A modular composite high-energy weapon cooling system and its control method

A heat dissipation system and composite technology, applied in directed energy weapons, cooling or heating systems, weapon types, etc., can solve the problems that restrict the flexibility, mobility and portability of high-energy weapons, and achieve simple and smooth pipeline design. Effect of reducing thermal load impact and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

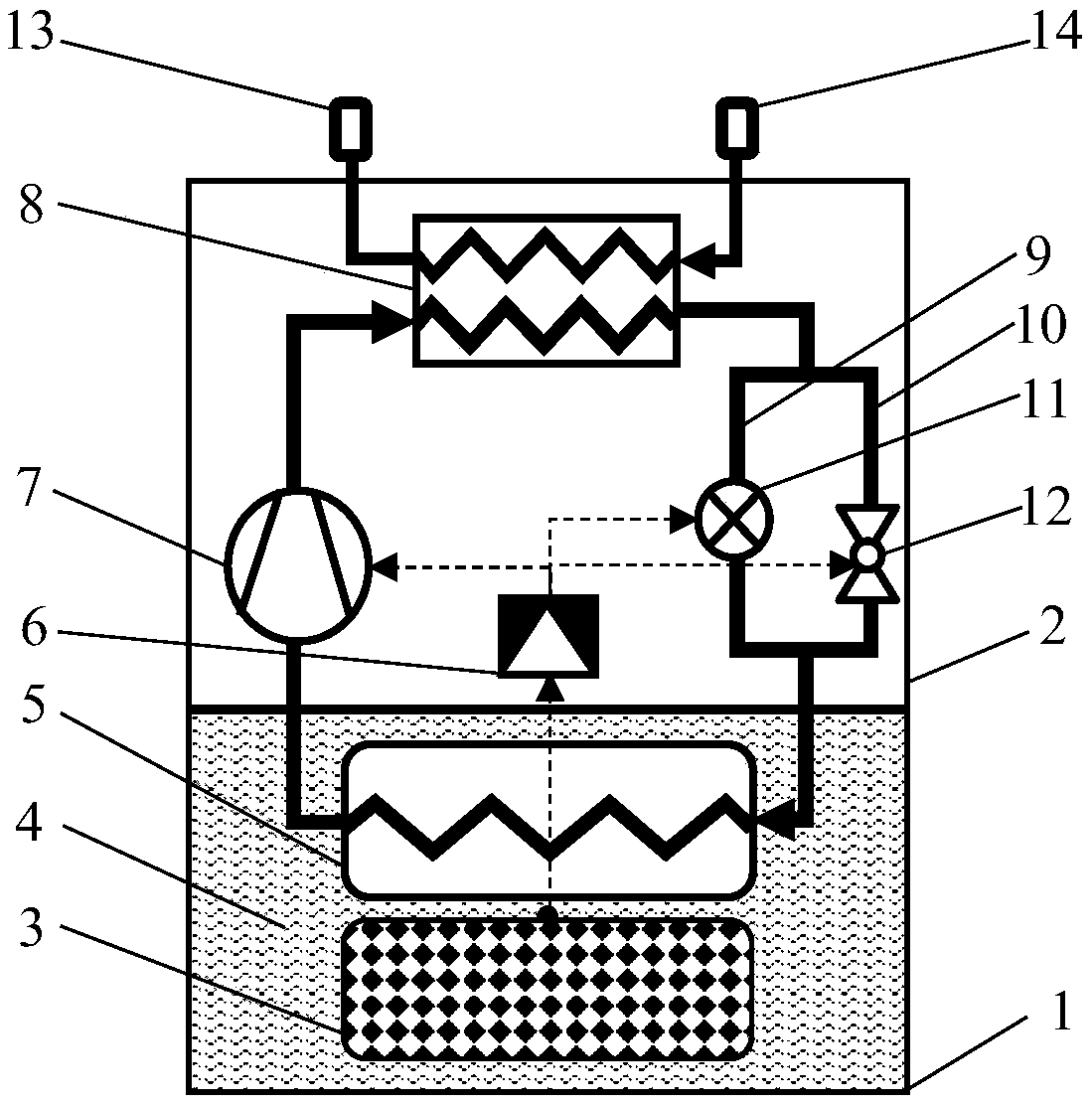

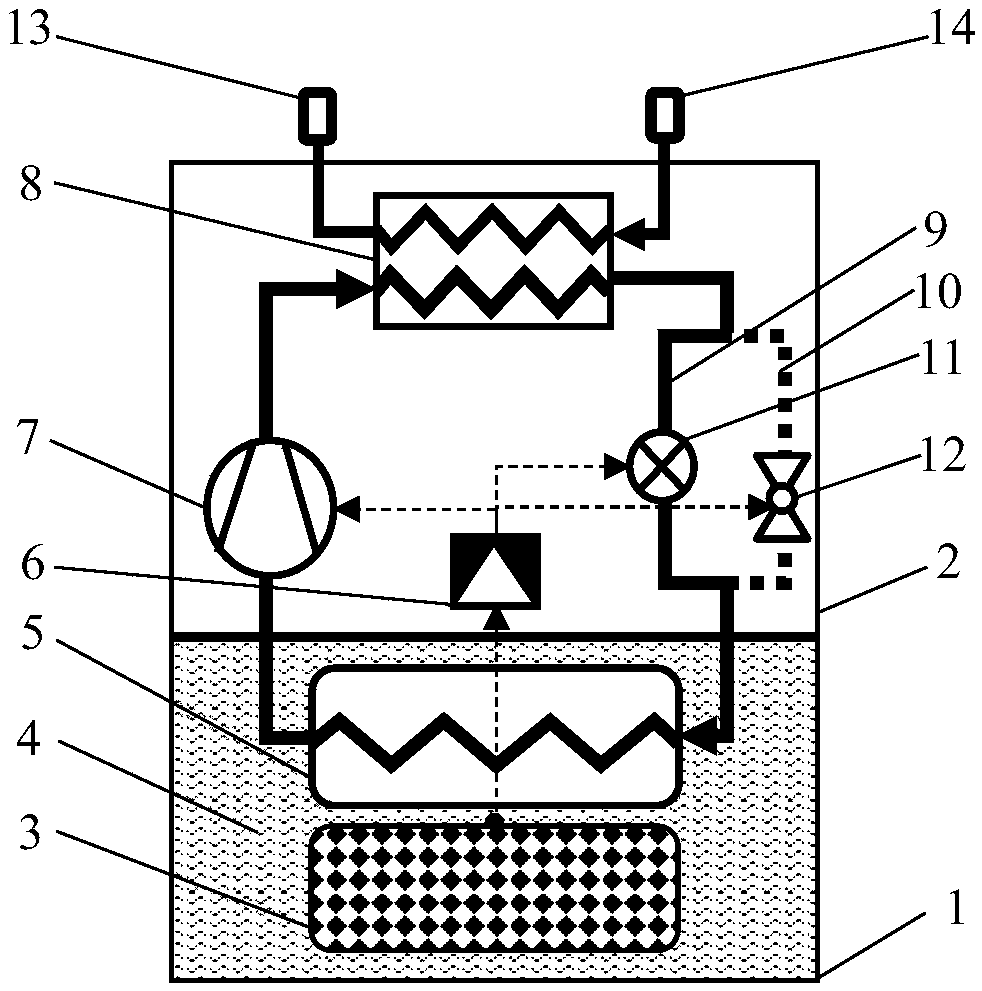

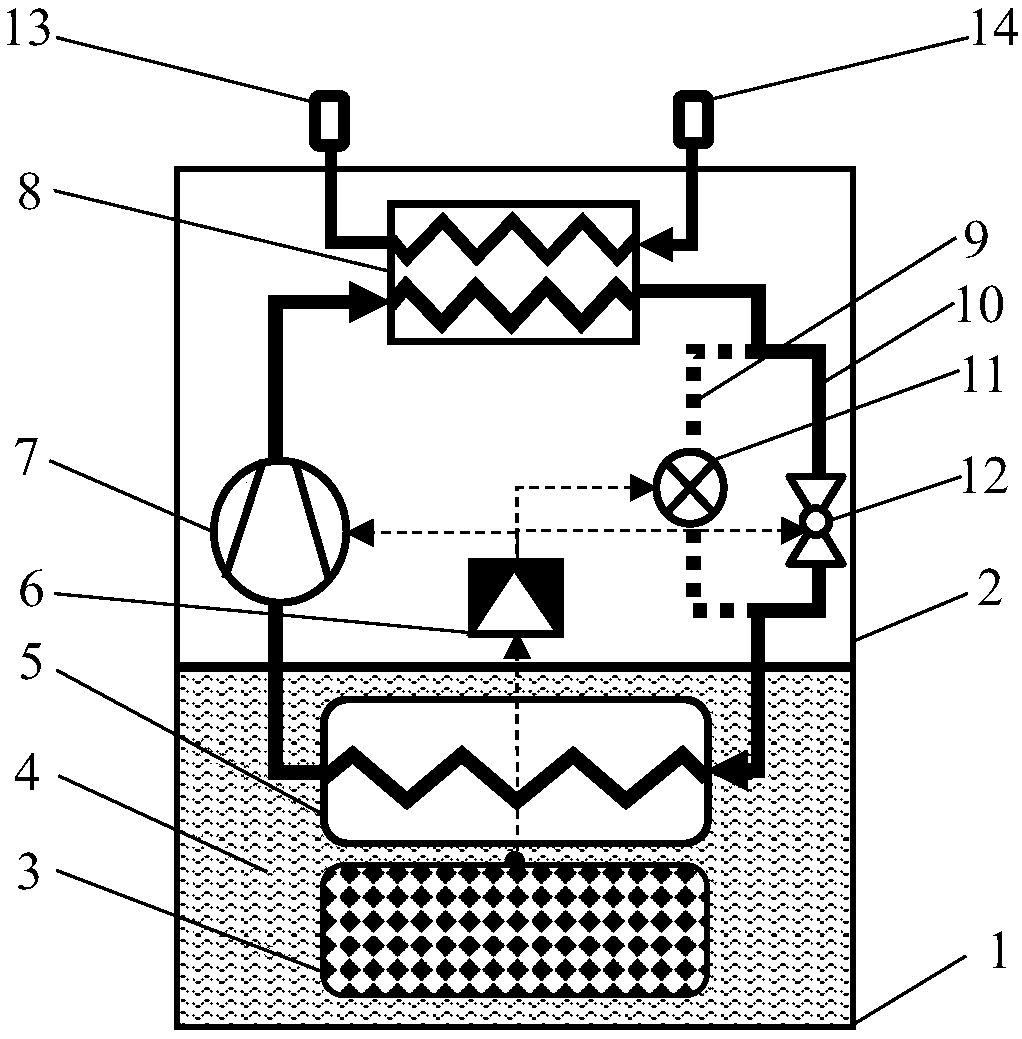

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] The modular composite high-energy weapon heat dissipation system of the present invention is composed of a high-energy weapon cabin 1 and a heat dissipation equipment cabin 2; a high-energy weapon 3 and an evaporator 5 are arranged in the high-energy weapon cabin 1, and phase transitions are filled around the high-energy weapon 3 and the evaporator 5 Material 4. A compressor 7, a condenser 8, a throttling branch 9, a bypass branch 10, a controller 6, a condenser fluid inlet 13 and a condenser fluid outlet 14 are arranged in the cooling equipment cabin 2; the evaporator 5 passes through the refrigerant pipeline Connect with compressor 7, condenser 8 and throttling branch 9 in sequence, throttling branch 9 and bypass branch 10 are set in parallel, throttling device 11 is set on throttling branch 9, and throttling device 11 is set on bypass branch 10 Bypass valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com