Multifunctional cylinder transfer machine with lifting function

A multi-functional, cylinder-moving technology, applied in auxiliary devices, applications, auxiliary welding equipment, etc., can solve the problems of large distance between rollers, difficult to connect other pipe fittings, high labor intensity of workers, etc., to achieve a wide range of applications, safe production and processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

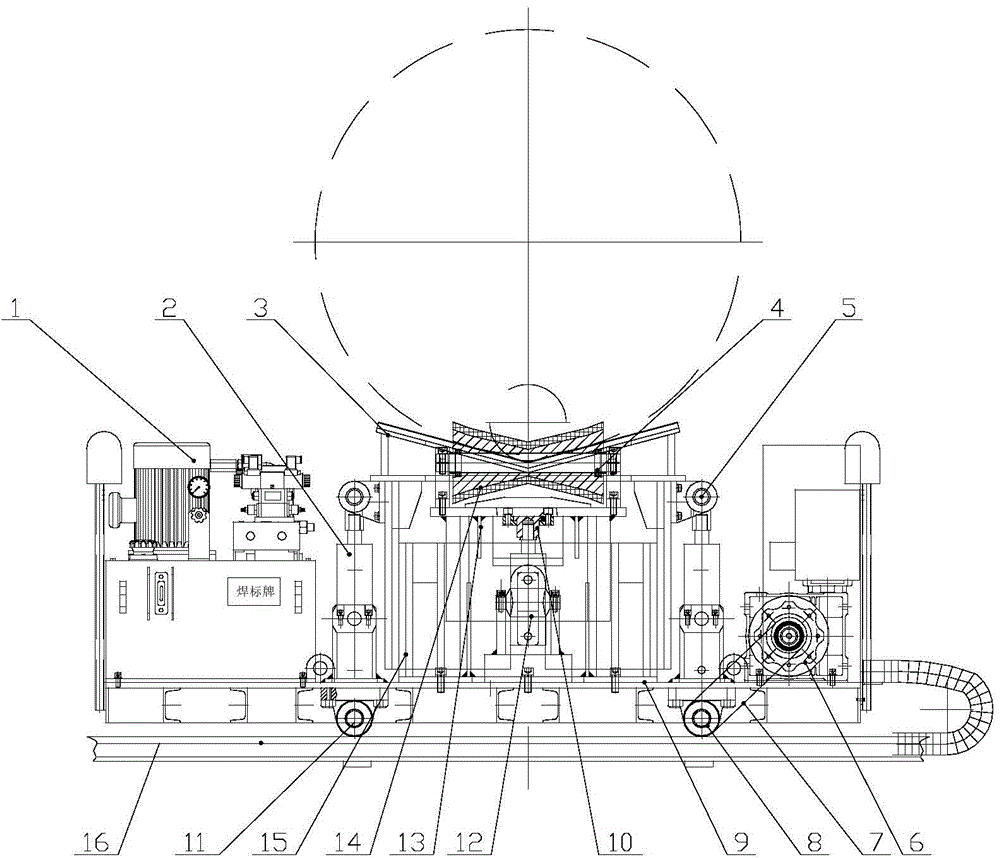

[0012] This embodiment provides a kind of multi-functional lifting and moving cylinder machine, such as figure 1 As shown, it includes a track and a base 9 with walking wheels. The walking wheels of the base are arranged on the track 16, and a two-way lifting hydraulic pump station 1, a V-shaped bracket mechanism and a roller bracket mechanism are also installed on the base. The rollers of the wheel bracket mechanism are V-shaped rollers 14 with large diameter at both ends and small middle, and the V-shaped bracket mechanism and the roller bracket mechanism are arranged on the same straight line; the V-shaped bracket mechanism includes V-shaped brackets 3 And two bracket engineering oil cylinders 2 vertically arranged, the 2 tops of bracket engineering oil cylinders are installed on the both sides of V-shaped bracket through pin shaft activity, and the bottom end of bracket engineering oil cylinders connects bracket engineering oil cylinders and bracket engineering oil cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com