Tremella fuciformis base cutting production line with continuous feeding

A technology for cutting ear bases and production lines, which is applied in conveyors, food processing, food science, etc., and can solve problems such as not meeting food hygiene requirements and having no production lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

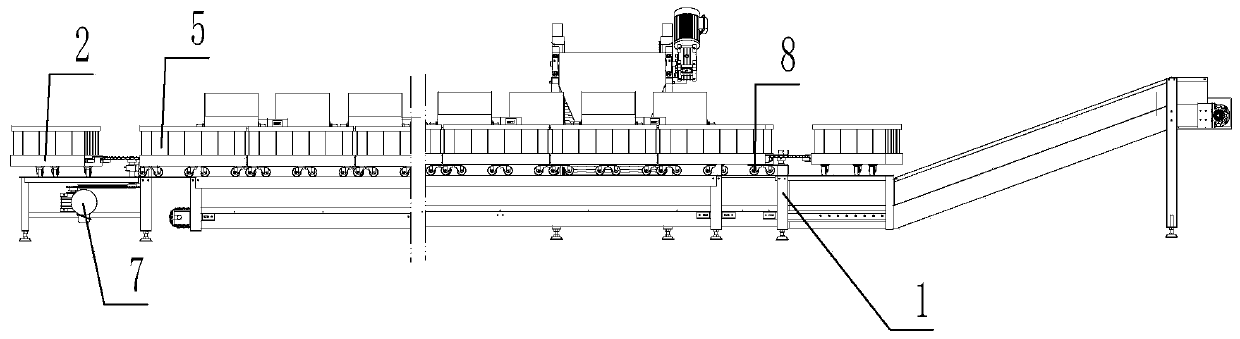

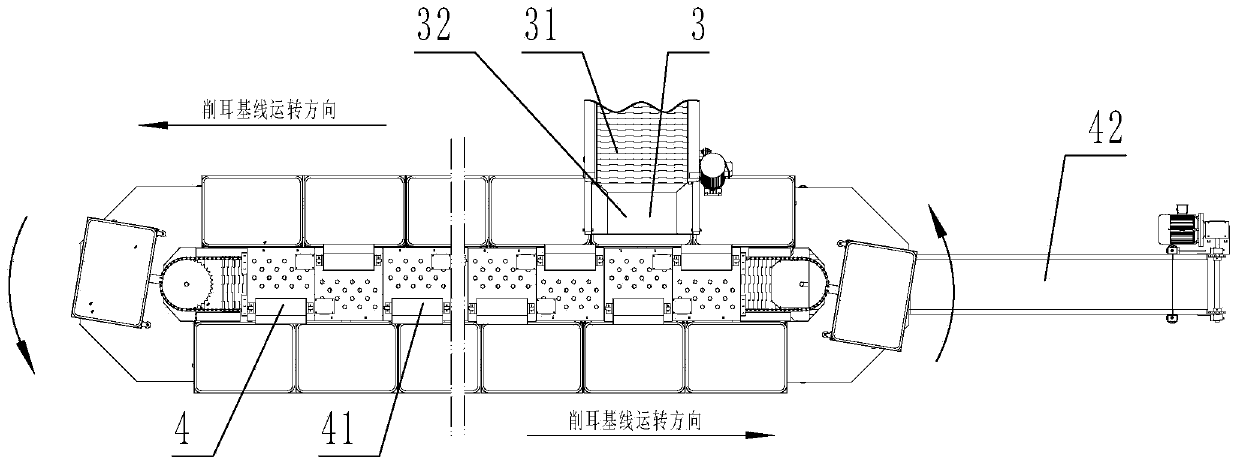

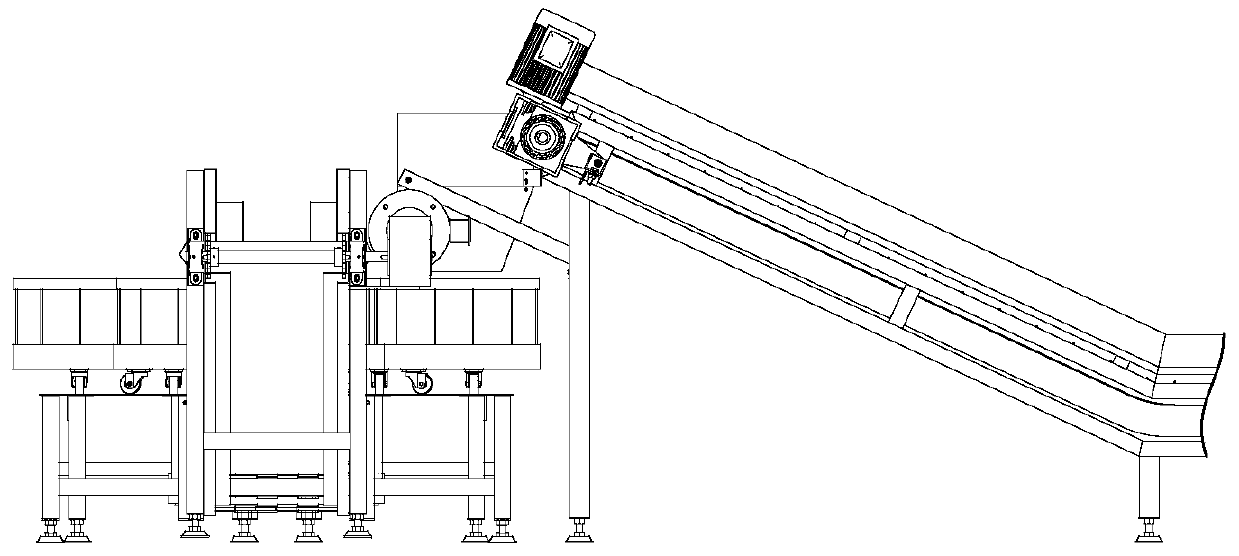

[0025] A kind of ear cutting production line of continuous feeding, comprising support 1, pallet 2, is provided with roller support rail 11, pallet guide rail 12 and conveying chain 13 on support, described conveying chain is horizontal setting, roller support rail and The pallet rail surrounds the outer circumference of the conveyor chain, and the roller rail is arranged horizontally. The pallet rail is arranged on the side and is higher than the roller rail. The bottom of the pallet is provided with a roller 21 that moves along the roller rail and is set on one side of the pallet. There are guide wheels 22 that can move along the tray guide rail, and the tray is also connected to the conveying chain through a connecting piece. On the ear-cutting base production line for continuous feeding, a feeding device 3 and a discharging device 4 are also provided. The feeding device Including a feeding line 31 and a feeding hopper 32, the lower part of the feeding hopper faces the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com