Folding corn header and docking mechanism thereof

A technology of docking mechanism and header, which is applied to headers, harvesters, agricultural machinery and implements, etc., can solve the problems of low harvesting efficiency and few rows harvested at the same time, and achieve high harvesting efficiency, convenient transportation and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

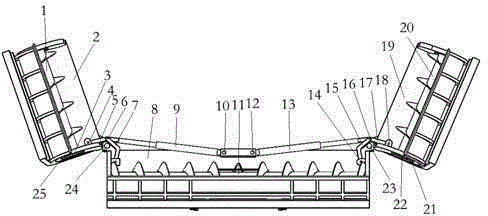

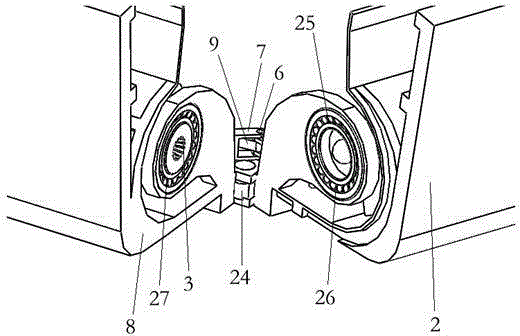

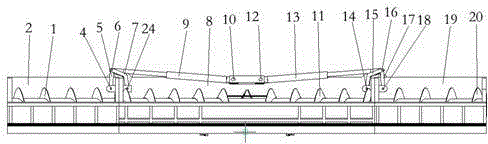

[0016] Refer to the attached figure 1 to attach Figure 4 A foldable corn header and its docking mechanism of the present invention will be described in detail below.

[0017] A foldable corn harvesting platform and its docking mechanism, comprising a conveying bucket 1 2, a conveying bucket 2 8 and a conveying bucket 3 19, the conveying bucket is provided with an auger mechanism, a connecting arm mechanism, a hydraulic cylinder, a bearing and a ball Gear coupling, the auger mechanism includes: auger one 1, which is connected with the conveying bucket one 2 through the bearing one 26, and is connected with the auger two 11 through the spherical gear coupling One 3 is cooperatively connected; the auger two 11 is cooperatively connected with the conveying bucket two 8 through the bearing two 27; the auger three 20 is cooperatively connected with the second spherical tooth coupling 22; the auger three 20, It is cooperatively connected with the delivery bucket three 19 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com