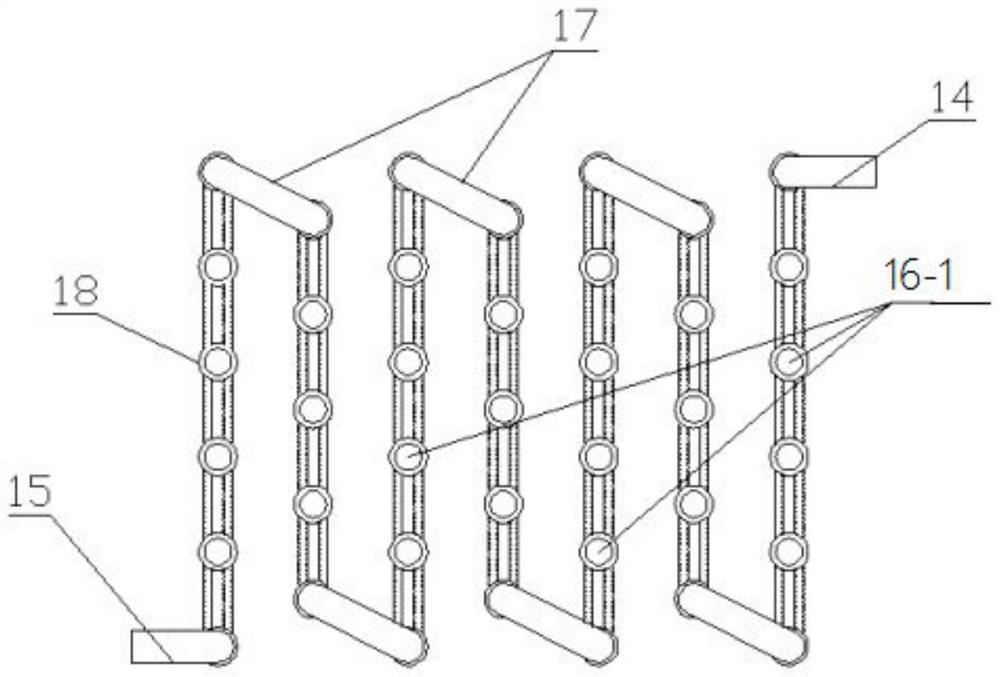

[0025] Such as Figure 1-7 As shown, the technical solution adopted by the present invention is: a heat exchange system of a heat recovery exchanger, the main structure of the heat exchange system is set as a heat exchanger 3, and one end of the heat exchanger 3 is connected to a heat circulation fan 2 A heat exchange tube 16 is installed inside the heat exchanger 3 , and a flow turbulence corrugation 19 is arranged inside the heat exchange tube 16 .

[0026] The front end of the heat exchanger 3 is set as a filter area 8, and the downstream of the filter area 8 is set as a planar heat exchange area 9, and the planar heat exchange area 9 is equipped with serpentine heat exchange tubes 16-1 arranged in a plane. The downstream of the planar heat exchange area 9 is set as a spiral heat exchange area 10, and the inside of the spiral heat exchange area 10 is equipped with spiral heat exchange tubes 16-2 arranged one-sidedly. In the exchange area 20, irregular heat exchange tubes 1...

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is:

[0036] The inside of the filter area 8 is filled with a mixture of activated carbon and alkaline reagent, the mixing ratio is 5:1, wherein the alkaline reagent is a mixture of wet sodium bicarbonate and sodium hydroxide, and the mixing ratio is 3:1.

Embodiment 3

[0038] The difference between this embodiment and embodiment 1 is:

[0039] The inside of the filter area 8 is filled with a mixture of activated carbon and an alkaline reagent, and the mixing ratio is 3:1, wherein the alkaline reagent is a mixture of wet sodium bicarbonate and sodium hydroxide, and the mixing ratio is 2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com