Patents

Literature

38results about How to "Realize automatic loading operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

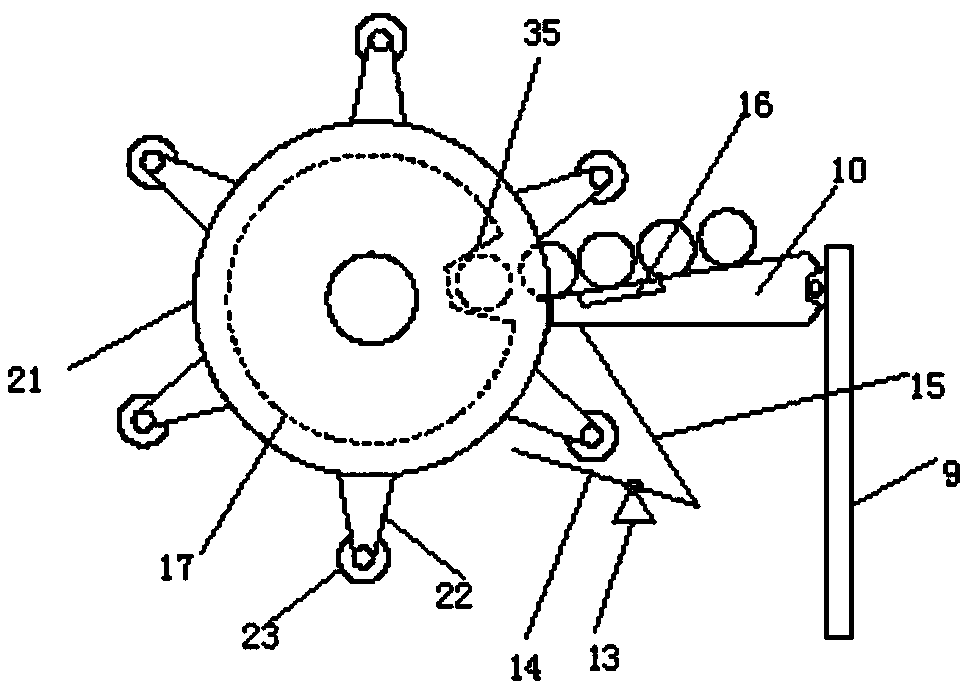

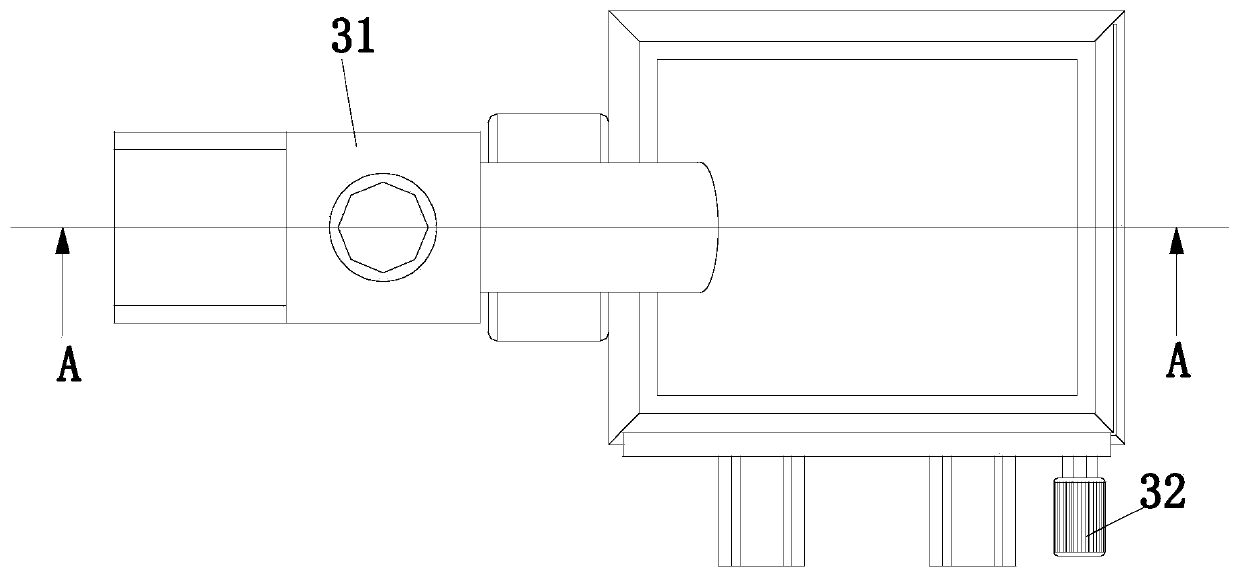

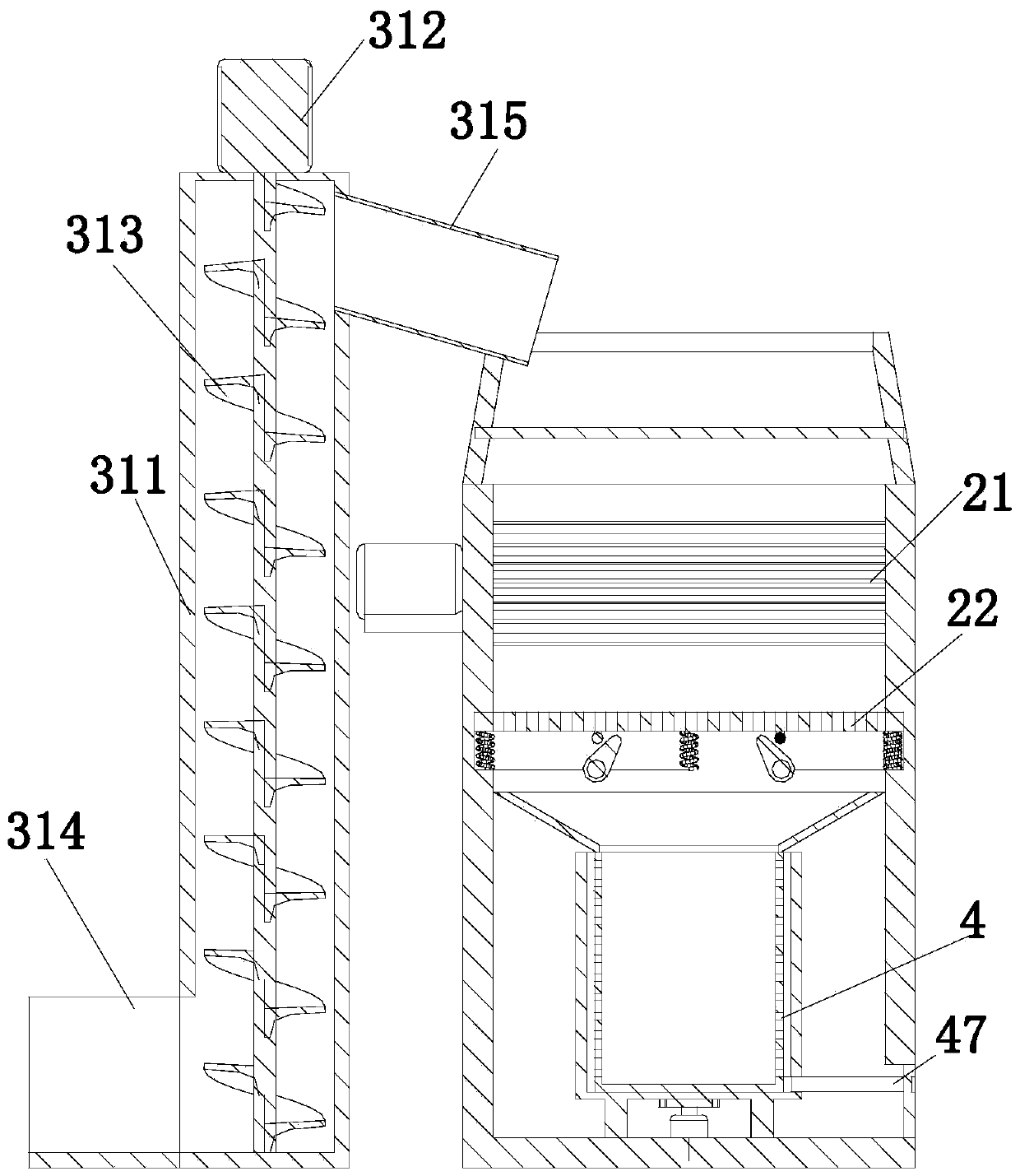

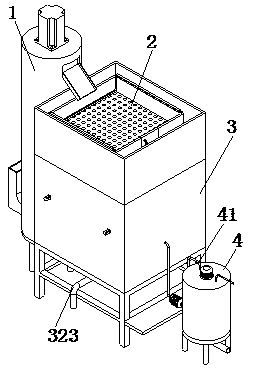

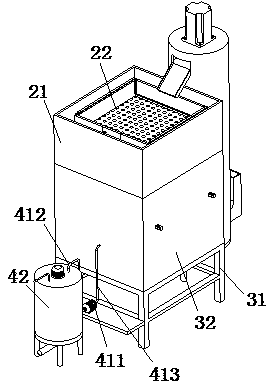

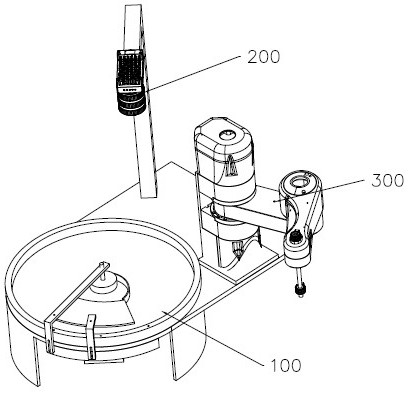

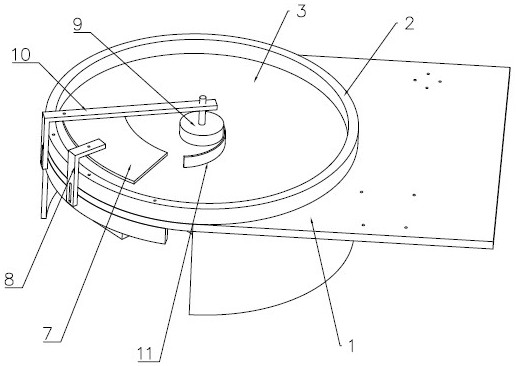

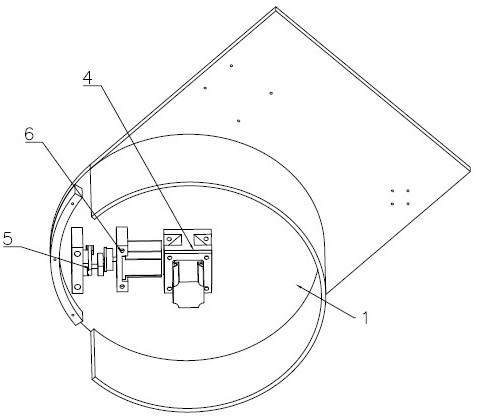

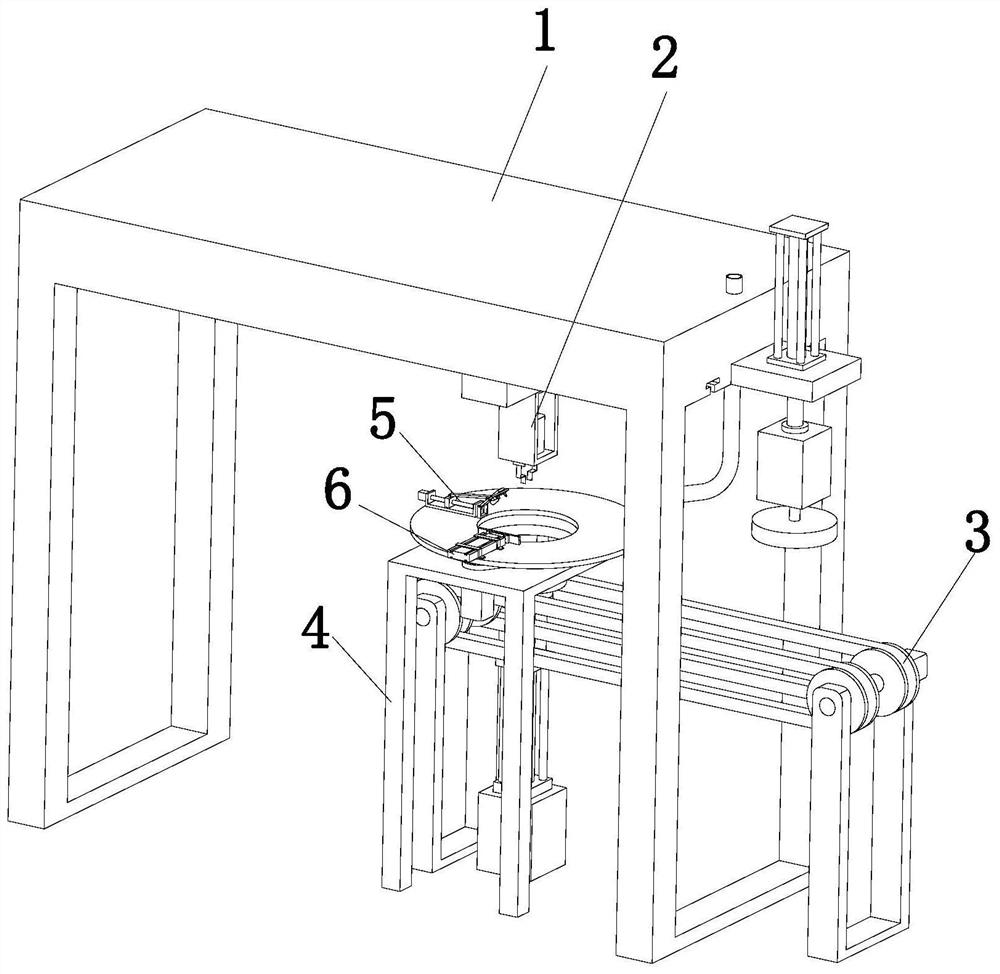

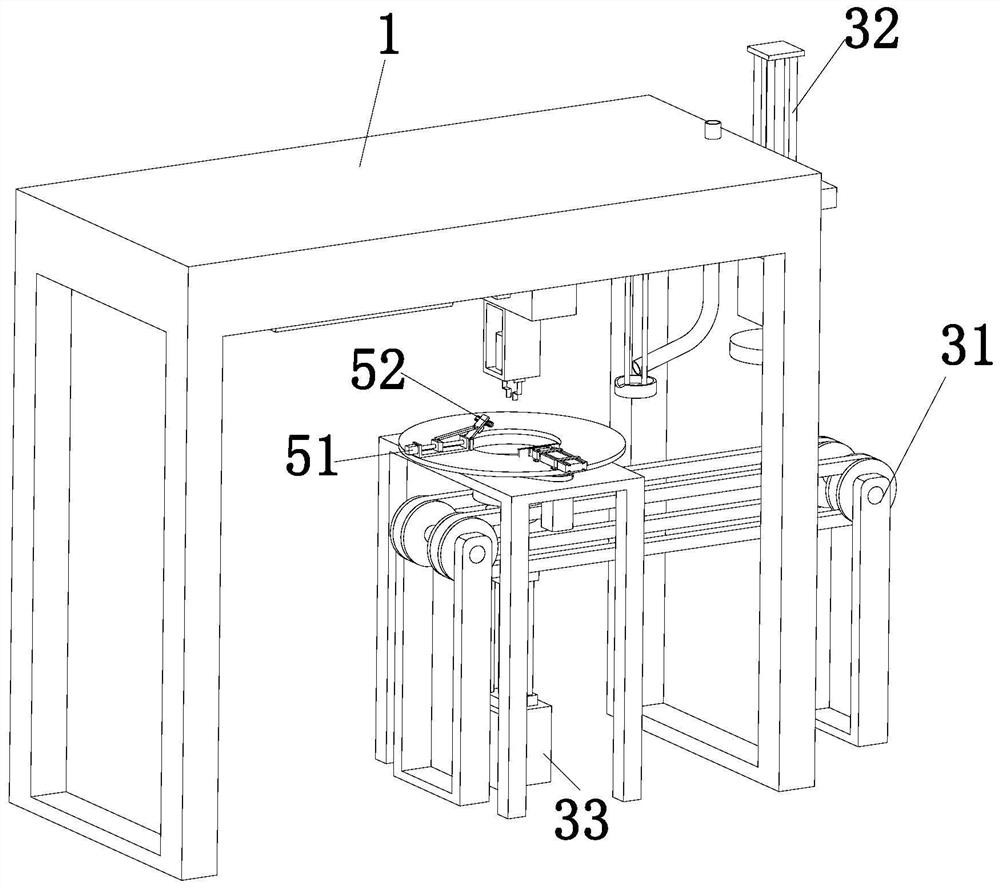

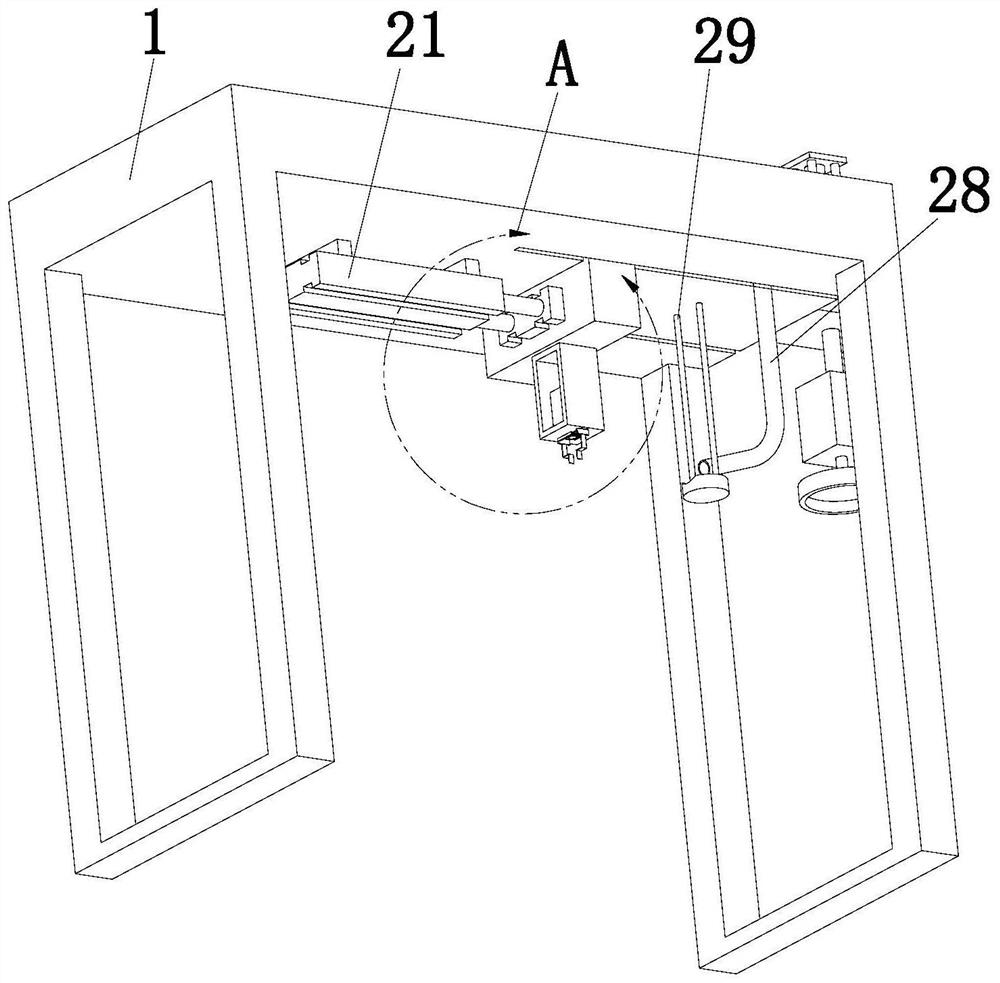

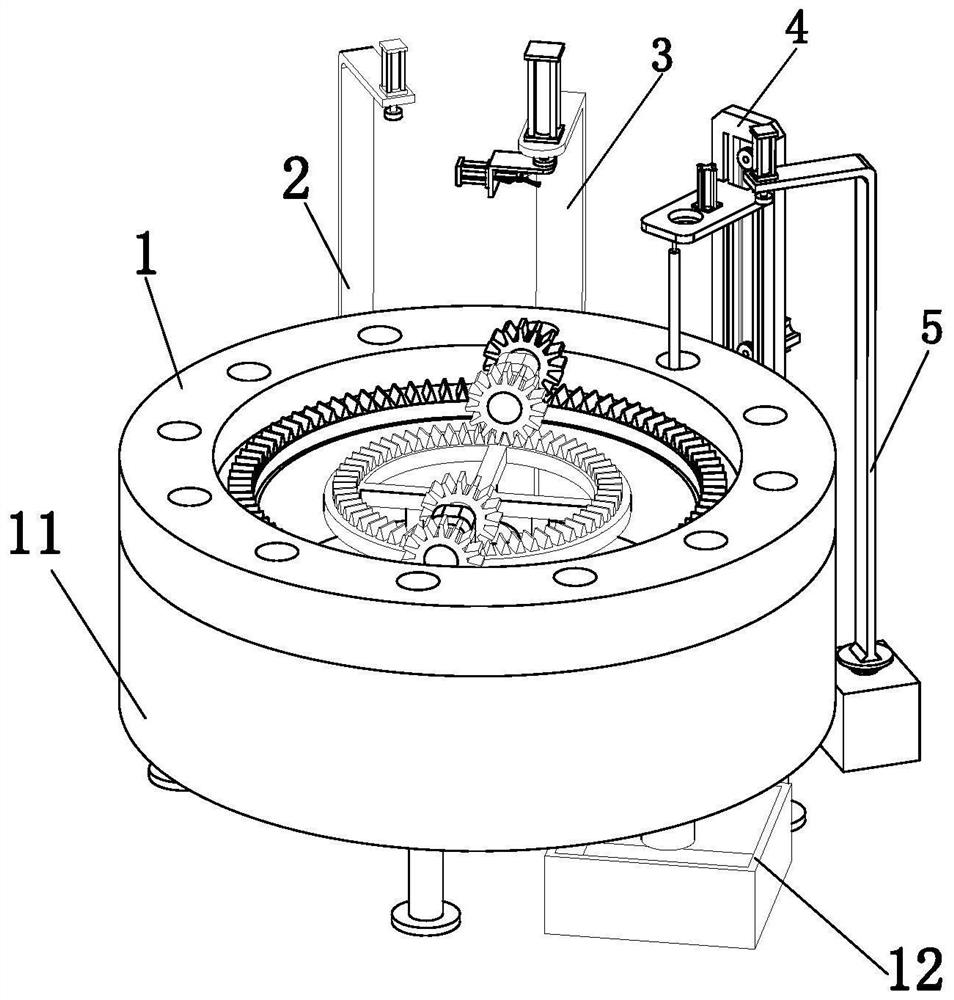

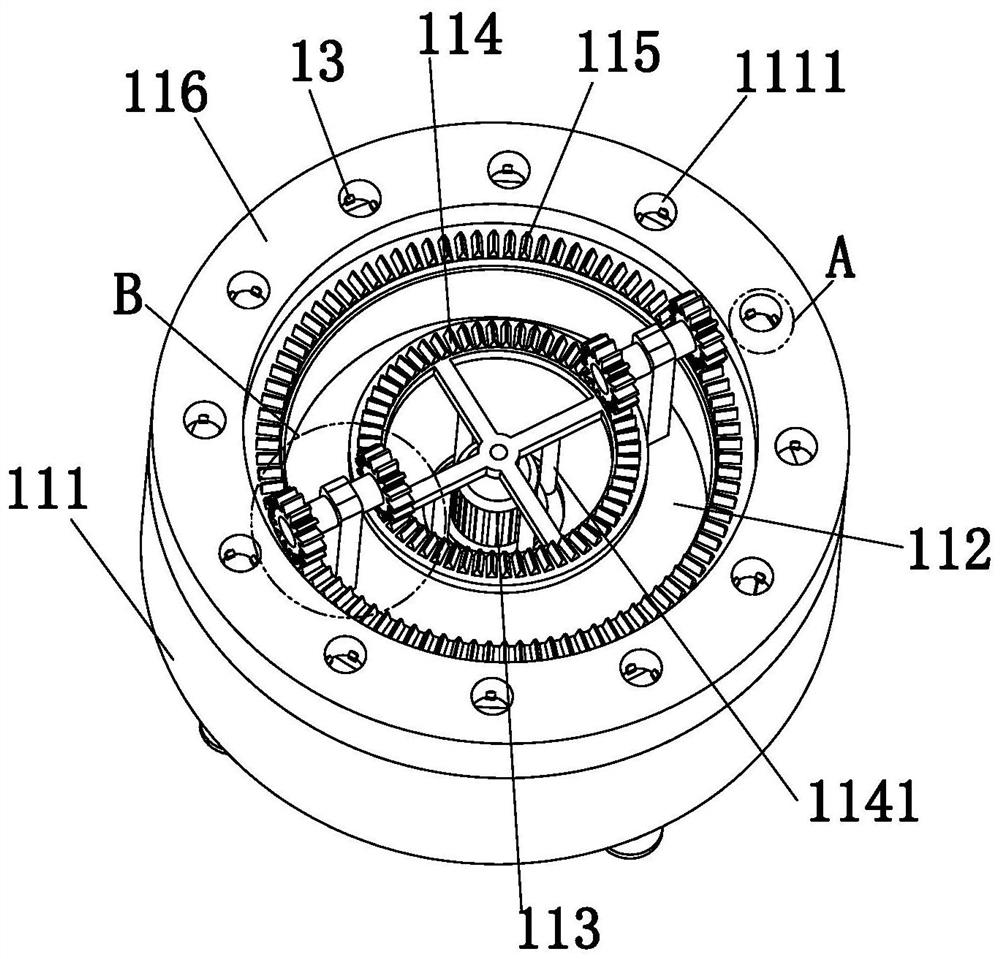

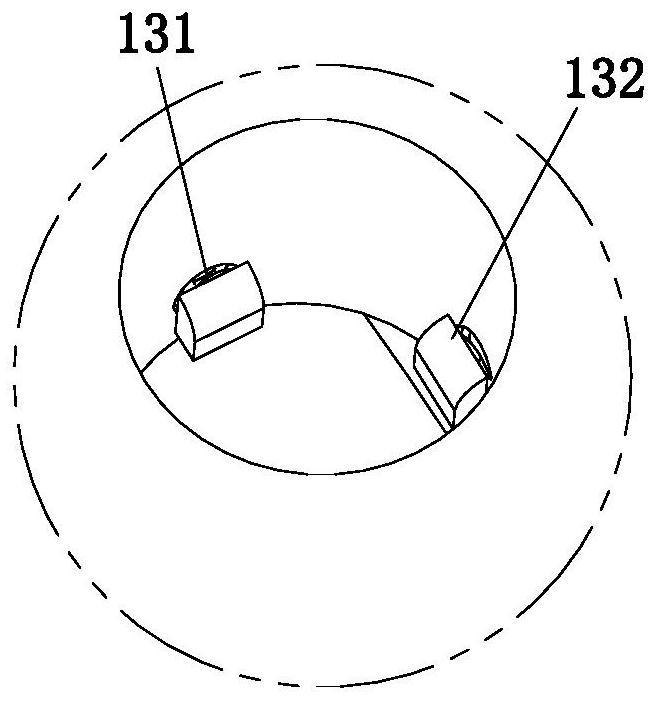

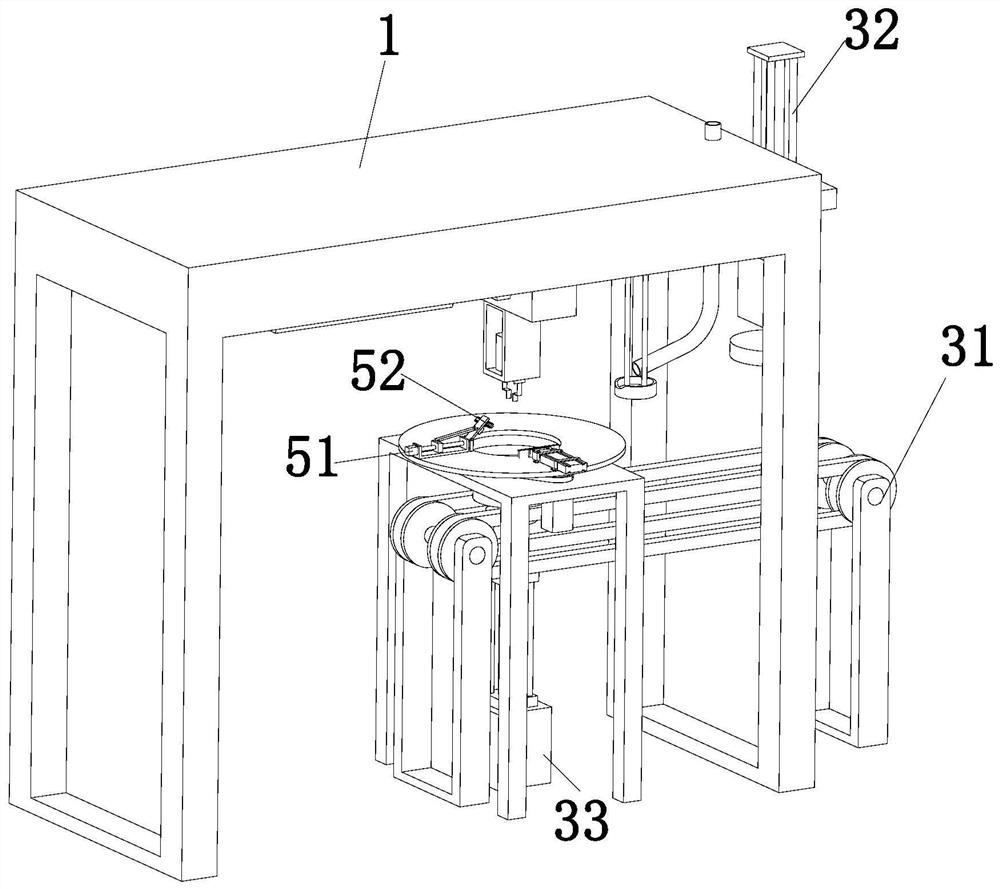

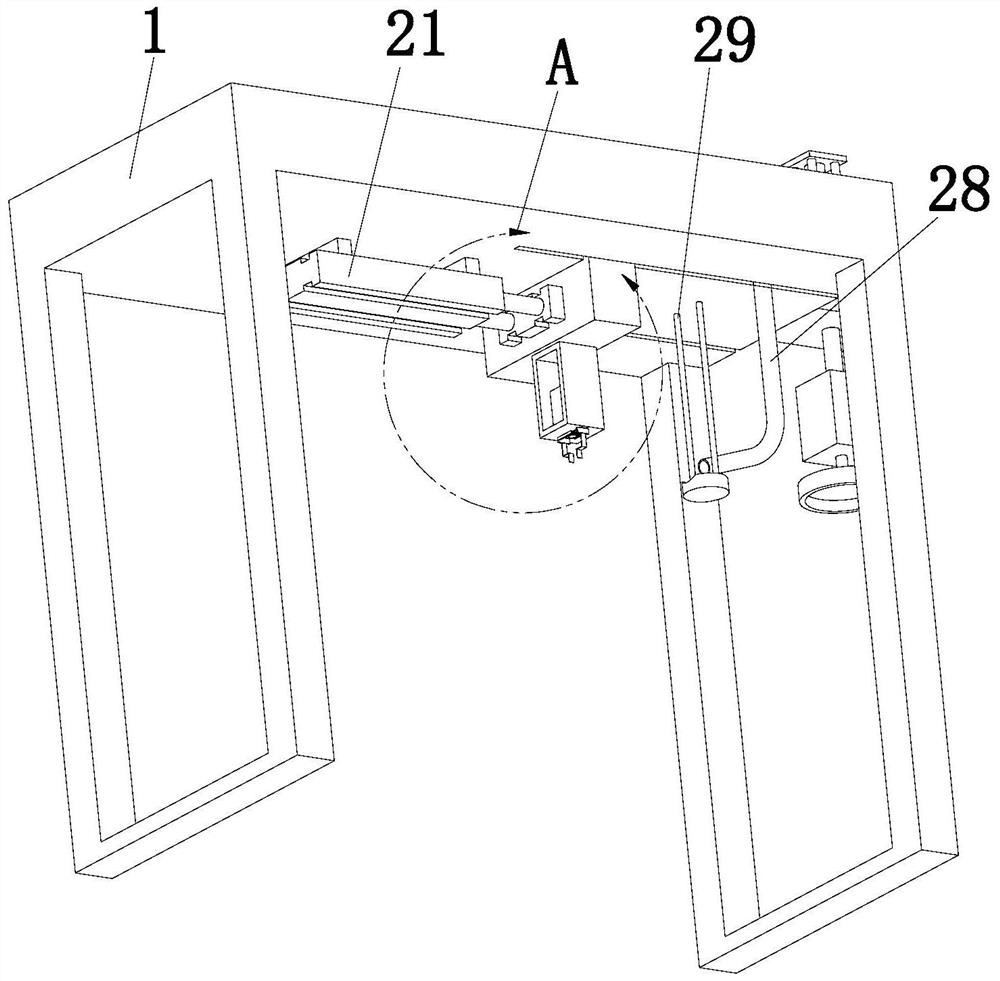

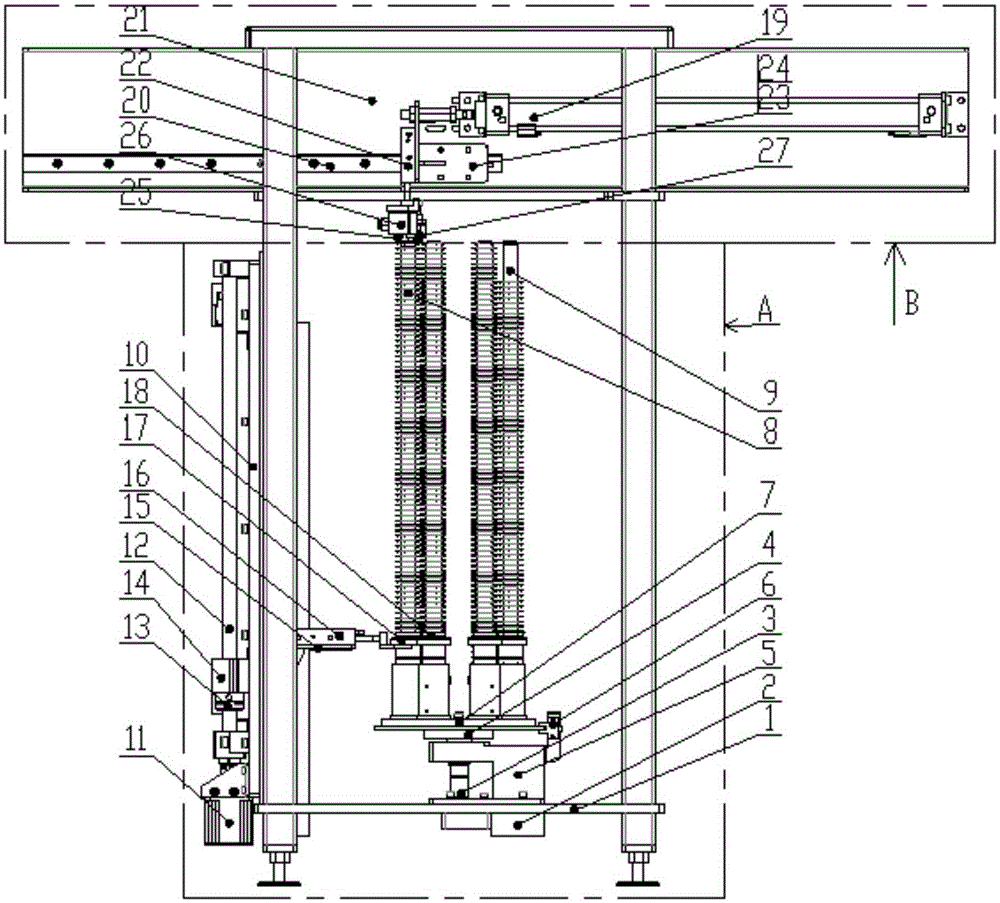

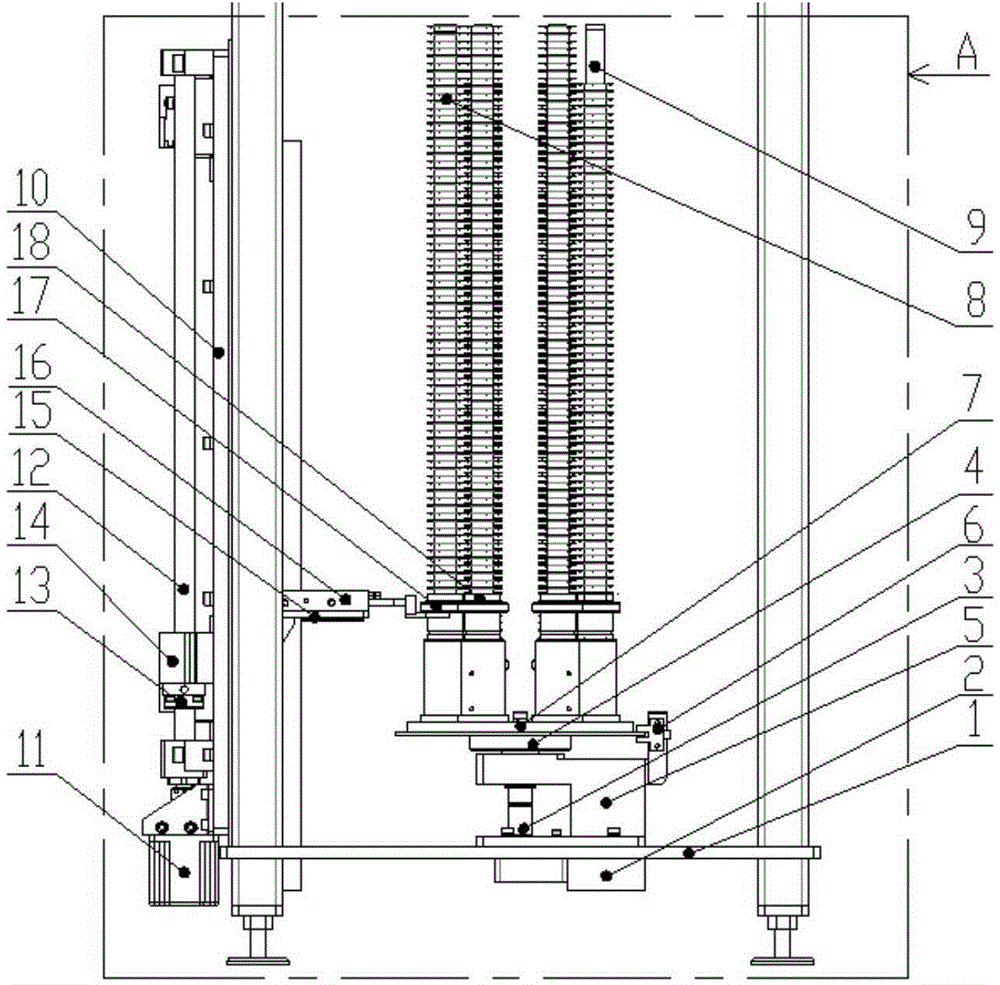

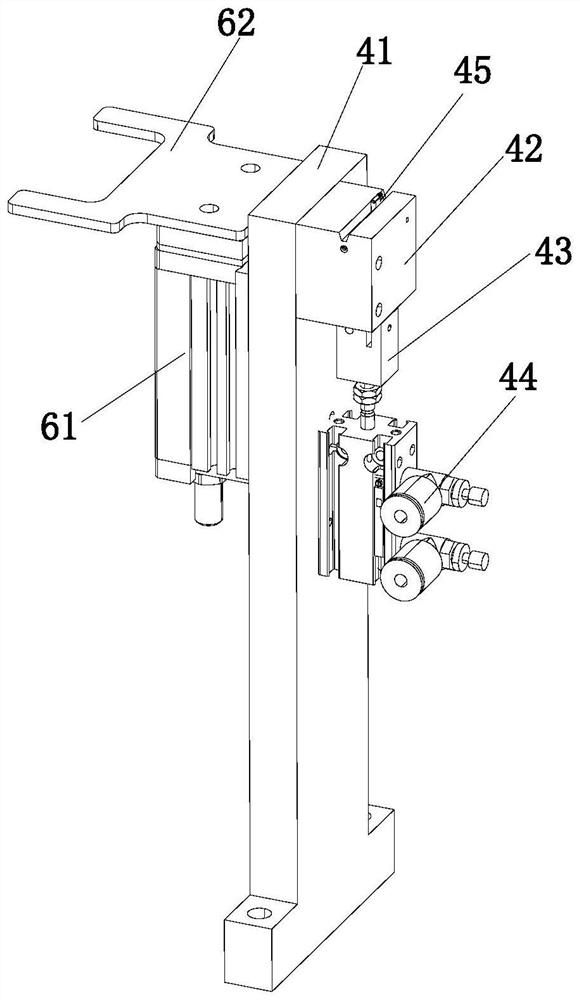

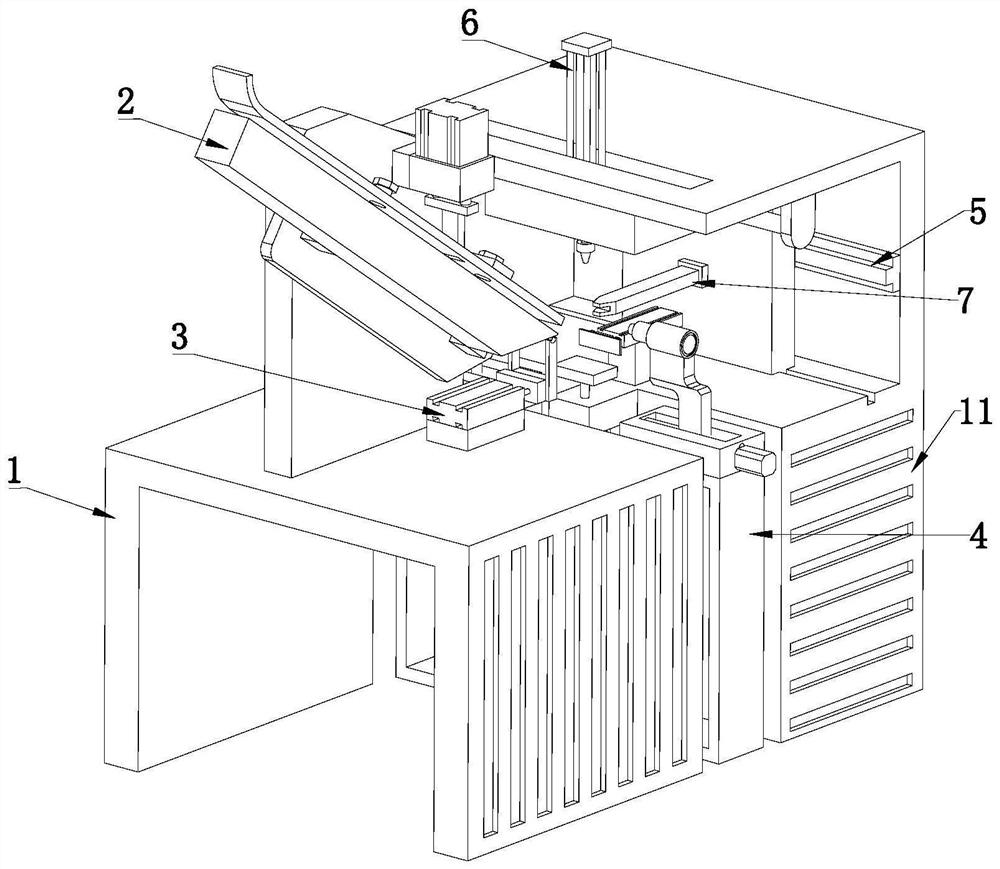

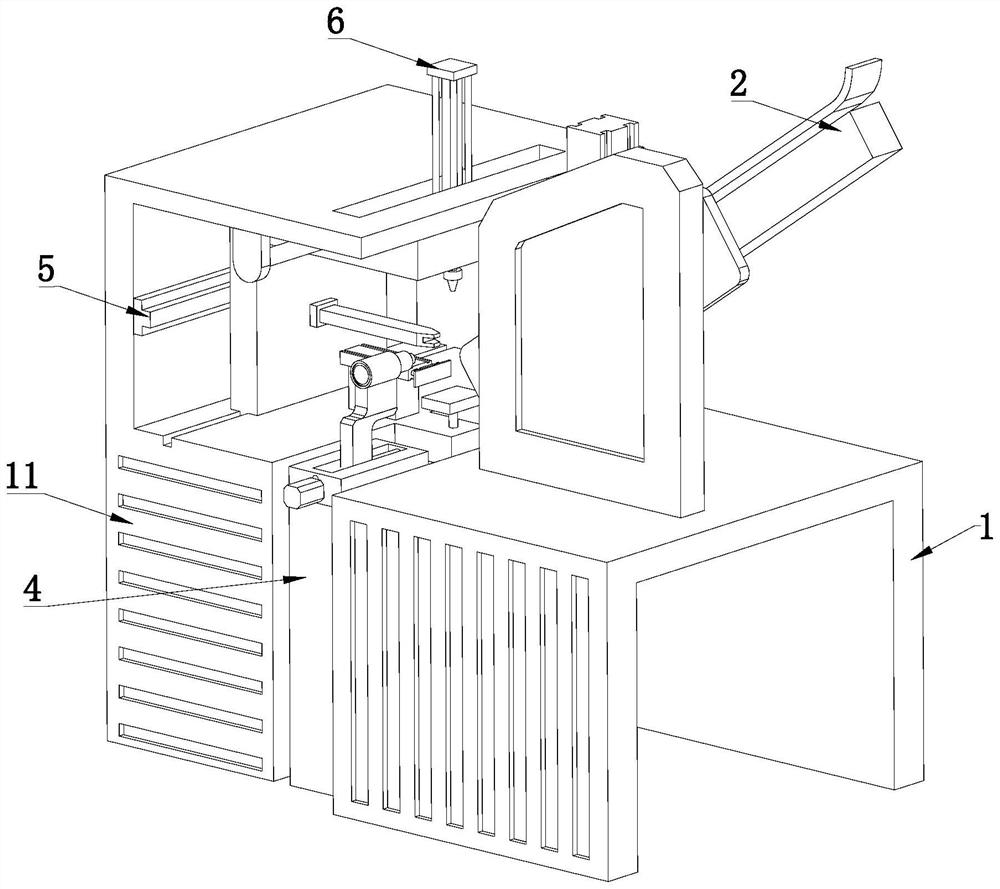

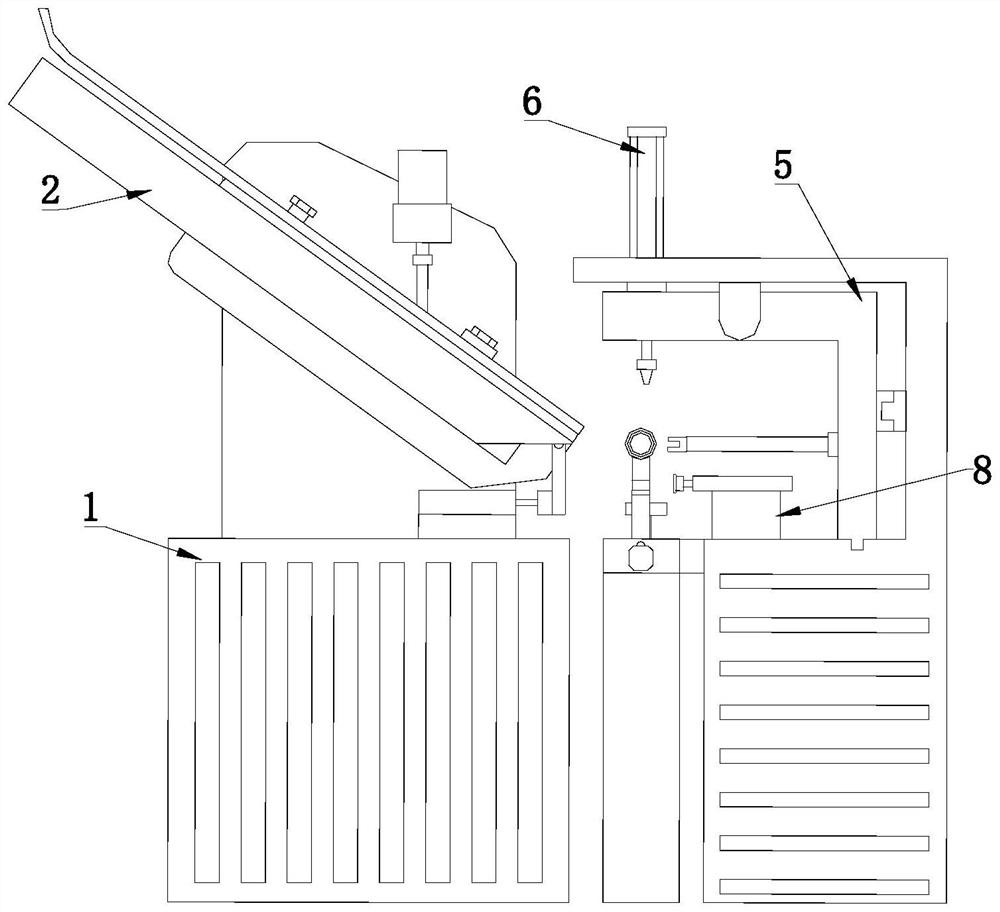

Automatic feeding device for core ring punching and based on rotary grinding wheel forming machine

ActiveCN104003193ARealize the delivery functionRealize automatic loading operationDe-stacking articlesConveyor partsPunchingEngineering

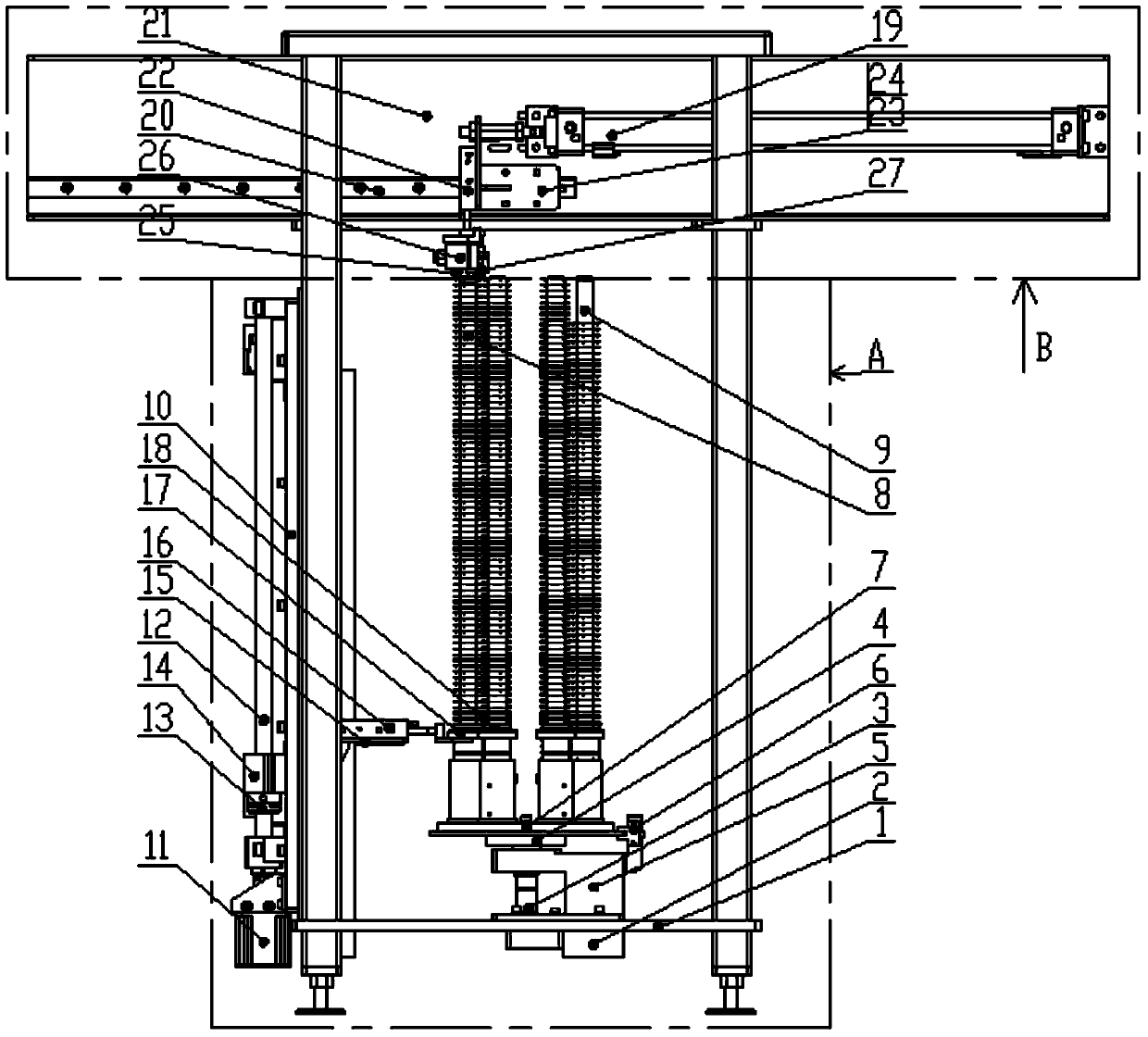

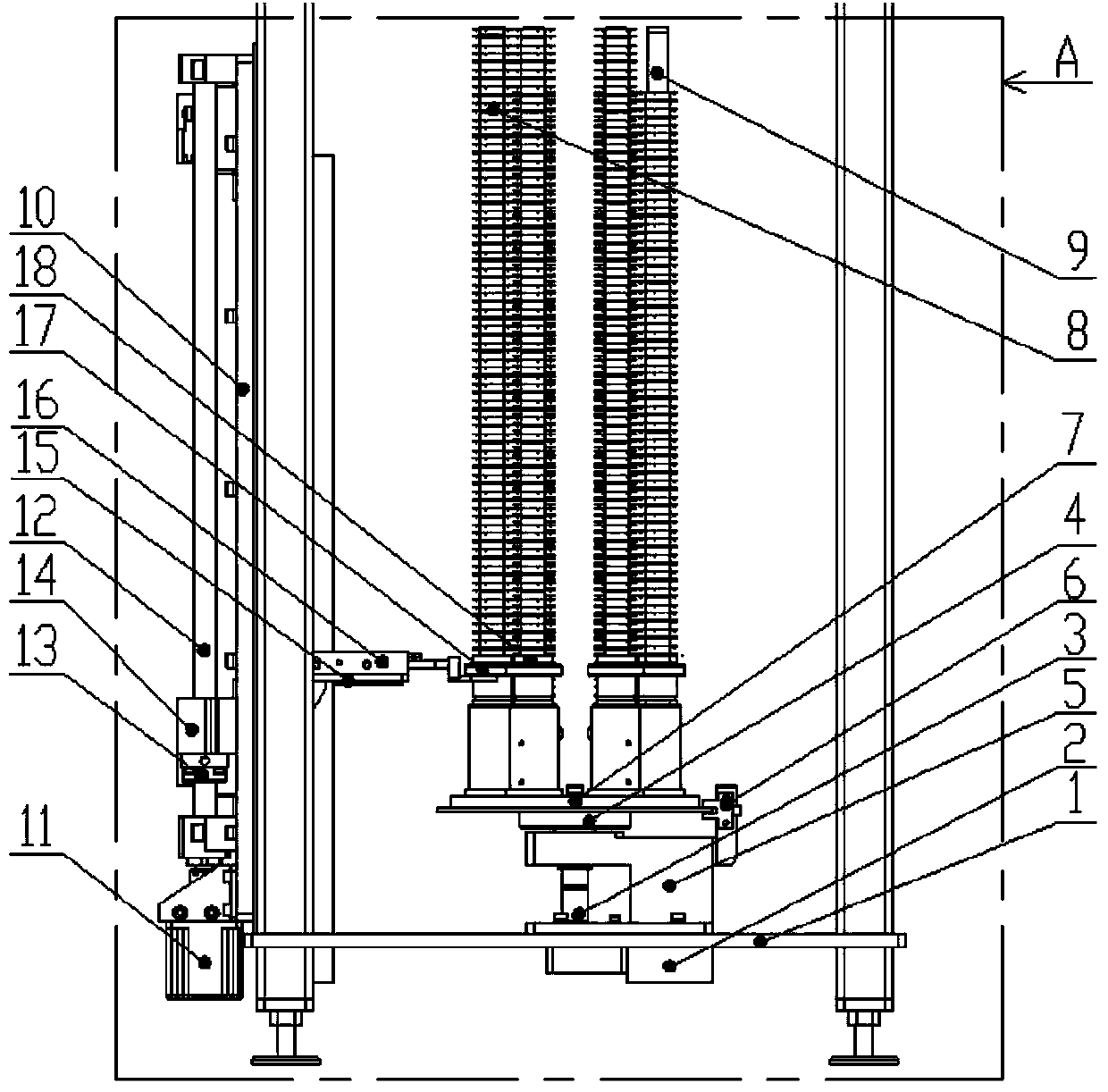

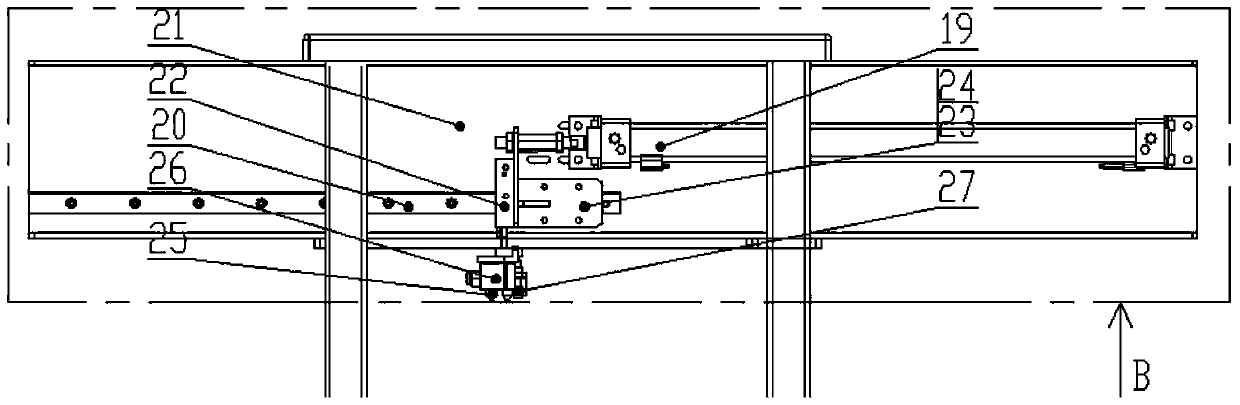

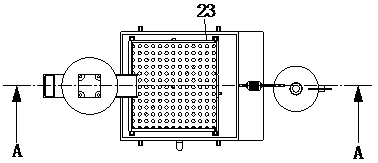

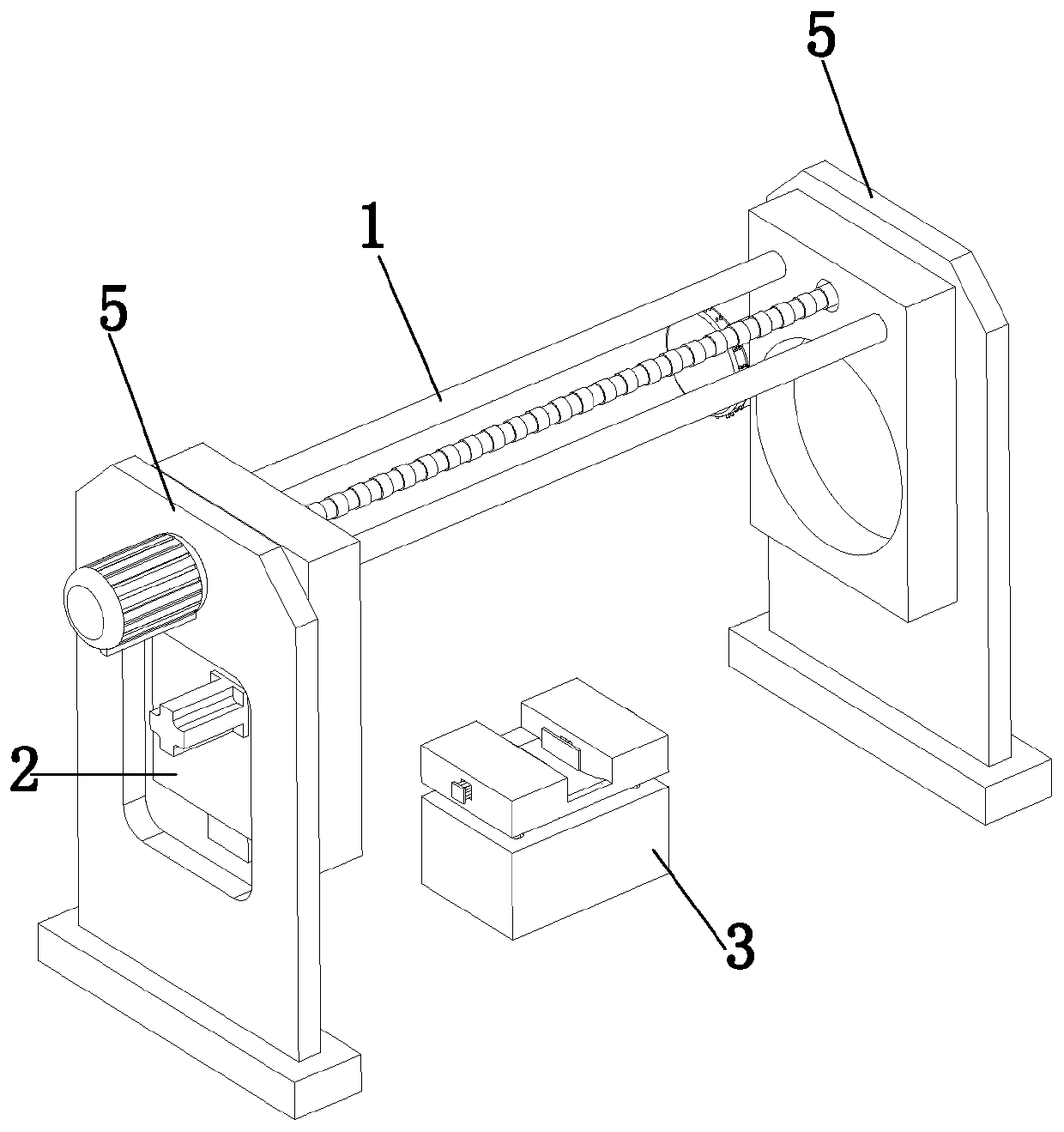

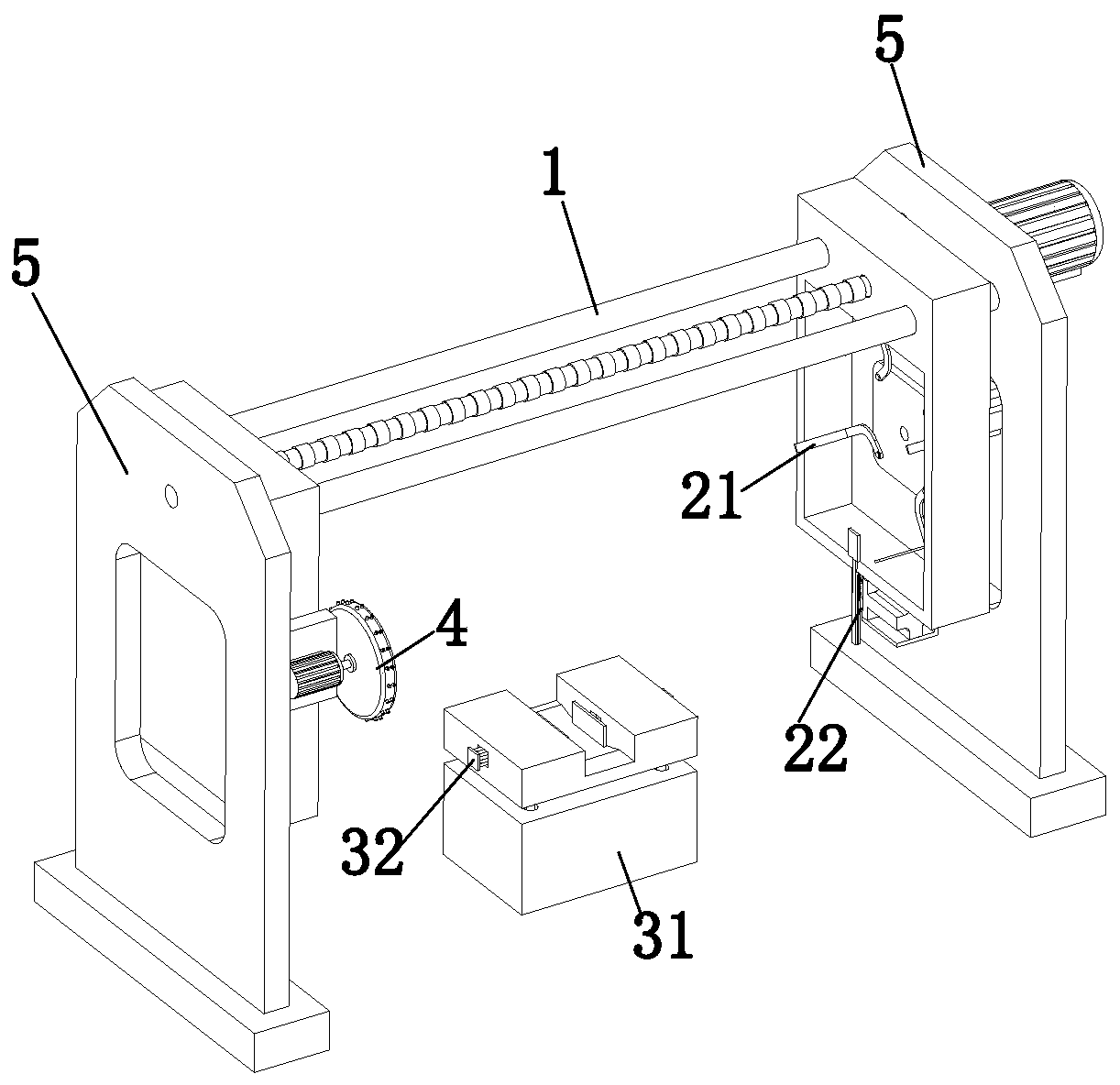

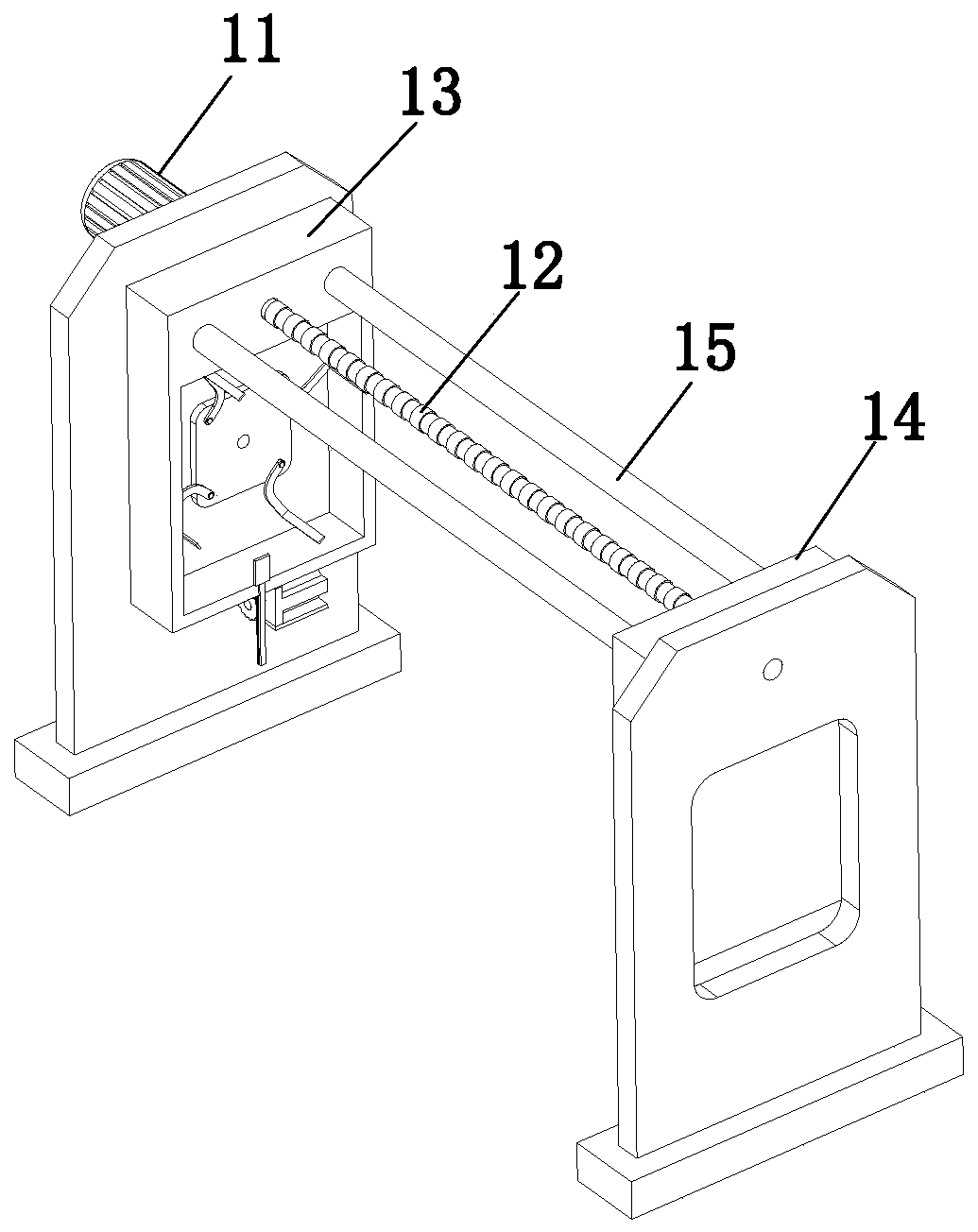

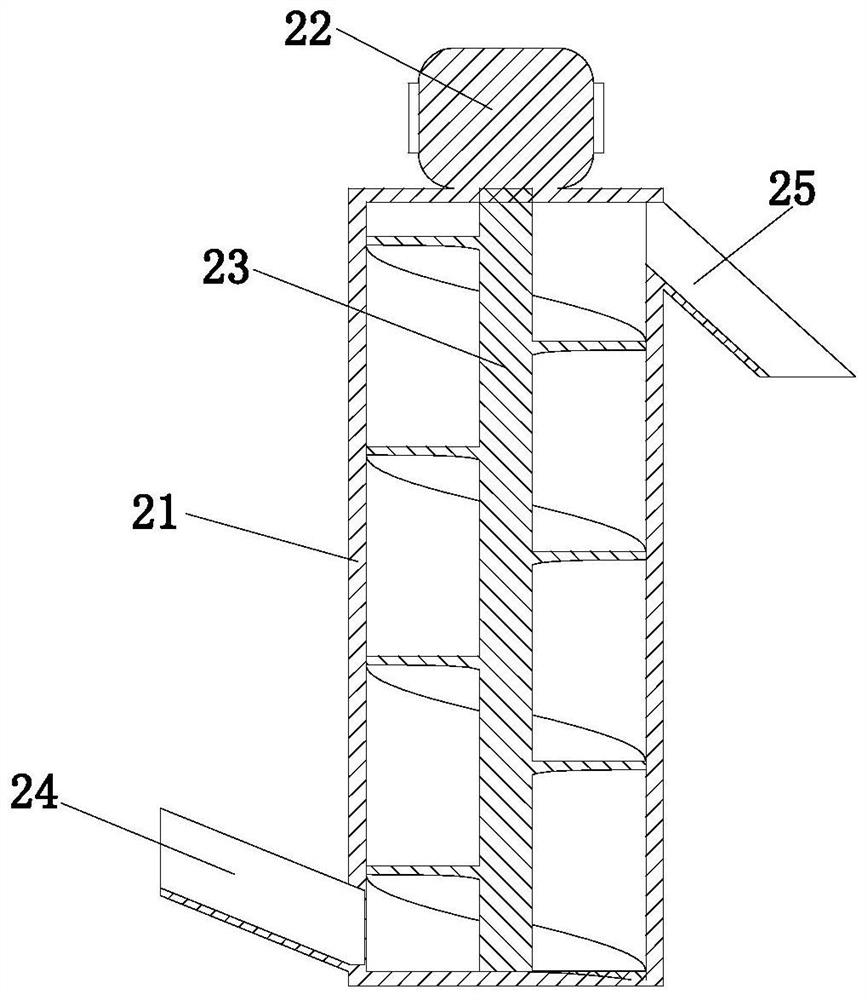

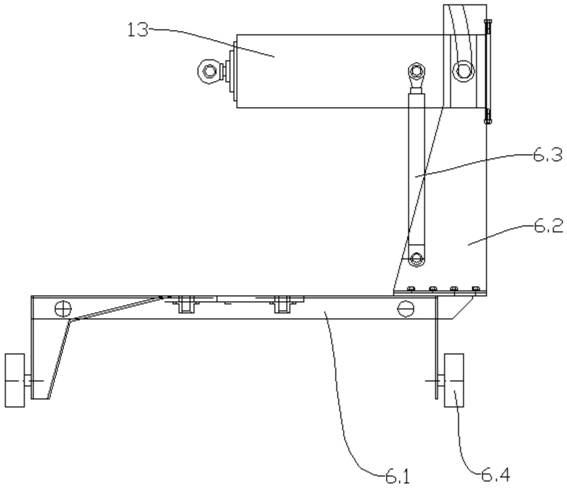

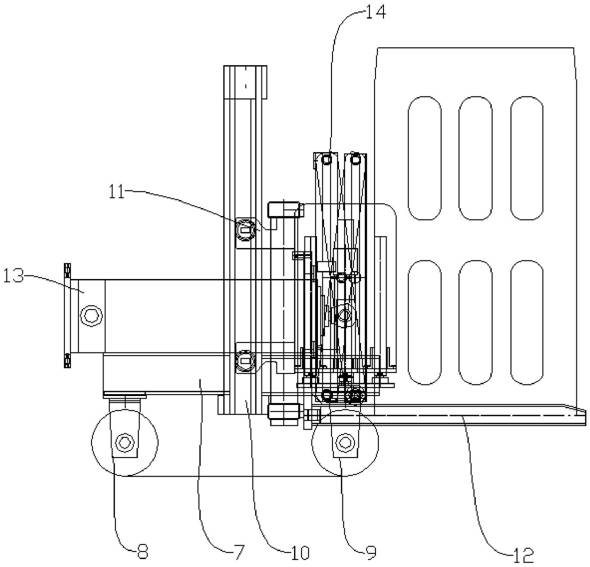

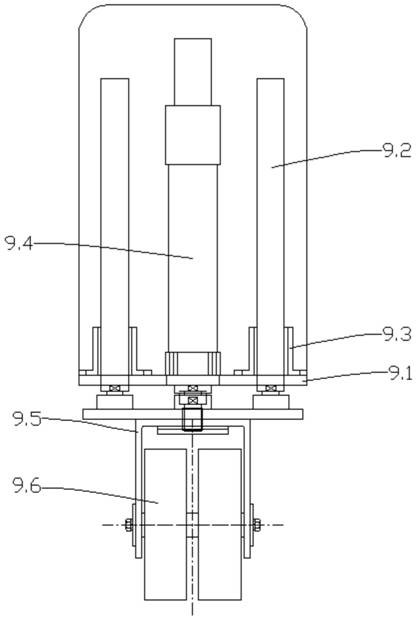

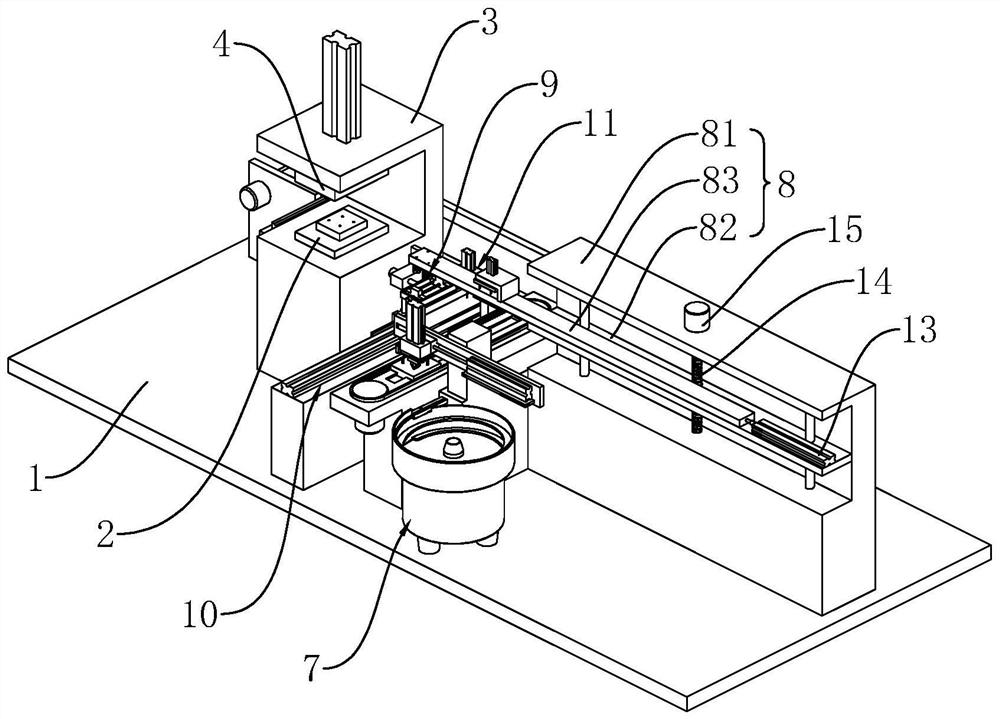

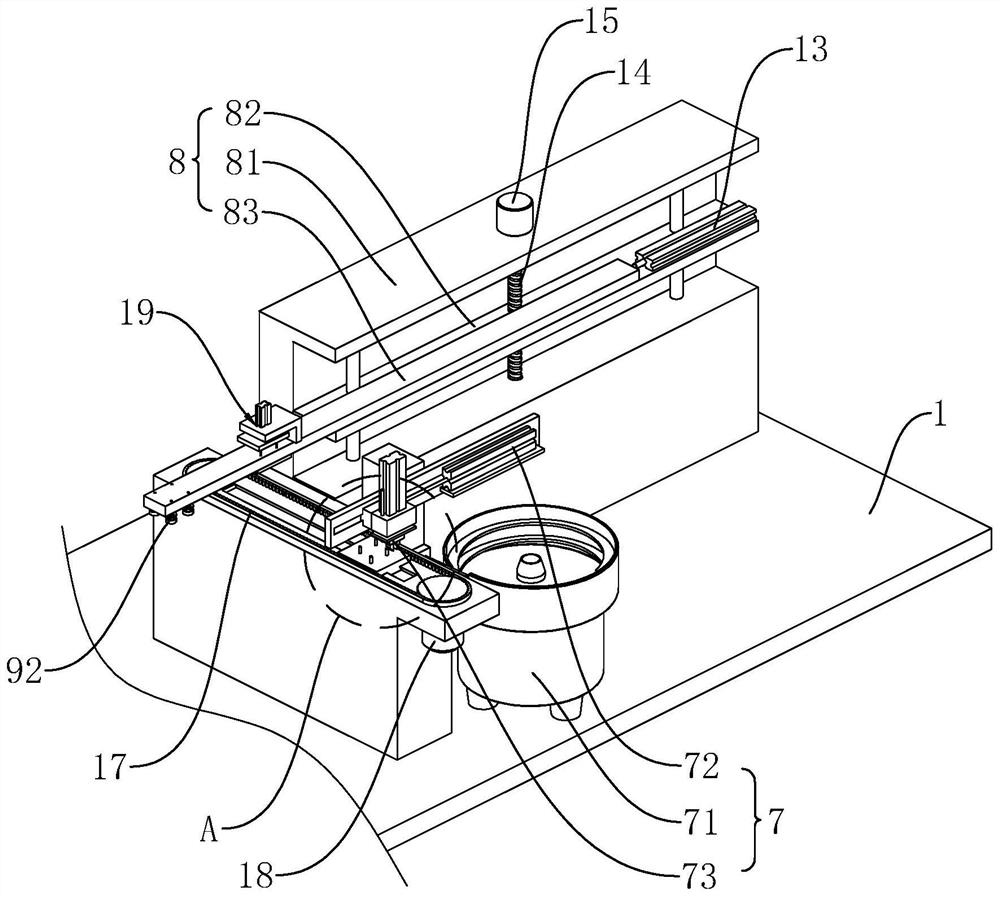

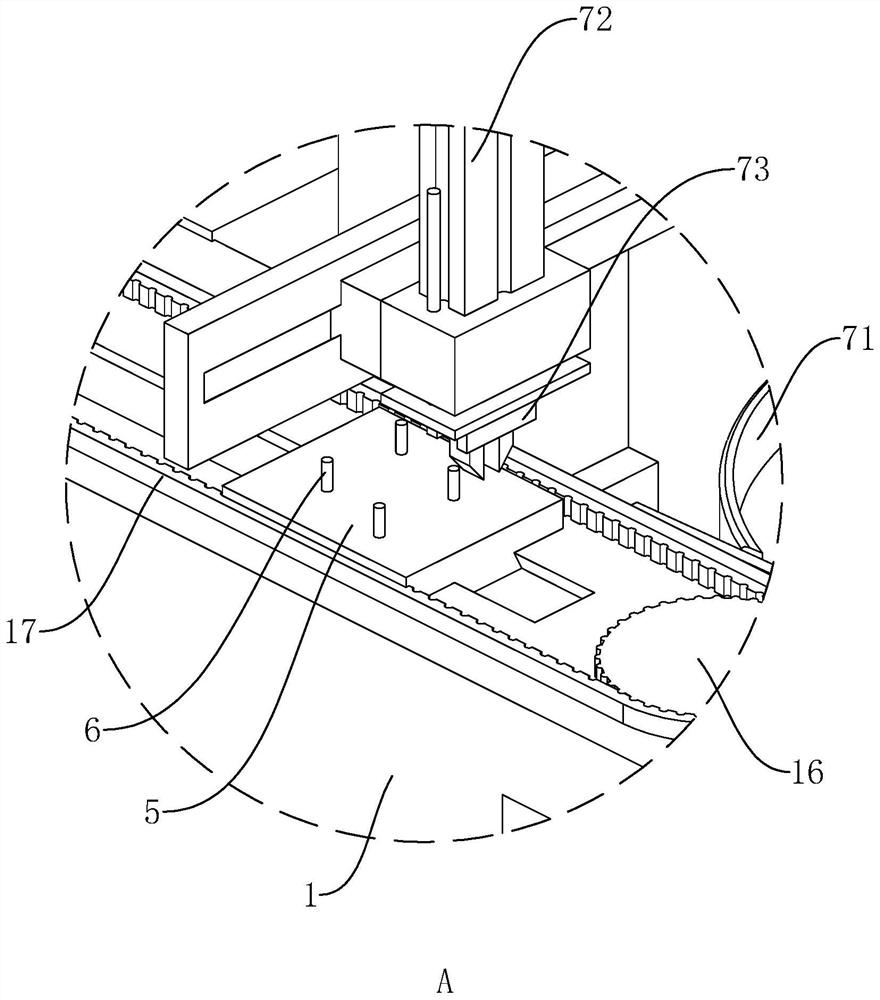

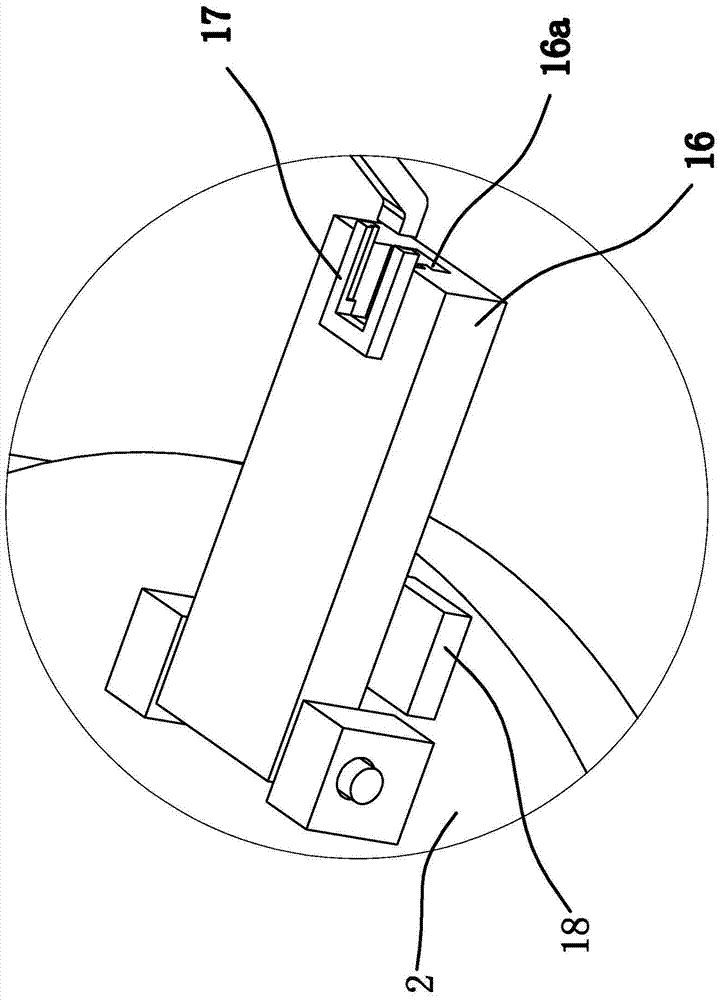

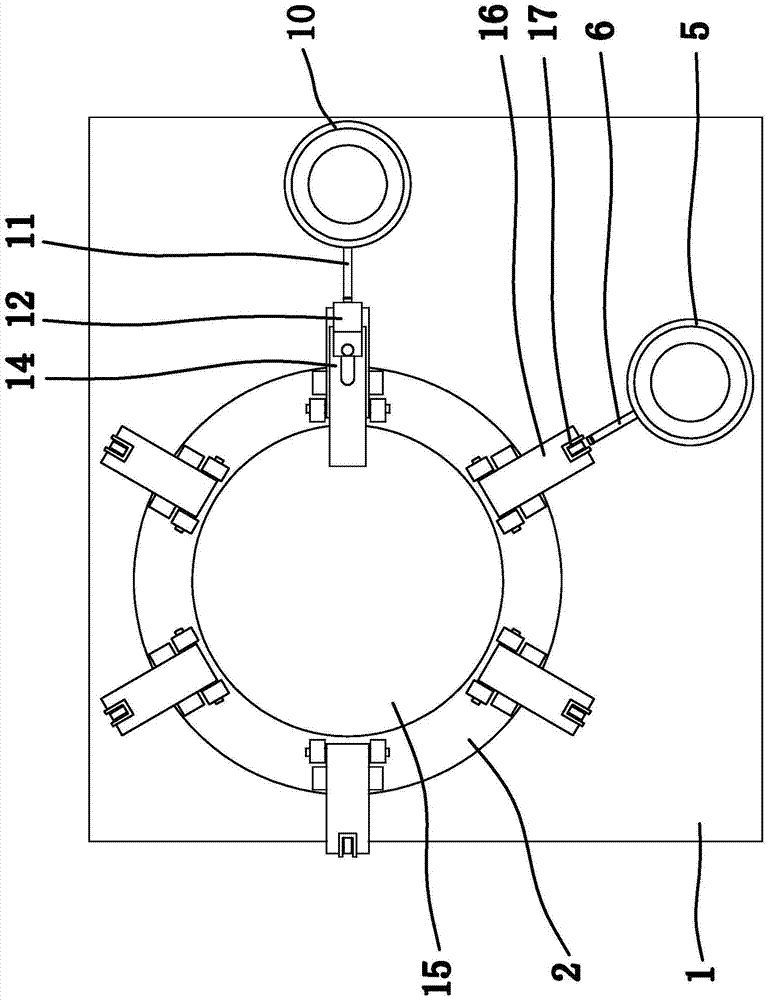

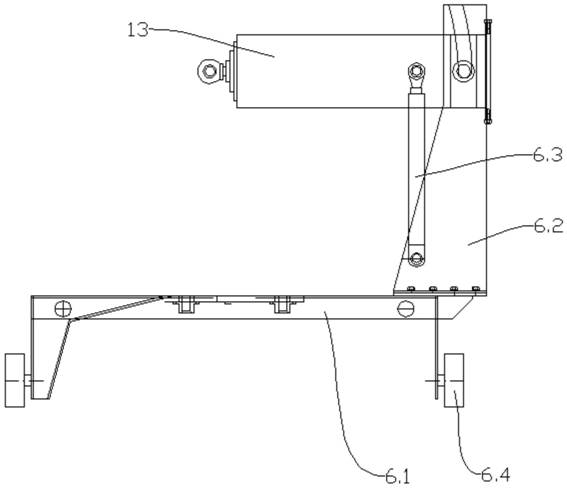

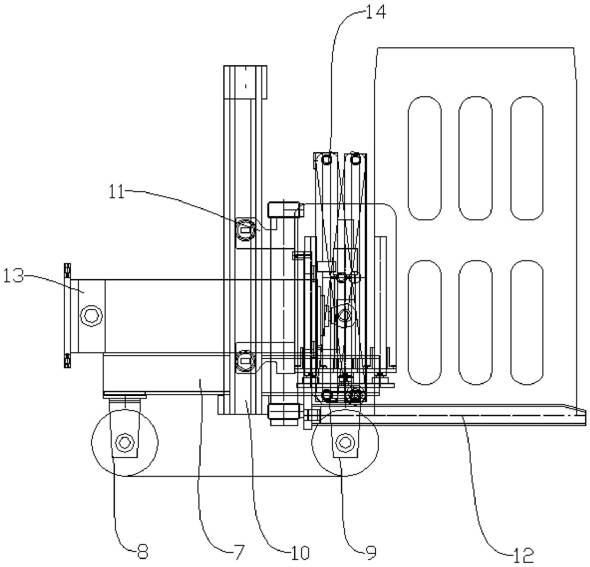

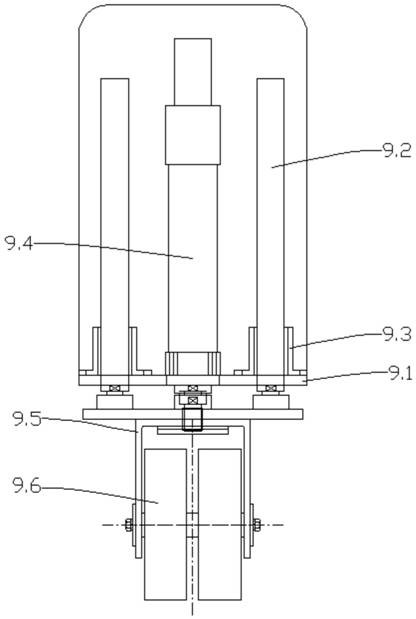

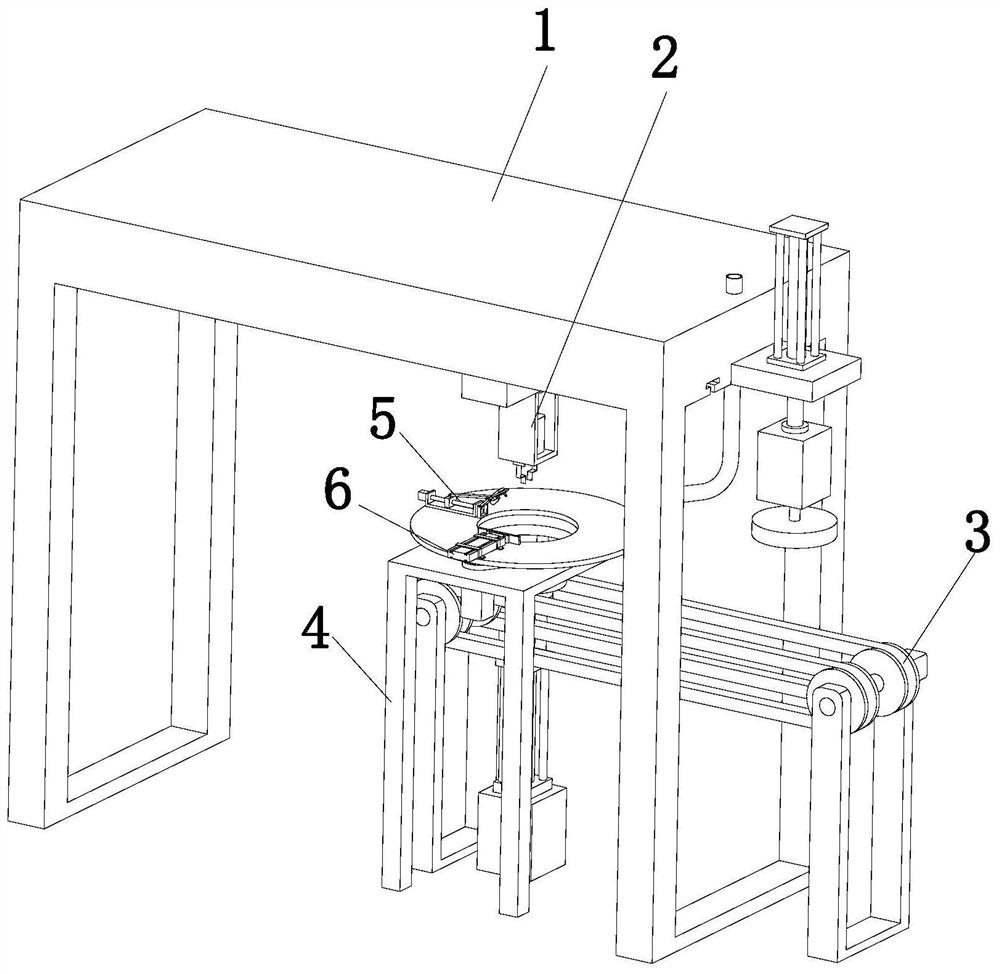

The invention discloses an automatic feeding device for core ring punching and based on a rotary grinding wheel forming machine. The automatic feeding device comprises a main frame body, a rotary disk type core ring stack is arranged on the main frame body, a vertical lifting type core ring conveying mechanism used for driving core rings to move upwards along a string column to achieve a core ring conveying function is arranged on the lateral side of the main frame body, horizontal reciprocating type core ring feeding mechanism is arranged at the top of the main frame body, the horizontal reciprocating type core ring feeding mechanism is used for placing the core rings on the rotary disk type core ring stack into punching work stations of the grinding wheel forming machine, and accordingly the task of automatically feeding the core rings is finished. The automatic feeding device is composed of the rotary disk type core ring stack, the vertical lifting type core ring conveying mechanism and the horizontal reciprocating type core ring feeding mechanism. The automatic feeding device can finish actions of jacking up the core rings, sucking the core rings, horizontally moving the core rings and releasing the core rings. Thus, the automatic feeding device achieves automatic feeding operation of the core rings, effectively avoids personal injury to operators and remarkably improves production efficiency of grinding wheels.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

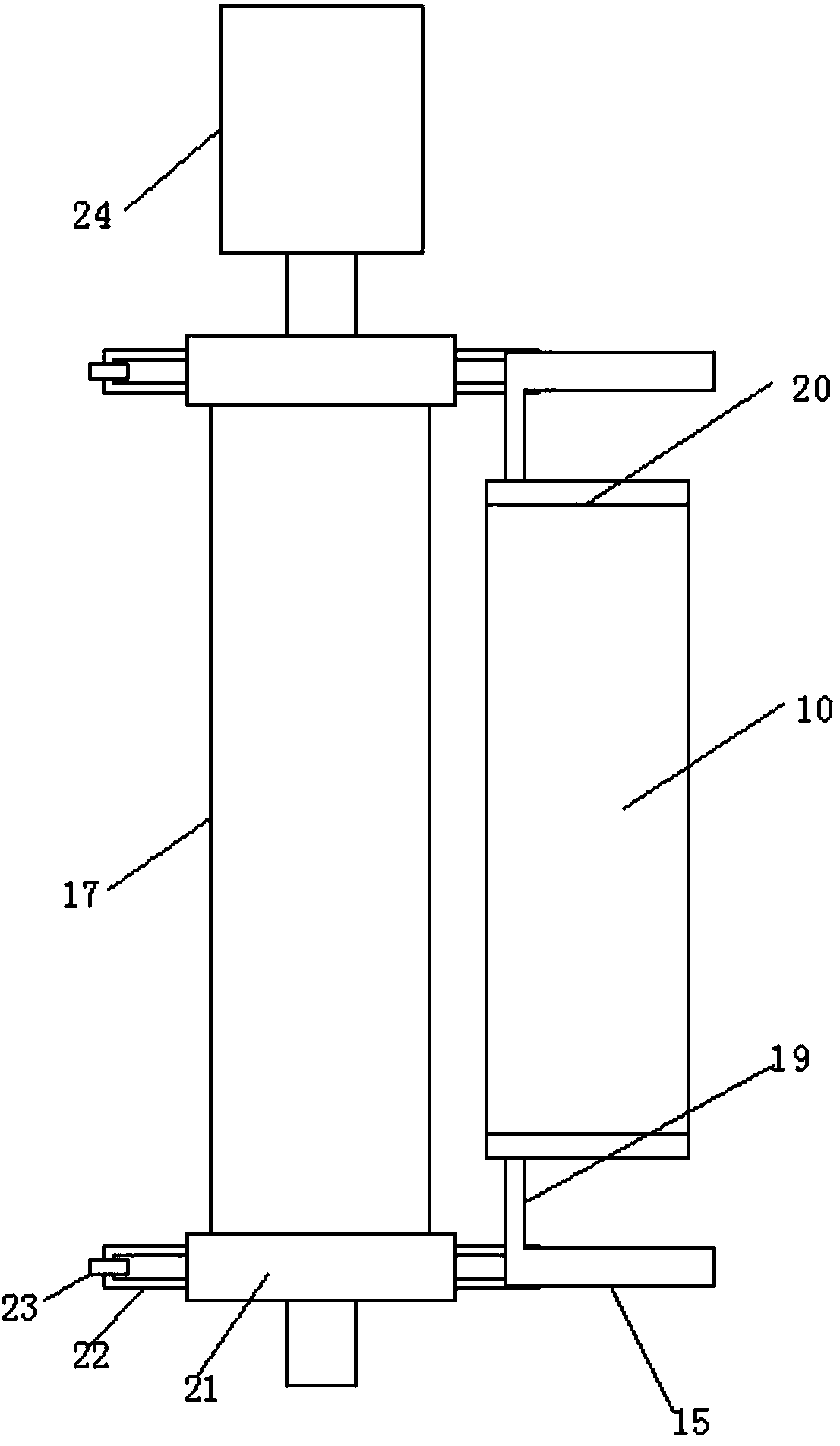

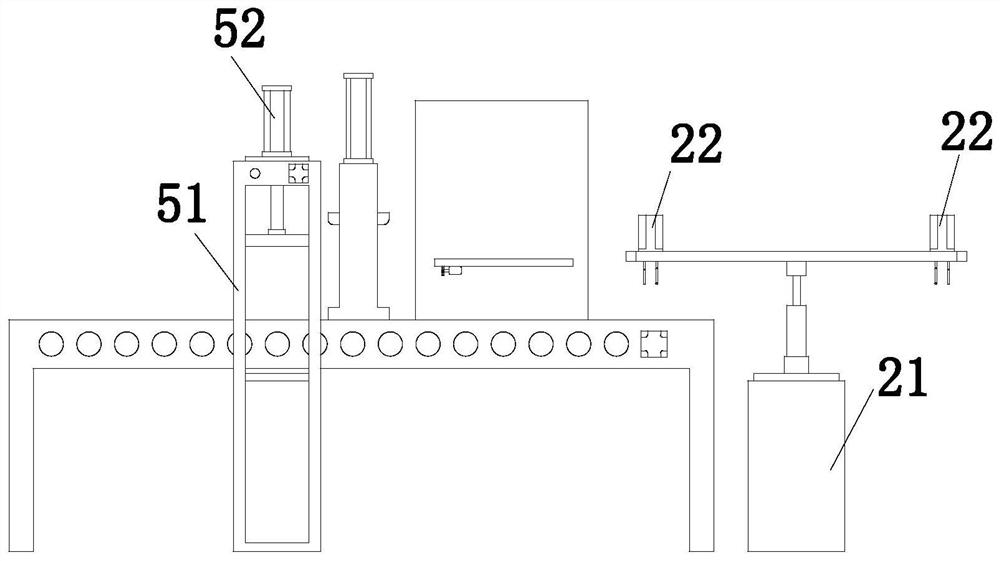

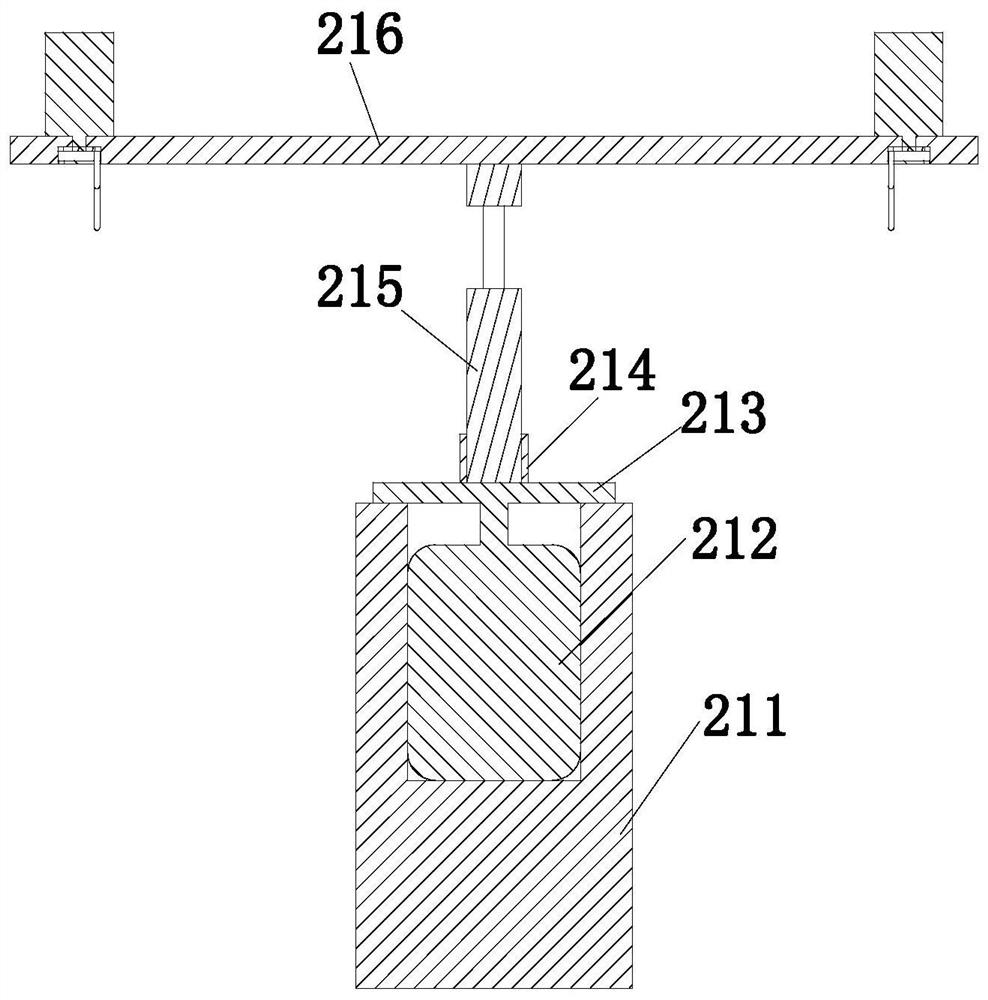

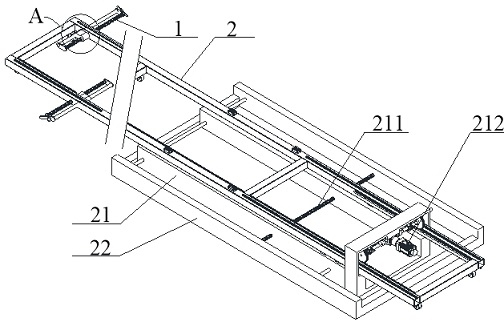

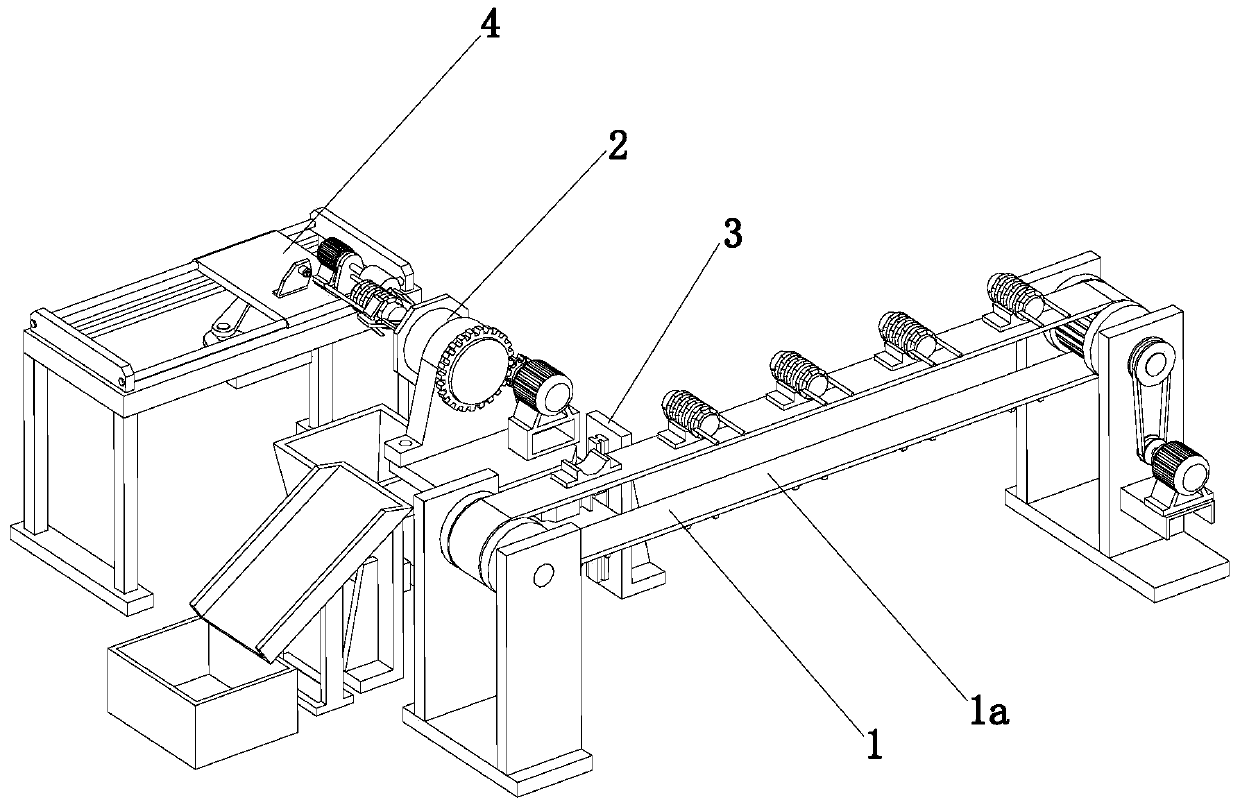

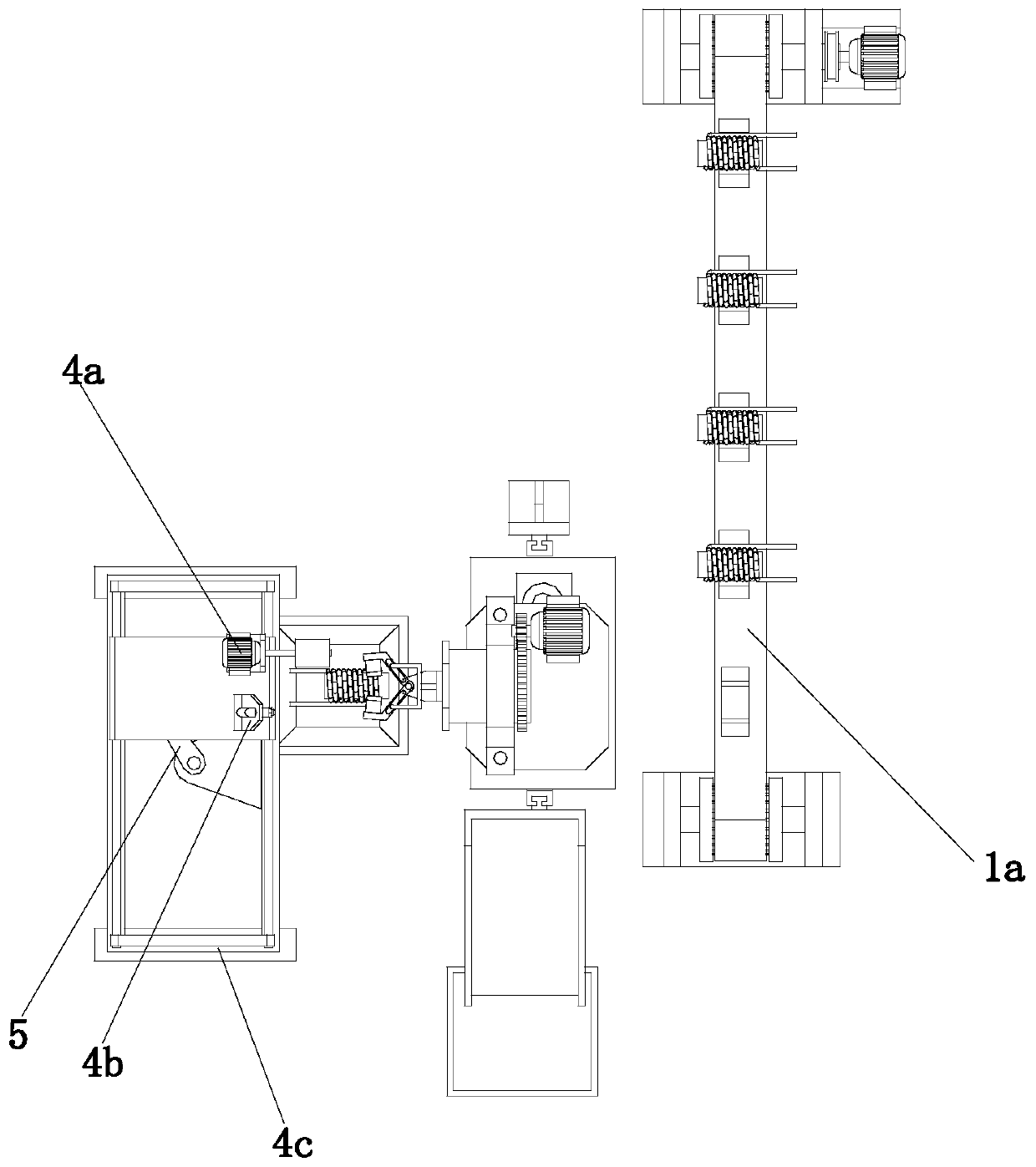

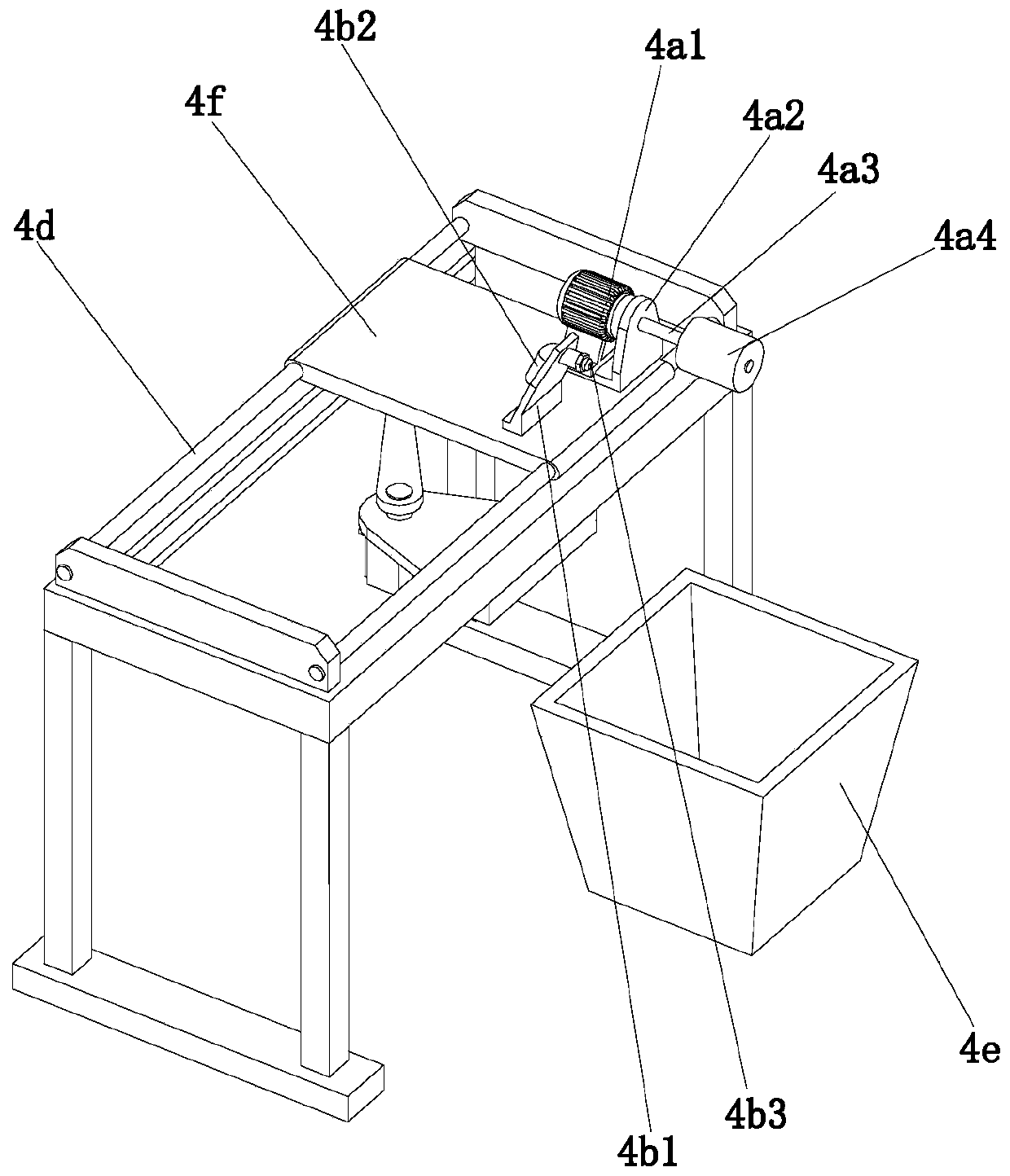

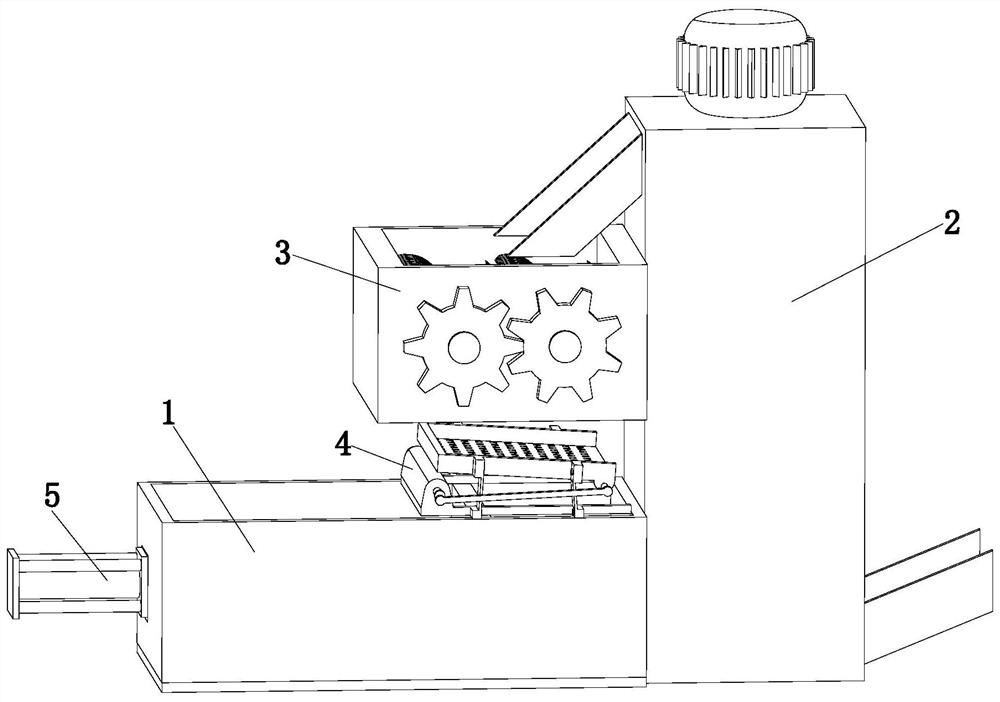

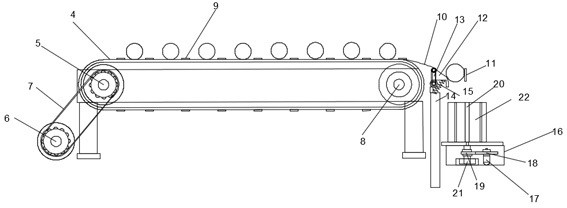

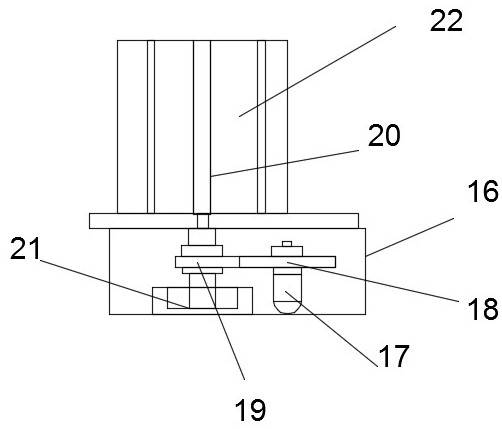

Steel tube feeding device

InactiveCN108557442ARealize automatic loading operationAvoid leaningConveyorsConveyor partsEngineeringUltimate tensile strength

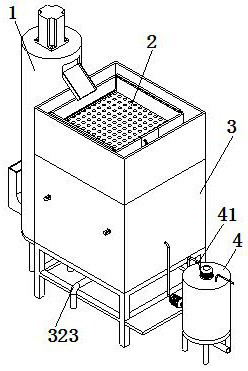

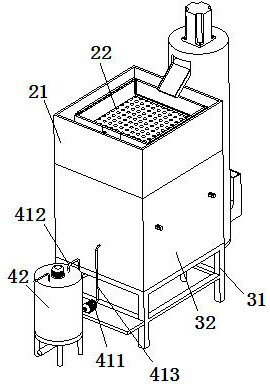

The invention discloses a steel tube feeding device, and relates to the technical field of steel tube production. The steel tube feeding device comprises a conveying rail, a frame, a controller, a storage device and a supplementing device, a conveying device and a receiving device, the conveying rail is driven by a first motor, one end of the supplementing device is connected with the conveying device, the other end of the supplementing device is connected with the storage device, two ends of the frame are connected on the conveying device and the storage device, steel tubes are conveyed ontothe receiving device by the conveying device, the steel tubes are conveyed onto the conveying rail by the conveying device, the conveying device comprises a vibration device, and the controller is electrically connected with the supplementing device, the conveying device and the receiving device. According to the device, the steel tubes are automatically fed, labor intensity of operators is greatly reduced, working efficiency is improved, and potential safety hazards are avoided when the workers carry the steel tubes.

Owner:芜湖良匠机械制造有限公司

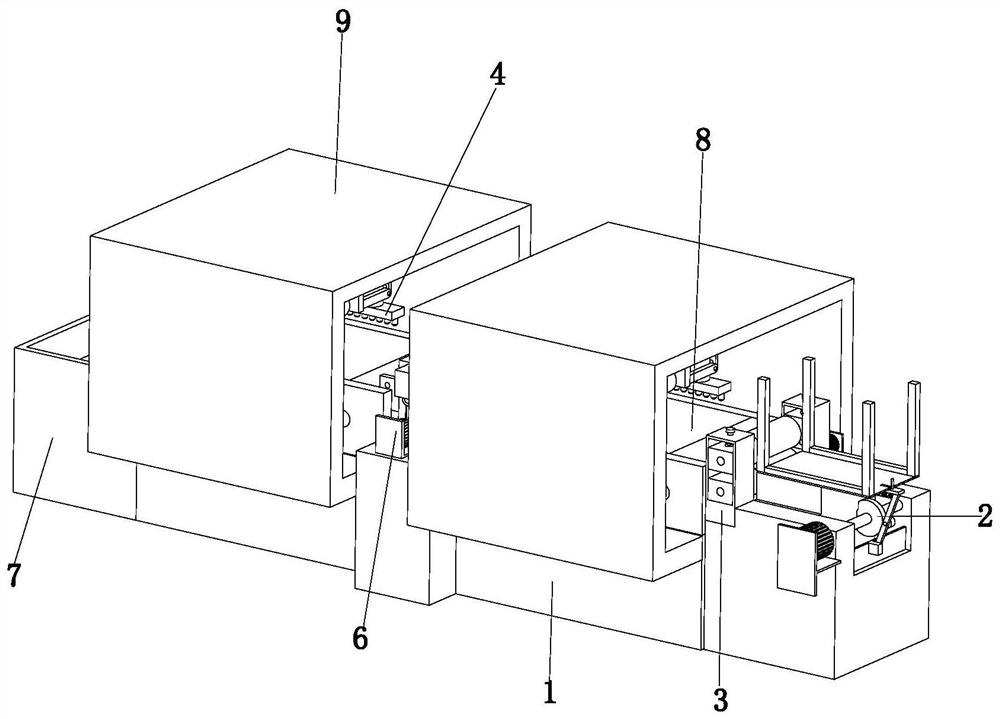

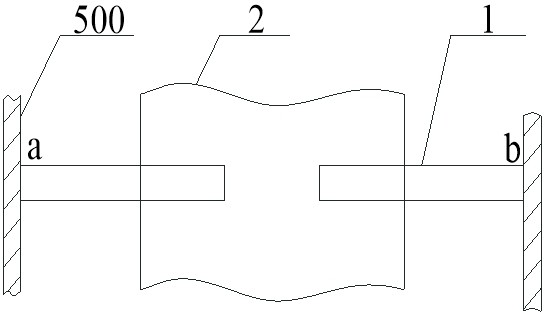

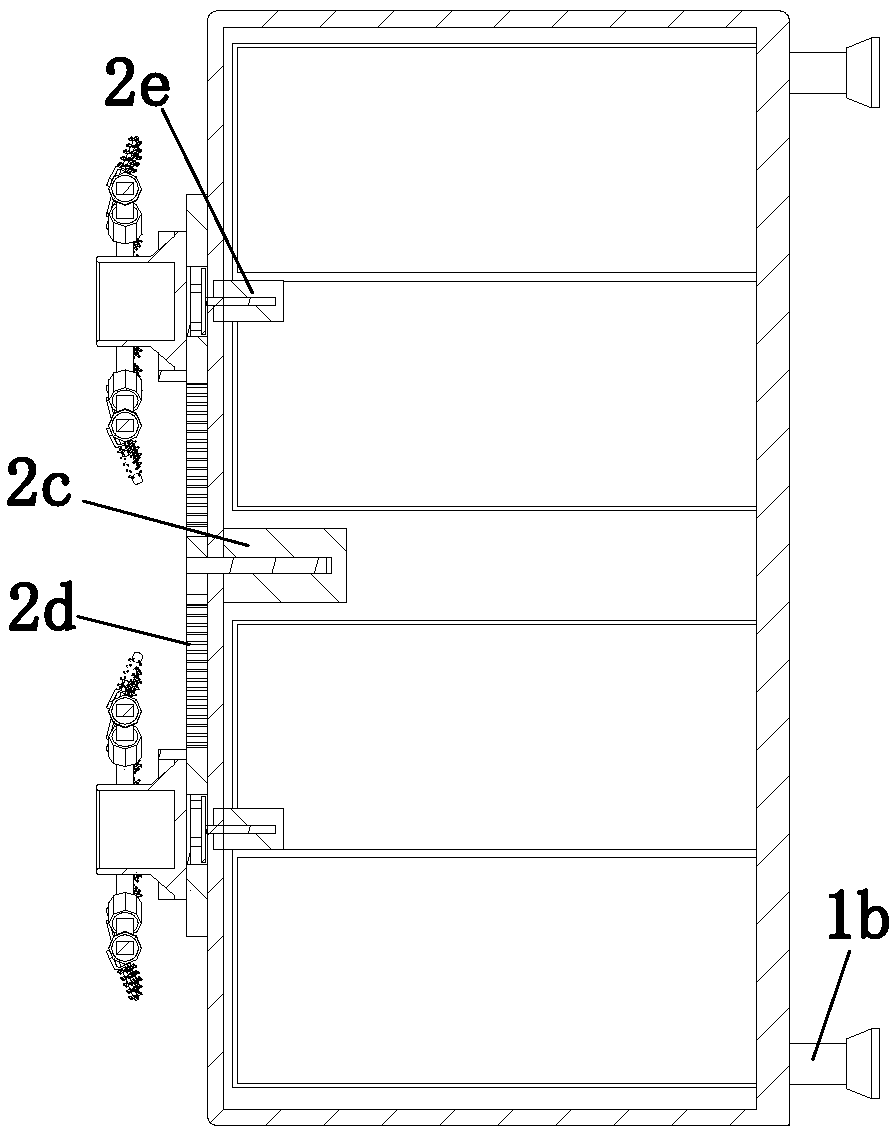

Aluminum alloy door and window double-face spraying equipment and spraying method thereof

InactiveCN112403771ARealize automatic loading operationAvoid wear and tearSpray boothsStructural engineeringWorkbench

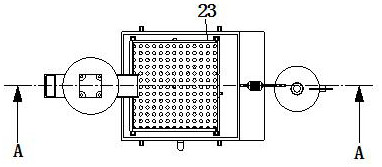

The invention relates to the technical field of aluminum alloy door and window spraying, in particular to aluminum alloy door and window double-face spraying equipment and a spraying method thereof. The aluminum alloy door and window double-face spraying equipment comprises a workbench, a feeding device, a guiding-out device, spraying devices, coating smearing devices, an overturning device, a drying device, two conveying belts and two bearing plates. The workbench is arranged on the ground. The conveying belts are symmetrically installed at the top of the workbench, the bearing plates are symmetrically installed on the workbench, and the feeding device is placed on the ground. The guiding-out device is installed at the top of the feeding device, the spraying devices are installed at the bottoms of the bearing plates, the coating smearing devices are installed at the bottoms of the bearing plates, and the overturning device is installed in the middle of the workbench. The drying deviceis arranged on the ground and located beside the other conveying belt. According to the aluminum alloy door and window double-face spraying equipment and the spraying method thereof, a surface coating of aluminum alloy doors and windows can be fully and evenly smeared through the coating smearing devices, the aluminum alloy doors and windows can be overturned through the overturning device, spraying can be conducted on the other faces directly, and the working efficiency is improved.

Owner:席帅

Mask production and packaging device

InactiveCN111674641AAutomate the packaging processIncrease productivityPackagingCap deviceIndustrial engineering

The invention discloses a mask production and packaging device, and belongs to the technical field of mask production and processing. The device comprises a conveying device, a mask box feeding device, a mask placing device, a mask compacting device and a packaging and sealing device. The conveying device is vertically arranged. The film box feeding device comprises a rotating part and two mobilefeeding parts. The rotating part is arranged on a laterally side of the conveying device. The two mobile feeding parts are symmetrically arranged on the rotating part, and the mask placement device isarranged on the top of the conveying device. The mask compacting device is arranged at the top of the conveying device. The mask compacting device is mounted on the conveying device, and the packaging and sealing device comprises a box cover moving part and a box cover taking part, and the box cover moving part is arranged on the top of the conveying device, and the box cover taking part is arranged on the box cover moving part. Through the mutual coordination of the devices, the mask production and packaging device can pack masks of small bags into mask boxes, and improve work efficiency.

Owner:程红梅

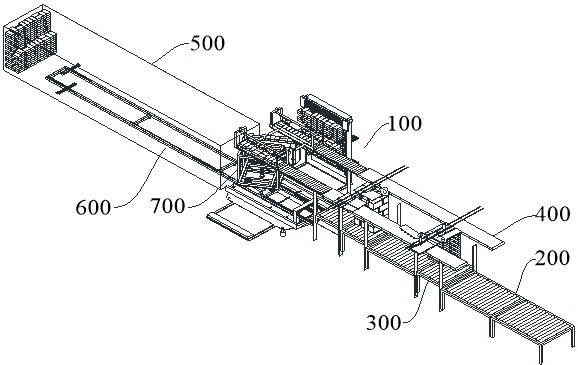

Automatic container loading system

ActiveCN112061816ARealize automatic loading operationNot easy to damageSupporting framesStacking articlesStructural engineeringIndustrial engineering

The invention relates to the technical field of automatic loading equipment, and provides an automatic container loading system which comprises an unstacking device, a row stacking mechanism, a conveying vehicle and a loading mechanism; the unstacking device is used for unstacking box stacks and conveying cargo boxes one by one, and the orientations of all the cargo boxes are consistent; the row stacking mechanism comprises a row forming assembly and a box receiving assembly, the row forming assembly is arranged at the output end of the unstacking device and used for arranging the multiple cargo boxes into cargo box columns with the preset length, and the box receiving assembly is used for receiving a preset number of layers of cargo box columns layer by layer to form cargo box rows; the conveying vehicle is used for receiving the cargo box rows from the box receiving assembly; and the loading mechanism can extend into containers, and the cargo box rows are placed at a preset position.Therefore, according to the automatic container loading system, the unstacking device and the row stacking mechanism are arranged outside the cargo boxes, so that the cargo box stacks are quickly disassembled, and the cargo box rows are formed according to the specifications of the containers; the loading mechanism extends into the containers, and the cargo box rows are integrally conveyed into the containers through the conveying vehicle; and the loading speed is high, goods are not prone to being damaged, the automation degree of the whole loading process is high, and automatic loading operation of the containers can be achieved under the unmanned condition.

Owner:山东伟豪思智能仓储装备有限公司

Construction waste recycled aggregate smashing equipment

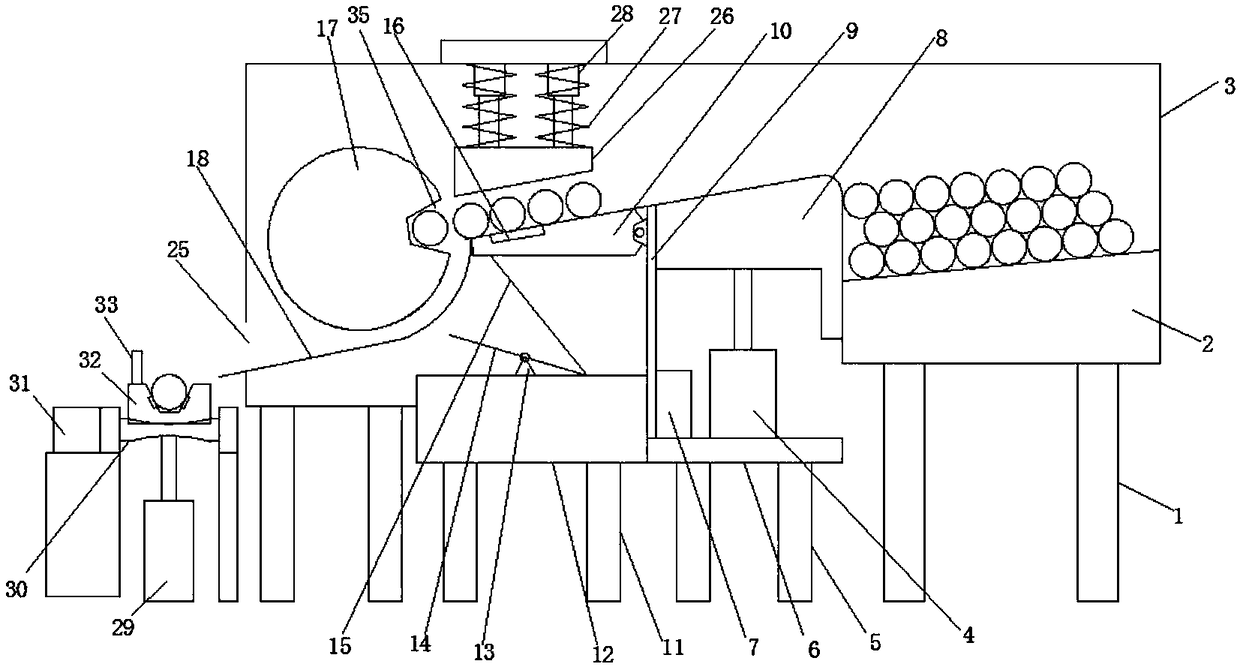

InactiveCN111570008ARealize automatic loading operationImprove work efficiencyGrain treatmentsDrive wheelDrive shaft

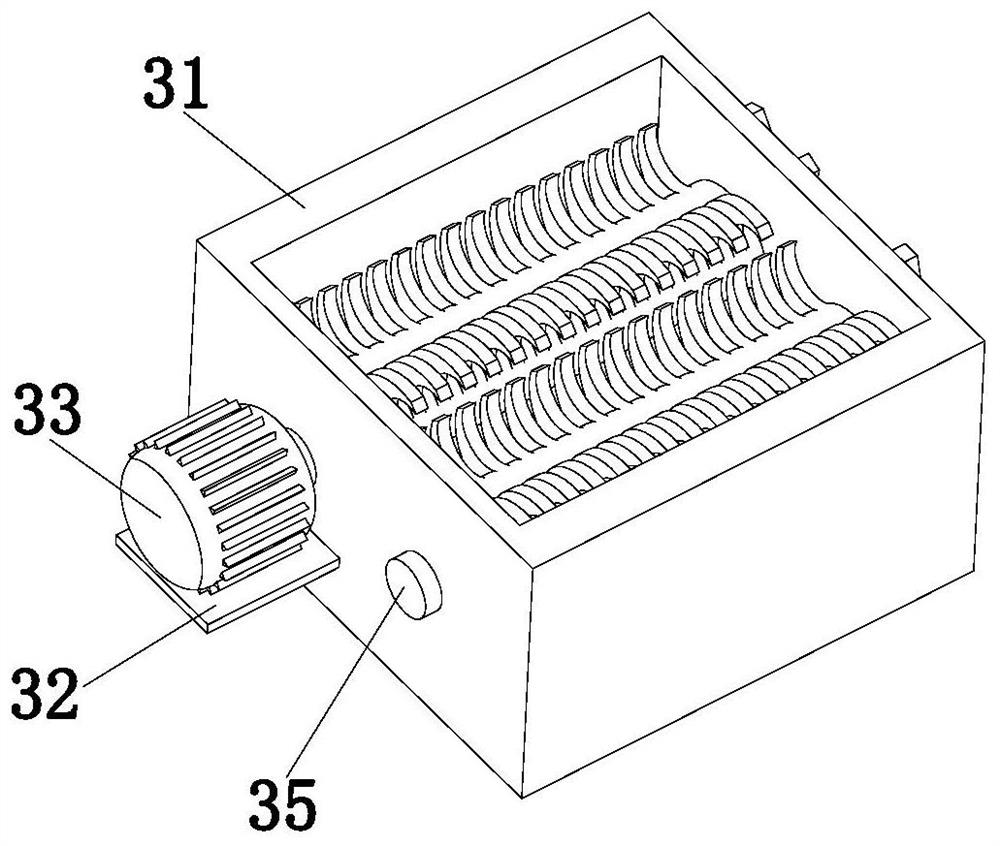

The invention discloses construction waste recycled aggregate smashing equipment and belongs to the technical field of coating production equipment. The construction waste recycled aggregate smashingequipment comprises a smashing box, a primary smashing component, a feeding component and a secondary smashing component; the feeding component comprises a feeding piece and a feeding closing piece; the feeding piece is arranged by the side of a smashing piece; the feeding closing piece is arranged on the top of the smashing box; the primary smashing component comprises a primary smashing piece and a screening piece; the primary smashing piece is arranged in the smashing box; and the secondary smashing component is vertically arranged at the bottom of the smashing box. According to the construction waste recycled aggregate smashing equipment, two drive motors work to drive two driving shafts to rotate on the smashing box; the two driving shafts rotate to drive two driving cams to rotate; and the two driving cams rotate to drive two driving wheels to rotate, so that a screening otter board is driven to generate vibration on the smashing box through a plurality of connecting springs, theprimarily smashed construction waste is filtered and screened, and the construction waste not meeting the standard is further smashed.

Owner:广东通兴再生资源科技有限公司

Waste recovery device for biotechnology pharmacy

The invention discloses a waste recovery device for biotechnology pharmacy, and belongs to the technical field of pharmaceutical equipment. The waste recovery device comprises a conveying assembly, a screening assembly, a compacting assembly and a drying assembly, wherein the compacting assembly comprises a mounting frame, a compacting box, a compacting member and a water filtering plate obliquely arranged in the compacting box; the screening assembly comprises a screening box, a screening member and a scraping member; the screening box is arranged at the top of the compacting box; the screening member is arranged in the screening box; one end of the screening member extends into the compacting box; the drying assembly comprises a conveying member and a drying member; the drying member is arranged by the side of the mounting frame; and the conveying member is arranged by the side of the mounting frame. According to the water recovery device, a compacting plate is driven through the rotation of four screw rods to move on a moving groove on the compacting box so as to squeeze the wastes, so that water in wastes is filtered out through the water filtering plate; and after the water in the wastes is squeezed out, the wastes can be dried conveniently, and therefore the water and the solid in the wastes are separated.

Owner:赵录翠

New energy automobile tire production positioner

The invention discloses a new energy automobile tire production positioner, and belongs to the technical field of tire production equipment. The new energy automobile tire production positioner comprises a moving assembly, a clamping and positioning assembly, a feeding assembly, a rotating assembly and two mounting seats, wherein the two mounting seats are symmetrically and vertically arranged; the moving assembly is arranged on the two mounting seats; the clamping and positioning assembly comprises a clamping piece and a positioning piece; the clamping piece is arranged at the moving end of the moving assembly; the positioning piece is arranged at the bottom of the moving end of the moving assembly; the feeding assembly comprises a lifting piece and a limiting piece; the lifting piece isvertically arranged between the two mounting seats; the limiting piece is arranged on the lifting piece; and the rotating assembly is arranged at one end of the moving assembly. According to the new energy automobile tire production positioner, a rotating motor works to drive a rotating gear to rotate, the rotating gear rotates to drive a moving toothed bar to move on a moving plate, the moving toothed bar moves to drive a positioning plate to move, the positioning plate is moved to the side of a tire to position the tire, and the tire is prevented from shaking in the moving process.

Owner:郑云龙

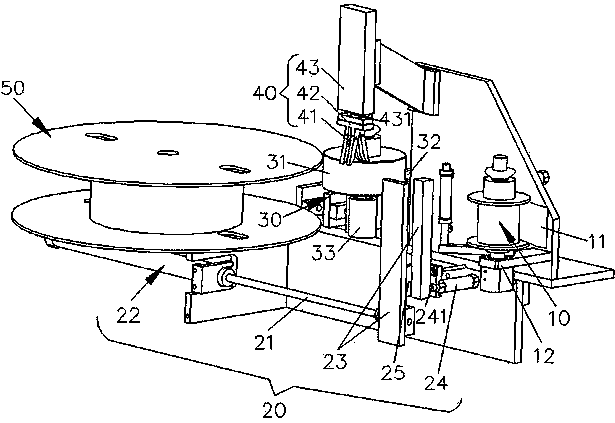

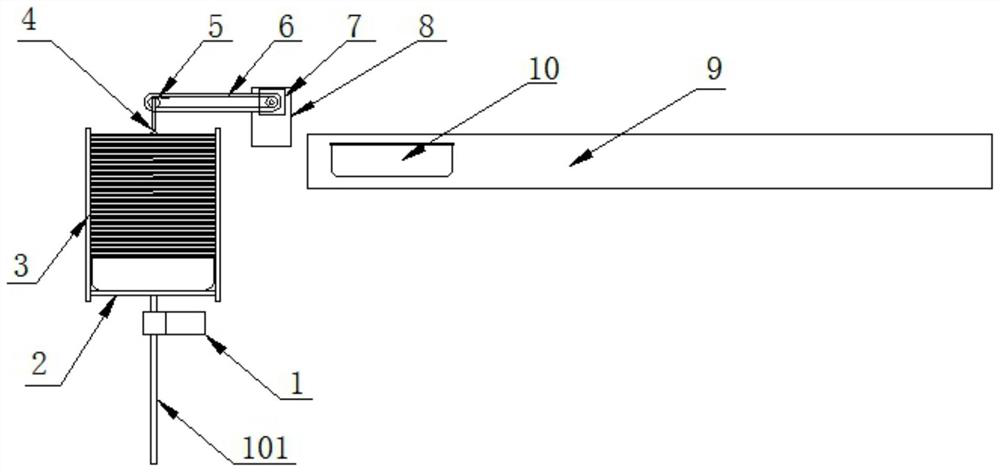

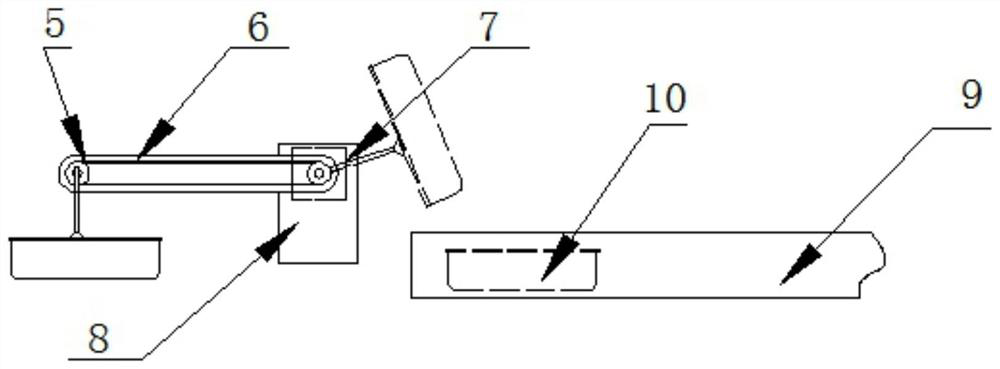

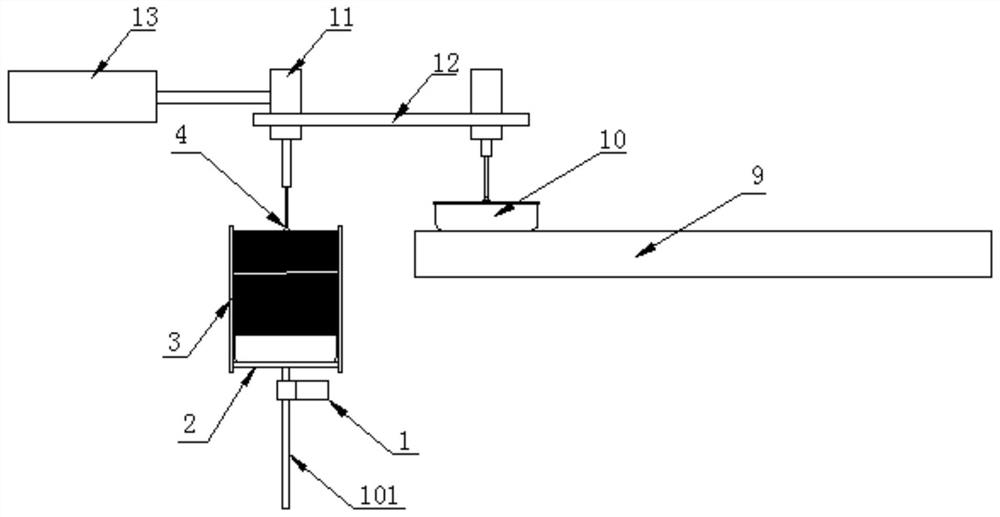

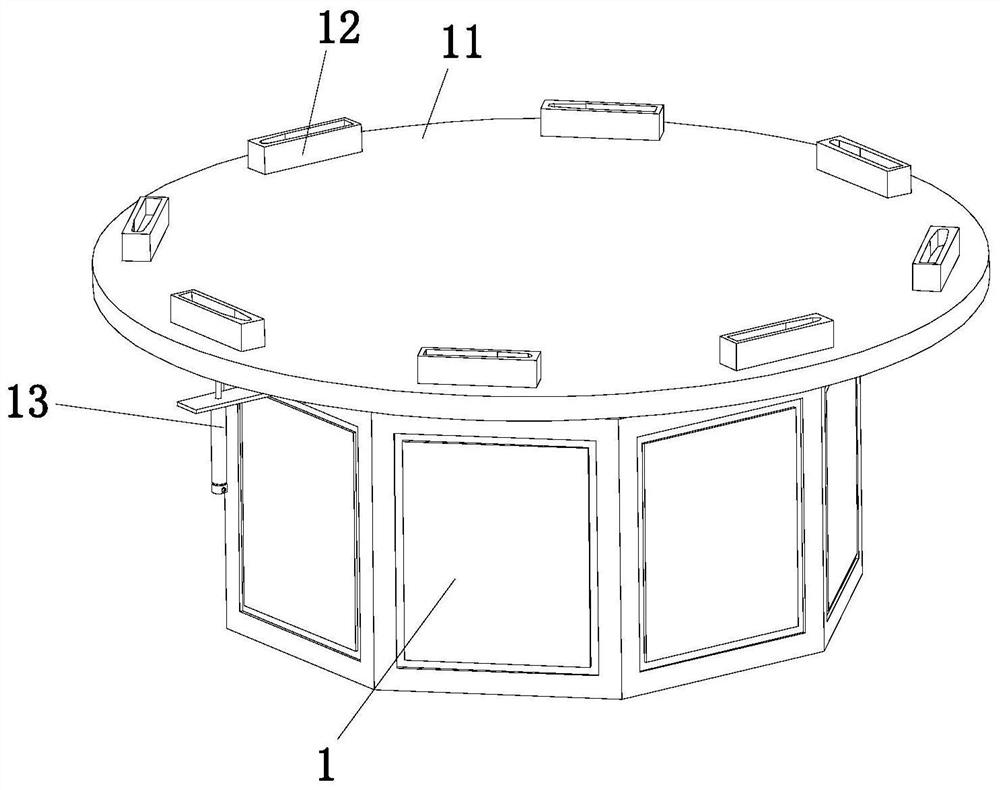

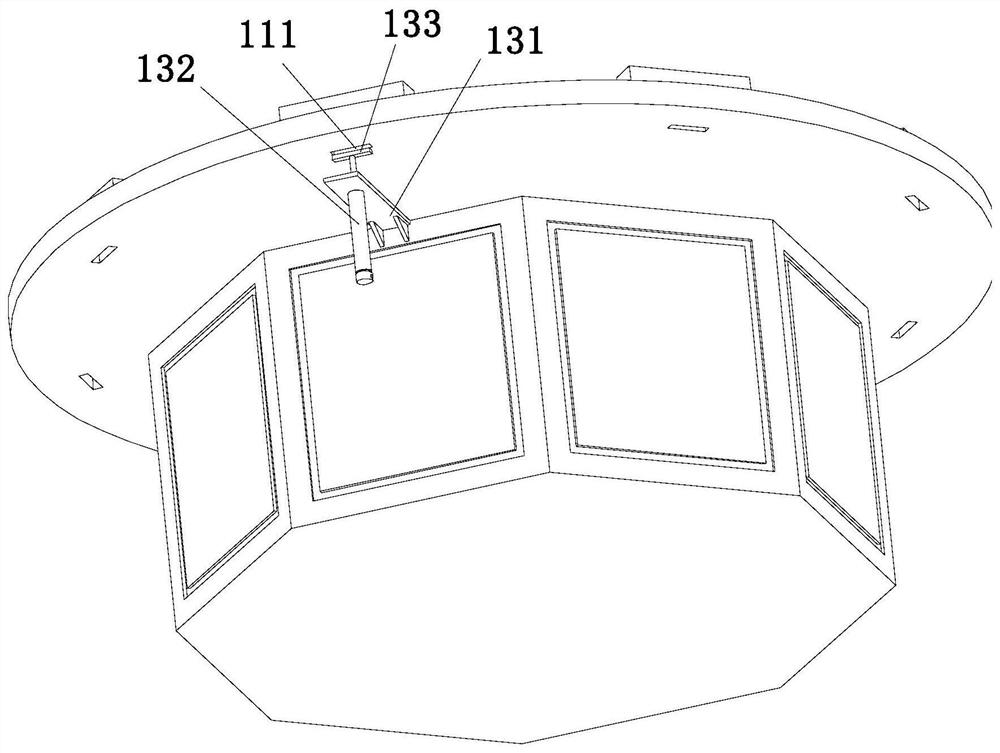

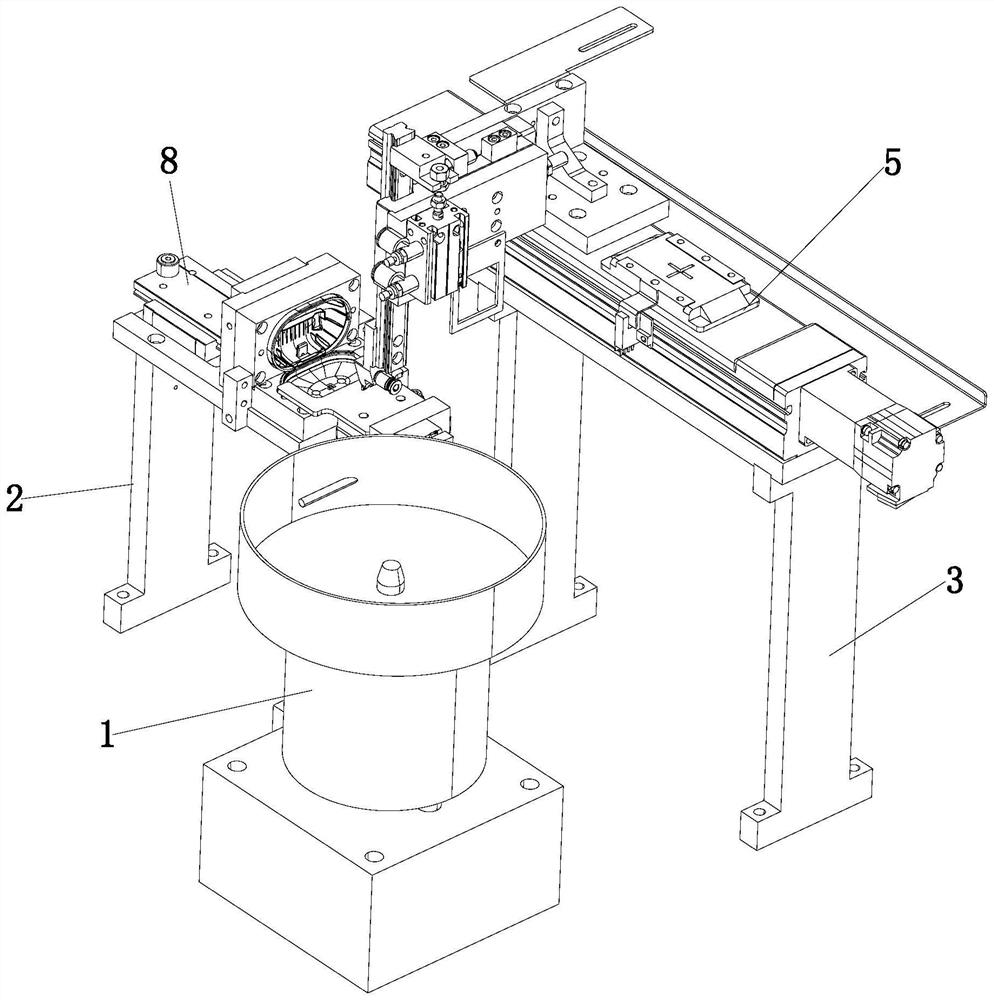

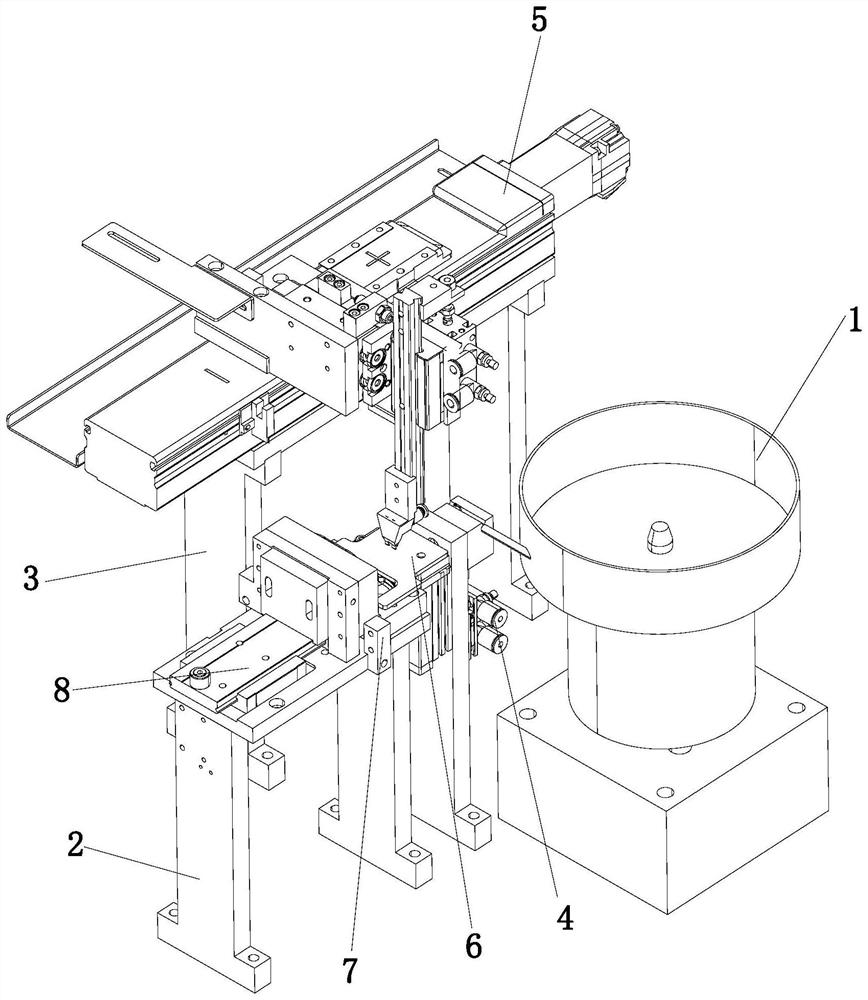

Vibration mechanism and feeding device

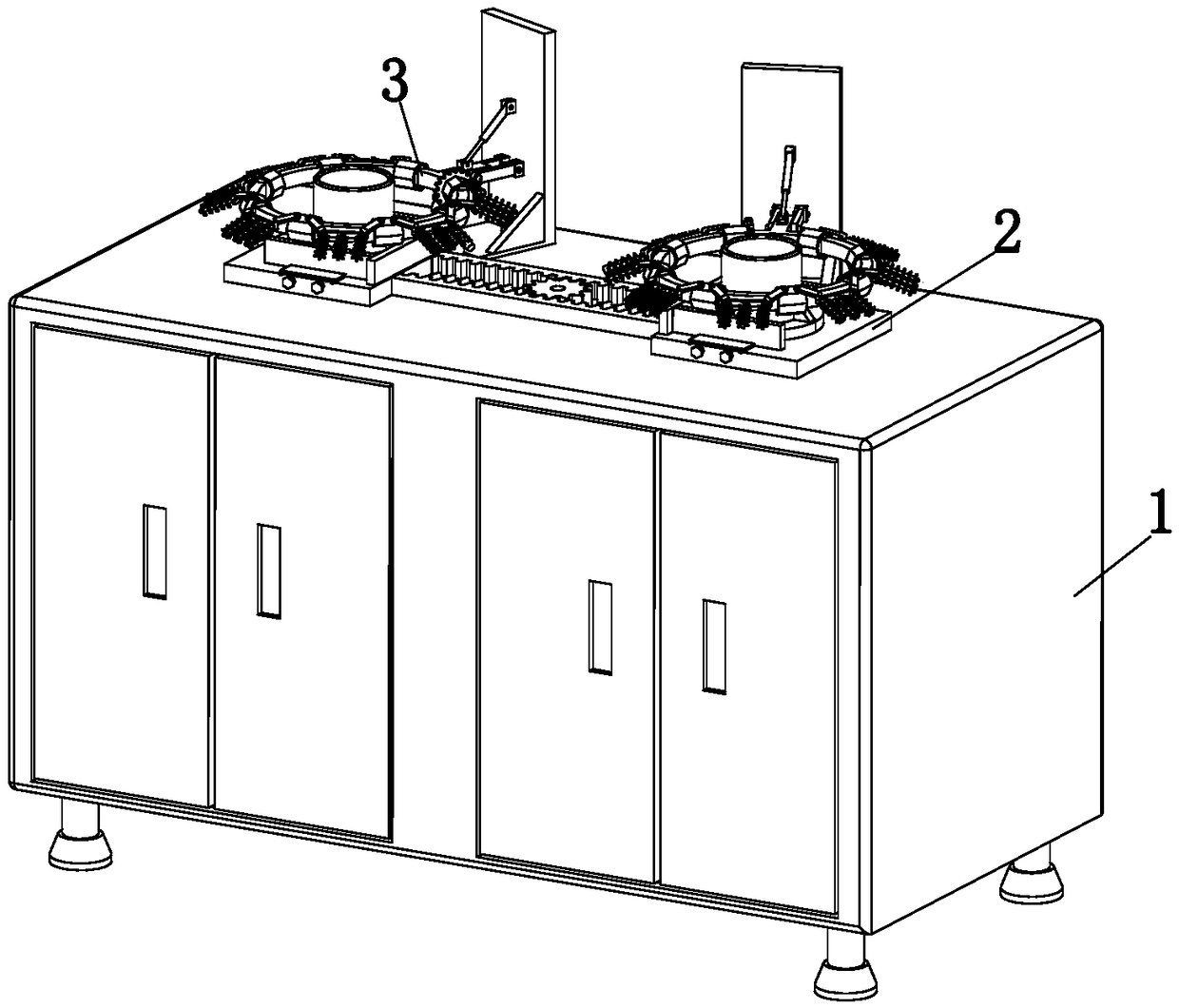

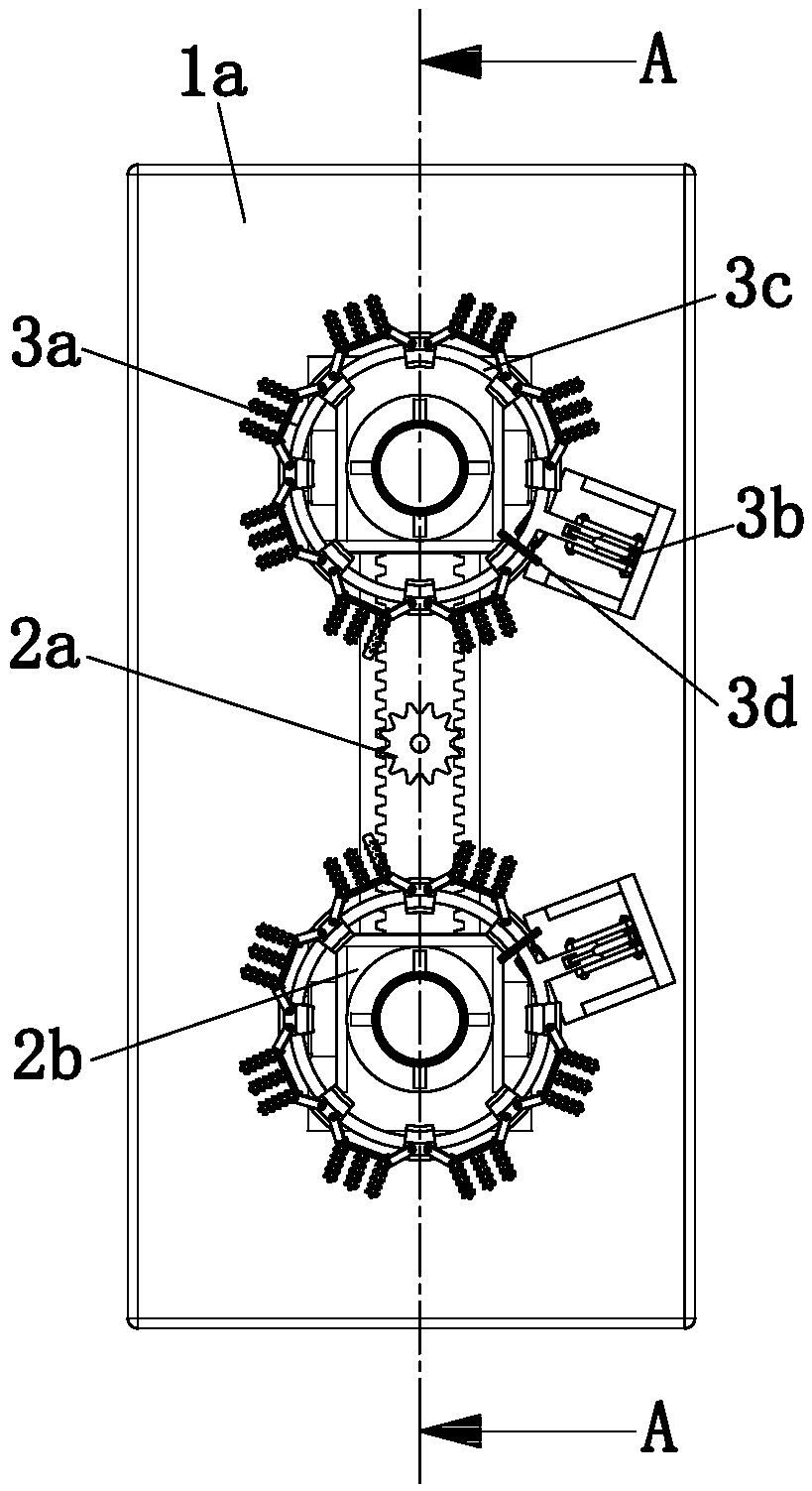

PendingCN113998398ARealize automatic loading operationFast loadingLoading/unloadingJigging conveyorsCircular discEngineering

The invention discloses a vibration mechanism and a feeding device. The vibration mechanism comprises a machine base, an annular check ring, a feeding disc, a first driving assembly, a vibration rod and a second driving assembly, the first driving assembly can drive the feeding disc to rotate in the annular check ring, and the second driving assembly can drive the vibration rod to achieve local vibration of the feeding disc. Through rotary feeding of the feeding disc and the local vibration effect, products can be continuously scattered and turned over and conveyed to the working range of the visual detection mechanism and the feeding robot, rapid and accurate feeding is achieved in cooperation with the visual detection mechanism and the feeding robot, and automatic feeding operation is achieved.

Owner:WENZHOU LUCHENG RIKANG SMOKING SETS FACTORY

Automatic packaging system

InactiveCN103434662ARealize automatic loading operationImprove packaging efficiencySolid materialControl circuitEngineering

The invention discloses an automatic packaging system. The automatic packaging system comprises a packaging tape disk, a packaging tape conveying mechanism, a pinch roller mechanism, a packaging tape cutting mechanism, a packaging tape disk to be packaged and a controller. A control circuit is formed by the controller, the packaging tape conveying mechanism, the pinch roller mechanism, the packaging tape cutting mechanism and the packaging tape disk to be packaged. In the working process, the packaging tape conveying mechanism conveys packaging tape for packaging the packaging tape disk to one side of the packaging tape disk to be packaged under the control of the controller, the pinch roller mechanism tightly presses the packaging tape to the position between the packaging tape disk to be packaged and the pinch roller mechanism under the control of the controller, the packaging tape turns along with the packaging tape disk to be packaged to be wound on the packaging tape disk to be packaged, after the packaging tape is wound N (N>=1) rounds set by the controller, the packaging tape cutting mechanism cuts the packaging tape under the control of the controller, and a cycle is completed. Compared with manual packaging tape packaging in the prior art, the automatic packaging system achieves automatic disk winding operation of the packaging tape, relieves labor intensity, saves labor cost and improves packaging efficiency of the packaging tape.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

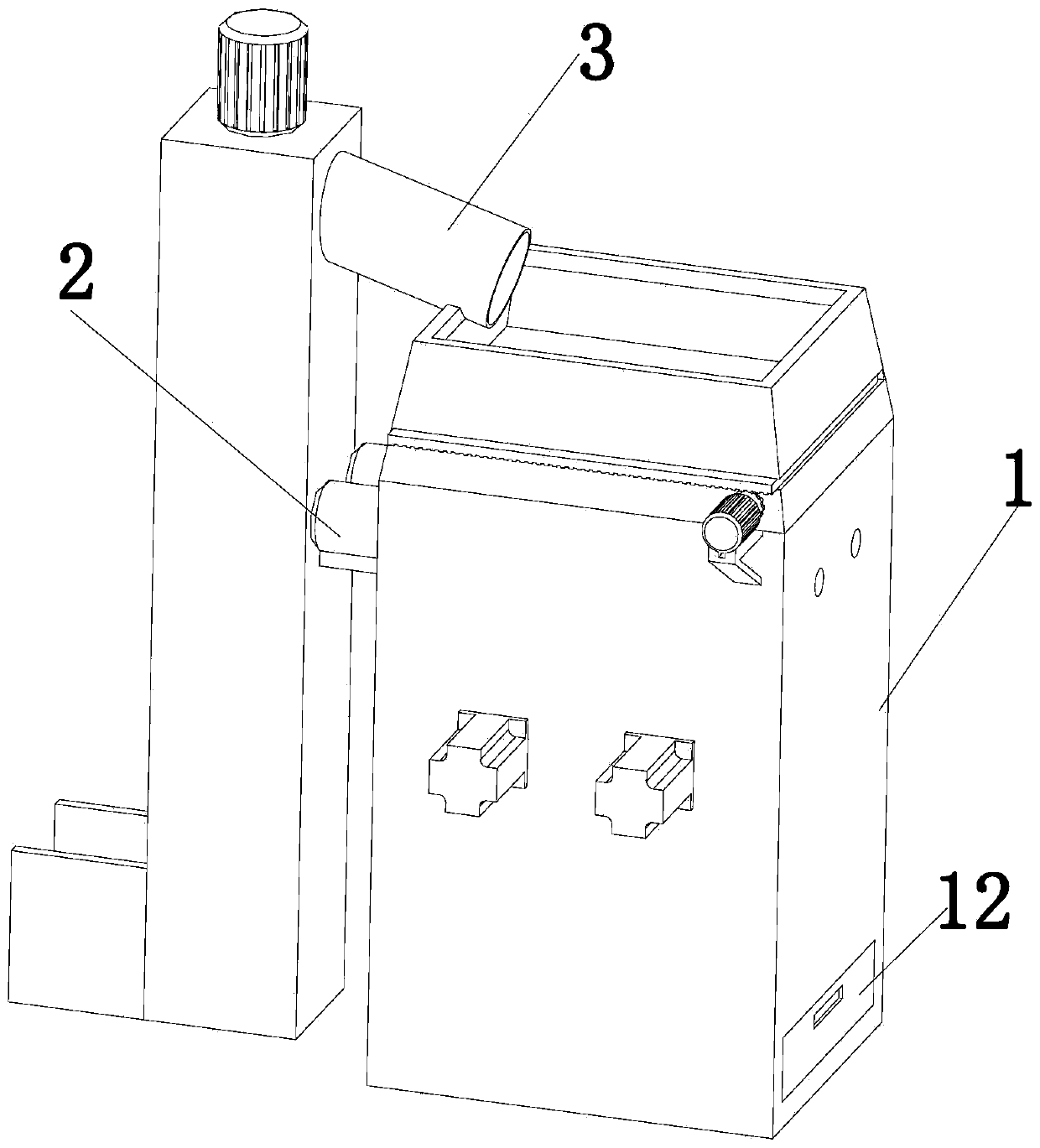

Inductor wire end automatic paint removal device

ActiveCN110280509ARealize feedingAchieve cleaningCleaning using toolsCleaning using liquidsSlide plateEngineering

The invention discloses an inductor wire end automatic paint removal device and belongs to the technical field of inductor production equipment. The inductor wire end automatic paint removal device comprises an inductor feeding mechanism, an inductor clamping mechanism, a position regulation mechanism and a wire end paint removal mechanism. The wire end paint removal mechanism comprises a paint removal component, a waste residue cleaning component, a sliding plate, a rack and a material moving component. The paint removal component and the waste residue cleaning component are both arranged on the top of the sliding plate. The material moving component is arranged below the sliding plate. The rack is provided with two horizontal supporting rods. The sliding plate is slidably arranged on the two supporting rods in a sleeving mode. The inductor wire end automatic paint removal device can realize feeding, paint removal, cleaning and discharging on inductors and is high in automation degree. Manual operation of a worker is not needed. Moreover, the inductor wire end automatic paint removal device can enable wire ends on the inductors to rotate through an angle adjustment assembly and can conduct paint removal treatment on the wire ends of the inductors in different azimuths through a paint removal wheel.

Owner:湖南俊宇电子科技有限公司

Device for treating leftover material of rubber product

InactiveCN112847949AEasy to stackEfficient use ofPlastic recyclingGrain treatmentsEngineeringMechanical engineering

The invention discloses a device for treating leftover materials of a rubber product, and relates to the technical field of rubber products. The device for treating rim charges of rubber products comprises a compaction box, a feeding assembly, a crushing assembly, a vibrating screen assembly and a compaction assembly, wherein the compaction box is arranged on the ground, the feeding assembly is fixedly arranged on the side of the compaction box, the crushing assembly is fixedly arranged on the side wall of the feeding assembly, the discharging end of the feeding assembly corresponds to the crushing assembly, the vibrating screen assembly is arranged above the compacting box, the working end of the vibrating screen assembly corresponds to the working end of the crushing assembly, and the compacting assembly is arranged on the compacting box. The leftover material is automatically fed by arranging the feeding assembly, the leftover material discharged by the feeding assembly is minced by arranging the smashing assembly, the minced leftover material is screened through the vibrating screen assembly, then the leftover material is compacted through the compacting assembly, and therefore, accumulation and utilization in the future are facilitated.

Owner:陈超

A waste recycling device for pharmaceuticals used in biotechnology

ActiveCN110252643BRealize automatic loading operationEasy to processSievingScreeningWater filterEnvironmental engineering

The invention discloses a pharmaceutical waste recycling device for biotechnology, which belongs to the technical field of pharmaceutical equipment, and includes a conveying component, a screening component, a compacting component and a drying component, and the compacting component includes a mounting frame, a compacting box, and a compacting part and the water filtering plate obliquely arranged in the compacting box, the screening assembly includes a screening box, a screening piece and a scraping piece, the screening box is set on the top of the compacting box, the screening piece is arranged in the screening box, and one end of the screening piece extends to In the compaction box, the drying part includes a conveying part and a drying part, the drying part is arranged beside the mounting frame, and the conveying component is arranged beside the mounting frame. The invention drives the moving groove of the compacting plate on the compacting box to move through the rotation of four threaded rods. The compacting plate moves to squeeze the waste, and the water in the waste is filtered out through the water filter plate, and the waste is removed. After the water in the waste is squeezed out, it is beneficial to the drying operation of the waste solids in the later stage, and the separation of water and solids in the waste is realized.

Owner:赵录翠

Filtering device for coating processing

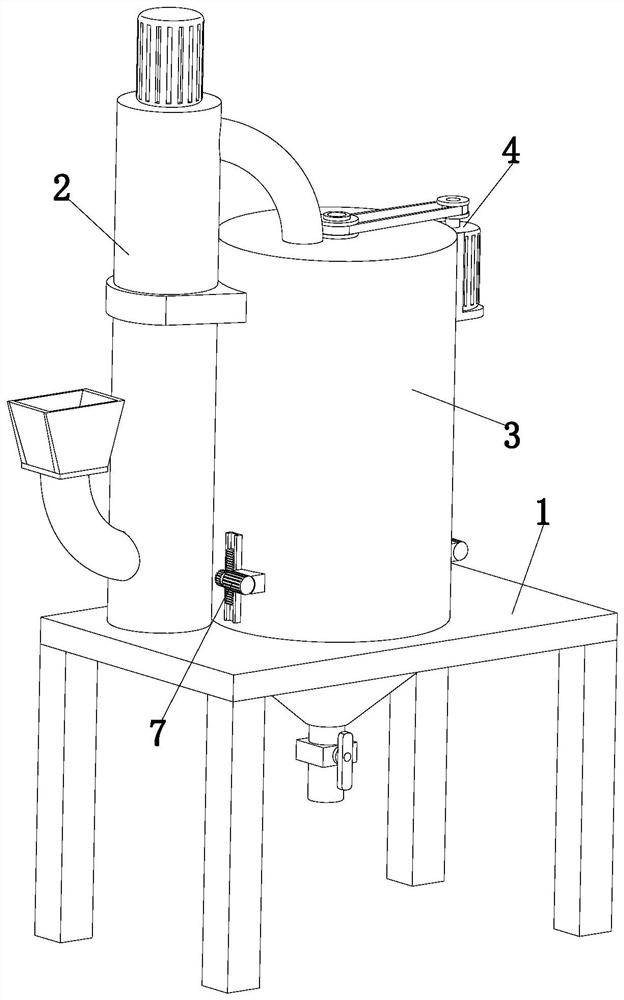

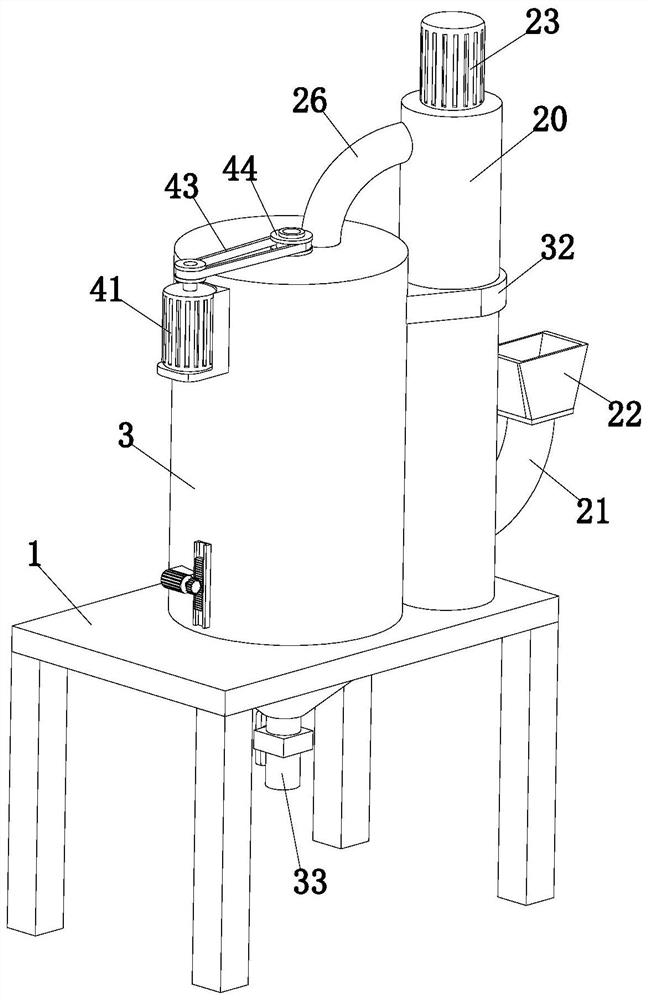

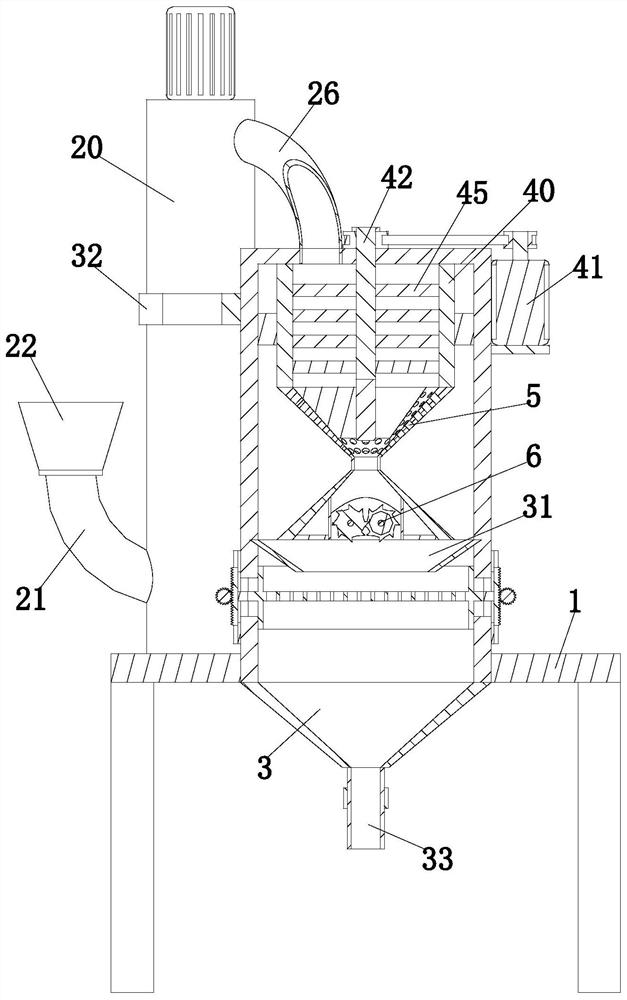

InactiveCN112619513AImprove filtering effectQuality improvementTransportation and packagingRotary stirring mixersMechanical engineeringPowder coating

The invention relates to the technical field of coating processing, in particular to a filtering device for coating processing. The filtering device comprises a processing table, a feeding device, a conical cylinder, a stirring device, a first filtering device, a crushing device and a second filtering device, the processing table is arranged on a horizontal plane, the feeding device is vertically arranged on the processing table, and the stirring device is arranged on the conical cylinder; the conical clamp is clamp on the processing table and located beside the feeding device, the stirring device is installed on the conical barrel, the first filtering device is arranged in the conical barrel and installed at the bottom of the stirring device, the crushing device is arranged in the first filtering device, the second filtering device is arranged in the second filtering device, and the second filtering device is arranged under the crushing device and is mounted on the conical cylinder. According to the powder coating filtering device, through mutual cooperation operation of all the devices, automatic feeding is achieved, secondary filtering can be conducted on powder coatings, the filtering effect of the powder coatings is better, the quality of the filtered powder coatings can be improved, and therefore the processing efficiency of the powder coatings is improved.

Owner:姚啸云

Automatic car loading machine for railway box car

The invention relates to the technical field of automatic car loading machines, in particular to an automatic car loading machine for a railway box car. The automatic car loading machine comprises a transverse moving vehicle plate which is connected to two parallel transverse moving ground rails in a rolling mode, wherein the transverse moving vehicle plate can transversely move along the transverse moving ground rails; a rotating device is arranged on the transverse moving vehicle plate, and a lifting assembly is arranged on the rotating end surface of the rotating device; a multi-section propeller is arranged on the transverse moving vehicle plate, the propelling end of the multi-section propeller is connected to a longitudinal moving trolley, and a transverse moving forklift is arranged on the longitudinal moving trolley. According to the automatic car loading machine disclosed by the invention, loading work such as automatic butt joint of a railway box car door, stacking of a whole row of cargoes, clamping and shaping of the cargoes and automatic stacking in two directions can be automatically achieved, and automatic loading operation of the cargoes of the railway box car is achieved, so that the labor intensity of loading is greatly reduced, and the work efficiency of loading is improved.

Owner:无锡宏盛智能装载技术有限公司

Production equipment of circuit breaker shell

ActiveCN112917880AReduce workloadIncrease productivityDomestic articlesProcess engineeringCircuit breaker

The application relates to production equipment of a circuit breaker shell, and relates to the technical field of production and processing of the circuit breaker shell, The production equipment comprises a workbench, an upper die and a lower die; the workbench is provided with a bearing plate; the bearing plate is provided with a positioning column for sleeving a connecting column; a loading mechanism, a feeding mechanism, a discharging mechanism, a conveying mechanism and a punching mechanism are arranged on the workbench; the feeding mechanism comprises a mounting frame, a supporting seat and a feeding plate; the supporting seat is vertically arranged on the mounting frame in a sliding mode; the feeding plate is horizontally arranged on the supporting seat in a sliding mode; the feeding plate is provided with a positioning groove for the connecting column to be clamped in; a pushing mechanism is arranged on the feeding plate; and and the pushing mechanism is used for pushing the connecting column out of the positioning groove. The loading mechanism is utilize to arrange the connecting column on the positioning column in a sleeving mode, then the feeding mechanism is utilized to grab the connecting column on the positioning column, and the connecting column is inserted into a die block of the lower die, so that the automatic loading operation of the connecting column is implemented, thereby reducing the workload of production personnel.

Owner:乐清市金池电器有限公司

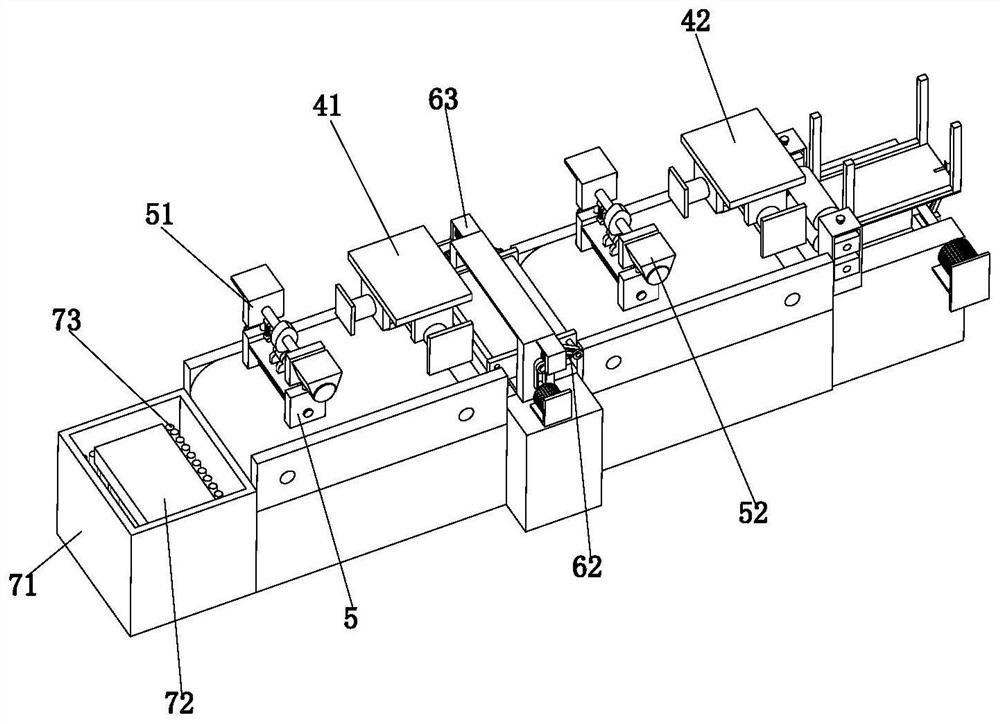

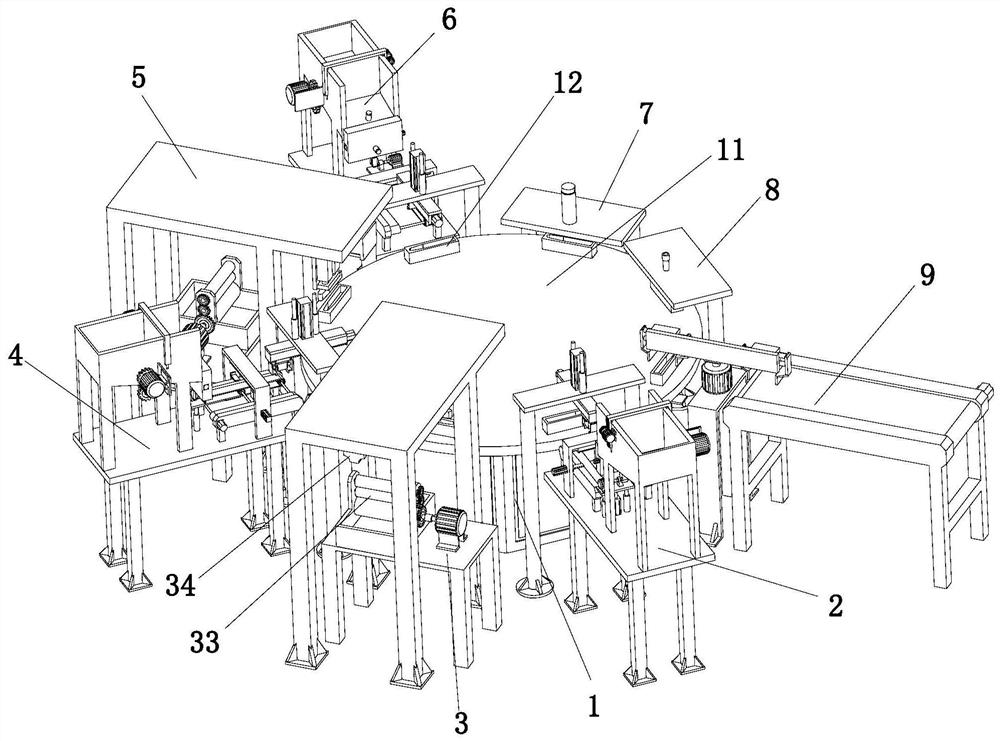

Automatic polishing equipment for multi-station anchor backing plate

InactiveCN109318097ARealize automatic loading operationReduce outputGrinding drivesGrinding machinesEngineeringMechanical engineering

The invention relates to the technical field of polishing equipment, in particular to automatic polishing equipment for a multi-station anchor backing plate. The automatic polishing equipment comprises an accommodating device, a bearing device and a polishing device. The accommodating device comprises an accommodating part and a supporting part arranged at the bottom of the accommodating part. Thebearing device comprises a bearing driving part and two bearing positioning parts symmetrically arranged on the accommodating part and capable of driving the two bearing positioning parts to move onthe accommodating part. The polishing device comprises two polishing parts arranged on the accommodating part, and the two polishing parts are in one-to-one correspondence to the two bearing positioning parts. By means of the automatic polishing equipment, the automatic feeding operation of the anchor backing plate is realized, the manual output is reduced, and the feeding accuracy is improved; rotation can be achieved in the polishing process of the anchor backing plate, so that automatic polishing of the anchor backing plate can be completed, and the polishing efficiency is improved.

Owner:安徽省含山县华平铸造厂(普通合伙)

Automatic artificial flower production line

InactiveCN112189925AAchieve fitReduce generationArtificial flowers and garlandsEngineeringMechanical engineering

The invention discloses an automatic artificial flower production line, which belongs to the technical field of artificial flower processing, and comprises a mounting frame, a ball feeding device, a petal feeding device, a laminating auxiliary device, a petal laminating device and an automatic discharging device.The ball feeding device is arranged on the mounting frame; the petal feeding device comprises a petal moving part, a petal adjusting part and a petal lifting part, the petal moving part is located below the mounting frame, the petal adjusting part is arranged on the side wall of the mounting frame, the petal lifting part is located below the petal moving part, and the attaching auxiliary device is erected above the petal moving part. The petal attaching device comprises a petal attaching moving part and a petal melting attaching part, the petal attaching moving part is arranged at the top of the attaching auxiliary device, the petal melting attaching part is arranged on the petal attaching moving part, and the automatic discharging device is arranged at the top of the attaching auxiliary device. According to the invention, automatic production of artificial flowers can be realized, and the working efficiency is improved.

Owner:林艺盛

An electrode rod cleaning device for electrolytic aluminum

ActiveCN110331418BImplement cleanupAffects cleanup operationsHollow article cleaningElectric machineryDust control

The invention discloses an electrode bar cleaning device for aluminum electrolysis, and belongs to the technical field of aluminum electrolysis. The electrode bar cleaning device comprises a storage assembly, a feeding assembly, a scraping assembly, a polishing assembly and a discharging assembly; both the feeding assembly and the discharging assembly are arranged on the sides of the storage assembly; the storage assembly comprises a rotary piece, a dedusting piece and a plurality of limiting pieces, the multiple limiting pieces are arranged on the rotary piece in the circumferential direction, one end of the dedusting piece is arranged on the side of the rotary piece, and the other end of the dedusting piece is arranged on the rotary piece; and the scraping assembly is arranged on the side of the rotary piece, and the polishing assembly is arranged on the side of the scraping assembly. According to the electrode bar cleaning device, a dedusting motor works to drive a rotary rod to rotate, the rotary rod rotates to drive a dedusting block to rotate in a storage groove, the dedusting block rotates to drive a dedusting hairbrush to rotate so that residues in the storage groove can bescraped away, the dedusting block rotates to remove the residues into a discharging pipe after scraping, the residues are conveyed into a storage box through the discharging pipe, and the storage boxstores the residues.

Owner:江苏垚沃机械科技有限公司

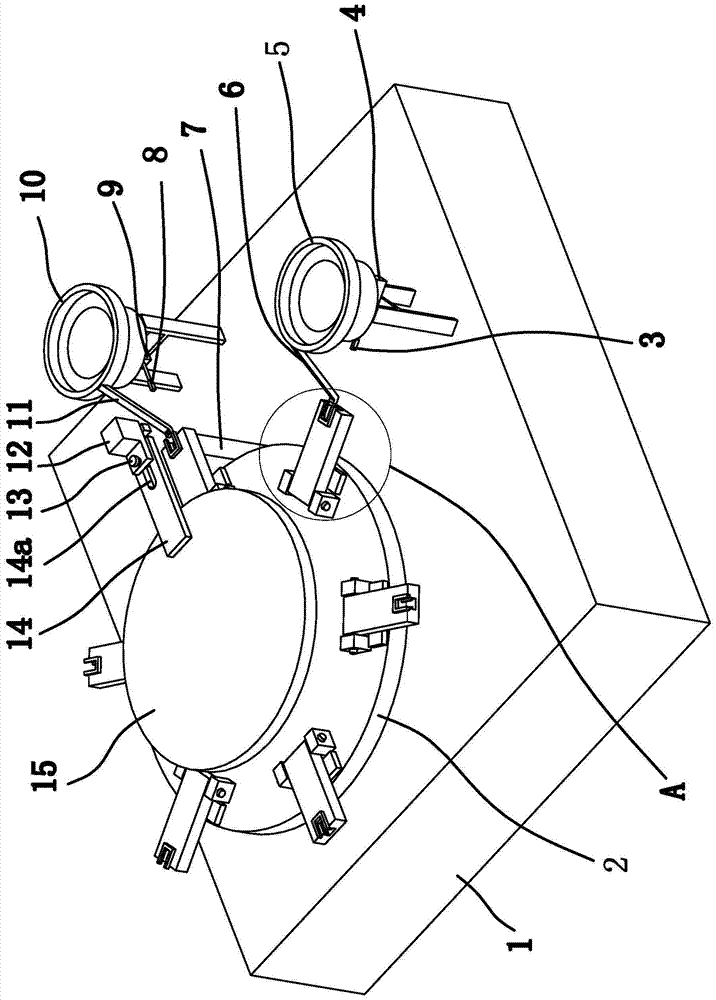

An assembly device for a slider in a zipper

InactiveCN104942164BRealize automatic loading operationContinuous uninterrupted assembly workSlide fastenersMetal-working feeding devicesEngineeringFastener

The invention provides an assembling device for pullers in zippers, and belongs to the technical field of machinery. By the aid of the assembling device, technical problems of low production efficiency, high labor intensity and the like due to the fact that assembling mechanisms in the prior art cannot be used for large-scale production operation and need to be manually operated can be solved. The assembling device for the pullers in the zippers comprises a framework, a fixing disc, a connecting rod, a turntable, a connecting barrel, a stamping assembly and a driving assembly. The upper end of the connecting rod is fixedly connected to the center of the fixing disc, a through hole is formed in the center of the turntable, the connecting rod penetrates the through hole in the turntable, the lower end of the connecting rod is fixedly connected onto the framework, the connecting barrel sleeves the connecting rod, the upper end of the connecting barrel is fixedly connected with the turntable, the lower end of the connecting barrel is connected with the driving assembly, a positioning mechanism capable of positioning a body is arranged at the edge of the turntable, and the stamping assembly is fixedly connected to the edge of the fixing disc and can be vertically aligned with the positioning mechanism after the driving assembly drives the turntable to intermittently rotate. The assembling device has the advantages of high assembling efficiency and good universality.

Owner:广州市正伟翔拉链有限公司

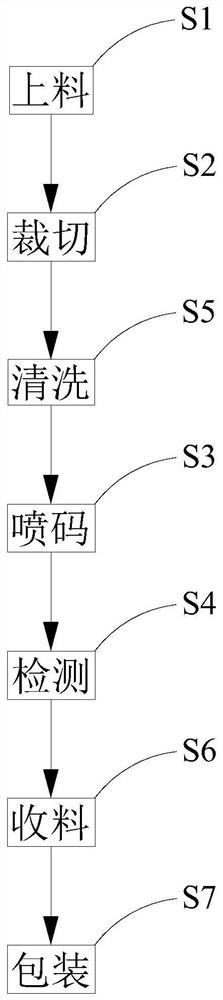

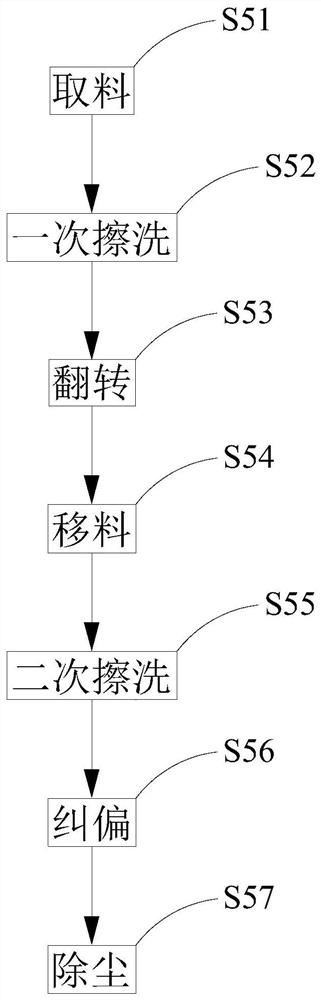

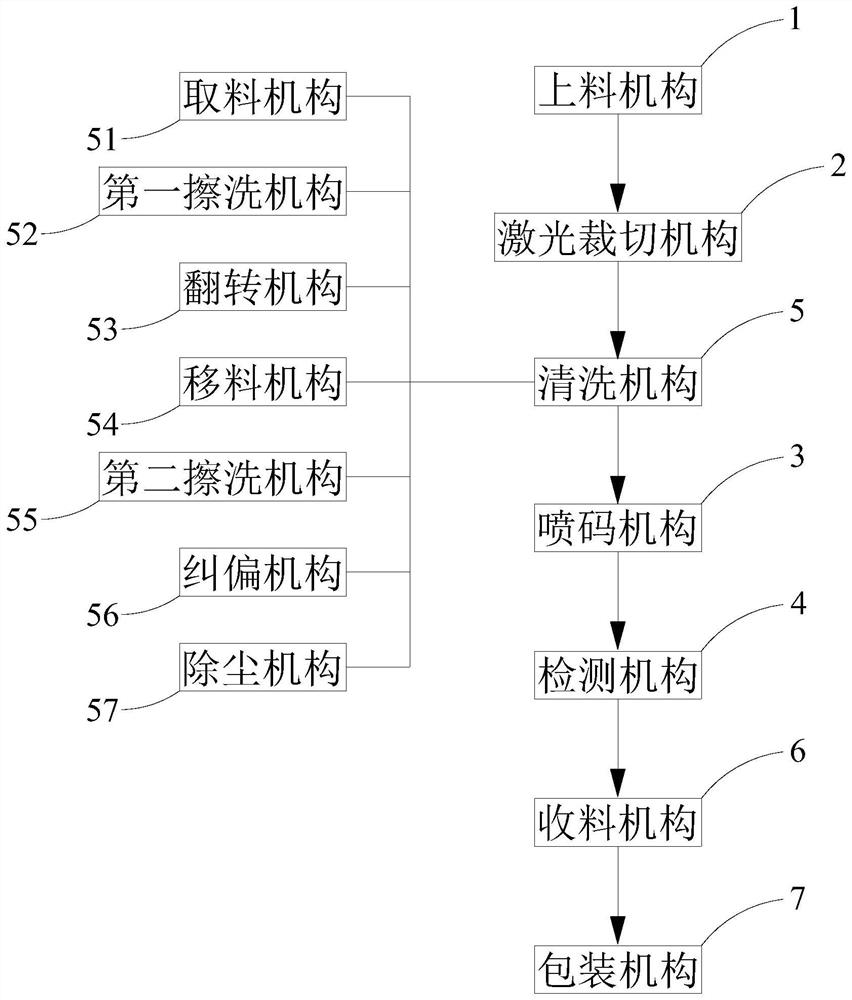

Production process method of polaroid

ActiveCN113210885AReduce in quantityLow costTypewritersLaser beam welding apparatusProcess engineeringLaser cutting

The invention provides a production process method of a polaroid. The production process method of the polaroid comprises the steps of feeding is conducted, specifically, a roll material is fed through a feeding mechanism; cutting is conducted, specifically, the material is cut into a plurality of sheets with the target sizes through laser; code spraying is conducted, specifically, code spraying is performed on each sheet through a code spraying mechanism; and detection is conducted, specifically,the sheets are detected through a plurality of detection mechanisms. According to the production process method of the polaroid, a preparation process of conducting cutting first and then conducting code spraying is adopted, so that the number of code spraying mechanisms can be reduced, and the cost is reduced. Burrs generated by laser cutting are few, and the product quality is good; and moreover, the preparation efficiency of the special-shaped polaroid needing to be punched or slotted is high. The automatic feeding operation of the roll material can be realized through the feeding mechanism; and the quality of each sheet can be detected through a plurality of detection mechanisms, so that the product yield is improved. Through integration of the feeding mechanism, the laser cutting mechanism, the code spraying mechanism and the multiple detection mechanisms, full-automatic operation can be achieved during production of the polaroids, efficiency is high, and the labor cost is low.

Owner:SHENZHEN SUNNYPOL OPTOELECTRONICS

Automatic feeding device for bulk traditional Chinese medicine dispensing medicine boxes

PendingCN112938485ARealize automatic loading operationSimple structureConveyorsConveyor partsElectric machineryEngineering

The invention discloses an automatic feeding device for bulk traditional Chinese medicine dispensing medicine boxes. The automatic feeding device comprises a linear row rod motor, a supporting table, a medicine box positioning frame, suction cups and a suction cup driving mechanism, wherein the top end of a working rod on the linear row rod motor is connected with the bottom face of the supporting table, the supporting table is located in the medicine box positioning frame and moves up and down along the inner side wall of the medicine box positioning frame, the plurality of medicine boxes are placed on the supporting table, the top ends of the suction cups are installed on the suction cup driving mechanism, and the medicine box positioning frame is located on one side of the starting end of a conveying belt. During working, after the suction cups suck medicine boxes, the suction cup driving mechanism drives the suction cups to move to transfer the medicine boxes to the conveying belt from the medicine box positioning frame. The automatic feeding device is simple in structure and compact and reasonable in layout, the medicine boxes can automatically move upwards through the design of the linear row rod motor, the medicine boxes can be transferred through the motor or air cylinder type suction cup driving mechanism after being sucked by the suction cups, time and labor are saved in operation, convenience and rapidness are achieved, the automatic feeding device is matched with automatic medicine taking equipment, automatic medicine box feeding operation is achieved, and the labor intensity of workers is greatly reduced.

Owner:南京埃伯顿自动化设备有限公司 +2

An automatic loading machine for railway boxcars

ActiveCN112850568BReduce labor intensityImprove work efficiencyLifting devicesControl theoryCar door

The invention relates to the technical field of automatic loading machines, in particular to an automatic loading machine for railway boxcars. The invention comprises a traverse vehicle plate, which is rollingly connected to two parallel ground rails, the traverse vehicle plate can move laterally along the traverse ground rails, and a turning device is arranged on the traverse vehicle plate A lifting assembly is arranged on the rotating end surface of the slewing device; a multi-section propeller is arranged on the traversing vehicle plate, and the propelling end of the multi-section propeller is connected to a longitudinally moving trolley, and a traversing forklift is arranged on the longitudinally moving trolley. The invention can automatically realize loading work such as automatic docking of doors of railway boxcars, stacking of whole rows of goods, cargo clamping and shaping, automatic stacking in two directions, etc., realizes automatic loading of goods on railway boxcars, and greatly reduces the labor intensity of loading. Improve the work efficiency of loading.

Owner:无锡宏盛智能装载技术有限公司

Automatic artificial flower production process

InactiveCN112189924AAchieve fitReduce generationArtificial flowers and garlandsEngineeringProcess engineering

The invention discloses an automatic artificial flower production process, which belongs to the technical field of artificial flower processing, and comprises the following steps of: 1, automaticallyfeeding, clamping and fixing a ball; 2, moving the petals to the position below the ball; 3, melting the surfaces of the petals, and fitting the petals with beads; 4, attaching different petals on thepetals to one another; 5, adjusting the attaching position of the next petal to be attached to the previous petal; and 6, conducting automatic discharging. The process is ingenious in design and smooth in procedure connection, automatic production of the artificial flowers is achieved, manual kneading is replaced, workers are prevented from being scalded by the heating head, the automation degreeis high, the production efficiency is greatly improved, and remarkable economic value is achieved.

Owner:林艺盛

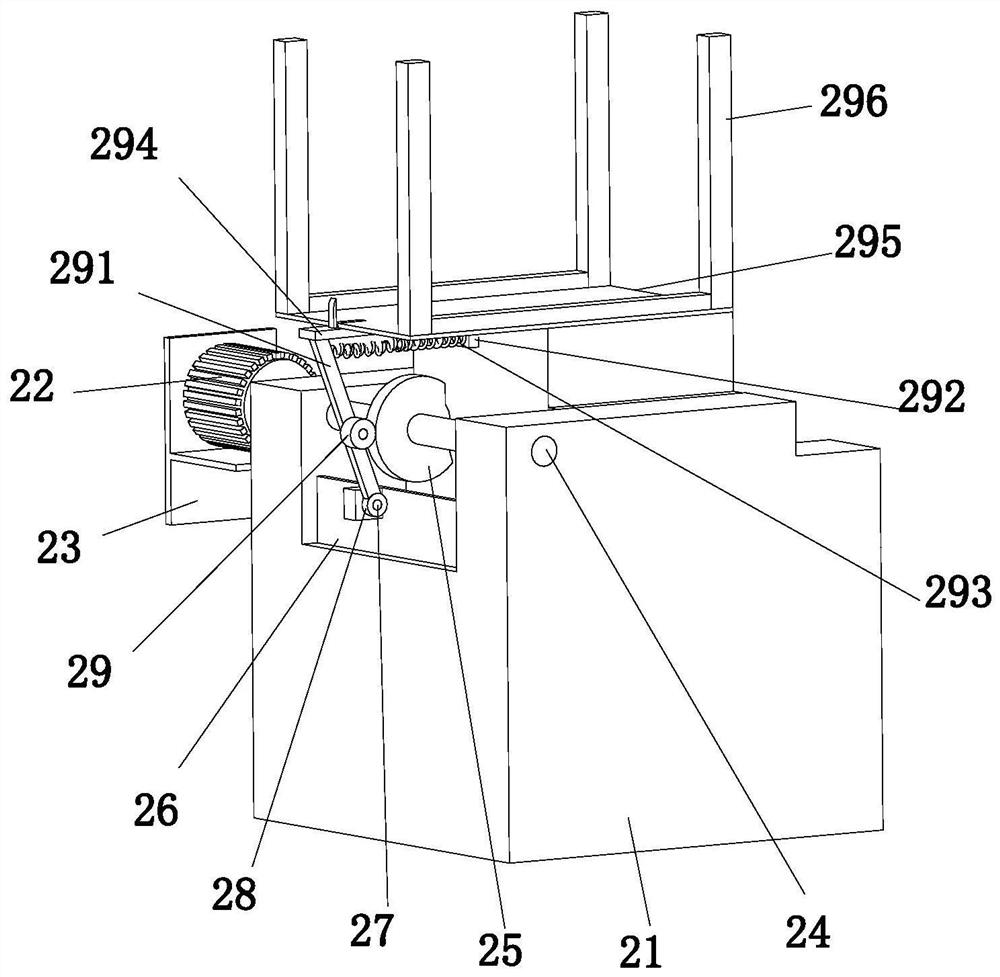

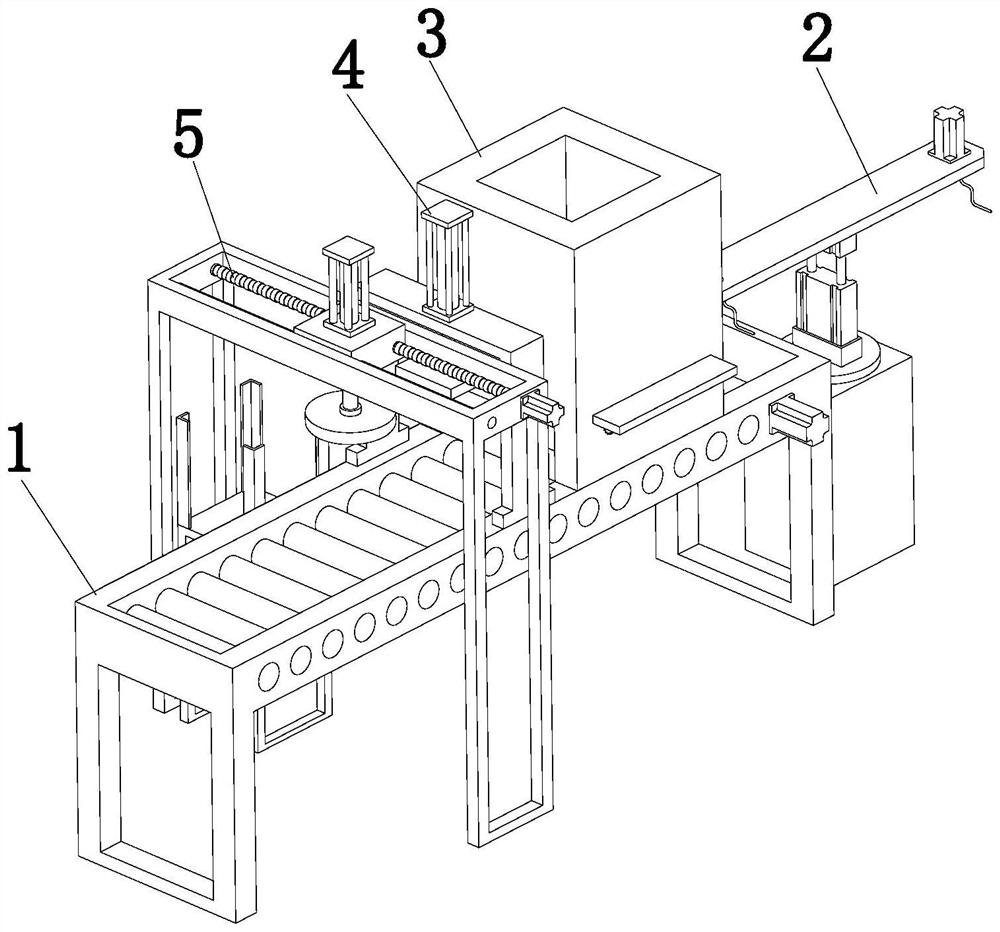

An automatic feeding device for stamping rings based on rotary grinding wheel forming core

ActiveCN104003193BRealize automatic loading operationAvoid personal injuryDe-stacking articlesConveyor partsPunchingEngineering

The invention discloses an automatic feeding device for core ring punching and based on a rotary grinding wheel forming machine. The automatic feeding device comprises a main frame body, a rotary disk type core ring stack is arranged on the main frame body, a vertical lifting type core ring conveying mechanism used for driving core rings to move upwards along a string column to achieve a core ring conveying function is arranged on the lateral side of the main frame body, horizontal reciprocating type core ring feeding mechanism is arranged at the top of the main frame body, the horizontal reciprocating type core ring feeding mechanism is used for placing the core rings on the rotary disk type core ring stack into punching work stations of the grinding wheel forming machine, and accordingly the task of automatically feeding the core rings is finished. The automatic feeding device is composed of the rotary disk type core ring stack, the vertical lifting type core ring conveying mechanism and the horizontal reciprocating type core ring feeding mechanism. The automatic feeding device can finish actions of jacking up the core rings, sucking the core rings, horizontally moving the core rings and releasing the core rings. Thus, the automatic feeding device achieves automatic feeding operation of the core rings, effectively avoids personal injury to operators and remarkably improves production efficiency of grinding wheels.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

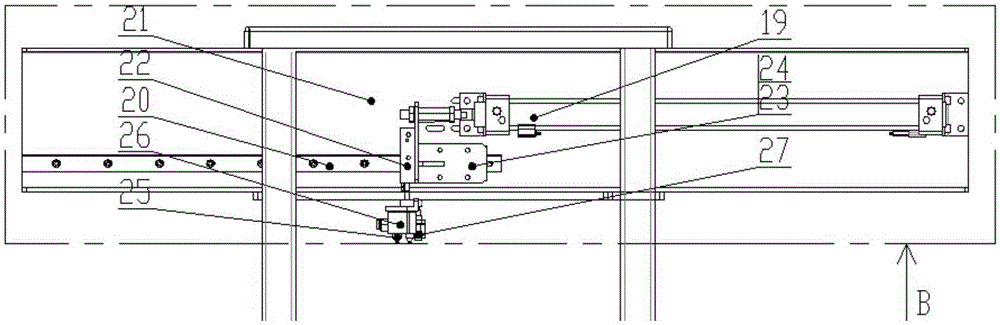

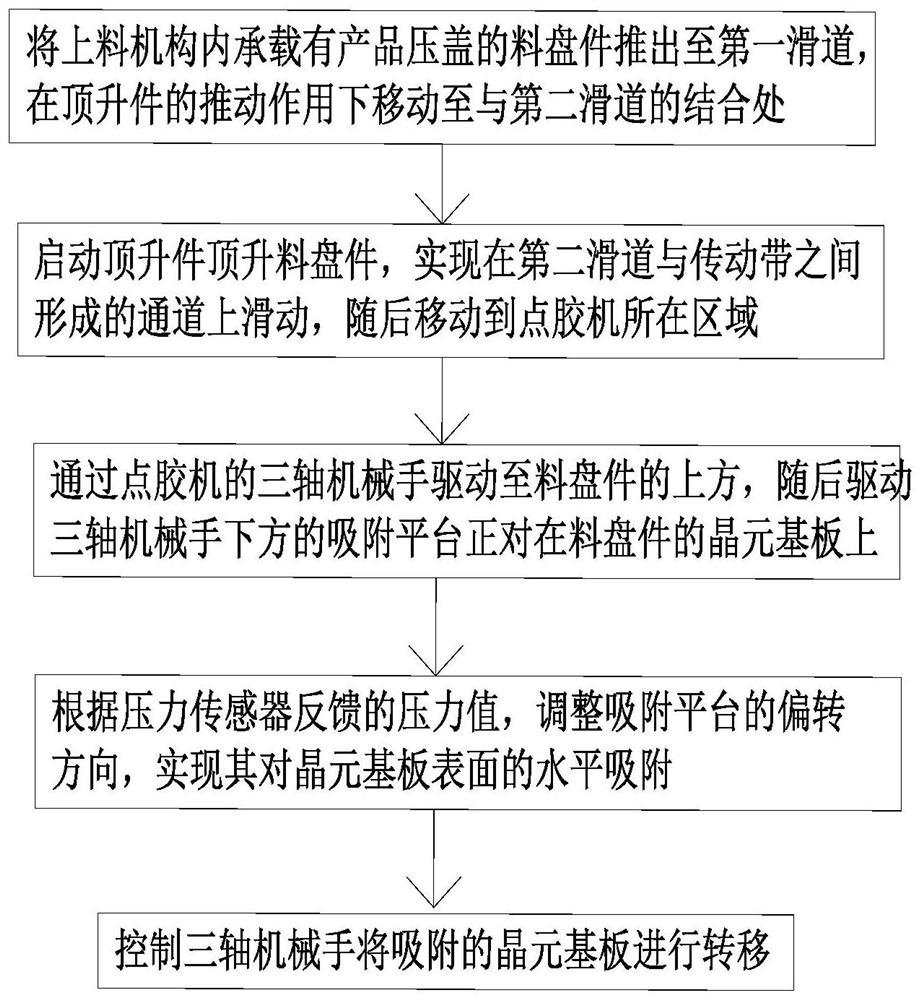

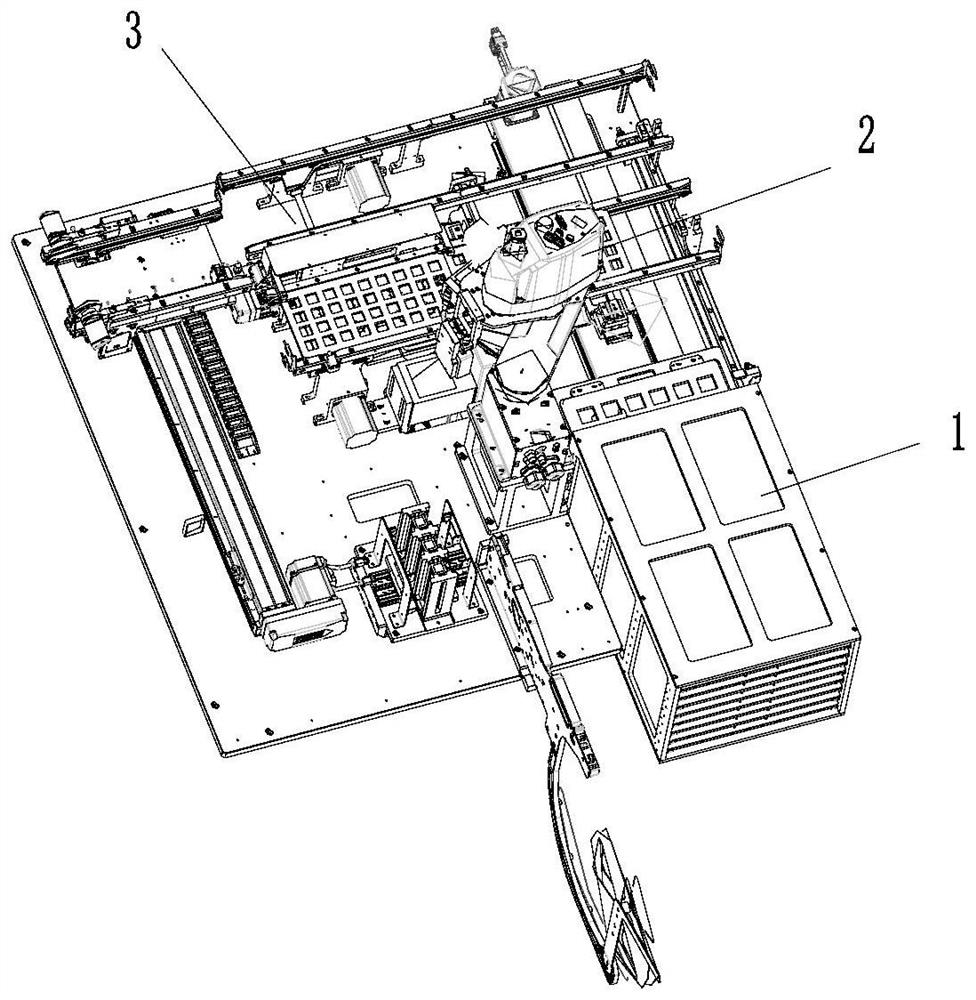

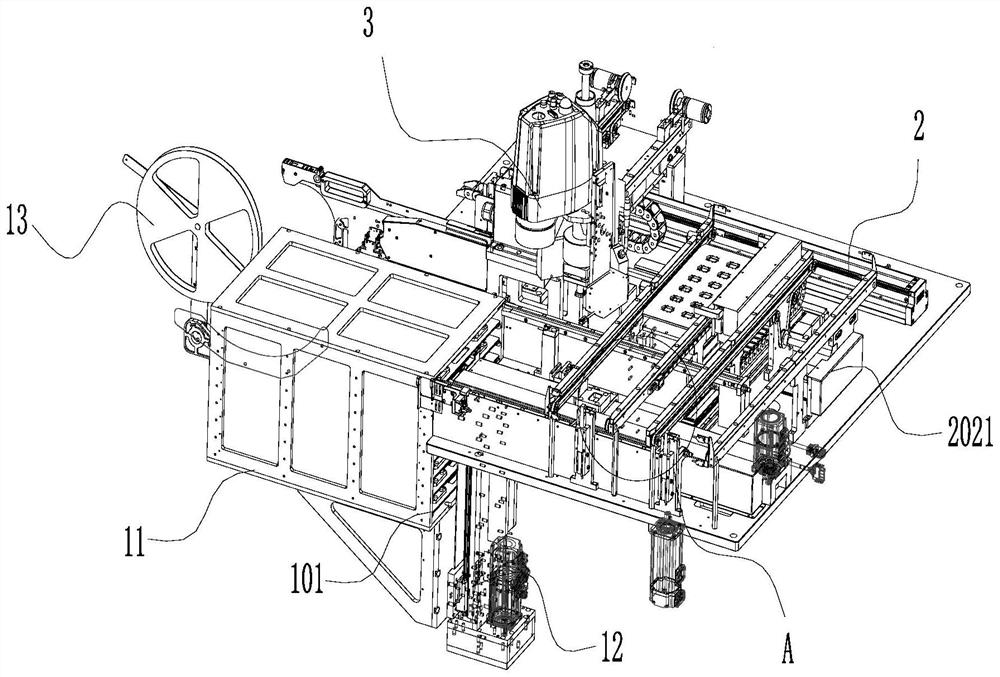

Full-automatic manipulator based on six-direction pressure feedback

InactiveCN113858183AHigh precisionImprove transport efficiencyProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention discloses a full-automatic manipulator on six-direction pressure feedback. The full-automatic manipulator comprises a feeding mechanism, a bearing platform and a manipulator body, wherein the manipulator body comprises a three-axis mechanical arm, pressure sensors and an adsorption platform, six sets of connecting holes are formed in the lower end part where the three-axis mechanical arm is located, the three-axis mechanical arm is connected with miniature connecting columns through telescopic pieces in the connecting holes respectively, the lower end parts of the micro connecting columns are connected with the adsorption platform, the positions, right opposite to the micro connecting columns, of the front end part of the adsorption platform are provided with the pressure sensors respectively, the adsorption platform adsorbs a wafer substrate on a material disc piece, and then the wafer substrate is transferred through the three-axis mechanical arm. By using the full-automatic manipulator disclosed by the invention, after the adsorption platform is firstly in contact with the wafer substrate, the relative position of the adsorption platform is adjusted to be matched with the wafer substrate according to pressure feedback during contact, so that the accuracy of the wafer substrate in the transfer process is greatly improved, and the transfer efficiency is improved.

Owner:苏州汇创芯精密智能装备有限公司

Feeding device and process of sponge nail file automatic production equipment

ActiveCN111409019BAccurate locationRealize automatic loading operationLiquid surface applicatorsControl devices for conveyorsDust controlNursing care

Owner:王树声

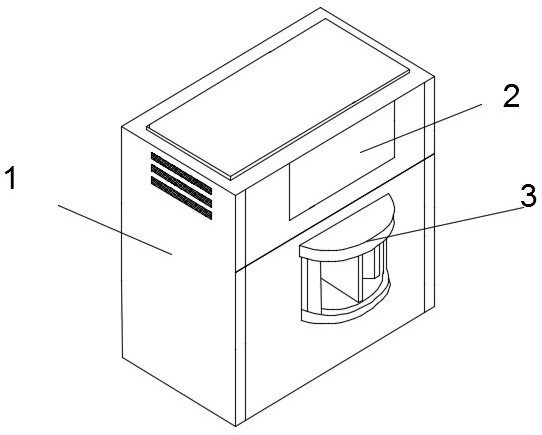

An artificial intelligence vending machine with automatic loading device

ActiveCN112863053BRealize automatic feeding functionAvoid damageCoin-freed apparatus detailsApparatus for dispensing discrete articlesDrive wheelEngineering

The invention relates to the technical field of intelligent vending machines, and discloses an artificial intelligence vending machine with an automatic loading device. Conveyor belt, a first driven wheel is fixedly installed inside the conveyor belt, a driving wheel is arranged outside the first driven wheel, a first belt is arranged between the first driven wheel and the driving wheel, and a second driven wheel is arranged on one side of the first driven wheel. The moving wheel, the surface of the conveyor belt is provided with a block, one end of the conveyor belt is provided with a slope, one side of the slope is provided with a longitudinal baffle, one side of the longitudinal baffle is provided with a card holder, one side of the card holder is provided with a rotating mechanism, and the bottom of the rotating mechanism is provided with a A strut, a shock-absorbing spring is arranged between the strut and the card holder. The artificial intelligence vending machine with an automatic loading device, by setting the automatic loading device, can automatically load the product after the product is sold, and the loading is stable and will not cause damage to the product.

Owner:驻马店市叶鑫商贸有限公司

Rotating shaft assembling device for wireless earphone charging box

PendingCN114260675ARealize automatic loading operationAchieve installationMetal working apparatusElectrical and Electronics engineeringSupport plane

The invention discloses a wireless earphone charging box rotating shaft assembling device, and belongs to the technical field of wireless earphone processing, the wireless earphone charging box rotating shaft assembling device comprises a rotating shaft vibration feeding disc, a mounting frame, a supporting frame, a feeding moving device, a clamping moving device, a limiting fixing device, a lifting adjusting device and a horizontal adjusting device, the mounting frame is arranged on the side of the rotating shaft vibration feeding disc, the feeding moving device is arranged on the side of the mounting frame, the limiting fixing device is arranged on the side wall of the feeding moving device, the clamping moving device is arranged on the top of the supporting frame, the lifting adjusting device is arranged on the mounting frame, and the horizontal adjusting device is arranged on the mounting frame. The lifting adjusting device and the horizontal adjusting device work at the same time to continuously adjust the position of the upper box cover, the upper box cover is adjusted to the position matched with the lower box cover, automatic assembling and mounting of the upper box cover and the lower box cover are achieved, and the working efficiency and the assembling accuracy are improved.

Owner:湖南长歌智能科技有限公司

Resistor winding machine with feeding function

PendingCN114360830ARealize automatic loading operationImprove work efficiencyResistive element windingsWinding machineControl theory

The invention discloses a resistor winding machine with a feeding function, and belongs to the technical field of resistor machining, the resistor winding machine comprises a mounting table, an automatic feeding mechanism, a feeding moving mechanism, a winding rotating mechanism, a winding moving mechanism, a winding fixing mechanism and a winding pay-off mechanism, the mounting table is horizontally arranged, the automatic feeding mechanism is located on the mounting table, and the feeding moving mechanism is located on the mounting table; the feeding moving mechanism is located on the mounting table, the number of the winding rotating mechanisms is two, the two winding rotating mechanisms are symmetrically arranged beside the mounting table, a placing table is arranged beside the winding rotating mechanisms, the winding moving mechanism is located on the placing table, and the winding moving mechanism is in sliding fit with the placing table; the winding fixing mechanism is located on the winding moving mechanism, the winding pay-off mechanism is located on the winding moving mechanism, and a resistor discharging mechanism is arranged on the placing table. According to the automatic resistor feeding device, automatic resistor feeding operation is achieved through the automatic feeding mechanism and the feeding moving mechanism, and the working efficiency is improved.

Owner:世盟电子(惠州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com