Vending machine

A vending machine and automatic vending technology, applied in the direction of instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve the high control requirements of the conveying device and the control process requirements Higher, not flexible enough, etc., to achieve the effect of wide application range, avoid interference, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

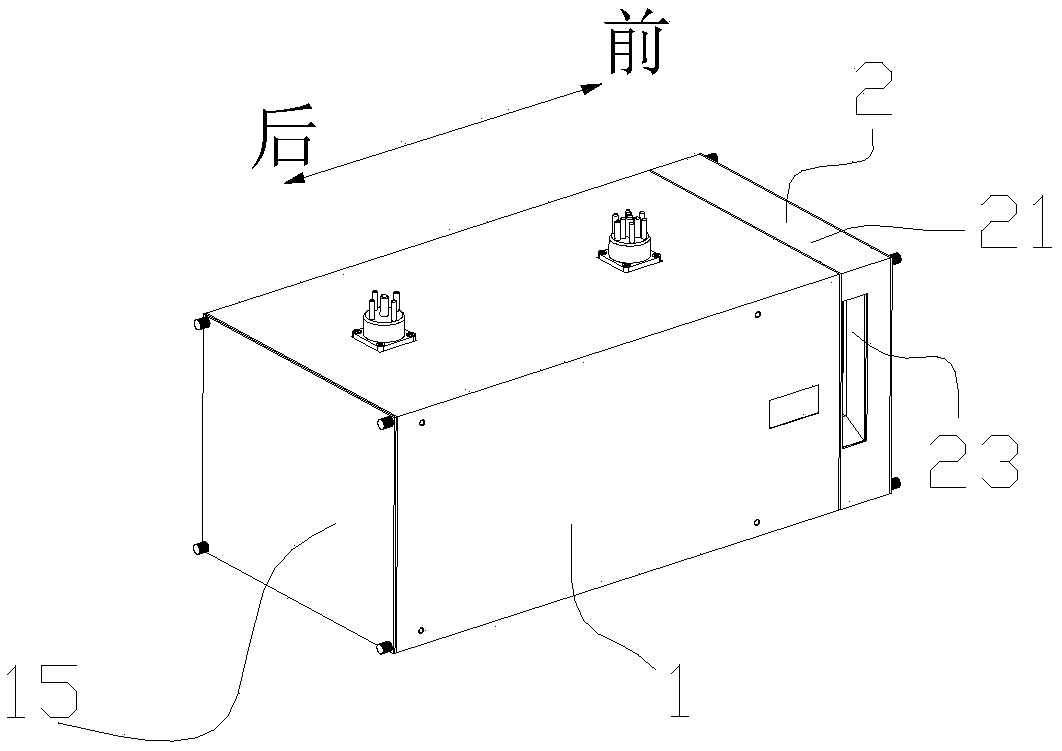

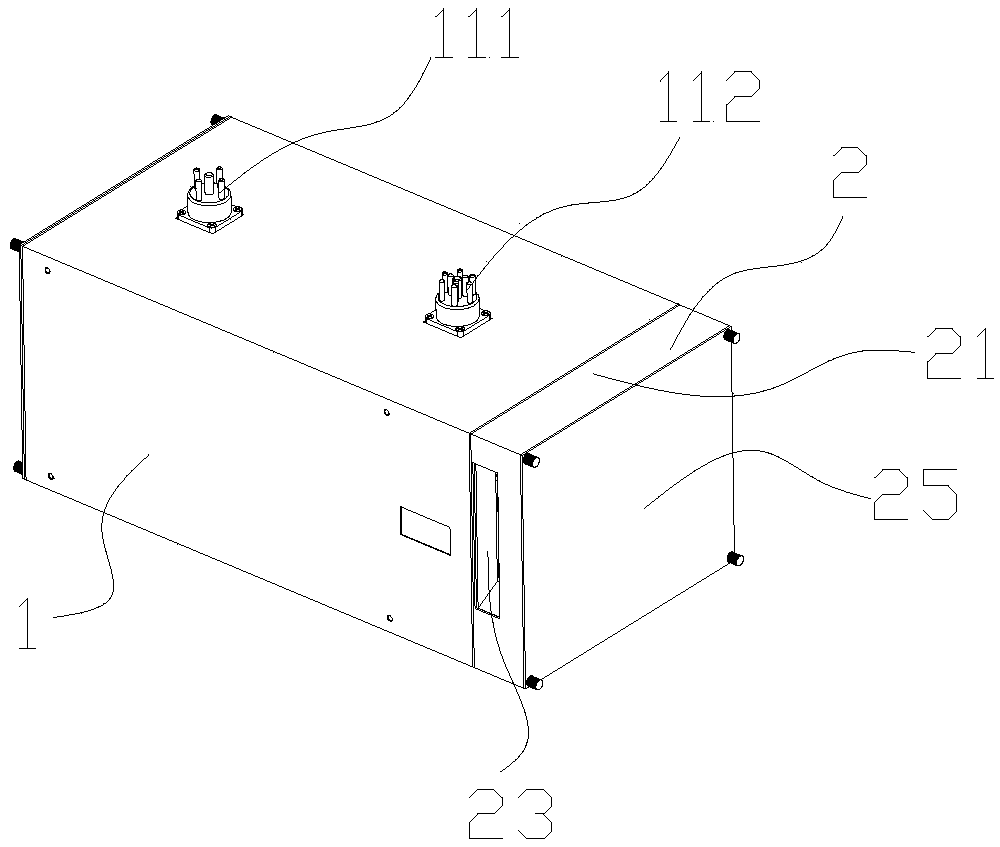

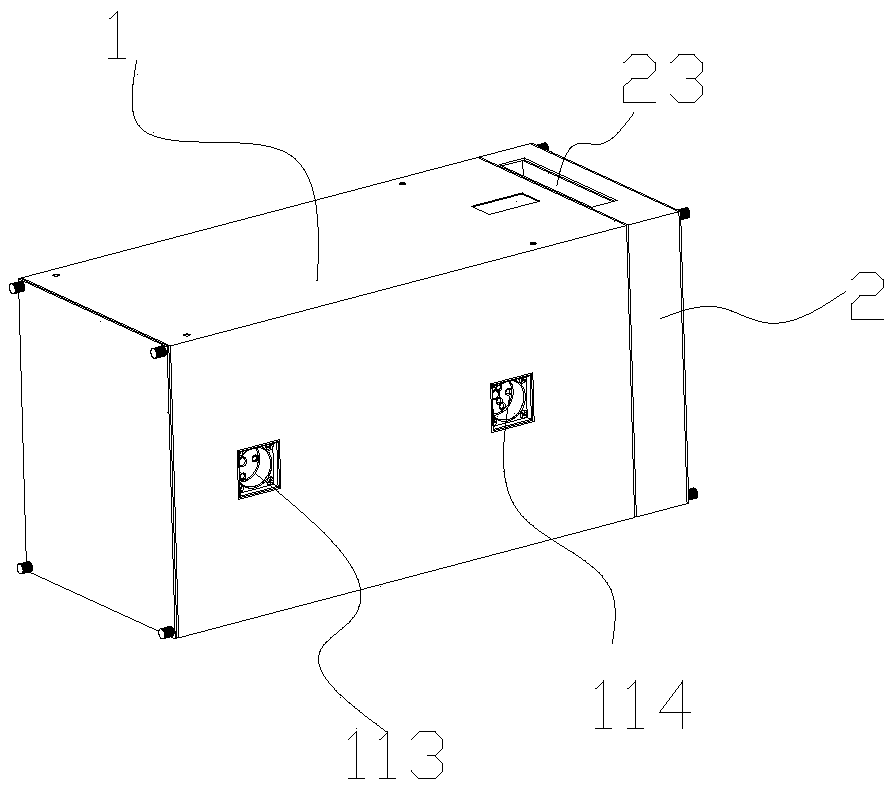

[0054] Such as Figure 1-16 , an automatic vending machine, comprising a panel 3 and a cover plate 4, the panel 3 has a touch screen 31 and a material retrieving port 32, at least one storage container 5 is arranged between the panel 3 and the cover plate 4, and in this embodiment, three storage containers As an example, the storage container 5 includes a frame 51 with side doors 52 on both sides of the frame 51. The inside of the two side doors 52 are all equipped with vending units 100 installed on the frame 51 in a stacked form. The height determines the number of stacks. In this embodiment, five vending units 100 are stacked as an example. In the middle of the storage container 5, there is a conveyor 53 that transfers the ejected materials from the vending unit 100 to the pick-up port 32; The number of 5 can be one or more, and the conveyors 53 of the front and rear storage containers 5 are connected, so that the continuous delivery of materials can be realized, and the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com