Fluid conveying device and method

A fluid conveying and fluid technology, applied in the field of fluid conveying devices, can solve the problems of complex control part, high equipment cost, huge system, etc., and achieve the effect of reducing volume, small volume and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

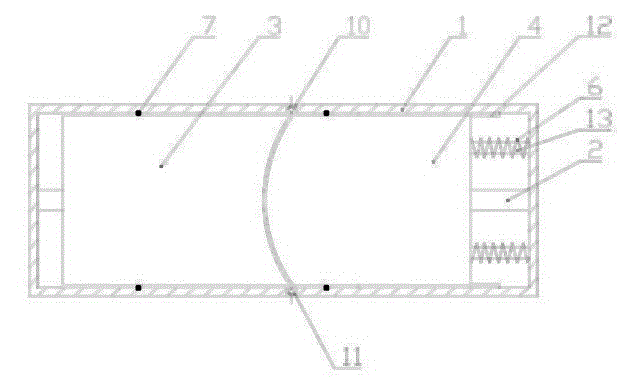

[0024] Such as figure 1 , figure 2As shown, in this embodiment, the rotation of an active element in the same cavity causes the position of a reciprocating element to move axially to form a volume to absorb fluid from the upstream side of the delivery direction or deliver the fluid to the downstream side for discharge. The end surfaces of the active element and the reciprocating element are both curved surfaces with at least one protrusion and at least one depression, and when the protrusion of the active element is located in the depression of the reciprocating element, they are in contact with each other; when the active The protruding part of the element can form a volume when it contacts the protruding part of the reciprocating element. As a preferred solution, the end faces of the active element and the reciprocating element are convex curved surfaces or concave curved surfaces. When the convex curved surface The volume is formed when the top arc contacts the top arc of...

Embodiment 2

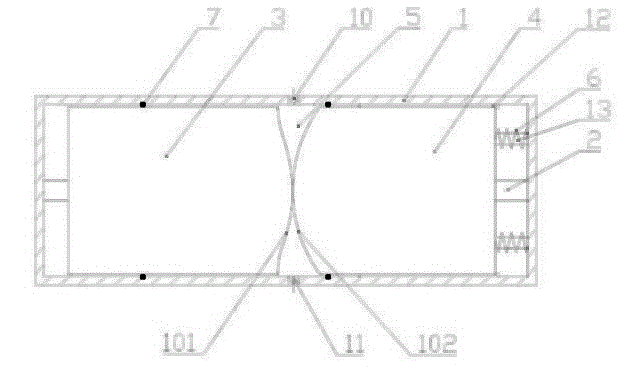

[0026] Such as image 3 , Figure 4 As shown, in this embodiment, the rotation of one active element is used in the same cavity to make the positions of the two reciprocating elements move axially respectively to form a volume, so as to suck fluid from the upstream side of the delivery direction and deliver the fluid to the downstream side Exhaust, the end surfaces of the active element and the reciprocating element are both curved surfaces with at least one protrusion and at least one depression, and when the protrusion of the active element is located in the depression of the reciprocating element, they fit together. A volume can be formed when the protrusion of the active element is in contact with the protrusion of the reciprocating element. As a preferred solution, the end faces of the active element and the reciprocating element are convex curved surfaces or concave curved surfaces. When the convex The volume is formed when the top arc of the curved surface is in contac...

Embodiment 3

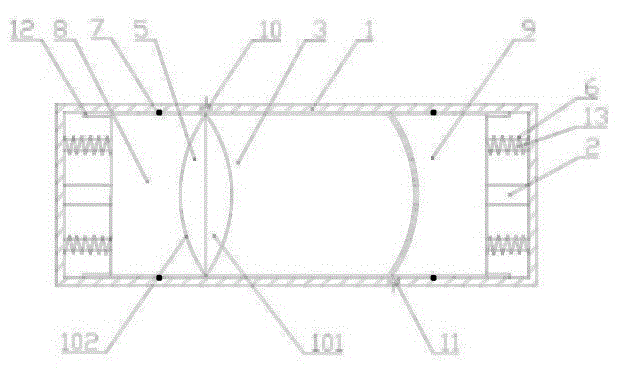

[0028] Such as Figure 5 , Figure 6 As shown, this embodiment is roughly the same as Embodiment 2, the difference is that instead of using a power shaft in this embodiment, a linkage shaft and an additional power device are used to rotate the rotating element 3, specifically , the fluid delivery device includes a cylinder 1, a linkage shaft 20 that is located in the cylinder 1 and rotates with the cylinder 1; a first sliding reciprocating piston 8 that is sequentially arranged on the linkage shaft 20 from front to back , a rotating element 3 adapted to the first sliding reciprocating piston 8 and a second sliding reciprocating piston 9 adapted to the rotating element 3, the rotating element 3 slidingly fits with the linkage shaft 20, and The rotating element 3 is provided with a one-way channel, the first sliding reciprocating piston 8 is synchronously linked with the second sliding reciprocating piston 9 through the linkage shaft 20, and the outer peripheral surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com