Continuous material feeding system and control method and elevating platform fire truck thereof

A technology of feeding system and control method, which is applied to servo motors, servo motor components, liquid variable capacity machinery, etc., can solve problems such as flow fluctuations, and achieve the effects of solving flow fluctuations, stable feeding, and continuous feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

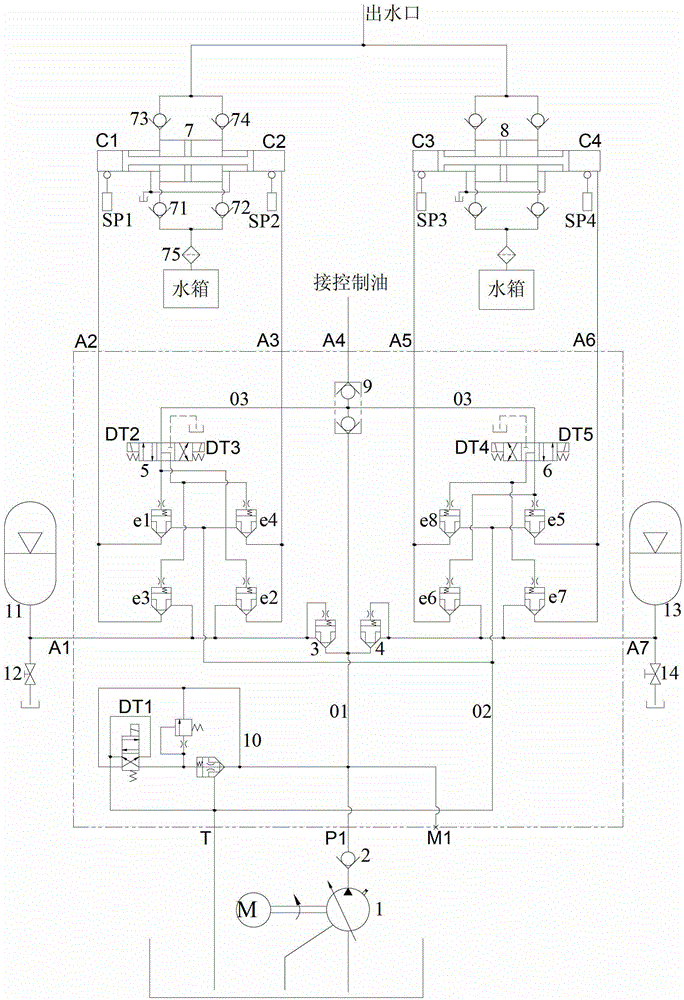

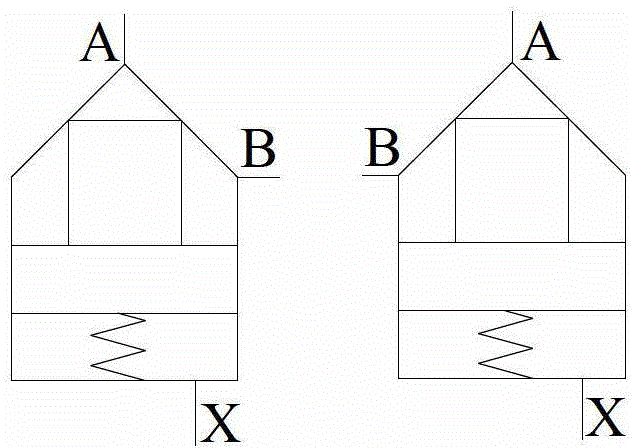

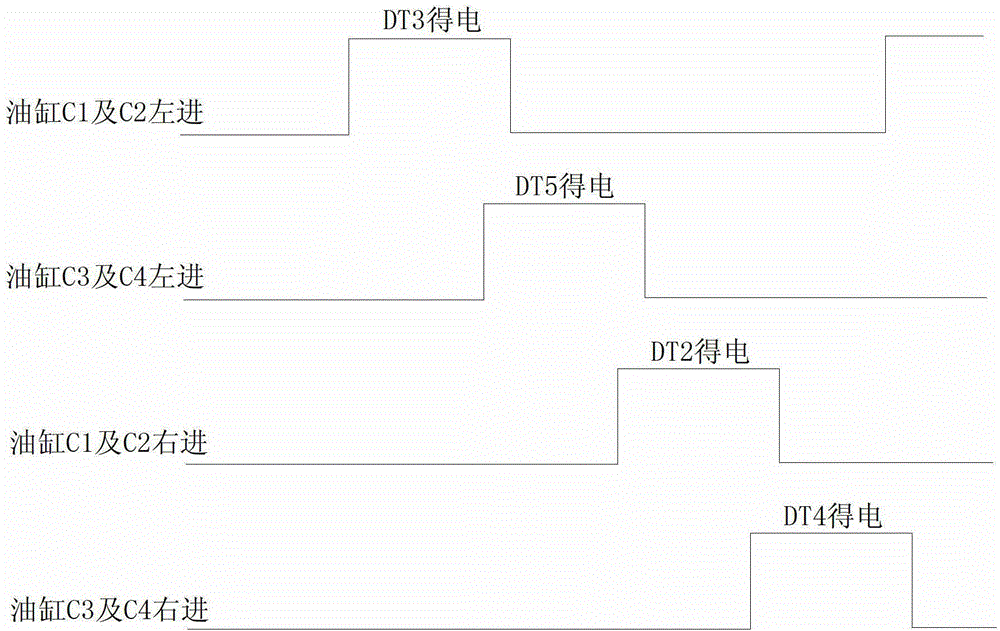

[0030] As a specific implementation, the reversing valve group includes a directional control valve 5, a first cartridge valve e1, a second cartridge valve e2, a third cartridge valve e3 and a fourth cartridge valve e4, wherein: combined figure 2 As shown, the first oil ports A of the first cartridge valve e1 and the fourth cartridge valve e4 communicate with the rodless chambers of the first oil cylinder C1 and the second oil cylinder C2 respectively, and the first cartridge valve e1 and the fourth cartridge valve The second oil port B of the valve e4 leads to the oil return circuit 02; the first oil port A of the third cartridge valve e3 and the second cartridge valve e2 are respectively connected to the rodless chamber of the first oil cylinder C1 and the second oil cylinder C2 In communication, the second oil port B of the third cartridge valve e3 and the second cartridge valve e2 is connected with the oil inlet oil circuit 02; the first cartridge valve e1, the second cart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com