Ultra-large floating production storage and offloading (FPSO) ship closure process

A super-large, crafted technology, applied in the direction of ships, etc., can solve the problems of long construction period, great difficulty, waste of quality inspection manpower and material resources, etc., to shorten the construction period, improve the construction progress, and ensure the effect of molding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

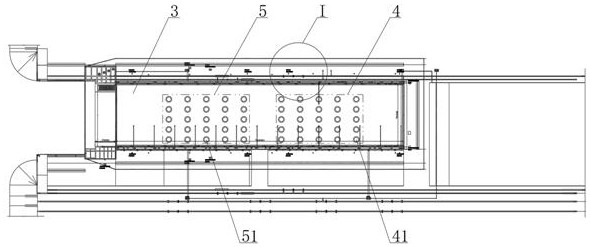

[0046] Below in conjunction with specific embodiments, the content disclosed in the present invention will be further described in detail, taking the ultra-large FPSO ship built in the port of Mauritania as an example, the design length is 294m, the width of the ship is 54m, the maximum width is 74m, and the depth is 32m. The closing process of the super-large FPSO ship mainly includes the following steps:

[0047] S1, the first hull section 1 and the second hull section 2 are manufactured and formed, which includes the following sub-steps:

[0048] S11. In the early stage of production technology preparation, determine the position of the segment line by understanding the design blueprint of the FPSO ship and the parameters of the manufacturing dock;

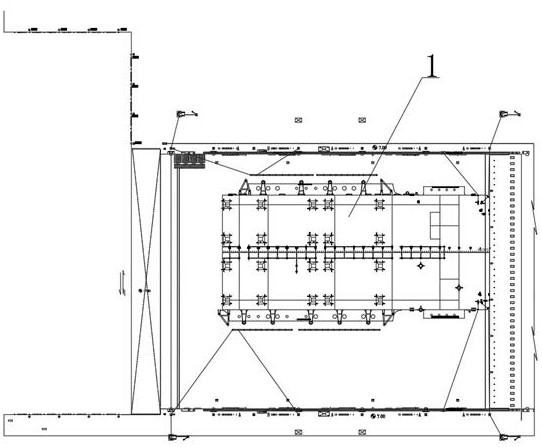

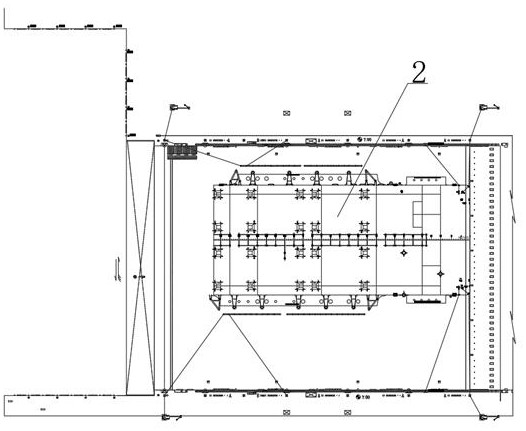

[0049] S12. In the two manufacturing docks, referring to the WPS welding procedure specification, synchronously complete the butt joint and welding work of the first hull section 1 and the second hull section 2 (such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com