Vibration mechanism and feeding device

A technology of vibrating mechanism and vibrating rod, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of difficulty in automatic feeding and high work intensity, and achieve automatic feeding operations and accurate feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

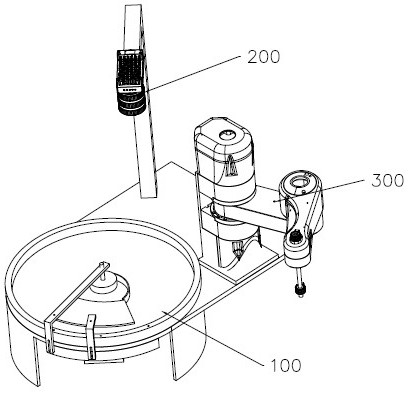

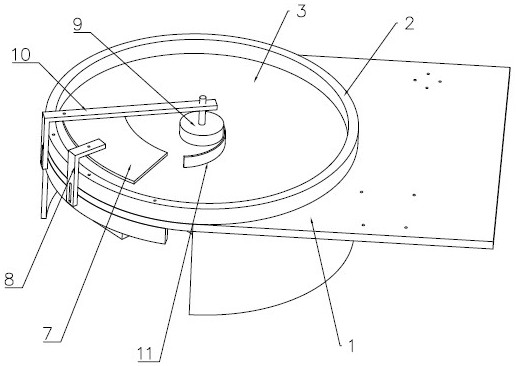

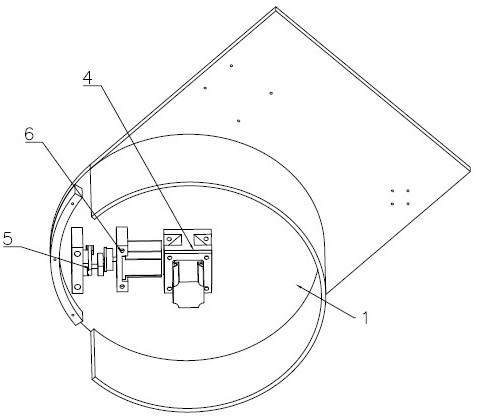

[0027] Such as figure 1 As shown, a feeding device includes a vibrating mechanism 100 , a visual inspection mechanism 200 , and a feeding robot 300 .

[0028] The vibrating mechanism 100 can disperse and turn over each product by vibrating, so that some products can be placed independently and in a specified direction (such as facing up).

[0029] The visual detection mechanism 200 can capture the image signal of the product in the vibration mechanism 100 by taking a camera, and then obtain the position of the product that is qualified and designated to face upward.

[0030] The loading robot 300 adopts a horizontal joint robot, which can accurately grab the corresponding product according to the information obtained by the visual inspection mechanism 200 and send it to the next process, so as to realize the purpose of automatic loading.

[0031] Both the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com