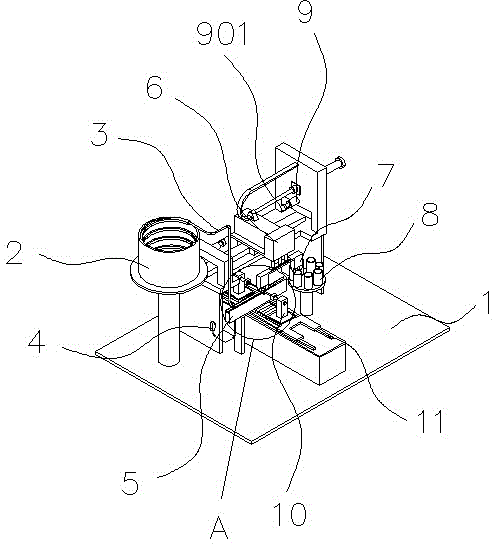

Automatic detection device for internal diameters of ceramic tubes

A detection device and ceramic tube technology, applied in the field of precision parts detection, can solve the problems of low operation efficiency, complex moving trajectory, complex main structure and control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

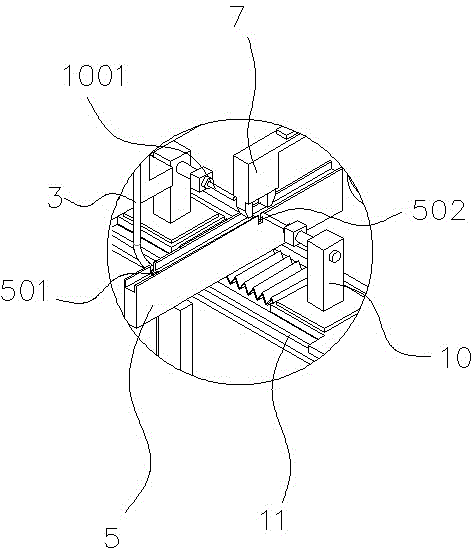

Embodiment 1

[0029]An automatic ceramic tube inner diameter detection device, comprising a working platform 1, on which a feeding mechanism is distributed sequentially according to the process, a transfer mechanism arranged behind the feeding mechanism, a detection mechanism matched with the transfer mechanism, and a The sorting mechanism behind the transfer mechanism and the detection mechanism. The transfer mechanism includes a load-bearing guide rail connected with the feeding mechanism. The load-bearing guide rail is provided with a horizontal groove-shaped guide rail 5. The groove-shaped guide rail 5 is provided with two clamping positions perpendicular to the groove-shaped guide rail 5. The clamping positions respectively include and The feeding card position 501 matched with the feeding mechanism and the detection card position 502 matched with the detection mechanism are provided with a moving arm 6 matching with the grooved guide rail 5 and including two synchronously running gripp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com