Cooling unit for traction transformers

A technology for traction transformers and cooling units, which is applied in the direction of transformer/inductor cooling, etc. It can solve problems such as potential safety hazards, cracking of cooling unit fan box and collector mounting plate, and reduced reliability of cooling units, so as to reduce maintenance costs , Prevent the cracking of the fan box and improve the efficiency of maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

[0034] In order to realize the safe operation of EMUs with a speed of 350 kilometers per hour, according to the technical specifications for the traction transformers of the 350 kilometers per hour Chinese standard EMUs, and aiming at the common faults of the cooling units of the traction transformers of the existing EMUs, an innovative design of the traction transformer cooling unit was carried out.

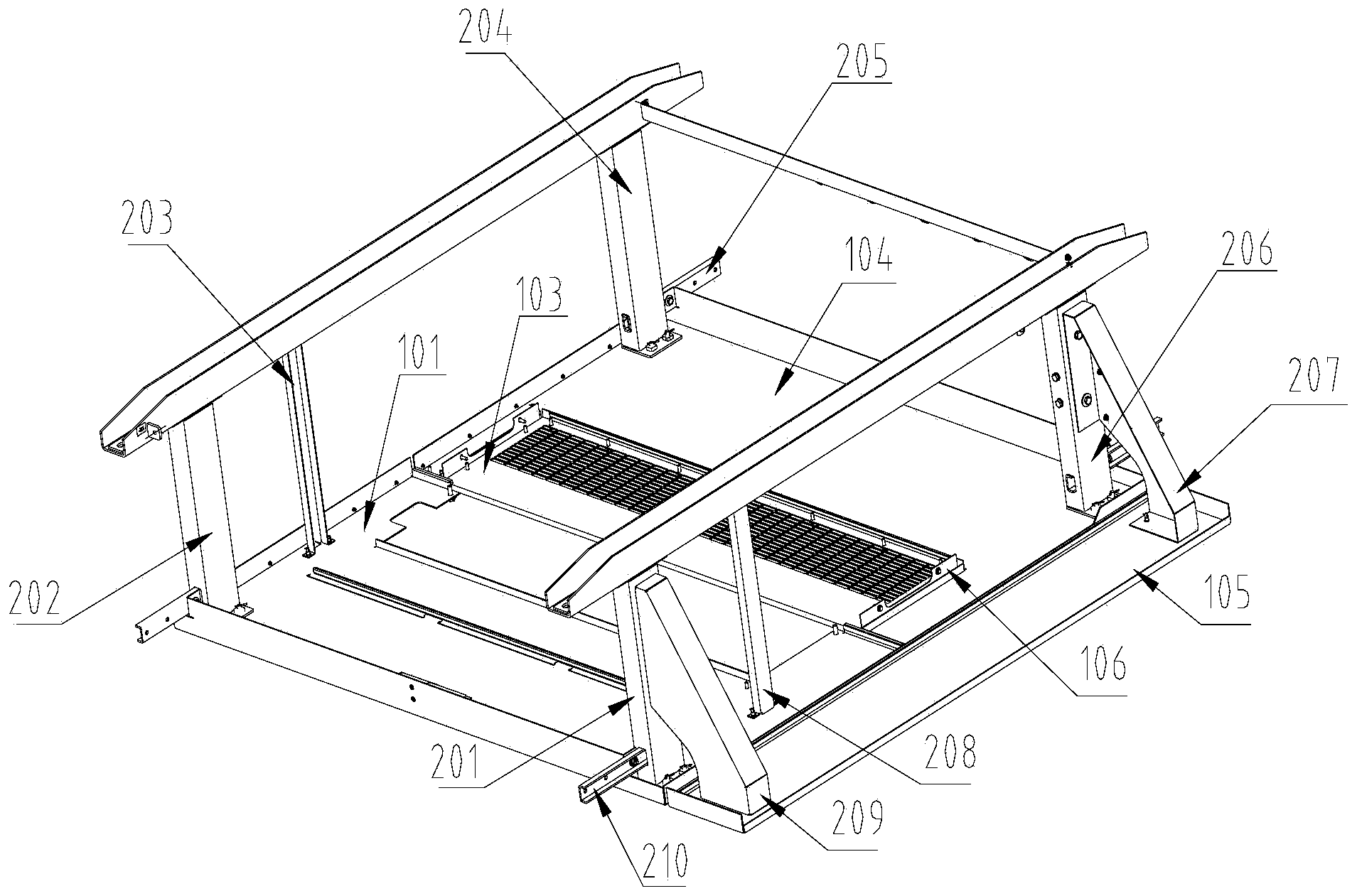

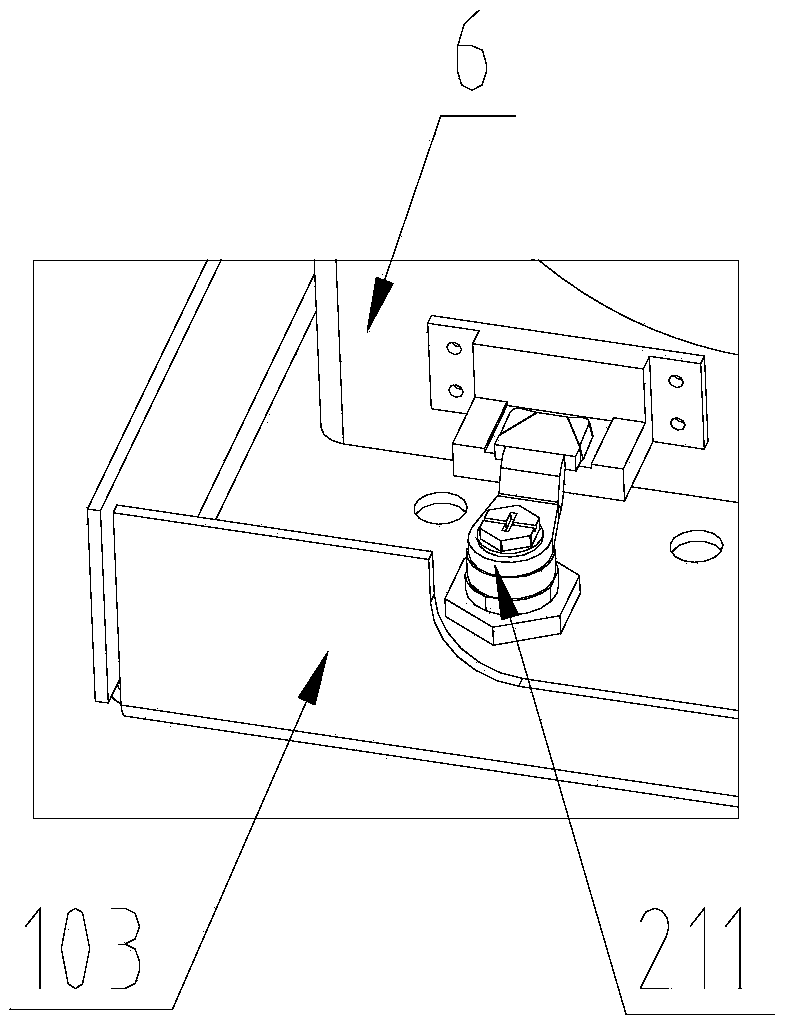

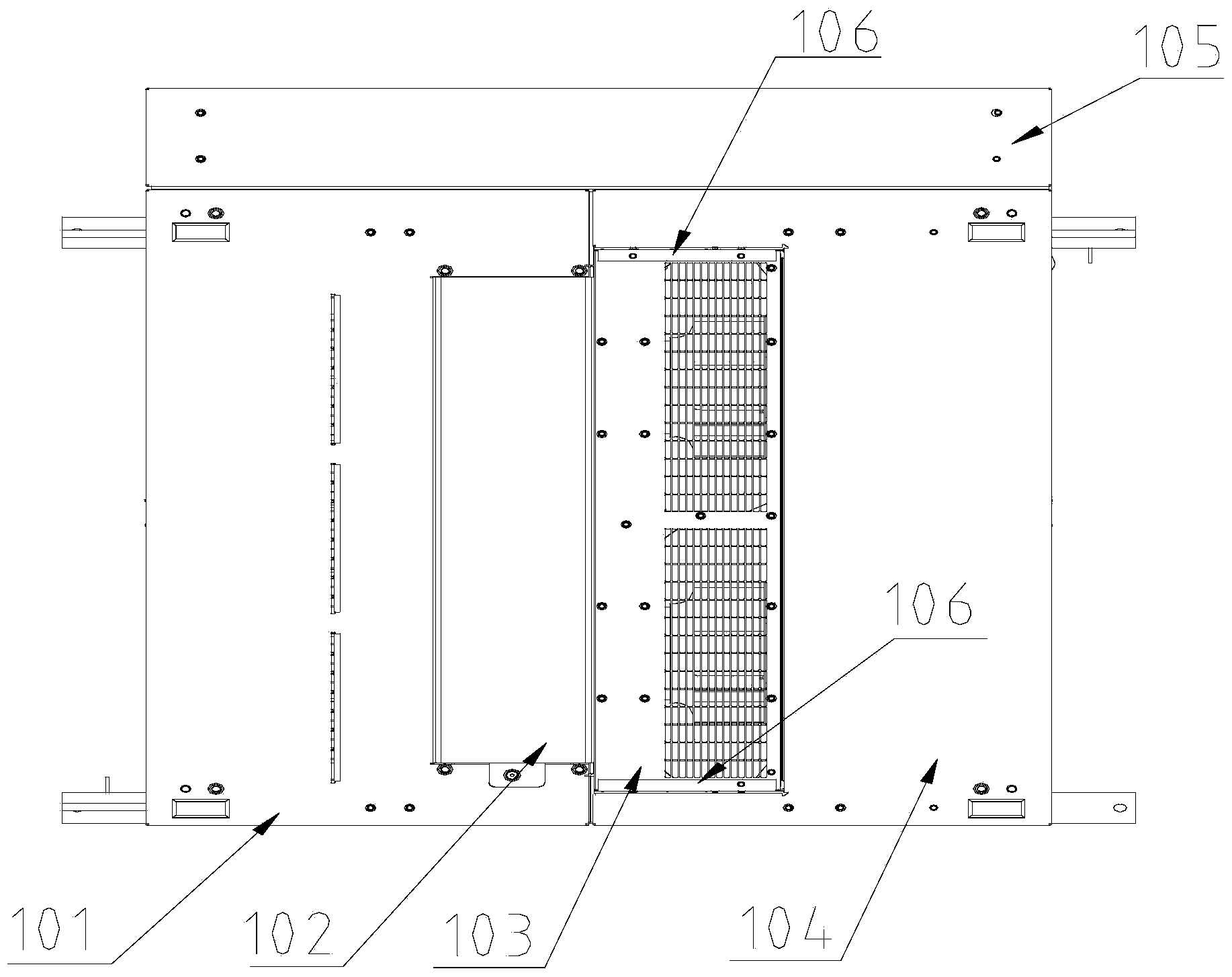

[0035] A cooling unit for traction transformers (such as figure 1 As shown), including protective base assembly 1, vertical load-bearing column assembly 2, top load-bearing installation frame assembly 3, filter assembly 4, radiator assembly 5, fan duct assembly 6, fan unit assembly 7, electrical connector or junction box Assembly 8, radiator inlet and outlet butterfly valve 9 and other components:

[0036]The top load-bearing installation frame assembly 3 is provided with tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com