Detection equipment for welding spot failure of whole set of white vehicle body

A technology for testing equipment and body-in-white, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve problems such as difficulty in operation, inability to provide timely feedback for offline detection, and failure to detect failure of body-in-white solder joints. The effect of shortening the verification development cycle and having commonality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

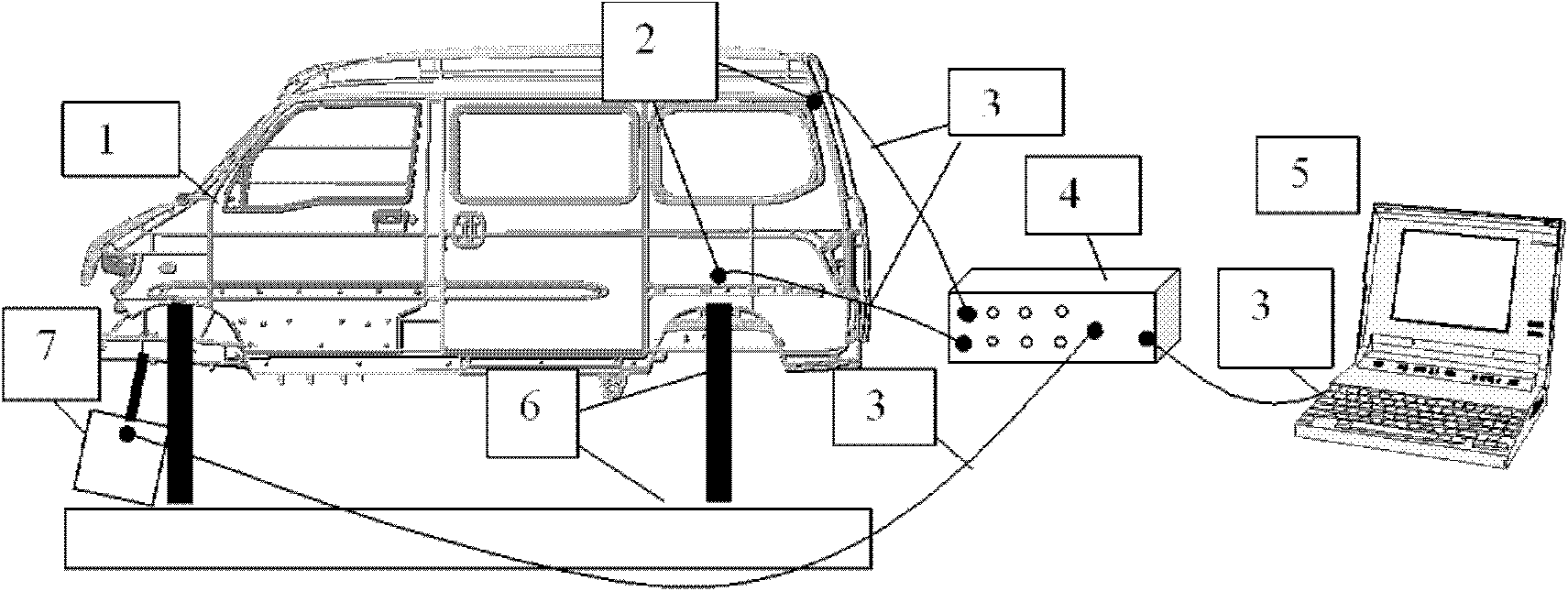

[0025] see figure 1 , which shows a complete set of body-in-white welding spot detection equipment of the present invention, its hardware equipment includes an exciter 7, a control and data acquisition system 4, an acceleration sensor 2, a microcomputer 5, a connecting cable 3, and a body-in-white 1 Corresponding clamping system6. Its software equipment includes signal processing systems. The specific installation method is as follows: the white body 1 is fixed on the stand 6 by a clamp, the exciter 7 is connected to the control and data system 4, the sensor 2 is connected to the control and data acquisition system 4, the control and data acquisition system 4 is connected to the microcomputer 5 Connection, the sensor 2 is pasted on the key parts of the vehicle body through magnets.

[0026] Wherein the body-in-white 1 used for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com