Straightening clamping conveying device

A technology of conveying device and clamping sleeve, which is applied in drilling equipment, earth-moving drilling, drill pipe, etc., can solve the problems of long time for starting the pipe, low guiding precision, no clamping and conveying function, etc., so as to improve the service life. , Improve work efficiency, save the effect of make-up and break-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

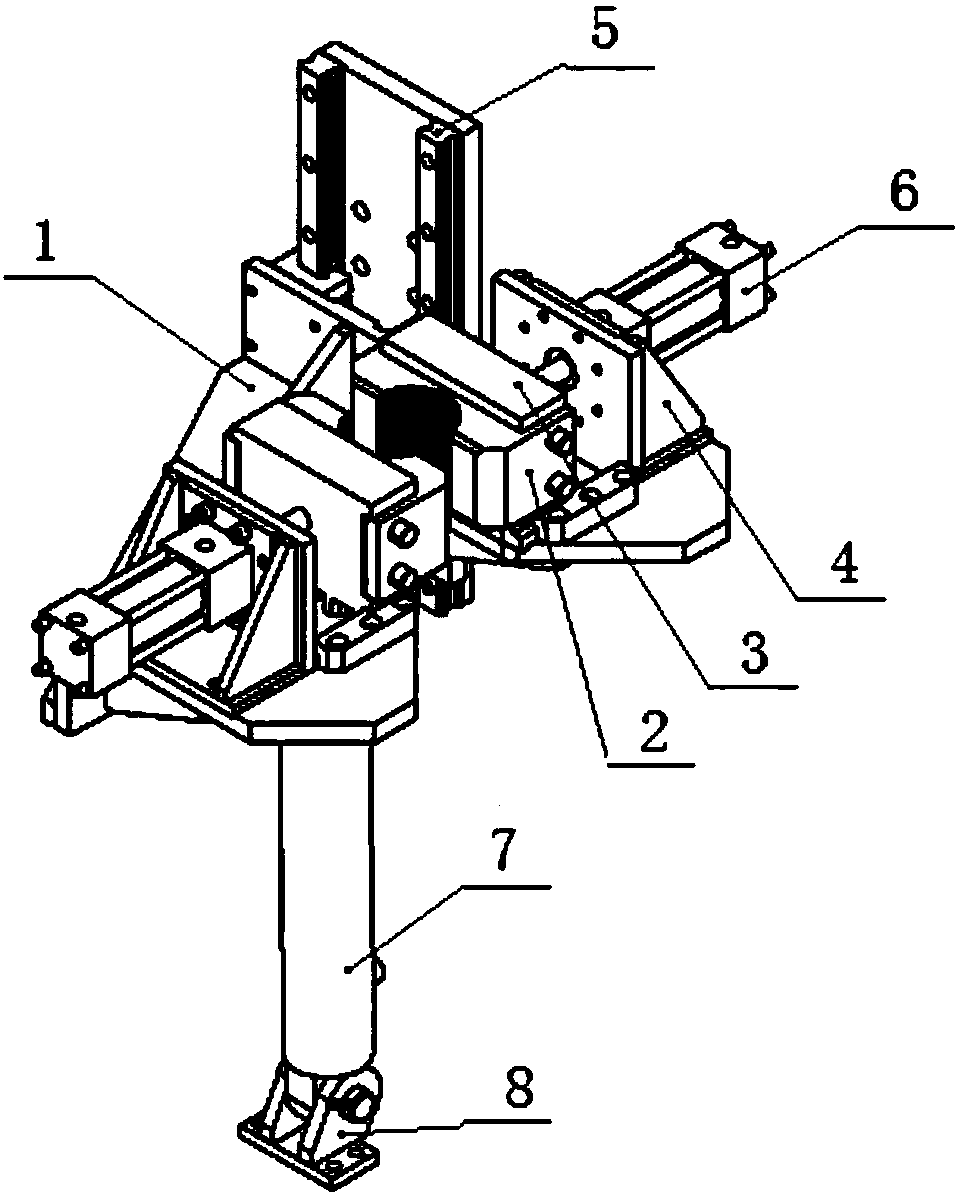

[0012] figure 1 Shown is the structural representation of the present invention.

[0013] The present invention includes a mounting bracket 1, a clamping sleeve 2, a clamping sleeve seat 3, a linear guide rail 5, a clamping oil cylinder 6 and a jacking oil cylinder 7.

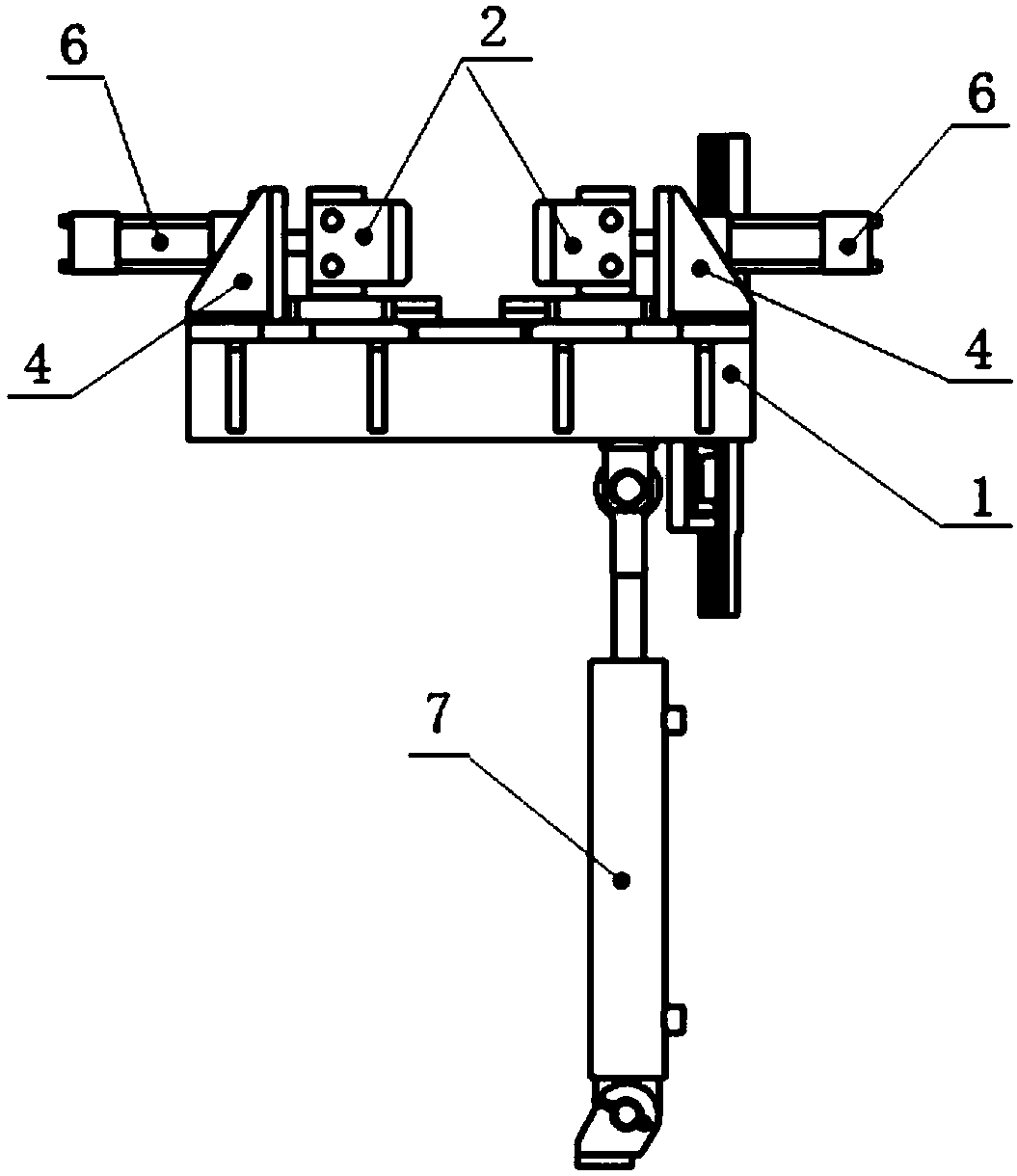

[0014] figure 2 Shown is a schematic front view of the structure of the present invention.

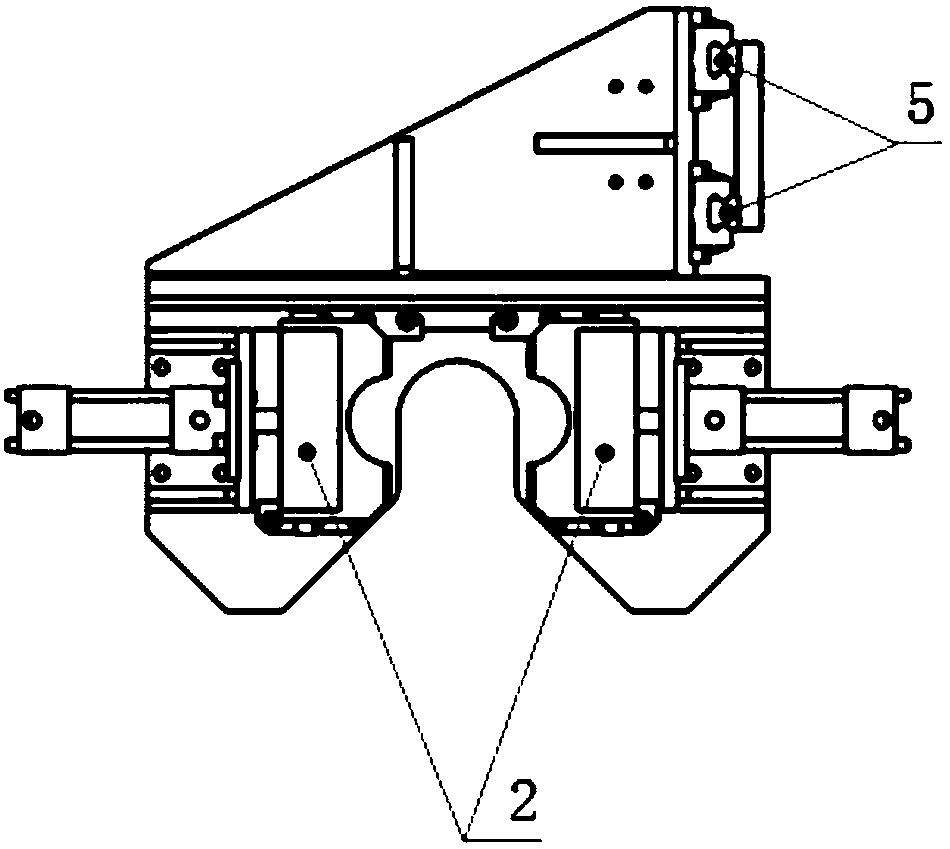

[0015] image 3 Shown is a schematic top view of the structure of the present invention.

[0016] The two clamping sleeves 2 are respectively installed on the clamping sleeve 3, the clamping cylinder 6 is fixed on the mounting bracket 1 through the clamping cylinder bracket 4, the piston rod of the clamping cylinder 6 is connected with the clamping sleeve 3, and the clamping Oil cylinder 6 pushes and pulls clamping sleeve 2 to realize clamping and loosening.

[0017] The upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com