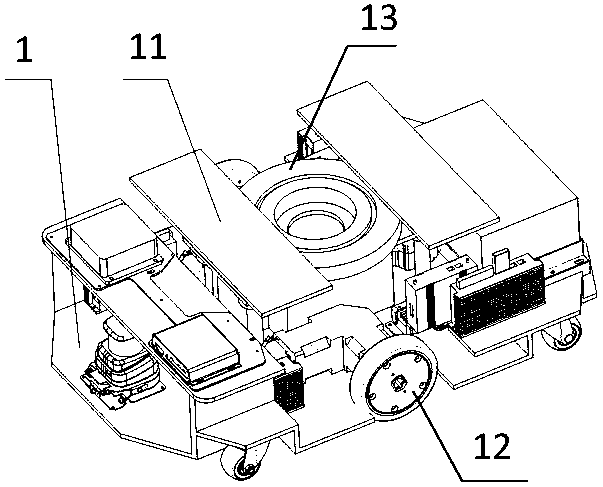

AGV, bearing system with longitudinal beams and use method thereof

A technology of longitudinal beams and car bodies, applied in the field of logistics services, can solve the problems of low site utilization, difficult and efficient handling, high cost of AGV forklifts, etc., and achieve the effect of stable lifting support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

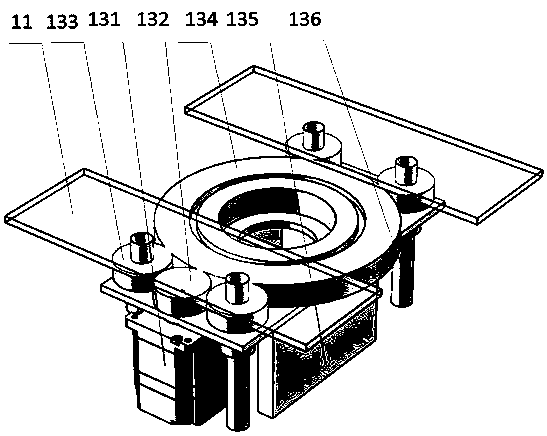

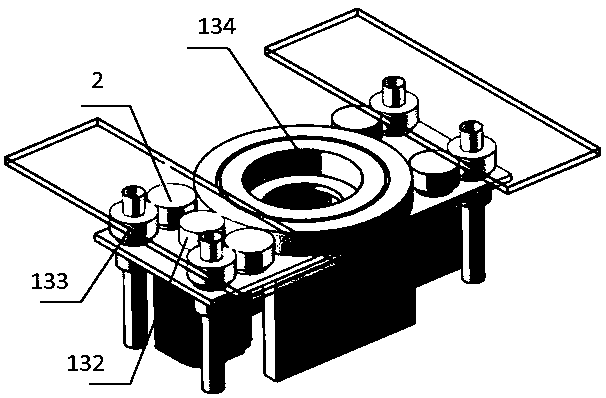

Embodiment 1

[0037] Example 1, such as Figure 4 and Figure 5 As shown, a tray holding system with longitudinal beams includes a plurality of support rails 3. In this embodiment, the support rails are 3 parallel steel profiles, and each profile is a single rail 31. Every two steel profiles can The pallets 4 together form a passage for the AGV vehicles to pass through. The pallets 4 are stacked along the support rails 3 to form a stable support structure. Such as Figure 5 As shown, the pallet storage area of a logistics distribution center is 35 meters x 25 meters. The pallet storage system is set up, including 13 groups of 26 profiles. The capacity is 169 pieces. The tray holding system can be adjusted according to the logistics area area, throughput and other parameters. The height of the AGV channel between the pallet 4 and the profile is 400mm.

[0038] There are two types of pallets in the logistics distribution center, the specifications are as follows:

[0039] 1100mm×1100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com