Full-automatic LED (light-emmiting diode) light bar processing device

A technology of LED light strips and processing equipment, which is applied in the direction of lighting and heating equipment, lighting devices, light sources, etc., and can solve the problems of high production cost, complicated operation process, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

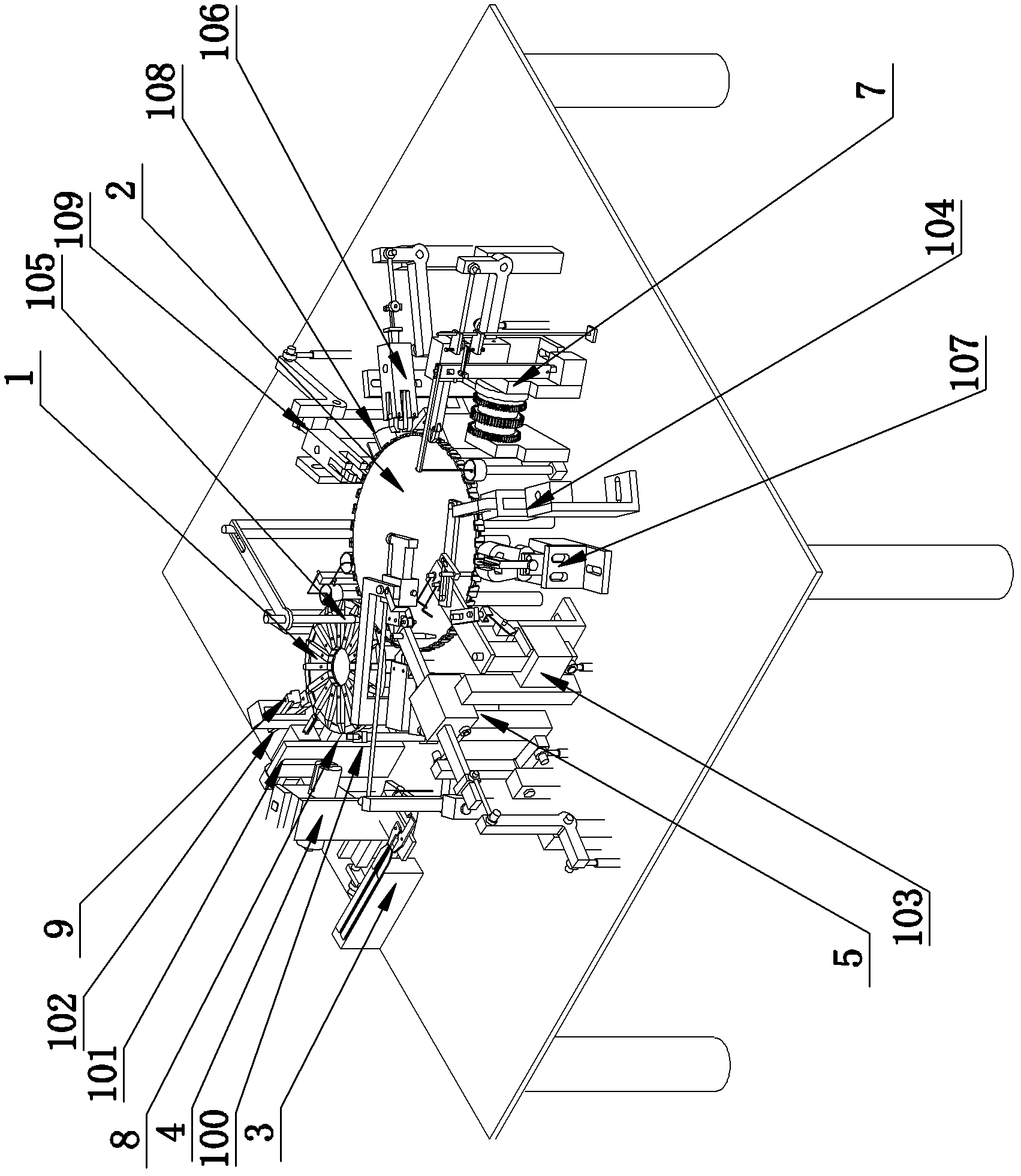

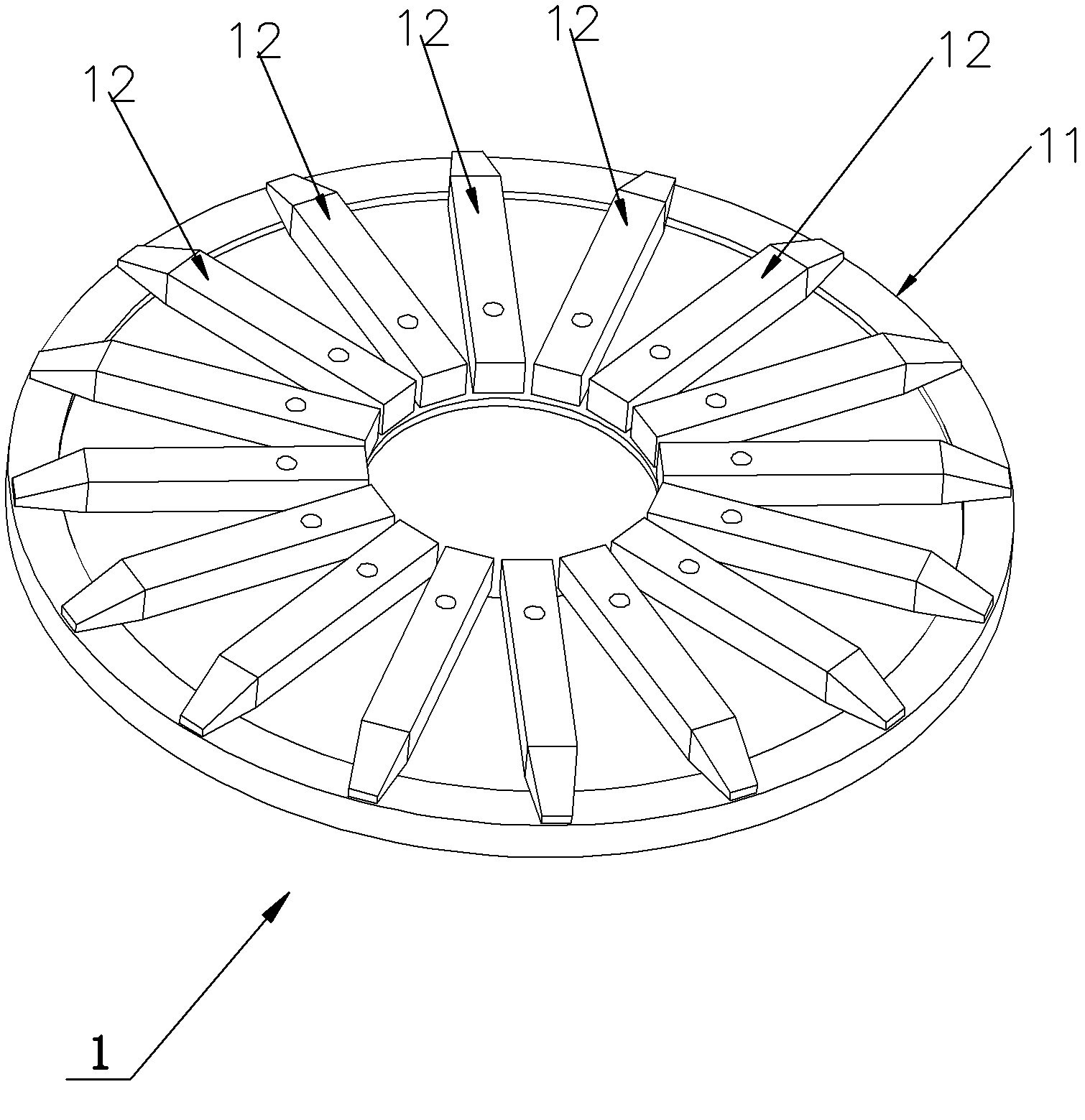

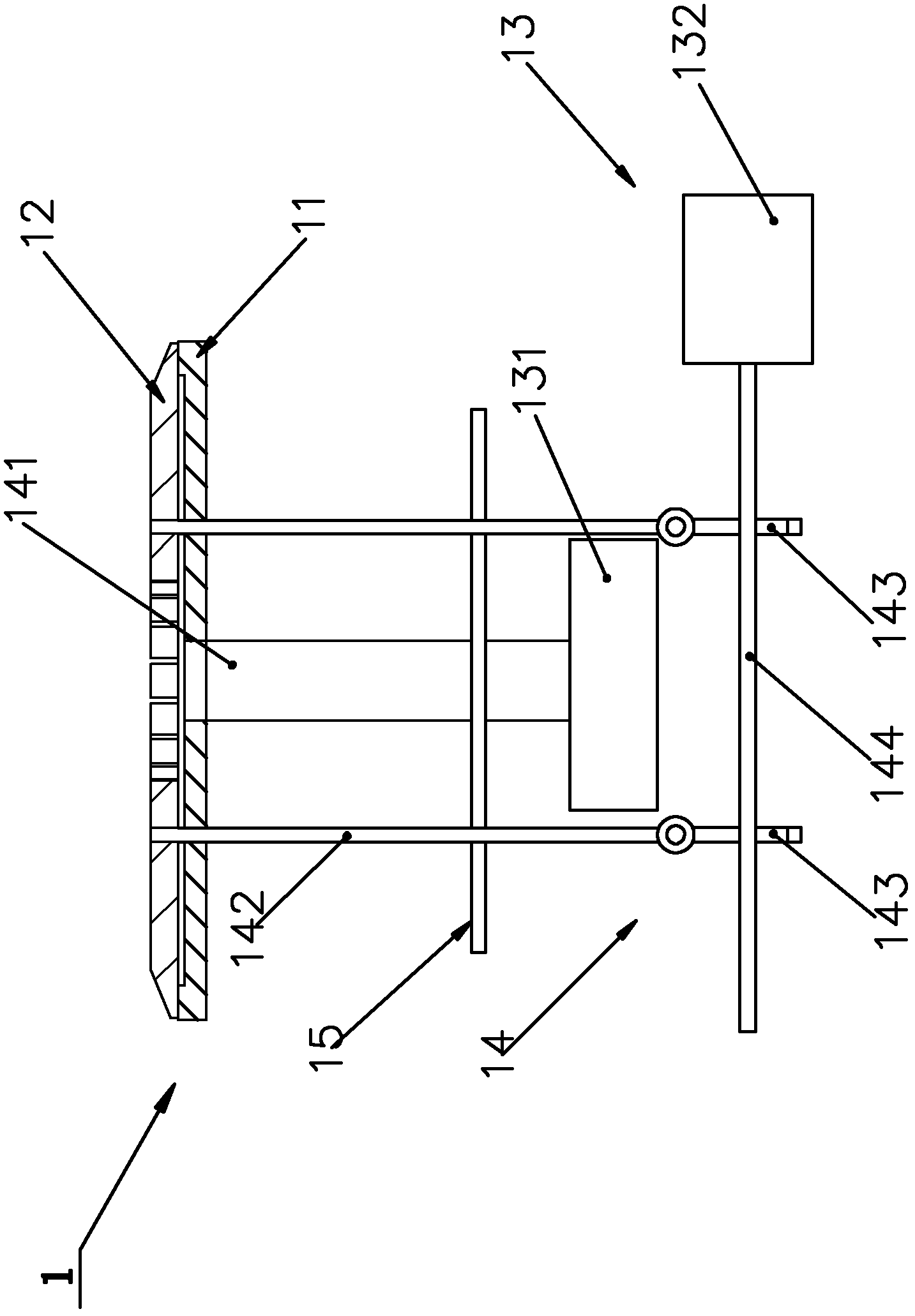

[0043] See attached figure 1 to attach Figure 6 , the LED light bar automatic processing equipment disclosed in the present invention includes a conveying tray 1 and a rotary winding table 2. The conveying tray 1 includes an annular rotating tray 11, a number of The clamping claws 12 , the driving assembly 13 that drives the rotating tray 11 to rotate and drives several clamping claws 12 to open and close on the rotating tray 11 , and the transmission assembly 14 arranged between the driving assembly 13 and the rotating tray 11 . The transmission assembly 14 between the rotary feed tray 11 and the drive assembly 13 includes a rotating shaft 141 connected to the rotary feed tray 11; A number of ejector rods 142 that can be extended and retracted along the axial direction of the rotating tray 11 respectively linked with each clamping claw 12, and the number of cams 143 and the linkage cam 143 that are provided at the other end of the ejector rod 142 relative to the end that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com