Feeding device and automatic vending machine

A feeding device and conveyor belt technology, which is applied to instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve the problems of complex structure of the feeding device, low installation accuracy and high use cost problem, to achieve the effect of simple and reliable transmission mode, low manufacturing cost and small energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

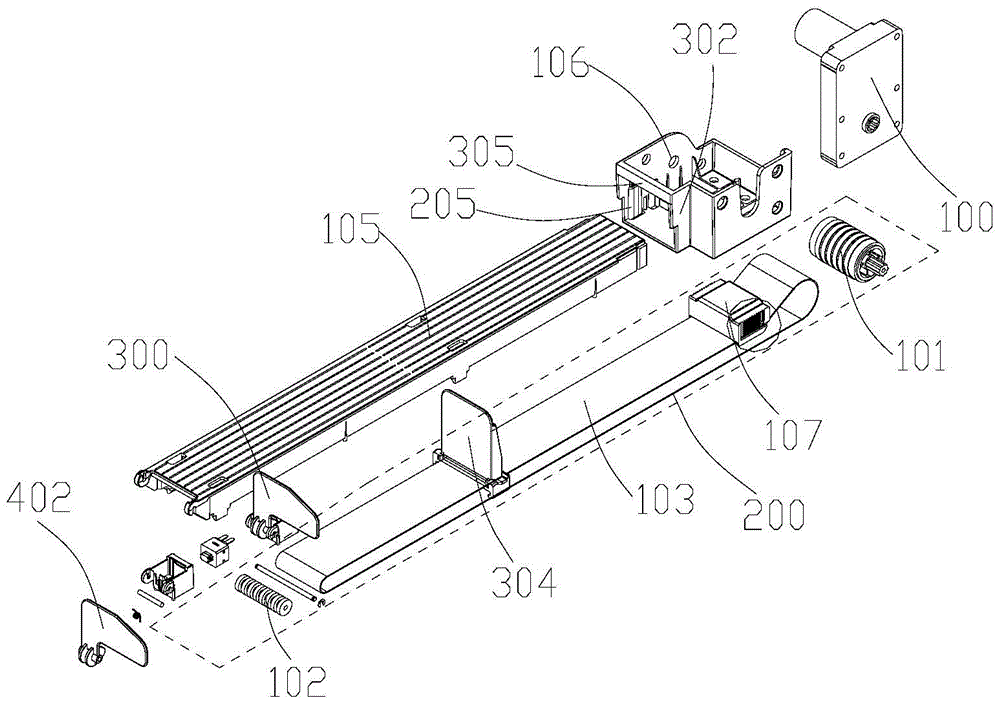

[0039] The feeding device of the existing automatic vending machine includes a transmission box, a transmission track and two driving wheels. The two driving wheels are arranged side by side, and the track is between the two driving wheels. transmission. The structure of the two driving wheels is complex, the installation is inconvenient, and the energy loss is large during operation, which is prone to failure.

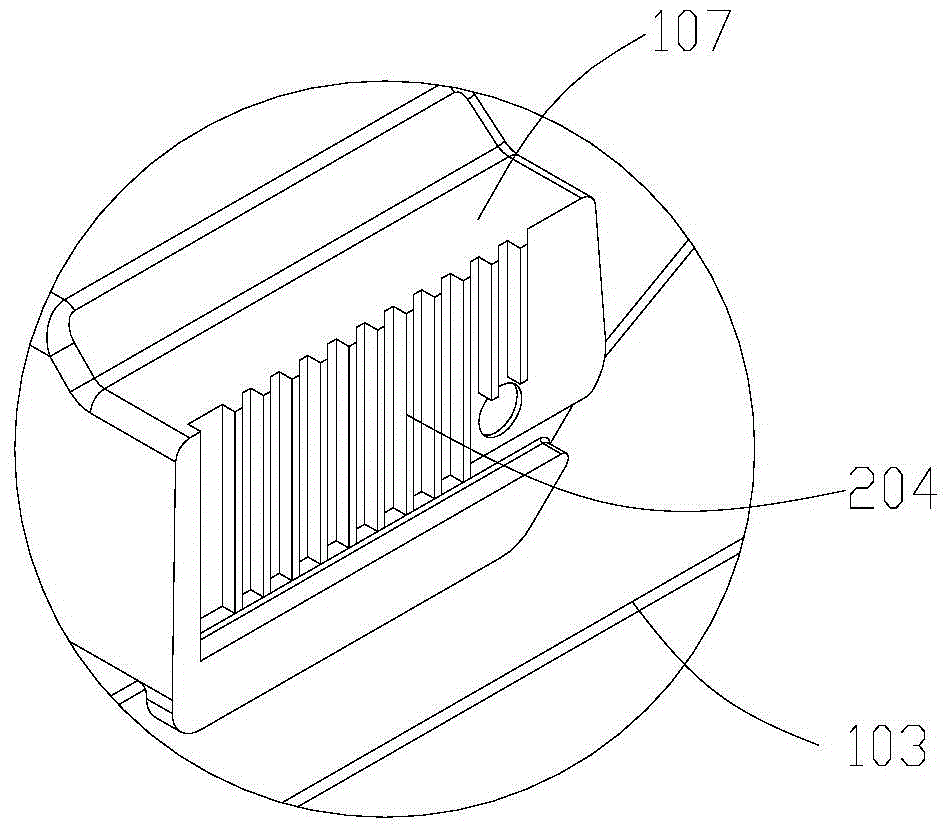

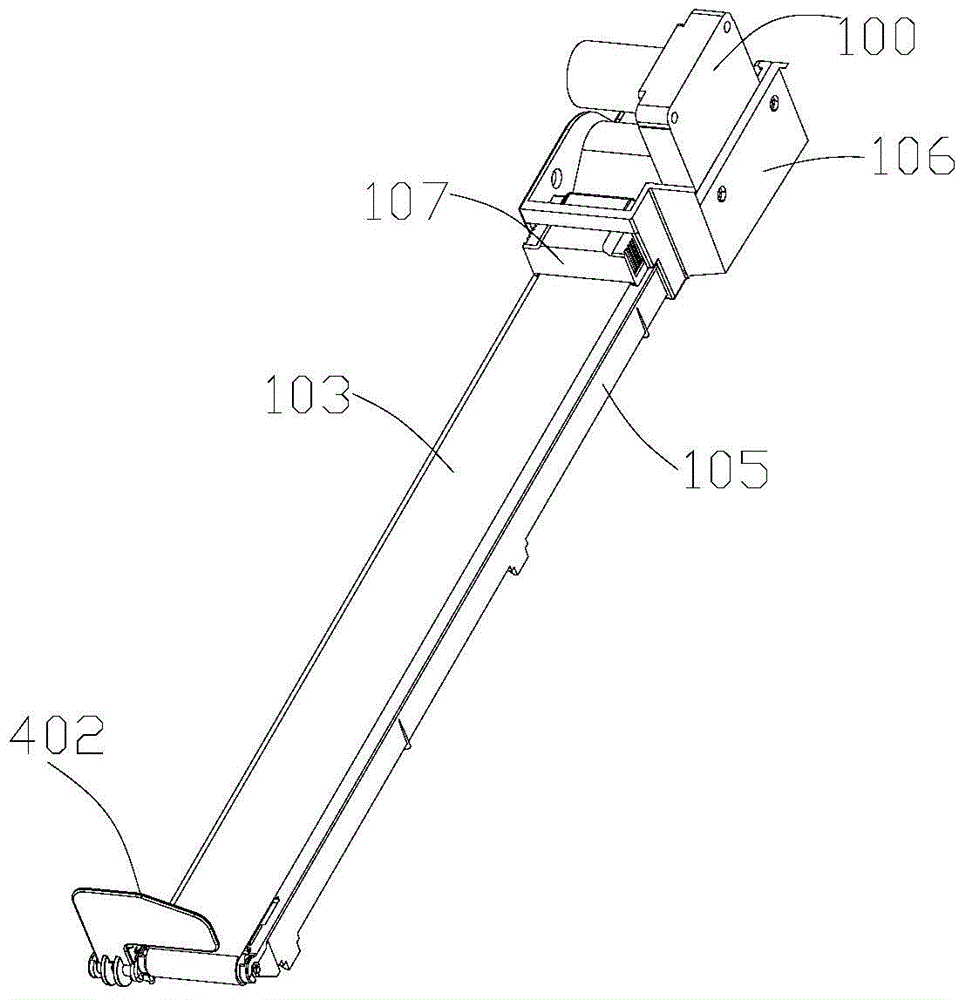

[0040] In view of this, the designer of the present invention designed a feeding device and a vending machine. The feeding device directly drives the driving wheel to rotate through the power unit, and then drives the conveyor belt connecting the driving wheel and the driven wheel to move. The structure is simple and reliable, and the installation is convenient; Adjust the tightness of the conveyor belt as needed to facilitate the smooth operation of the conveyor belt.

[0041] In order to make the purpose, technical solutions and advantages of the embodiments of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com