Patents

Literature

70results about How to "Realize the delivery function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

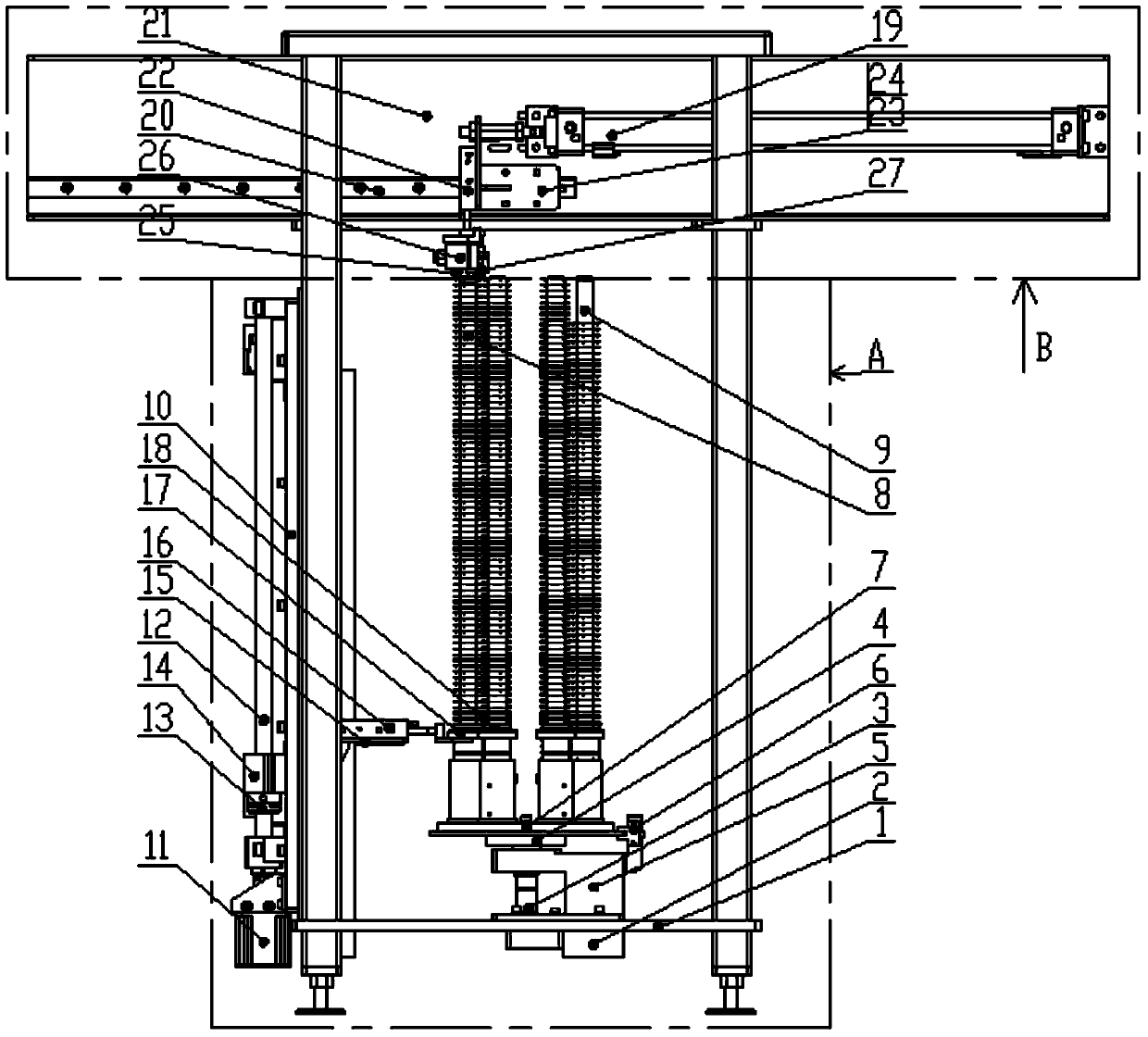

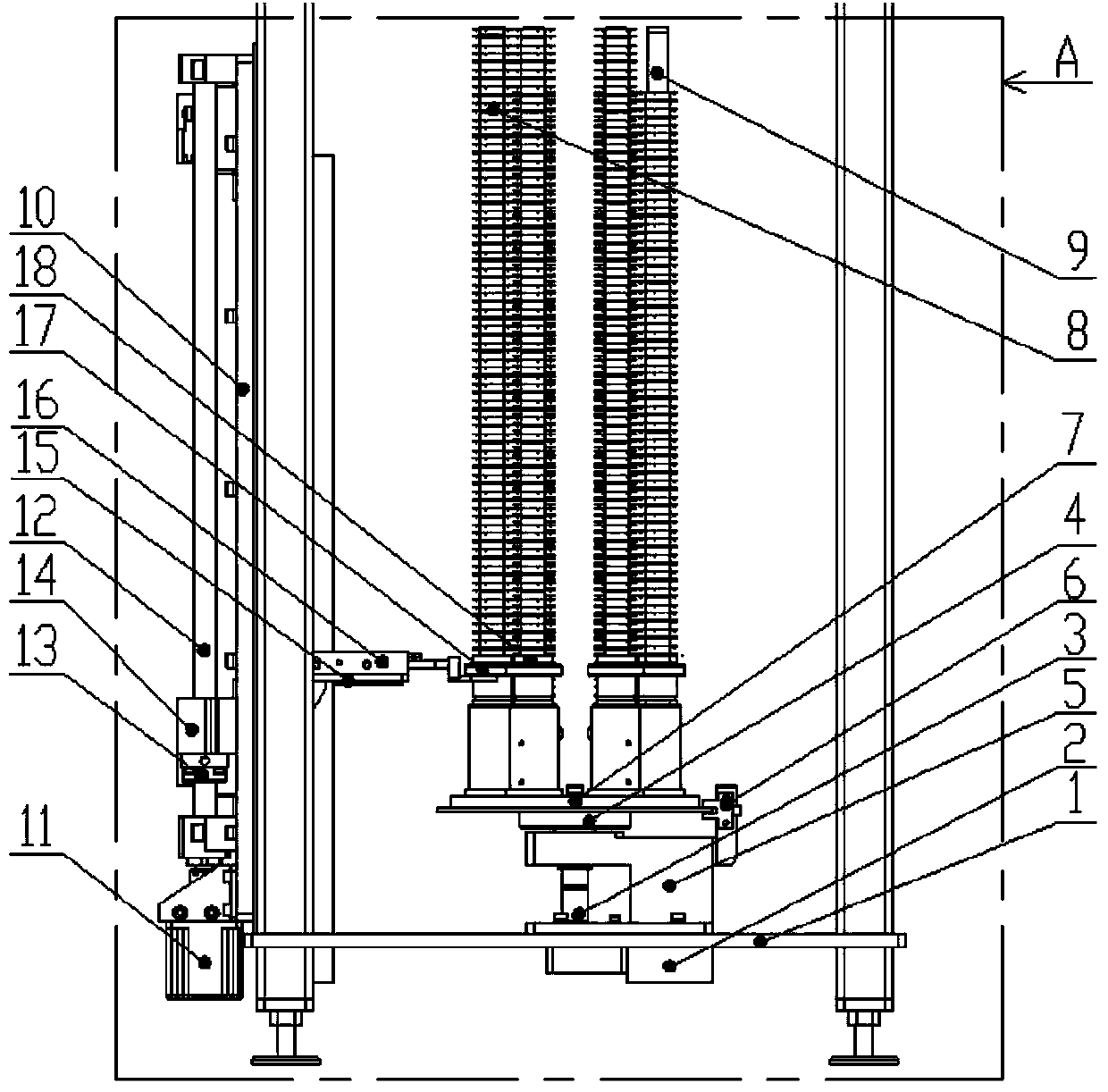

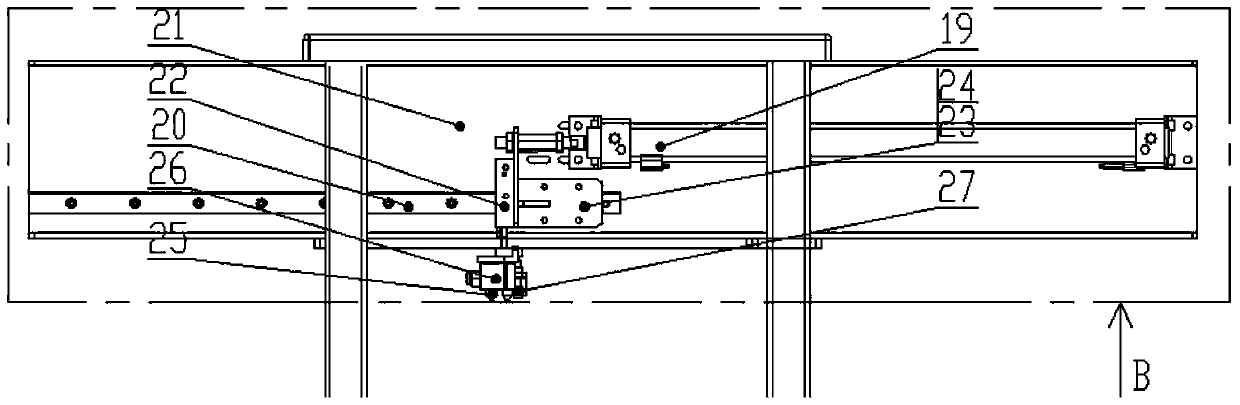

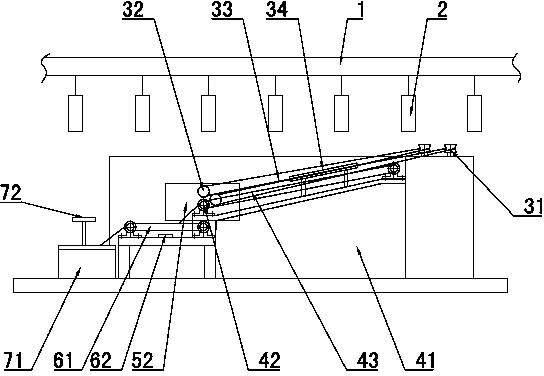

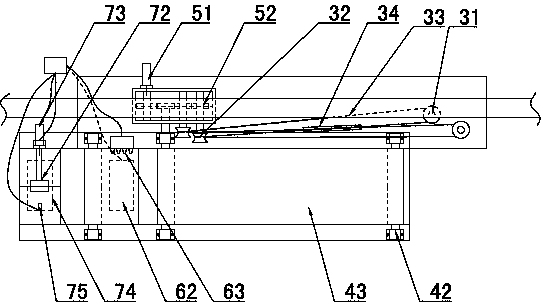

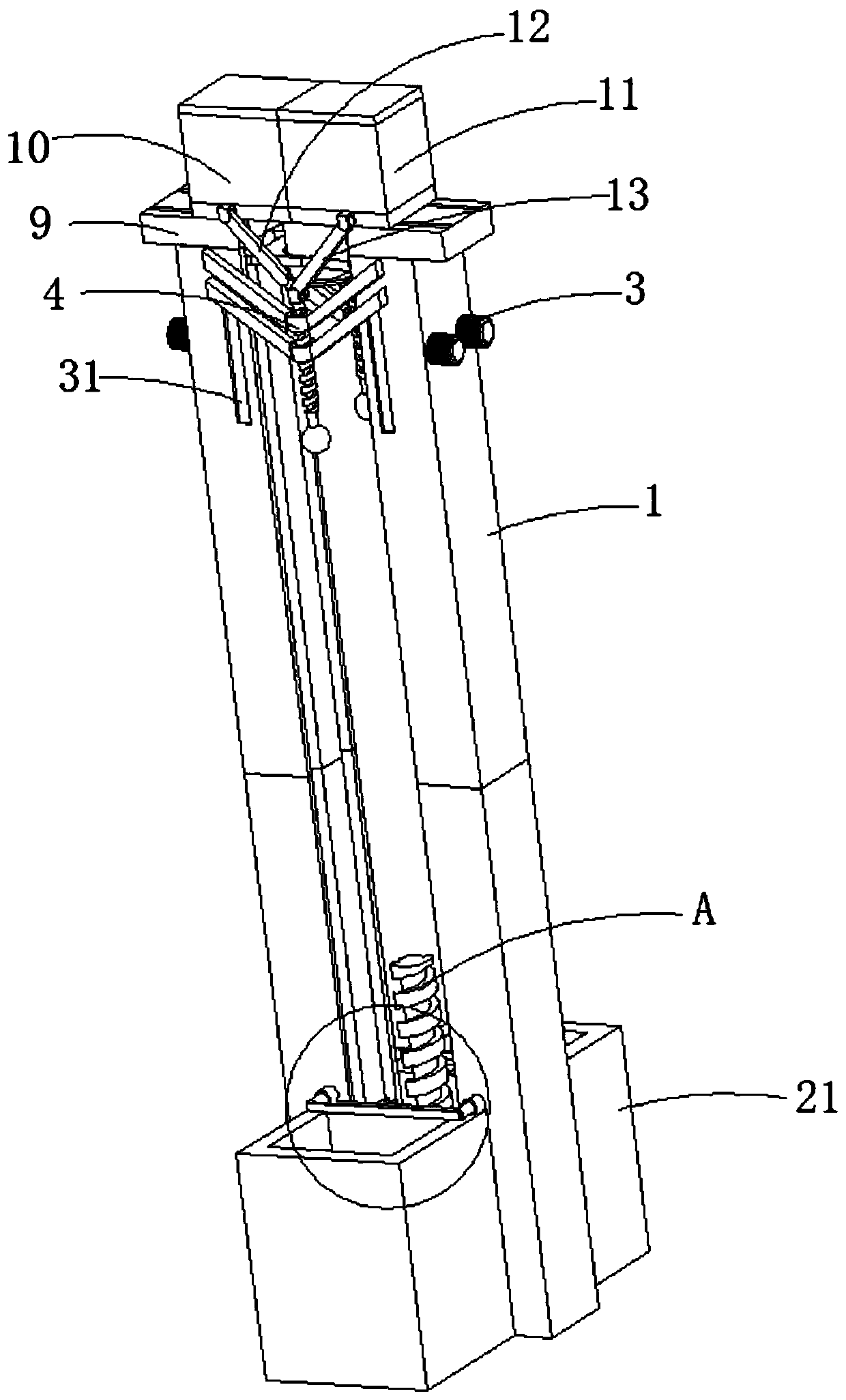

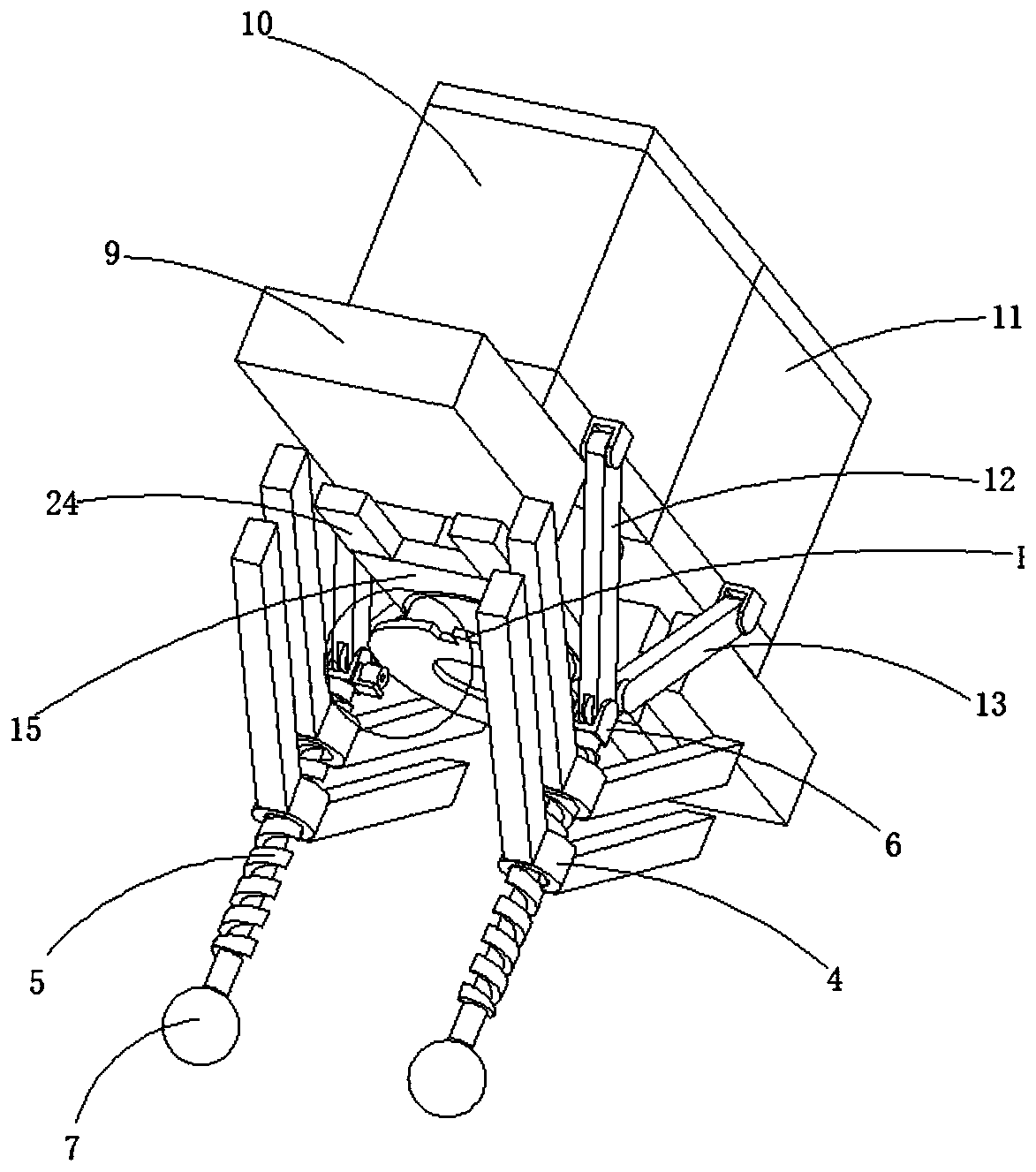

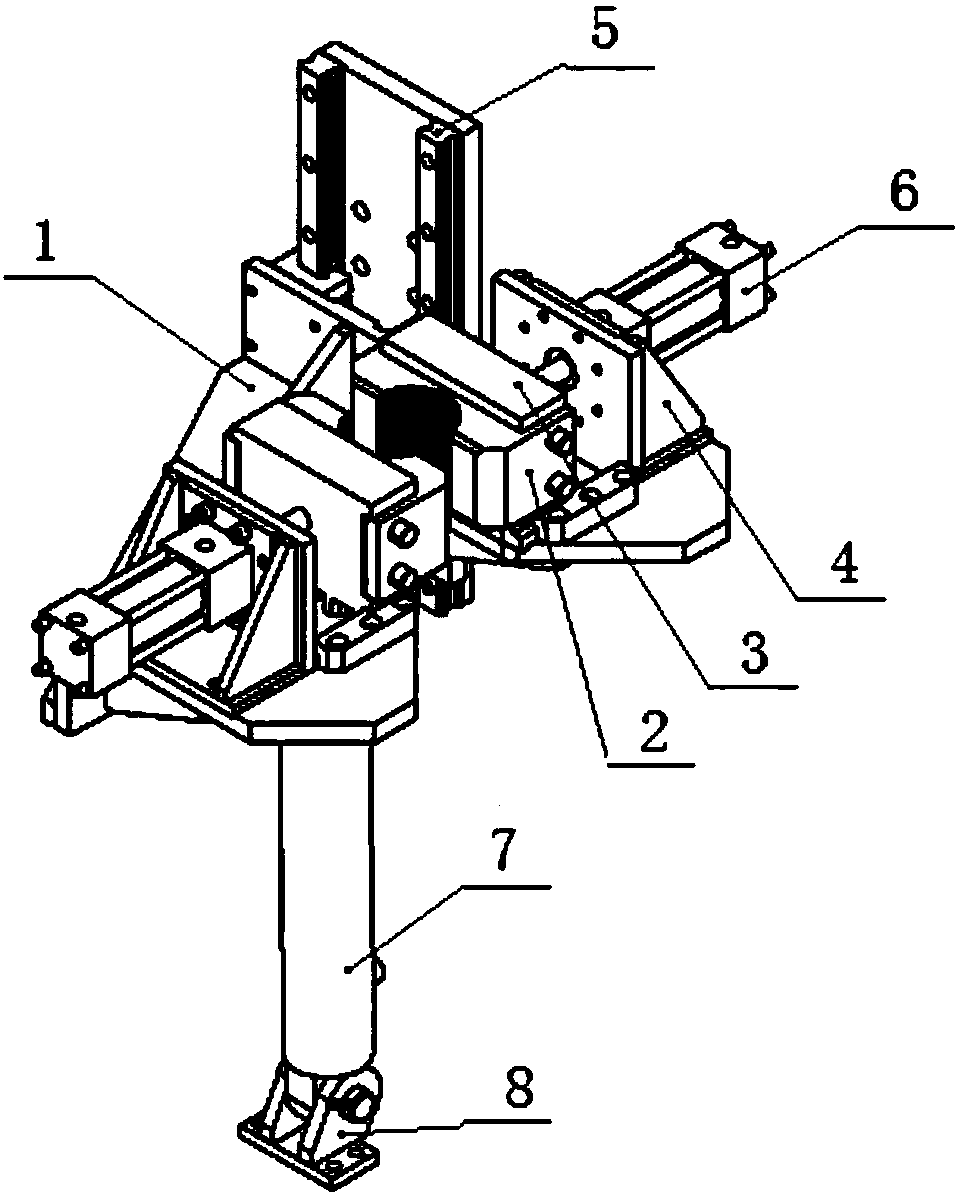

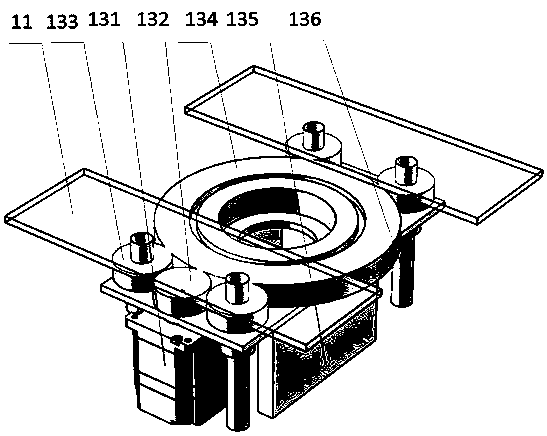

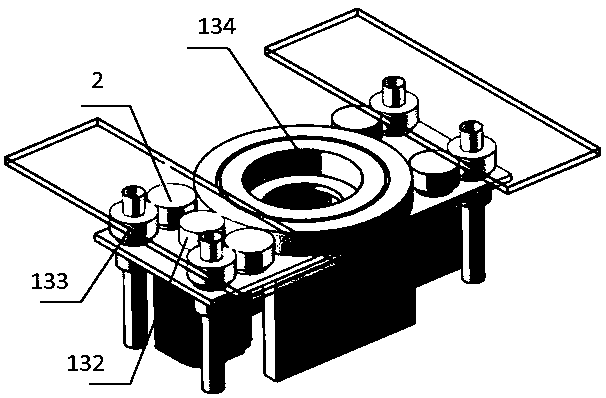

Automatic feeding device for core ring punching and based on rotary grinding wheel forming machine

ActiveCN104003193ARealize the delivery functionRealize automatic loading operationDe-stacking articlesConveyor partsPunchingEngineering

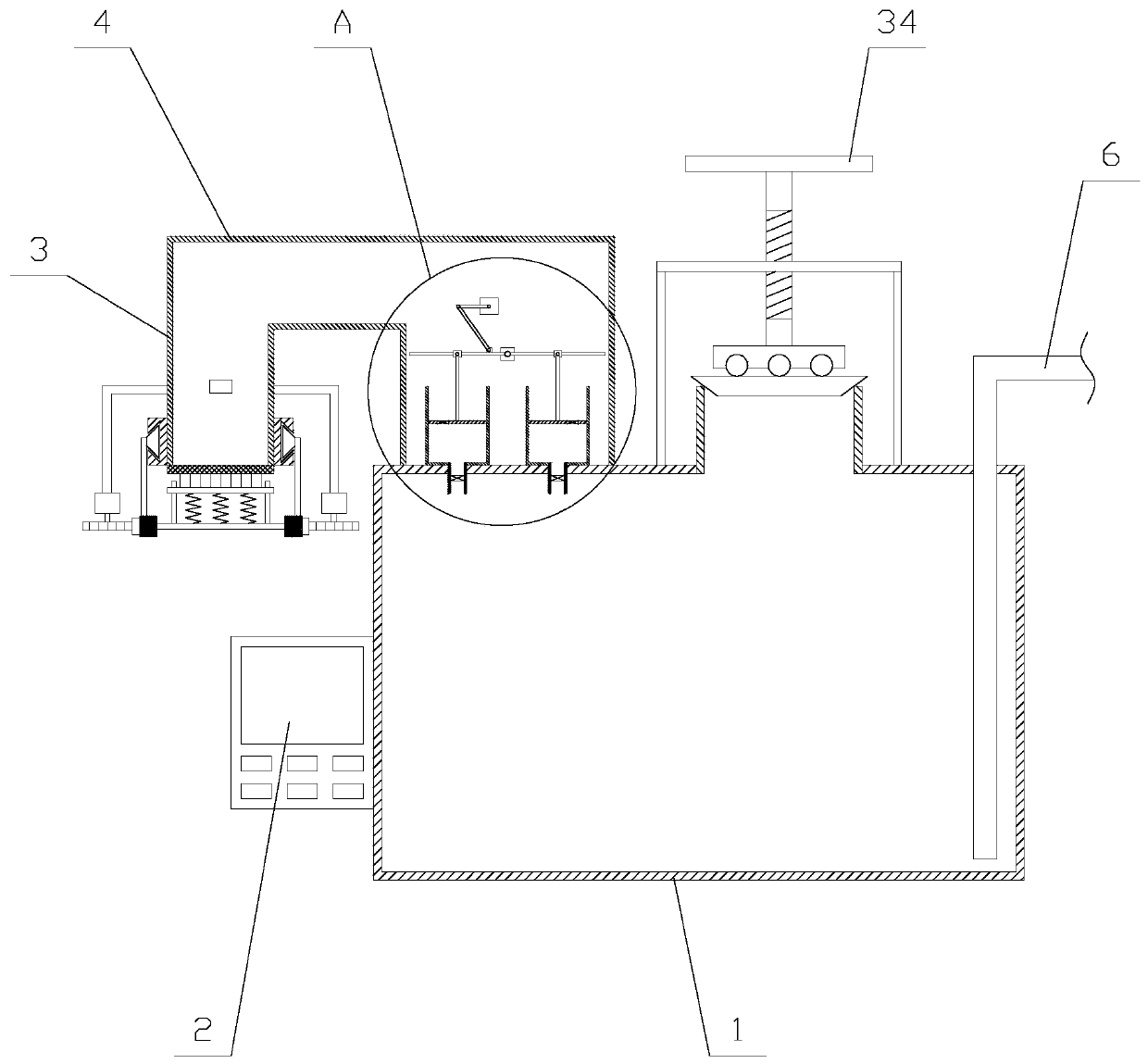

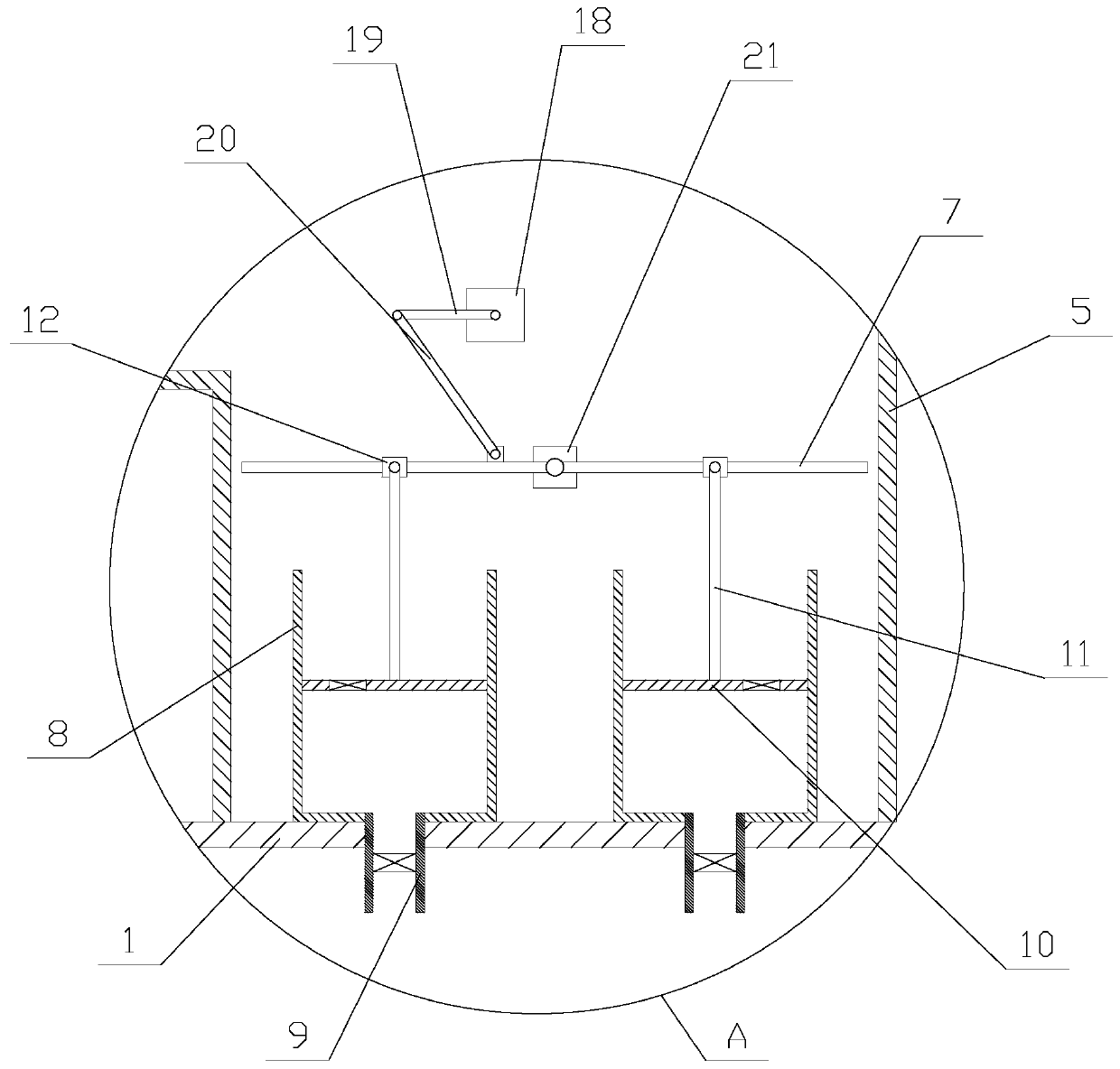

The invention discloses an automatic feeding device for core ring punching and based on a rotary grinding wheel forming machine. The automatic feeding device comprises a main frame body, a rotary disk type core ring stack is arranged on the main frame body, a vertical lifting type core ring conveying mechanism used for driving core rings to move upwards along a string column to achieve a core ring conveying function is arranged on the lateral side of the main frame body, horizontal reciprocating type core ring feeding mechanism is arranged at the top of the main frame body, the horizontal reciprocating type core ring feeding mechanism is used for placing the core rings on the rotary disk type core ring stack into punching work stations of the grinding wheel forming machine, and accordingly the task of automatically feeding the core rings is finished. The automatic feeding device is composed of the rotary disk type core ring stack, the vertical lifting type core ring conveying mechanism and the horizontal reciprocating type core ring feeding mechanism. The automatic feeding device can finish actions of jacking up the core rings, sucking the core rings, horizontally moving the core rings and releasing the core rings. Thus, the automatic feeding device achieves automatic feeding operation of the core rings, effectively avoids personal injury to operators and remarkably improves production efficiency of grinding wheels.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

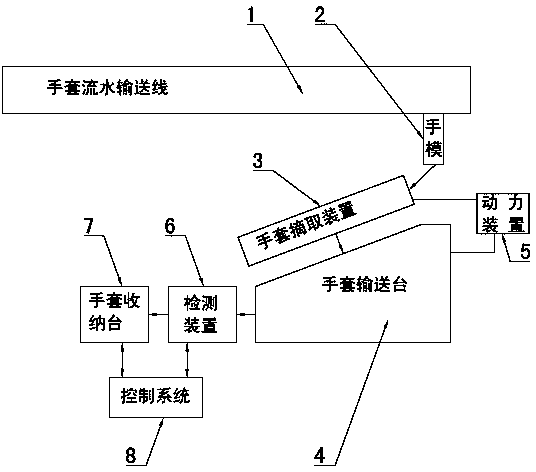

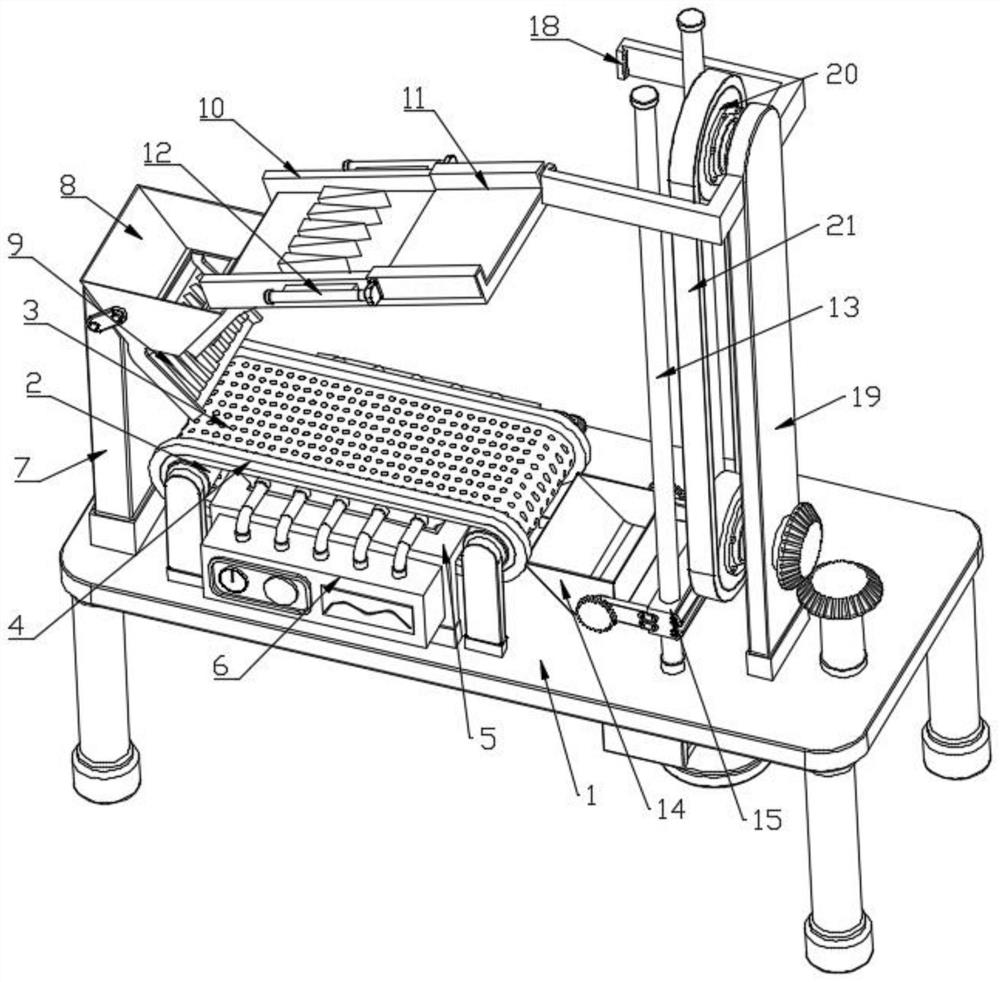

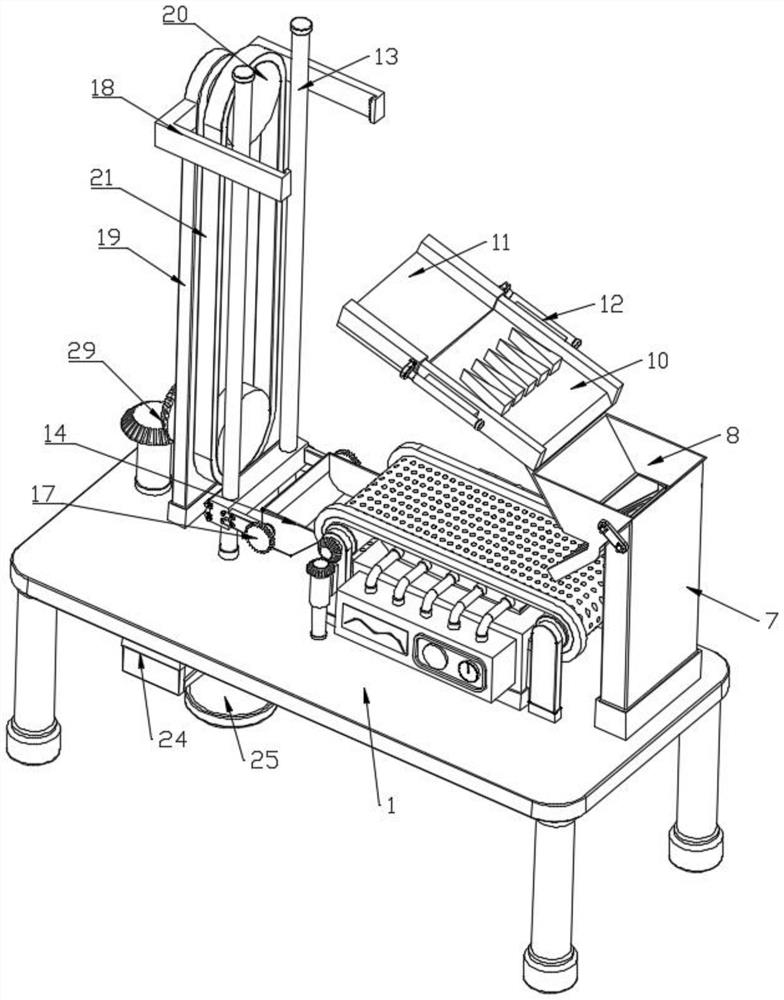

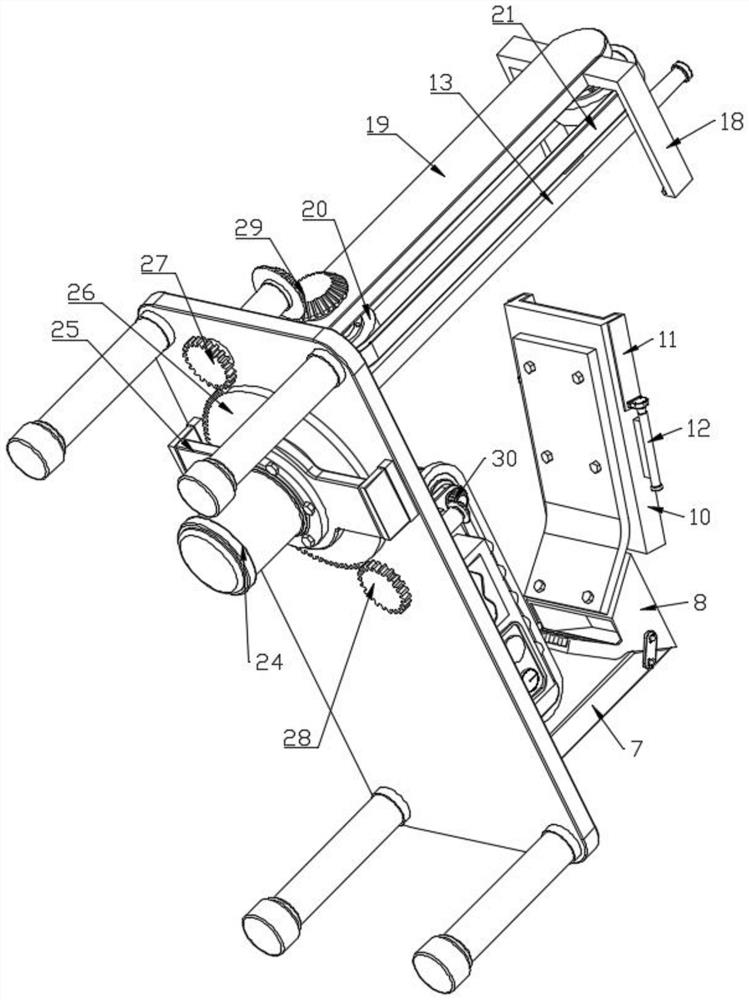

Full-automatic glove counting and stacking machine

The invention provides a full-automatic glove counting and stacking machine, and belongs to the field of production devices of vinyl gloves, butyronitrile gloves and latex gloves. The full-automatic glove counting and stacking machine comprises a glove assembly conveying line (1), a plurality of hand moulds (2) are hung on the lower portion of the glove assembly conveying line (1), and gloves are arranged on the surfaces of the hand moulds (2) in a sleeved mode in the conveying process. The full-automatic glove counting and stacking machine is characterized in that a glove picking device (3) and a power device (5) are arranged below the glove assembly conveying line (1), a glove conveying table (4) with an inclined conveying face is arranged on one sides of the glove picking device (3) and the power device (5), the power device (5) drives the glove conveying table (4) and the glove picking device (3) to work at the same time, a detection device (6) is arranged at the output end of the glove conveying table (4), and the rear portion of the detection device (6) is connected with a glove storing table (7). The full-automatic glove counting and stacking machine is simple in structure, high in efficiency, free of cylinder control, convenient to maintain, and capable of achieving glove picking, detecting, conveying, and stacking functions.

Owner:ZIBO CHENGXUN AUTOMATION EQUIP

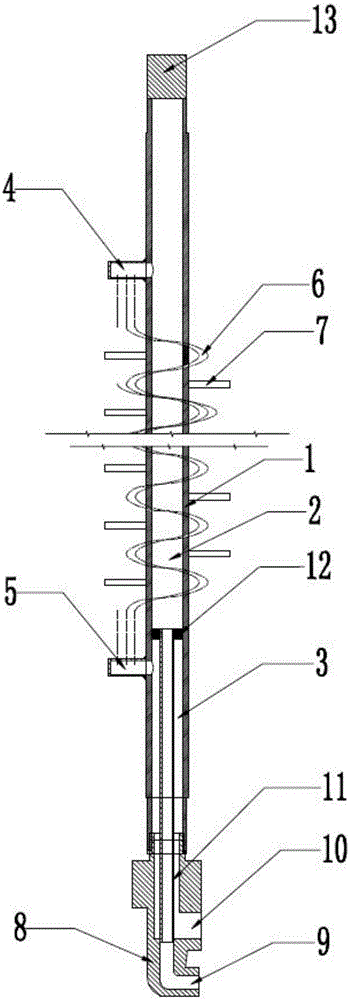

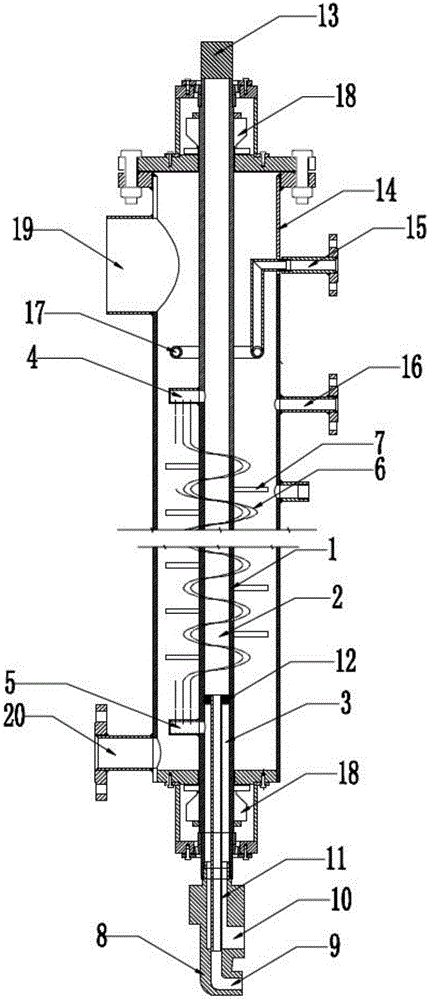

Novel heat exchange stirring shaft and tubular reactor

ActiveCN106179038ARealize the delivery functionStir wellRotary stirring mixersTransportation and packagingChemical reactionEngineering

The invention discloses a novel heat exchange stirring shaft, and belongs to the field of chemical reaction devices. The novel heat exchange stirring shaft comprises a main shaft, wherein a first chamber and a second chamber which are isolated from each other are formed in the main shaft; an opening is formed in each of the first and second chambers at one end of the main shaft; a first connecting pipe communicated with the first chamber is arranged on the main shaft; a second connecting pipe communicated with the second chamber is arranged on the main shaft; at least one spiral pipe for communication is arranged between the first and second connecting pipes. According to the novel heat exchange stirring shaft, a heat exchange medium is introduced into an inner communicated pipeline area to implement heat exchange in a reactor; by a structure formed by spirally winding the main shaft with the spiral pipe, a function of stirring a reaction raw material is realized, and meanwhile, the reaction raw material is driven to be delivered to one end of the axial direction of the main shaft; a heat exchange pipeline can be in contact with the reaction raw material more fully by the rotary movement of stirring columns, so that the heat exchange efficiency is greatly improved.

Owner:HIMILE MECHANICAL MFG

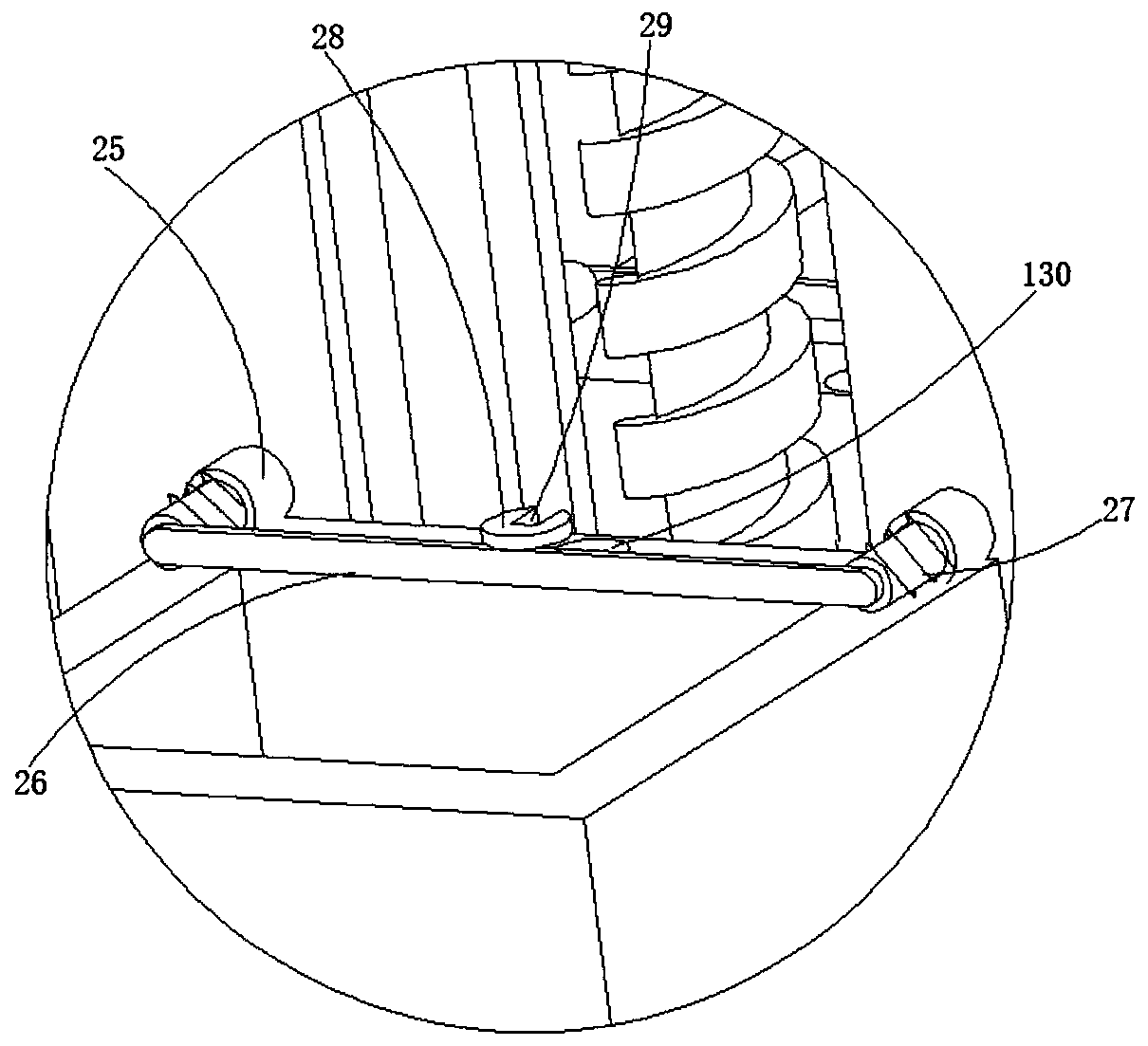

Vertical lifting type communication maintenance equipment

ActiveCN111005614AReduce the amount of work at heightImprove maintenance efficiencyTowersBuilding support scaffoldsElectric machineryDrive motor

The invention discloses vertical lifting type communication maintenance equipment, and belongs to the technical field of communication equipment. The vertical lifting type communication maintenance equipment comprises two oppositely-arranged stand columns, the opposite sides of the two stand columns are slidably connected with a lifting workbench, the top of the lifting workbench is fixedly connected with a first screw, the outer side walls, close to the top ends, of the stand columns are further provided with driving motors, the driving ends of the driving motors are connected with the lifting workbench through mooring ropes, the outer side walls, close to the top ends, of the stand columns are fixedly connected with symmetrically-distributed nut bases through supports, and a second screwis in threaded connection with the interior of each nut base. According to the vertical lifting type communication maintenance equipment, the automatic separation function of an outer communication box in the ascending process of the lifting workbench is achieved, the locking function of alignment embedding of the outer communication box is achieved through the dead weight of an inner communication box, the embedding stability of the outer communication box is improved, the excellent protection performance of the outer communication box is kept, the efficiency of high-altitude disassembling of the damaged communication box is improved, and the danger under high-altitude operation is reduced.

Owner:陕西通信规划设计研究院有限公司

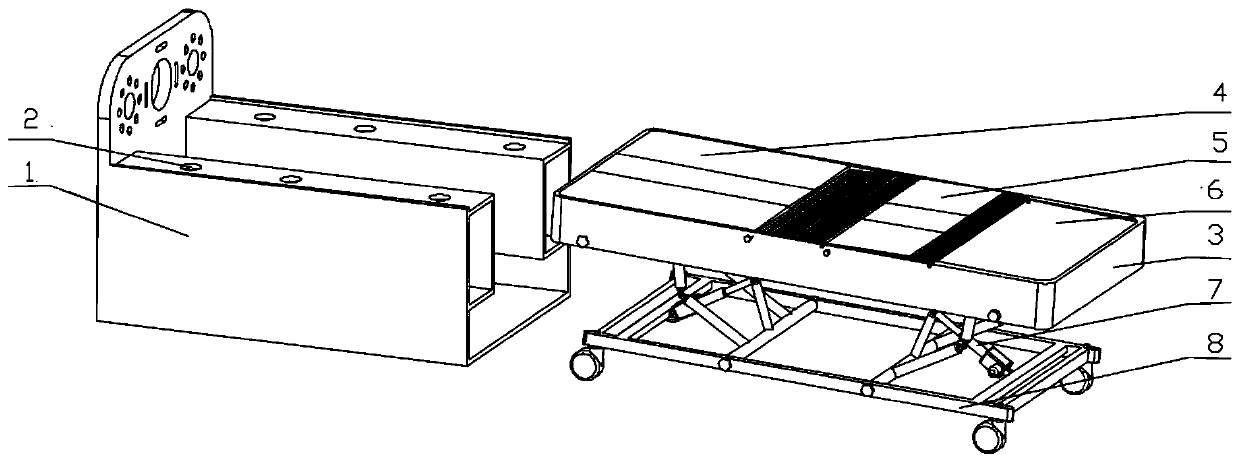

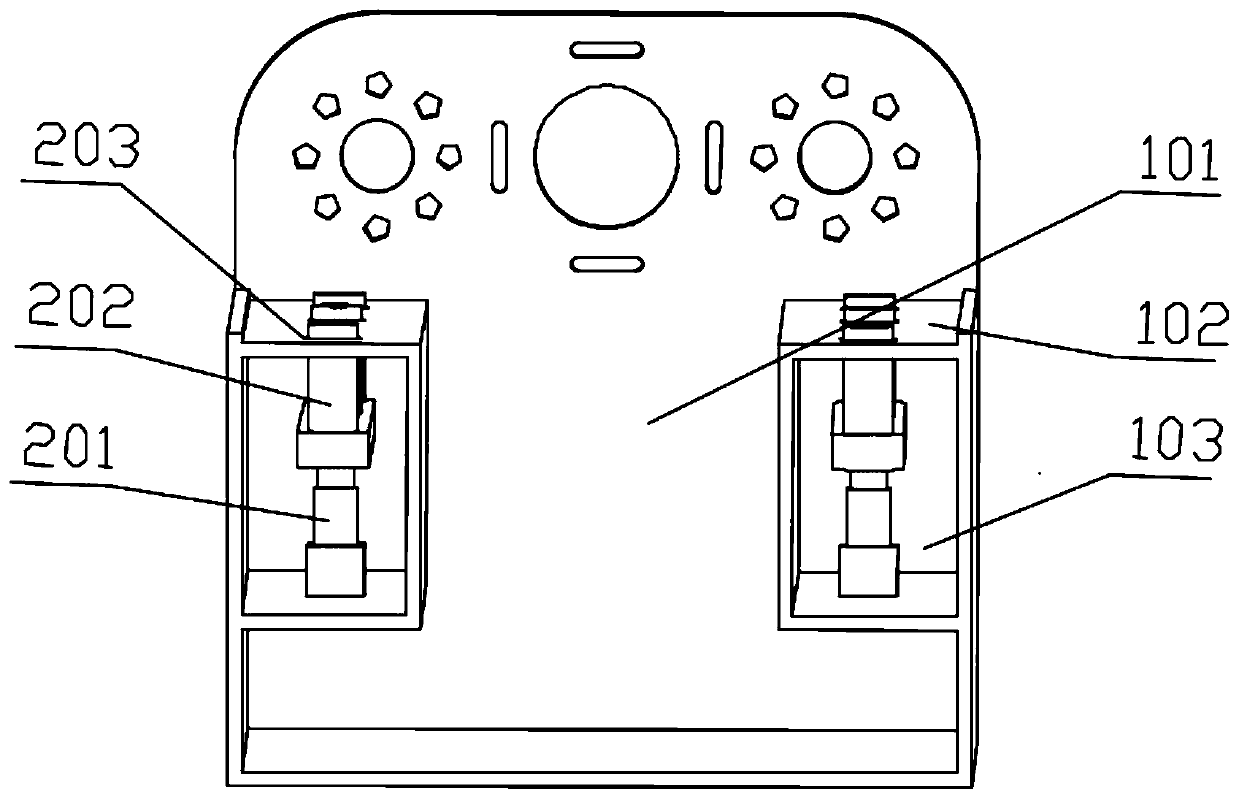

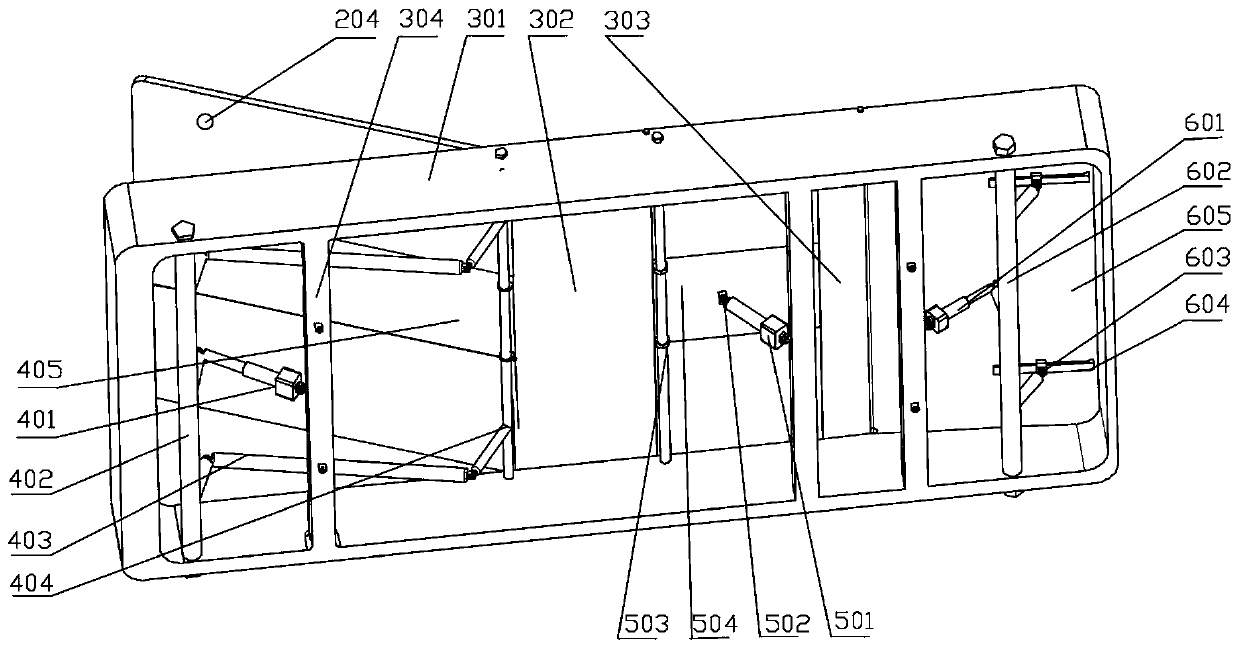

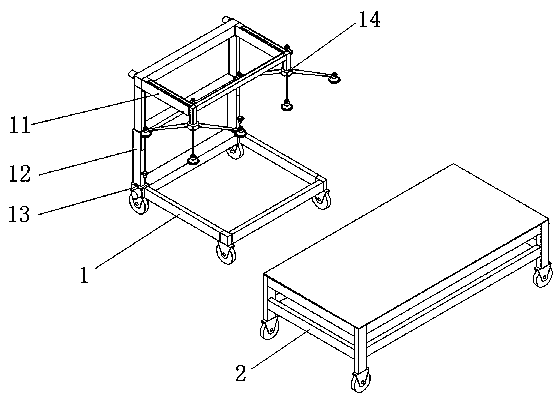

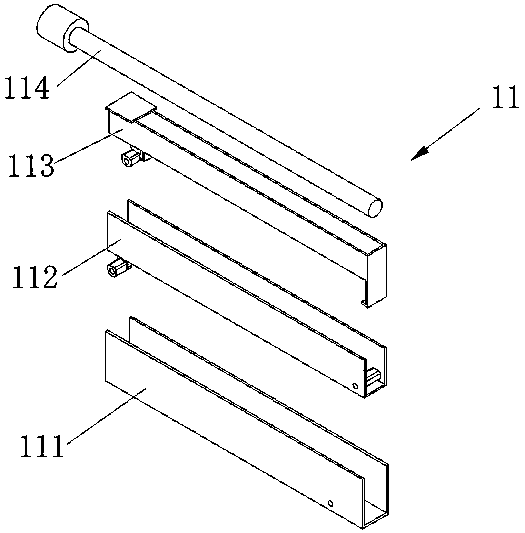

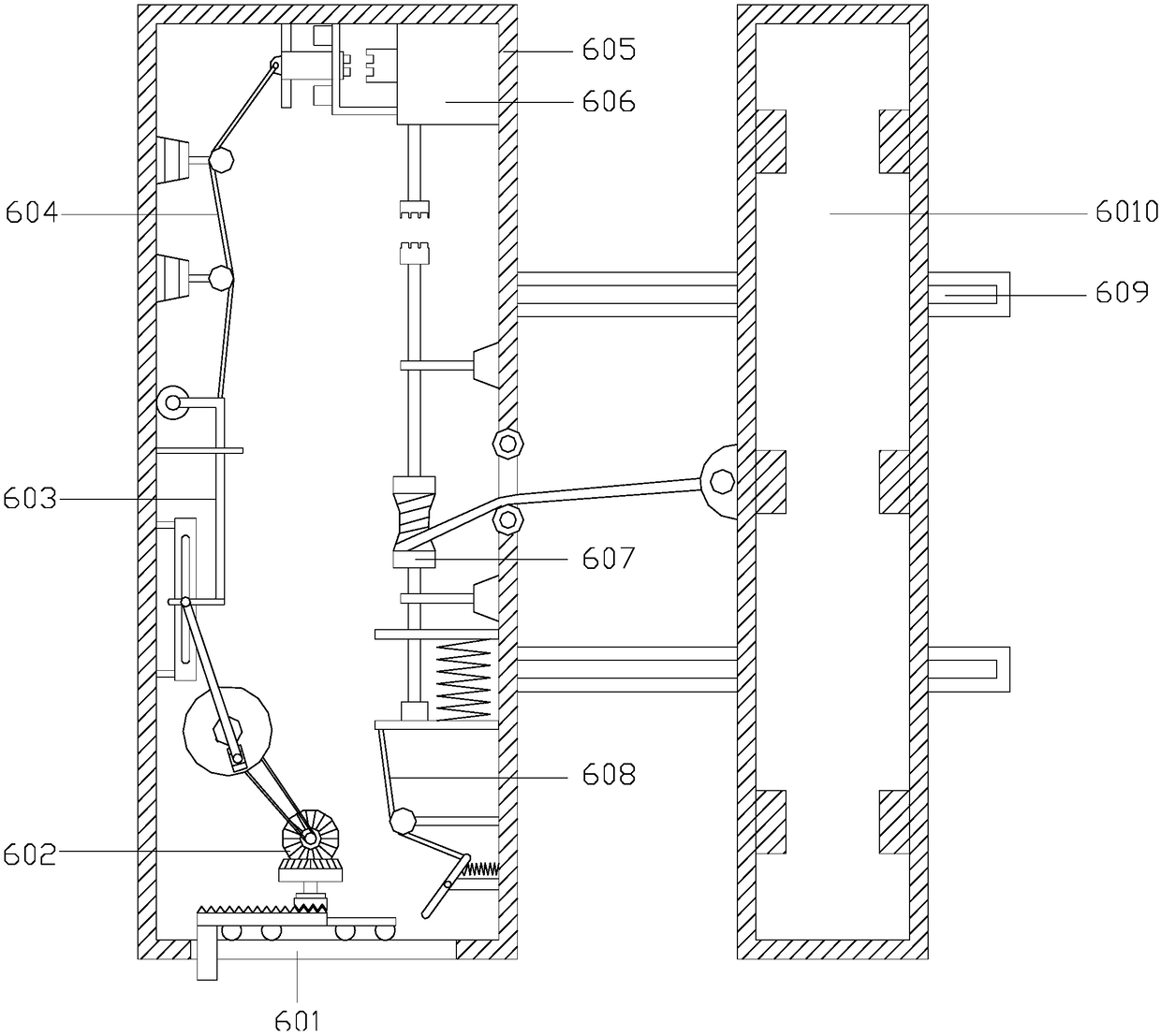

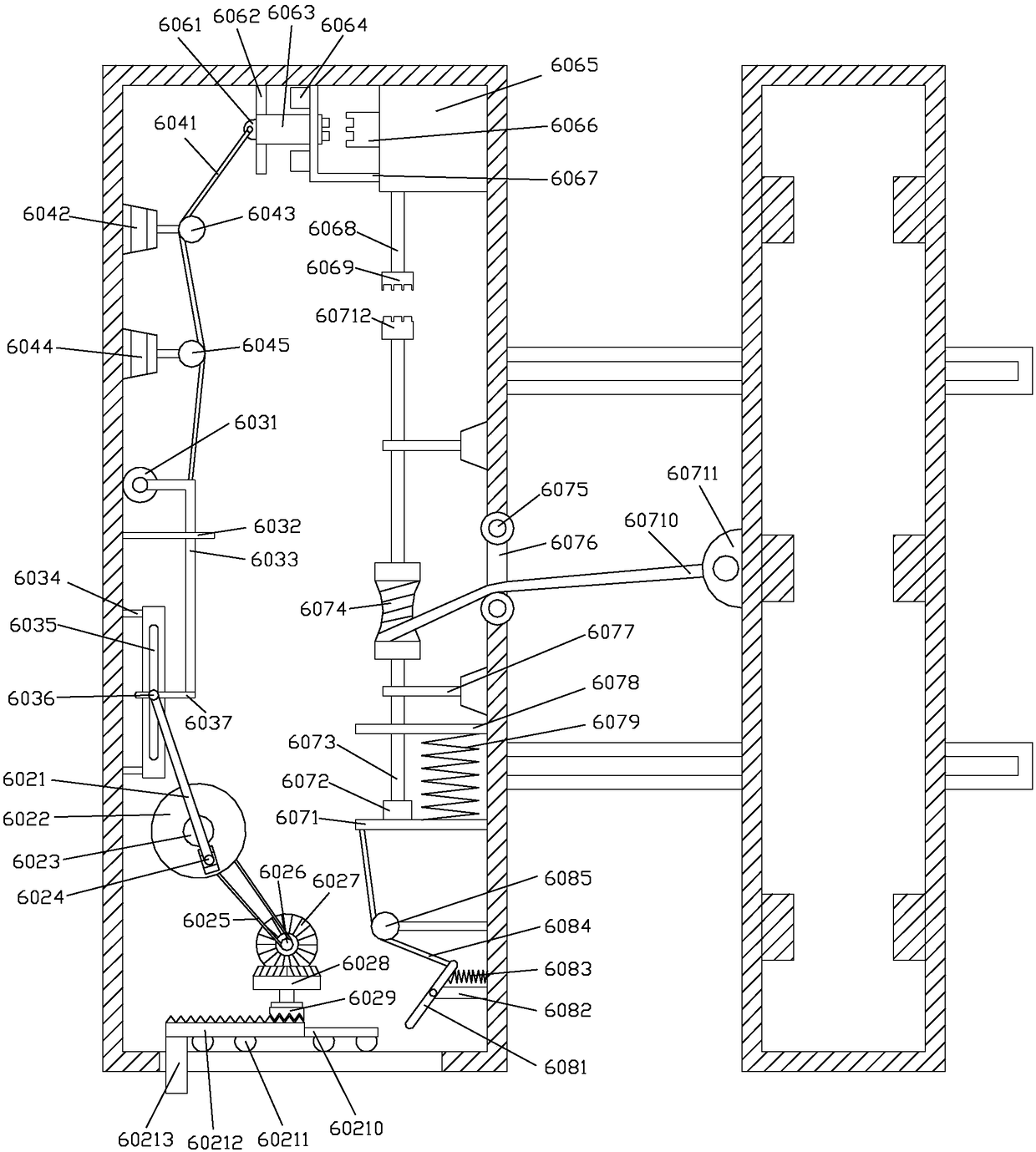

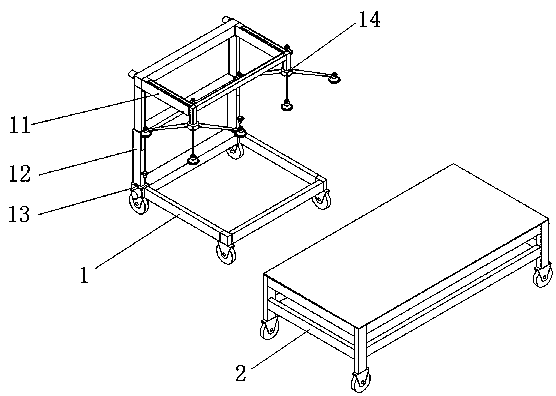

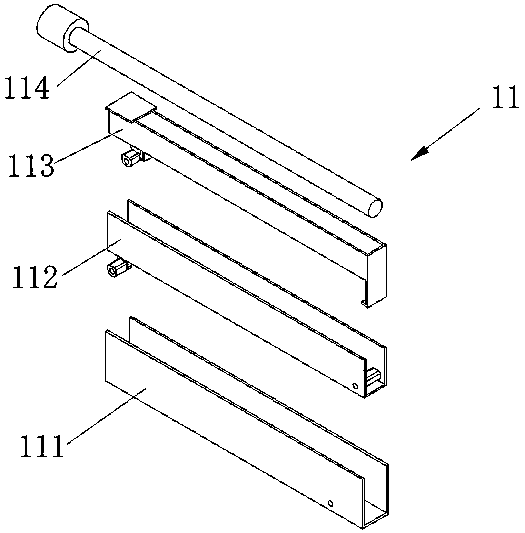

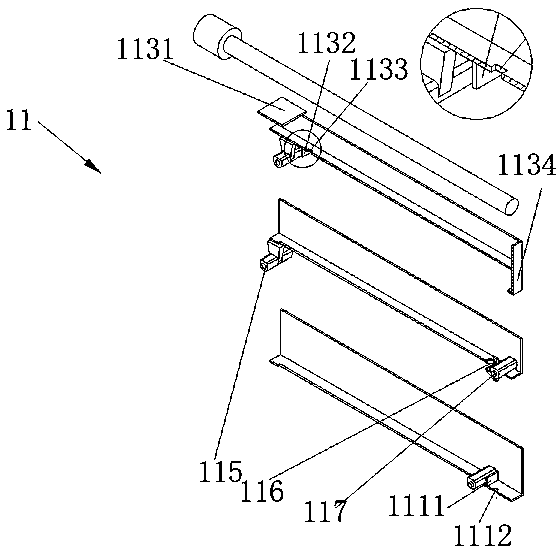

Separated type self-moving multifunctional nursing bed device

ActiveCN110063853ARealize the delivery functionReduce work intensityNursing bedsFixed bedEngineering

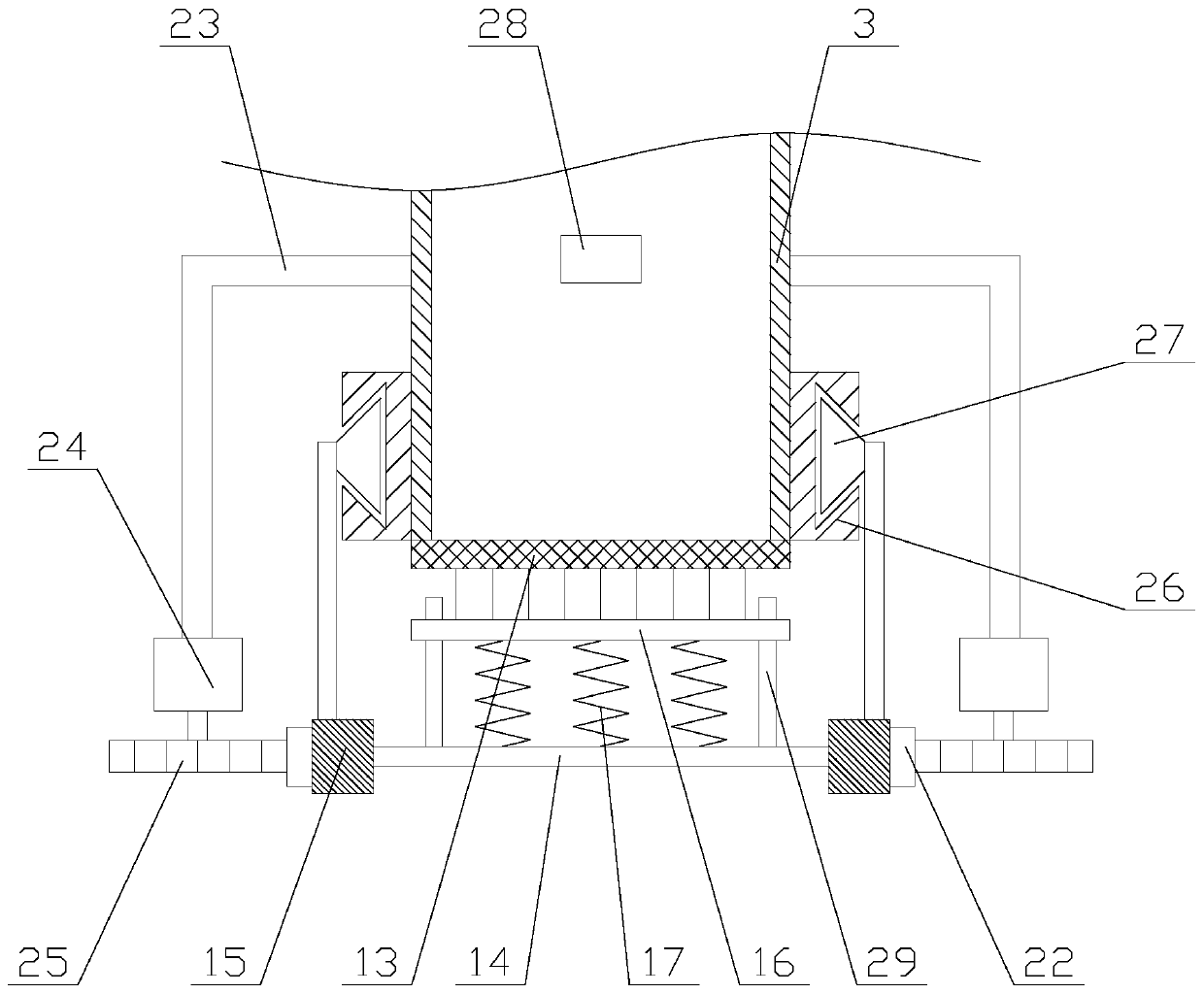

The invention relates to a separated type self-moving multifunctional nursing bed device. The bed device includes a fixed bed body and a movable bed body which are detachably connected, a side turn mechanism is installed in the fixed bed body and movably connected with the movable bed body, the movable bed body is provided with a movable bed board, the movable bed board includes a back lifting movable bed board body, a leg lifting movable bed board body and a leg bending movable bed board body which are sequentially arranged, the back lifting movable bed board body is correspondingly providedwith a back lifting mechanism, the leg lifting movable bed board body is correspondingly provided with a leg lifting mechanism, and the leg bending movable bed board body is correspondingly provided with a leg bending mechanism. The bottom of the movable bed board body is provided with a lifting mechanism and a moving and steering mechanism, and the lifting mechanism is arranged on the moving andsteering mechanism. Compared with the prior art, the nursing bed device has the advantages of having multiple functions, being convenient to use, flexible to adjust and able to reduce the work intensity of nurses and the like.

Owner:SHANGHAI UNIV OF MEDICINE & HEALTH SCI +1

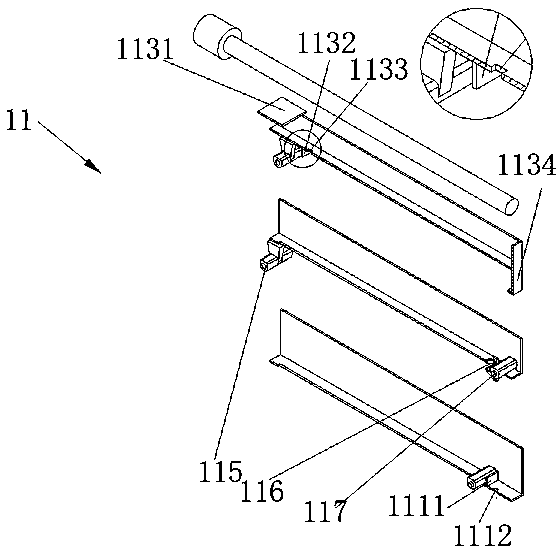

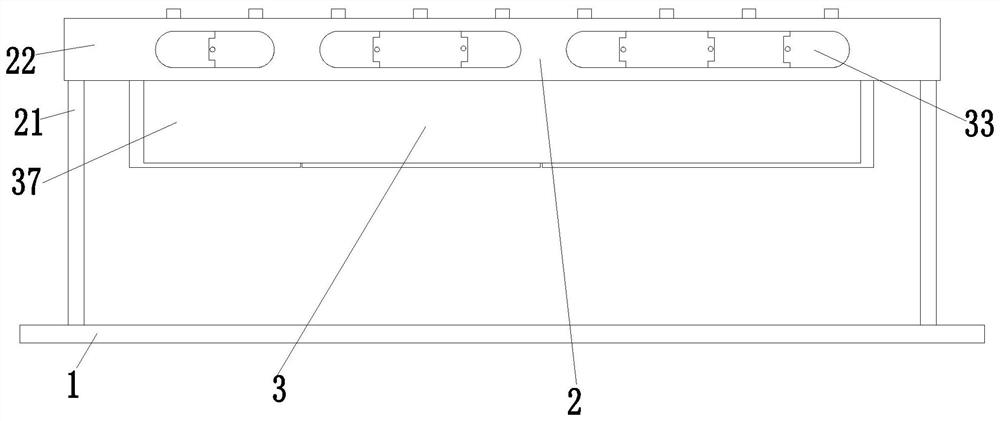

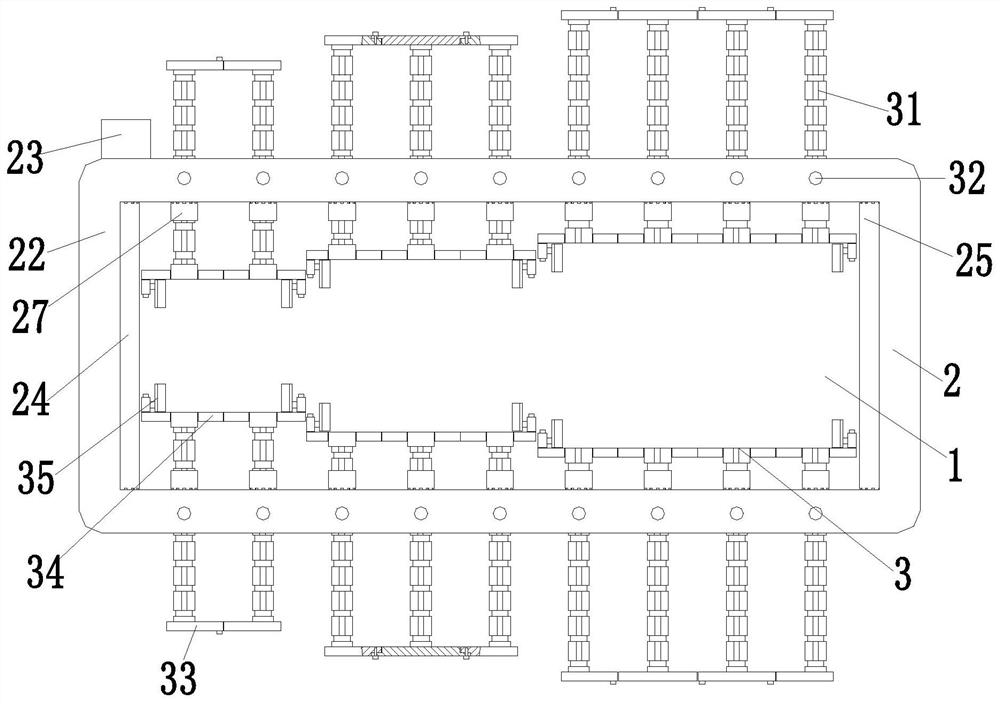

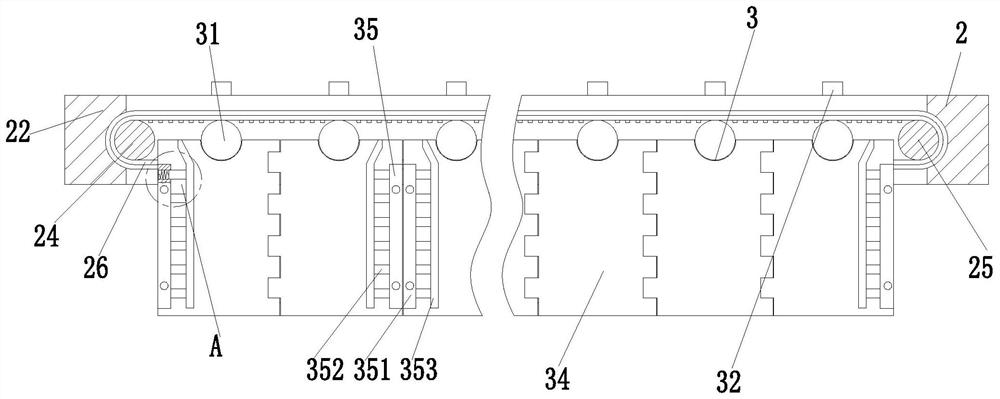

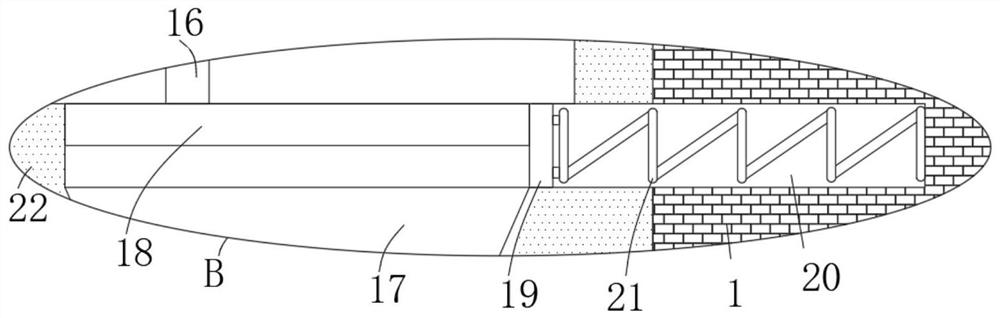

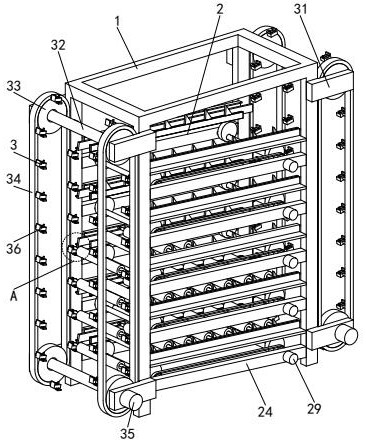

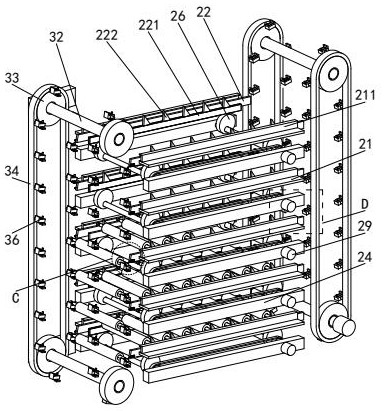

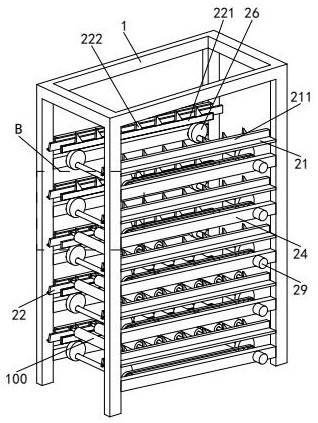

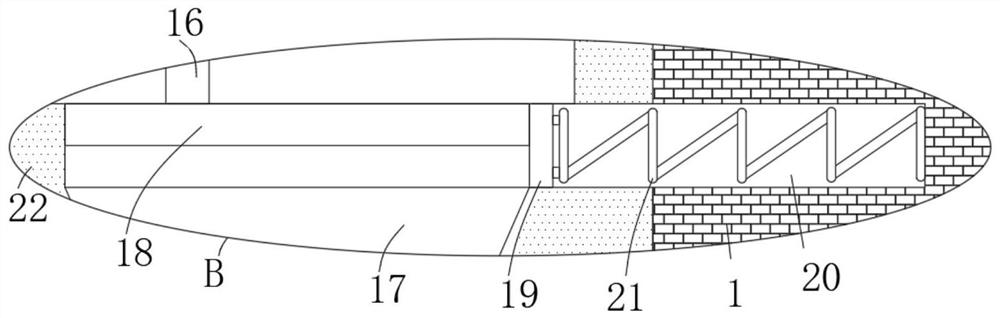

Plate conveying device

ActiveCN109795881ARealize the delivery functionSimple structureStacking articlesDe-stacking articlesEngineeringMechanical engineering

Owner:李传聪

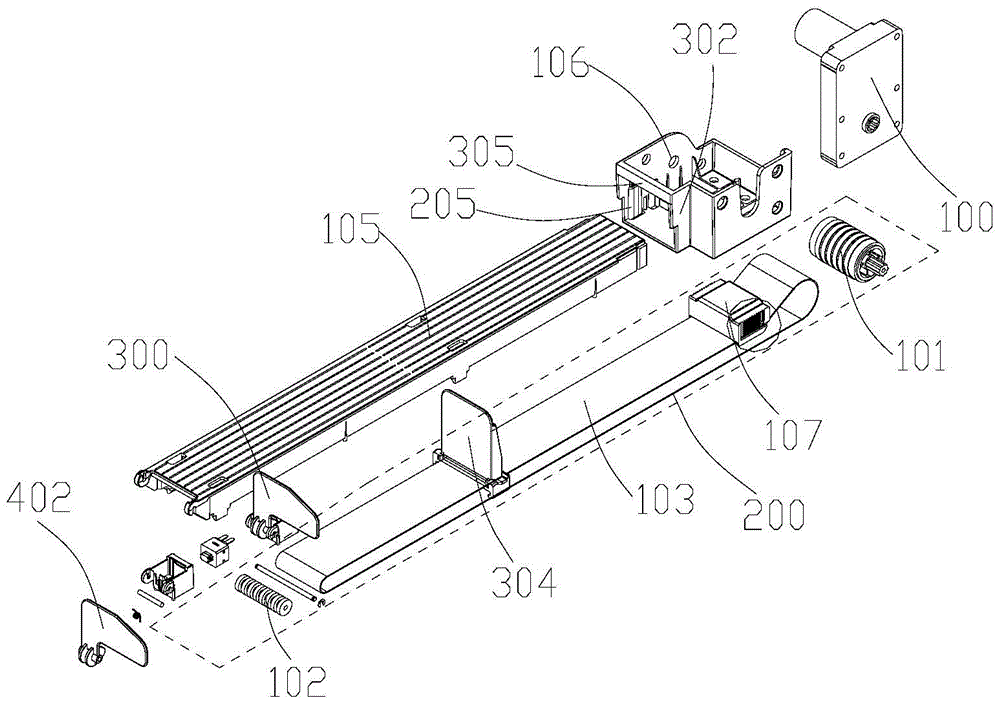

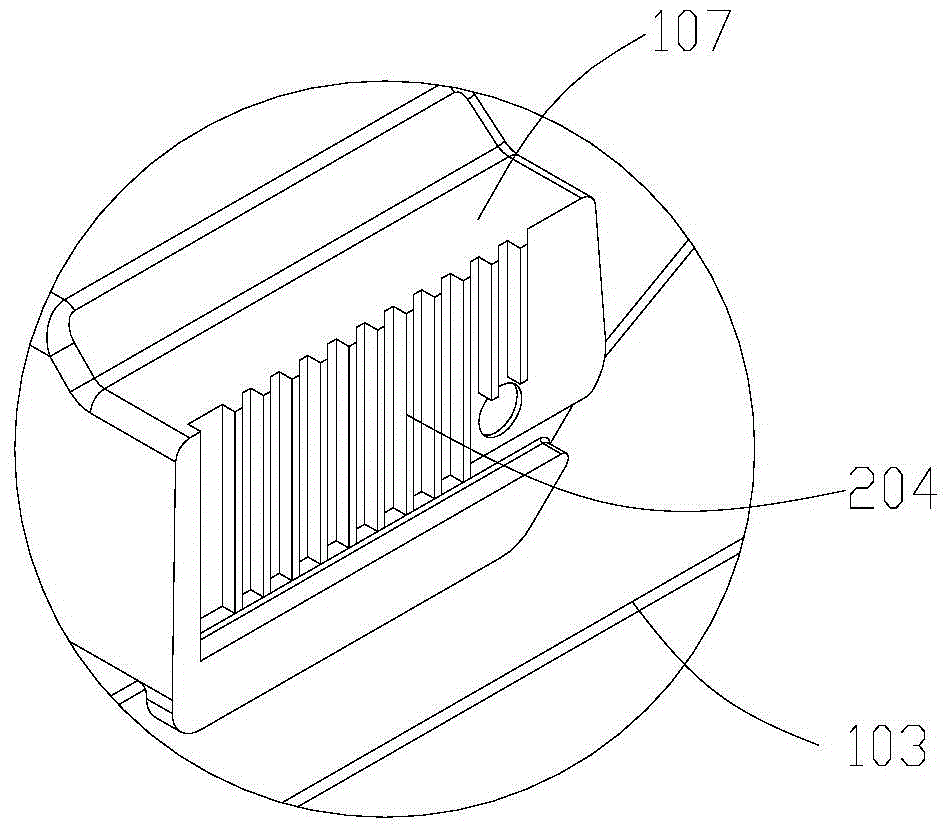

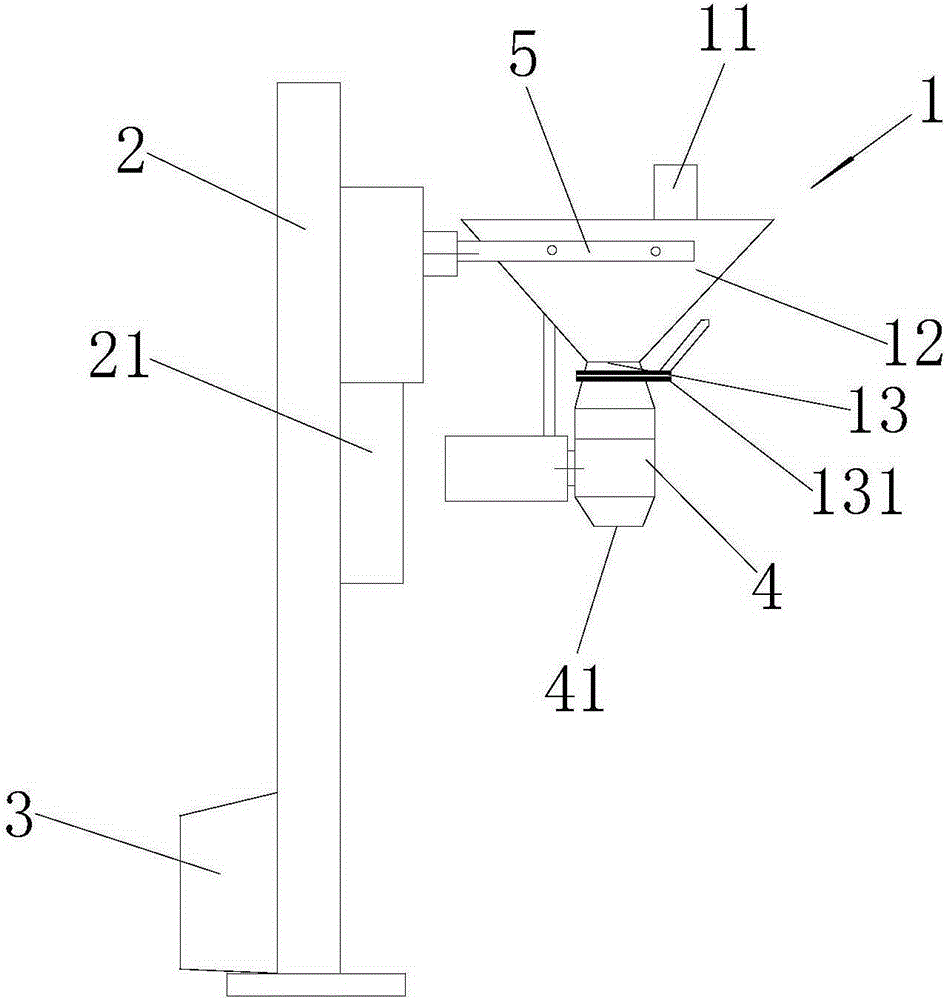

Feeding device and automatic vending machine

ActiveCN105719396ASimple structureEasy to processCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringPower unit

The invention provides a feeding device and an automatic vending machine, and belongs to the technical field of automatic vending equipment. The feeding device comprises a power unit, a conveying unit and an adjustment unit, wherein the conveying unit comprises a driving wheel, a driven wheel and a conveying belt; the driving wheel is connected with the driven wheel through the conveying belt; the output end of the power unit is connected with the input end of the driving wheel and is used for driving the driving wheel to rotate to make the conveying belt rotate synchronously; the adjustment unit is positioned on the conveying belt; the adjustment unit is used for adjusting a contact area between the conveying belt and the wheel surface of the driving wheel. The automatic vending machine comprises the feeding device. The feeding device is convenient to mount; the drive mode is simple and reliable, and the energy loss is low; in the material conveying process, looseness between the conveying belt and the driving wheel can be adjusted to prevent slippage between the conveying belt and the driving wheel in the operating process, so that motion of the conveying belt is facilitated.

Owner:GUANGZHOU BAODA COMP SOFTWARE

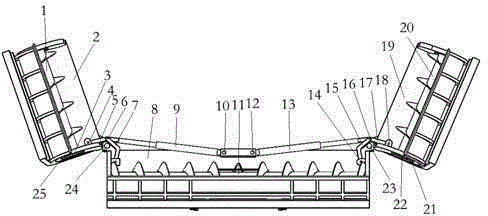

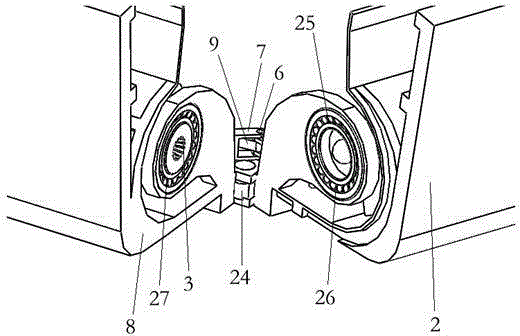

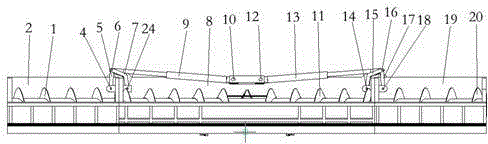

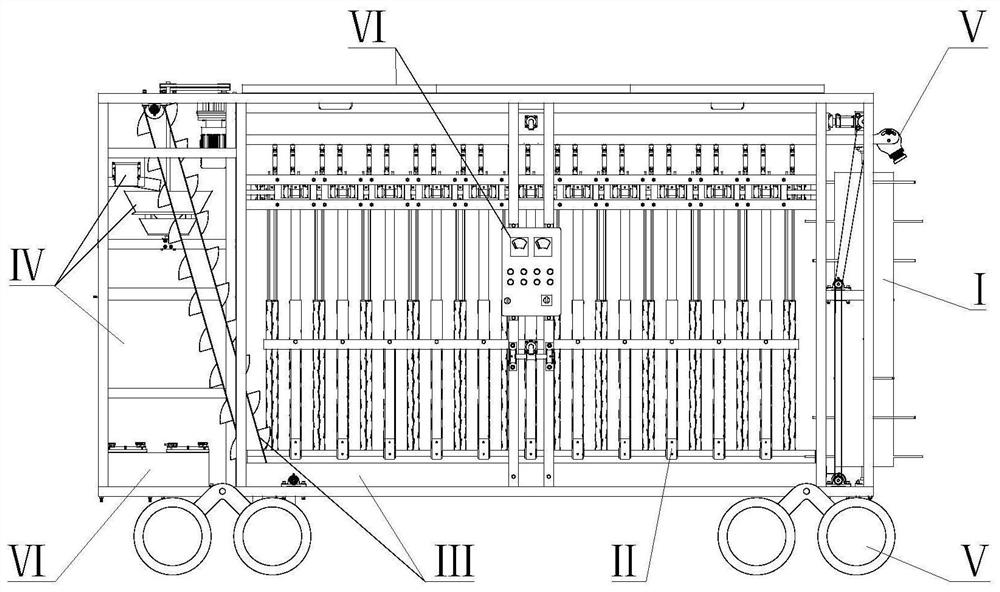

Folding corn header and docking mechanism thereof

The invention discloses a folding corn header and a docking mechanism thereof, and belongs to the technical field of machine manufacturing. The folding corn header and the docking mechanism thereof aim at solving the problem that in the prior art, the harvesting efficiency is low. The folding corn header and the docking mechanism thereof comprise a first conveying hopper, a second conveying hopper, a third conveying hopper, a connecting arm mechanism, ball-tooth type couplings and bearings; the first conveying hopper is provided with a first packing auger; the second conveying hopper is provided with a second packing auger and a hydraulic cylinder mechanism; the third conveying hopper is provided with a third packing auger; the first packing auger is connected with the second packing auger in a matched mode through the first ball-tooth type coupling; the second packing auger is connected with the third packing auger in a matched mode through the second ball-tooth type coupling; the connecting arm mechanism comprises four connecting arms which are connected with the first conveying hopper, the second conveying hopper and the third conveying hopper. The folding corn header and the docking mechanism thereof are ingenious in design, low in cost, high in efficiency, convenient to transport and high in harvesting efficiency.

Owner:UNIV OF JINAN

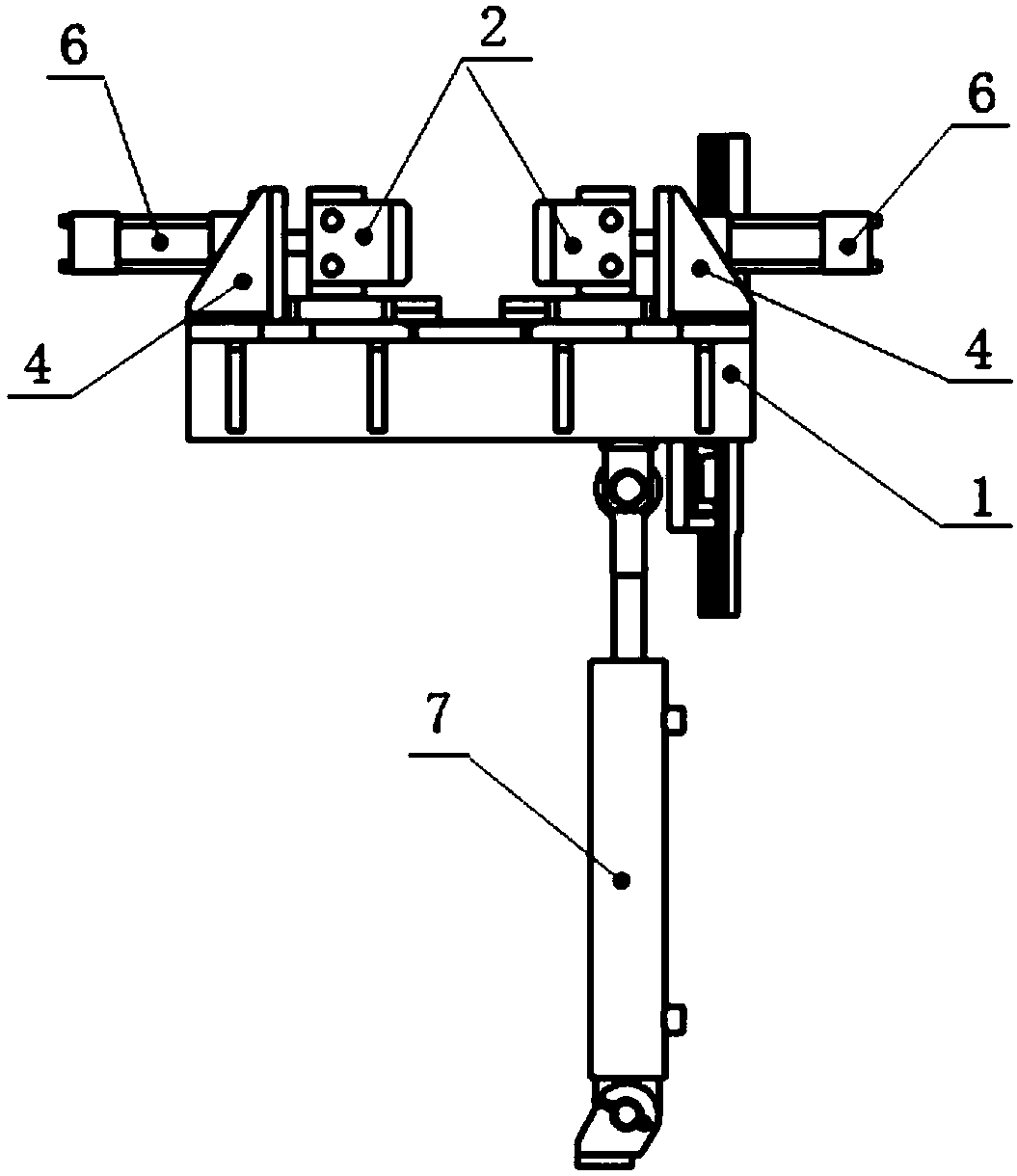

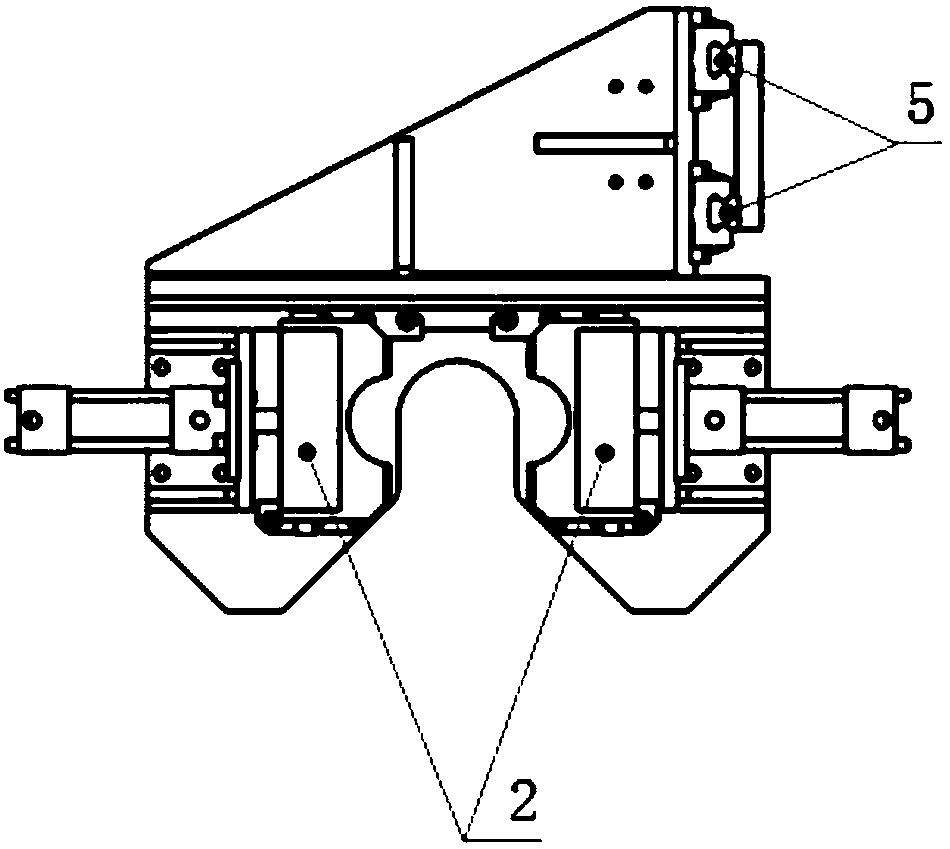

Straightening clamping conveying device

PendingCN107939315ARealize guidanceRealize the clamping functionDrilling rodsDrilling casingsMechanical engineeringPiston rod

The invention discloses a guiding and clamping conveying device, which comprises a mounting bracket, a clamping sleeve, a clamping sleeve seat, a linear guide rail, a clamping oil cylinder and a jacking oil cylinder, and the two clamping sleeves are oppositely installed on the clamping sleeve seat respectively. On the top, the clamping cylinder is fixed on the installation bracket through the clamping cylinder bracket, the piston rod of the clamping cylinder is connected with the clamping sleeve seat, and the clamping cylinder pushes and pulls the clamping sleeve to realize clamping and loosening; the upper end of the jacking cylinder is installed At the bottom of the mounting bracket, the lower end of the jacking cylinder is installed on the hydraulic pipe wrench workbench through the jacking cylinder mount. The invention can realize the guiding, clamping and conveying functions of the oil pipe, improve the accuracy of the wellhead alignment, increase the service life of the oil pipe, reduce the deviation of the oil pipe, hydraulic pipe wrench and the wellhead on a straight line, and save make-up and unloading. Deduction of time, improve work efficiency.

Owner:SENIOR AI EQUIP CO LTD

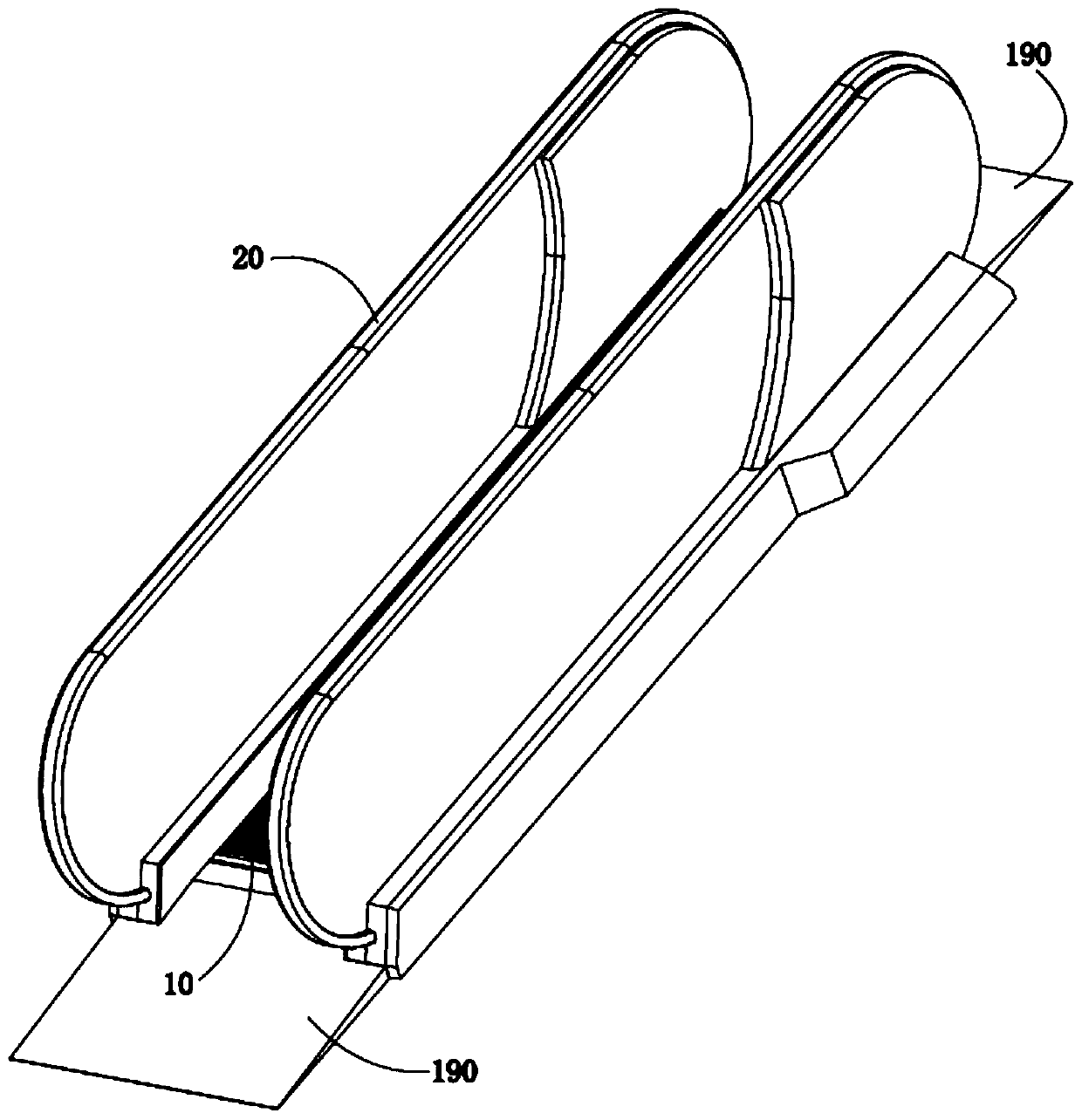

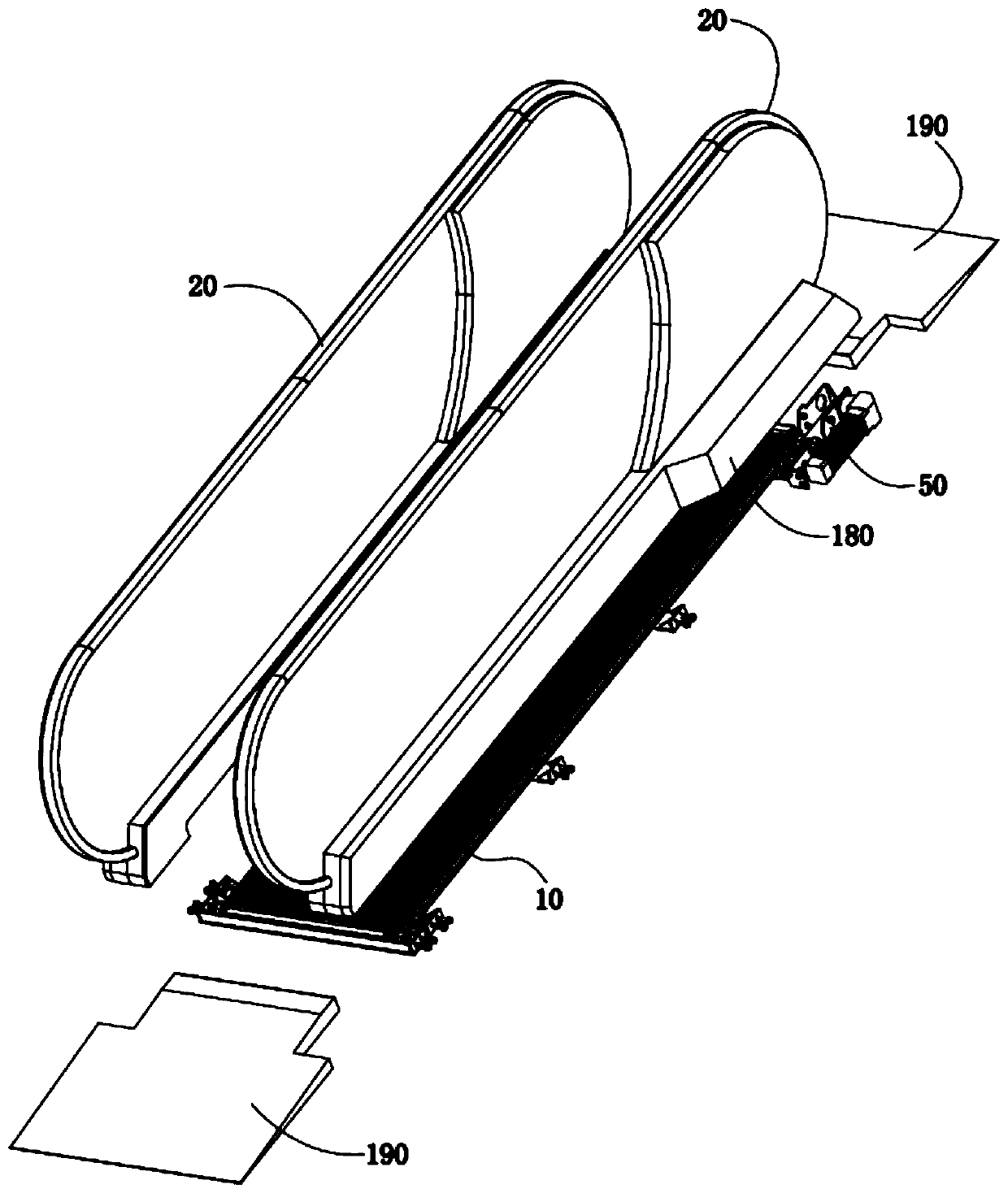

Automatic sidewalk

The invention discloses an automatic sidewalk. The sidewalk comprises a pedal assembly, a handrail belt assembly and a transmission mechanism, the transmission mechanism comprises a first conveying mechanism, and a second conveying mechanism and a driving device for synchronously driving the first conveying mechanism and the second conveying mechanism; the first conveying mechanism comprises a driving shaft and a driven shaft which are arranged at intervals in parallel, and a plurality of sets of chain wheel assemblies are arranged between the driving shaft and the driven shaft, the driving shaft is connected with the driving device; and each chain wheel assembly comprises a driving chain wheel arranged on the driving shaft, a driven chain wheel arranged on the driven shaft, and a chain matched with the driving chain wheel and the driven chain wheel; the chain comprises a plurality of outer chain plates, the outer sides of outer chain plates are connected with mounting pieces; and thepedal assembly comprises a plurality of pedals, and pedals are fixedly connected with mounting pieces. The automatic sidewalk has the advantages that the structure is simple and reliable, the thickness of the transmission mechanism can be effectively reduced, the occupied space is small, the construction is simple, and the production cost is reduced.

Owner:SHENZHEN SHENGSHI ELEVATOR CO LTD

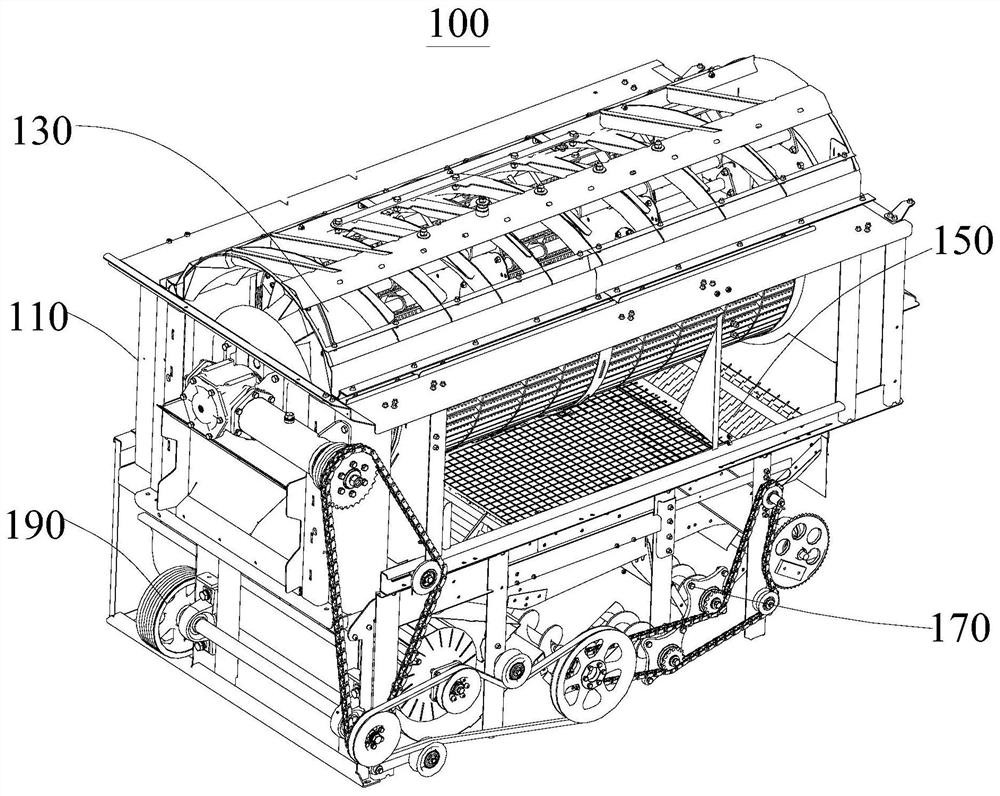

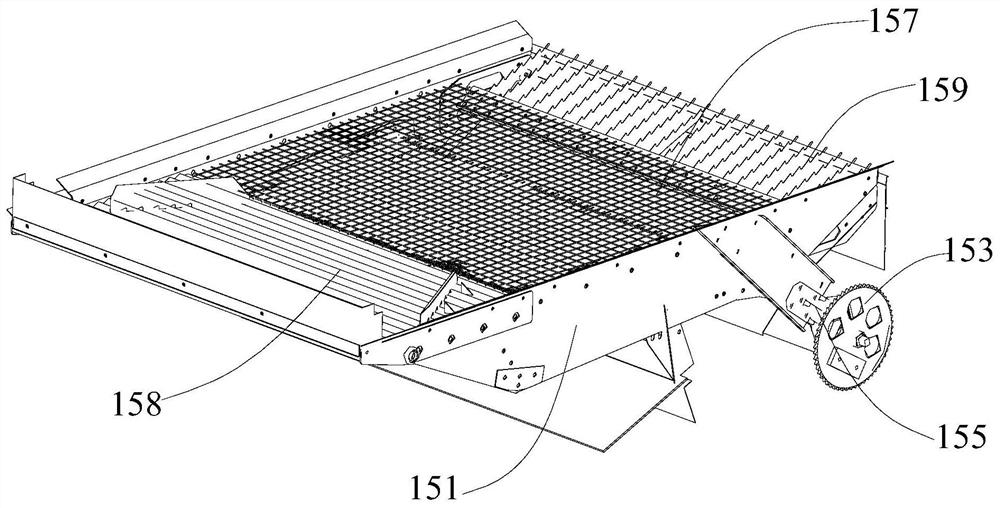

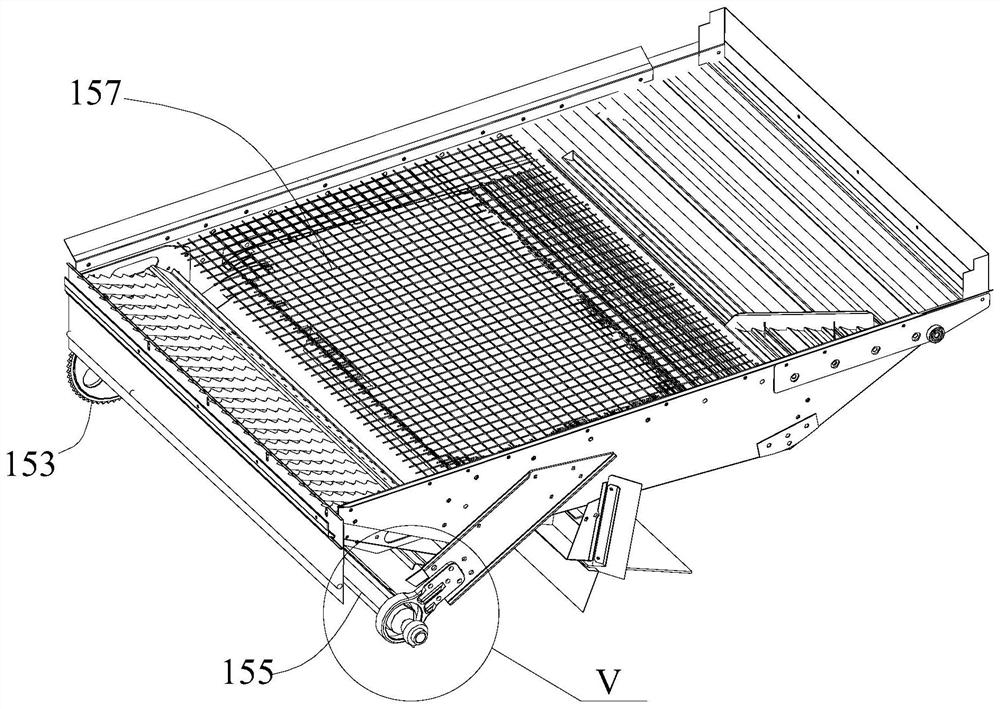

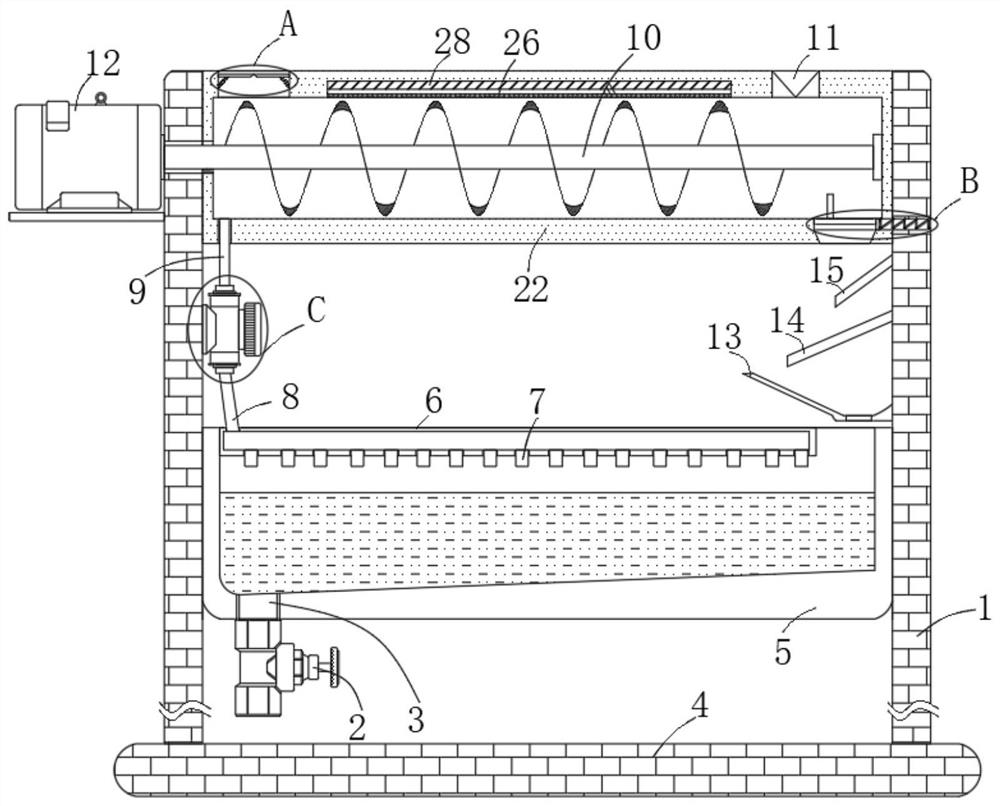

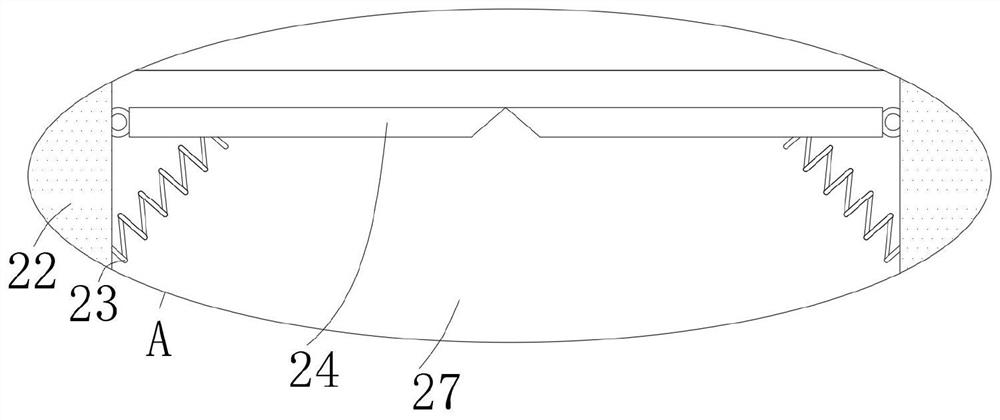

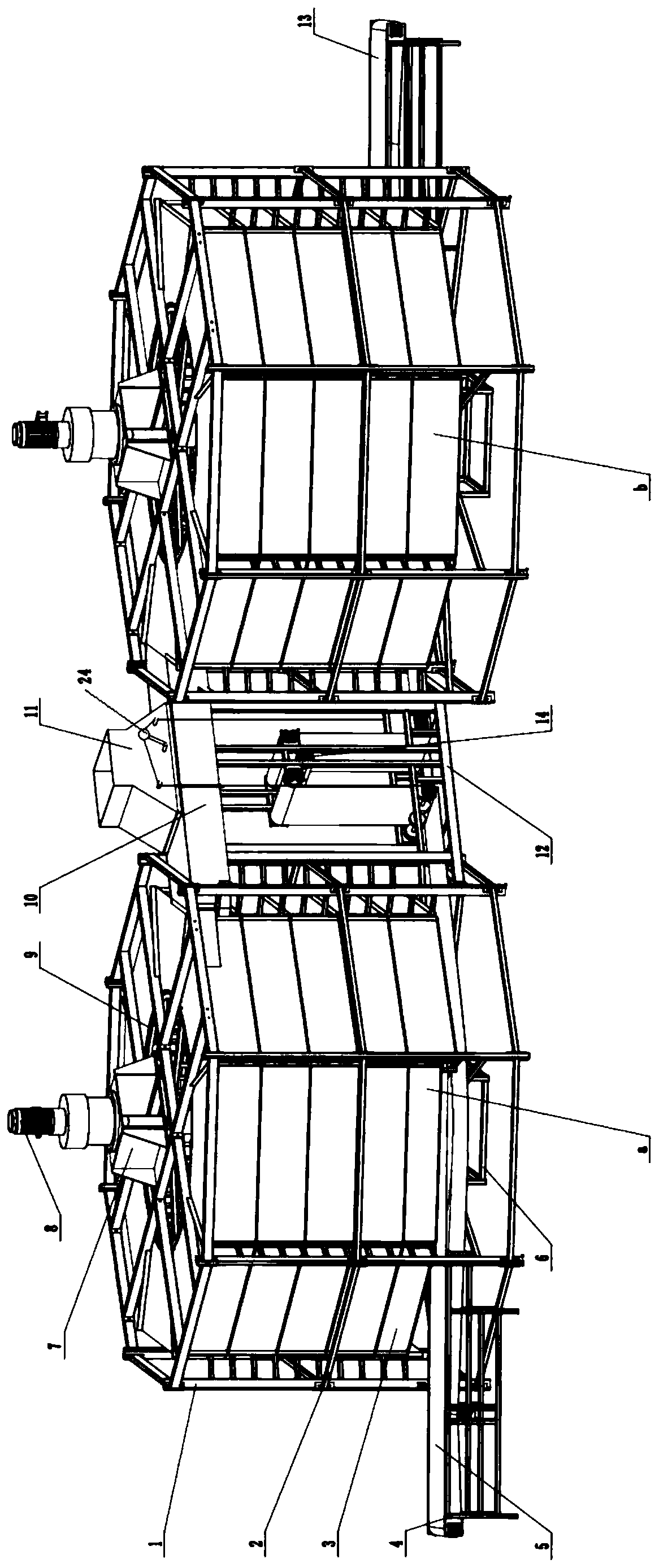

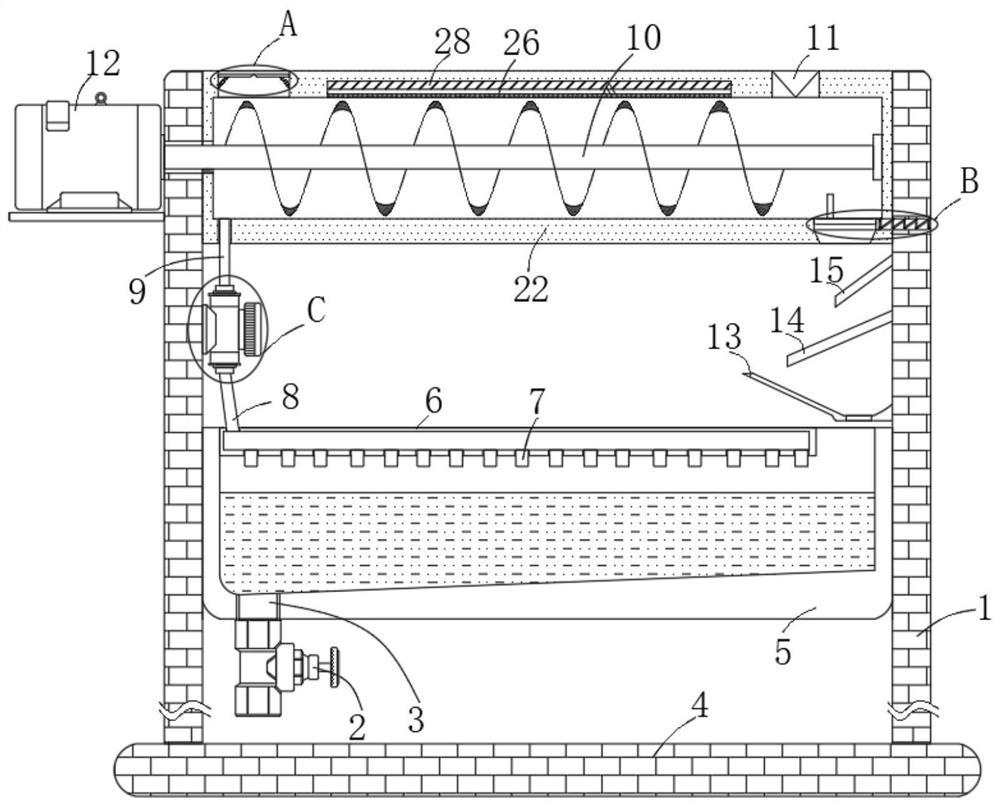

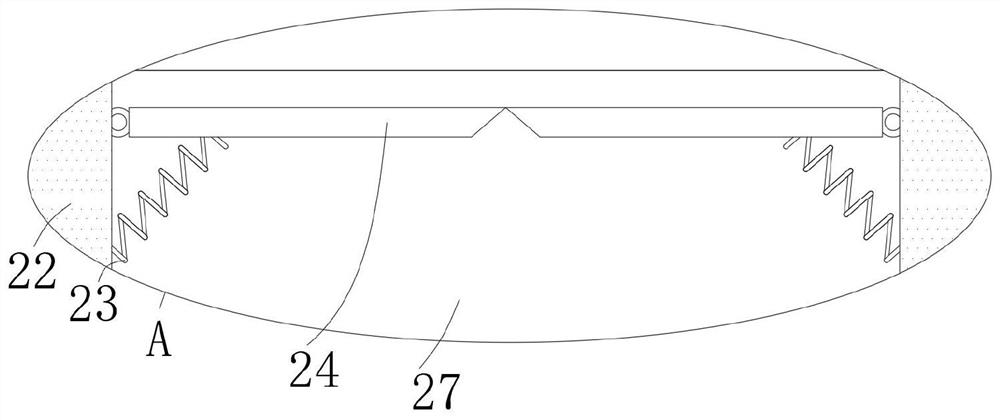

Seed threshing and cleaning device

PendingCN111742717AReduce impurityThreshing achievedThreshersAgricultural scienceAgricultural engineering

The embodiment of the invention provides a seed threshing and cleaning device, and relates to the field of agricultural machinery. The seed threshing and cleaning device comprises a rack, a roller threshing mechanism, a vibration screening mechanism, a material conveying mechanism and a driving mechanism, wherein the roller threshing mechanism is arranged at the top of the rack, the vibration screening mechanism is arranged in the middle of the rack and located below the roller threshing mechanism, the material conveying mechanism is arranged at the bottom of the rack and located below the vibration screening mechanism, and the driving mechanism is arranged on one side of the rack and is in transmission connection with the roller threshing mechanism, the vibration screening mechanism and the material conveying mechanism. Compared with the prior art, the seed threshing and cleaning device can achieve the function of threshing, cleaning and conveying forage grass seed; and meanwhile, thecleaning effect can be improved by adopting a multi-layer vibration woven screening mode, and the rate of impurities in the seeds is low.

Owner:GRASSLAND RES INST OF CHINESE ACAD OF AGRI SCI

Automatic identification and sorting device

The invention relates to an automatic identification and sorting device. The automatic identification and sorting device comprises a bottom plate, a conveyor and a sorting mechanism, the conveyor is arranged at the upper end of the bottom plate, the sorting mechanism is arranged at the lower end of the conveyor, and the sorting mechanism is installed on the conveyor. The conveyor comprises a support column, a frame body, a driving motor, a driving roller, a driven roller, a conveyor belt and a rotating cylinder. The sorting mechanism comprises a sorting rod, a positioning pin, a connecting plate, a guide plate, a limit frame, a connecting rod and a working plate. The automatic identification and sorting device completes the function of sorting packages according to the size through the cooperation of the conveyor and the sorting mechanism, the overall structure of the equipment is simple, the occupied area is small, the corresponding structure can be adjusted according to the size of the packages to be sorted, and the application scope of the equipment is expanded; and the packages can be guided and limited in the sorting process, the package turning over is avoided, and the integrity of fruits inside the packages is ensured.

Owner:保正(上海)供应链管理股份有限公司

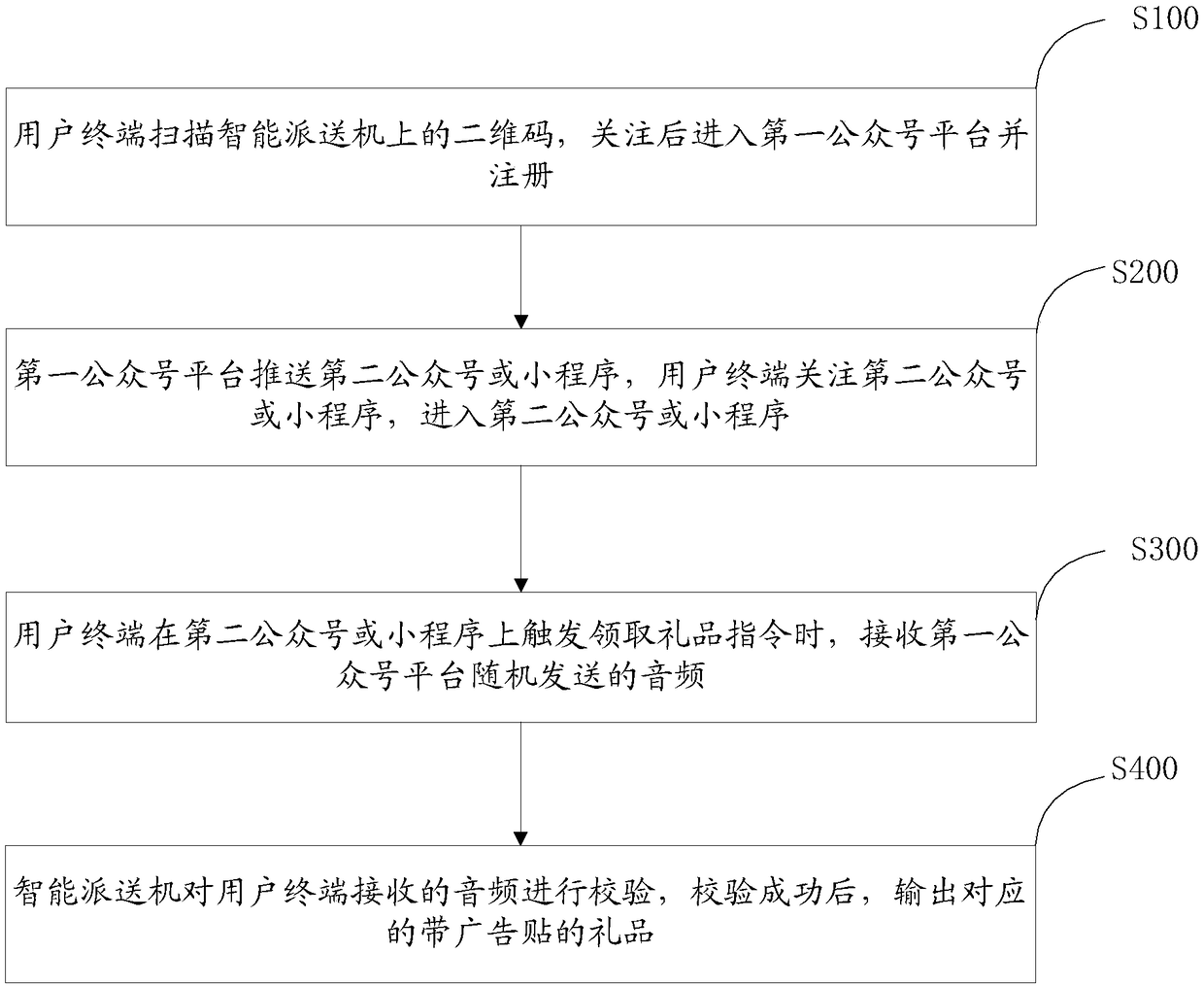

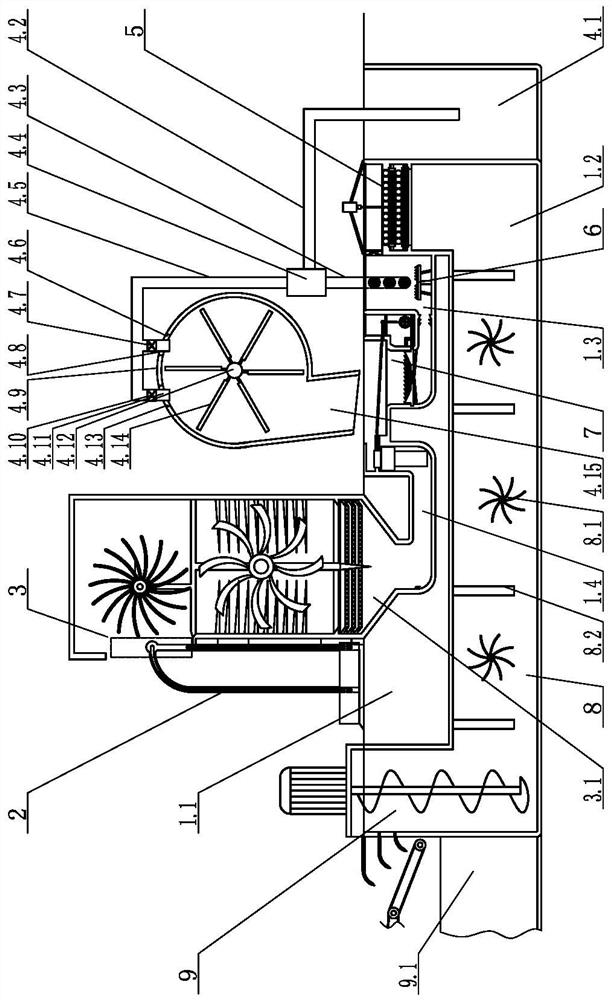

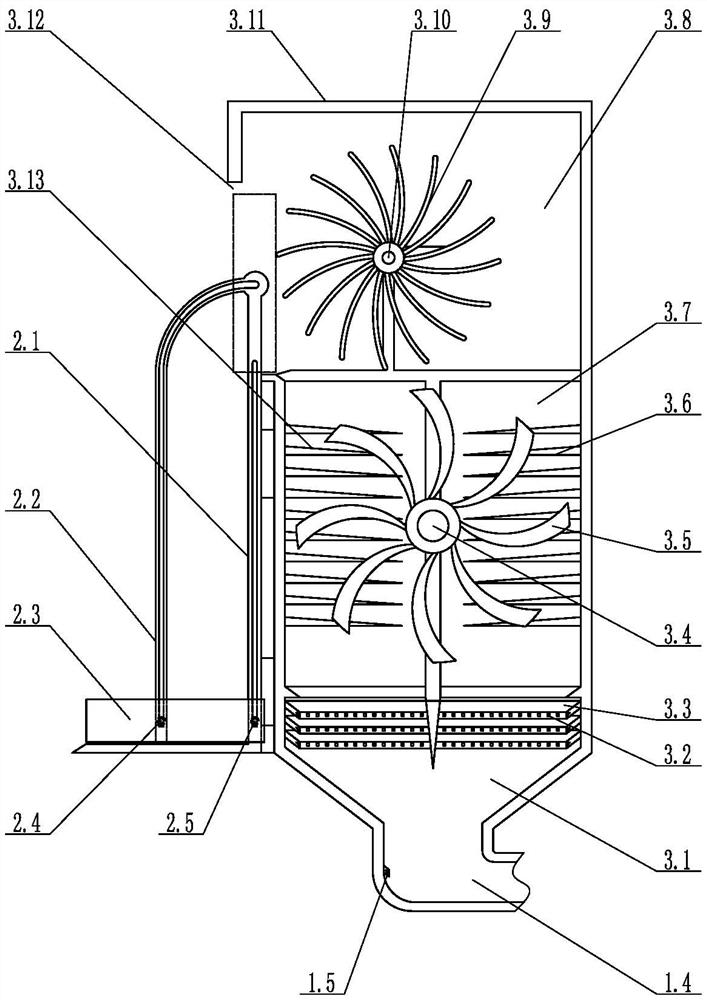

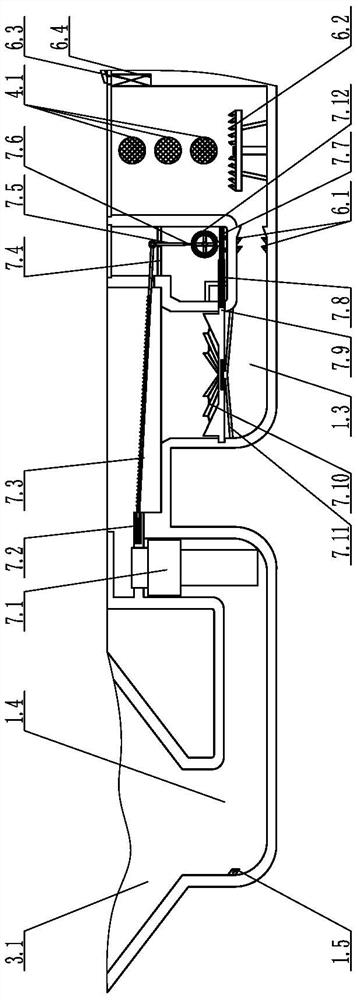

Method and system for setting intelligent delivery machine switch through following official account

InactiveCN108573400ARealize the function of gift deliveryRealize the delivery functionAdvertisementsWorld Wide Web

The invention discloses a method and a system for setting an intelligent delivery machine switch through following an official account. The method comprises the following steps that a user terminal scans a two-dimensional code on an intelligent delivery machine, follows and enters into a first official account platform and registers; the first official account platform pushes a second official account or an applet, and the user terminal follows the second official account or the applet and enters into the second official account or the applet; when triggering a gift receiving instruction on the second official account or the applet, the user terminal receives an audio randomly sent by the first official account platform, and the intelligent delivery machine verifies the audio received by the user terminal; and after verification is successful, a corresponding gift with an advertisement post is output. In the invention, a gift delivery function is realized, simultaneously, an advertisement associated with a merchant and the official account are pushed to a user so that advertising promotion and drainage functions are realized.

Owner:深圳弘光中能科技有限公司

Efficient environment-friendly papermaking production line

ActiveCN112342811AQuality improvementReduce labor intensityWashing/displacing pulp-treating liquorsPaper recyclingPaper dustPapermaking

The invention relates to an efficient environment-friendly papermaking production line, belonging to the technical field of papermaking mechanical equipment. The efficient environment-friendly papermaking production line is characterized by comprising pulping equipment, wherein a feeding device of the pulping equipment can feed waste paper raw materials into a coarse crushing device; the coarse crushing device can crush the waste paper raw materials into coarse paper pulp; the coarse paper pulp is conveyed into a screening device through water flow assistance; the coarse paper pulp enters a pulp washing device after being screened and filtered by the screening device; and the pulp enters a fine grinding device after being cleaned by the pulp washing device, and enters a storage device after being finely ground by the fine grinding device. According to the invention, fine paper pulp can be finally obtained through automatic feeding, coarse crushing, paper material circulating and infiltrating, screening and paper scrap grinding and refining, and is stored for papermaking operation.

Owner:山东海天造纸机械有限公司

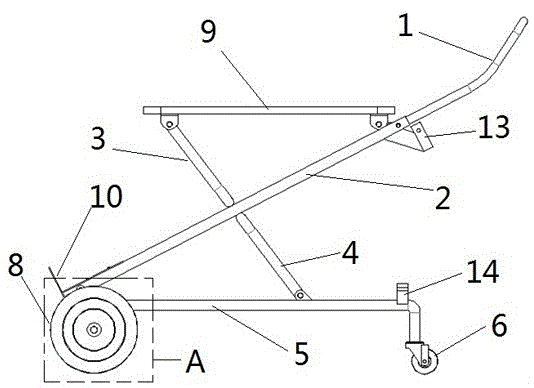

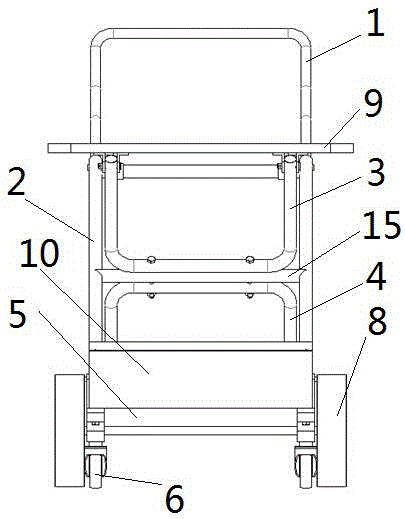

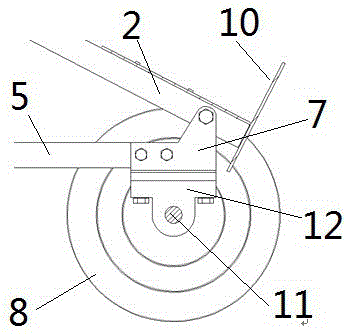

Multifunctional folded trolley

ActiveCN105416355ASimple working platformLabor-saving operationHand carts with multiple axesVehicle frameRoad condition

The invention discloses a multifunctional folded trolley which comprises a handle, a roll-over stand, an upper support rod, a lower support rod, a frame, a universal wheel, a front wheel bracket, a front wheel and a deck plate, wherein the lower end of the handle is connected with the upper end of the roll-over stand through a bolt; the lower end of the roll-over stand is connected with the front wheel bracket; the front wheel bracket is connected with the front end of the frame; the front wheel is installed on the front wheel bracket; the lower end of the upper support rod is detachably connected with the cross beam of the roll-over stand, the upper end of the upper support rod is connected with the front end of the deck plate through a pin shaft, and the rear end of the deck plate is connected with the upper end of the roll-over stand through a pin shaft; the upper end of the lower support rod is detachably connected with the cross beam of the roll-over stand, and the lower end of the lower support rod is connected with the middle part of the frame through a bolt; and the universal wheel is installed at the rear end of the frame. The multifunctional folded trolley disclosed by the invention is small in volume and convenient to operate; a transport mode can be selected according to the shape and weight of a transported material, the road condition and the like; and a deck can be folded and disassembled and can be used flexibly.

Owner:NAT UNIV OF DEFENSE TECH

Multifunctional electric power construction machine

InactiveCN108217298ARealize the take-up functionAchieve spacing adjustmentFilament handlingElectric machineryEngineering

The invention discloses multifunctional electric power construction machinery which structurally comprises a cable inlet roller, a cable inlet frame, a main conveyor, a transmission motor, a mountingplate, an adjusting device, a fixed bottom plate, a cable outlet frame, a cable outlet roller, an auxiliary conveyor and a conveying belt. The construction machinery has the advantages that the construction machinery is provided with the adjusting device, the adjusting device drives a first bevel gear and a second bevel gear through control of a handle in a main transmission mechanism, so that a second transmission mechanism releases a first transmission rope in a third transmission mechanism, a power plug in a driving device and a motor socket can be powered on to drive a driving roller and adriving clamping sleeve to rotate, a lifting mechanism drives a linkage shaft clamping sleeve to rise, the linkage shaft clamping sleeve and the driving clamping sleeve are driven in a sleeving manner, a winding function of a winding roller is achieved, a base of the auxiliary conveyor can move in a driving manner, cables with different thicknesses are conveniently conveyed, use functions are widened, adjusting convenience is greatly optimized, and use of workers is facilitated.

Owner:陈秀珍

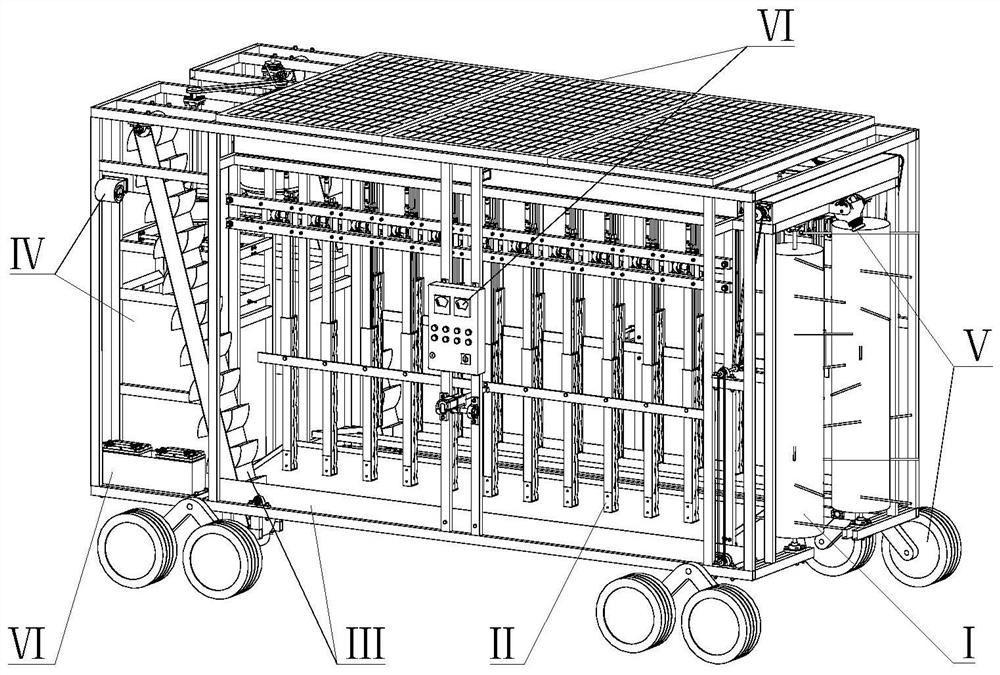

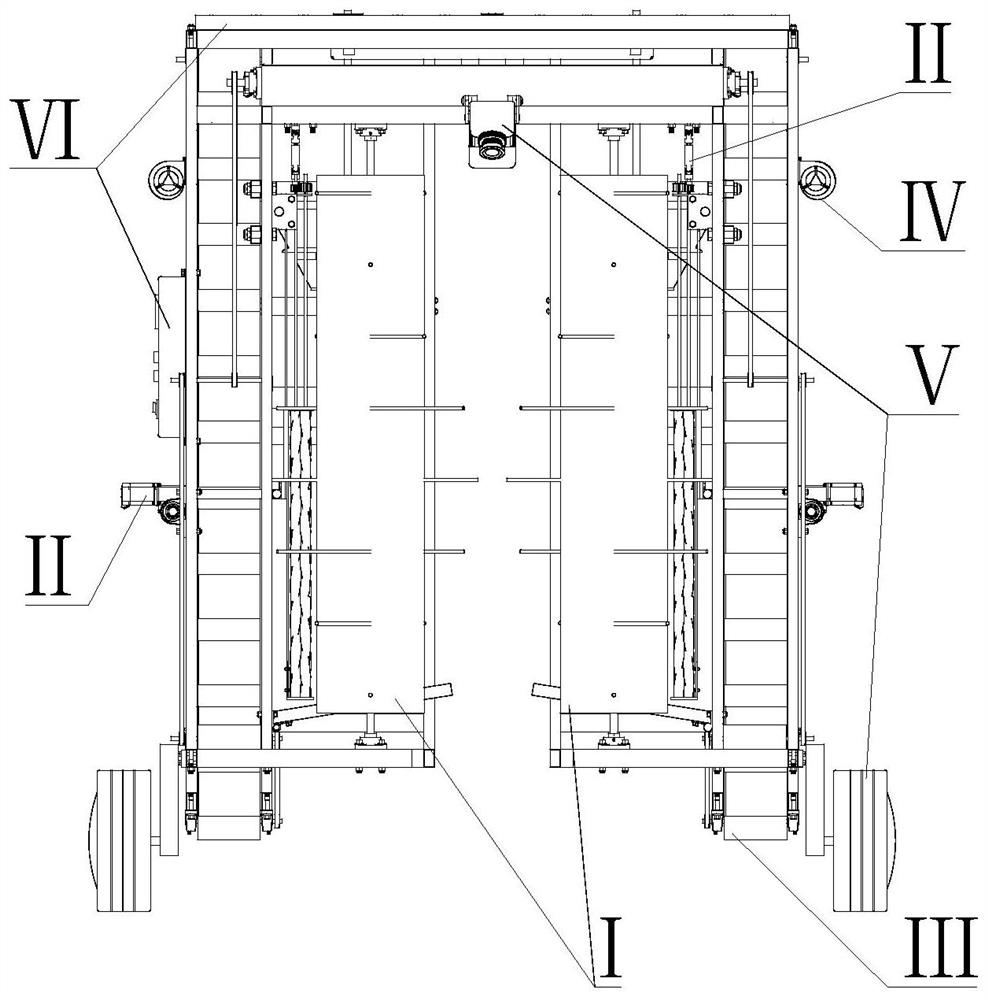

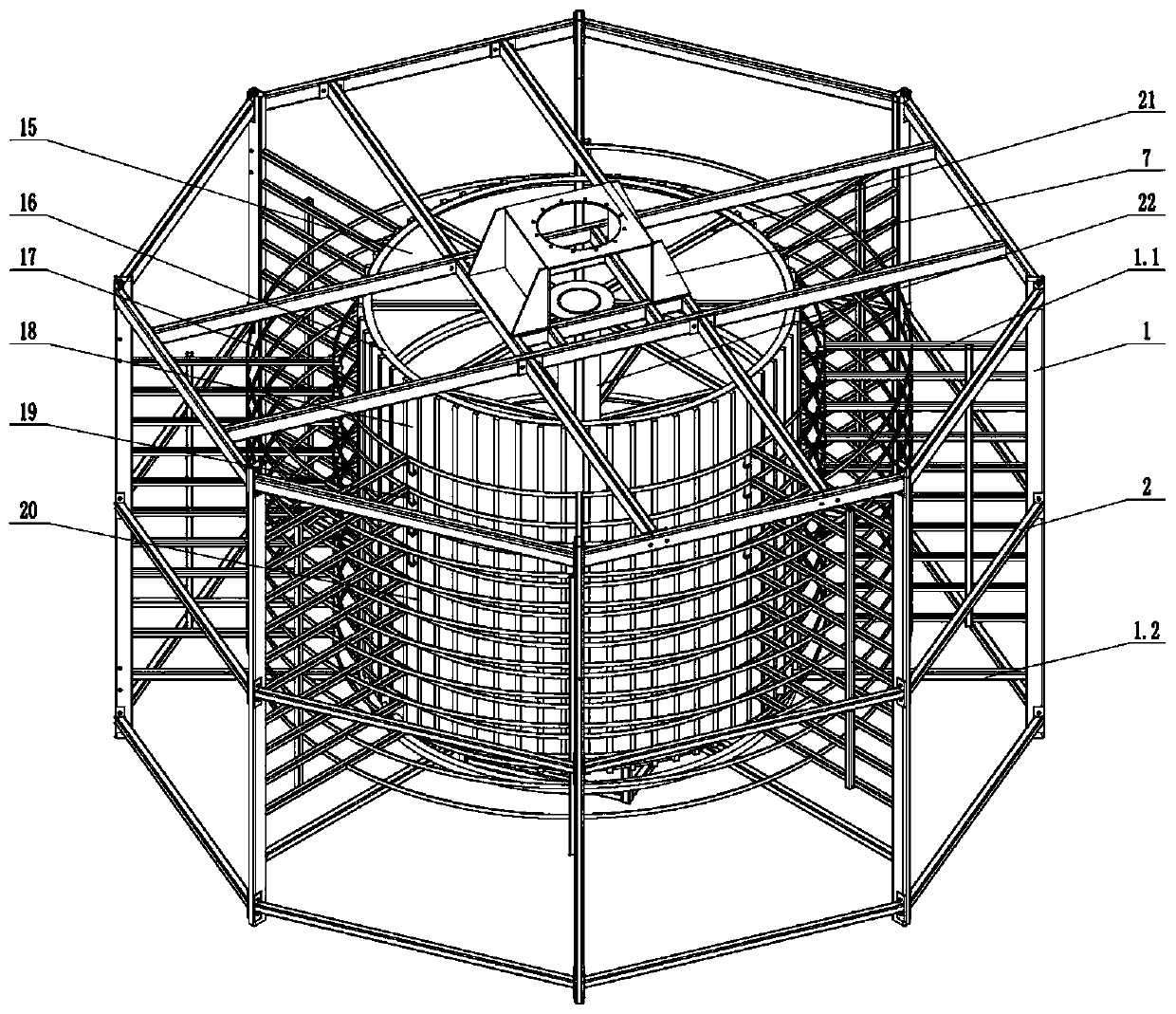

Honeysuckle picking and separating equipment for flower buds

ActiveCN114145132AProtect from harmFree laborDrying solid materials without heatRenewable energy machinesBudSelf adaptive

The invention discloses honeysuckle picking and separating equipment for flower buds. The honeysuckle picking and separating equipment comprises a spiral lifting and righting system, a bionic self-separation picking system, a conveying system, a centrifugal separation storage system, a self-adaptive navigation walking system and an accessory system. The spiral lifting and righting system is used for carding, lifting and righting disorderly spreading honeysuckle plants by utilizing a spiral lifting principle; when the bionic self-separation picking system works, only flower buds are picked, and leaves are protected to be intact; the conveying system is responsible for gathering the scattered flower buds after picking and conveying the flower buds to the centrifugal separation and storage system; the centrifugal separation and storage system is used for screening out flower buds and retaining leaves under the centrifugal action, so that the effect of separating the flower buds from the leaves is realized; the self-adaptive navigation walking system carries an autonomous navigation technology, automatically plans a walking path and completes walking and steering; the accessory system VI is responsible for control, power supply, energy circulation and the like of the whole machine. The device has a navigation function, and the picking efficiency and the picking quality are improved.

Owner:BEIJING UNIV OF TECH

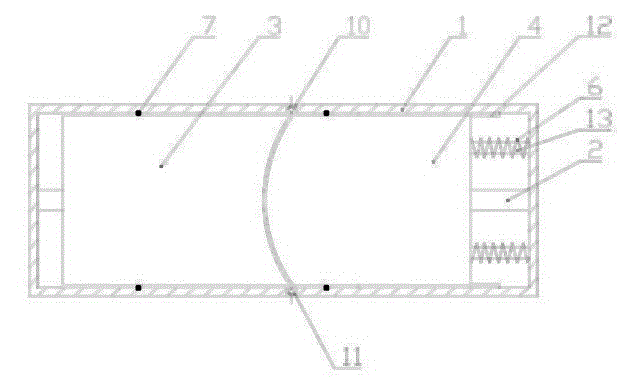

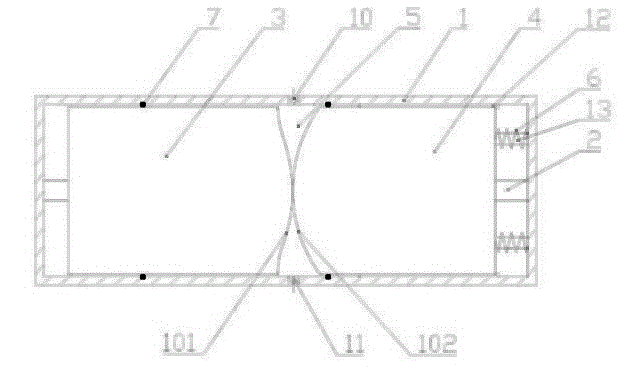

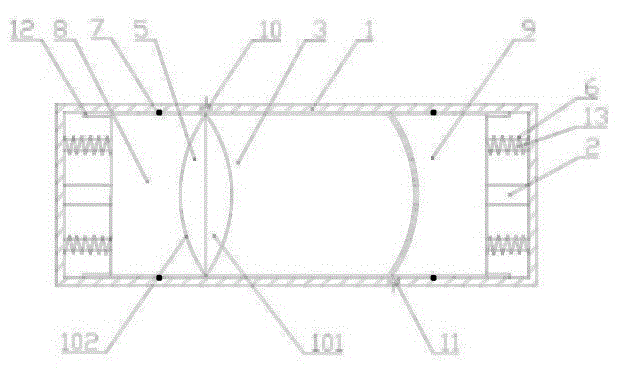

Fluid conveying device and method

InactiveCN103334906ASimple resultReduce volumeFlexible member pumpsPositive-displacement liquid enginesPistonDriven element

The invention discloses and provides a fluid conveying device which is simple in structure, smaller in volume, lower in energy consumption, and convenient to operate, and a method. The method is characterized in that a volume is formed after at least one driving element rotates to allow a position of at least one reciprocation element to be moved axially in the same cavity, in order to suck a fluid from an upstream side of a conveying direction or convey the fluid to a downstream side to be discharged; each of the end faces of the driving element and the reciprocation element is a curved surface with at least one bulge and at least one sunk part; when the bulge of the driving element is positioned in the sunk part of the reciprocation element, the driving element is bonded with the reciprocation element; and when the bulge of the driving element is contacted with the bulge of the reciprocation element, the volume is formed after the reciprocation element is moved axially. The fluid conveying device comprises a cylinder body, a power shaft positioned in the cylinder body, a rotating element arranged on the power shaft, and a sliding reciprocation piston adapted to a rotating piston, wherein a suction inlet and a discharge outlet are formed in the cylinder body, and when the rotating element rotates, the rotating element allows the sliding reciprocation piston to move axially on the power shaft, and the suction inlet is communicated with the discharge outlet after the volume is formed.

Owner:华国红

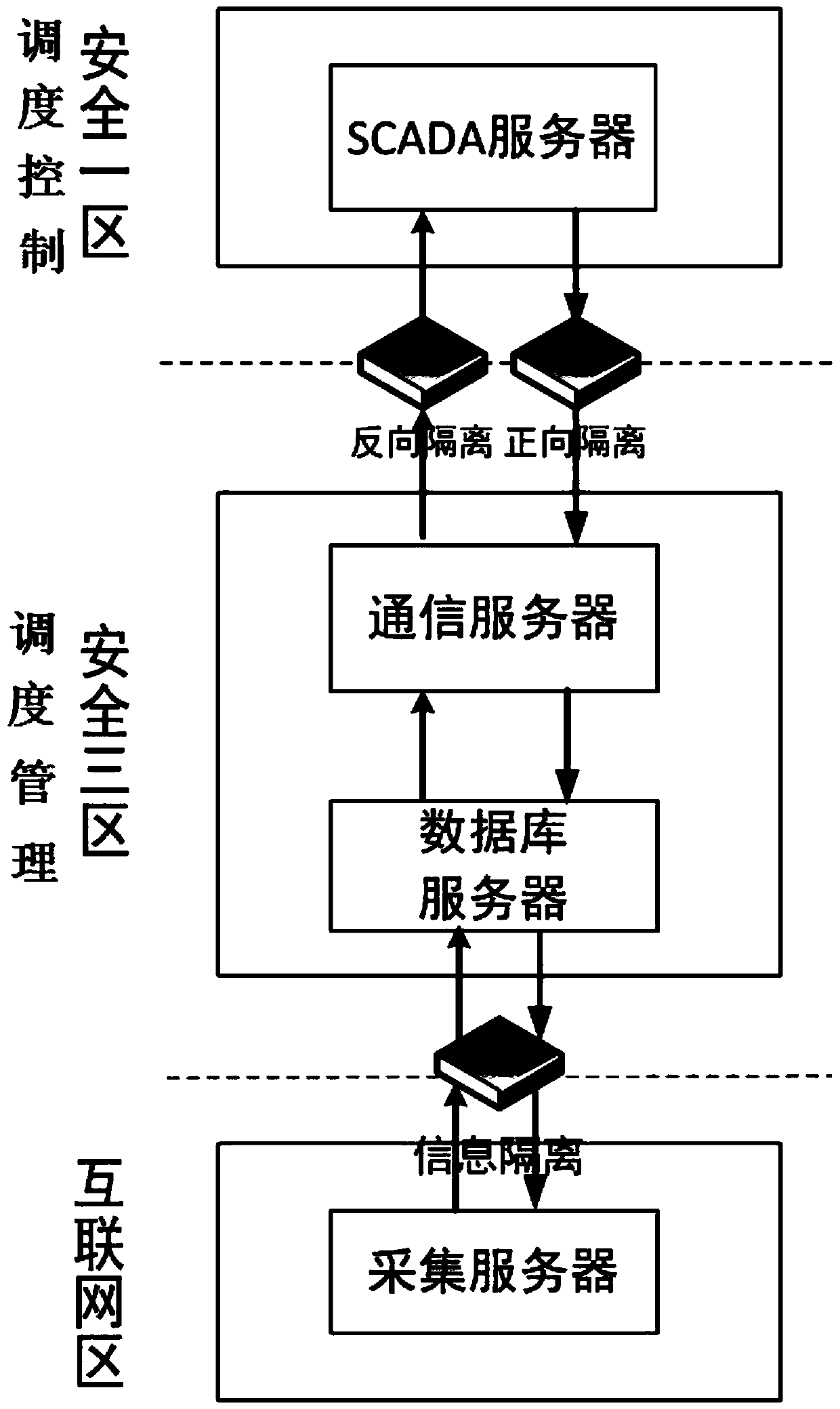

Cross-security intranet and Internet data security interaction system and method

ActiveCN111431923ASecurityRealize transmissionDatabase distribution/replicationTransmissionCommunications serverData bank

The invention discloses a cross-security intranet and Internet data security interaction system and method. The data security interaction system comprises an SCADA server, a communication server, a database server and an acquisition server, a forward network security isolation device and a reverse network security isolation device are arranged between the SCADA server and the communication server.A data transmission client of the communication server is connected with a data server of the database server, and an information security network isolation device is arranged between the database server and the acquisition server. The mode that the network security isolation equipment is matched with the information security network isolation device is adopted, cross-security intranet and Internet transmission of electric power data is achieved, a data interaction barrier between an electric power dispatching automation system and a ubiquitous resource aggregator system is broken through, and the security of data interaction is guaranteed.

Owner:NARI TECH CO LTD +3

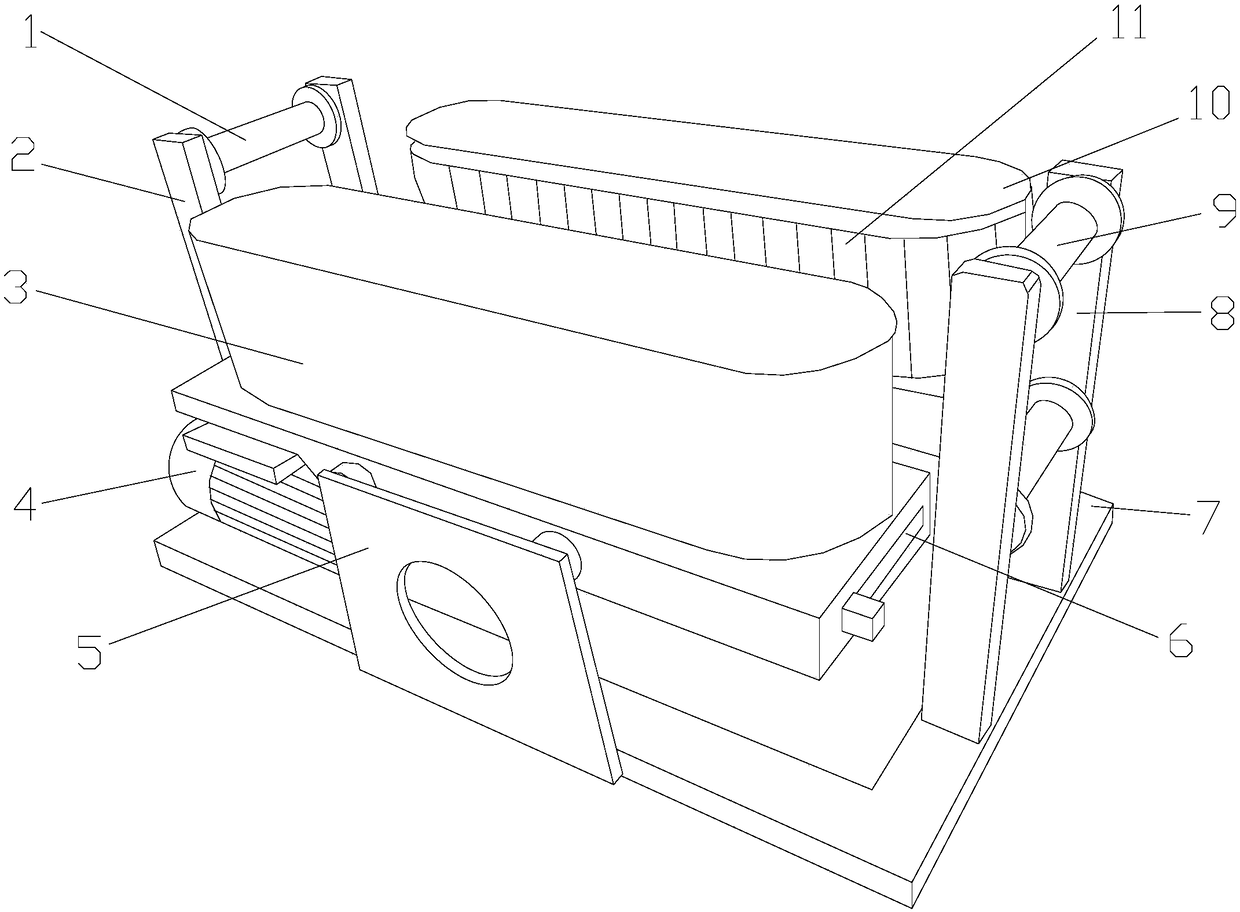

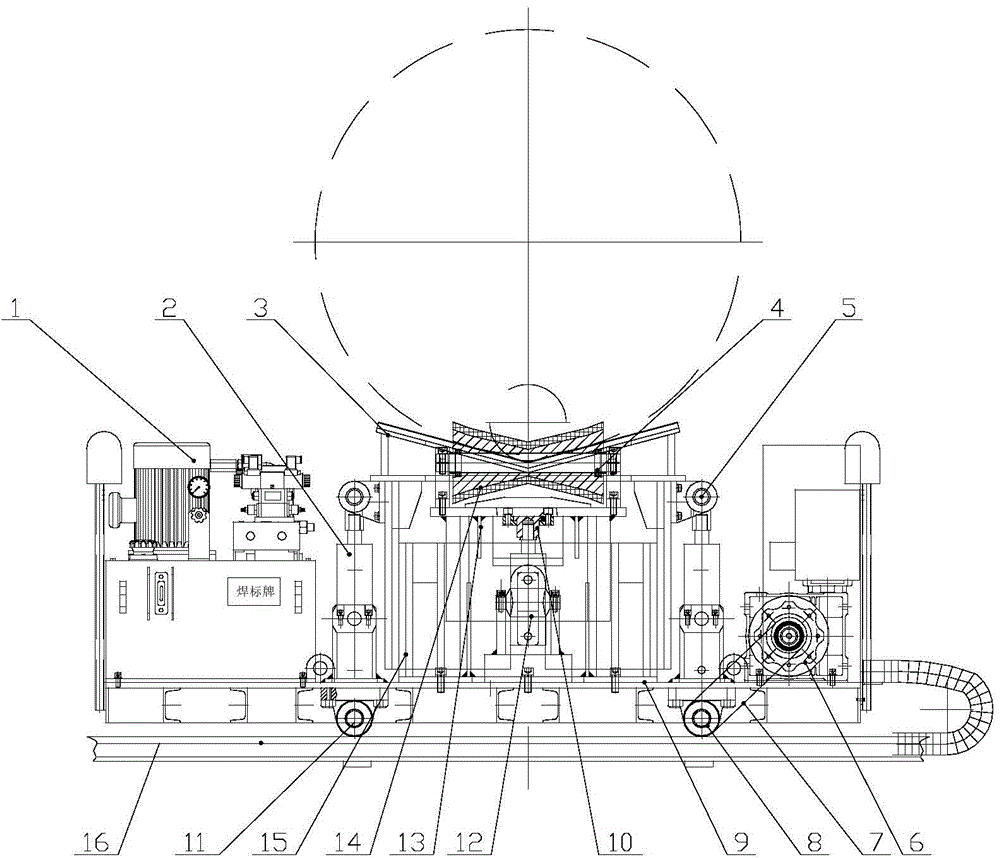

Multifunctional cylinder transfer machine with lifting function

ActiveCN104353961AMake up for too much spacingMake up for the defect that the short tube is easy to slipWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineering

The invention relates to a multifunctional cylinder transfer machine with a lifting function. The multifunctional cylinder transfer machine comprises two paths of lifting hydraulic stations, a V-shaped support structure, a roller support structure, a walking mechanism and a track, wherein the lifting hydraulic stations are used for respectively controlling the V-shaped support structure and the roller support structure to ascend and descend. Since the multifunctional cylinder transfer machine mainly comprises the two paths of lifting hydraulic stations, the V-shaped support structure, the roller support structure, the walking mechanism and the track, the lifting and conveying functions of pipeline supporting are achieved; in the movement process of a short pipeline L which is less than or equal to 1m, a roller support independently ascends and descends to lift a roller to the same height as that of a logistical conveying roller way, so that the defects that roller clearance is too large and the short pipeline is easy to fall off are overcome.

Owner:NANJING AUTO ELECTRIC

A continuous heat treatment device for alloy steel fasteners

ActiveCN111607692BRealize the delivery functionRealize the heating functionFurnace typesHeat treatment furnacesElectric machineEngineering

The invention discloses a continuous heat treatment device for alloy steel fasteners, which relates to the technical field of alloy steel fasteners, and comprises two installation plates, the bottoms of the two installation plates are jointly fixedly connected with a base, and the two installation plates The opposite side walls are fixedly connected with the delivery box, one of the side walls of the installation plate is fixedly connected with the drive motor, and the end of the output shaft of the drive motor runs through the installation plate and the side wall of the delivery box in sequence and is fixedly connected with the Jiaolong conveyor , the upper side wall of the delivery box is provided with a feed plate, a feed mechanism is installed in the feed plate, a heater is installed on the top of the delivery box, and a ventilating plate is fixedly connected to the inner top of the delivery box , the conveying function of the fastening piece is realized through the cooperative use of the driving motor, the conveying box, the Jiaolong conveyor, and the feeding mechanism, and the heating function of the fastening piece is realized due to the effect of the heater and the breathable plate.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

A plate conveying device

ActiveCN109795881BRealize the delivery functionSimple structureStacking articlesDe-stacking articlesStructural engineeringMechanical engineering

Owner:李传聪

A textile production workshop placement rack

ActiveCN113561151BImprove space utilizationEasy to take outWork tools storageElectric machinerySprocket

The present invention relates to the technical field of textiles, in particular to a placing frame for a textile production workshop, including a mounting frame, a stacking mechanism and a conveying mechanism, the mounting frame is equipped with a stacking mechanism, and the left and right sides of the mounting frame are provided with conveying mechanisms , the stacking mechanism includes a fixed plate, a stacking plate, a stacking rod, a fixed block, a rotating shaft, an eccentric wheel, a linkage sprocket, a transmission chain and a rotating motor. The invention can improve the space utilization rate of the rack, ensure that more textiles are placed on the rack, and at the same time, the textiles can be easily placed on the upper layers of the rack and the textiles located on the upper layers of the rack can be easily taken out. The invention can ensure that Textiles will not accumulate during placement, thereby avoiding the deformation of textiles due to extrusion.

Owner:江苏盛斯达纺织科技有限公司

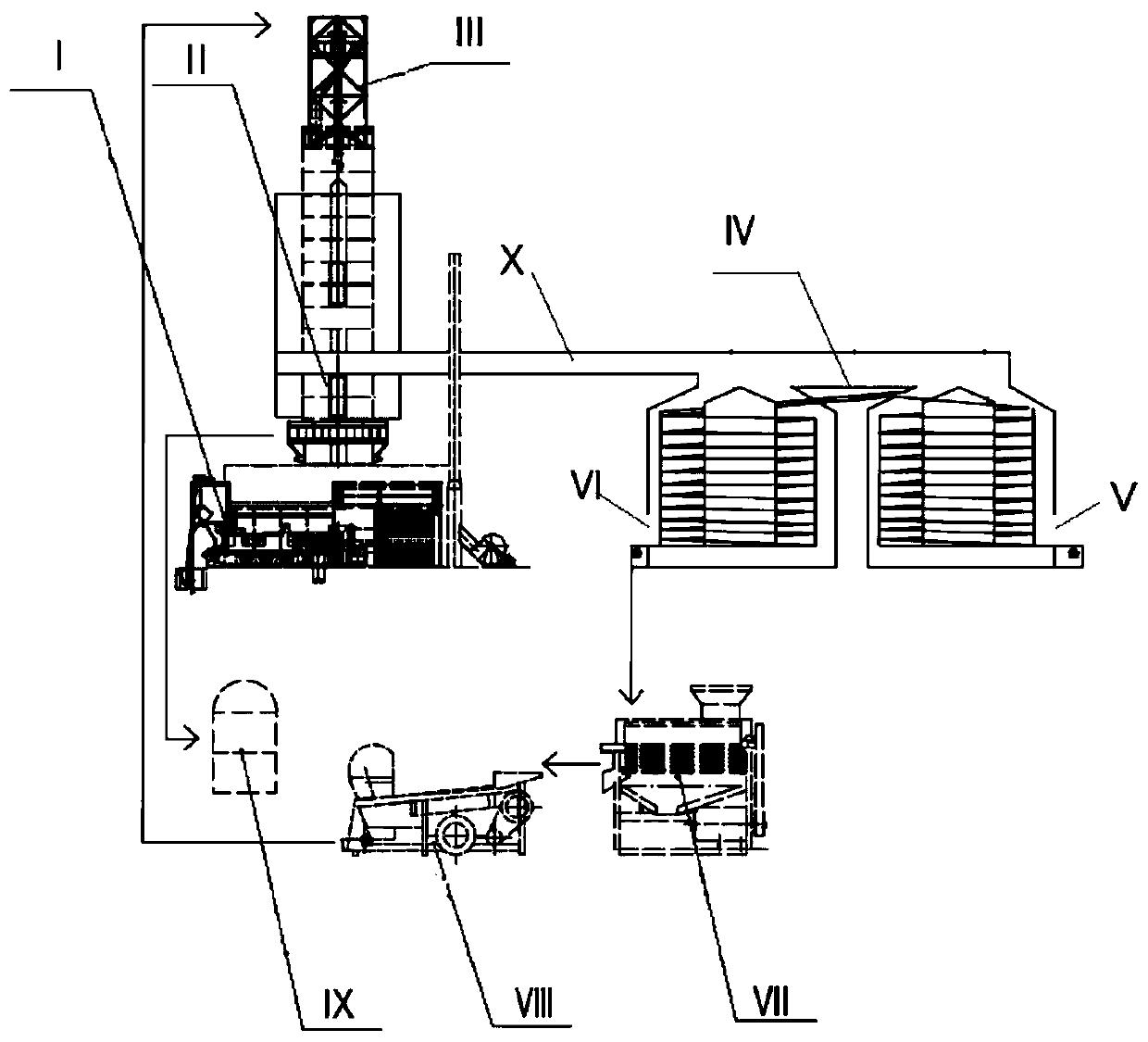

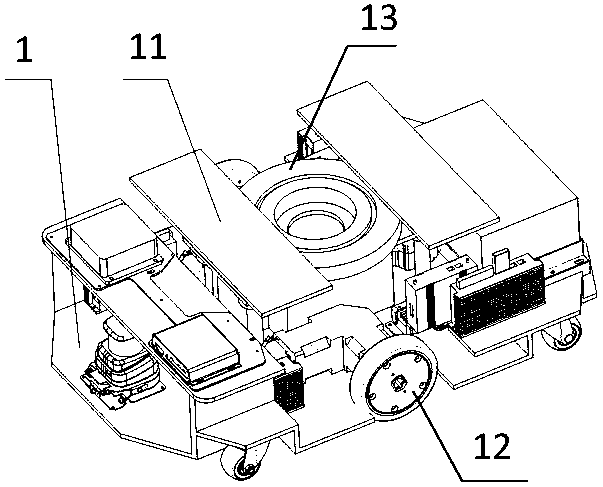

Corn ear and kernel linkage drying production line

InactiveCN110608598AImprove qualityRealize secondary useDrying gas arrangementsThreshersProduction lineAgricultural engineering

The invention discloses a corn ear and kernel linkage drying production line. The production line comprises a ear drying machine, a corn thresher, a grain cleaning and separating machine, a kernel drying machine and a finished product warehouse, wherein the ear drying machine is used for drying corn ears; the corn thresher is used for threshing dried corn ears; the grain cleaning and separating machine is used for cleaning and separating the threshed corn kernels; the kernel drying machine is used for drying the cleaned and separated corn kernels; the finished product warehouse is used for storing the dried corn kernels; an exhaust air outlet of the kernel drying machine is connected to an air inlet of the ear drying machine through a pipeline, the corn ears are dried by utilizing waste heat of the kernel drying machine, a fan is arranged at the air inlet of the ear drying machine, and the fan is connected with a controller. According to the corn ear and kernel linkage drying production line, the whole process flow of "ear drying, kernel threshing, cleaning and separating, kernel drying and warehousing" is realized with leaving no step, and great significance is brought to the cornhigh-quality rapid warehousing.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Automobile cabin top washing device

InactiveCN105270351AHelps fixHelp to fixCleaning apparatus for vehicle exteriorsOpen waterWater level

The invention relates to an automobile cabin top washing device. The automobile cabin top washing device comprises an open water tank, a side frame and a control box, wherein the open water tank comprises an injection pipe, a water tank body and a water outlet; a water level window is arranged on the water tank body; a bypass pipe and a gate valve are arranged on the water outlet; the lower end of the water outlet is connected with a spray gun; a spray head is arranged at the lower end of the spray gun; a fixing clamp is arranged on one side of the side frame; the open water tank is fixedly connected with the fixing clamp through a bolt; an auxiliary box is arranged in the side frame; and the auxiliary box is connected with the fixing clamp and the water level window through data acquisition wires. According to the invention, supplying and conveying of washing water are favorably realized by the arrangement of the open water tank in which the injection pipe and other parts are mounted; spraying of washing water is favorably realized by the arrangement of the spray gun, which is provided with the spray head, and the gate valve; and the open water tank is favorably fixed by the arrangement of the fixing clamp. The automobile cabin top washing device provided by the invention is simply structured, economic and practical and can be operated conveniently.

Owner:DEVON ENERGY CORP

AGV, bearing system with longitudinal beams and use method thereof

The invention relates to the technical field of logistics service, in particular to an AGV, a bearing system with longitudinal beams and a use method thereof. The technical scheme is as follows: the AGV comprises a body, the body is provided with a traveling structure, support plates and a jacking structure connected with the body and used for driving the support plates to rise and fall, and the support plates extend in the horizontal direction. The invention provides the AGV, the bearing system with the longitudinal beams and the use method thereof. The AGV is suitable for trays with longitudinal beams, and can lift and transmit the trays, thereby being convenient to operate and stable to travel.

Owner:NOBLEELEVATOR INTELLIGENT EQUIP CO LTD +2

Continuous heat treatment device for alloy steel fasteners

ActiveCN111607692ARealize the delivery functionRealize the heating functionFurnace typesHeat treatment furnacesElectric machineDrive motor

The invention discloses a continuous heat treatment device for alloy steel fasteners, and relates to the technical field of alloy steel fasteners. The continuous heat treatment device comprises two mounting plates; the bottoms of the two mounting plates are jointly and fixedly connected with a base, the opposite side walls of the two mounting plates are fixedly connected with a conveying box, a driving motor is fixedly connected to the side wall of one mounting plate, the tail end of an output shaft of the driving motor sequentially penetrates through the mounting plates and the side wall of the conveying box and is fixedly connected with an auger conveyor, a feeding plate is arranged on the side wall of the upper end of the conveying box, a feeding mechanism is mounted in the feeding plate, a heater is mounted at the top of the conveying box, and an aerating plate is fixedly connected to the inner top of the conveying box. The conveying function of the fastening pieces is achieved through cooperative use of the driving motor, the conveying box, the auger conveyor and the feeding mechanism, and meanwhile the heating function of the fastening pieces is achieved under the action of the heater and the aerating plate.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

Circulating drying equipment for silver peak tea production

InactiveCN114396786ARealize the delivery functionRealize the circulation drying functionPre-extraction tea treatmentTea dryingEngineeringProcess engineering

The invention is applicable to the related technical field of tea processing equipment, and provides circulation drying equipment for silver peak tea production, the circulation drying equipment comprises a base, two driving rollers rotatably mounted on the base and a conveying belt connected with the two driving rollers in a rolling manner, and a plurality of small ventilation holes are formed in the conveying belt; a mounting seat is further mounted on the base, a drying device used for drying tea leaves is mounted on the mounting seat, the conveying belt is used for horizontally conveying the tea leaves, encirclement rings are further arranged at the two ends of the conveying belt, a vertical plate perpendicular to the base is fixedly mounted on the base, and the vertical plate is fixedly mounted on the base. A material hopper is movably arranged on the side, facing the conveying belt, of the vertical plate through a reciprocating driving mechanism, and due to the fact that the work automation of the device and the matching degree of all mechanisms and components in the device are high, the tea leaf processing work efficiency is greatly improved, and an effective guarantee is provided for the tea leaf production progress.

Owner:聂仁忠

Anti-corrosion fluid conveying machine for chemical production

InactiveCN110500323ASmooth circulationAvoid corrosionDispersed particle filtrationTransportation and packagingInjection airLiquid injection

The invention relates to an anti-corrosion fluid conveying machine for chemical production. The machine comprises a material box, a controller, an air inlet pipe, a transverse pipe, a vertical pipe, aliquid outlet pipe and a liquid injection mechanism. A compression mechanism comprises a swing assembly, a swing rod and two compression assemblies, wherein the compression assembly comprises a compression pipe, an air injection pipe, a compression plate, a vertical rod and a lantern ring; and a purification mechanism comprises a filter screen, a rotating assembly, a cross rod, a circular ring, arotating rod and a plurality of springs. According to the anti-corrosion fluid conveying machine for chemical production, the compression plate continuously presses a solution in the material box into the liquid outlet pipe through taking air as a medium through the compression mechanism, so that the conveying function is realized, and the compression plate is prevented from being corroded due tothe contact with the solution; moreover, the air entering the vertical pipe is purified through a filtering mechanism, the rotating rod can be driven to rotate through the rotating assembly, the filter screen is cleaned and dredged, and it is ensured that the air circulation is smooth, so that the practicability of the equipment is further improved.

Owner:特尼格日

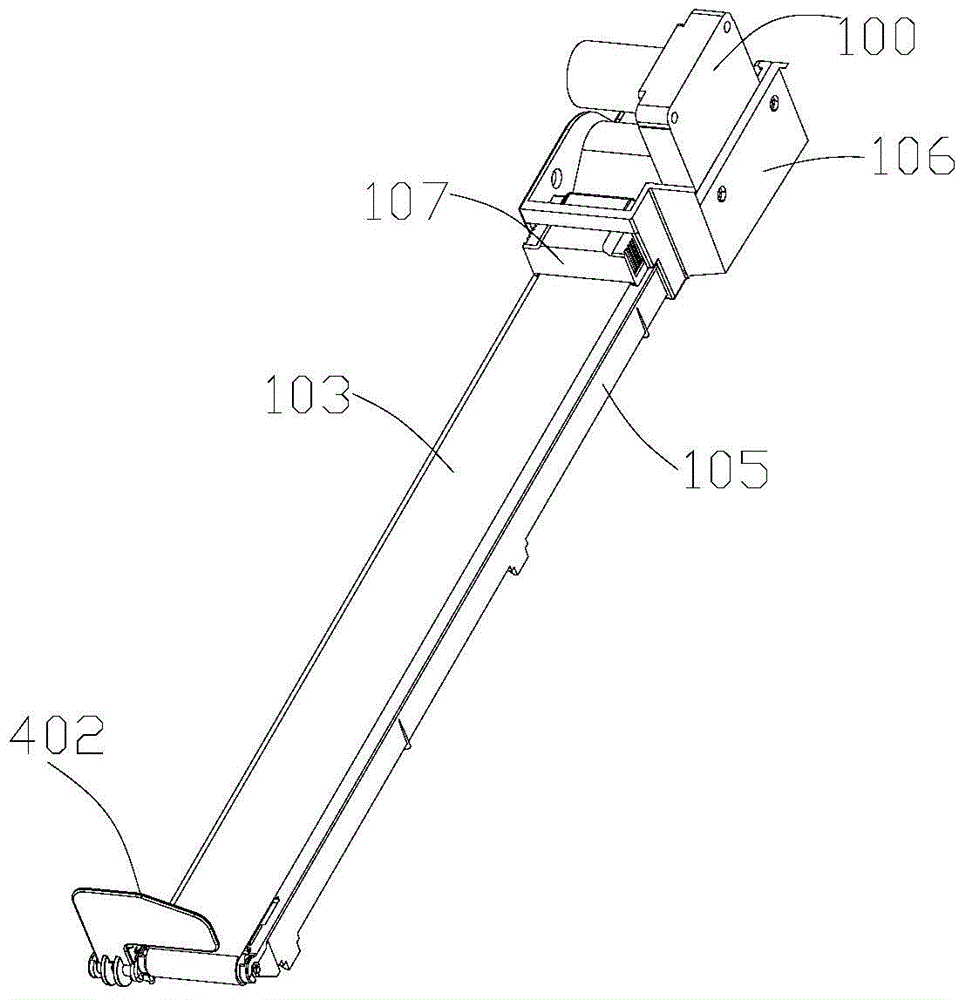

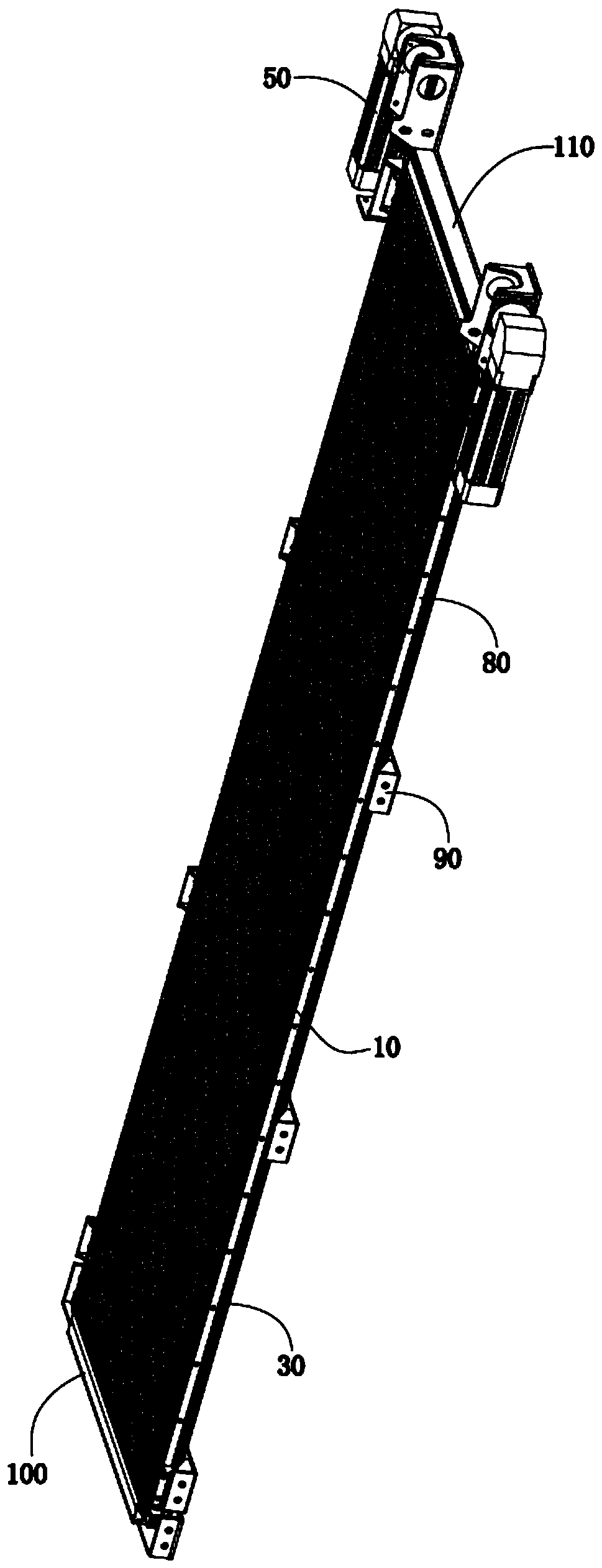

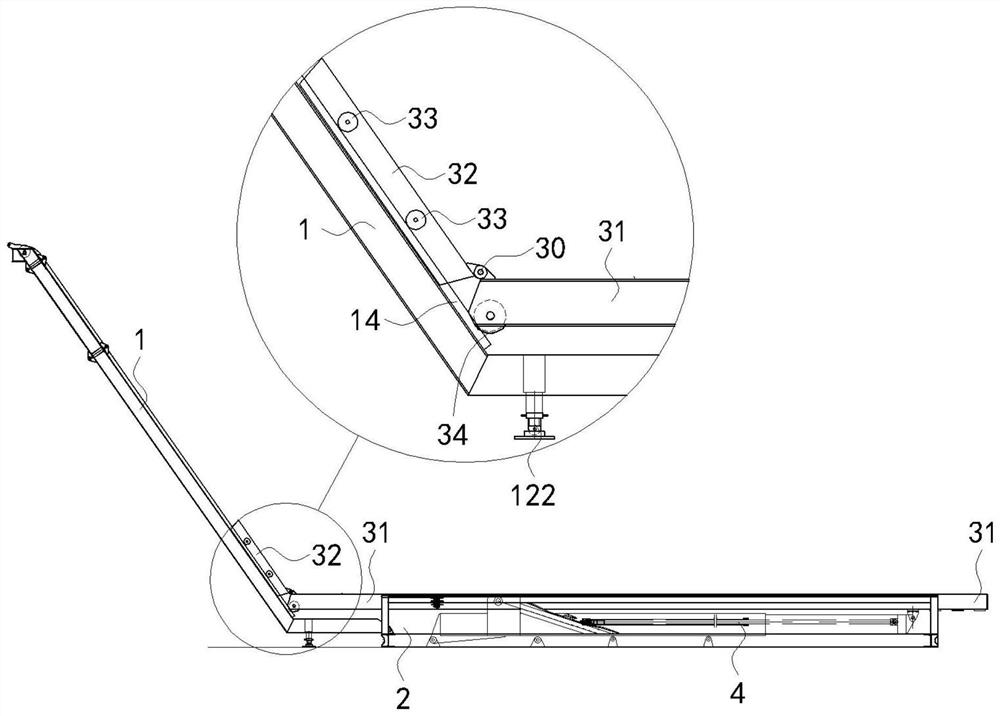

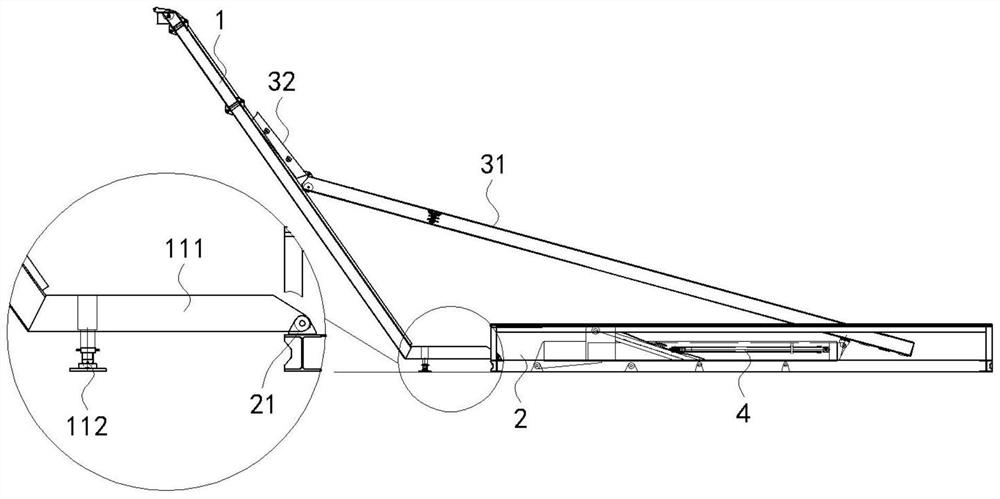

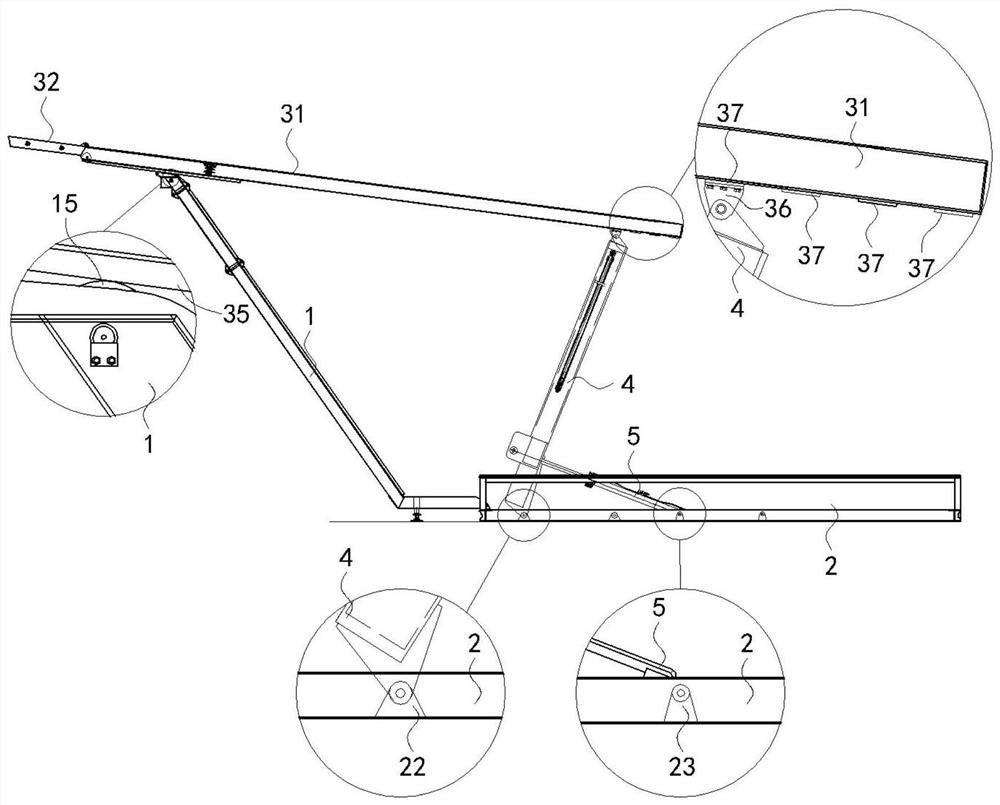

A power catwalk

ActiveCN112696159BRealize the delivery functionReduce manufacturing costDrilling rodsDrilling casingsEngineeringMechanical engineering

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com