Multitube heating rotary pulverized coal pyrolysis system

A rotary, pulverized coal technology, applied in the direction of indirect heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the problems of unsatisfactory large-scale production, poor overall economic efficiency and environmental protection performance, waste of resources, etc., and achieve a favorable concentration Disposal and environmental protection, improving overall economic performance, achieving recycling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

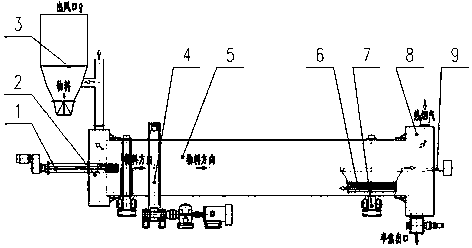

[0026] With the improvement of coal mining mechanization in my country, the pyrolysis utilization of pulverized coal, especially low-rank pulverized coal, will become increasingly important. It is undeniable that the utilization of pulverized coal in China is still at a backward stage, and the accumulation of a large amount of pulverized coal causes resource waste and environmental pollution. The development of pulverized coal pyrolysis technology has important energy strategic significance. However, it needs to be emphasized that the existing coal pyrolysis equipment is mainly used to process lump coal with a diameter greater than 20 mm, and it is difficult to process small particle coal or pulverized coal with a diameter less than 20 mm; at the same time, the existing coal pyrolysis equipment The processing capacity of a single machine is generally small, which cannot meet the requirements of large-scale pyrolysis of pulverized coal. In order to solve the above problems, the...

Embodiment 2

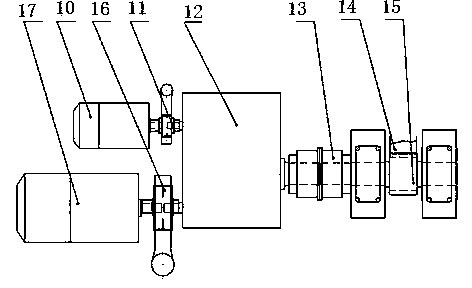

[0034] The rotating cylinder 5 is supported by two sets of supporting wheel devices 7. There are multiple sets of heating pipes 6 installed in the rotating cylinder 5. couplet. The rotation of the rotary cylinder 5 is realized by the transmission mechanism 4 . When the rotary cylinder 5 rotates, the differential gearbox 12 is driven by the large motor 17 and the small motor 10 with frequency conversion, respectively through the brake coupling 16 of the large motor and the brake coupling 11 of the small motor, and then through the gear coupling. The shaft device 13 drives the pinion 15, and the pinion 15 drives the large gear 14 installed on the rotary cylinder 5, so as to realize the rotation of the rotary cylinder 5 and the adjustment of the rotational speed.

[0035] A feeder 1 is connected to the feed end of the rotary cylinder 5 . The feeder 1 extends to the rotary cylinder 5 through the gas outlet gas collection distribution box 2, and the pulverized coal is input into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com