Workshop electricity monitoring system with electric leakage monitoring function

A monitoring system and workshop technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as transformer burnout, low production voltage, dangerous equipment using electricity, and worker's life safety, so as to prevent lightning damage , Realize the effect of intelligent control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

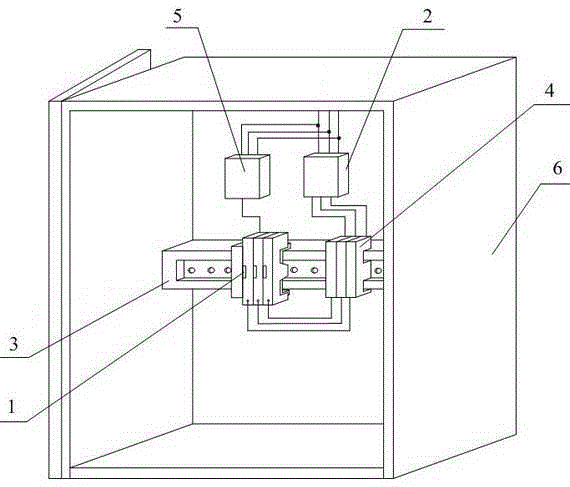

[0021] Such as figure 1 As shown, the workshop electricity monitoring system with the leakage monitoring function includes a switch 4, an electric energy meter 2, a data acquisition controller 1, and a lightning protection unit 5 arranged in the distribution box 6. The rear panel of the distribution box 6 A slide rail 3 is arranged on the top, the switch 4 and the data acquisition controller 1 are installed on the slide rail 3, the switch 4 is connected with the electric energy meter 2 and the data acquisition controller 1; the lightning protection unit 5 is connected with the data acquisition controller 1 connected.

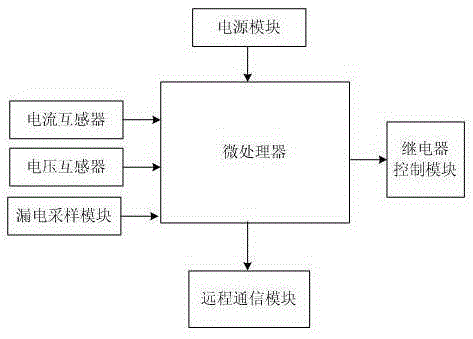

[0022] Such as figure 2 As shown, the data acquisition controller 1 includes a microprocessor, a power module, a relay control module, and a remote communication module, and the power module, relay control module, and remote communication module are all connected to the microprocessor.

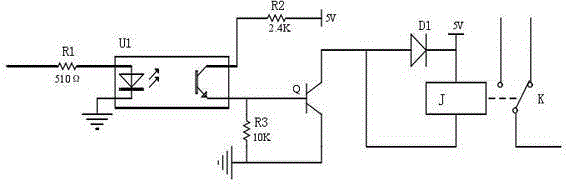

[0023] Such as image 3 As shown, the relay control module includes a c...

Embodiment 2

[0030] On the basis of Embodiment 1, in order to prevent the impact of lightning on the power consumption monitoring system, the lightning protection unit 5 is also improved as follows in this embodiment:

[0031] Such as Figure 4As shown, the lightning protection unit 5 includes a lightning protection module, a lightning protection ground bar, an air-core coil current sensor connected between the lightning protection module and the lightning protection ground bar, and a counter connected to the air-core coil current sensor. The lightning protection module is connected to the input terminal of the electric energy meter 2, and the counter is connected to the data acquisition controller 1. The lightning protection module is a Class B lightning protection module. The air-core coil current sensor is set on the wire connecting the lightning protection module and the lightning protection grounding bar, and can sample the current flowing from the B-level lightning protection module...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com