Feeding device and process of sponge nail file automatic production equipment

An automatic production and nail file technology, which is applied to the device for coating liquid on the surface, grinding device, metal processing equipment, etc., can solve problems such as affecting the production efficiency of sponge nail files, and achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

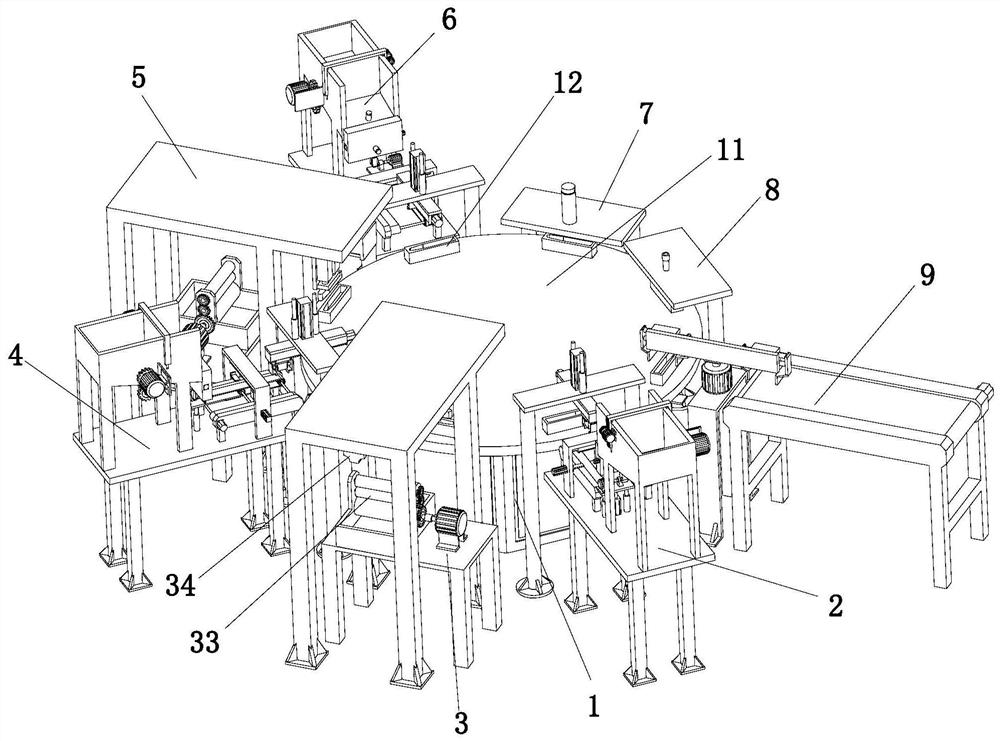

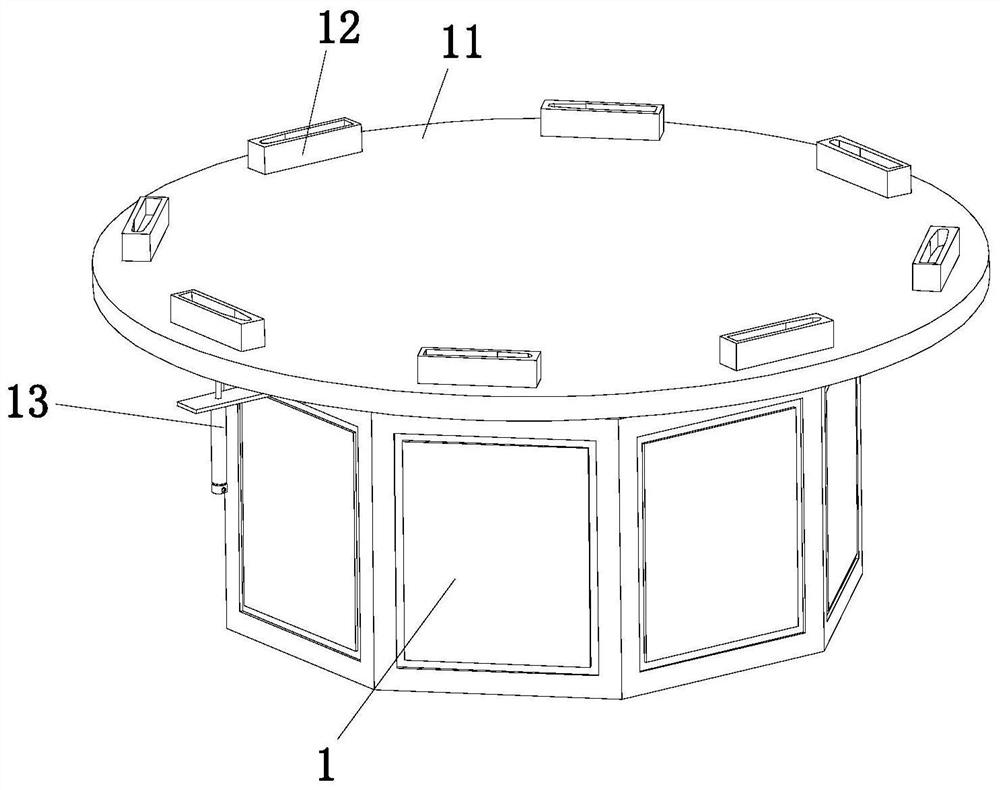

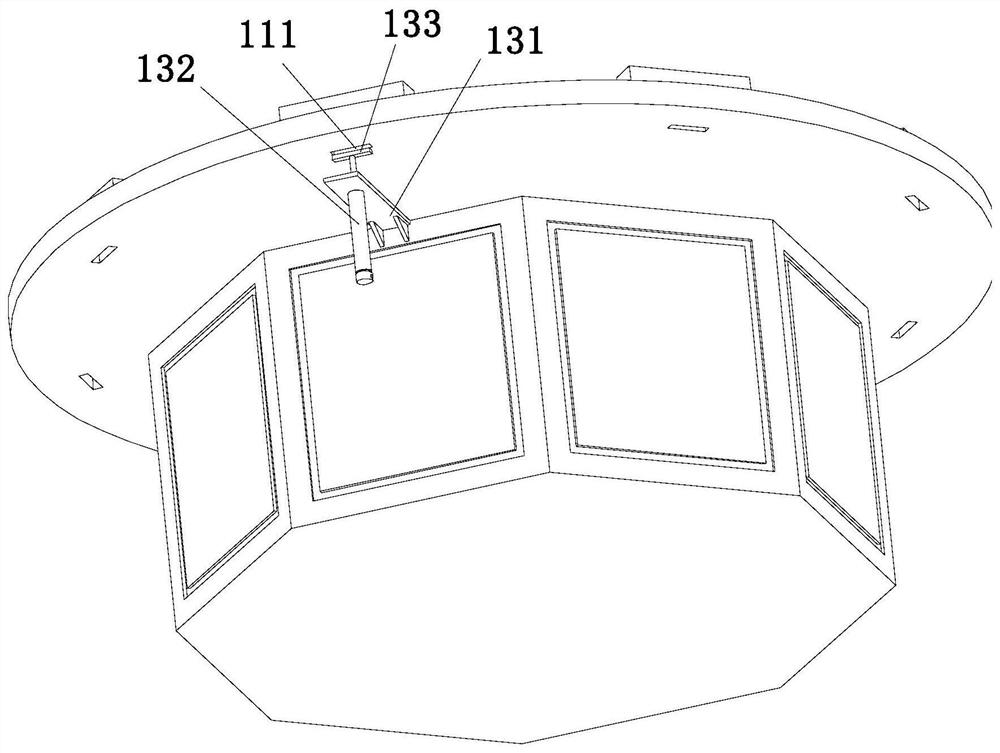

[0040] Combine below Figure 1 to Figure 17 As shown, the embodiment of the present invention provides an automatic production equipment for sponge nail files, including a workbench 1, the workbench 1 is provided with a stepper motor with the output end facing upwards, and the output end of the stepper motor is A turntable 11 arranged horizontally is installed, and the turntable 11 is provided with a plurality of placement jigs 12 arranged at equal angles along its circumference. Gluing device 3, the second feeding device 4, the second gluing device 5, the third feeding device 6, pressing device 7, drying device 8 and unloading device 9, the outer wall of the workbench 1 is provided with The ejector assembly 13 that cooperates with the blanking device 9; when the present invention is working, the file body is placed in the first feeding device 2 and the third feeding device 6 respectively, and the connecting piece is placed in the second feeding device 4, then the stepping mo...

Embodiment 2

[0056] The process of the feeding device of the sponge nail file automatic production equipment includes the following steps:

[0057] Step 1. First, the stepper motor drives the turntable 11 to perform step-by-step rotation, and all the fixtures 12 on the turntable 11 also rotate simultaneously with it. When rotating, the first file is first passed through the first feeding device 2 Put the body into the fixture 12;

[0058] Step 2. Then, drive the driving gear 243 by the anti-blocking motor 242, the driving gear 243 drives the driven gear 244 and the installation rod 245 to rotate around the axis of the installation rod 245, the shaking part 246 rotates synchronously with the installation rod 245, and the shaking part 246 resists shaking plate 241 to produce shaking effect when rotating;

[0059]Step 3. The file body in the discharge frame 22 can shake and enter between the extension plate 224 and the inner bottom wall of the discharge frame 22 along the inner bottom wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com