Novel heat exchange stirring shaft and tubular reactor

A technology for tubular reactors and stirring shafts, which is applied in chemical/physical/physicochemical fixed reactors, mixer accessories, mixers with rotating stirring devices, etc. Problems such as high energy consumption of the device structure, increased heat transfer load, etc., achieve the effect of saving internal space, occupying a small space, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

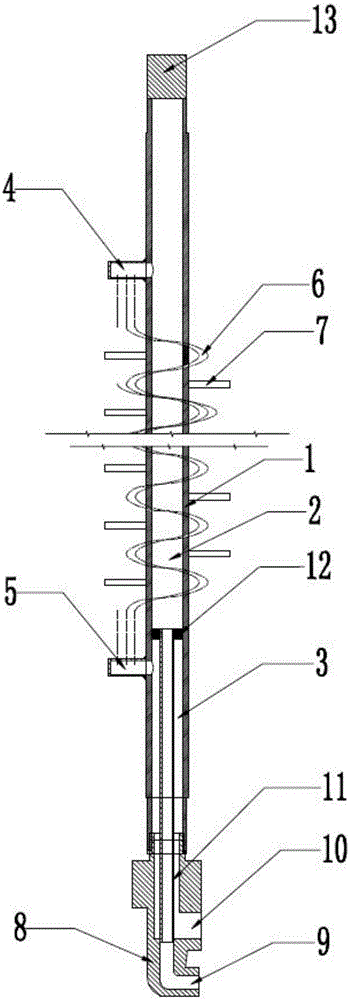

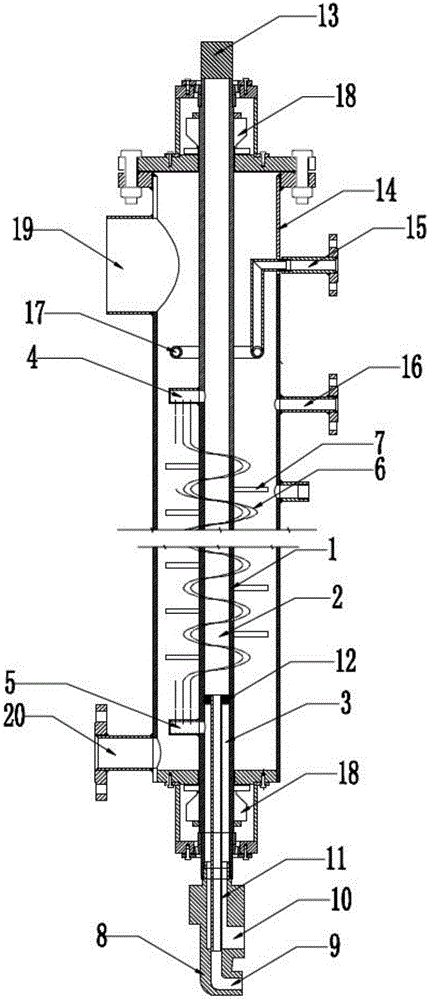

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

[0026] figure 1 It is a schematic diagram of the overall structure of a new type of heat exchangeable stirring shaft in the present invention, including a main shaft 1, inside the main shaft 1 there are a first chamber 2 and a second chamber 3 isolated from each other, and the first chamber 2 and the second chamber 3 are all provided with an opening on one end of the main shaft 1, the main shaft 1 is provided with a first connecting pipe 4 communicating with the first chamber 2, and the main shaft 1 is provided with a second connecting pipe 5 communicating with the second chamber 3, the first A winding pipe 6 is provided between the connecting pipe 4 and the second connecting pipe 5 for communication, and a plurality of stirring columns 7 are provided on the main shaft 1 .

[0027] One end of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com