Drying heat exchange system for water-based ink printing

A heat exchange system, water-based ink technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problems of low heat exchange efficiency, low heat utilization rate, poor heat transfer effect, etc., to meet the heat transfer requirements. , Conducive to heat and mass transfer, improve the effect of heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

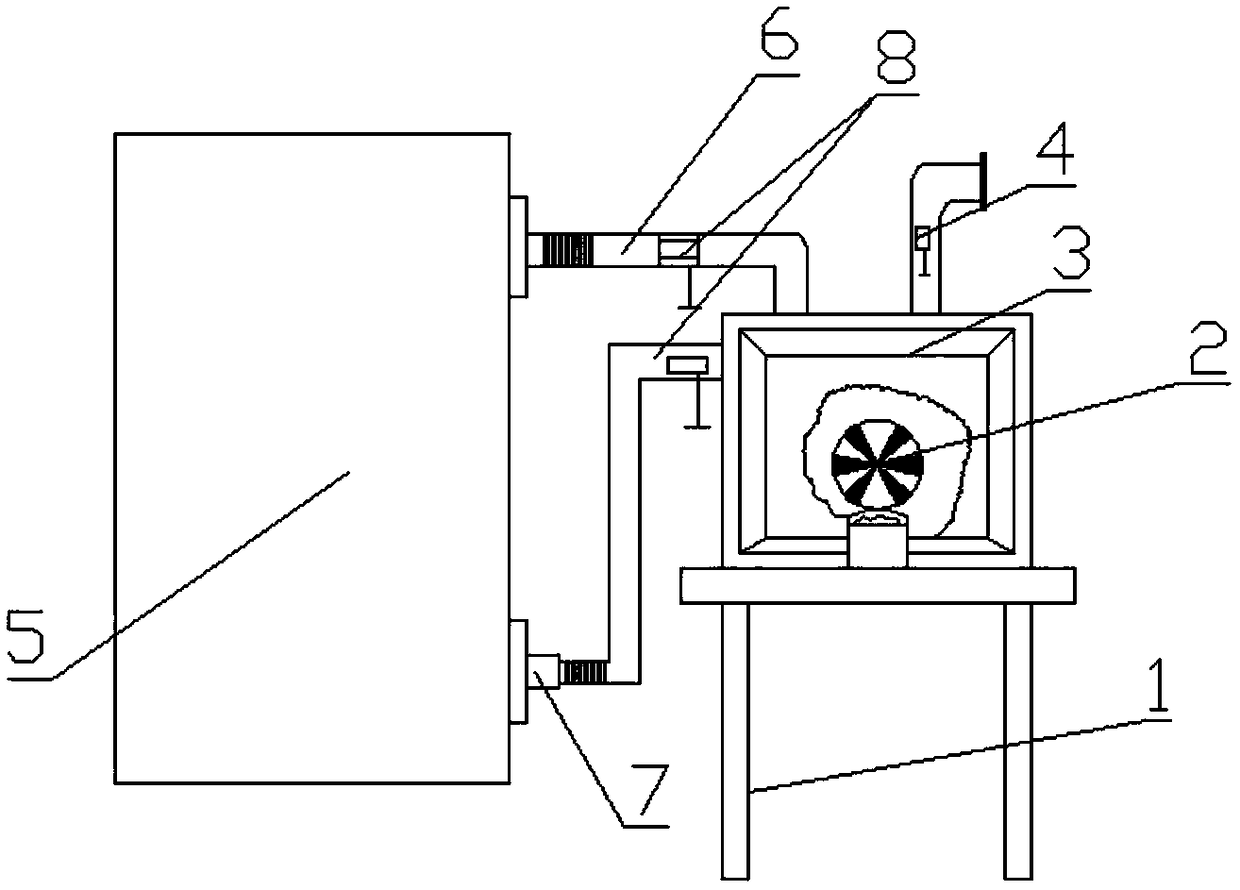

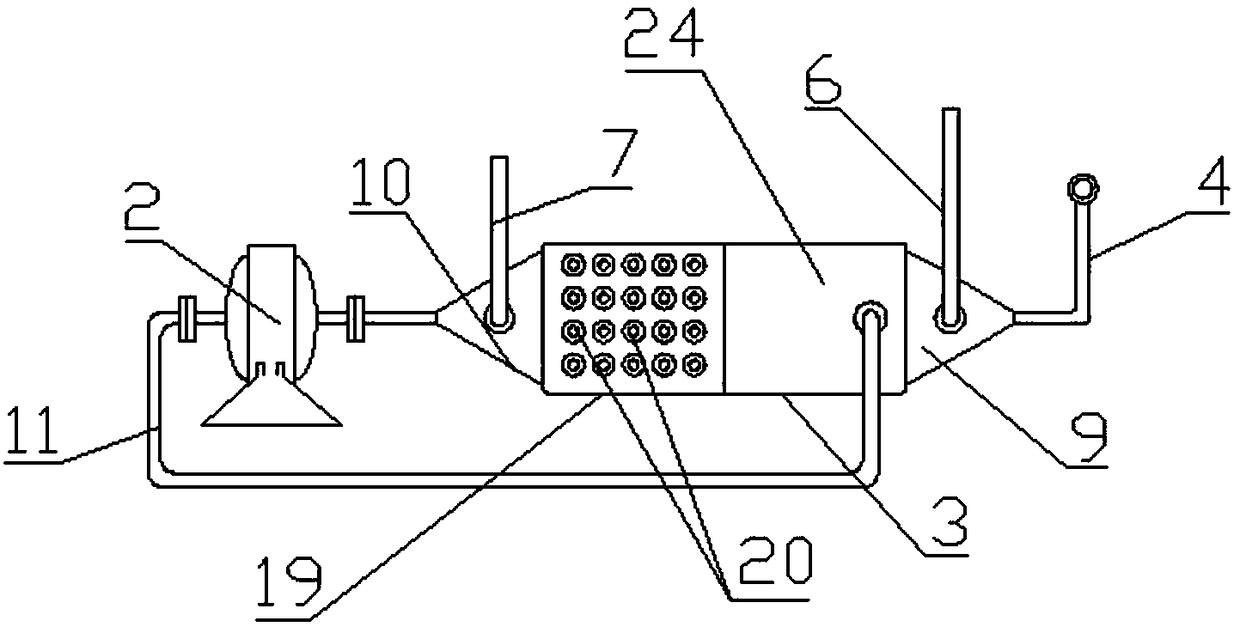

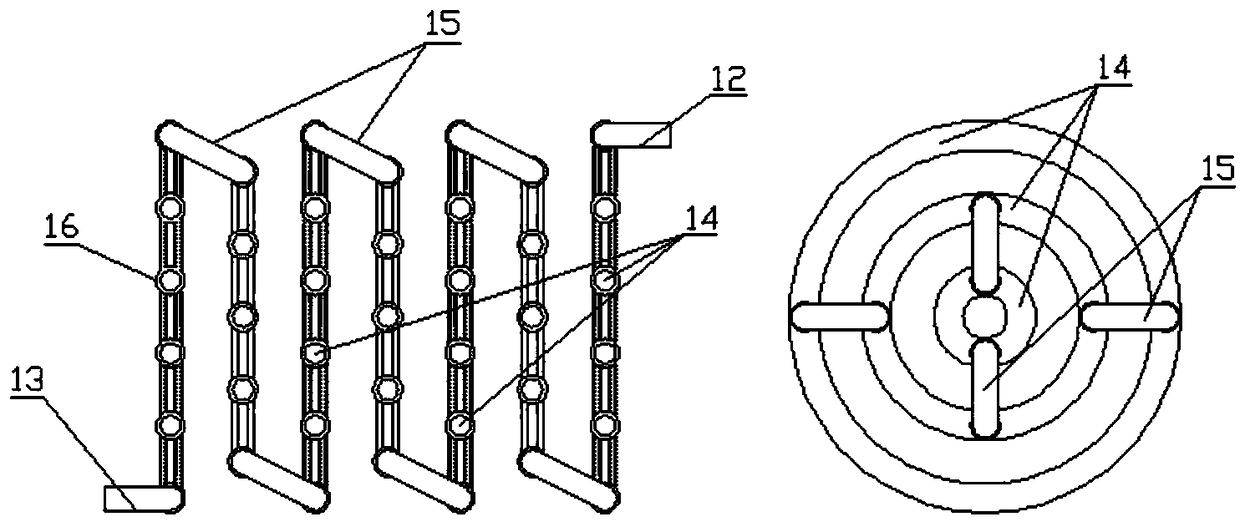

[0025] like Figure 1-7 As shown, the technical solution adopted by the present invention is: a drying heat exchange system for water-based ink printing, the drying heat exchange system includes a drying bellows 5 and a heat exchanger 3, and the heat exchanger 3 is placed on the support frame 1 Above, the inside of the drying bellows 5 is equipped with a medium-wave ultraviolet lamp 23, and the medium-wave ultraviolet lamp 23 is installed on the lamp rotator 22, and the lamp rotator 22 drives the medium-wave ultraviolet lamp 23 between 0° and 360°. The lamp tube outer cover of the medium-wave ultraviolet lamp tube 23 is provided with lamp tube gold-plated at 20-160°, the front part of the drying bellows 5 is provided with a glass louver 21, and the downstream of the heat exchanger 3 is connected to a heat exchange pump 2. The heat exchanger 3 and the heat exchange pump 2 are connected by a heat circulation pipe 11. The interior of the heat exchanger 3 is divided into two parts...

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is:

[0035] The filter area 9 of the exchanger is filled with a mixture of coconut shell activated carbon, silica gel and quicklime, and the mixing ratio is 3:2:1;

[0036] The lamp tube rotator 22 drives the medium-wave ultraviolet lamp 23 to rotate at an angle of 135°, and the phase difference between the working state and the shutdown state of the medium-wave ultraviolet lamp 23 is 180°;

[0037] The glass louvers 21 are deployed to the inside of the drying bellows 5, and the deployment angle is set to 75°.

Embodiment 3

[0039] The filter area 9 of the exchanger is filled with a mixture of coconut shell activated carbon, silica gel and quicklime, and the mixing ratio is 4:2:1;

[0040] The lamp tube rotator 22 drives the medium-wave ultraviolet lamp 23 to rotate at an angle of 160°, and the phase difference between the working state and the shutdown state of the medium-wave ultraviolet lamp 23 is 180°;

[0041] The glass louvers 21 are deployed to the inside of the drying bellows 5, and the deployment angle is set to 60°.

[0042]Working principle: When in use, start the heat exchange pump 2, and the heat exchange pump 2 draws air into the heat exchange pump 2 from the air inlet 4, and then enters the inside of the heat exchanger 3, and the air first enters the front end of the heat exchanger 3 In the filter area 9 of the exchanger, the coconut shell activated carbon, silica gel and quicklime inside absorb and filter out large particles of impurities, acid gases and moisture in the air. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com