Patents

Literature

41results about How to "With counting function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

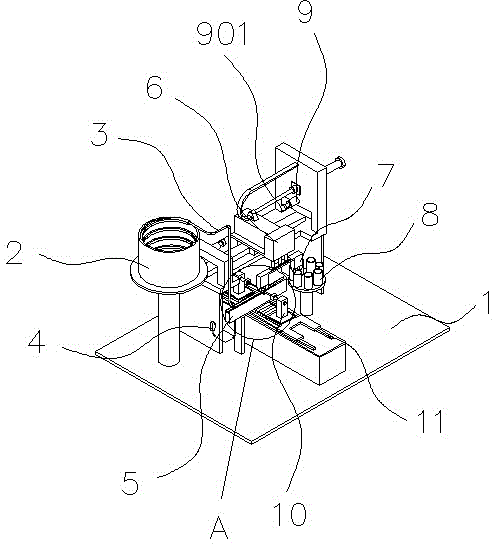

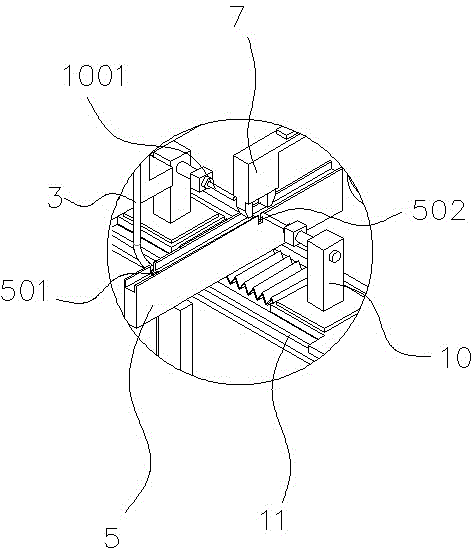

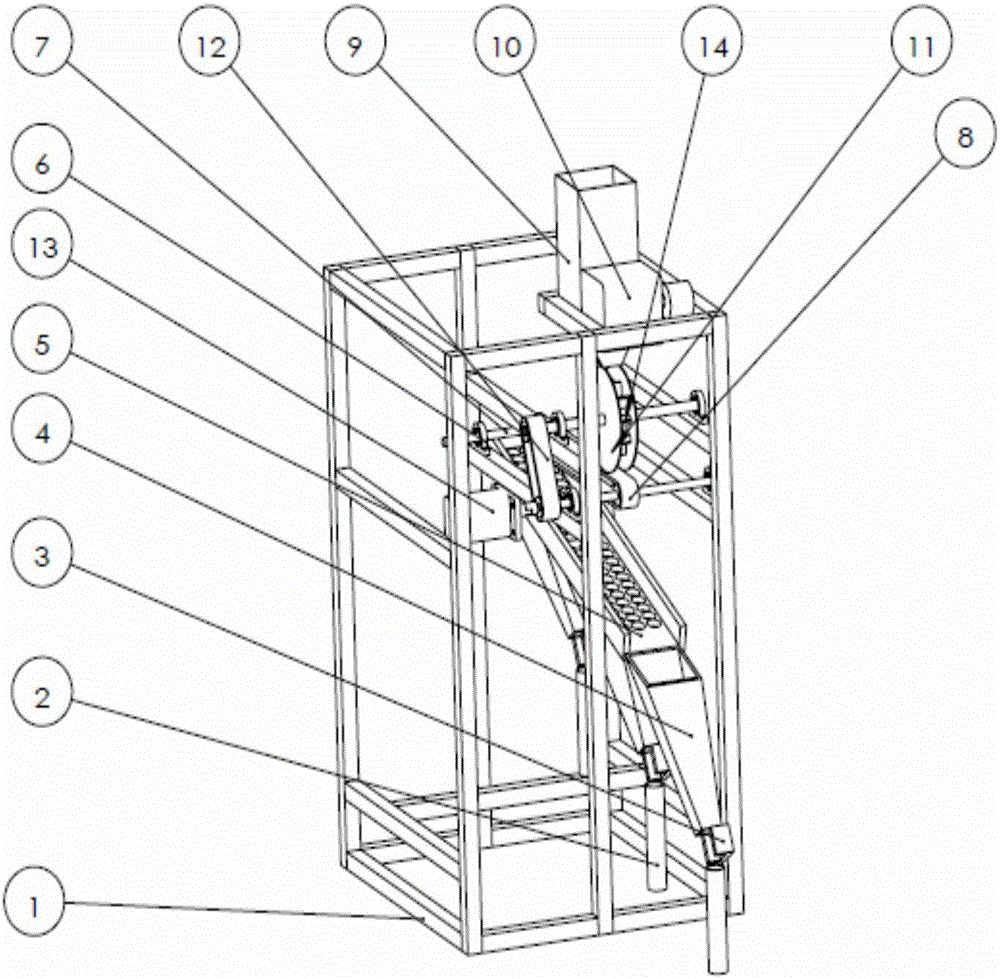

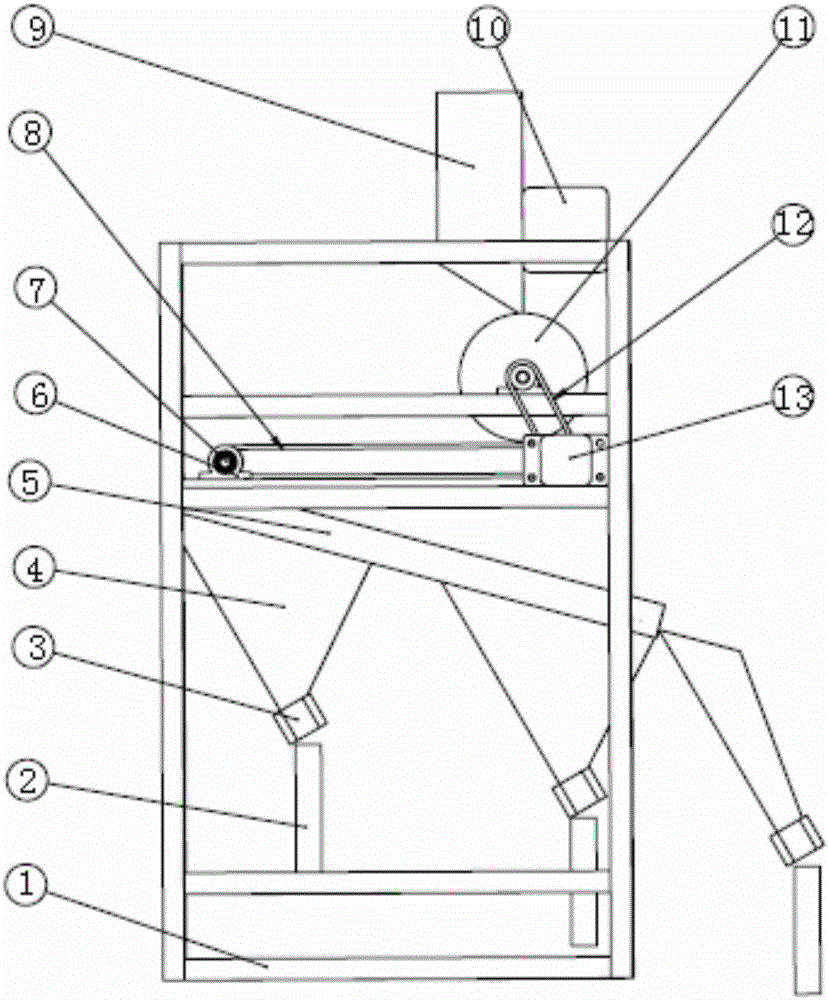

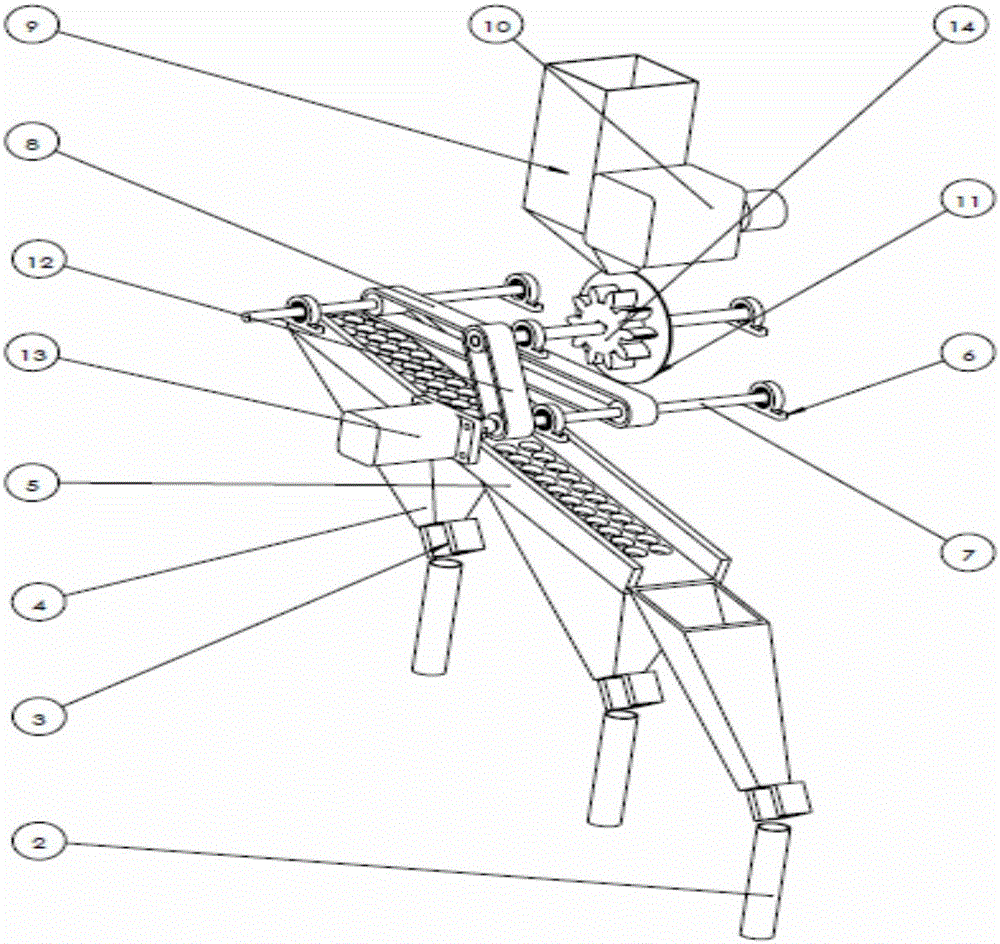

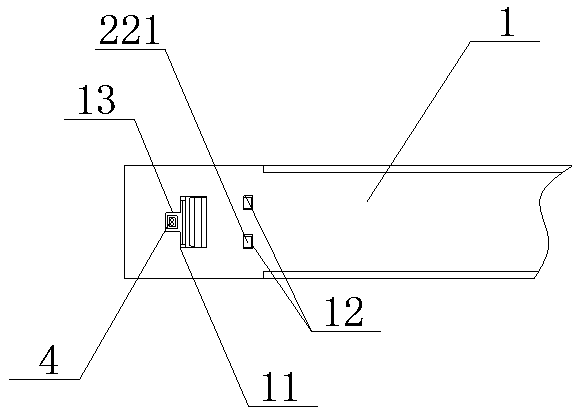

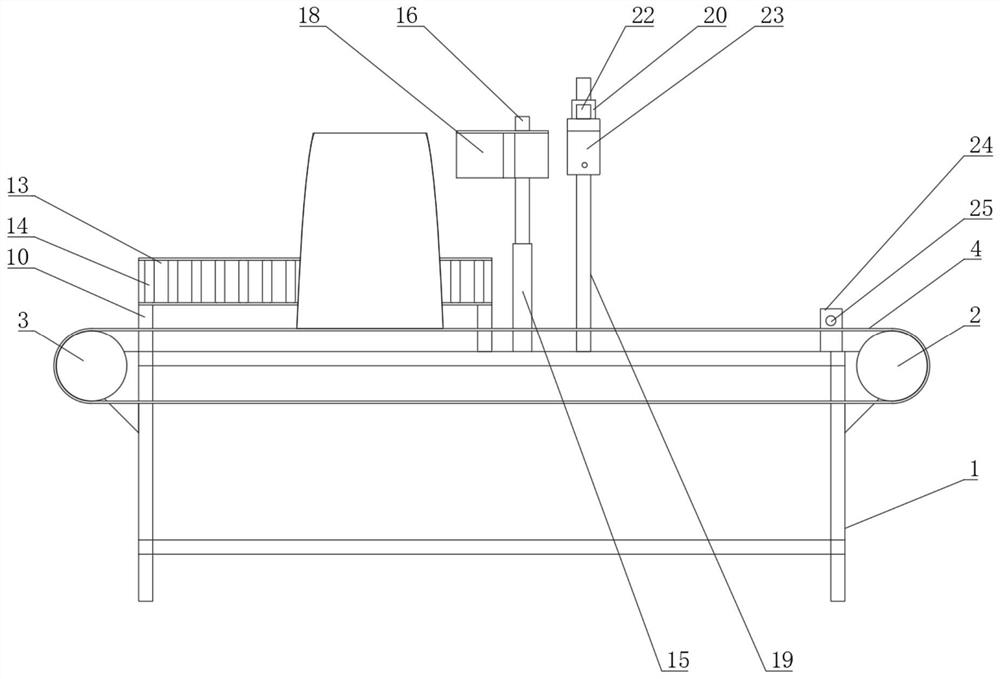

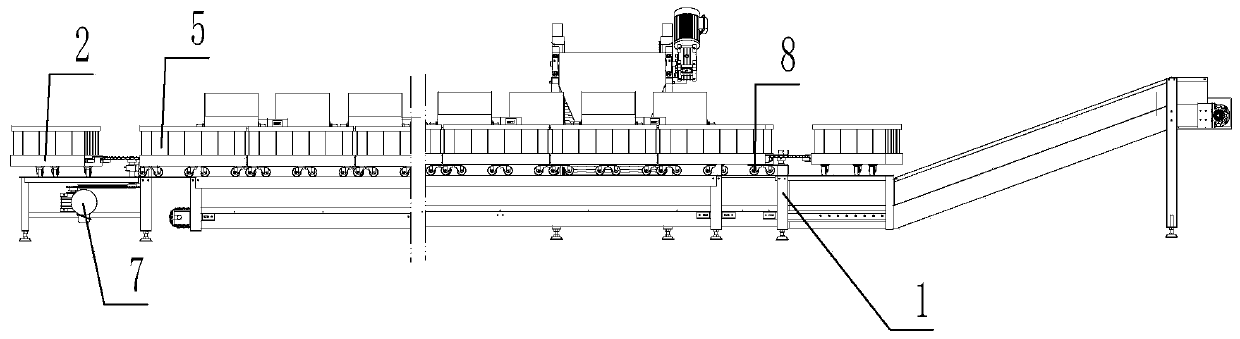

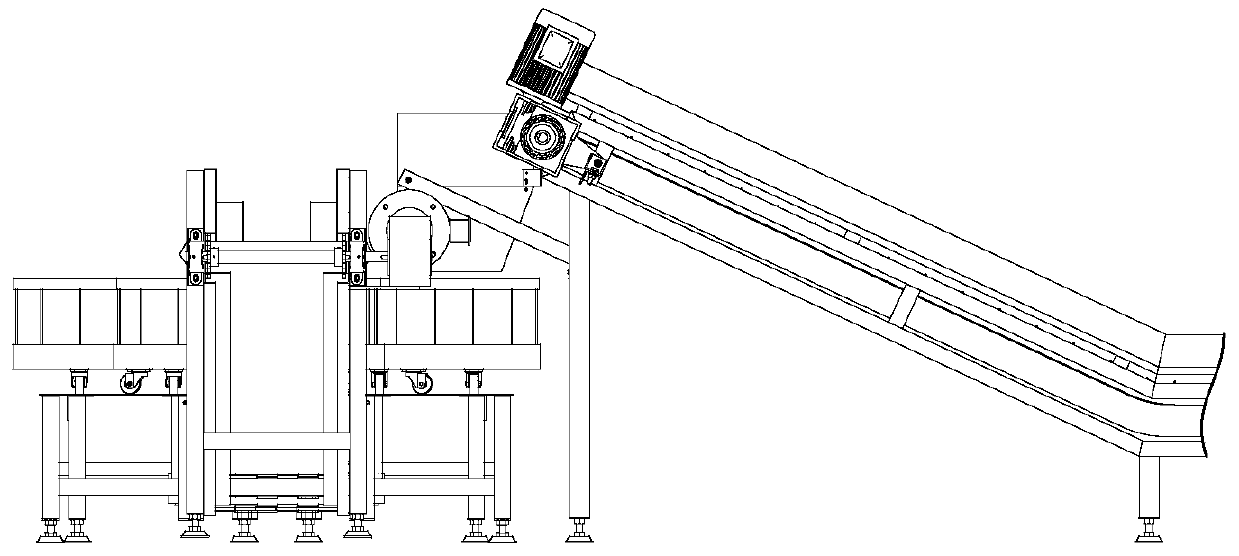

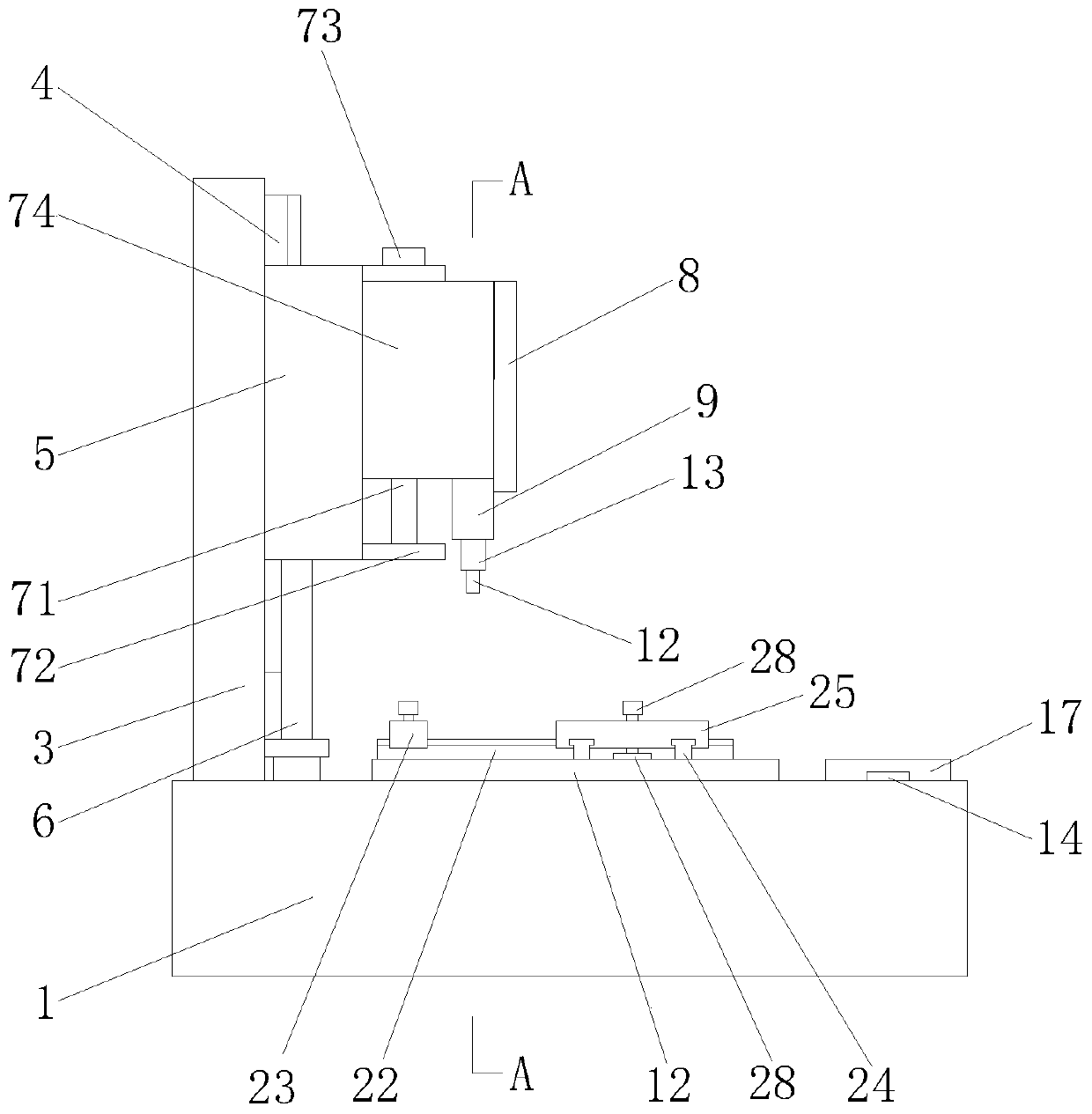

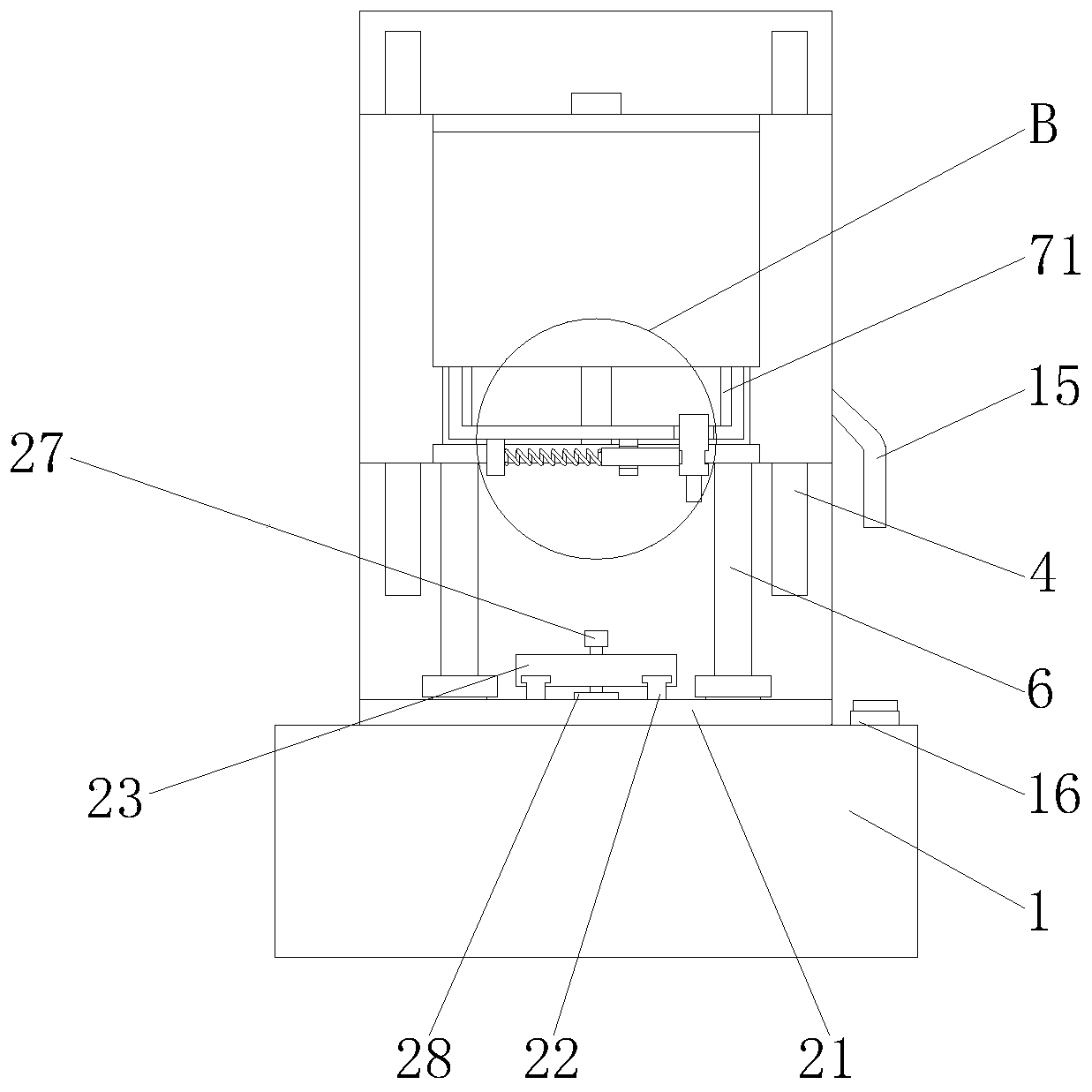

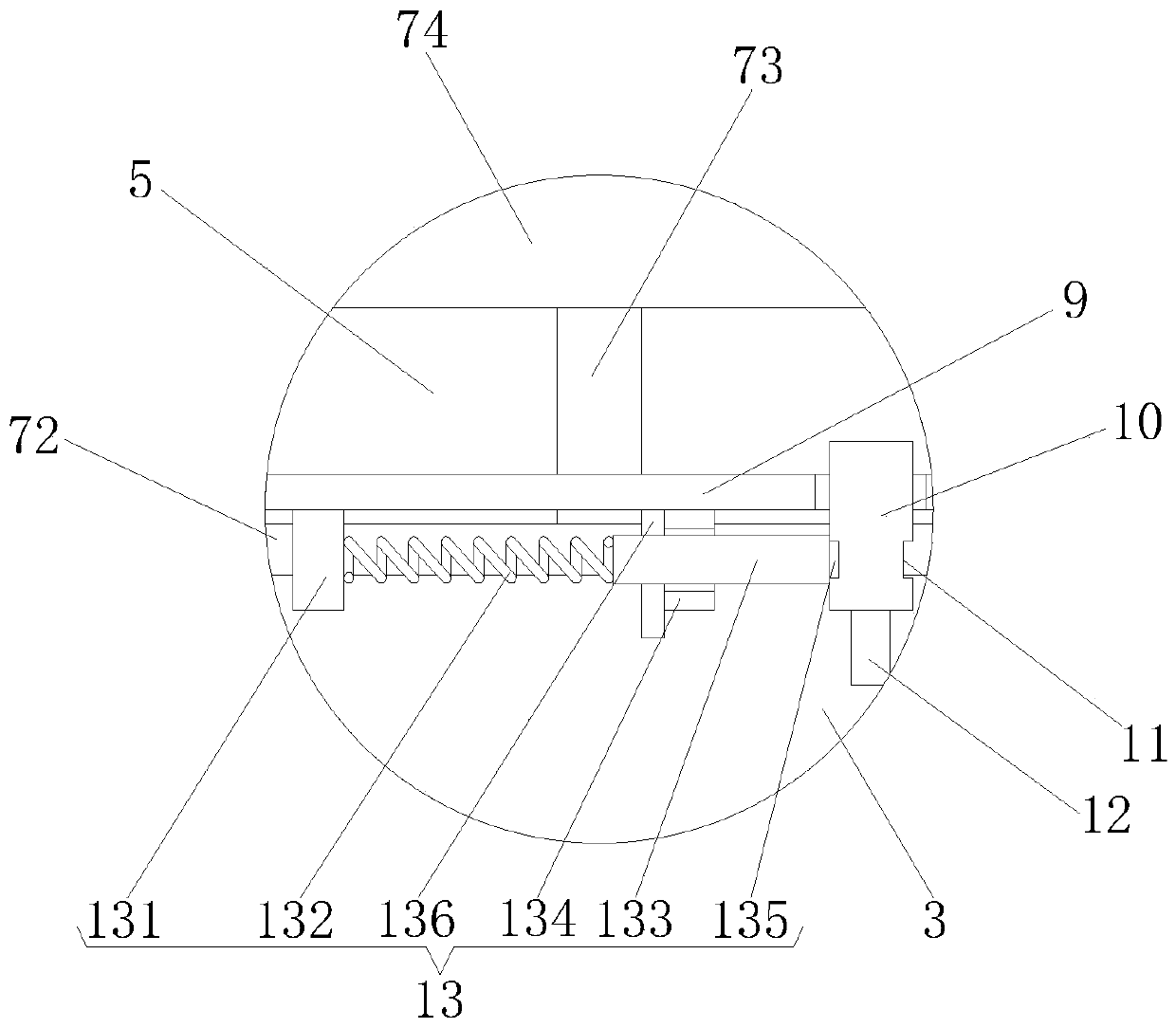

Full-automatic glove counting and stacking machine

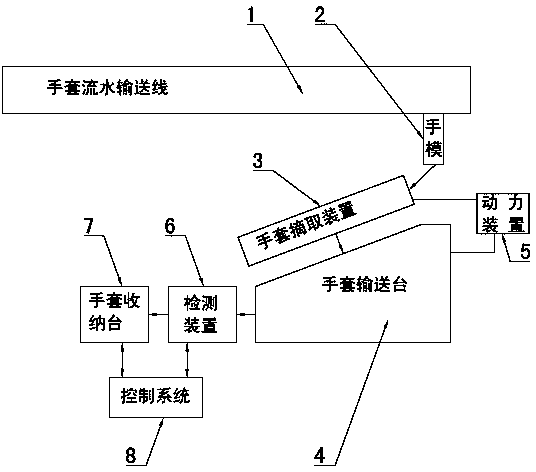

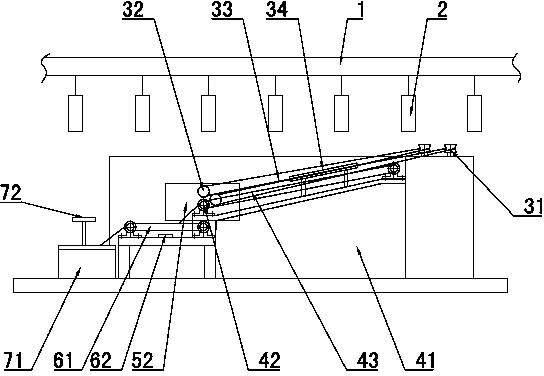

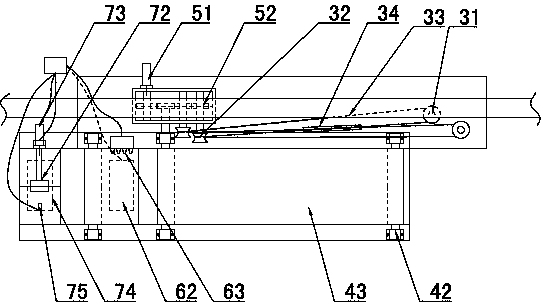

The invention provides a full-automatic glove counting and stacking machine, and belongs to the field of production devices of vinyl gloves, butyronitrile gloves and latex gloves. The full-automatic glove counting and stacking machine comprises a glove assembly conveying line (1), a plurality of hand moulds (2) are hung on the lower portion of the glove assembly conveying line (1), and gloves are arranged on the surfaces of the hand moulds (2) in a sleeved mode in the conveying process. The full-automatic glove counting and stacking machine is characterized in that a glove picking device (3) and a power device (5) are arranged below the glove assembly conveying line (1), a glove conveying table (4) with an inclined conveying face is arranged on one sides of the glove picking device (3) and the power device (5), the power device (5) drives the glove conveying table (4) and the glove picking device (3) to work at the same time, a detection device (6) is arranged at the output end of the glove conveying table (4), and the rear portion of the detection device (6) is connected with a glove storing table (7). The full-automatic glove counting and stacking machine is simple in structure, high in efficiency, free of cylinder control, convenient to maintain, and capable of achieving glove picking, detecting, conveying, and stacking functions.

Owner:ZIBO CHENGXUN AUTOMATION EQUIP

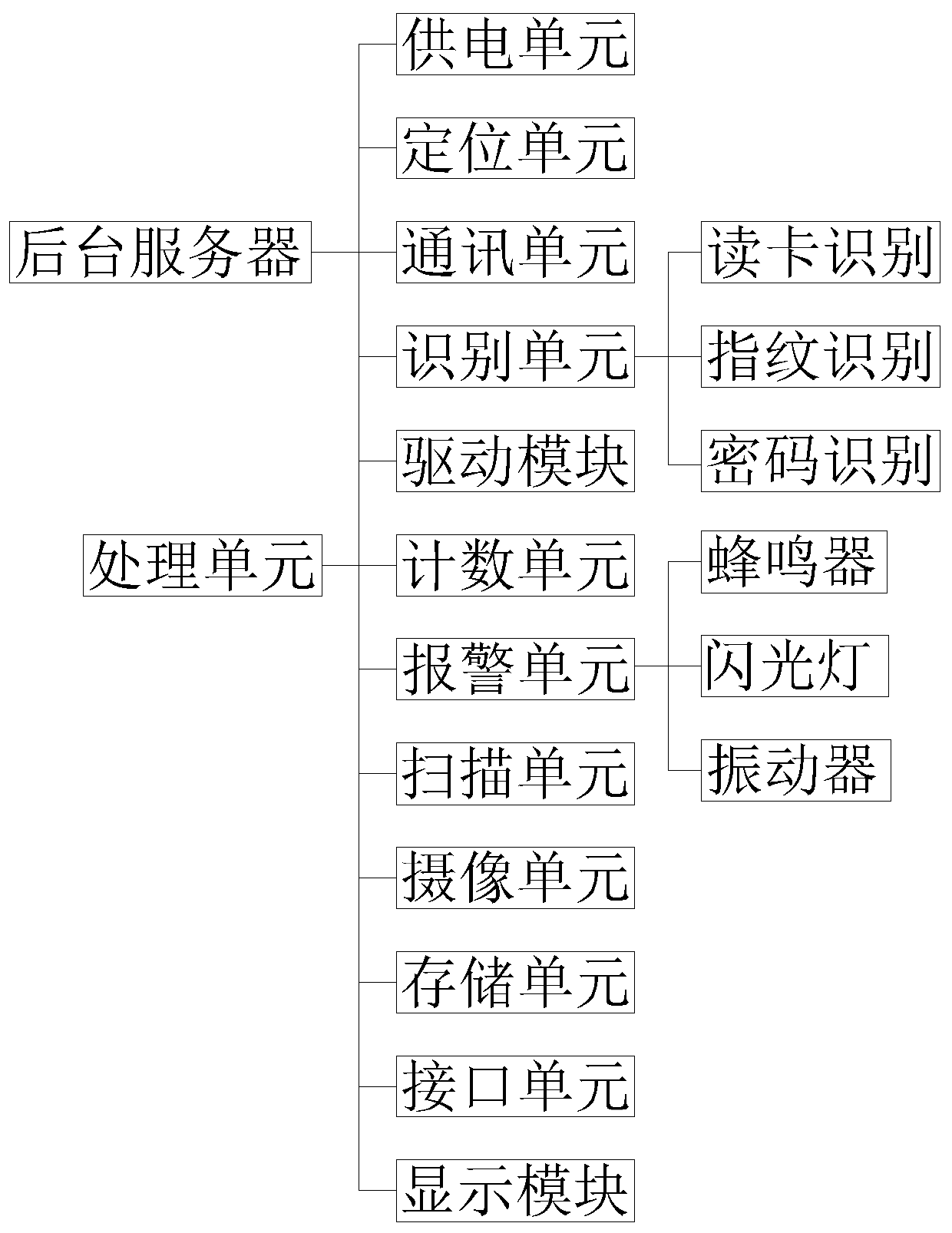

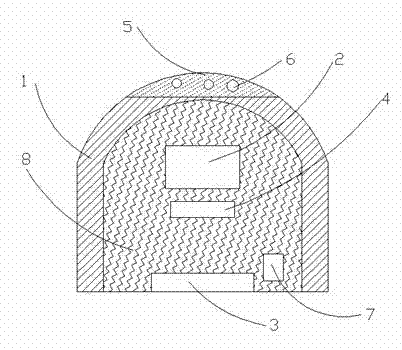

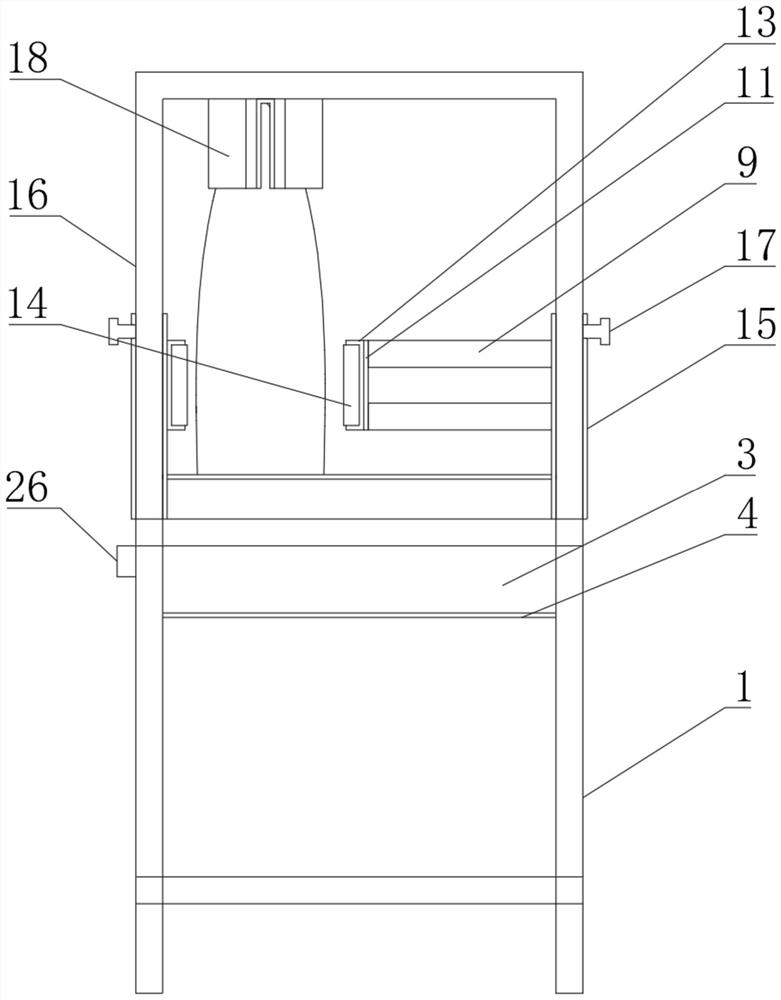

Intelligent seal and using method thereof

The invention provides an intelligent seal and a using method thereof. The intelligent seal comprises a shell; a seal body and an intelligent control module are arranged in the shell; and the intelligent control module comprises a processing unit and further comprises a power supplying unit, a positioning unit, a communication unit, an identifying unit, a driving module, a scanning unit, a storageunit and an interface unit which are electrically connected with the processing unit. According to the intelligent seal, an Internet of Things system is adopted, and a moving path, a user and a usingenvironment of the seal are monitored in real time and stored so as to be real-timely looked up and traced in the later period; meanwhile, files which are sealed for multiple times are scanned and backed up so as to be real-timely looked up and traced in the later period, and safety is high; and the intelligent seal has a counting function to record the number of sealing times, using safety is improved, illegal abuse of the seal is avoided, and the enterprise risk is lowered.

Owner:国星奔野控股(宁波)有限公司

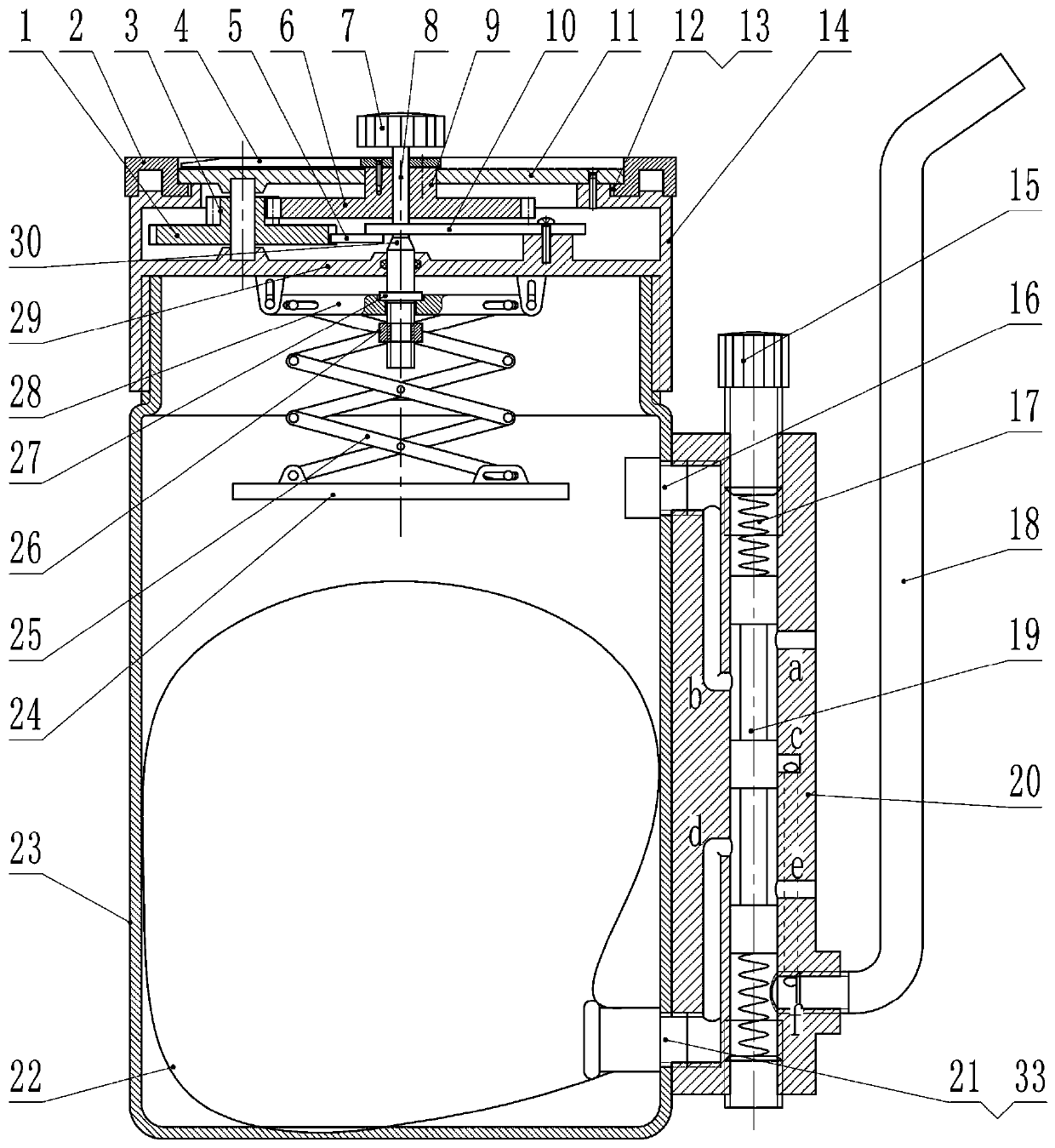

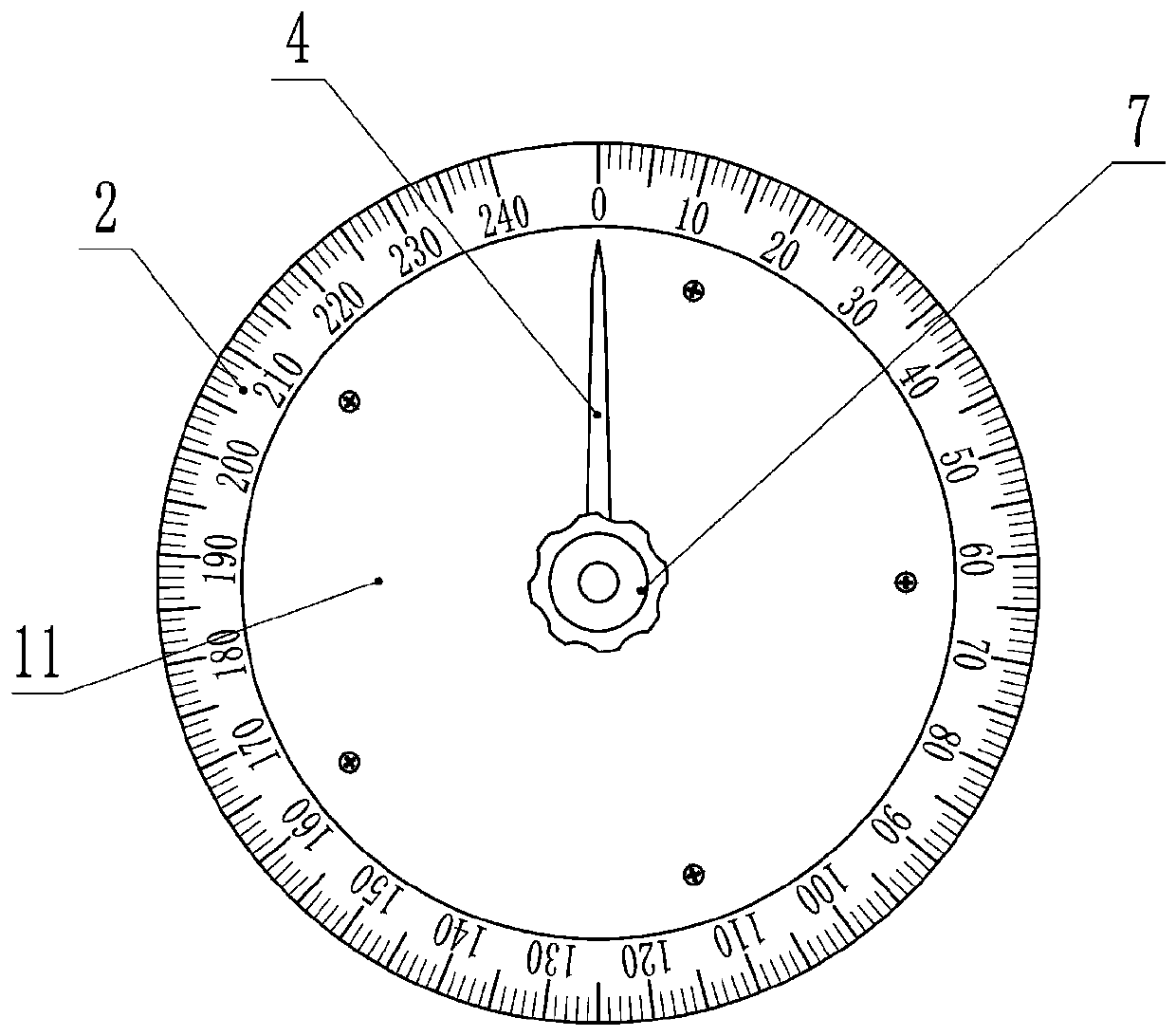

Multifunctional breathing exercise device

InactiveCN110368650AEasy to applyPlay a role in exercising lung capacityGymnastic exercisingThreaded pipeGas cylinder

The present invention discloses a multifunctional breathing exercise device, and belongs to the field of medical instruments. The multifunctional breathing exercise device comprises: a gas valve, a gas cylinder and a bottle cap; the bottle cap is arranged above the gas storage bottle, and the bottle cap is in a sealed connection with the gas cylinder; the gas valve is fixed on the side wall of thegas cylinder, and comprises a valve body, a valve core, a valve spring, an adjusting stud and a blowing pipe; the physical connection between the valve body and the gas cylinder, and the communication between the valve body and the internal cavity are realized by using the threaded pipes; a balloon is arranged in the gas cylinder; the bottle cap comprises an upper wall, a lower wall, a main shaft, a gear, a lever, a dial, a ratchet mechanism and a scissor mechanism; and pointers are arranged above the upper wall. Compared with the prior art, the multifunctional breathing exercise device provided by the present invention has the characteristics of capabilities of counting, and adjusting the air impedance and the amount of gas.

Owner:威海市妇幼保健院

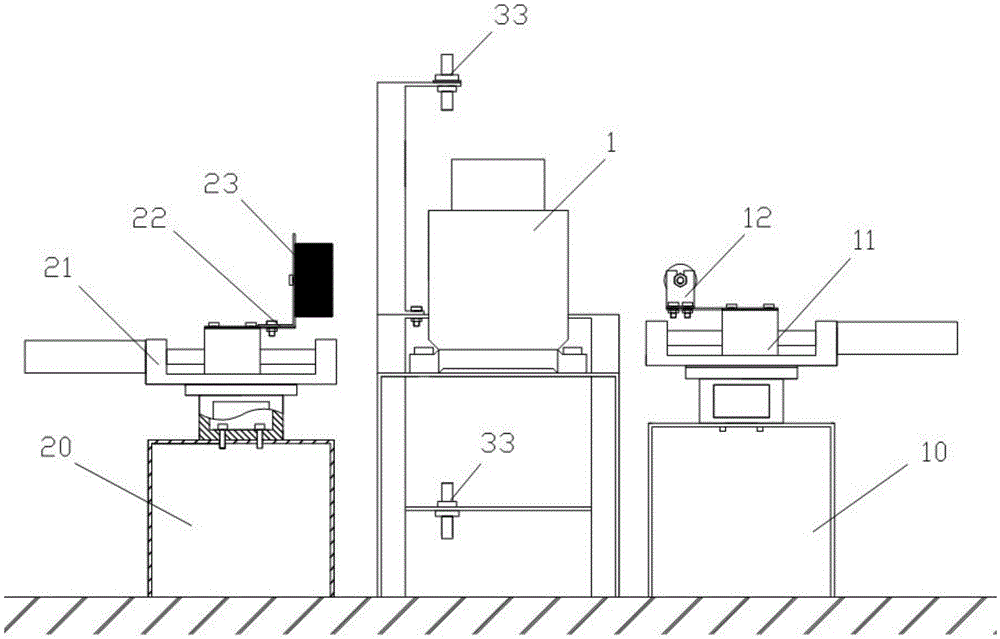

Automatic detection device for internal diameters of ceramic tubes

ActiveCN103954225ASimple running trackSimple structureUsing optical meansEngineeringMechanical engineering

An automatic detection device for the internal diameters of ceramic tubes comprises a working platform. A feed mechanism, a moving and loading mechanism, a detection mechanism and a sorting mechanism are sequentially distributed on the working platform according to the process. The moving and loading mechanism is arranged behind the feed mechanism. The detection mechanism is matched with the moving and loading mechanism. The sorting mechanism is arranged behind the moving and loading mechanism and the detection mechanism. The operating track of the moving and loading mechanism is extremely simple, and accordingly the structure is simple. The ceramic tubes are fetched and detected at the same time, and are discharged and sorted synchronously, and the overall operating efficiency is remarkably improved.

Owner:浙江西比通信科技有限公司

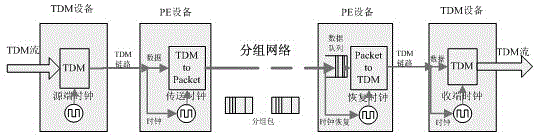

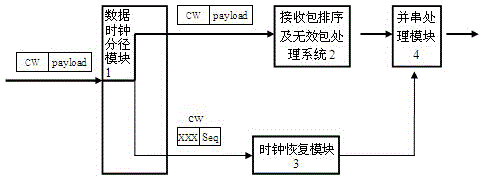

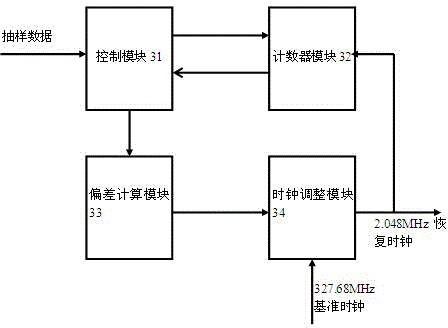

Received packet sorting and null packet processing system

ActiveCN104410483AImprove sorting efficiencyInvalid packet handling hasTime-division multiplexSynchronising arrangementNetwork communicationNetwork data

The invention relates to the field of network communication, in particular to a received packet sorting and null packet processing system. The system comprises a write-in control module, a read-out control module and a jiggle cache module, wherein the input end of the write-in control module is connected with a data receiving port, the output end of the write-in control module is connected with the jiggle cache module, and the jiggle cache module is connected with the read-out control module; the write-in control module is used for controlling the write-in of network data; the jiggle cache module is used for storing the network data; the read-out control module is used for controlling the read-out of the network data in the jiggle cache module. According to the system, a method for directly storing packets in corresponding positions according to serial numbers is adopted, so that the sorting efficiency is relatively high; meanwhile, the system has the functions of losing the packets, processing null packets and counting.

Owner:CHENGDU LONGRAISE TECH DEV

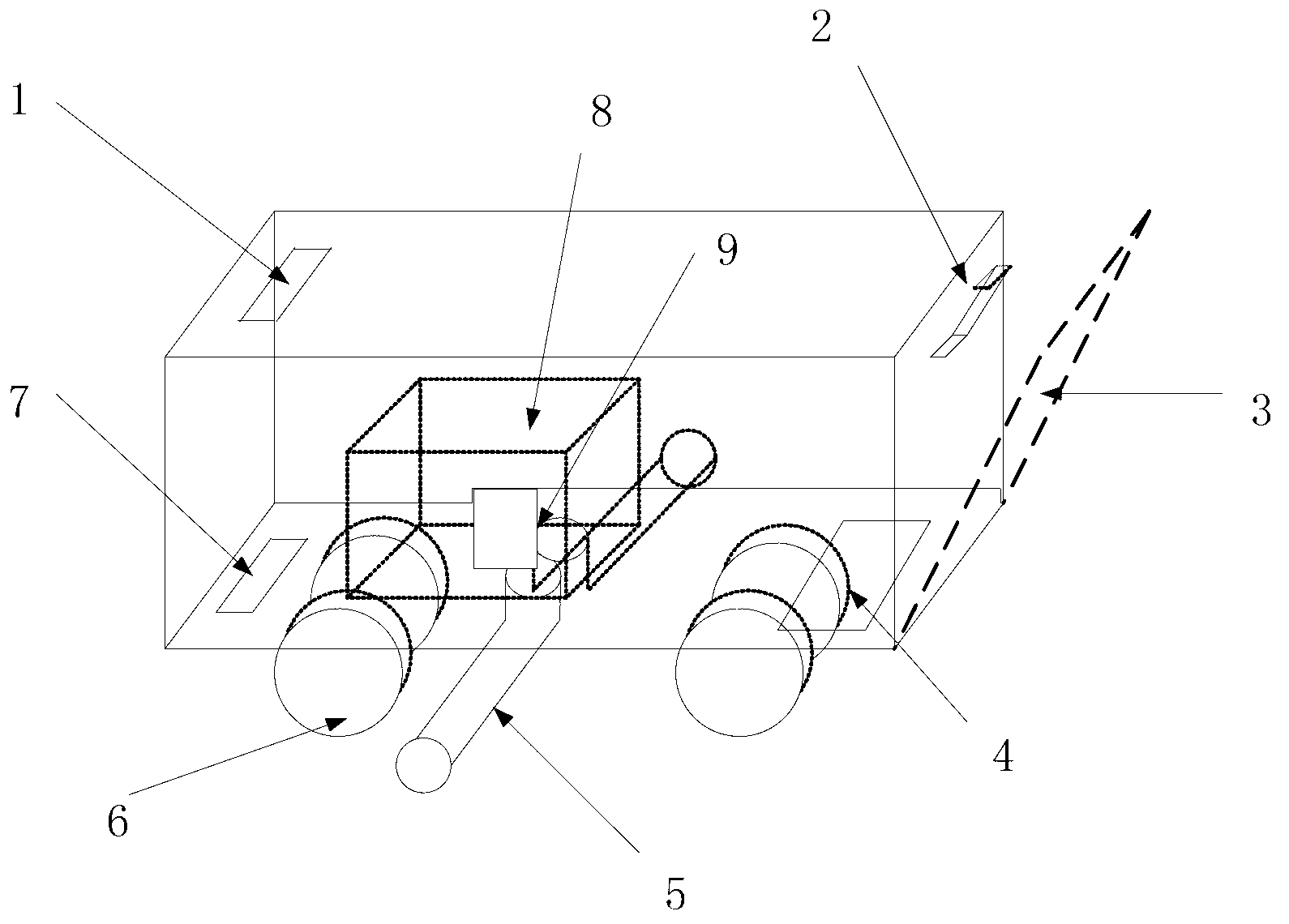

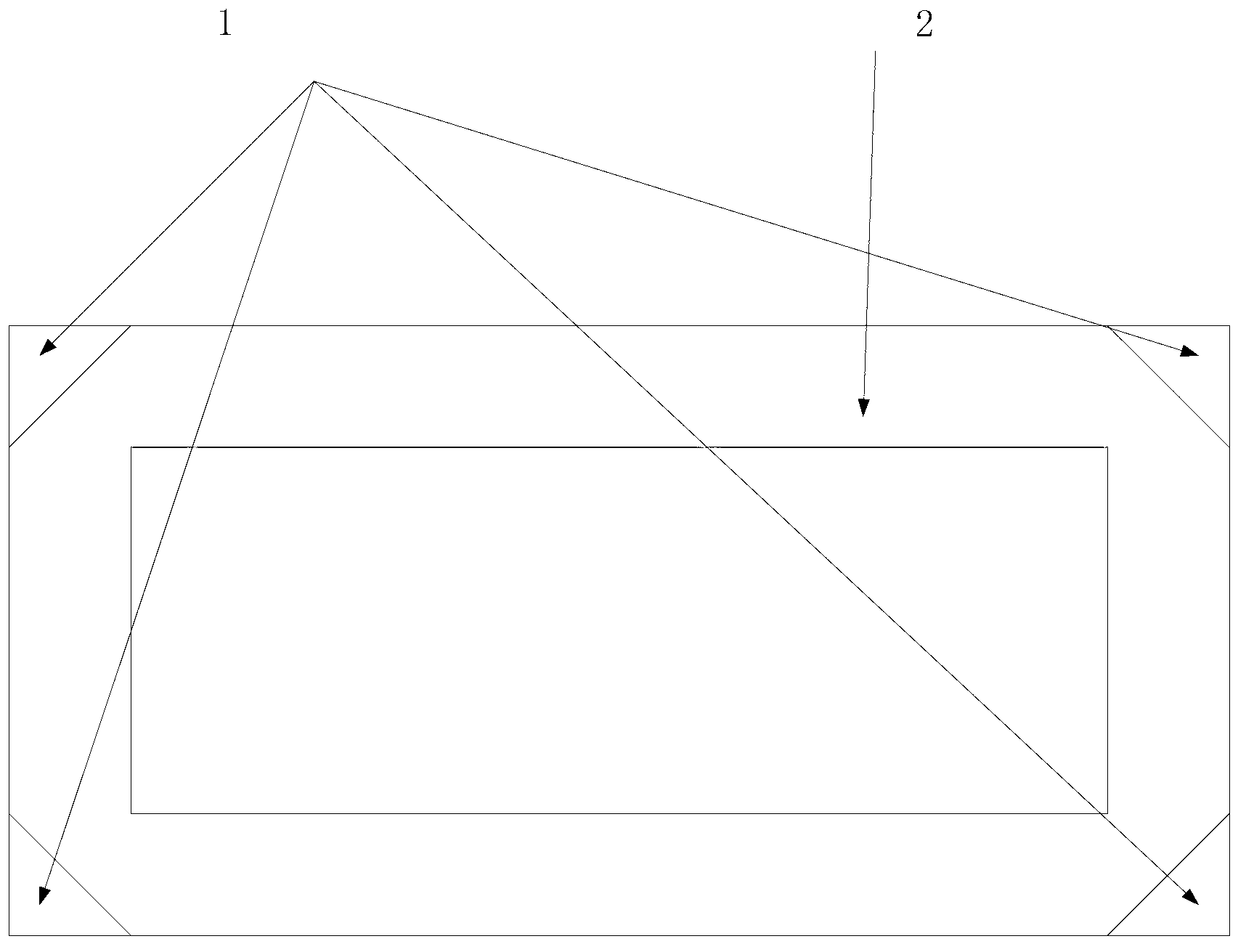

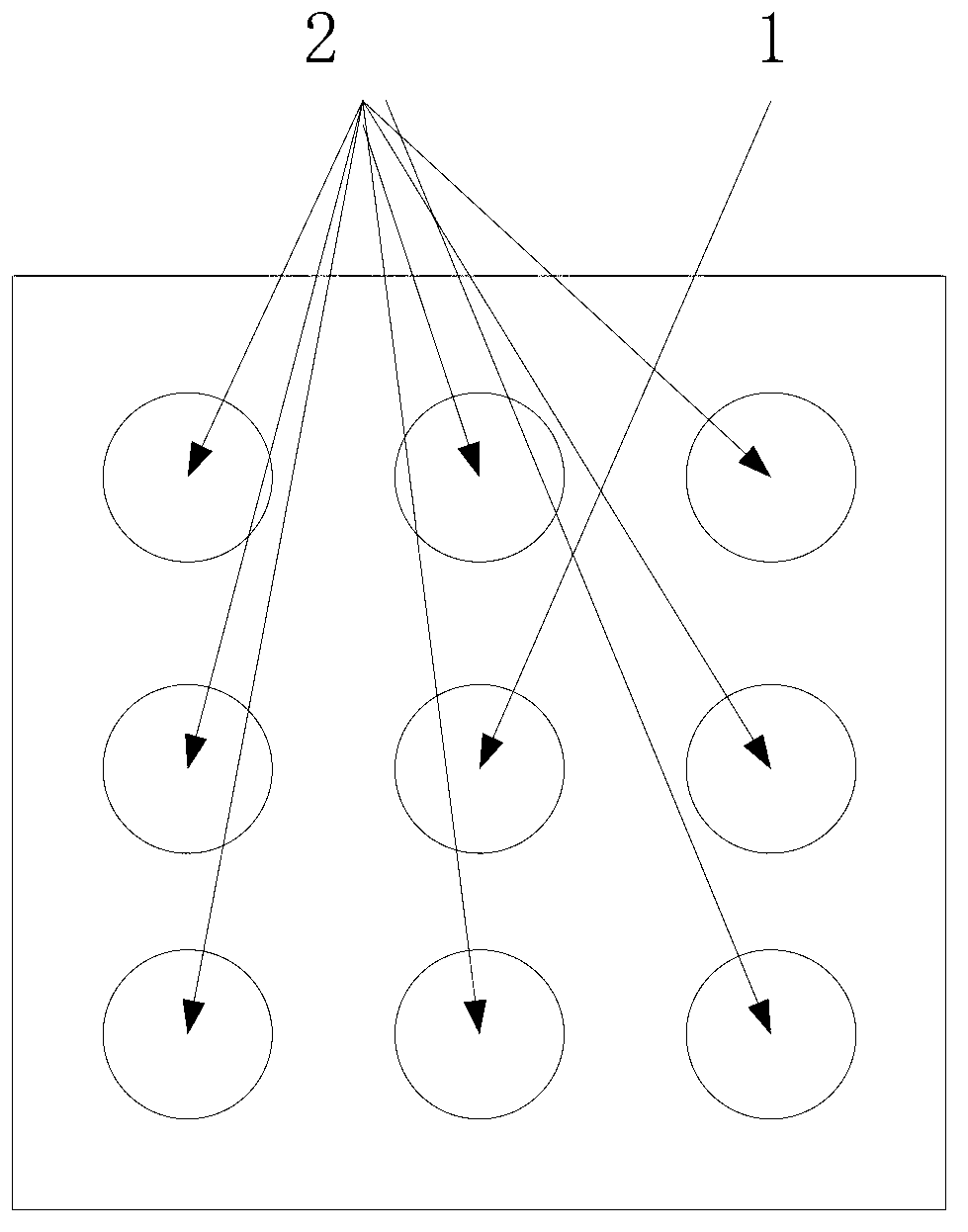

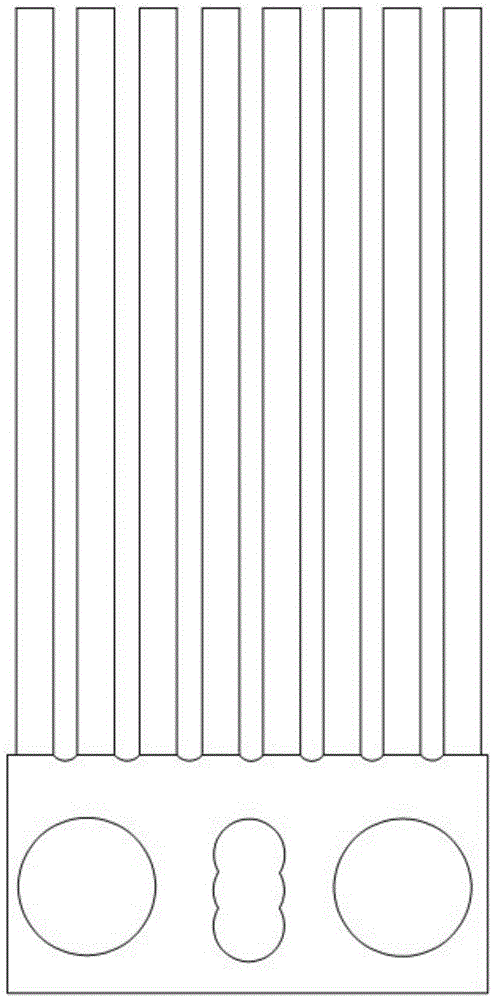

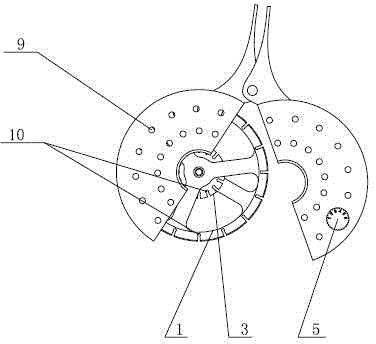

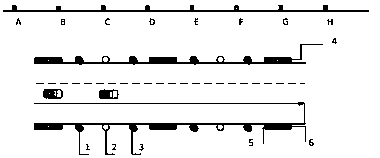

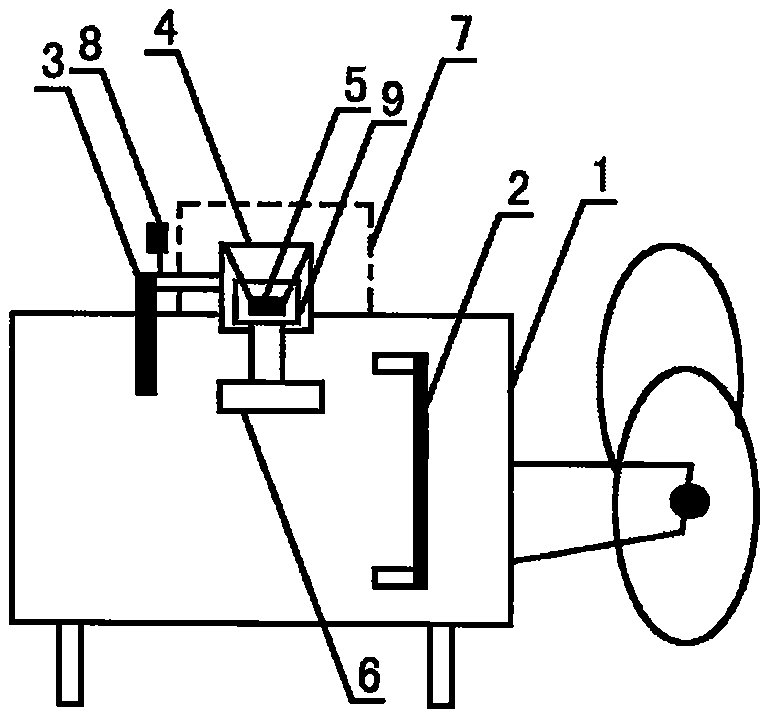

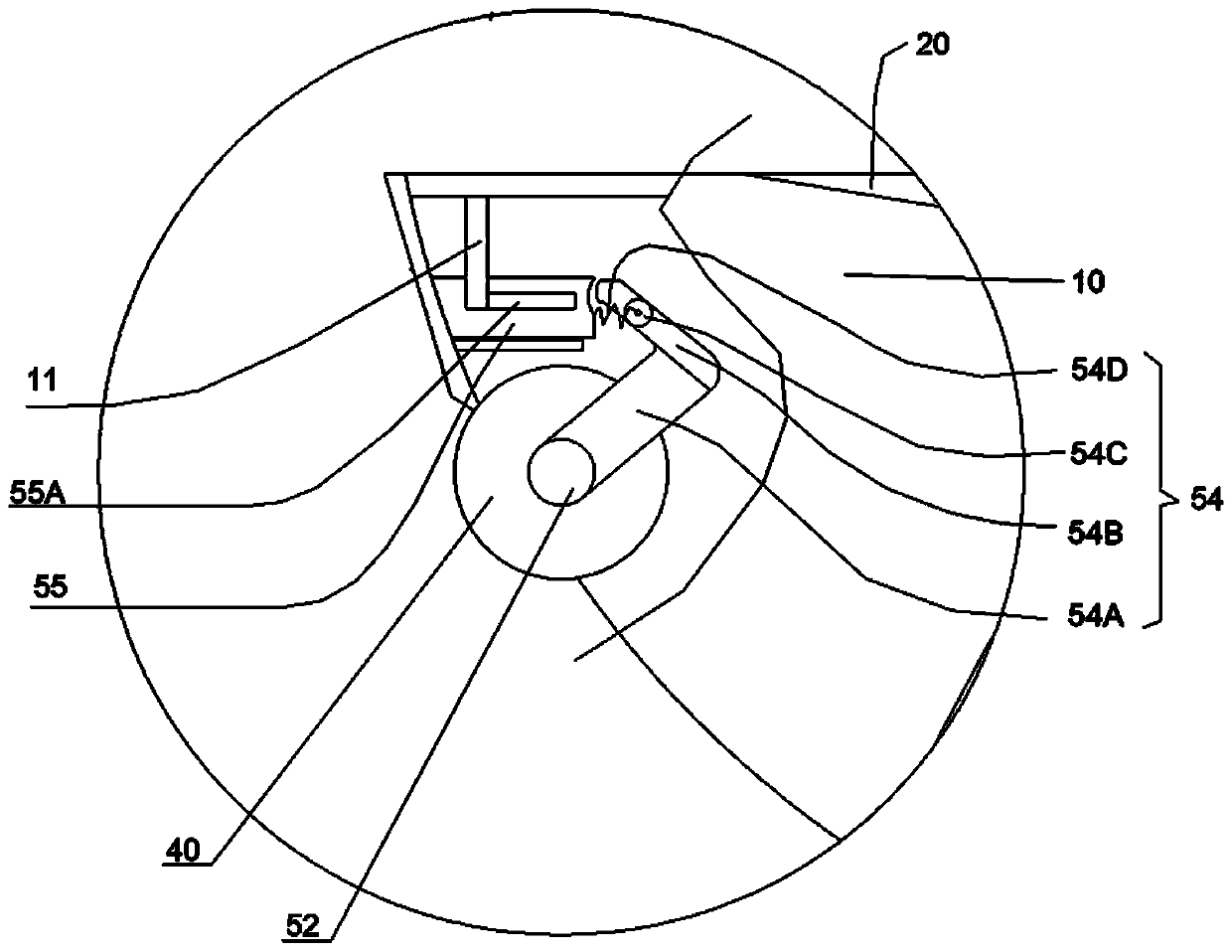

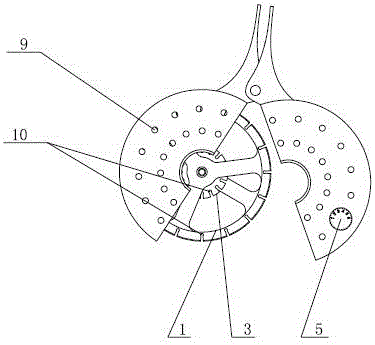

Table tennis ball picking device with counting function

InactiveCN103007498ARealize automatic picking functionWith counting functionBall sportsStopped workEngineering

The invention discloses a table tennis ball picking device with a counting function, which comprises a four-wheel trolley, a remote controller, a steering sensor (7), a ball suction pipeline (5), a suction fan (9), a ball containing box (8) and a rail. Due to use of the steering sensor (7), the table tennis ball picking device with the counting function can travel along the rail to pick up table tennis balls; the table tennis ball picking device has the counting function; and when the number of the picked table tennis balls reaches a certain preset number, the device can automatically stop working.

Owner:HARBIN HESON SCI & TECH

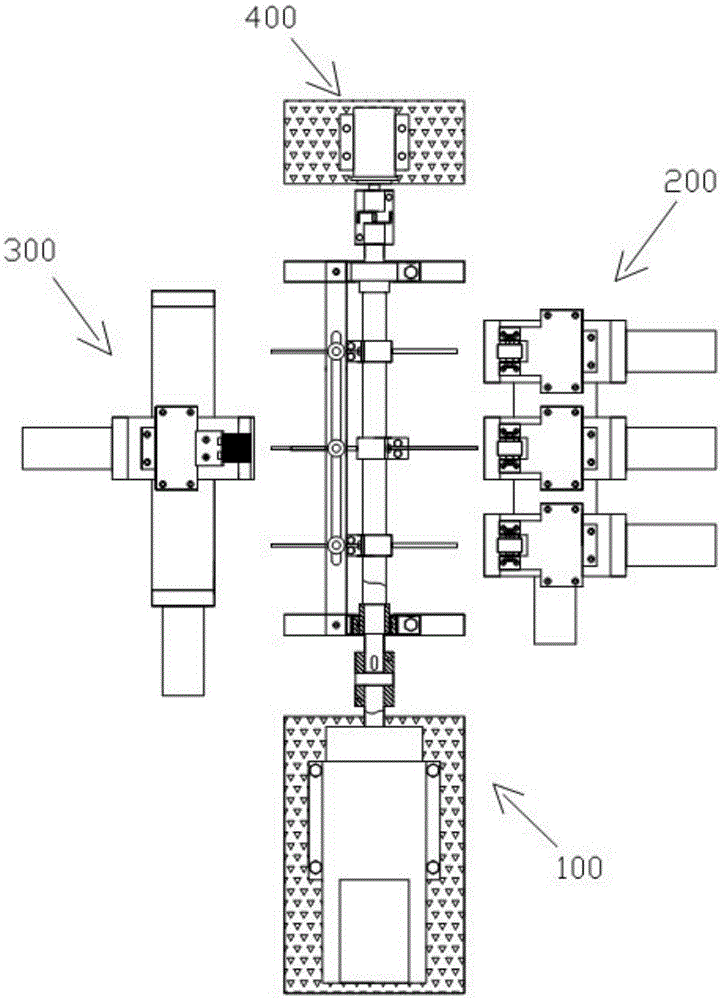

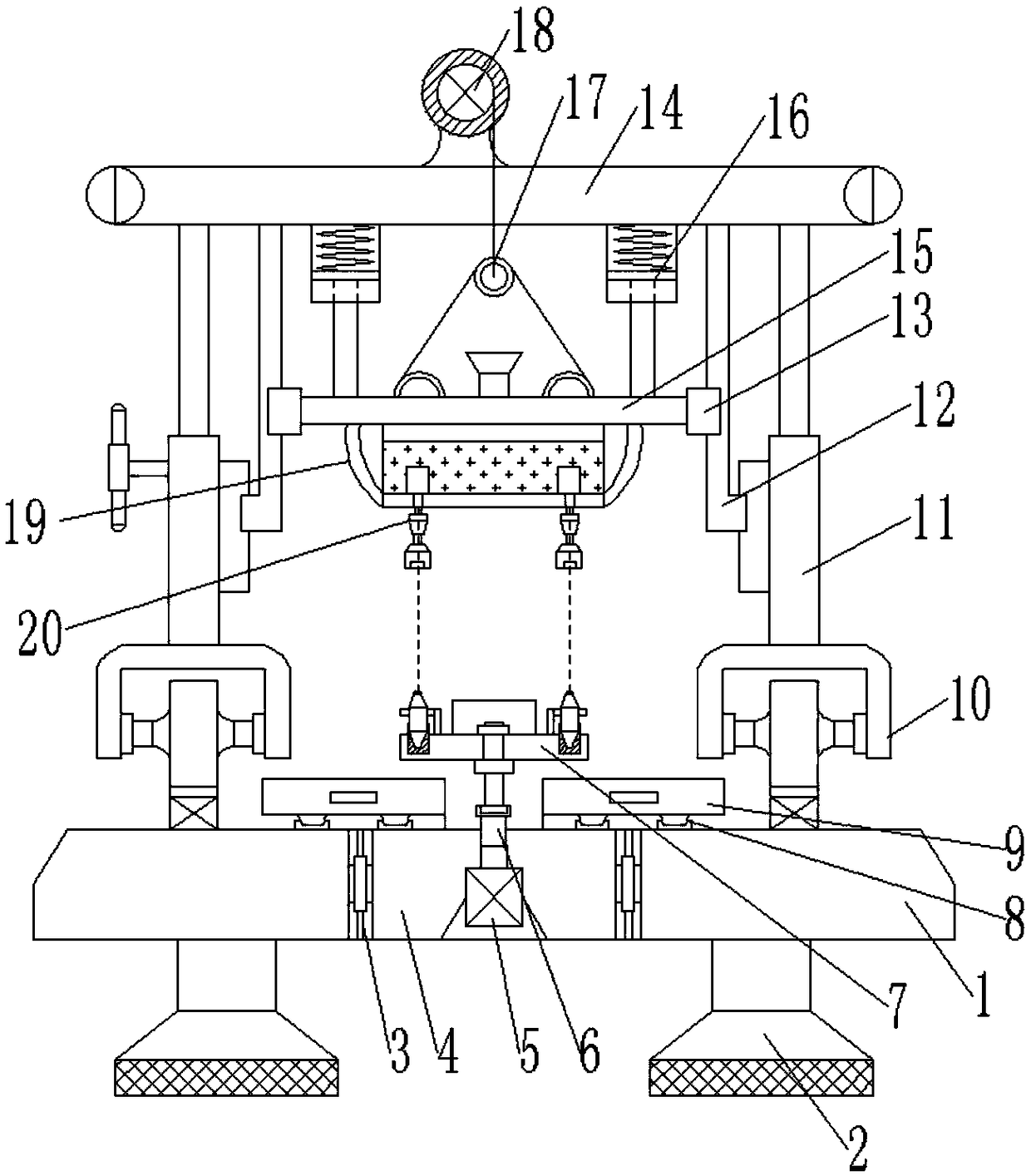

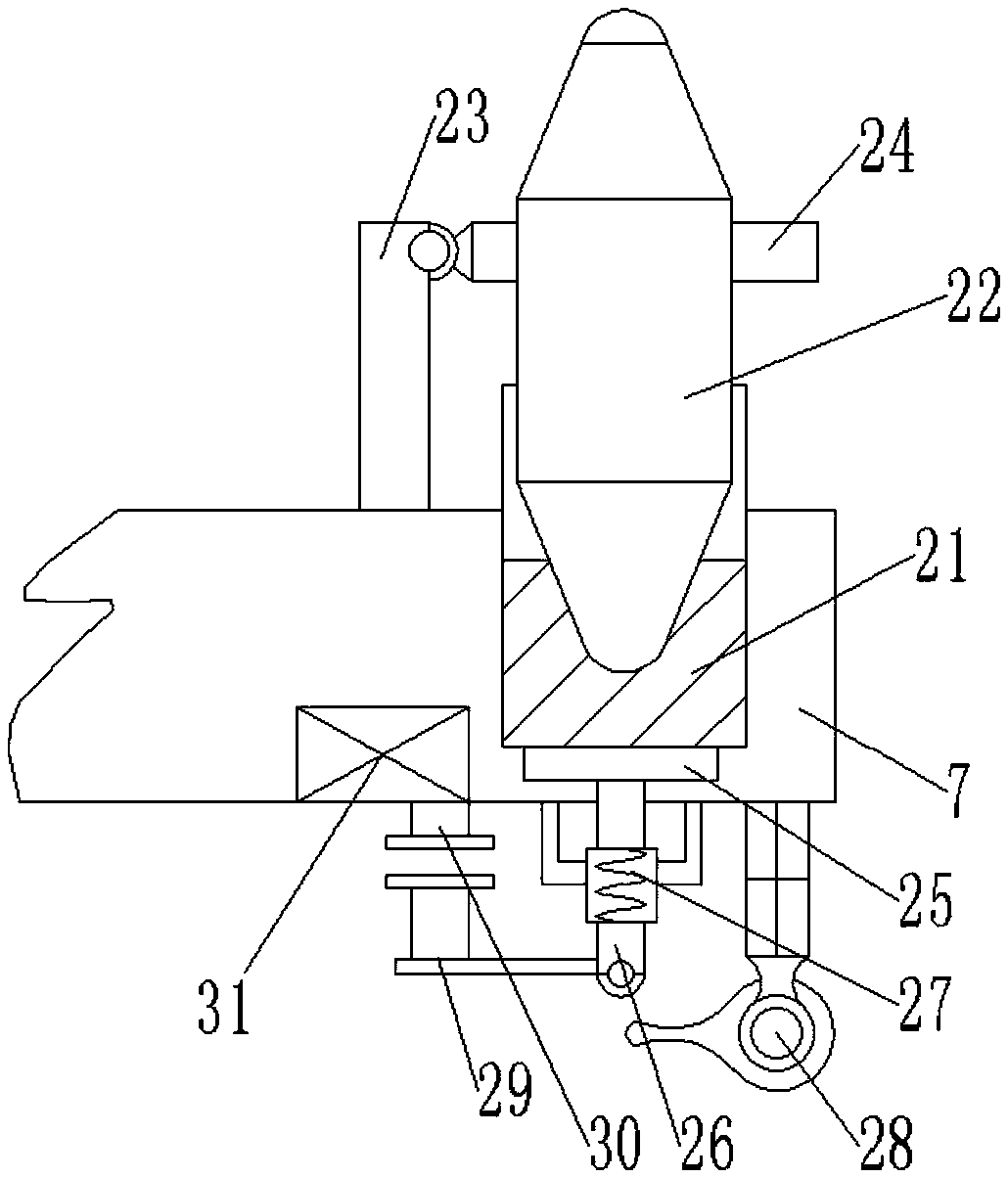

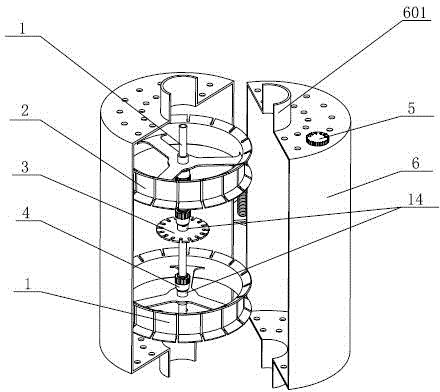

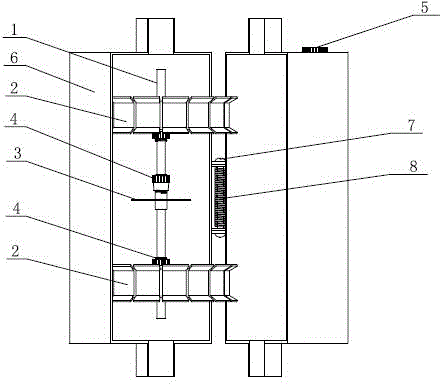

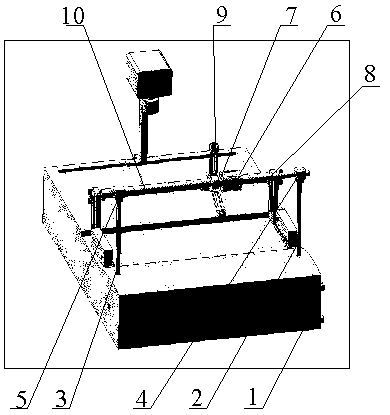

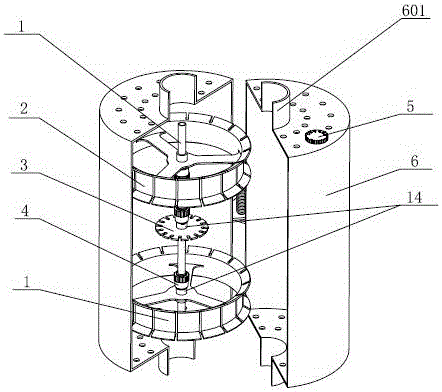

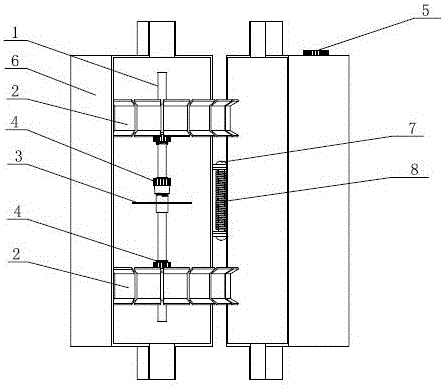

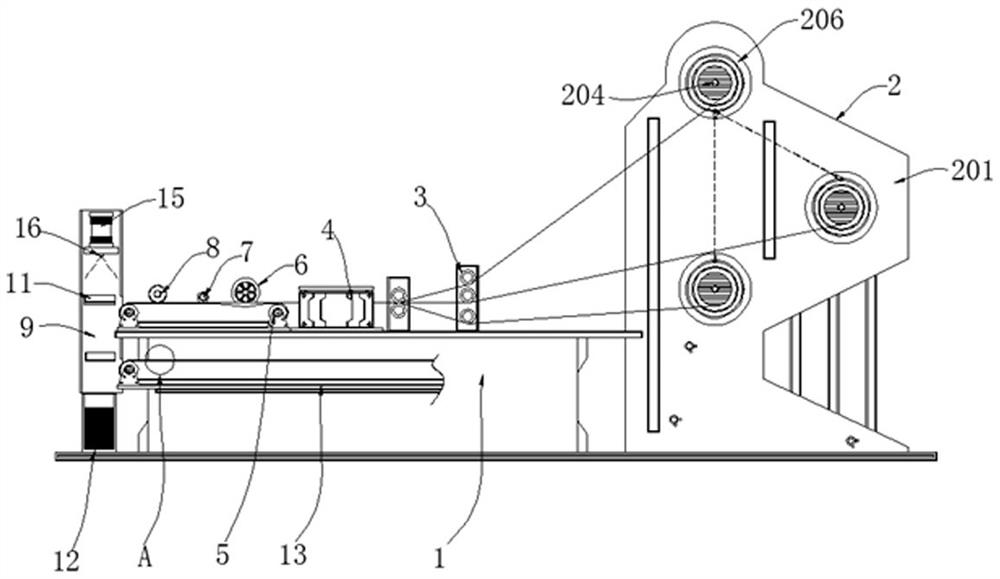

Fatigue testing machine for sugarcane detrashing machine detrashing element

ActiveCN105424352AConvenient speed controlControllable stagger depthMachine part testingFatigue fracturesFatigue testing

The invention discloses a fatigue testing machine for a sugarcane detrashing machine detrashing element. The testing machine comprises a driving component, a loading component which is arranged at one side of the driving component, a measuring component which is arranged at the other side of the driving component, and a counting component which is connected with the driving component in a mutual matching way. The driving component is used for providing driving force to drive a detrashing element sample to rotate. The loading component provides different interleaving depths for testing. The measuring component is used for detecting working length and impact force of the detrashing element sample. The counting component is used for recording the service life (cycle index) of the sample and can also judge fatigue fracture of the sample and stop counting at the time of fracture. According to the testing machine, the optimal selection of rotating speed and interleaving depth of a sugarcane detrashing machine can be obtained through analysis and summary of experimental data together with the actual situations so that the testing machine has important significance for reducing consumption of the detrashing element, enhancing the service life and detrashing efficiency of the sugarcane detrashing machine and reducing cost when the sugarcane detrashing machine normally works.

Owner:GUANGXI UNIV

Soft capsule filling machine

InactiveCN108888520ARealize the collectionEasy to transportCapsule deliveryVertical planeDrive shaft

The invention discloses a soft capsule filling machine. The soft capsule filling machine comprises a fixing base, the outer wall of one side of the fixing base is provided with a cavity, both sides ofthe inner wall of the cavity are welded with rotating hinges, one outer walls of the rotating hinges are welded with sealing door sheets, the inner wall of the bottom of the cavity is connected witha servo motor through bolts, the output shaft of the servo motor is welded with a transmission shaft, and the outer wall of the top end of the transmission shaft is connected with a storage plate in asleeve mode. The soft capsule filling machine can achieve capsule collection and facilitate transferring of capsules by operators to improve the working efficiency of the operators and enhance the adjustability, a lifting plate can lift up and down on a vertical plane to complete capsule filling, and counting treatment can be performed during a capsule body returning process so that the soft capsule filling machine can record the number of processed capsule bodies within a certain period of time.

Owner:NANJING ZHENGKUAN MEDICAL TECH

Coin sorter

InactiveCN105931353AEasy to pack and transportSimple mechanical structureCoin/paper handlersDrive motorVibration exciter

The invention relates to a coin sorter. The coin sorter comprises a support, a driving belt and a tunnel, the tunnel is arranged over the support, the size of an outlet of the tunnel equals to the thickness of one and a half 1-yuan coins, the sidewall of the tunnel is connected with a vibration exciter, a gear whose two sides are provided with baffle plates respectively is arranged blow the tunnel, the driving belt is arranged under the gear, the driving belt and the gear are mounted on the support via a bearing and a bearing pedestal respectively, the side, below the gear, of the driving belt is connected with a driving motor via a shaft, the gear is connected with the driving motor via a small belt and a shaft, the other side of the driving belt is connected with a skewed slot, the skewed slot is provided with holes of the sizes of corresponding coins, the lower portions of the holes are connected with corresponding collecting boxes, the lower ends of the collecting boxes are connected with transparent cylinders respectively, and outlet ends of the collecting boxes are provided with counters respectively. According to the invention, all devices are mounted inside the support, packaging and transportation are convenient, the mechanical structure is simple, and the coin sorter is capable of sorting.

Owner:DONGHUA UNIV

Novel medicine dispensing device with counting function and method thereof

InactiveCN103735088ARealize the out-of-warehouse workWith counting functionRacksMechanical engineeringEngineering

The invention discloses a novel medicine dispensing device with the counting function. The novel medicine dispensing device comprises medicine dispensing grooves, flexible plates, the sensing portions and the driving portions; the medicine dispensing grooves are provided with first through holes, second through holes and third through holes; the flexible plates move in a seesaw mode and are arranged under the medicine dispensing grooves; the first baffle portions and the second baffle portions are arranged at two moving ends which are arranged on the flexible plates and are opposite to each other respectively; the first baffle portions shuttle in the first through holes; the second baffle portions shuttle in the second through holes; the sensing portions are arranged under the medicine dispensing grooves, located in the third through holes and used for sensing medicine boxes passing through the sensing portions and generating and sending counting signals to control chips; the driving portions are arranged under the medicine dispensing grooves and used for driving the flexible plates to move. According to the novel medicine dispensing device with the counting function, the work of take-out-of-storage of every box of medicine can be achieved firmly, the respective counting can be performed on the respective medicine grooves, and accordingly the counting efficiency can be improved and meanwhile the efficient medicine dispensing can be achieved.

Owner:SUZHOU IRON TECH

Fixed-line protection device for watertight wire connection sealing

ActiveCN104836187AFree from harmQuality improvementCoupling device detailsCable junctionsEngineeringSilicon rubber

The present invention relates to a fixed-line protection device for watertight wire connection sealing. The device comprises a round rod. At least one large fixed-line disk and small fixed-line disk are fixed on the round rod through tightening nuts. The periphery of the round rod, the large fixed-line disk and the small fixed-line disk is also provided with a protection device which is formed by the movable connection of a pair of protection clamps through a rotation shaft. The device has the advantages of simple structure and easy operation, watertight wires can be uniformly separated and fixed by using the large fixed-line disk and the small fixed-line disk, the sealing operation by test personnel is facilitated, by using the protection device, a connector in the sealing process is prevented from the damage of an external environment (sunshine, rain, grease, and dust), the adhesion quality and sealing effect of the silicon rubber on the connector are greatly improved, and the workload is reduced significantly.

Owner:中国船舶重工集团公司第七〇二研究所

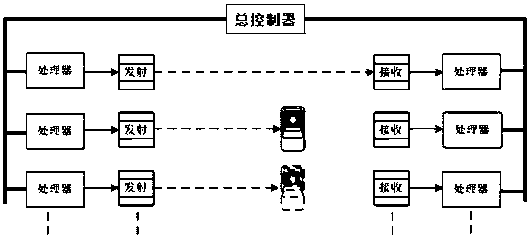

High-speed lighting and early warning system and control method thereof

PendingCN111402607ASave energyServe as a warningControlling traffic signalsAnti-collision systemsEarly warning systemMicrocontroller

The invention discloses a high-speed lighting and early warning system and a control method thereof, a master controller is in signal connection with a transmitting unit microcontroller through a signal transmission module to control the transmitting unit microcontroller to transmit signals, and a signal transmitting unit is controlled by the transmitting unit microcontroller to transmit optical signals with a certain frequency; the signal receiving unit is used for receiving the optical signal transmitted by the signal transmitting unit and transmitting the received optical signal informationto the master controller through the receiving unit microcontroller; the master controller judges whether there is a running vehicle on the expressway or not and the speed of the running vehicle according to the received feedback signal; and a signal for controlling the on / off of the warning lamp is sent to the transmitting unit microcontroller and the receiving unit microcontroller according tothe running state of the vehicle, and the on / off of the warning lamp is controlled through the transmitting unit microcontroller and the receiving unit microcontroller.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

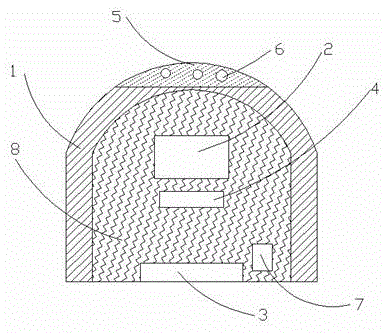

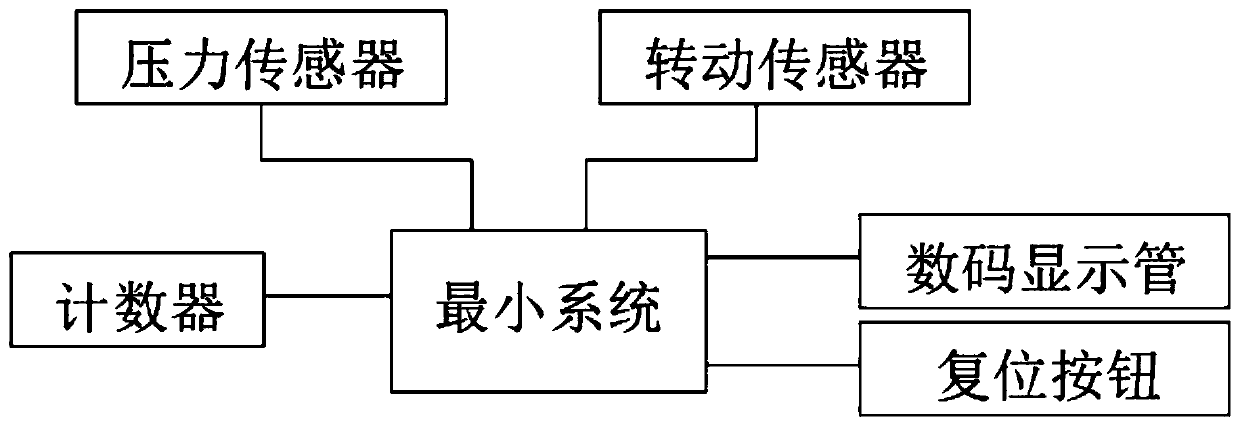

Badminton ball with counting function

The invention discloses a badminton ball with a counting function. The badminton ball comprises a badminton ball head, wherein a feather piece is arranged on the badminton ball head, a cavity is formed in the badminton ball head, a button battery is sequentially arranged on the vertical penetrated central line of the cavity, a display screen is arranged at the opening of the cavity, the display screen is provided with a switch, a control panel is arranged between the display screen and the button battery, a round pressure sensing layer is arranged at the end part of the badminton ball head, the pressure sensing layer is 0.2-1mm thick and has a diameter of 2-5mm, a plurality of miniature pressure sensors are arranged in the pressure sensing layer and connected to the control panel, and foam is filled around the control panel and the button battery; the badminton ball with the counting function has good balance, and meanwhile has the counting function, thus increasing joy in a sport process.

Owner:苏州盛泽科技创业园发展有限公司

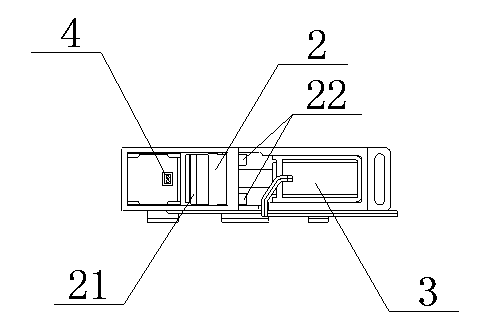

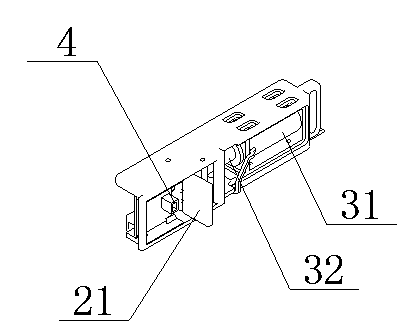

Labeling assembly connected with packing machine

InactiveCN107284779AReasonable structural designImplement one-step packaging requirementsLabelling flat rigid surfacesCartonEngineering

A labeling assembly connected to a packing machine, comprising a packing machine body (1), a positioning column device (2) is arranged on the packing surface of the body (1), and a labeling structure including a bending frame device (3) is arranged along one side , a positioning groove device (4), an annular separating device (5), a pushing device (6), and a collecting frame (7) is provided at the bottom of the body (1). The self-adhesive is inhaled along the positioning groove for separation and pasting; a prompt device (8) is provided, and the prompt information is displayed by sound or LED light; the upper end of the separation device (4) is provided with a height-adjustable cutting component (9), according to the operation It needs to adjust the running state; increase the structural design and effectively implement the one-step packaging demand, which provides convenience for the operator. At the same time, it has a counting function to ensure the accuracy of output statistics, and is economical and practical.

Owner:XINCHANG XINCHENG IND DESIGN CO LTD

Intelligent biding document stamp machine

InactiveCN108859452AReduce labor intensityExpand the scope of workStampingClosed loopStamping process

Owner:康凯

Vending machine

PendingCN108665624ASquare shapeEasy to transportCoin-freed apparatus detailsApparatus for dispensing discrete articlesElectrical and Electronics engineeringEngineering

The invention relates to the technical field of vending, in particular to a vending machine. The vending machine comprises a panel and a sealing plate, wherein the panel is provided with a touch screen and a material taking opening, at least one goods storage cabinet is arranged between the panel and the sealing plate and comprises a rack, two sides of the rack are provided with side doors, the two side doors are internally installed on vending units installed on the rack in a stacked way, the middle of each goods storage cabinet is provided with a conveyer for conveying materials popping outof the vending units to the material taking opening, and the vending machine can achieve automatic position selectin and quick stacking and piling and is high in timeliness.

Owner:张旭

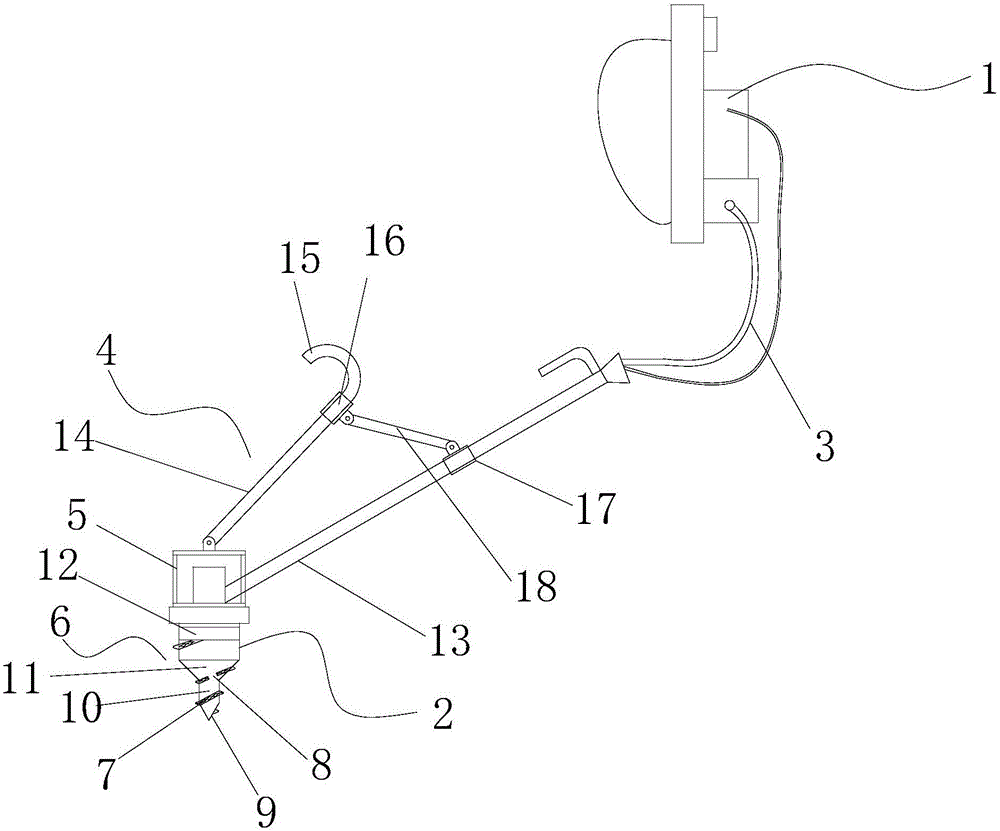

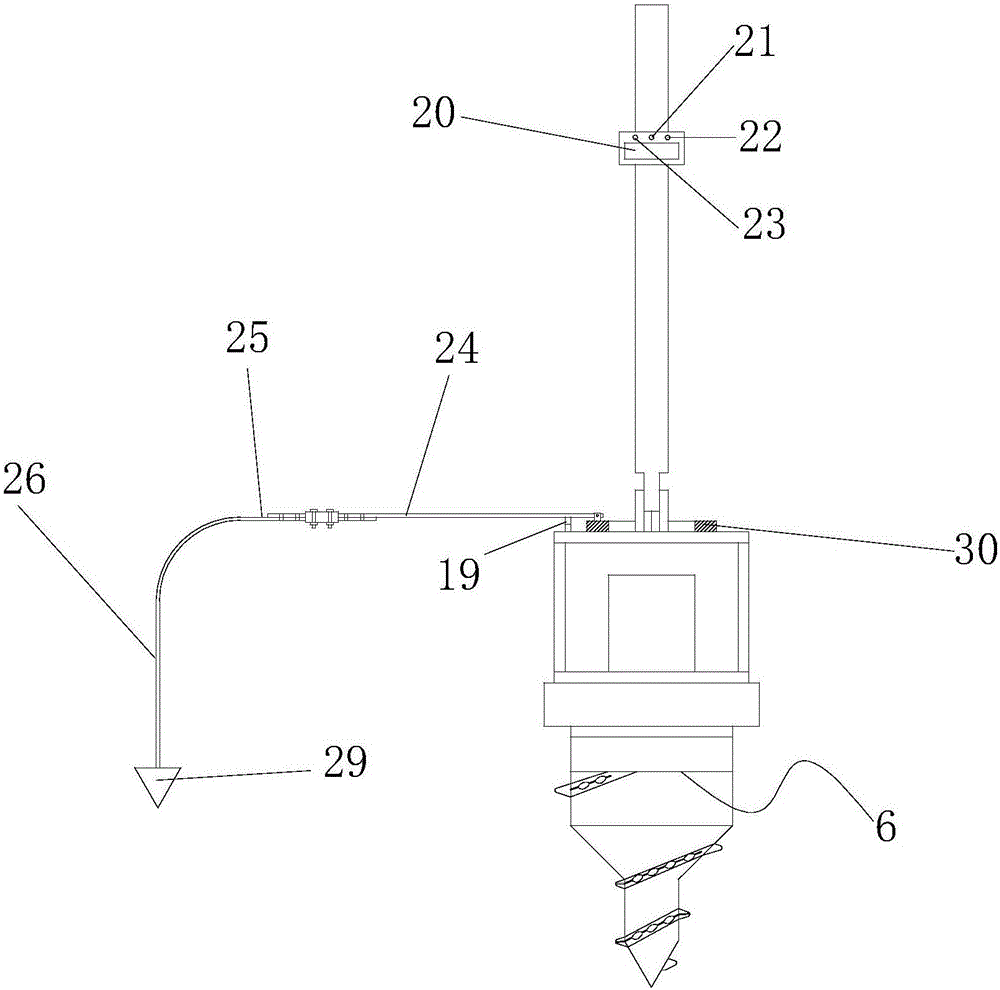

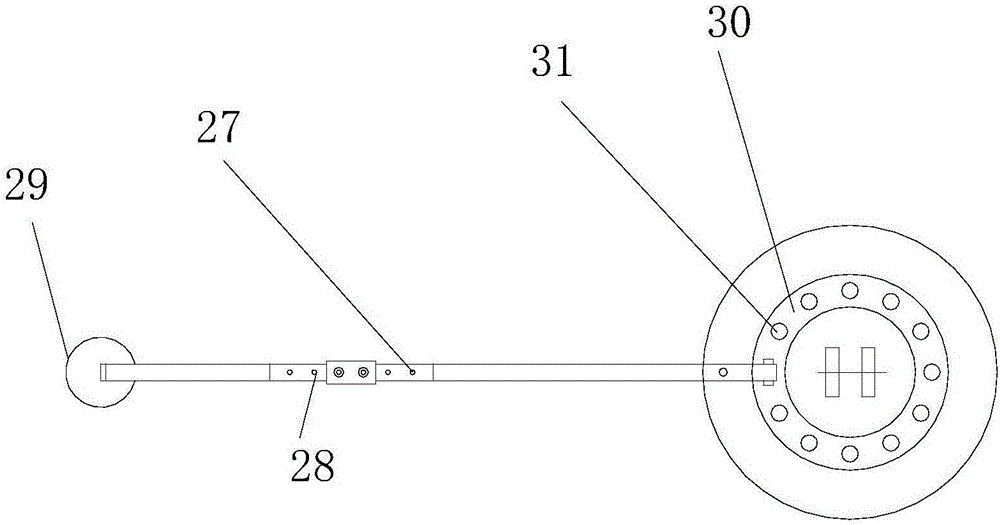

Portable spiral backpack punching machine

ActiveCN106612760AImprove applicabilityImprove comfortPlantingFurrow making/coveringComing outPunching

The invention discloses a portable spiral backpack punching machine, which comprises a power device, a drill bit assembly, a drive flexible shaft and an operation assembly, wherein the operation assembly comprises a shaft sleeve bar and an operation lever; the operation lever and the shaft sleeve bar are in single-degree-of-freedom running fit in a manner of a fixable included angle; the tail end of the operation lever forms an arc-shaped handle; a drill bit stably enters the soil and smoothly comes out of the soil in the vertical direction through coordinated operation of the operation lever and the shaft sleeve bar; the operation lever and the shaft sleeve bar form a triangular structure, so that vibration of the drill bit at the front end can be inhibited and the position accuracy and the hole forming effect of the hole are improved; the height of the arc-shaped handle can be adjusted, so that the condition that the punching machine has better operability, applicability and comfort is ensured; the condition that an operator can select the best fit holding angle from different angles is ensured through the arc-shaped handle and the comfort of the operation is improved as high as possible; and the portable spiral backpack punching machine has a counting function and more scientific management of punching work is ensured.

Owner:GUIZHOU TOBACCO SCI RES INST +1

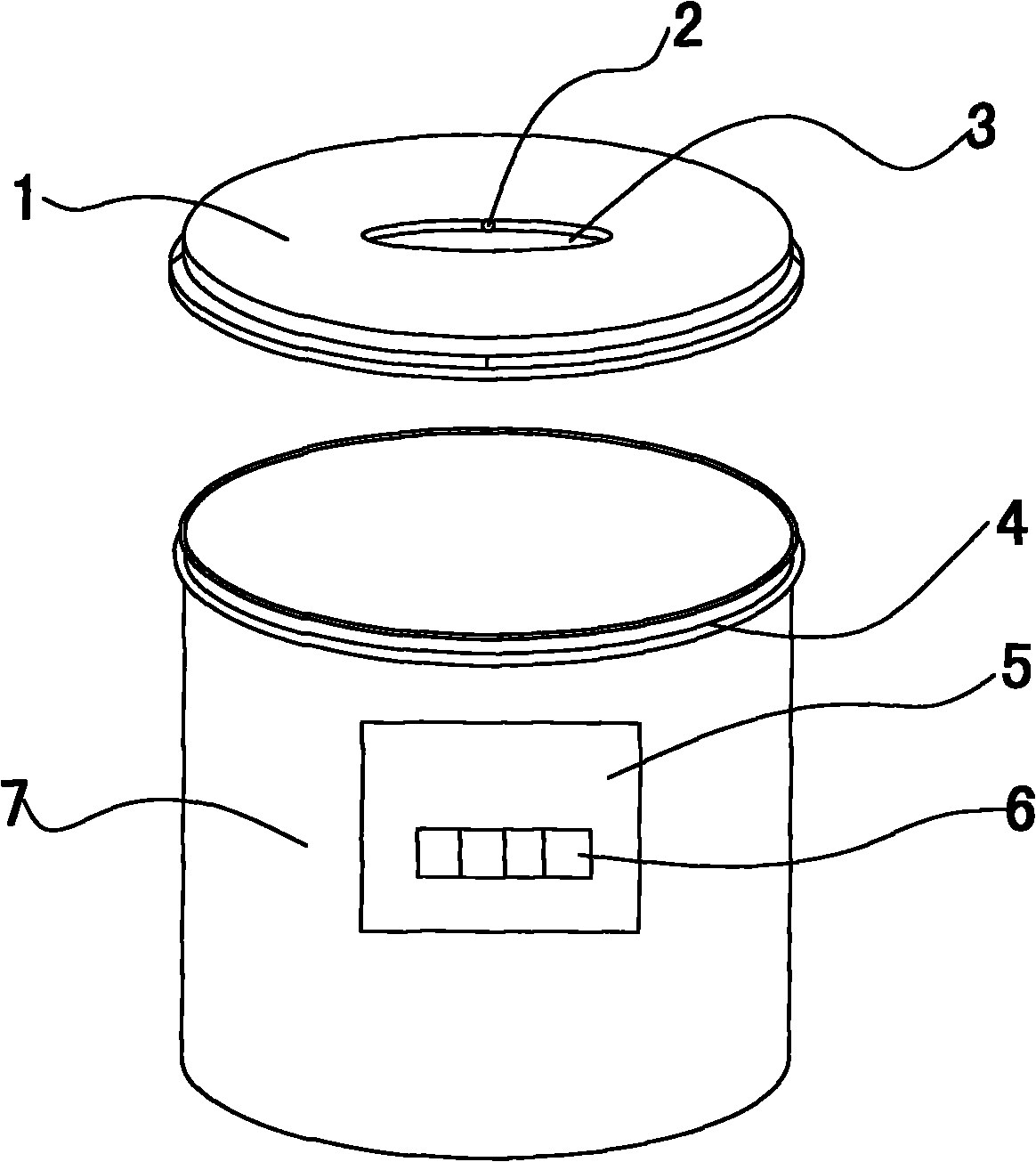

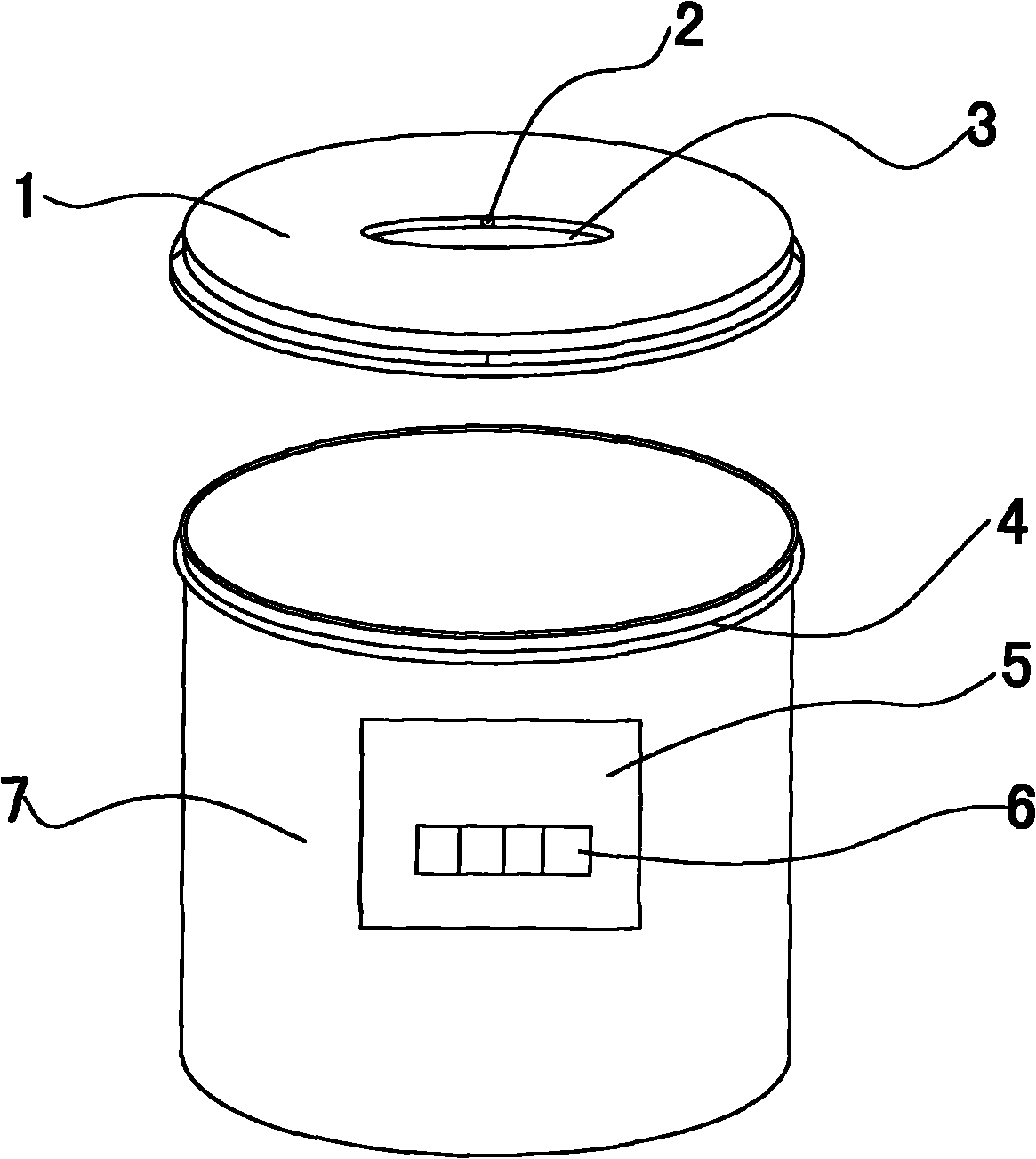

Counting coin box

A counting coin box comprises a box body and a cover, wherein an opening is disposed on the cover for putting coins into the box. The counting coin box is characterized in that a grating sensor is disposed at the opening; a counter is disposed on the box body; the grating sensor is connected with the counter; and a display screen is disposed on the counter. The counting coin box has the advantage of counting function. The counting coin box has a simple structure and low cost, and is suitable for popularization.

Owner:SHANGHAI JINGAN NO 1 CENT PRIMARY SCHOOL

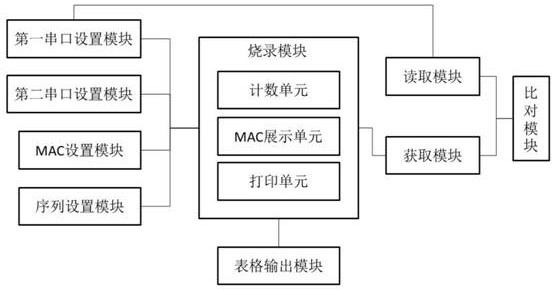

Burning device for MAC address and SN sequence of equipment

PendingCN113778467AReduce programming stepsSave programming timeInternal/peripheral component protectionSoftware deploymentEngineeringReal-time computing

The invention discloses a burning device for an MAC address and an SN sequence of equipment. The burning device is used for burning the MAC address into the equipment, and comprises: an MAC setting module used for setting a starting address and an ending address of the MAC address; a sequence setting module used for setting an initial sequence of the SN sequence; and a burning module used for burning the MAC address into the equipment from the initial address to the end address and burning the SN sequence into the equipment from the initial sequence, wherein one MAC address and one SN sequence are burnt in one piece of equipment, and wherein the burning module comprises a counting unit, and is used for adding 1 to the burnt previous MAC address and SN sequence after the burning of one piece of equipment is completed, so as to form the MAC address and SN sequence of the next piece of equipment. According to the burning device, the burning steps of equipment can be reduced, the burning time can be shortened, the burning efficiency can be improved, the completeness and accuracy of data burning can be ensured, and repeated burning can be avoided.

Owner:SHENZHEN PROITAV TECH CO LTD

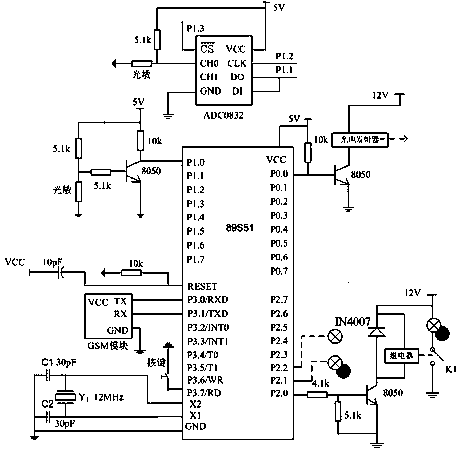

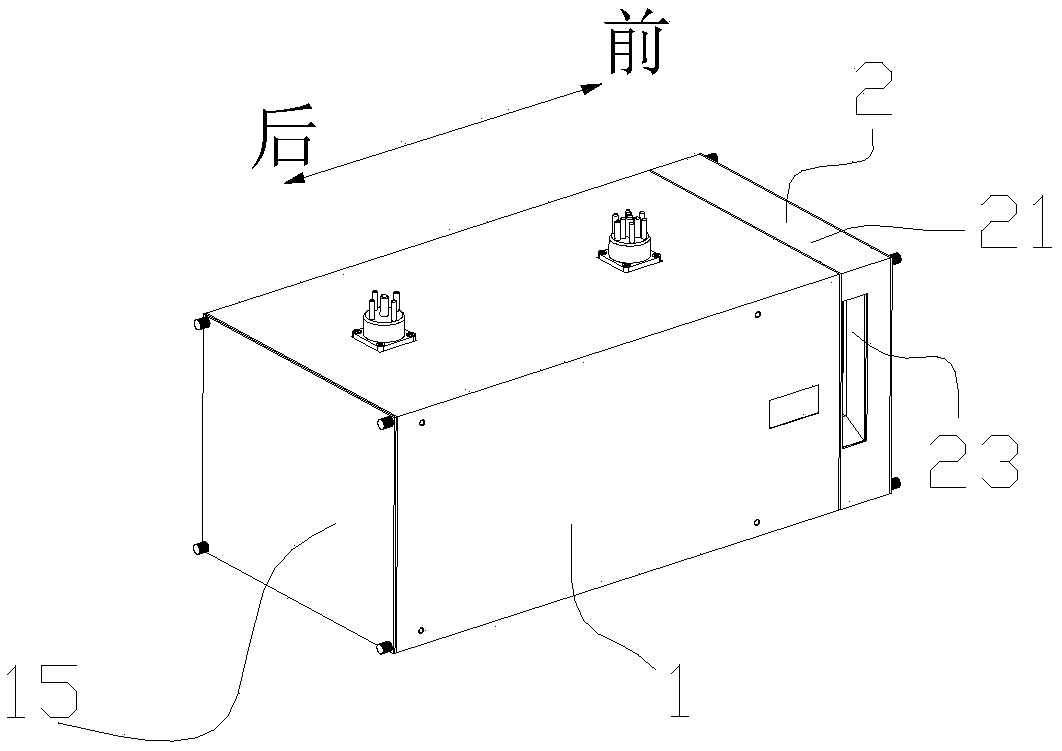

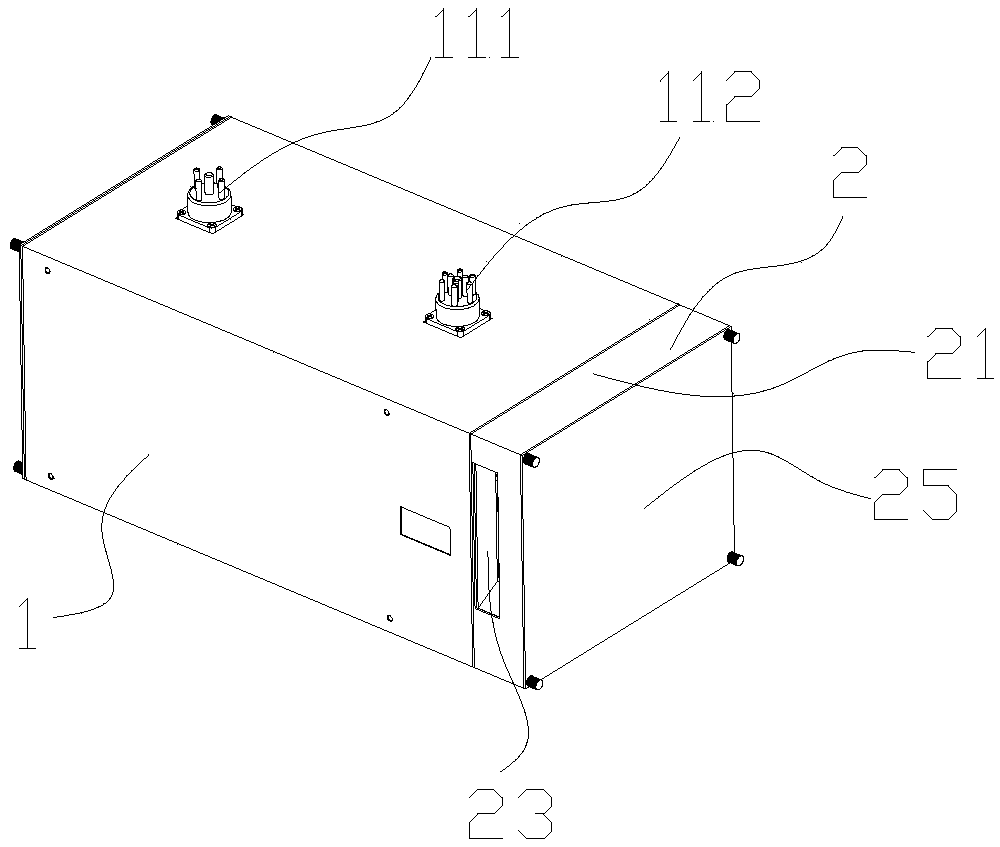

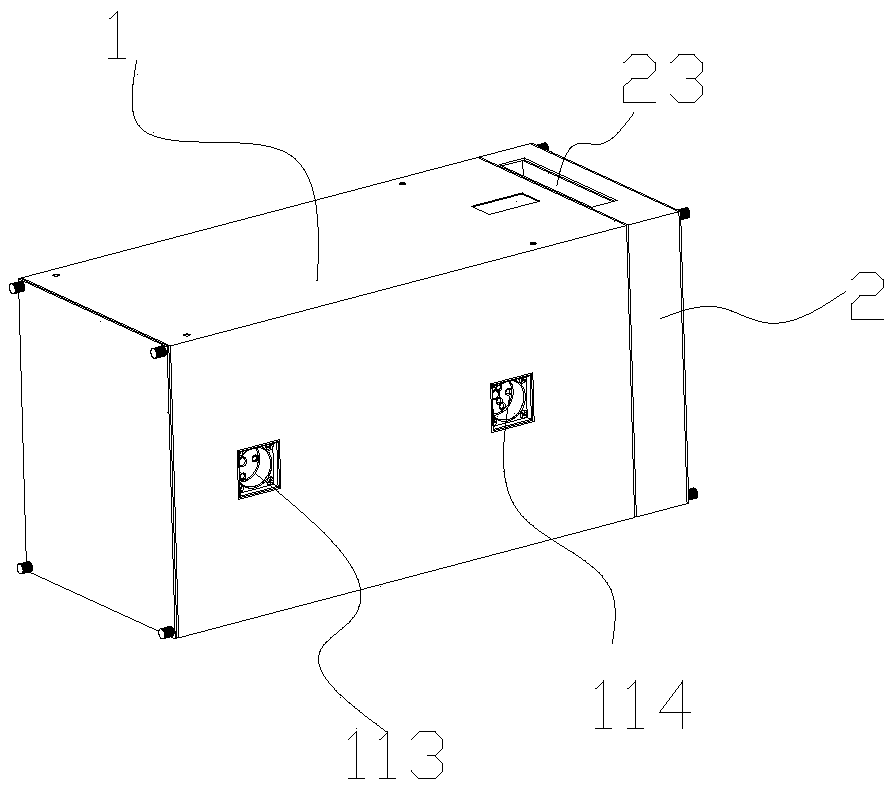

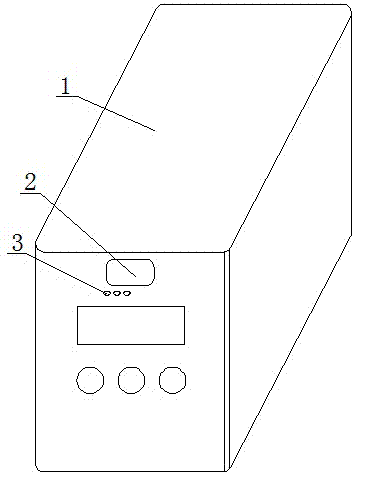

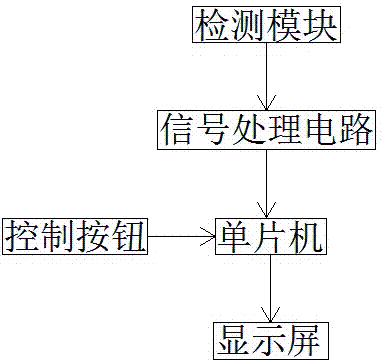

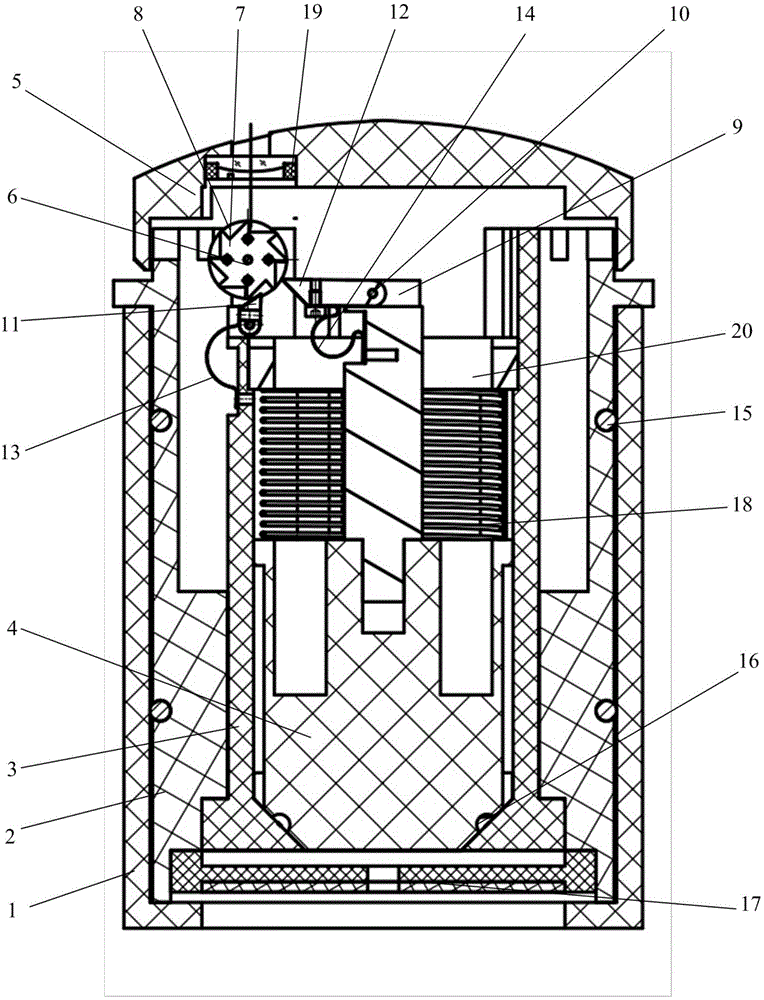

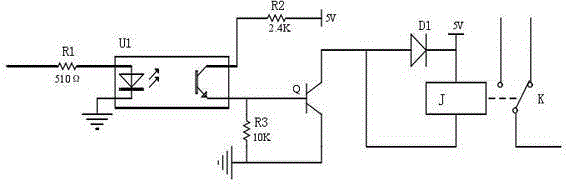

UPS power source with counting function

InactiveCN104734239AWith counting functionAvoid the problem that the use quality declines and cannot meet the power supply demandBatteries circuit arrangementsElectric powerIntegrated circuitEngineering

The invention belongs to the technical field of mobile power sources, and particularly relates to a UPS power source with a counting function. The UPS power source comprises a shell, a storage battery arranged in the shell, a display screen, control buttons, an integrated circuit board and a detecting module, wherein the display screen and the control buttons are arranged on the shell, the display screen is arranged in the middle of the upper portion of the front face of the shell, the control buttons are arranged below the display screen, the integrated circuit board and the detecting module are arranged in the shell, a signal processing circuit and a single chip microcomputer are arranged on the integrated circuit board, and the detecting module is arranged at the output end of the storage battery of the UPS power source. The UPS power source with the counting function has the function of monitoring the number of times of storage battery discharging in the UPS power source, the using condition of the storage battery can be well recorded, and the problem that as the storage battery is not repaired or replaced in time after being used for a too long time, the using quality of the UPS power source is reduced, and the power supply requirement cannot be met is avoided.

Owner:XIAN HENGFEI ELECTRONICS TECH

Large-dose powder packaging machine

InactiveCN111619889APackaging diversificationSmooth slidingWrapper twisting/gatheringPackaging machinesEngineeringPhysics

The invention discloses a large-dose powder packaging machine. The machine comprises a fixing frame, a conveying belt, a first guide plate, a second guide plate, an adjusting frame, a guide groove anda sewing and packaging machine. When the large-dose powder packaging machine is used, the adjusting frame is first pulled, the two ends of the adjusting frame slide in a sleeve, so that the height ofthe guide groove is adjusted, when the height of the guide groove is flush with the upper portion of a packaging bag, a first fixed handle is rotated, so that the first fixed handle contacts with theouter wall of the adjusting frame, the position relationship between the adjusting frame and the sleeve is fixed, then the height of a lantern ring on a third supporting frame is adjusted, the lantern ring drives the sewing and packaging machine to ascend and descend through a cross rod, finally, the sewing and packaging machine corresponds to a sewn mouth of the packaging bag, then a second fixed handle is rotated, so that the second fixed handle touches the outer wall of the third supporting frame, the position relationship between the lantern ring and the third supporting frame is fixed, so that the height of the sewing and packaging machine is fixed, and device adjusting tooling is completed.

Owner:上海鼎江包装机械制造有限公司

Badminton with counting function

The invention discloses a badminton ball with a counting function. The badminton ball comprises a badminton ball head, wherein a feather piece is arranged on the badminton ball head, a cavity is formed in the badminton ball head, a button battery is sequentially arranged on the vertical penetrated central line of the cavity, a display screen is arranged at the opening of the cavity, the display screen is provided with a switch, a control panel is arranged between the display screen and the button battery, a round pressure sensing layer is arranged at the end part of the badminton ball head, the pressure sensing layer is 0.2-1mm thick and has a diameter of 2-5mm, a plurality of miniature pressure sensors are arranged in the pressure sensing layer and connected to the control panel, and foam is filled around the control panel and the button battery; the badminton ball with the counting function has good balance, and meanwhile has the counting function, thus increasing joy in a sport process.

Owner:苏州盛泽科技创业园发展有限公司

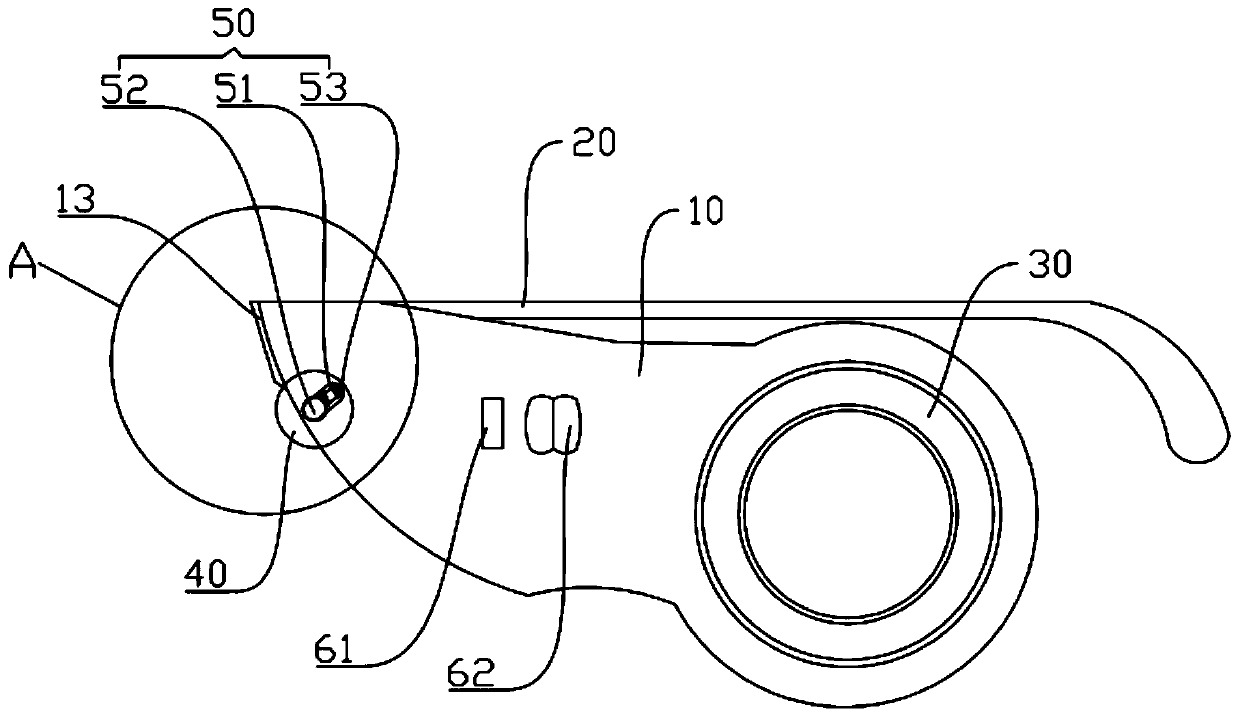

A tape sealer with rotation counting and its application method

ActiveCN108284988BWith counting functionEliminate the link of quantity estimationWrapper twisting/gatheringPackaging machinesAdhesive beltCarton

The invention discloses a rotary counting packaging tape carton sealer. The rotary counting packaging tape carton sealer comprises a main body, a cover body, a drum shaft, a guide wheel, a cutter assembly and a counting device. The cover body is connected to the main body. The drum shaft is movably arranged on the main body and used for installing and releasing a packaging tape. The guide wheel ismovably arranged at the end, far away from the drum shaft, of the main body so as to guide the packaging tape released by the drum shaft. The cutter assembly is arranged on the main body. By pressingthe cover body up and down, the guide wheel can be driven to move up and down so as to make the cutter assembly extend out of the main body for cutting the packaging tape or returning into the main body. The counting device is arranged on the main body and used for counting the counting frequency of the cutter assembly. In this way, the guide wheel can be driven to move downwards so as to make the cutter assembly move out of the main body for packaging tape cutting by pressing the cover body with hands of people. According to the technical scheme, the tape cutting and carton sealing processesare convenient and fast, manpower is saved, the cutting frequency of the cutter assembly can be counted through the counting device arranged on the main body, and hence the packaging tape carton sealer can achieve the counting function.

Owner:温州华菲食品机械科技有限公司

A solid wire protection device for watertight electric wire butt joint sealing

ActiveCN104836187BFree from harmQuality improvementCoupling device detailsCable junctionsButt jointScrew cap

The present invention relates to a fixed-line protection device for watertight wire connection sealing. The device comprises a round rod. At least one large fixed-line disk and small fixed-line disk are fixed on the round rod through tightening nuts. The periphery of the round rod, the large fixed-line disk and the small fixed-line disk is also provided with a protection device which is formed by the movable connection of a pair of protection clamps through a rotation shaft. The device has the advantages of simple structure and easy operation, watertight wires can be uniformly separated and fixed by using the large fixed-line disk and the small fixed-line disk, the sealing operation by test personnel is facilitated, by using the protection device, a connector in the sealing process is prevented from the damage of an external environment (sunshine, rain, grease, and dust), the adhesion quality and sealing effect of the silicon rubber on the connector are greatly improved, and the workload is reduced significantly.

Owner:中国船舶重工集团公司第七〇二研究所

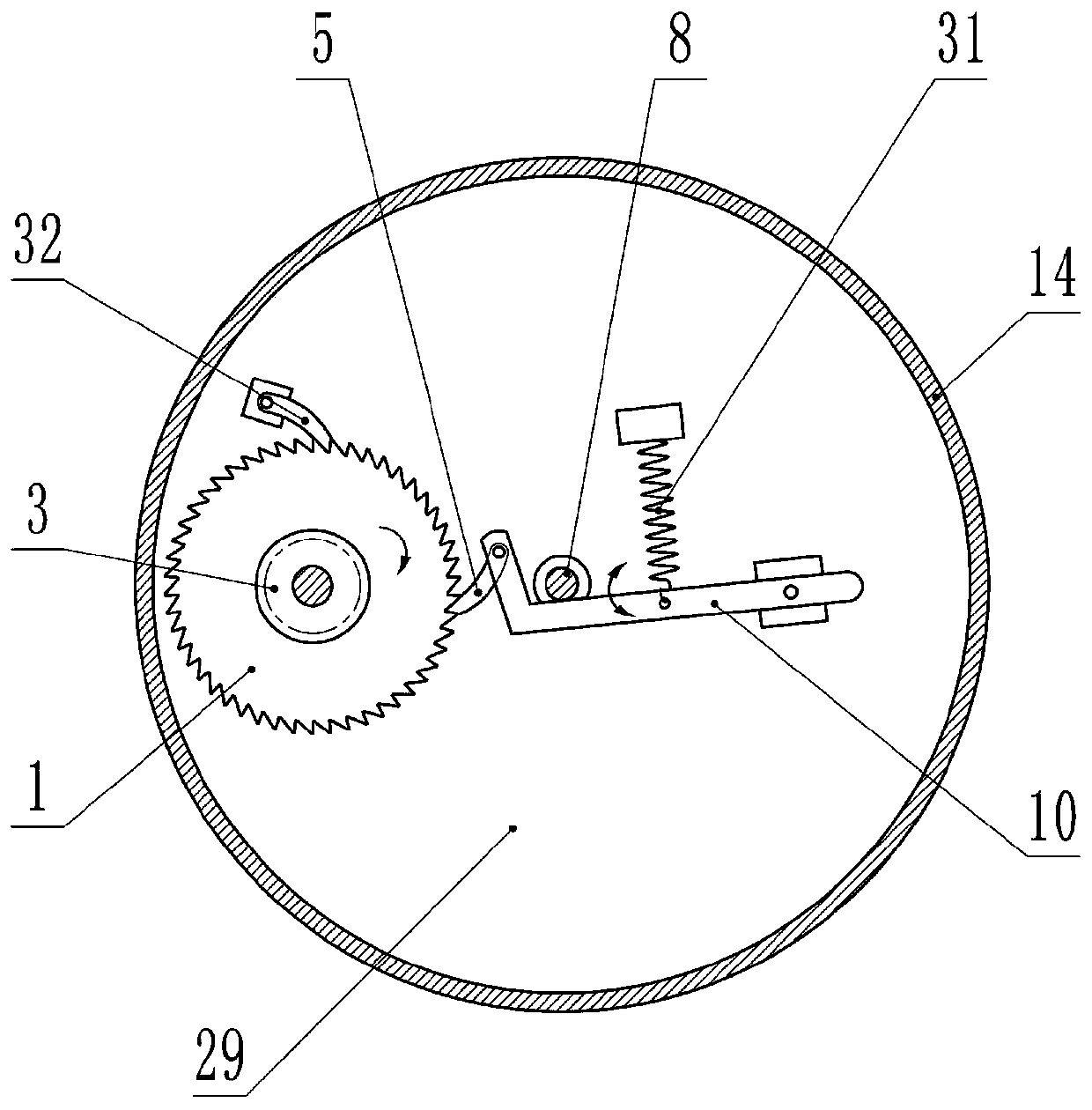

Mechanical counting non-return drainer with ratchet

ActiveCN104154311AImprove work efficiencyAvoid enteringCheck valvesMembrane filtersRubber ringEngineering

The invention relates to a mechanical counting non-return drainer with a ratchet and belongs to the technical field of ground water drainage facilities in hydraulic engineering. The mechanical counting non-return drainer comprises a valve sleeve, an inner casing, a center tube, a spool, a top cover, the ratchet, a counting disc, a spool post and a filter mesh. The valve sleeve is connected with the bottom of a pond to form a communicator; the inner casing is connected to the inside of the valve sleeve; the inner casing is connected with the valve sleeve through a rubber ring a; the center tube is disposed inside the inner casing; the outside of the center tube is connected with the inner casing; the inside of the center tube is connected with the spool. The ratchet and the counting disc are disposed on the spool inside the center tube and are fixed together. Compared with like products, the mechanical counting non-return drainer has the functions of counting and silt control, is simple in structure and long in service life and has the function of unidirectional return avoidance.

Owner:长春市艾必利务科技有限公司

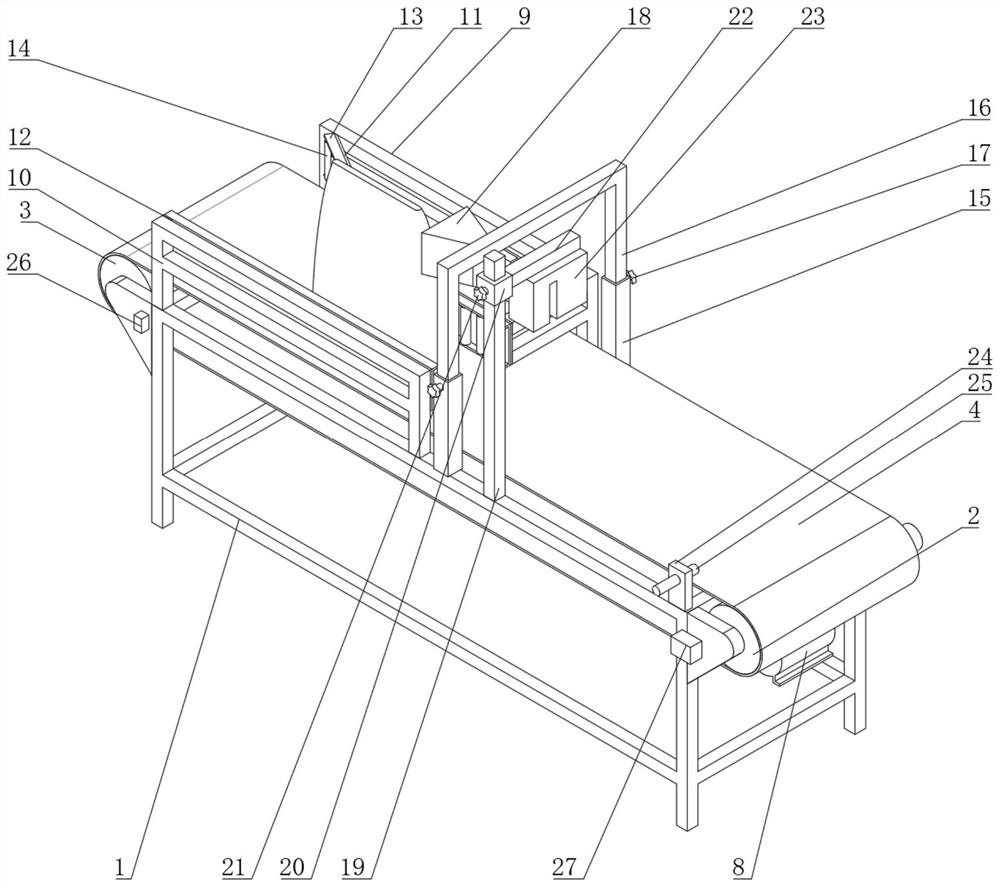

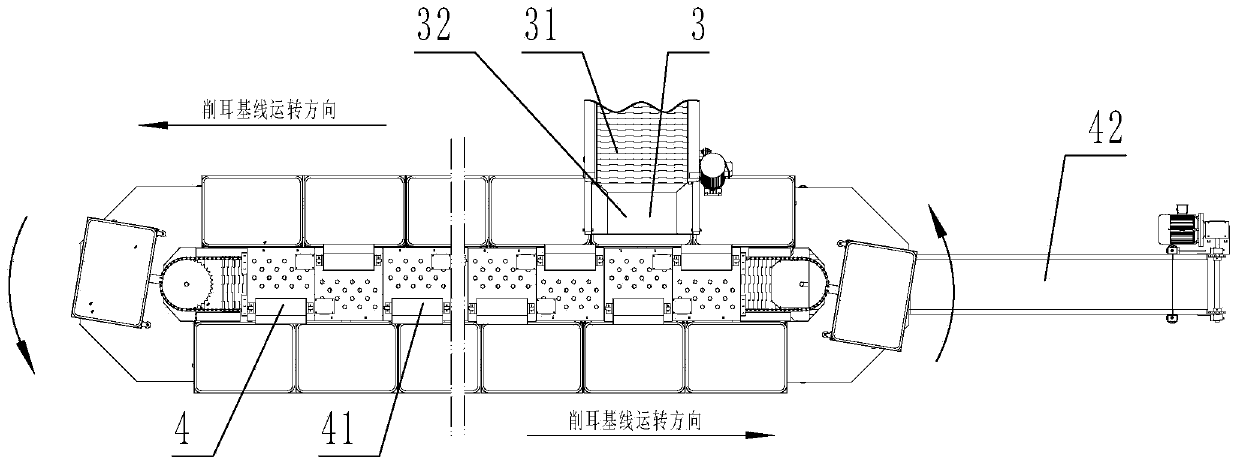

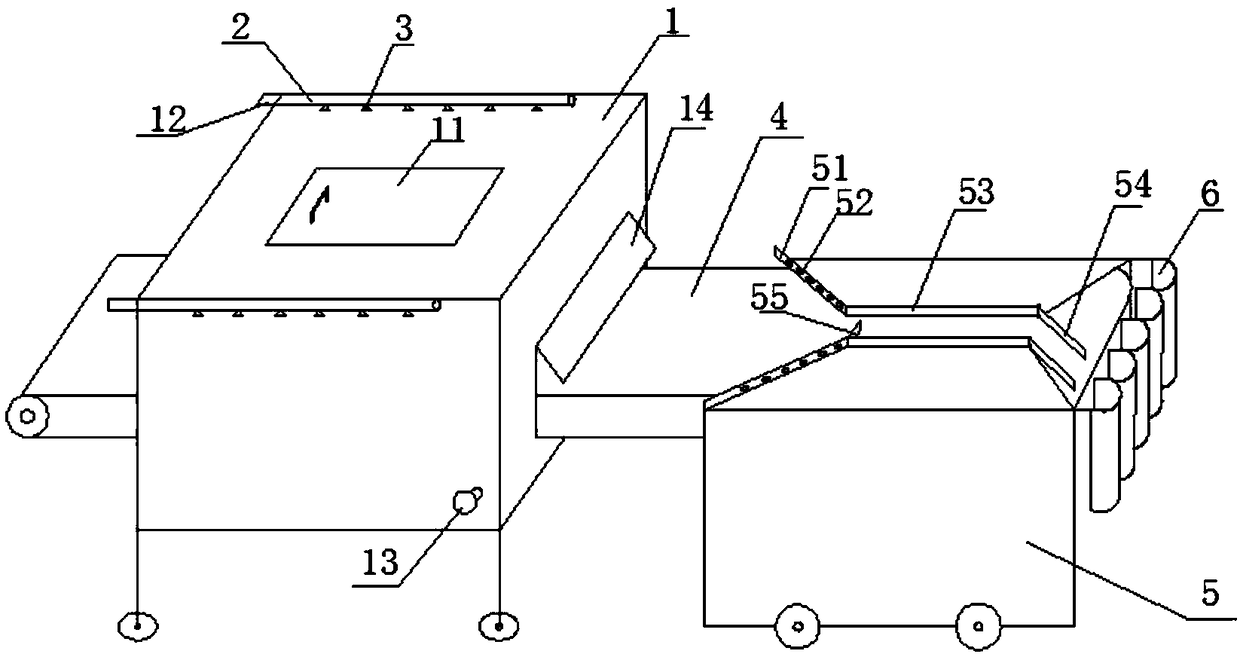

Tremella fuciformis base cutting production line with continuous feeding

PendingCN111483763ARealization of continuous feedingAutomatic provisioningConveyorsConveyor partsBiotechnologyProduction line

The invention discloses a tremella fuciformis base cutting production line with continuous feeding. A conveying chain is horizontally arranged, a roller supporting rail and a tray guide rail surroundthe periphery of the conveying chain, the roller supporting rail is horizontally arranged in a plane, the tray guide rail is arranged on the side face and higher than the roller supporting rail, rollers and guide rollers are arranged at the bottom of a tray, and the tray is further connected to the conveying chain through a connecting piece. A feeding device and a discharging device are further arranged on the tremella fuciformis base cutting production line with continuous feeding, wherein the feeding device comprises a feeding line and a feeding hopper, and the lower part of the feeding hopper face charging baskets on the tray. A plurality of stations are arranged on the tremella fuciformis base cutting production line with continuous feeding, each station comprises a discharging hopper,and outlets of the discharging hoppers lead to a discharging conveying line of the discharging device. According to the tremella fuciformis base cutting production line with continuous feeding, automatic supply of raw materials is realized, production of the raw materials can be realized without landing, and counting and checking functions are realized.

Owner:FUJIAN PROV AGRI MACHANIZATION INST

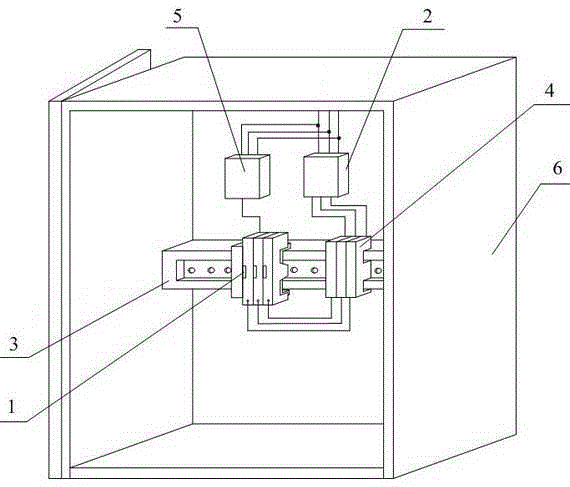

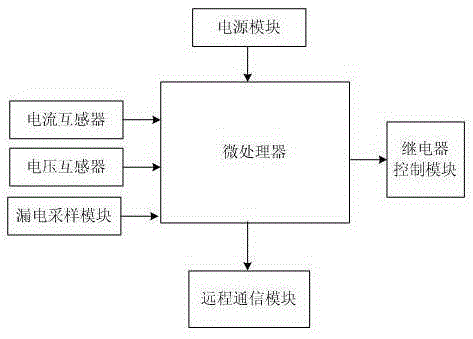

Workshop electricity monitoring system with electric leakage monitoring function

InactiveCN105259824ARealize intelligent controlAvoid Lightning DamageProgramme controlComputer controlElectric energyElectricity

Provided is a workshop electricity monitoring system with an electric leakage monitoring function. The system comprises a switch, an electric energy meter, a data acquisition controller, and a lightning protection unit arranged in a distribution box, the switch is both connected with the electric energy meter and the data acquisition controller, the lightning protection unit is connected with the data acquisition controller, the data acquisition controller is also connected with a voltage sensor, a current sensor, and an electric leakage sampling module, the data acquisition controller comprises a microprocessor, a power supply module, a relay control module, and a remote communication module, and the power supply module, the relay control module, and the remote communication module are all connected with the microprocessor. According to the system, conditions of voltage and current of electricity equipment can be monitored in real time, the phenomenon of electric leakage can be monitored, the switch of the electricity equipment is turned off via the relay control module during electric leakage, the control of the switch of the electricity equipment is realized, and intelligent control of power utilization of factories is realized.

Owner:成都贝发信息技术有限公司

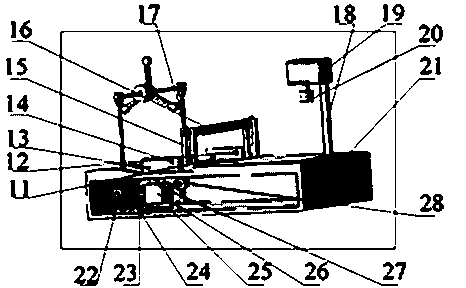

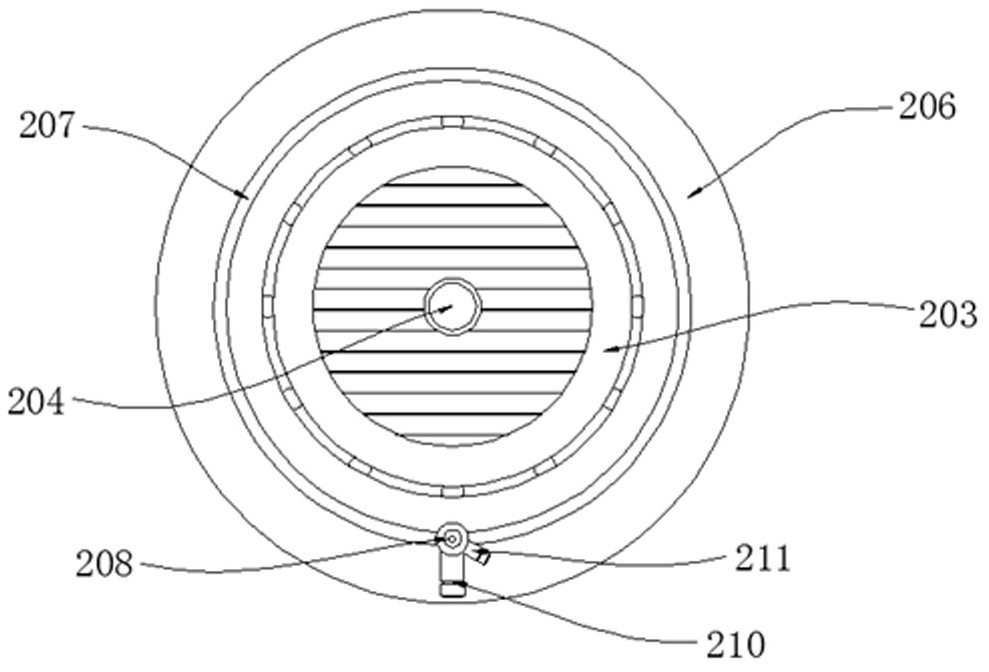

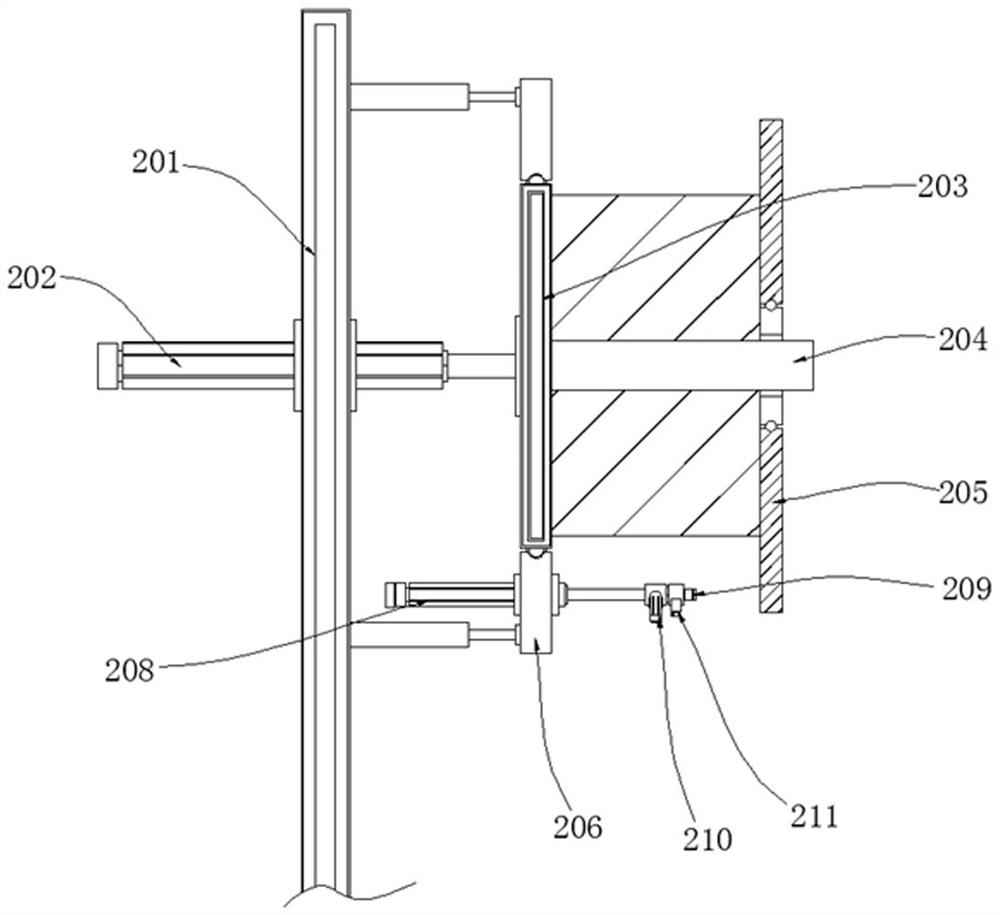

Mask tablet making machine with storage structure and counting function

ActiveCN114030195AAvoid misalignmentAvoid joint phenomenonUsing optical meansCounting mechanisms/objectsMechanical engineeringPleat

The invention discloses a mask tablet making machine with a storage structure and a counting function, and relates to the technical field of mask tablet making machines. The mask tablet making machine in particular comprises a tablet making table and a cloth placing assembly, the cloth placing assembly is arranged at the right side of the tablet making table, a telescopic push rod is rotatably connected in a support, a bearing shaft is fixed to the middle of the side face of an inner disc, and the interior of a sliding rail groove is connected with an adjusting push rod through an electric pulley. According to the mask tablet making machine with the storage structure and the counting function, cloth layers are kept on a same center line after being released and overlapped by adjusting and positioning the positions of cloth rolls with different widths, and dislocation between the cloth layers is avoided; fan fold indentation and fan fold pressing effects on the cloth layers can be completed at the same time after edge sealing is conducted on the cloth layers, the fan pleats can be processed at one time, the structure of a device can be simplified, and the size of the device can be reduced; the cut masks are separated and stored, so that the phenomenon that the masks are connected when being taken in the later period is avoided.

Owner:海安美佳医用敷料有限公司

Plastic part cleaning and packing integration machine

PendingCN109047125AShorten completion timeSave human and financial resourcesPackaging automatic controlCleaning using liquidsProduction modelAssembly line

The invention creatively provides a plastic part cleaning and packing integration machine. The plastic part cleaning and packing integration machine comprises a box body, a conveying belt, water pipes, high pressure spray heads, a packing rack, first baffles, second baffles, moving baffles, auxiliary bearings and packing tanks, wherein the water pipes are disposed on the two sides of the top of the box body, the high pressure spray heads are fixedly connected with the water pipes, the box body is arranged at the head portion of the conveying belt, the conveying belt penetrates through the boxbody, the classification packing rack is disposed at the tail portion of the conveying belt, and the packing tanks are fixedly connected with the classification packing rack. The plastic part cleaningand packing integration machine can clean and pack sealing caps at the same time in an assembly line way, greatly shortens the production distance and production processes, saves manpower and material resources, improves the production efficiency and reflects an efficient production model of enterprises.

Owner:TIANJIN RUILING TECH DEV CO LTD

Testing tool for testing mainboard on water treatment equipment

PendingCN111579971AEasy alignmentThe testing process is simpleElectronic circuit testingMeasurement instrument housingSlide plateWater treatment

The invention relates to the technical field of mainboard testing, and discloses a testing tool for testing a mainboard on water treatment equipment, and the testing tool comprises a pedestal, the upper surface of the pedestal is fixedly connected with a limiting mechanism through a bolt, the upper surface of the pedestal is fixedly connected with a vertical column, and the vertical column is located at the left side of the limiting mechanism. The tool is provided with the pedestal, the limiting mechanism, the stand column, a first T-shaped sliding column, a sliding plate, an electric push rod, an adjusting mechanism, a test mainboard and a needle head. When the product mainboard needs to be tested, firstly, a product main board is positioned through a first limiting block and a second limiting block, so that the IO interface on the product mainboard is aligned with the needle head. Then the electric push rod is opened, the needle head is inserted into the IO interface, at the moment,the test mainboard sends and receives a signal, whether the product is qualified or not is judged in combination with a corresponding range value, and then the test process of the product mainboard issimpler.

Owner:浙江西盈科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com