Chemical heat exchange device

A heat exchange equipment and chemical technology, applied in lighting and heating equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as the risk of large pipe blockage, avoid internal pipe blockage, reasonable structure, and heat exchange effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

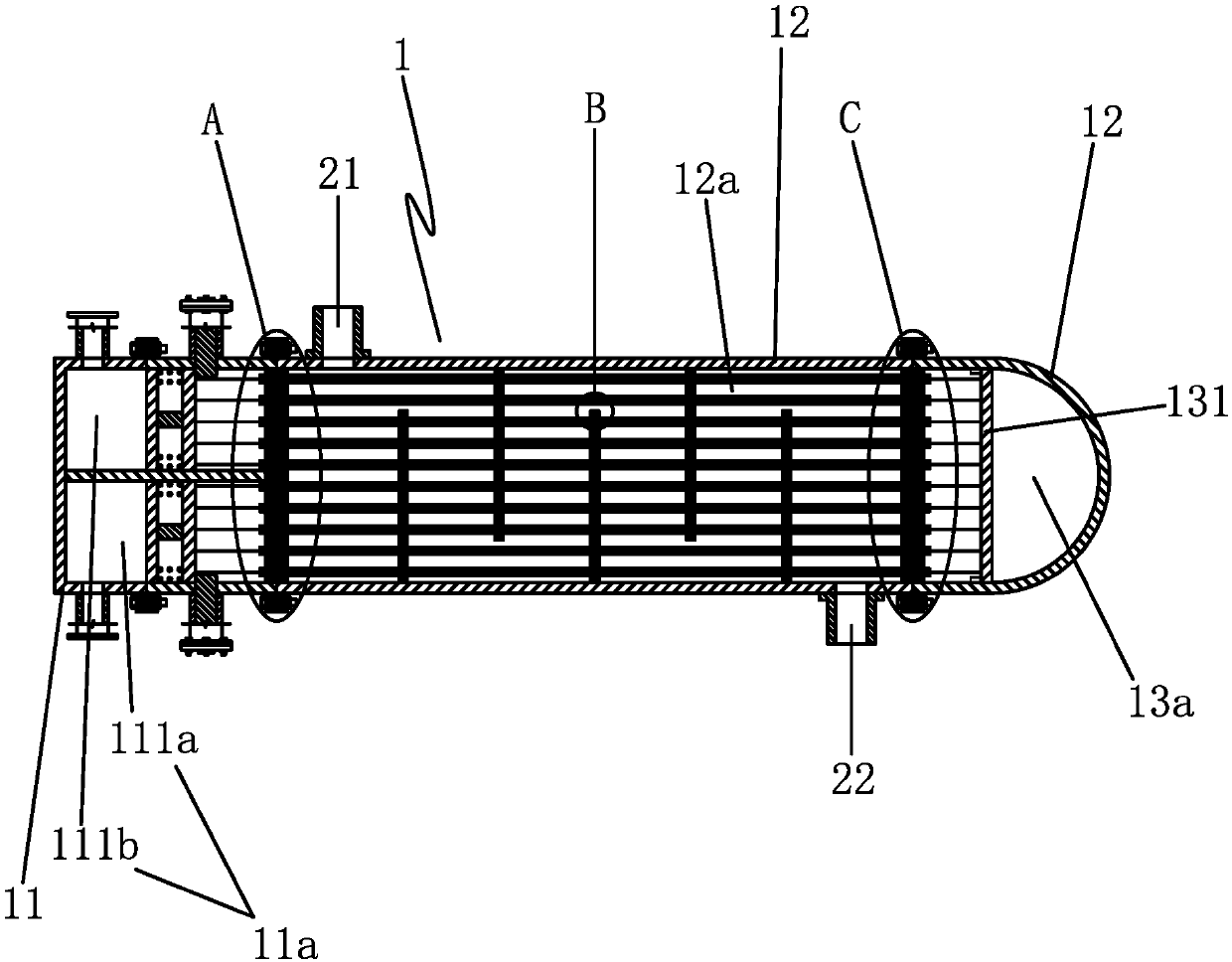

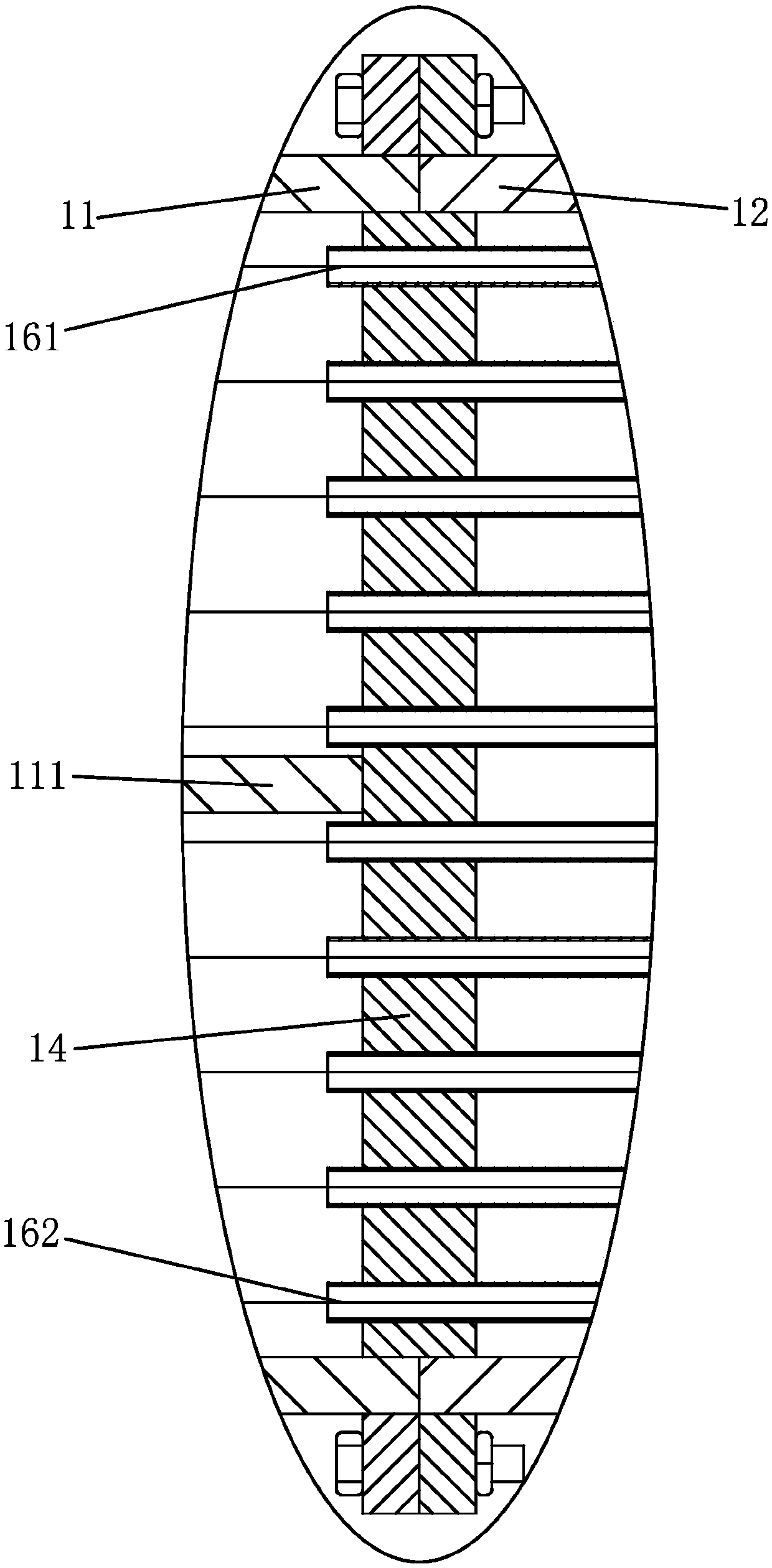

[0037] Embodiment 1: as Figure 1 to Figure 5 as shown,

[0038] A chemical heat exchange device, comprising a main shell 1, an inner chamber liquid inlet pipe 21, an inner chamber liquid outlet pipe 22, an outer chamber liquid inlet pipe 31 and an outer chamber liquid outlet pipe 32;

[0039] The main casing includes a front shell head 11, a shell tube 12 and a rear shell head 13. One end of the shell tube is connected to the front shell head by a number of connecting bolts, the joint between the shell tube and the front shell head is sealed, and the other end of the shell tube is connected to the rear The shell head is connected by several connecting bolts, and the connection between the shell tube and the rear shell head is sealed;

[0040] The front of the main housing is provided with a front seat plate 14, a rear seat plate 15, a plurality of inner liquid inlet pipes 161 and a plurality of inner liquid outlet pipes 162, the front seat plate and the front shell head join...

Embodiment 2

[0050] Embodiment 2: based on embodiment 1, as Figure 6 to Figure 11 as shown,

[0051] It also includes an outer frame and an outer shaft 4 coaxially arranged with the shell tube. The outer frame is provided with an outer seat 51, and the outer seat is provided with a guide sleeve 52. One end of the outer shaft is connected with the rear shell head, and the outer shaft is connected with the The guide sleeve is slidingly connected, the slidable direction of the outer shaft is parallel to the axis of the shell tube, the guide sleeve is connected to the outer seat in rotation, the center line of rotation of the guide sleeve coincides with the axis of the shell tube, and an inner ring seat 132 is provided on the outer wall of the rear shell head; The outer frame is provided with a cleaning turbine pump 53, a guide fixing seat 54 and a cleaning drive mechanism. The cleaning drive mechanism includes a first connecting rod 61, a second connecting rod 62, a driving lever 63, a clean...

Embodiment 3

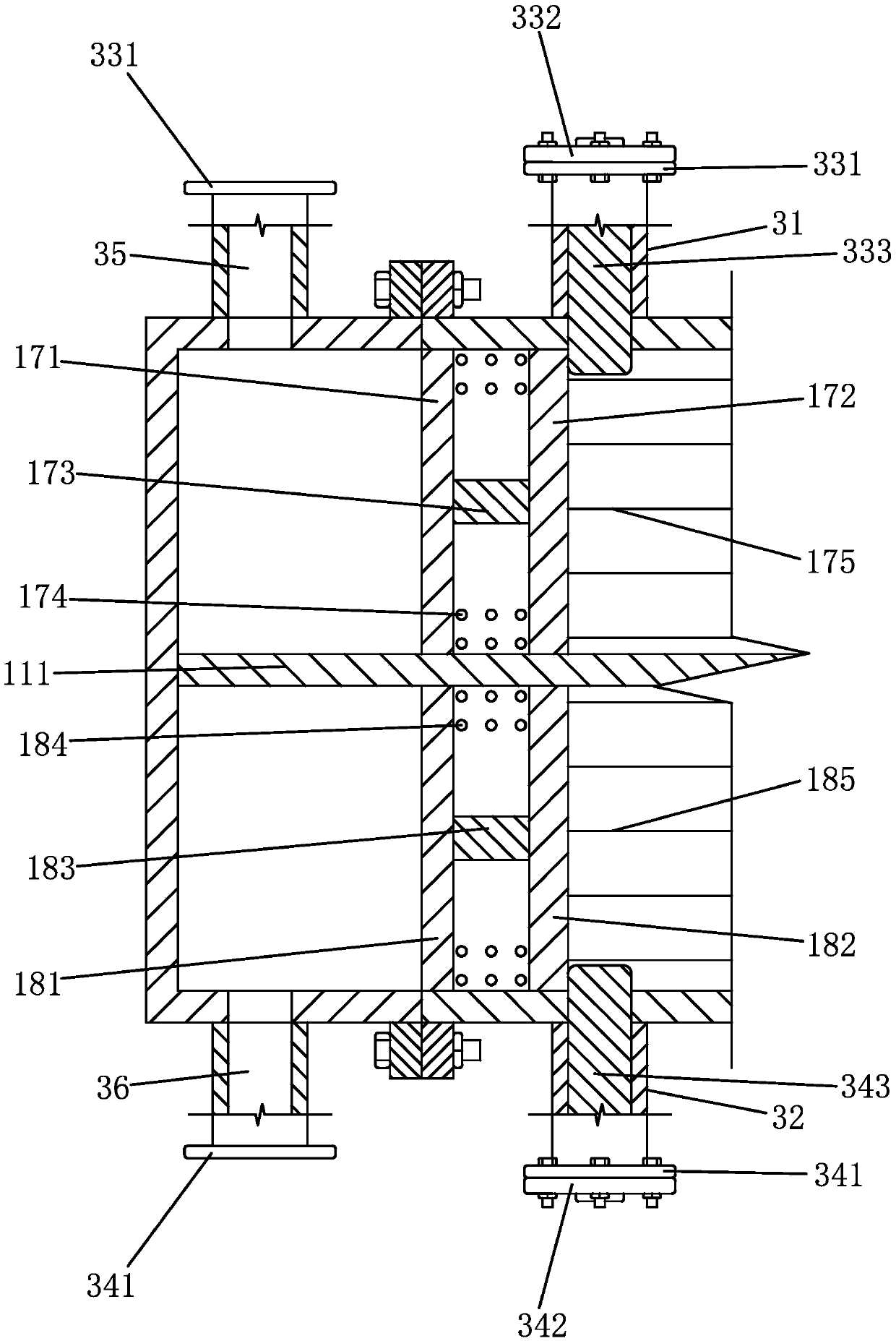

[0054] Embodiment 3: based on embodiment 1, as Figure 12 to Figure 16 as shown,

[0055] It also includes an outer frame and an outer shaft 4 coaxially arranged with the shell tube. The outer frame is provided with an outer seat 51, and the outer seat is provided with a guide sleeve 52. One end of the outer shaft is connected with the rear shell head, and the outer shaft is connected with the The guide sleeve is slidingly connected, the slidable direction of the outer shaft is parallel to the axis of the shell tube, the guide sleeve is connected to the outer seat in rotation, the center line of rotation of the guide sleeve coincides with the axis of the shell tube, and an inner ring seat 132 is provided on the outer wall of the rear shell head; The outer frame is provided with a cleaning piston pump, a guide first seat 71, a guide second seat 72 and a cleaning drive mechanism, and the cleaning drive mechanism includes a first transmission rod 81, a second transmission rod 82,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com